Professional Documents

Culture Documents

Appliance Switching Using Eye Movement For Paralyzed People

Uploaded by

IAEME PublicationOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Appliance Switching Using Eye Movement For Paralyzed People

Uploaded by

IAEME PublicationCopyright:

Available Formats

International INTERNATIONALCommunication Engineering & Technology (IJECET), ISSN 0976 Journal of Electronics and JOURNAL OF ELECTRONICS AND 6464(Print),

, ISSN 0976 6472(Online) Volume 3, Issue 3, October- December (2012), IAEME

COMMUNICATION ENGINEERING & TECHNOLOGY (IJECET)

ISSN 0976 6464(Print) ISSN 0976 6472(Online) Volume 3, Issue 3, October- December (2012), pp. 187-196 IAEME: www.iaeme.com/ijecet.asp Journal Impact Factor (2012): 3.5930 (Calculated by GISI) www.jifactor.com

IJECET

IAEME

APPLIANCE SWITCHING USING EYE MOVEMENT FOR PARALYZED PEOPLE

OMKAR S. DESHPANDE E & TC Department, PVPIT, Bavdhan, Pune, Maharashtra, India. E-Mail: deshpandeomkar10@yahoo.com Prof. B.L. MAHAJAN Lecturer, E & TC Department, PVPIT, Bavdhan, Pune, Maharashtra, India. INDRANEEL P. CHAVAN E & TC Department, PVPIT, Bavdhan, Pune, Maharashtra, India. E-mail: chavan.indraneel@gmail.com BRIJESH B. CHAUDHARY E & TC Department, PVPIT, Bavdhan, Pune, Maharashtra, India. E-mail: vijesh.chuodhary@gmail.com ABSTRACT Paralysis is loss of muscle function, loss of feeling (sensory loss) in one or more affected areas. If there is sensory damage as well as motor & such people suffer from Motor Neuron Disease. In other words these people are in near vegetative state with only their eyes moving. Such people are completely dependent on other individuals for all of their work, starting from feeding to general change in position. So, a system needs to be developed to help these people to become independent. There are systems available in the market that are developed to help paralyzed people in some way or the other, but they are limited to only those people who are only partially paralyzed, that means, fully paralyzed people have little or no use of these systems. Also, these systems are very costly, bulky & less portable. Our system will be cost effective, portable & moreover it will help even those people who are completely paralyzed with only their eyes moving. This system will be based on only the movement of the eyes hence eliminating the need of any limb or any other body movements. Keywords: Eye-Sensing mechanism, LDR, microcontroller, RF transreceiver module, LCD

187

International Journal of Electronics and Communication Engineering & Technology (IJECET), ISSN 0976 6464(Print), ISSN 0976 6472(Online) Volume 3, Issue 3, October- December (2012), IAEME

1. INTRODUCTION Eye tracking is a technique whereby an individuals eye movements are measured so that the researcher knows both where a person is looking at any given time and the sequence in which their eyes are shifting from one location to another. The annual report of the Ministry of Public Health and Welfare states that 0.73 million people have a motor disability on the legs and arms. For people with these disabilities, many different kinds of activities like switching fan, tubelight, etc. on/off become very problematic due to restricted movements of these body parts. These people are dependent on others for switching any home devices whenever they want to. So, a solution to this using eye-motion technology is proposed by us in this paper.

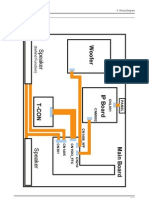

2. BLOCK DIAGRAM OF TRANSMISSION SECTION

Fig. 1: Block diagram of Transmission Section

(A) Eye Sensing Mechanism Requirements of sensing apparatus: The sensor should be able to detect minute changes in the movement of the iris. It should have minimum or no dependence on ambient light. Sensor placement should not depend upon the size of the iris. It should give maximum states with minimum movement of eye. It should have minimum eye fatigue, and should not harm the eye. What can we use to sense the movement of the eye? Can we use the lens of a camera which produces the image of the eye and then detect its motion? A digital camera circuit is a possible solution to the sensing problem. It has less dependence on ambient light and can detect minute movements of the eye. But the circuit is expensive to make and is complex for its requirement of rapid transmission of large data. There must be a simpler, cheaper and yet exquisite solution of the problem. LDRs are used for sensing the movement of the eye. It measures the reflected intensity of light by varying its resistance according to the light intensity incident on it. When the light intensity increases, it resistance decreases and vice-versa. LDR then converts it into voltage so that ADC of microcontroller can measure it. In reality, the normal eye movement without fatigue is the left and right movement only. The up movement of the eye, if done for more times, introduces fatigue to the eye. So it is preferable not to use the upward movement of the eye for control. In this system, we have used 2 LDRs which are positioned as- one to the left of the eyeball & another one to the right of eyeball-as shown in following figure:188

International Journal of Electronics and Communication Engineering & Technology (IJECET), ISSN 0976 6464(Print), ISSN 0976 6472(Online) Volume 3, Issue 3, October- December (2012), IAEME

Fig. 2: Positions of two LDRs with respect to eye

Now, we know that the visible portion of the eye has two parts namely white portion (called sclera in medical terminology) and the coloured portion (pertaining to the iris). These white and black parts of the eye have difference in the way they reflect light. The white sclera reflects most of the light falling on it, while the coloured iris will not reflect light with so much intensity. This intensity difference in the reflected light gives us our sensing mechanism. For the left-right movement of the eye, we have 2 cases:Case 1:- When the eyeball is rotated towards left

Fig. 3: Position of Focus of LDRs when eye is turned left

In this case, as seen from fig. 4, the focus of LDR1 moves on the black iris area of the eye while the focus of LDR2 is white sclera region. Since, black iris will absorb much of the incident light, the intensity of light reflected towards LDR1 will be less. And the intensity of light reflected towards LDR2 will be greater. So, the o/p voltage from LDR 1 will be more & o/p voltage of LDR2 will be greater (The maximum voltage from both LDRs will be same & the threshold levels of LDRs are equal to their maximum voltages). Hence, device corresponding to LDR2 will get toggled. Case 2:- When the eyeball is rotated towards right

Fig. 4: Position of Focus of LDRs when eye is turned right

189

International Journal of Electronics and Communication Engineering & Technology (IJECET), ISSN 0976 6464(Print), ISSN 0976 6472(Online) Volume 3, Issue 3, October- December (2012), IAEME

In this case, as seen from fig. 4, the focus of LDR1 moves on the black iris area of the eye while the focus of LDR2 is white sclera region. Since, black iris will absorb much of the incident light, the intensity of light reflected towards LDR1 will be greater. And the intensity of light reflected towards LDR2 will be less. So, the o/p voltage from LDR2 will be more & o/p voltage of LDR2 will be greater. Hence, device corresponding to LDR1 will get toggled.

Table 1: Truth Table for LDR1 & LDR2

(B) Conversion of Sensor Output into Digital Form:The RF module requires data serially and it also gives back the data serially. Hence it requires some assembly which converts the three or four bits of data acquired from the conversion mechanism to a sequence of serial data. As per our requirement, it is also necessary that this data should not be corrupted by any intervention of the same frequency. This means that we also must have some pre-sequence of at least three bits which is predefined, and this sequence should be checked at the decoder side to validate the data. All this can be taken

care of by the ADC (Analog-to-Digital) of microcontroller PIC16F877A.

The input to this ADC is the analog voltage signal from the corresponding LDR. Since we have used 2 LDRs, there will be two voltage signals (one from each LDR) applied to the two corresponding input pins of ADC. The converter then generates a digital result of this analog level via successive approximation. The A/D conversion of the analog input signal results in a corresponding 10-bit digital number. That means the output of the ADC will be in terms of 1s and 0s. This output is given to RF transmitter which is CMOS compatible & hence dont require line driver like MAX232. Why LCD connected to microcontroller? The output of ADC is given to the RF transmitter as well as to the LCD. This is done so that the user could know the ADC readings of both LDRs during the trials.. Also, we have displayed which device has been toggled at the receiver end merely for the sake of convenience. The user can disconnect LCD whenever he wants to.

190

International Journal of Electronics and Communication Engineering & Technology (IJECET), ISSN 0976 6464(Print), ISSN 0976 6472(Online) Volume 3, Issue 3, October- December (2012), IAEME

(C) Data Transmission Module After digital data has been made from the iris movement, this data needs to be transmitted without any error to a distant place, preferably near to the switchboards already installed in the room wirelessly. Wireless transmission is preferred to wired transmission here to avoid a jumble of wires spreading across the room. A point to be noted is that it is more economic to use wires if the switchboard is nearby. But wires may become inconvenient for the user in most cases. Requirements: The following are the main requirements of data transmission and reception: The transmission and reception should be essentially error free. Any disturbance of the same frequency must not hinder. It should have high distance range. Multiple samples of the eye per second should be sent. Size of the transmitter circuit should be so small that it can be implemented in spectacles itself. The RF module, we have used, operates at Radio Frequency. The corresponding frequency range varies between 30 kHz & 300 GHz. In this RF system, the digital data is represented as variations in the frequency of carrier wave. This kind of modulation is known as Frequency Shift Keying (FSK). This RF transmitter operates at a frequency of about 2.4GHz. It receives serial data in digital form from the output of microcontroller. It will convert this digital data into corresponding radio wave of the said frequency. The transmission occurs at the rate of around 250 kbps. 3. BLOCK DIAGRAM OF RECEIVER SECTION

Fig. 5: Block Diagram of Receiver Section

(A) RF Receiver This RF receiver will receive the RF signal at frequency 2.4 GHz from the RF transmitter. It will then convert the received signal into its equivalent digital form as it was at the input of RF transmitter. This digitally converted data is fed to the decision making section that is microcontroller PIC16F877A.

191

International Journal of Electronics and Communication Engineering & Technology (IJECET), ISSN 0976 6464(Print), ISSN 0976 6472(Online) Volume 3, Issue 3, October- December (2012), IAEME

(B) Decision Making Section The decision making block processes on the data available to it from the RF receiver. The microcontroller PIC16F877A is used for this purpose, where the main job of the controller is to make certain decisions according to the available data and send its decisions to the relay board. In addition to data processing, the microcontroller also double checks any false triggering, takes into account the delay caused due to wireless channel and checks whether the transmission is valid or not. Depending on the intensity of light reflection from eyes, microcontroller makes the decision on which of the devices (connected at output) will toggle its state depending on the program. Here, we have program the microcontroller in such way that if LDR1 gets stronger reflections, Relay 1 will be activated whereas LDR2 gets stronger reflections, Relay 2 will be activated. (C) Output Section The output section consists of the relay driver that drives the relays at its output. Since we have used only two devices to show the final output of our system, we require only two relayseach for one device. 4. SOFTWARE DESIGN (A)Software Used for Programming PIC16F877A For programming our microcontroller PIC16F877A, we have used software known as MPLAB IDE v8.56. Software Description MPLAB Integrated Development Environment (IDE) is a free, integrated toolset for the development of embedded applications employing Microchip's PIC and dsPIC microcontrollers. MPLAB IDE runs as a 32-bit application on MS Windows, is easy to use and includes a host of free software components for fast application development and super-charged debugging. MPLAB IDE also serves as a single, unified graphical user interface for additional Microchip and third party software and hardware development tools. MPLAB IDE has the same user interface for all tools. MPLAB IDE has highly optimized compilers for the PIC18 series microcontrollers, high performance PIC24 MCUs, dsPIC digital signal controllers and PIC32MX MCUs and not for PIC16 series. So, for compiling the code for PIC16 series we require third party compiler. Compiler:The third party compiler we have used for PIC16F887A microcontroller is Hi-tech C Compiler for PIC10/12/16 MCUs.

192

International Journal of Electronics and Communication Engineering & Technology (IJECET), ISSN 0976 6464(Print), ISSN 0976 6472(Online) Volume 3, Issue 3, October- December (2012), IAEME

(B)Flowchart of System Programming

193

International Journal of Electronics and Communication Engineering & Technology (IJECET), ISSN 0976 6464(Print), ISSN 0976 6472(Online) Volume 3, Issue 3, October- December (2012), IAEME

5. RESULT Here we have used red LED to represent the reflected light that will come from eye & will be incident on the LDRs. This is done merely for the sake of demonstration. The actual working & result of system is shown through photographic presentation from Fig. 6(a) to Fig. 6 (f).

Fig. 6 (a): Whole Circuit after turning ON

Fig. 6(b): Receiver LCD showing Device1 & Device2 initially in OFF state

194

International Journal of Electronics and Communication Engineering & Technology (IJECET), ISSN 0976 6464(Print), ISSN 0976 6472(Online) Volume 3, Issue 3, October- December (2012), IAEME

Fig. 6 (c): LED focus on LDR1 & Receiver LCD showing Device1 in ON state

Fig. 6 (d): LED refocused on LDR1 & Receiver LCD showing Device1 in OFF state

Fig. 6 (e): LED focused on LDR2 & Receiver LCD showing Device2 in ON state

Fig. 6 (f): LED refocused on LDR2 & Receiver LCD showing Device2 in OFF state

6. COMPARISON Our system is basically based on the system in [1]. But our system has some major differences compared to the above system. System [1] uses photodiode sensors whereas we have used LDR due to easy availability. This is done because of we already had a set of LDRs available with us. Although, using photodiodes will give good results. The signal conditioning circuit is required for system [1], but our system does not require any signal conditioning since o/p of sensor is suitable enough for further processing. Due to this, our system is less bulky. System [1] uses different modules for encoding, decoding, data transmission & reception,

195

International Journal of Electronics and Communication Engineering & Technology (IJECET), ISSN 0976 6464(Print), ISSN 0976 6472(Online) Volume 3, Issue 3, October- December (2012), IAEME

whereas our system uses single CC2500 RF transreceiver module which performs encoding, transmission, reception & decoding. This again reduces bulkiness of system & moreover reduces programming efforts since all functions are performed by same module. Microcontroller used in system [1] is basic 89C51 which cannot be used in case of any additional functionality needs to be added. Our system uses PIC16F877A which is superior to 89C51 in terms of operation speed, functionality, etc. Also, system [1] uses GUI on computer to display output. Hence, there are limitations on its portability & requires experts to maintain the GUI. Our system uses simple 16x2 LCD panel to display the output status. Thus, it is more portable & does not require any special expertise. Hence, our system is much cheaper, portable & technically robust.

7. CONCLUSION Right from the sensor module to the output, each module is working as expected. Our endeavor of the semester is successful Light Dependent Diode (LDRs) work well for good light intensity but not in poor light conditions. A way still needs to be found to reduce the dependence on ambient light. Attempts were also made to make the output of the device more reliable. But due to lack of time, funds we are restricted to very few attempts. This system can further be made more accurate, work in real world by making some optimizations. Few are listed below: We can use IR sensors to get more accurate output. We can create a Graphical User Interface (GUI) with visual and sound effects, so that it would be very easy and user-friendly device. We can make the data transmission more accurate & secure by using Xigbee (due to high cost of Xigbee as compared to CC2500; we have avoided using it & used CC2500 instead). 8. REFERENCES [1] Pethani Kishan V., Gor Mehul K. and Raja Jimit S. (2011), Intermediate Progress Report on ELECTRONIC SPECTACLES FOR PARALYZED PATIENTS Submitted in the partial fulfilment of ALL INDIA YOUNG ENGINEERS HUMANITARIAN CHALLENGE 2011 [2] Tim Wilmshurst (2009), Designing Embedded Systems with PIC Microcontrollers, Second Edition: Principles and Applications, Newnes Publications [3] Paul Horowitz, Winfield Hill, The Art of Electronics - 2nd Edition, Cambridge University Press.

196

You might also like

- A Study On The Reasons For Transgender To Become EntrepreneursDocument7 pagesA Study On The Reasons For Transgender To Become EntrepreneursIAEME PublicationNo ratings yet

- Determinants Affecting The User's Intention To Use Mobile Banking ApplicationsDocument8 pagesDeterminants Affecting The User's Intention To Use Mobile Banking ApplicationsIAEME PublicationNo ratings yet

- Analyse The User Predilection On Gpay and Phonepe For Digital TransactionsDocument7 pagesAnalyse The User Predilection On Gpay and Phonepe For Digital TransactionsIAEME PublicationNo ratings yet

- A Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurDocument7 pagesA Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurIAEME PublicationNo ratings yet

- A Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiDocument16 pagesA Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiIAEME PublicationNo ratings yet

- Broad Unexposed Skills of Transgender EntrepreneursDocument8 pagesBroad Unexposed Skills of Transgender EntrepreneursIAEME PublicationNo ratings yet

- Modeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyDocument14 pagesModeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyIAEME PublicationNo ratings yet

- Gandhi On Non-Violent PoliceDocument8 pagesGandhi On Non-Violent PoliceIAEME PublicationNo ratings yet

- Impact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesDocument10 pagesImpact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesIAEME PublicationNo ratings yet

- Voice Based Atm For Visually Impaired Using ArduinoDocument7 pagesVoice Based Atm For Visually Impaired Using ArduinoIAEME PublicationNo ratings yet

- Visualising Aging Parents & Their Close Carers Life Journey in Aging EconomyDocument4 pagesVisualising Aging Parents & Their Close Carers Life Journey in Aging EconomyIAEME PublicationNo ratings yet

- Influence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiDocument16 pagesInfluence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiIAEME PublicationNo ratings yet

- Application of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDDocument19 pagesApplication of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDIAEME PublicationNo ratings yet

- Role of Social Entrepreneurship in Rural Development of India - Problems and ChallengesDocument18 pagesRole of Social Entrepreneurship in Rural Development of India - Problems and ChallengesIAEME PublicationNo ratings yet

- A Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaDocument9 pagesA Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaIAEME PublicationNo ratings yet

- Moderating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorDocument7 pagesModerating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorIAEME PublicationNo ratings yet

- Attrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesDocument15 pagesAttrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesIAEME PublicationNo ratings yet

- EXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESDocument9 pagesEXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESIAEME PublicationNo ratings yet

- Knowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentDocument8 pagesKnowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentIAEME PublicationNo ratings yet

- Various Fuzzy Numbers and Their Various Ranking ApproachesDocument10 pagesVarious Fuzzy Numbers and Their Various Ranking ApproachesIAEME PublicationNo ratings yet

- Optimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsDocument13 pagesOptimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsIAEME PublicationNo ratings yet

- A Multiple - Channel Queuing Models On Fuzzy EnvironmentDocument13 pagesA Multiple - Channel Queuing Models On Fuzzy EnvironmentIAEME PublicationNo ratings yet

- A Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksDocument10 pagesA Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksIAEME PublicationNo ratings yet

- Financial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelDocument9 pagesFinancial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelIAEME PublicationNo ratings yet

- Dealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsDocument8 pagesDealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsIAEME PublicationNo ratings yet

- Prediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsDocument13 pagesPrediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsIAEME PublicationNo ratings yet

- Analysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsDocument13 pagesAnalysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsIAEME PublicationNo ratings yet

- A Review of Particle Swarm Optimization (Pso) AlgorithmDocument26 pagesA Review of Particle Swarm Optimization (Pso) AlgorithmIAEME PublicationNo ratings yet

- Quality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceDocument7 pagesQuality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceIAEME PublicationNo ratings yet

- Analysis On Machine Cell Recognition and Detaching From Neural SystemsDocument9 pagesAnalysis On Machine Cell Recognition and Detaching From Neural SystemsIAEME PublicationNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Motorola T6500 ManualDocument2 pagesMotorola T6500 ManualJazzejohnNo ratings yet

- Gulfstream GV Communications Systems GuideDocument30 pagesGulfstream GV Communications Systems GuideGourav DasNo ratings yet

- Course Description: Adama Science and Technology UniversityDocument7 pagesCourse Description: Adama Science and Technology UniversityTesfaye OlanaNo ratings yet

- MBC An SeriesDocument4 pagesMBC An SeriesPrity RaiNo ratings yet

- Chapter 3 NewDocument18 pagesChapter 3 NewCicie_RawkstarNo ratings yet

- LADSIMDocument2 pagesLADSIMLaily Fitria SbsquadNo ratings yet

- Auma Actuator DataDocument11 pagesAuma Actuator Datachinthala madhu babu67% (3)

- SDPDocument6 pagesSDPJay SuguitanNo ratings yet

- Two Way Radio ProtocolDocument2 pagesTwo Way Radio ProtocolwbuthodNo ratings yet

- AirLive WN-300R ManualDocument110 pagesAirLive WN-300R ManualAdde Arya KrisnamurttiNo ratings yet

- 01 - Von Neumann ArchitectureDocument3 pages01 - Von Neumann ArchitectureBernard BraingixNo ratings yet

- 2 The Zero-Order Hold and The DAC Model: 2.1 Transfer Function of The ZOHDocument4 pages2 The Zero-Order Hold and The DAC Model: 2.1 Transfer Function of The ZOHYassine DjillaliNo ratings yet

- An 5277Document6 pagesAn 5277balvercNo ratings yet

- Price of Age ComputersDocument90 pagesPrice of Age Computerslike pageNo ratings yet

- CQ Ts7471aDocument35 pagesCQ Ts7471ahyper_stormNo ratings yet

- Existing: BCCH (6 3) Ad-Hoc Hopping TCH - Sec1 Ad-Hoc Hopping TCH - Sec2 Ad-Hoc Hopping TCH - Sec3Document29 pagesExisting: BCCH (6 3) Ad-Hoc Hopping TCH - Sec1 Ad-Hoc Hopping TCH - Sec2 Ad-Hoc Hopping TCH - Sec3Doni AriyantoNo ratings yet

- Wiring Diagram Details for Multiple Display ConnectorsDocument5 pagesWiring Diagram Details for Multiple Display ConnectorsFernando CoutoNo ratings yet

- Bluetooth Module UART RKI-1546Document5 pagesBluetooth Module UART RKI-1546ShwetaSingh100% (1)

- Y4 - Module 4 - Serviciong and Repairing High-End Cellular PhoneDocument78 pagesY4 - Module 4 - Serviciong and Repairing High-End Cellular PhoneAlfie LariosaNo ratings yet

- T-3845 TETRA Base StationDocument2 pagesT-3845 TETRA Base StationSolomon GebreselassieNo ratings yet

- Marine Radio Co. Central Paging System for ShipsDocument2 pagesMarine Radio Co. Central Paging System for ShipskamranNo ratings yet

- Assignment PDFDocument2 pagesAssignment PDFTAPAS KUMAR MAJINo ratings yet

- Recloser NOJA 560 04Document12 pagesRecloser NOJA 560 04Richard Q. RojasNo ratings yet

- Bluetooth ArchitectureDocument29 pagesBluetooth Architecturellqa001No ratings yet

- Her 3006 PTDocument3 pagesHer 3006 PTameer_jaburNo ratings yet

- NTE261 (NPN) & NTE262 (PNP) Silicon Complementary Transistors Darlington Power AmplifierDocument2 pagesNTE261 (NPN) & NTE262 (PNP) Silicon Complementary Transistors Darlington Power Amplifiercriman45No ratings yet

- Eagle RLB150Document5 pagesEagle RLB150Vitor TorresNo ratings yet

- DS Sen SMT400 091509Document2 pagesDS Sen SMT400 091509bianhuiNo ratings yet

- Unit 2 First Class EceDocument26 pagesUnit 2 First Class EceKKS100% (1)

- DSP Solutions Section 1Document11 pagesDSP Solutions Section 1Mukesh KumarNo ratings yet