Professional Documents

Culture Documents

Attached Wps

Uploaded by

nourfarmajidOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Attached Wps

Uploaded by

nourfarmajidCopyright:

Available Formats

consultant 1

client

purchaser

contract Doc.

Manufacturer

By :A. Ka Chk'd : P.T.E Appr'd : S.M.Ta

Welding Process:SMAW(shielded metal arc welding)Manual. Welding Type: Manual Supporting PQR No: Base Metal Thicness Range:5 to 6 mm Base Metals:Carbon Steel. P1,Group1 to P1,Group 1 Tank Base Metals Thickness:Max 6 mm / Min 5 mm Welding Travel Speed:50 to 150 mm/min Single or Multiple Passes:Either Maximum Pass Thickness: 5 to 6 mm

(ST 37)

2 3 4 5 6 7 8 9

Applicable Standard:ASME Section 9

10 Initial Cleaning:Chemical or Mechanical;Joint Shall be Dry Prior to Welding. 11 Interpass Cleaning:Mechanicaly Only 12 13 14 15 16 17

Electrical Characteristics Electrode:

Dia.mm:

Type:AMA

Current :

Amperes:120 to 190 A Polarity: DC EP:Electride Positive(Reverse Polarity) Electrode Preheating Method: by Oven

2.5-3.2

Classification:E 7018 F Number: 4 A Number: 1

18 Filler Metal Specification: ANSI/AWS or ASME 19 Preheat Temperature:

150-300 deg C

20 Preheat Maintenance: Continuous or Special Heating not Required 21 Interpass Temperature:Minimum5 degree celsius ,max 500 degree celsius 22 String or Weave:String and Weave 23 Permited Position:All / Vertical Progression:Uphill 24 Joint: Drawing Spec.Reference Document.

Grove: -------

Fillet: 1F,2F,3F

Weld layers 1 2 3

Process SMAW SMAW --

Filler dia. 2.5 mm 3.2 mm --

Clasification E7018 E7018 --

Polarity EP EP --

5mm

T JOINT

5 mm

3.5 mm

PLATE 45PIPE toto PLATE PLATE NECK PLATE

consultant 1

client

purchaser

contract Doc.

Manufacturer

By :A. Ka Chk'd : P.T.E Appr'd :S.M.Ta

Welding Process:SMAW(shielded metal arc welding)Manual. Welding Type: Manual Supporting PQR No: Base Metal Thicness Range:5 to 8 mm Base Metals:Carbon Steel. P1,Group1 to P1,Group 1 Tank Base Metals Thickness:Max 6mm / Min 5mm Welding Travel Speed:50 to 150 mm/min Single or Multiple Passes:Either Maximum Pass Thickness: 5 to 6 mm

(ST 37)

2 3 4 5 6 7 8 9

Applicable Standard:ASME Section 9

10 Initial Cleaning:Chemical or Mechanical;Joint Shall be Dry Prior to Welding. 11 Interpass Cleaning:Mechanicaly Only 12 13 14 15 16 17

Electrical Characteristics Electrode:

Dia.mm:

Type:AMA

Current :

Amperes:120 to 190 A Polarity: DC EP:Electride Positive(Reverse Polarity) Electrode Preheating Method: by Oven

2.5-3.2

Classification:E 7018 F Number: 4 A Number: 1

18 Filler Metal Specification: ANSI/AWS or ASME 19 Preheat Temperature:

150-300 deg C

20 Preheat Maintenance: Continuous or Special Heating not Required 21 Interpass Temperature:Minimum5 degree celsius ,max 500 degree celsius 22 String or Weave:String and Weave 23 Permited Position:All / Vertical Progression:Uphill 24 Joint: Drawing Spec.Reference Document.

Grove: ------

Fillet: 1F,2F,3F

Weld layers 1 2 3

Process SMAW SMAW --

Filler dia. 2.5 mm 3.2 mm --

Clasification E7018 E7018 --

Polarity EP EP --

5 mm

3.5 mm T JOINT

5 mm

45

45PIPE to PLATE

NECK PLATE

consultant 1

client

purchaser

contract Doc.

Manufacturer

By :A. Ka Chk'd : P.T.E Appr'd :S.M.Ta

Welding Process:SMAW(shielded metal arc welding)Manual. Welding Type: Manual Supporting PQR No: Base Metal Thicness Range:5 to 6 mm Base Metals:Carbon Steel. P1,Group1 to P1,Group 1 Tank Base Metals Thickness:Max 6mm / Min5 mm Welding Travel Speed:50 to 150 mm/min Single or Multiple Passes:Either Maximum Pass Thickness: 5 to 6 mm

(ST 37)

2 3 4 5 6 7 8 9

Applicable Standard:ASME Section 9

10 Initial Cleaning:Chemical or Mechanical;Joint Shall be Dry Prior to Welding. 11 Interpass Cleaning:Mechanicaly Only 12 13 14 15 16 17

Electrical Characteristics Electrode:

Dia.mm:

Type:AMA

Current :

Amperes:120 to 190 A Polarity: DC EP:Electride Positive(Reverse Polarity) Electrode Preheating Method: by Oven

2.5-3.2

Classification:E 7018 F Number: 4 A Number: 1

18 Filler Metal Specification: ANSI/AWS or ASME 19 Preheat Temperature:

150-300 deg C

20 Preheat Maintenance: Continuous or Special Heating not Required 21 Interpass Temperature:Minimum5 degree celsius ,max 500 degree celsius 22 String or Weave:String and Weave 23 Permited Position:All / Vertical Progression:Uphill 24 Joint: Drawing Spec.Reference Document.

Grove: 1G,2G,3G

Fillet:

Weld layers 1 2 3

Process SMAW SMAW --

Filler dia. 2.5 mm 3.2 mm --

Clasification E7018 E7018 --

Polarity EP EP --

a

a=60 degree R=2+1.5-1.5 f=not limited

BUTT JOINT

PLATE TO PLATE

consultant 1

client

purchaser

contract Doc.

Manufacturer

By :A. Ka Chk'd : P.T.E Appr'd : S.M.Ta

Welding Process:SMAW(shielded metal arc welding)Manual. Welding Type: Manual Supporting PQR No: Base Metal Thicness Range:5 to 6 mm Base Metals:Carbon Steel. P1,Group1 to P1,Group 1 Tank Base Metals Thickness:Max 6 mm / Min 5 mm Welding Travel Speed:50 to 150 mm/min Single or Multiple Passes:Either Maximum Pass Thickness: 5 to 6 mm

(ST 37)

2 3 4 5 6 7 8 9

Applicable Standard:ASME Section 9

10 Initial Cleaning:Chemical or Mechanical;Joint Shall be Dry Prior to Welding. 11 Interpass Cleaning:Mechanicaly Only 12 13 14 15 16 17

Electrical Characteristics Electrode:

Dia.mm:

Type:AMA

Current :

Amperes:120 to 190 A Polarity: DC EP:Electride Positive(Reverse Polarity)

2.5-3.2

Classification:E 7018 F Number: 4 A Number: 1

Electrode Preheating Method: by Oven

18 Filler Metal Specification: ANSI/AWS or ASME 19 Preheat Temperature:

150-300 deg C

20 Preheat Maintenance: Continuous or Special Heating not Required 21 Interpass Temperature:Minimum5 degree celsius ,max 500 degree celsius 22 String or Weave:String and Weave 23 Permited Position:All / Vertical Progression:Uphill 24 Joint: Drawing Spec.Reference Document.

Grove: 1G,2G,3G

Fillet: ---

Weld layers 1 2 3

Process SMAW SMAW --

Filler dia. 2.5 mm 3.2 mm --

Clasification E7018 E7018 --

Polarity EP EP --

a and b 60 degree min R=2+1.5-1.5 f=not limited

BUTT JOINT

R b

PLATE TO PLATE

consultant 1

client

purchaser

contract Doc.

Manufacturer

By :A. Ka Chk'd : P.T.E Appr'd : S.M.Ta

Welding Process:SMAW(shielded metal arc welding)Manual. Welding Type: Manual Supporting PQR No: Base Metal Thicness Range:5 to 6 mm Base Metals:Carbon Steel. P1,Group1 to P1,Group 1 Tank Base Metals Thickness:Max 6 mm / Min 5 mm Welding Travel Speed:50 to 150 mm/min Single or Multiple Passes:Either Maximum Pass Thickness: 5 to 6 mm

(ST 37)

2 3 4 5 6 7 8 9

Applicable Standard:ASME Section 9

10 Initial Cleaning:Chemical or Mechanical;Joint Shall be Dry Prior to Welding. 11 Interpass Cleaning:Mechanicaly Only 12 13 14 15 16 17

Electrical Characteristics Electrode:

Dia.mm:

Type:AMA

Current :

Amperes:120 to 190 A Polarity: DC EP:Electride Positive(Reverse Polarity)

2.5-3.2

Classification:E 7018 F Number: 4 A Number: 1

Electrode Preheating Method: by Oven

18 Filler Metal Specification: ANSI/AWS or ASME 19 Preheat Temperature:

150-300 deg C

20 Preheat Maintenance: Continuous or Special Heating not Required 21 Interpass Temperature:Minimum5 degree celsius ,max 500 degree celsius 22 String or Weave:String and Weave 23 Permited Position:All / Vertical Progression:Uphill 24 Joint: Drawing Spec.Reference Document.

Grove: -----

Fillet: 1F,2F,3F

Weld layers 1 2 3

Process SMAW SMAW --

Filler dia. 2.5 mm 3.2 mm --

Clasification E7018 E7018 --

Polarity EP EP --

4 mm t=flange thickness T=pipe thickness

CORNER JOINT

NECK PLATE /PIPE TO FLANGE

consultant 1

client

purchaser

contract Doc.

Manufacturer

By :A. Ka Chk'd : P.T.E Appr'd : S.M.Ta

Welding Process:SMAW(shielded metal arc welding)Manual. Welding Type: Manual Supporting PQR No: Base Metal Thicness Range:5 to 6 mm Base Metals:Carbon Steel. P1,Group1 to P1,Group 1 Tank Base Metals Thickness:Max 6 mm / Min 5 mm Welding Travel Speed:50 to 150 mm/min Single or Multiple Passes:Either Maximum Pass Thickness: 5 to 6 mm

(ST 37)

2 3 4 5 6 7 8 9

Applicable Standard:ASME Section 9

10 Initial Cleaning:Chemical or Mechanical;Joint Shall be Dry Prior to Welding. 11 Interpass Cleaning:Mechanicaly Only 12 13 14 15 16 17

Electrical Characteristics Electrode:

Dia.mm:

Type:AMA

Current :

Amperes:120 to 190 A Polarity: DC EP:Electride Positive(Reverse Polarity)

2.5-3.2

Classification:E 7018 F Number: 4 A Number: 1

Electrode Preheating Method: by Oven

18 Filler Metal Specification: ANSI/AWS or ASME 19 Preheat Temperature:

150-300 deg C

20 Preheat Maintenance: Continuous or Special Heating not Required 21 Interpass Temperature:Minimum5 degree celsius ,max 500 degree celsius 22 String or Weave:String and Weave 23 Permited Position:All / Vertical Progression:Uphill 24 Joint: Drawing Spec.Reference Document. 25

Grove: 1G,2G,3G

Fillet: 1F,2F,3F

Weld layers 1 2 3

Process SMAW SMAW --

Filler dia. 2.5 mm 3.2 -CORNER JOINT

Clasification E7018 E7018 --

Polarity EP EP --

a R

a and b 60 degree min R=2+1.5-1.5

PIPE/PIPE TO PLATE

f=not limited

You might also like

- WELDING PROCEDURE FOR STEERING BRACKETSDocument1 pageWELDING PROCEDURE FOR STEERING BRACKETSViktorNo ratings yet

- PT6 Training ManualDocument64 pagesPT6 Training ManualAnderson Guimarães100% (2)

- Affidavit of Consent For Shared Parental AuthorityDocument2 pagesAffidavit of Consent For Shared Parental AuthorityTet LegaspiNo ratings yet

- PreheatDocument2 pagesPreheatScott TrainorNo ratings yet

- API Welding ProcedureDocument2 pagesAPI Welding ProcedureSamarakoon BandaNo ratings yet

- Weld Log - 5000 WeldDocument234 pagesWeld Log - 5000 WeldRichard MitchellNo ratings yet

- IRCLASS Systems and Solutions Pvt. Ltd. (A Wholy Owned Subsidiary of Indian Register of Shipping)Document4 pagesIRCLASS Systems and Solutions Pvt. Ltd. (A Wholy Owned Subsidiary of Indian Register of Shipping)Mostafizur RahmanNo ratings yet

- MMA Electrode ClassificationDocument5 pagesMMA Electrode ClassificationRama Krishna Reddy DonthireddyNo ratings yet

- Alignment Methods in Rotating EquipmentDocument6 pagesAlignment Methods in Rotating EquipmentInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- STAINLESS Filler Selector Guide PDFDocument1 pageSTAINLESS Filler Selector Guide PDFArul Edwin VijayNo ratings yet

- Appendix B3-10 Welding Procedure Specification EPI-11-WP6 Rev.1 - A4A2E9Document24 pagesAppendix B3-10 Welding Procedure Specification EPI-11-WP6 Rev.1 - A4A2E9Tahir AliNo ratings yet

- Bolt Grade Markings and Strength Chart: Head Marking Grade and Material Nominal Size Range Mechanical PropertiesDocument2 pagesBolt Grade Markings and Strength Chart: Head Marking Grade and Material Nominal Size Range Mechanical PropertiesDeepakGawasNo ratings yet

- Calculating Weld Wire ConsumptionDocument1 pageCalculating Weld Wire ConsumptionDavid D'AgostinoNo ratings yet

- PRES TIG Hot Wire Narrow Gap Welding enDocument25 pagesPRES TIG Hot Wire Narrow Gap Welding enRavishankarNo ratings yet

- Cost Calculation Program For Productivity in WeldingDocument20 pagesCost Calculation Program For Productivity in WeldingiyigunNo ratings yet

- BS 3604-2 - 1991 Steel Pipes and Tubes For Pressure Purposes Ferritic Alloy Steel With Specified ElevatedDocument24 pagesBS 3604-2 - 1991 Steel Pipes and Tubes For Pressure Purposes Ferritic Alloy Steel With Specified ElevatedtienlamNo ratings yet

- Welding Gauges PDFDocument4 pagesWelding Gauges PDFsopan kharcheNo ratings yet

- WELD DESIGN CHECK FOR ANCHOR SUPPORTDocument8 pagesWELD DESIGN CHECK FOR ANCHOR SUPPORTUmer AziqNo ratings yet

- Rotary JointDocument7 pagesRotary JointGlobe Star Engineers Pvt LtdNo ratings yet

- Inspection RoleDocument18 pagesInspection Rolesribd9128No ratings yet

- Elding Rocedure Pecification: 7200-HDPE Butt WeldDocument2 pagesElding Rocedure Pecification: 7200-HDPE Butt Weldsamer8saifNo ratings yet

- Heat Input CalculatorDocument2 pagesHeat Input Calculatormahi1437No ratings yet

- ATTAR Phased Array Visualisation ToolDocument3 pagesATTAR Phased Array Visualisation ToolGOUTHAM RATHINAMNo ratings yet

- Welding Procedure Specification TIG Stainless Steel PipeDocument2 pagesWelding Procedure Specification TIG Stainless Steel PipeShajahan ShagulNo ratings yet

- ITP Inspection and Test Plan for Aqaba Screening Project Steel FabricationDocument3 pagesITP Inspection and Test Plan for Aqaba Screening Project Steel FabricationKhaled GamalNo ratings yet

- Uponor Montazni Manual EN FIN PDFDocument72 pagesUponor Montazni Manual EN FIN PDFAmar BayasgalanNo ratings yet

- QA vs QC vs INSPECTION: The Key DifferencesDocument138 pagesQA vs QC vs INSPECTION: The Key DifferencesMohd SharainiNo ratings yet

- ASME PQR - MMA/SMAW Fillet Welds on OGAP Supplies PartsDocument1 pageASME PQR - MMA/SMAW Fillet Welds on OGAP Supplies Partssathi_mechNo ratings yet

- Weld Cost CalculationDocument15 pagesWeld Cost CalculationMustafa KaramürselNo ratings yet

- DGS in Phased Array ModeDocument18 pagesDGS in Phased Array ModeOteloElMoroNo ratings yet

- ThesisDocument48 pagesThesismuhammad amir100% (1)

- Optimum pipe purging for economy and qualityDocument3 pagesOptimum pipe purging for economy and qualityshridharbshenoyNo ratings yet

- Fit-Up Inspection Report: Location: Weld Type Equipment Description: Date: Report No.: SystemDocument1 pageFit-Up Inspection Report: Location: Weld Type Equipment Description: Date: Report No.: SystemAnonymous 0rt9KWmNNo ratings yet

- 14250A ch3 PDFDocument82 pages14250A ch3 PDFKamarul NizamNo ratings yet

- PREQUALIFIED WELDING PROCEDURE SPECIFICATIONDocument1 pagePREQUALIFIED WELDING PROCEDURE SPECIFICATIONErick VazquezNo ratings yet

- WPSPQRDocument11 pagesWPSPQR0502raviNo ratings yet

- Lloyd S Register Sec IX 2017 Edition Key ChangesDocument38 pagesLloyd S Register Sec IX 2017 Edition Key ChangesDilip Varadharajan100% (1)

- WELDING PROCEDURE SPECIFICATIONSDocument6 pagesWELDING PROCEDURE SPECIFICATIONSMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Welding Qualification: by Hema SantoshDocument45 pagesWelding Qualification: by Hema Santoshravi00098No ratings yet

- Welcome To: Training Program On GUIDED TOUR OF Asme CodesDocument120 pagesWelcome To: Training Program On GUIDED TOUR OF Asme CodesDiego HenriqueNo ratings yet

- Badger Knowledge Base Metal Bellows Expansion Joint HandbookDocument24 pagesBadger Knowledge Base Metal Bellows Expansion Joint HandbookliNo ratings yet

- Procedure Qualification Record (PQR) Khewari Development ProjectDocument2 pagesProcedure Qualification Record (PQR) Khewari Development Projectsar sarNo ratings yet

- Dye Penetrant Inspection - Wikipedia, The Free EncyclopediaDocument5 pagesDye Penetrant Inspection - Wikipedia, The Free Encyclopediaviswamanoj100% (1)

- Pipe ScheduleDocument33 pagesPipe ScheduleDavid MacatangayNo ratings yet

- CV Mechanical Engineer Project Manager 11 Years ExperienceDocument2 pagesCV Mechanical Engineer Project Manager 11 Years ExperienceDARA SINGHNo ratings yet

- QAP For Ducting V1 R0Document1 pageQAP For Ducting V1 R0Hema NandhNo ratings yet

- Welding Cost Managment Layout ModifiedDocument13 pagesWelding Cost Managment Layout ModifiedmrNo ratings yet

- ASTM A131 Steel, Grade DDocument1 pageASTM A131 Steel, Grade DjulianmorantesNo ratings yet

- Work Instruction FOR: Tensile TestDocument4 pagesWork Instruction FOR: Tensile TestmahendraNo ratings yet

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraNo ratings yet

- Go Back To Wilson Supply Gas - Welding Supplies Page: AWS Class Polarity DescriptionDocument2 pagesGo Back To Wilson Supply Gas - Welding Supplies Page: AWS Class Polarity DescriptionmohamedabubackerNo ratings yet

- Wps Sp14 Reva PDFDocument9 pagesWps Sp14 Reva PDFravi00098No ratings yet

- Welder Qualification Certificate for MainuddinDocument1 pageWelder Qualification Certificate for MainuddinAnirban Sen SharmaNo ratings yet

- 4 - PRESSURE VESSEL (Inspection and Testing)Document69 pages4 - PRESSURE VESSEL (Inspection and Testing)Wahyu Lailil FaisNo ratings yet

- Weld Defects and Imperfections GuideDocument43 pagesWeld Defects and Imperfections Guideraju100% (1)

- Procedure Qualification Record (PQR) FormDocument1 pageProcedure Qualification Record (PQR) FormEarl HarbertNo ratings yet

- Welder Test Param19!03!201211Document151 pagesWelder Test Param19!03!201211VapaVapaNo ratings yet

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad PathanNo ratings yet

- UDocument1 pageUmohd as shahiddin jafriNo ratings yet

- The Complete Guide to Telephone Interview Questions and AnswersFrom EverandThe Complete Guide to Telephone Interview Questions and AnswersNo ratings yet

- WPSDocument1 pageWPSNidhinkorothNo ratings yet

- ListDocument4 pagesListnourfarmajidNo ratings yet

- ListDocument4 pagesListnourfarmajidNo ratings yet

- Iran Shirvan Gas Turbine Power Plant Water Treatment Equipment Data SheetDocument3 pagesIran Shirvan Gas Turbine Power Plant Water Treatment Equipment Data SheetnourfarmajidNo ratings yet

- SEWAGE O&M Rev.0Document23 pagesSEWAGE O&M Rev.0nourfarmajidNo ratings yet

- 30ME06ZKZ001Document7 pages30ME06ZKZ001nourfarmajidNo ratings yet

- Tag Number Kind NO. Size: Fire Fighting Water Supply Tag - No List - Plastic REV. BY EHSAN POURANG (17/07/2008)Document4 pagesTag Number Kind NO. Size: Fire Fighting Water Supply Tag - No List - Plastic REV. BY EHSAN POURANG (17/07/2008)nourfarmajidNo ratings yet

- Valve List FOR Water Treatment Plant: I.P.D.C. Project: Shirvan Gas Turbine Power PlantDocument2 pagesValve List FOR Water Treatment Plant: I.P.D.C. Project: Shirvan Gas Turbine Power PlantnourfarmajidNo ratings yet

- 30ME06ZKZ002Document8 pages30ME06ZKZ002nourfarmajidNo ratings yet

- Valve List FOR Water Treatment Plant: I.P.D.C. Project: Shirvan Gas Turbine Power PlantDocument2 pagesValve List FOR Water Treatment Plant: I.P.D.C. Project: Shirvan Gas Turbine Power PlantnourfarmajidNo ratings yet

- 30ME06ZKN001Document24 pages30ME06ZKN001nourfarmajidNo ratings yet

- T925Document3 pagesT925nourfarmajidNo ratings yet

- WTP I&C Conceptual and Basic Design: I.P.D.C. Roject: Shirvan Gas Turbine Power PlantDocument20 pagesWTP I&C Conceptual and Basic Design: I.P.D.C. Roject: Shirvan Gas Turbine Power PlantnourfarmajidNo ratings yet

- 60gaa30-Aa004 60gaa30-Aa005 60gaa30-Aa006 60gaa30-Aa007 60gaa30-Aa008 60gaa30-Aa009 60gaa30-Aa010 60gaa30-Aa802 60gaa30-Aa804Document2 pages60gaa30-Aa004 60gaa30-Aa005 60gaa30-Aa006 60gaa30-Aa007 60gaa30-Aa008 60gaa30-Aa009 60gaa30-Aa010 60gaa30-Aa802 60gaa30-Aa804nourfarmajidNo ratings yet

- Water Treatment Plant Tag, Label-01Document12 pagesWater Treatment Plant Tag, Label-01nourfarmajidNo ratings yet

- Fire Fighting & Water Supply Tag-Label-01Document5 pagesFire Fighting & Water Supply Tag-Label-01nourfarmajidNo ratings yet

- Fire Fighting & Water Supply Tag-LabelDocument10 pagesFire Fighting & Water Supply Tag-LabelnourfarmajidNo ratings yet

- Cathodic Protection System Calculation: I.P.D.C ProjectDocument10 pagesCathodic Protection System Calculation: I.P.D.C ProjectnourfarmajidNo ratings yet

- LabelDocument1 pageLabelnourfarmajidNo ratings yet

- Cathodic Protection System Calculation: I.P.D.C ProjectDocument10 pagesCathodic Protection System Calculation: I.P.D.C ProjectnourfarmajidNo ratings yet

- Cathodic Protection System Calculation: I.P.D.C ProjectDocument10 pagesCathodic Protection System Calculation: I.P.D.C ProjectnourfarmajidNo ratings yet

- Technical Specification FOR Cathodic Protection Materials: I.P.D.C ProjectDocument12 pagesTechnical Specification FOR Cathodic Protection Materials: I.P.D.C ProjectnourfarmajidNo ratings yet

- Cathodic Protection System Calculation: I.P.D.C ProjectDocument10 pagesCathodic Protection System Calculation: I.P.D.C ProjectnourfarmajidNo ratings yet

- Forwarding Pump House Power Cable Sizing Calculation: May.05 May.05 May.05Document4 pagesForwarding Pump House Power Cable Sizing Calculation: May.05 May.05 May.05nourfarmajidNo ratings yet

- Mto of Cathodic Protection System: MP-SVG-31ED-06-AE0-001Document4 pagesMto of Cathodic Protection System: MP-SVG-31ED-06-AE0-001nourfarmajidNo ratings yet

- Technical Specification FOR Cathodic Protection Materials: I.P.D.C ProjectDocument12 pagesTechnical Specification FOR Cathodic Protection Materials: I.P.D.C ProjectnourfarmajidNo ratings yet

- Inspection & Test Plan For Electrical Equipment of Natural Gas SystemDocument3 pagesInspection & Test Plan For Electrical Equipment of Natural Gas SystemnourfarmajidNo ratings yet

- Technical Specification FOR Cathodic Protection Materials: I.P.D.C ProjectDocument12 pagesTechnical Specification FOR Cathodic Protection Materials: I.P.D.C ProjectnourfarmajidNo ratings yet

- Inspection & Test Plan For Electrical Equipment of Natural Gas SystemDocument3 pagesInspection & Test Plan For Electrical Equipment of Natural Gas SystemnourfarmajidNo ratings yet

- Technical Specification FOR Cathodic Protection Materials: I.P.D.C ProjectDocument12 pagesTechnical Specification FOR Cathodic Protection Materials: I.P.D.C ProjectnourfarmajidNo ratings yet

- Technical Specification FOR Cathodic Protection Materials: I.P.D.C ProjectDocument12 pagesTechnical Specification FOR Cathodic Protection Materials: I.P.D.C ProjectnourfarmajidNo ratings yet

- CERADocument10 pagesCERAKeren Margarette AlcantaraNo ratings yet

- The Girls Center: 2023 Workout CalendarDocument17 pagesThe Girls Center: 2023 Workout Calendark4270621No ratings yet

- English Financial Assistance ApplicationDocument4 pagesEnglish Financial Assistance ApplicationAlyssa JenningsNo ratings yet

- Valvula de Leve MasterDocument20 pagesValvula de Leve Masterguillermo trejosNo ratings yet

- Insurance Principles, Types and Industry in IndiaDocument10 pagesInsurance Principles, Types and Industry in IndiaAroop PalNo ratings yet

- FileDocument284 pagesFileJesse GarciaNo ratings yet

- Siemens MV Gas Insulated Switch GearDocument14 pagesSiemens MV Gas Insulated Switch GearSajesh Thykoodan T VNo ratings yet

- TA-Ingles IX - UAPDocument10 pagesTA-Ingles IX - UAPmanuel brennerNo ratings yet

- Dr. Namrata Misra Head of Bioinnovations at KIIT UniversityDocument1 pageDr. Namrata Misra Head of Bioinnovations at KIIT Universitymanisha maniNo ratings yet

- DVAIO R3 PRO HD Sound Quality In-Ear Wired Earphone Amazon - in ElectronicsDocument1 pageDVAIO R3 PRO HD Sound Quality In-Ear Wired Earphone Amazon - in Electronicsdinple sharmaNo ratings yet

- FB77 Fish HatcheriesDocument6 pagesFB77 Fish HatcheriesFlorida Fish and Wildlife Conservation CommissionNo ratings yet

- Universal Basic IncomeDocument31 pagesUniversal Basic IncomeumairahmedbaigNo ratings yet

- Carpentry Shop: Building, Doors, Windows, Trusses, WorkbenchesDocument105 pagesCarpentry Shop: Building, Doors, Windows, Trusses, WorkbenchesVinod KumarNo ratings yet

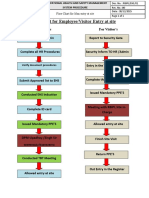

- fLOW CHART FOR WORKER'S ENTRYDocument2 pagesfLOW CHART FOR WORKER'S ENTRYshamshad ahamedNo ratings yet

- Grab Go Porter S 5 ForcesDocument2 pagesGrab Go Porter S 5 ForcesUtkarsh SharmaNo ratings yet

- Practical Examination Marking Guideline Grade 12 Physical Science 2019 PDFDocument5 pagesPractical Examination Marking Guideline Grade 12 Physical Science 2019 PDFWonder Bee Nzama100% (1)

- Genetically Engineered MicroorganismsDocument6 pagesGenetically Engineered Microorganismsaishwarya joshiNo ratings yet

- Growth Developt Pearl MilletDocument17 pagesGrowth Developt Pearl MilletdarmaNo ratings yet

- QRF HD785-7Document2 pagesQRF HD785-7Ralf MaurerNo ratings yet

- Proper restraint techniques for dogs and catsDocument153 pagesProper restraint techniques for dogs and catsjademattican75% (4)

- Jounce Therapeutics Company Events and Start DatesDocument48 pagesJounce Therapeutics Company Events and Start DatesEquity NestNo ratings yet

- Medpet Pigeon ProductsDocument54 pagesMedpet Pigeon ProductsJay Casem67% (3)

- ASR1201D ASR1201D-D: Slim Water-Proof RFID ReaderDocument1 pageASR1201D ASR1201D-D: Slim Water-Proof RFID ReaderCatalin BailescuNo ratings yet

- Job Satisfaction RRLDocument39 pagesJob Satisfaction RRLMarie Tiffany100% (1)

- CHAPTER3 Foundations of Individual BehaviorDocument32 pagesCHAPTER3 Foundations of Individual BehaviorLynoj AbangNo ratings yet

- Switzerland: Food and CultureDocument18 pagesSwitzerland: Food and CultureAaron CoutinhoNo ratings yet

- Bentel J408Document64 pagesBentel J408Bojan MarkovicNo ratings yet

- A. Kumar Aswamy Job Offer LetterDocument1 pageA. Kumar Aswamy Job Offer LetterHimanshu PatelNo ratings yet