Professional Documents

Culture Documents

How To Make A Simple Sinker EDM For Under $100

Uploaded by

ryanrenzeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

How To Make A Simple Sinker EDM For Under $100

Uploaded by

ryanrenzeCopyright:

Available Formats

Space-Age Machining in Your Home Shop

For less than $5(1960s Dollars), you can make a device that harnesses electric sparks to chip out holes and cavities in metal This file was created and is distributed by masterplans/ Plans That Work. Do not re-sell!

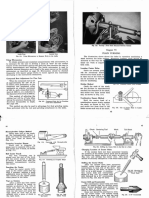

This experimental EDM device did the machining shown at the top of the page. You can assemble one for less than $5.

Tiny electric sparks are the newest aid to industry's use of the tough, exotic spaceage metals that resist cutting by ordinary machine tools. The benefits extend even to common, every-day materials because contours too intricate for shaping by standard methods are handled routinely by this electric wonder. EDM are the initials by which this h e lp f u l giant is known. The letters stand for "electric-discharge machining." The phenomenon of an electric spark blasting a particle off metal has been known in the lab for a quarter of a century. Rut only in the last decade have American machine-tool manufacturers made electric-discharge machines commercially available and only within the last few years has EDM moved into most well-equipped machine shops. One reason for the slow adoption is money. It takes a well-heeled shop to afford EDM; even an unfancy u n it costs in the thousands, But you can put EDM to work in your own home shop for a five-dollar hill and have change left over. The secret lies in the little experimental machine pictured and described. We'll call this one the EDm. Tn this case the letters stand for "electric-discharge midget." But take a look at the photographs and see what this midget does to a piece of aluminum. The cavities and the through holes were all cut using soft-brass male forms or "tools." Calling the form a "tool" is more a matter of custom than of description because this tool never actually contacts the workpiece. It's a jumping-off place for the sparks. To understand why a spark chips off particles of metal, think of a steel b u lle t fired point blank at a large object wit h a brittle surface. Assuming that the bullet hasn't the power to pierce, it will chip the surface, leaving a little crater. 'The sparks act in the same manner. Since there are myriads of them, all the tiny spark craters merge into continually new surfaces as the cutting progresses. This can form a cavity or go through to form a hole. One controlling feature is important in order to maintain the bullet to surface relationship: The sparks must be made to go in only one direction- toward the workpiece. This is accomplished by making the tool negative a n d the workpiece positive. Theoretically it. would be quite possible to have the sparks occur in air just as lightning does. In actual practice this would be more difficult and les,s effective because a property of materials known as the dielectric constant determines the amount of energy each spark can carry. The dielectric constant of air is approximately I, of kerosene more than twice as great. Further up on

the scale are alcohol at 2.1), and water with an astronomical 80. Kerosene is the choice. Industry chooses kerosene for the dielectric in its commercial EDM machines. You may wonder why, because the above figures would seem to make other liquids more efficient. The answer is that kerosene is cheap, universally available, not too flammable, and does not cause rust. In our EDm we are going to tag along with the industry and choose kerosene. Again theoretically, alcohol could be used and would yield some cutting a d v a n t a g e s . But it is expensive, its vapor.-, are explosive, and its handling requires caution. On the basis of its high dielectric constant, water would seem to the perfect medium;. Actually, it is practically worthless for EDM because the voltage between the tool and the workpiece dissociates it i n t o hydrogen and oxygen, an explosive pair. Stripped to its mechanical basics, our EDm combines a means for securing a workpiece in a can of kerosene means fur positioning a tool and then moving it accurately up and down without backlash. However, there is nothing sacred about either the design chosen here, or the size, and you can use your own ingenuity as long as you achieve the hold-down for the submerged workpiece and the no-backlash vertical motion of the tool. The pan used was plastic; it' could be glass or even metal. Commercial EDMs contain complicated power supplies and even more involved pulsing circuits to time and control the sparks. We arc "going to accomplish an almost equivalent result in simpler fashion and at far less cost.

Understanding EDM action. As a tool comes close to work, sparks begin to chip off tiny particles (A). A cavity forms (B) as toot advances. As cavity deepens, ar important factor overcutcomes into play (C). This is a term fo' the amount hole is larger than tool. Since an electric spark al ways takes shortest route, cutting takes place in overcut as tool advances (D). Chips are blasted out OVEB-CUT

Relative cutting speeds of various metals tint you could use for tools in EDM work are indicated on this chart. Graphite makes a good, long-lasting tool.

An experimental machine can be quickly put together by applying the ideas in this ebook.

Through holes can be made with the experimental EDM machine and the holes will be exactly the shape of the tool cross section. See photo above. Drilling center hole first (sketch) gives closer cuts.

Modern silicon rectifier that'll pass at least two amperes and make experimental EDM machine useful is Size of cap screw, costs less than a dollar(again this was 1960s dollars, we purchased the one above on eBay for less than $10).

You feed the tool. In all honesty, there is one point on which our EDm must bow to its superiors: The commercial EDM feeds the tool continuously and automatically until the culling is completed. It does this with electronic sensing circuits that control servo mechanisms. In our EDm the tool feeding w i l l be done by your hands. The tool must always be negative and the workpiece positive. This implies direct current. Since house wiring is alternating current a rectifier is needed. This rectifier must pass at least a couple of amperes in order to make our machine useful. Once this would have meant a clumsy problem, but the modern silicon rectifier with this current rating is little larger than a cap screw and costs under a dollar. In the electrical circuit the lamp bulbs control operation. Bulb A limits the maximum current the unit will draw from the house mains and keeps it within the rating of the rectifier. (The rule is approximately 100 watts per rectifier ampere; our EDm has a two-ampere rectifier, and so lamp A can never exceed 200 watts.) Lamp B controls the pulse rate and is found by experiment for each cutting job. In our EDm it can be anything from 200 watts down; the smaller wattages make finer cuts and are slower. Tine capacitors are of the electrolytic type and should have u working voltage rating of at least 150 volts to be adequate. Higher voltage ratings cost more but are added insurance for

longevity. The capacitors chosen here are 200 mfd. and these provide a respectable cutting rate. You might want to glamorize your EDm by adding several capacitors of different capacitances selectable by a switch for fine tuning to each job. (The important thing about booking up rectifiers and electrolytics is to be meticulous about observing correct polarity.) The first, capacitor acts as a reservoir to hold a supply of "juice" constantly in readiness. The second capacitor determines the pulsing of the sparks because it charges slowly through the lamp bulb and then hurls this charge at the work-piece in the form of a spark. One caution: The metal parts of our EDm are "hot." Place it on a pad of newspapers when in use and don't, bring it in contact with water pipes, radiators, or damp garage and collar floors. The only part you touch d u r i n g operation is the handle on the insulated screw. No switch is provided. This is an on-purpose omission because the plug should be pulled during a ll setup a n d preliminary adjustments. Incidentally the wiring is- a sort of "fail safe" because any short circuit in capacitors, work, or rectifier will simply light the lamps and won't bother the house fuses or breakers. And now to get down to the business of cutting metal. Before the first shakedown cruise, check and make sure that the tool is really negative. Do this by putting a workpiece in place and holding it down with the cross rods that also make the electrical connection. Bring the tool down close to the work but not touching. Fill the pan with plain water. Insert a 200-watt bulb at A and a 100-watt bulb at B. Put in the plug. Bubbles should form at the tool only. If this checks out. pull the plug, discharge the capacitors by gently running the tool down to touch the work, and dump the water. Fill the pan with kerosene. Replace the plug and you are on your way to the magic experience of electric-discharge machining. Cu t t in g is controlled by starting with [he tool touching the work; this will light both bulbs. Back the tool off slightly; the bulbs will dim and the cutting will commence with a continuous crackling sound. The louder this noise the coarser the cut. A little practice will enable you to keep feeding the tool down to maintain a gentle p u rrin g that means a fine, close cut. The kerosene will become dark from the millions of particles knocked off the workpiece. At the end of the job it can be placed in a jar to settle, the clear liquid decanted and re-used. (Commercial EDM's have pumps and filters to take care of this.) One-half (urn of the feed screw runs the tool down 1 / 3 2 inch. Depth of cut can therefore be monitored by counting the number of h a l f turns after the tool starts cutting. The workpiece should be blocked up off the bottom oi' the pan when making through holes so the tool can make a clean pass. The beauty of EDM is that the tools can be made from relatively soft, easily machined material. For the range, check over the accompanying chart. In industry, the preferred choice is graphite. Your EDm lets you make dies, molds, odd-shaped holes...

Dies and molds in all kinds of shapes are a factor in your shop work with the little EDM machine. Photo top shows how a stamping was made from a bit of sheet metal, using a drill press to exert pressure. Second frame shows an EDM machine making a mold for a badge. This method is also used in making coins.

Original circuit diagram

Schematics of a version using a bridge rectifier and capacitors salvaged from a computers power supply. See other files for more details.

You might also like

- Onboard Welder Using A GM Delco 140 Amp AlternatorDocument12 pagesOnboard Welder Using A GM Delco 140 Amp AlternatorWorldRead100% (1)

- Reverse Electroplating of SilverDocument2 pagesReverse Electroplating of SilverMohammad Umer AsgherNo ratings yet

- Mill Keyways On LatheDocument1 pageMill Keyways On LatheJim100% (3)

- Hardinge HLV-H Maintenance ManualDocument186 pagesHardinge HLV-H Maintenance ManualOogway MasterNo ratings yet

- WPS 39 Model Engineers Workshop Projects PDFDocument55 pagesWPS 39 Model Engineers Workshop Projects PDFabeeraj100% (3)

- Techcatalogue EbookDocument87 pagesTechcatalogue EbookPablo Valenzuela ArredondoNo ratings yet

- Fault Code: 1682 - SPN: 3362 - FMI: 31: B6.7 CM2350 B121BDocument17 pagesFault Code: 1682 - SPN: 3362 - FMI: 31: B6.7 CM2350 B121BJeisson MendozaNo ratings yet

- EDM ConstructionDocument8 pagesEDM ConstructionNacer Mezghiche100% (1)

- Ralph Patterson Tailstock Camlock 2Document13 pagesRalph Patterson Tailstock Camlock 2supremesportsNo ratings yet

- 3 Cylinder Radial Steam EngineDocument3 pages3 Cylinder Radial Steam Engineidriss0% (1)

- Breadboard Experiments NImyDAQ and MultisimDocument84 pagesBreadboard Experiments NImyDAQ and MultisimmadangkNo ratings yet

- Lathes and Lathe Machining OperationsDocument18 pagesLathes and Lathe Machining Operationssarasrisam100% (1)

- 27 - SpindlesDocument81 pages27 - SpindlessanderribeiroNo ratings yet

- South Bend 9" Compound Slide Screw Fabrication For A Large Dial/Thrust Bearing Conversion by Ed Godwin 8 December, 2007Document16 pagesSouth Bend 9" Compound Slide Screw Fabrication For A Large Dial/Thrust Bearing Conversion by Ed Godwin 8 December, 2007asdfNo ratings yet

- Acoustic Tractor Beam: 35 Steps (With Pictures) PDFDocument38 pagesAcoustic Tractor Beam: 35 Steps (With Pictures) PDFAmirNo ratings yet

- 48V DCDB 1 & 2Document16 pages48V DCDB 1 & 2Hytech Pvt. Ltd.100% (1)

- Drill Grinding With The PP-U3 Grinder Copy of The Deckel SO GrinderDocument14 pagesDrill Grinding With The PP-U3 Grinder Copy of The Deckel SO GrinderAndy L100% (1)

- Turning Lathes - A Manual For Technical Schools And Apprentices - A Guide To Turning, Screw-Cutting Metal SpinningFrom EverandTurning Lathes - A Manual For Technical Schools And Apprentices - A Guide To Turning, Screw-Cutting Metal SpinningRating: 2.5 out of 5 stars2.5/5 (2)

- 8454 PDFDocument72 pages8454 PDFjon@libertyintegrationcom100% (2)

- Metal SpinningDocument4 pagesMetal SpinningfranklynNo ratings yet

- Voltage Regulator Equipment: InstructionsDocument28 pagesVoltage Regulator Equipment: Instructionslxd.hepNo ratings yet

- A Mini Spark Erosion Machine for Model EngineersDocument11 pagesA Mini Spark Erosion Machine for Model EngineersWedy Lim100% (1)

- How To Weld - TIG WeldingDocument14 pagesHow To Weld - TIG Weldingjumpupdnbdj100% (1)

- From Industry To Alchemy - Burgmaster A Machine Tool Company PDFDocument408 pagesFrom Industry To Alchemy - Burgmaster A Machine Tool Company PDFLaurence DuterteNo ratings yet

- The C3 Mini Lathe IDocument3 pagesThe C3 Mini Lathe IAnonymous mKdAfWifNo ratings yet

- Engmod2T: The Multi-Cylinder Two-Stroke Engine SimulatorDocument8 pagesEngmod2T: The Multi-Cylinder Two-Stroke Engine SimulatorByndy95No ratings yet

- Diamond Tool Holder for Mini LatheDocument12 pagesDiamond Tool Holder for Mini Latheian_newNo ratings yet

- The String Method of Wheel AlignmentDocument5 pagesThe String Method of Wheel Alignmentrb4069100% (1)

- 2562 The Model EngineerDocument31 pages2562 The Model Engineerstilmix60No ratings yet

- PowerTIG 250EX 2016Document32 pagesPowerTIG 250EX 2016Bob john100% (1)

- 3 PhaseDocument9 pages3 PhaseArnulfo LavaresNo ratings yet

- Tramming Bridgeport MillDocument13 pagesTramming Bridgeport Millva3ttn100% (2)

- Series 7 Lathes: Technical Support Explaining Changewheel Sets For Lathes With Changewheel Driven LeadscrewsDocument8 pagesSeries 7 Lathes: Technical Support Explaining Changewheel Sets For Lathes With Changewheel Driven LeadscrewsTomas MalyNo ratings yet

- Analog Parts Kit - DigilentDocument6 pagesAnalog Parts Kit - DigilentMario AcostaNo ratings yet

- Inside Type Outside Type: Fit. 113. Turain! e Steet Shaft Mounted Betw M CeotercDocument22 pagesInside Type Outside Type: Fit. 113. Turain! e Steet Shaft Mounted Betw M CeotercRick ManNo ratings yet

- Building PYRTE: The Simplest Live-Steam Pull-You-Round Traction EngineDocument14 pagesBuilding PYRTE: The Simplest Live-Steam Pull-You-Round Traction EngineRazaMobizoNo ratings yet

- MyfordDocument1 pageMyfordPeanut d. DestroyerNo ratings yet

- Operating: Maintenance ManualDocument18 pagesOperating: Maintenance ManualAnonymous reYe6iCCNo ratings yet

- Hardinge Lathe HLV H ManualDocument35 pagesHardinge Lathe HLV H ManualJhonatanRengifoBecerra100% (2)

- Cold Setting The Valves On A 1953 Dodge M37 Power WagonDocument2 pagesCold Setting The Valves On A 1953 Dodge M37 Power Wagoncriag100% (1)

- Crucible Size and Surounding Space Size For Furnace - Home Model Engine MachinistDocument4 pagesCrucible Size and Surounding Space Size For Furnace - Home Model Engine MachinistKhin Aung ShweNo ratings yet

- 8454 PDFDocument72 pages8454 PDFjon@libertyintegrationcomNo ratings yet

- EscortsDocument2 pagesEscortspratikNo ratings yet

- The Art of Centered Eye BendingDocument29 pagesThe Art of Centered Eye BendingKhin Aung Shwe100% (1)

- Schaublin 102N Lathe Technical DetailsDocument1 pageSchaublin 102N Lathe Technical DetailsFranciscoNo ratings yet

- Aluminium-Welding: Course Book GBDocument58 pagesAluminium-Welding: Course Book GBlilux519No ratings yet

- Shaper MachineDocument81 pagesShaper Machinesam clastineNo ratings yet

- Biax 7EL assembly guideDocument6 pagesBiax 7EL assembly guideKarsten BergNo ratings yet

- Rebuild ManualDocument55 pagesRebuild Manualaccujack0% (1)

- LaserDocument29 pagesLaserGaurav YadavNo ratings yet

- Modification and Development of Work Holding Device - Steady-RestDocument6 pagesModification and Development of Work Holding Device - Steady-RestInternational Journal of Innovative Science and Research Technology100% (1)

- Machining FundamentalsDocument32 pagesMachining FundamentalsCh TalhaNo ratings yet

- Measuring tools and techniques in metalworkingDocument2 pagesMeasuring tools and techniques in metalworkingInstruktur MesinNo ratings yet

- Rivett Lathe 1020S ManualDocument54 pagesRivett Lathe 1020S Manualhhelp12255No ratings yet

- Southbend Shaper V2 Parts ListDocument6 pagesSouthbend Shaper V2 Parts ListStephen HowardNo ratings yet

- Craftsman 6-Inch Lathe ManualDocument8 pagesCraftsman 6-Inch Lathe ManualfarfromfreedNo ratings yet

- Functional Composite Materials: Manufacturing Technology and Experimental ApplicationFrom EverandFunctional Composite Materials: Manufacturing Technology and Experimental ApplicationNo ratings yet

- 7.smart Meter With Non-Intrusive Load Monitoring For Use in Smart HomesDocument3 pages7.smart Meter With Non-Intrusive Load Monitoring For Use in Smart HomesE-dot ProjectNo ratings yet

- Name of WorkDocument14 pagesName of WorkNitin KambleNo ratings yet

- C - EN+ES+DE - R410A+R32 - Installation Manual - A5 - WEBDocument68 pagesC - EN+ES+DE - R410A+R32 - Installation Manual - A5 - WEBYeison MendozaNo ratings yet

- Room AutomationDocument18 pagesRoom Automationmostafa HusseinNo ratings yet

- APT - Line CB (E3) : Service ManualDocument100 pagesAPT - Line CB (E3) : Service ManualDavid EguezNo ratings yet

- F7 - 923312025 - 09 - 003 - Bsi-1 - 2Document4 pagesF7 - 923312025 - 09 - 003 - Bsi-1 - 2SaraNo ratings yet

- TT CPN1 Fuse Operation Under DC Conditions ENDocument7 pagesTT CPN1 Fuse Operation Under DC Conditions ENanak1.bintangNo ratings yet

- Makita 9046 Manual Lixadeira Orbital Treme TremeDocument8 pagesMakita 9046 Manual Lixadeira Orbital Treme TremepaulofloresjuniorNo ratings yet

- An5 PDFDocument2 pagesAn5 PDFJonathan JaegerNo ratings yet

- Int. Horario AD1NO-R-15m ABBDocument3 pagesInt. Horario AD1NO-R-15m ABBErik Marcelo BarrenecheaNo ratings yet

- RA12-55 Battery Specs - 12V 55Ah AGM VRLA Battery for UPS, Telecom, MedicalDocument2 pagesRA12-55 Battery Specs - 12V 55Ah AGM VRLA Battery for UPS, Telecom, MedicalGeorgeNo ratings yet

- Harmony XVR Xvr12b05sDocument3 pagesHarmony XVR Xvr12b05sSarlo11No ratings yet

- Autoclave PM Inspection Sheet: Plumbing - PressuresDocument2 pagesAutoclave PM Inspection Sheet: Plumbing - PressuresAd MinNo ratings yet

- Kwik-Lock / Ratchet & Roll Kit: Parts ListsDocument16 pagesKwik-Lock / Ratchet & Roll Kit: Parts ListsJonah RagleNo ratings yet

- Parts list for multiple KW-AVX modelsDocument23 pagesParts list for multiple KW-AVX modelsCarlos Alonso Gonzalez VazquesNo ratings yet

- Abb Satellite Level 3 DiplomaDocument4 pagesAbb Satellite Level 3 DiplomaMiguelNo ratings yet

- Paper Single Slope ADCDocument4 pagesPaper Single Slope ADCArdittoTrianggada100% (1)

- Practica 35 ThermistorDocument4 pagesPractica 35 ThermistorDiego Ruben Varela ArriagaNo ratings yet

- motionSCOUT Next Generation Personal Alert SafetyDocument2 pagesmotionSCOUT Next Generation Personal Alert SafetySantosh MaliNo ratings yet

- Red Box Tools BrochureDocument28 pagesRed Box Tools Brochureabduelhalim albseerNo ratings yet

- Datasheet of OT FIT 7 TEDocument3 pagesDatasheet of OT FIT 7 TEpeter hansenNo ratings yet

- Tiri StoresDocument2 pagesTiri StoresgdgdgdgNo ratings yet

- Laborator 2 - Signal ConditioningDocument46 pagesLaborator 2 - Signal ConditioningIon Daniel-EduardNo ratings yet

- Schurter 4304.6090 DatasheetDocument6 pagesSchurter 4304.6090 DatasheetvvvNo ratings yet

- ReflexWing Manual Rev 3Document40 pagesReflexWing Manual Rev 3Jon Pio DinopolNo ratings yet

- INSTALLATION MANUAL TITLEDocument18 pagesINSTALLATION MANUAL TITLEAgung PrasetyoNo ratings yet

- Lesson 8 Final Control ElementDocument9 pagesLesson 8 Final Control ElementRachel Renti CruzNo ratings yet