Professional Documents

Culture Documents

Valves Description

Uploaded by

priyanka236Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Valves Description

Uploaded by

priyanka236Copyright:

Available Formats

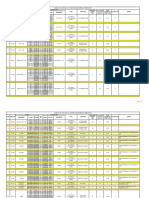

Type Gate valves

Description Linear motion valves used to start and stop flow. The valve is completely opened when the disk is removed from the flow stream. Classification of gate valves is made by the type of disk used: solid wedge, flexible wedge, split wedge, or parallel disk.

Advantage No resistance to flow when open Little pressure drop Good sealing when closed Little/no leakage

Image Credit: Cameron

Globe valves Linear motion valves used to start, stop and regulate flow. The disk moves perpendicular to the seat to open or close the flow so the annular space between the disk and seat ring gradually changes. There are three body designs for globe valves: Z-body, Y-body, and angle and three designs for the disk: ball disk, composition disk, and plug disk. Throttling and regulating flow Less seat leakage than Gate Valve

Image Credit: Flowserve

Ball valves

Rotational motion valves used to start, stop or throttle flow. It uses a ball shaped disk with a hole in it. When the valve is opened the hole of disk is turned in-line with the direction of the flow. When the valve is shut, the ball is rotated so that the hole is perpendicular to flow direction.

Less expensive Low maintenance costs Low torque Quick action on/off

Image Credit: Cameron

Compact No lubrication Tight sealing

Plug valves

Rotation motion valves used to stop and start fluid flow. The disk is a solid tapered or cylindrical plug with a bored passage at the right angle to the longitudinal axis of the plug. When open, the plug lines up with the inlet and outlet port of the valve body. The plugs are either round or cylindrical with a taper. Plug valves are easy to adapt

Rotational motion Suitable for multi-port designs

Image Credit: Cameron

Diaphragm valves

Linear motion vales that are used to start, regulate, and stop fluid flow. The disk is flexible and seals with the seat in an open area at the top of the valve body.

Well-suited for difficult environments (corrosive chemicals, slurries, radioactive fluids)

Ability to throttle

Image Credit: Dharmi engineers

Reducing Valves Automatic valves that reduce supply pressure to a preselected pressure. The supply pressure must remain at least as high as the selected pressure. The simplest of any valve design. Pinch valves consist of a Automatically reduces supply pressure to preselected pressure Relatively inexpensive

Pinch valves

sleeve molded of rubber or other synthetic material and a pinching mechanism. The pinching mechanism, a bar or gate, is lowered onto the valve body to cut off the flow through the system.

On/off as well as throttling/regulating

Good for slurries, solids Well-suited for difficult environments On/off as well as throttle/regulate Easily/quickly operated Good for large flow/low pressure applications due to saving in weight/size/cost Good for slurries/suspended solids.

Image Credit: Flowrox

Butterfly valve Rotary motion valves that can be used in on-off and throttling systems. They are quick and easy to operate. The flow control element is on either a vertical or horizontal axis and is opened when the handle is rotated 90 degrees and closed when the valve is turned an additional 90 degrees.

Image Credit: Cameron

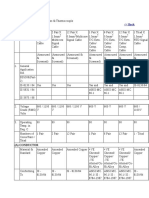

Needle valves Needle valves have a long, tapered, needle-like point that is used to make relatively fine adjustments in the amount of fluid flow. They are sometimes used as component parts for other valves because the needle allows for a gradual change in the size of the fluid flow opening. Check valves are used in systems employing gate valves because they prevent the reversal of flow in the piping system and there is a low pressure drop across the valve. The pressure of the fluid through the system opens the system, while the weight of the check mechanism will close the valve if the flow is reversed. A relief valve opens slowly as the pressure increases about the set-point and only opens as necessary. A safety valve rapidly opens as the pressure setting is reached and will stay open until the pressure is lower than the actuating pressure set-point. Both valves are used to prevent damage by relieving accidental overpressurized fluid systems. Good for fine adjustment throttling

Check valves

Prevents reverse flow

Image Credit: Cameron

Relief and safety valves

Prevents over-pressurization

Relief valves are used for incompressible fluids such as water or oil

Image Credit: Watts

Safety valves are used for compressible fluids such as steam.

http://www.globalspec.com/learnmore/flow_control_fl ow_transfer/valves/industrial_valves

You might also like

- 005-WPL-26-003 - 33kV Line-3 (D3) Control Cable Sch. & Term.Document4 pages005-WPL-26-003 - 33kV Line-3 (D3) Control Cable Sch. & Term.priyanka236No ratings yet

- D2 ANIMALA PSS_33kV LINE-2 CONTROL CABLE SCHEDULEDocument4 pagesD2 ANIMALA PSS_33kV LINE-2 CONTROL CABLE SCHEDULEpriyanka236No ratings yet

- Animala PSS 33kV Line-1 Control Cable ScheduleDocument7 pagesAnimala PSS 33kV Line-1 Control Cable Schedulepriyanka236No ratings yet

- 2 30Document1 page2 30priyanka236No ratings yet

- Animala PSS 33kV Line-1 Control Cable ScheduleDocument7 pagesAnimala PSS 33kV Line-1 Control Cable Schedulepriyanka236No ratings yet

- D2 ANIMALA PSS_33kV LINE-2 CONTROL CABLE SCHEDULEDocument4 pagesD2 ANIMALA PSS_33kV LINE-2 CONTROL CABLE SCHEDULEpriyanka236No ratings yet

- 005-WPL-26-003 - 33kV Line-3 (D3) Control Cable Sch. & Term.Document4 pages005-WPL-26-003 - 33kV Line-3 (D3) Control Cable Sch. & Term.priyanka236No ratings yet

- Short-Circuit Analysis of Industrial plant-IJAERDVO5IO346787 PDFDocument9 pagesShort-Circuit Analysis of Industrial plant-IJAERDVO5IO346787 PDFpriyanka236No ratings yet

- Type 2 Surge Arrester - VAL-MS 800/30 VF/FM - 2805402: Key Commercial DataDocument10 pagesType 2 Surge Arrester - VAL-MS 800/30 VF/FM - 2805402: Key Commercial Datapriyanka236No ratings yet

- FOX505 Product Manual 1KHW001973 Ed02d PDFDocument139 pagesFOX505 Product Manual 1KHW001973 Ed02d PDFpriyanka236No ratings yet

- A Leading Manufacturer of Instrumentation Cables Eng 287827Document24 pagesA Leading Manufacturer of Instrumentation Cables Eng 287827priyanka236No ratings yet

- Instrumentation Screened CablesDocument5 pagesInstrumentation Screened Cablespriyanka236No ratings yet

- 1 - 117 - FOX505 NL PDFDocument2 pages1 - 117 - FOX505 NL PDFpriyanka236No ratings yet

- 2 30 PDFDocument1 page2 30 PDFpriyanka236No ratings yet

- Details Works Executed For JVVNL PDFDocument4 pagesDetails Works Executed For JVVNL PDFpriyanka236No ratings yet

- Electrical Design Calculations GuideDocument34 pagesElectrical Design Calculations GuideAji Istanto Rambono86% (7)

- C.B Tripping Setting-Motor Data (28!5!11)Document31 pagesC.B Tripping Setting-Motor Data (28!5!11)KIS610No ratings yet

- BS1 - Trip - Close Coil Voltage Drop Calculation Rev ADocument11 pagesBS1 - Trip - Close Coil Voltage Drop Calculation Rev Apriyanka236No ratings yet

- 3RH29111GA40 Datasheet enDocument6 pages3RH29111GA40 Datasheet enEvomax EngenhariaNo ratings yet

- Type 2 Surge Arrester - VAL-MS 800/30 VF/FM - 2805402: Key Commercial DataDocument10 pagesType 2 Surge Arrester - VAL-MS 800/30 VF/FM - 2805402: Key Commercial Datapriyanka236No ratings yet

- Relay Coordination Using ETAP PDFDocument6 pagesRelay Coordination Using ETAP PDFRihlesh ParlNo ratings yet

- 3RH29111GA40 Datasheet enDocument6 pages3RH29111GA40 Datasheet enEvomax EngenhariaNo ratings yet

- Model Question Paper - 2006 National Certification Examination Energy Managers & Energy AuditorsDocument7 pagesModel Question Paper - 2006 National Certification Examination Energy Managers & Energy AuditorsimkamleshNo ratings yet

- 3RH29111GA40 Datasheet enDocument6 pages3RH29111GA40 Datasheet enEvomax EngenhariaNo ratings yet

- 1MRK506267-WEN C en REL670 Setting Example 1Document42 pages1MRK506267-WEN C en REL670 Setting Example 1john82% (17)

- Guide To Forms of Separation FinalDocument31 pagesGuide To Forms of Separation FinalMucha MuchanNo ratings yet

- Display The Curve of A Phase Overcurrent Device in A Ground Time-Current Curve (TCC) PlotDocument2 pagesDisplay The Curve of A Phase Overcurrent Device in A Ground Time-Current Curve (TCC) Plotchellaae2748100% (1)

- Details Works Executed For JVVNLDocument4 pagesDetails Works Executed For JVVNLpriyanka236No ratings yet

- Conference Programes I 2019Document4 pagesConference Programes I 2019priyanka236No ratings yet

- Model Question Paper - 2006 National Certification Examination Energy Managers & Energy AuditorsDocument7 pagesModel Question Paper - 2006 National Certification Examination Energy Managers & Energy AuditorsimkamleshNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Cereal Partners World Wide (Case Presentation)Document42 pagesCereal Partners World Wide (Case Presentation)Misbah JamilNo ratings yet

- Applying problem solving techniques to routine computer issuesDocument2 pagesApplying problem solving techniques to routine computer issuesBirhanu Atnafu0% (1)

- Senior High School Core Curriculum SubjectsDocument3 pagesSenior High School Core Curriculum Subjectsmarylou austriaNo ratings yet

- The Power Elite and The Secret Nazi PlanDocument80 pagesThe Power Elite and The Secret Nazi Planpfoxworth67% (3)

- Diploma Engineer Question Paper-1Document1 pageDiploma Engineer Question Paper-1Nahid RahmanNo ratings yet

- Specifications For Metro Ethernet 13-Sdms-10Document30 pagesSpecifications For Metro Ethernet 13-Sdms-10ashrafNo ratings yet

- Cau Truc To HopDocument1,258 pagesCau Truc To Hopkhôi trươngNo ratings yet

- Introducing Global PoliticsDocument8 pagesIntroducing Global PoliticsMeann Joy BaclayonNo ratings yet

- Bus 102 QuestionsDocument4 pagesBus 102 Questionsali2aliyuNo ratings yet

- Practice Notes FOR Quantity SurveyorsDocument7 pagesPractice Notes FOR Quantity SurveyorsYasirNo ratings yet

- Face Detection PythonDocument5 pagesFace Detection PythonAADISH JAINNo ratings yet

- Service Manual Aire Central Lg. Ln-C0602sa0 PDFDocument31 pagesService Manual Aire Central Lg. Ln-C0602sa0 PDFFreddy Enrique Luna MirabalNo ratings yet

- Ds Gigavue FM Fabric ManagerDocument9 pagesDs Gigavue FM Fabric ManagerMARCELOTRIVELATTONo ratings yet

- Image Processing Toolbox - FunctionsDocument16 pagesImage Processing Toolbox - Functionsabcd efghNo ratings yet

- TOTO Indonesia Sanitary CatalogDocument40 pagesTOTO Indonesia Sanitary CatalogiaqistiNo ratings yet

- Essay 5 Practice Activities - DBS IntroductionsDocument6 pagesEssay 5 Practice Activities - DBS IntroductionsLeyla IsayevaNo ratings yet

- DesertationDocument145 pagesDesertationhishamromi760% (1)

- Concreting PlantsDocument9 pagesConcreting PlantsSabrina MustafaNo ratings yet

- Alignment Cooling Water Pump 4A: Halaman: 1 Dari 1 HalamanDocument3 pagesAlignment Cooling Water Pump 4A: Halaman: 1 Dari 1 Halamanpemeliharaan.turbin03No ratings yet

- HHF-1600 Direct-Drive Pump Utilization Parts ListDocument27 pagesHHF-1600 Direct-Drive Pump Utilization Parts ListJohn Simanca100% (1)

- Royal Harare Golf Club: An Oasis of Excellence in The Midst of Political and Economic DevastationDocument24 pagesRoyal Harare Golf Club: An Oasis of Excellence in The Midst of Political and Economic DevastationCompleatGolferNo ratings yet

- Final IEQC MICRODocument10 pagesFinal IEQC MICROWMG NINJANo ratings yet

- Why Delegate Authority and Empower EmployeesDocument5 pagesWhy Delegate Authority and Empower EmployeesHarold MaribojocNo ratings yet

- Theory of Elinor OstromDocument5 pagesTheory of Elinor OstromSanjana KrishnakumarNo ratings yet

- Science Room Rules Teaching PlanDocument1 pageScience Room Rules Teaching PlanraqibsheenaNo ratings yet

- Specijalni Elektrici MasiniDocument22 pagesSpecijalni Elektrici MasiniIgor JovanovskiNo ratings yet

- Netflix AccountsDocument2 pagesNetflix AccountsjzefjbjeNo ratings yet

- Material SelectionDocument99 pagesMaterial SelectionRaj Bindas100% (8)

- Ramdump Modem 2021-06-26 00-06-27 PropsDocument15 pagesRamdump Modem 2021-06-26 00-06-27 PropsKoikoiNo ratings yet

- Introduction To TQMDocument24 pagesIntroduction To TQMSimantoPreeom100% (1)