Professional Documents

Culture Documents

Shed Plans

Uploaded by

Francis Wolfgang UrbanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shed Plans

Uploaded by

Francis Wolfgang UrbanCopyright:

Available Formats

just sheds inc.

www.just-sheds.com

PLEASE READ THROUGH ENTIRELY

THESE PLANS ALLOW YOU TO BUILD ON A CONCRETE SLAB, A WOODEN FLOOR SUPPORTED BY CONCRETE PIERS, OR A WOODEN FLOOR SUPPORTED ON SKIDS SEE OUR FREE ON LINE CONSTRUCTION GUIDE FOR MORE DETAILS

LEFT SIDE 8- 2 WALL AND FLOOR HEIGHT 8- 8 FRONT 10- 2

RIGHT SIDE 8- 2 WALL AND FLOOR HEIGHT 6- 0 BACK 10- 2

CONTENTS

PAGE PAGE PAGE PAGE PAGE PAGE PAGE PAGE PAGE PAGE PAGE PAGE PAGE PAGE PLUS 1 2 3 4 5 6 7 8 9 10 11 12 13 14 2 ELEVATIONS CROSS SECTION 1 FLOOR PLAN CONCRETE PAD SKID FOUNDATION CROSS SECTION 2 LEFT WALL DETAILS RIGHT WALL DETAILS FRONT WALL DETAILS BACK WALL DETAILS RAFTER PLACEMENT RAFTER CUTTING SPECIFICATIONS MATERIAL LIST TEMPLATES

SOME E-MAIL SOFTWARE MAY CHANGE SCALES SLIGHTLY

ELEVATIONS SCALE = 1- 0 DRAWN JUNE 2005 SIZE

THESE PLANS ARE FOR PERSONAL USE ONLY 2002 Just Sheds Inc. All rights reserved

10X8

PLAN

FREE 1

3/8 PLYWOOD SHEETING SUPPORT EDGES WITH H CLIPS 2X 4 ROOF RAFTERS 16 O. C. METAL CAP FLASHING 4/12 ROOF PITCH 3-TAB ASPHALT ROOF SHINGLES 2X 5 FASCIA BOARD 6 VINYL FASCIA

VENTED SOFFIT ALL AROUND 6 UNIFORM ROOF OVERHANG 4 VINYL SIDING

NOTE FILLING THE CONCRETE BLOCKS BELOW WILL HELP PREVENT WATER FROM COLLECTING AND DAMAGING THE BLOCK DURING ANY FREEZE THAW CYCLES

FRONT WALL HEIGHT 8 - 0

# 15 ASPHALT PAPER OVER- LAPPED TO SHED WATER

7/16 ASPENITE INTERIOR SHEETING WALL SHEETS WILL SUPPORT THE EDGES OF CEILING SHEETS WHEN INSTALLED AS SHOWN

5/8 TONGUE AND GROOVE PLYWOOD

2X 4 WALL STUDS 16 O.C 7/16 ASPENITE SHEETING OVER

2X 8 FLOOR JOIST 16 O.C. USE JOIST HANGERS AS SHOWN USE DOUBLE JOIST UNDER SIDE WALLS

3-PC 2X 8 BUILT UP BEAM 3 STEEL SADDLE ANCHOR SIDING TO COVER CONCRETE BY

FILL ANY SPACE UNDER BEAM OR DOUBLE JOIST WITH MORTAR

KEEP ALL WOOD AT LEAST 6 INCHES ABOVE GRADE

8 CONCRETE BLOCK FILLED WITH CONCRETE OR 10X 12 SOLID CONCRETE PIER

RECOMMENDED FOUNDATION 25X 25X 6 CONCRETE FOUNDATION INSTALLED ON UNDISTURBED SOIL BELOW KNOWN FROST PENETRATION

CROSS SECTION 1 1 = 1- 0 SIZE

10X8

PLAN

FREE 2

ANCHOR BOLTS IF YOU CHOOSE TO BUILD ON A CONCRETE PAD PLACE 1 ANCHOR BOLT NEAR EACH END OF THE RIGHT AND LEFT WALLS AND 3 EACH IN THE BACK & FRONT WALLS ( TOTAL OF 10 BOLTS )

TYPICAL 25X 25X 6 CONCRETE FOUNDATION 8 BLOCK, 3 SADDLE ANCHOR, 3-PC 2X 8 BUILT UP BEAM

THE TOTAL WIDTH OF THE WALL FRAMING AND THE CONCRETE PAD OR PIER BENEATH IS 10- 0 PLUS THE THICKNESS OF THE SIDING

2X 8 JOIST HELD BY JOIST HANGER 5/8 T+G PLYWOOD TOTAL DEPTH OF FRAMING AND THE CONCRETE 8- 0 PLUS SIDING

R.S.O. 26 1/8X 57 INSTALL 25 ABOVE FLOOR 2-PC 2X 4 LINTEL OVER

R.S.O. 34 X 82 2-PC 2X 4 LINTEL OVER

DOUBLE FLOOR JOIST

23 3/8

26 1/8

16

34 1/2

20

LUMBER CUTTING LIST FOR THIS FLOOR DESCRIPTION SIZE LENGTH QUAN NOTES 3 PC. BEAM 2X8 119 1/8 6 USE 3 PC. FOR EACH SIDE JOIST 2X8 86 1/8 11 For more information on cutting lumber see section 4 of our Construction Guide.

NOTE

2X8 floor joists are recommended for this shed to achieve a 40 lbs live load rating. Which is similar to homes.

Whether you need a shed for growing plants, a place for youngsters to play and build lifelong memories or just a place for the lawn equipment; we have the plans for you. With all our styles and sizes combined, we have over 120 plans to choose from. Whether the shed captures the charm of New England or one that utilizes maintenance-FREE materials, when you need more space think of us and visit our family of web sites.

FLOOR PLAN SCALE = 1- 0 SIZE

10X8

PLAN

We have the worlds largest collection of shed plans.

FREE 3

Some common words and phrases used in our plans and specifications may be unfamiliar to you in your area. This is because of different trade names used by different manufacturers. Suppliers in your area will know of a similar and equivalent product.

See the Glossary of Terms in our online free Construction Guide for more details.

FOR MORE CROSS SECTION DETAILS SEE PAGE 2

BACK WALL HEIGHT 5- 4

ANCHOR BOLT PLACED AS PER PAGE 3 SIDING TO COVER CONCRETE BY

1500 P.S.I. 4 CONCRETE PAD ( 9X 9 MIN. UNDER WALLS ) ON GRAVEL COMPACTED TO SUIT REMOVE ALL SOD AND FIBROUS MATERIALS DOWN TO UNDISTURBED SOIL

KEEP ALL WOOD AT LEAST 6 ABOVE GRADE

12

Choosing to build your shed on a concrete pad will change the appearance. Compared to the wooden-floor version shown on page 1, the version shown here uses about 8 inches of siding less than the other.

CONCRETE PAD 1 = 1- 0 SIZE

We appreciate and Thank you for all Your referrals

10X8

PLAN

FREE 4

FREE CONSTRUCTION GUIDE

Use our easy to read, printable free Construction Guide designed for the do-it-yourselfer. It was written exclusively for all of our shed plans. With text and lots of illustrations it deals with interesting professional wood framing techniques, the three kinds of foundations that many of our plans use and much more. Check it out and

DISCOVER WHAT WE WILL HELP YOU BUILD.

NOTE

WHEN THE REQUIRED 7/16 WALL SHEETING IS INSTALLED OVER THE JOIST FRAMING IT WILL BECOME THE SIZE AS SHOWN ON THE FLOOR PLAN

MAKE THE TOTAL DEPTH OF FLOOR JOIST FRAMING 7 -11 1/8 TYPICAL 2X6 FLOOR JOIST INSTALL 16 O.C. NAILED TO EACH 6X6 SKID AND TO THE HEADER JOIST AT EACH END USING 3, 3 NAILS AS OUTLINED IN THE SPECIFICATIONS ITEMS 12, 13 AND 16. BEFORE INSTALLING THE PLYWOOD MOVE A SKID BACKWARDS OR FORWARDS SO THAT THE FRAME IS COMPLETELY SQUARE

MAKE THE TOTAL WIDTH OF FLOOR JOIST FRAMING 9 -11 1/8

NOTE

Here the shorter joist span calls for 2X6 floor joists to achieve a 40 lbs live load rating. Which is similar to homes.

TYPICAL 6X6 WOODEN PRESSURE TREATED SKID LAID ON LEVEL COMPACTED GRAVEL BED (SEE CROSS SECTION 2) CUT SKID 3 SHORTER THAN JOIST FRAMING. INSTALL 1 IN AT THE SKIDS END AND 6 IN FROM ITS SIDE

TYPICAL 2X6 HEADER JOIST

2X6 SOLID BRIDGING STAGGER FOR EASIER NAILING LUMBER CUTTING LIST FOR THIS FLOOR

TYPICAL DOUBLE 2X6 FLOOR JOIST AT EACH END

DESCRIPTION SIZE LENGTH QUAN NOTES BEAM 6X6 116 1/8 2 HEADER JOIST 2X6 119 1/8 2 JOIST 2X6 92 1/8 11 BRIDGING 2X6 14 1/2 7 BRIDGING 2X6 ? 1 CUT THE LAST ODD PIECE TO SUIT For more information on cutting lumber see section 4 of our Construction Guide.

SKID FOUNDATION SCALE 3/8 = 1- 0 SIZE

10X8

PLAN

FREE 5

THE ROOF RAFTER ENDS MUST REST ON THE WALLS THAT HAVE THE 6 X 6 SKID 6 AWAY. NOT ON THE WALL WITH THE DOUBLE FLOOR JOISTS UNDER THEM

KEEP ALL UNTREATED WOOD AT LEAST 6 INCHES ABOVE GRADE

2X 4 WALL STUDS 16 O.C 7/16 ASPENITE SHEETING OVER

TYPICAL 2X6 FLOOR JOIST 5/8 PLYWOOD OVER

HORIZONTAL OR VERTICAL VINYL SIDING AS SHOWN ON PAGE 1

TYPICAL 6X6 WOODEN PRESSURE TREATED SKID LAID ON LEVEL COMPACTED GRAVEL BED 6 IN FROM WALL MINIMUM 6 X 18 LEVEL COMPACTED GRAVEL BED. REMOVE ALL SOD AND FIBROUS MATERIALS DOWN TO UNDISTURBED SOIL

TYPICAL GRADE. GRADE SO THAT ALL WATER DRAINS AWAY FROM SHED.

Join the tens of thousands who have used our shed plans throughout the world.

CROSS SECTION 2 SCALE 1 = 1- 0 SIZE

Visit our family of web sites to get your free catalog of shed plans

10X8

PLAN

FREE 6

STEPS FOR WALL FRAMING AND LUMBER CUTTING 1 ND 2 RD 3 TH 4

ST

Cut and layout at 16 O.C. the BP1 for studs starting from the right. Cut and layout TP1 for studs at 16 7/8 O.C. starting at S9 Cut and nail all of the studs to BP1. Nail TP1 to the studs in place, install wall sheeting as advised in the Construction Guide and finish nailing as per specifications

NOTE! The 90 angle cuts needed are not listed in the angle column. The lengths mentioned here, when there is an angle cut, are always measured at the longest points. When there is a second figure in the angle column, it is for the bottom or the right end that needs to be cut. For more information on cutting lumber see section 4 of our Construction Guide. FOR CLARITY ON ANGLE CUTTING ORIENTATION SEE THE RAFTER CUTTING PAGE DESCRIPTION BOTTOM PLATE TOP PLATE WALL STUD WALL STUD WALL STUD WALL STUD WALL STUD WALL STUD WALL STUD WALL STUD WALL STUD CODE BP1 TP1 S1 S2 S3 S4 S5 S6 S7 S8 S9 USE 2X4 2X4 2X4 2X4 2X4 2X4 2X4 2X4 2X4 2X4 2X4 CUT LENGTH 95 1/8 101 1/4 60 3/8 61 1/2 65 70 5/8 76 1/8 81 3/4 87 1/2 92 1/2 93 1/8 QUAN. 1 1 1 1 1 1 1 1 1 1 1 ANGLE 19/19 19 19 19 19 19 19 19 19 19 NOTES Cut as shown Cut as shown Cut as shown Cut as shown Cut as shown Cut as shown Cut as shown Cut as shown Cut as shown Cut as shown

TYPICALLY SPACED WALL STUDS 16 7/8 O.C. ALONG THIS ANGLED TOP PLATE, WHICH WILL ALIGN WITH 16 O.C. ON THE BOTTOM PLATE

S5 S4 S3

TP1

S6

S2

S7

S1

S8

S9

BP1 WALL BUILDING STEP # 1 THE SECTION OF WALL SHOWN HERE IS WITHOUT SHEETING TO AID IN ILLUSTRATION. FOR THIS SHED PLAN IT IS RECOMMENDED THAT IT BE BUILT ON THE FLOOR FIRST AS BUILDING STEP NUMBER 1 OF 4 PUT ASIDE AND INSTALLED LATER AS INSTALLATION STEP NUMBER 2 OF 4. WITH SHEETING IT WILL WEIGH ABOUT 110 LBS.

LEFT SIDE WALL DETAILS SCALE 3/8 = 1- 0 SIZE

10X8

PLAN

FREE 7

STEPS FOR WALL FRAMING AND LUMBER CUTTING 1 ND 2 RD 3 TH 4

ST

Cut and layout at 16 O.C. the BP1 for studs starting from the left. Cut and layout TP1 for studs at 16 7/8 O.C. starting at S9. Cut and nail all of the studs to BP1. Nail TP1 to the studs in place, install wall sheeting as advised in the Construction Guide and finish nailing as per specifications. CODE BP1 TP1 S1 S2 S3 S4 S5 S6 S7 S8 S9 USE 2X4 2X4 2X4 2X4 2X4 2X4 2X4 2X4 2X4 2X4 2X4 CUT LENGTH 95 1/8 101 1/4 60 3/8 61 1/2 65 70 5/8 76 1/8 81 3/4 87 1/2 92 1/2 93 1/8 QUAN. 1 1 1 1 1 1 1 1 1 1 1 ANGLE 19/19 19 19 19 19 19 19 19 19 19 NOTES Cut as shown Cut as shown Cut as shown Cut as shown Cut as shown Cut as shown Cut as shown Cut as shown Cut as shown Cut as shown

DESCRIPTION BOTTOM PLATE TOP PLATE WALL STUD WALL STUD WALL STUD WALL STUD WALL STUD WALL STUD WALL STUD WALL STUD WALL STUD

TYPICALLY SPACED WALL STUDS 16 7/8 O.C. ALONG THIS ANGLED TOP PLATE, WHICH WILL ALIGN WITH 16 O.C. ON THE BOTTOM PLATE S5 S4

S3 S6 TP1 S7

S2 S8 S1 S9

BP1

WALL BUILDING STEP # 2 THE SECTION OF WALL SHOWN HERE IS WITHOUT SHEETING TO AID IN ILLUSTRATION. FOR THIS SHED PLAN IT IS RECOMMENDED THAT IT BE BUILT ON THE FLOOR AS BUILDING STEP NUMBER 2 OF 4 PUT ASIDE AND INSTALLED LATER AS INSTALLATION STEP NUMBER 4 OF 4. WITH SHEETING IT WILL WEIGH ABOUT 110 LBS.

RIGHT SIDE WALL DETAILS SCALE 3/8 = 1- 0 SIZE

10X8

PLAN

FREE 8

STEPS FOR WALL FRAMING AND LUMBER CUTTING 1 ND 2 RD 3 TH 4

ST

Cut and layout BP1 and TP1, for studs and trimmer studs at opening locations (shown on the floor plan) at 16 O.C. Cut and nail studs and trimmer studs to BP1 and then nail the studs to TP1. Cut remaining lumber. Nail in DL1 and WL1 on top of trimmer studs and WS1 in between the windows TS2. Nail on the STP1. Nail the rest of the studs in place, install wall sheeting as advised in the Construction Guide and finish nailing as per specifications page. CODE BP1 TP1 STP1 S1 TS1 TS2 DL1 WL1 WS1 CS1 CS2 USE 2X4 2X4 2X4 2X4 2X4 2X4 2X4 2X4 2X4 2X4 2X4 CUT LENGTH 9-4 1/8 9-4 1/8 9-4 1/8 91 1/2 81 81 37 1/2 29 1/8 26 1/8 7 22 1/4 QUAN. 1 1 1 6 2 2 2 2 1 3 1 ANGLE NOTES

DESCRIPTION BOTTOM PLATE TOP PLATE SECOND TOP PLATE WALL STUD TRIMER STUD TRIMER STUD DOOR LINTEL WINDOW LINTEL WINDOW SILL CRIPPLE STUD CRIPPLE STUD

One 2x4 install on the flat side

STP1

CS2 TP1

WL1

DL1

TS2

S1

WS1

TS1

CS1 BP1

WALL BUILDING STEP # 3 THE SECTION OF WALL SHOWN HERE IS WITHOUT SHEETING TO AID IN ILLUSTRATION. FOR THIS SHED PLAN IT IS RECOMMENDED THAT IT BE BUILT AS BUILDING STEP NUMBER 3 OF 4 AND INSTALLED AS INSTALLATION STEP NUMBER 1 OF 4. WITH SHEETING IT WILL WEIGH ABOUT 110 LBS.

FRONT WALL DETAILS SCALE 3/8 = 1- 0 SIZE

10X8

PLAN

FREE

STEPS FOR WALL FRAMING AND LUMBER CUTTING 1 ND 2 RD 3

ST

Cut and layout at 16 O.C. the BP1 and TP1 for studs starting from the right. Cut and nail studs to BP1 and then nail to TP1 and then cut and nail STP1. Install wall sheeting as advised in the Construction Guide and finish nailing as per specifications.

DESCRIPTION BOTTOM PLATE TOP PLATE SECOND TOP PLATE WALL STUD

CODE BP1 TP1 STP1 S1

USE 2X4 2X4 2X4 2X4

CUT LENGTH 9-4 1/8 9-4 1/8 9-4 1/8 59 1/2

QUAN. 1 1 1 8

ANGLE

NOTES

STP1

TP1

S1

BP1

WALL BUILDING STEP # 4 THE SECTION OF WALL SHOWN HERE IS WITHOUT SHEETING TO AID IN ILLUSTRATION. FOR THIS SHED PLAN IT IS RECOMMENDED THAT IT BE BUILT AS BUILDING STEP NUMBER 4 OF 4 AND INSTALLED AS INSTALLATION STEP NUMBER 3 OF 4. WITH SHEETING IT WILL WEIGH ABOUT 90 LBS. BACK WALL DETAILS SCALE 3/8 = 1- 0 SIZE

10X8

PLAN

FREE 10

LUMBER CUTTING INFORMATION FOR ROOF SECTION DESCRIPTION RAFTERS FRONT & BACK FASCIA SIDE FASCIA LOOKOUT RAFTERS SIZE 2X4 2X5 2X5 2X4 LENGTH QUAN ANGLE NOTES

CUT IN AN AMOUNT AND AS SHOWN ON THE RAFTER CUTTING PAGE 132 2 CUT OR TRIM TO FIT AFTER IT IS INSTALLED 2 MEASURE AND CUT TO LENGTH 19/19 14 1/2 12 6 FOR EACH SIDE WALL

NOTE! The 90 angle cuts needed are not listed in the angle column. The lengths mentioned here, when there is an angle cut, are always measured at the longest points. When there is a second figure in the angle column, it is for the bottom or the right end that needs to be cut. For more information on cutting lumber see section 4 of our Construction Guide.

SLOPED TOP PART OF THE SIDE WALL TYPICAL 2X4 ROOF RAFTER 16 O.C. USE LOOKOUT RAFTER ON ITS FLAT SIDE TO TIE THE FASCIA BOARDS, WALLS AND ROOF RAFTERS ALL TOGETHER AT THE SIDE WALLS. SPACE 16 O.C. ALONG THIS ANGLED TOP PLATE

TYPICAL 2X5 FASCIA BOARD

TYPICAL ROOF RAFTER INSTALL FIRST AND LAST RAFTER 10 IN FROM THE OUTSIDE EDGE OF THE WALL

TYPICAL 2X5 FASCIA BOARD CUT TO LENGTH OR TRIM TO FIT AFTER

TOP OF FRONT WALL

AFTER INSTALLING THE FASCIA BOARD ON THE ENDS OF THE RAFTERS INSTALL THE NEXT FASCIA BOARD 16 O.C. OUT FROM THE RAFTER THIS WILL GIVE THE REQUIRED 6 UNIFORM OVERHANG.

RAFTER PLACEMENT SCALE 1 = 1- 0 SIZE

10X8

PLAN

FREE 11

CUT 7 RAFTERS EACH OF THEM 112 LONG THEN CUT THE BIRDS MOUTH AND THE 19 ANGLES AT EACH END AS SHOWN (19 IS THE ANGLE USED FOR A 4/12 ROOF PITCH)

TYPICAL 2X 5 FASCIA BOARD FOR THE FRONT, BACK AND BOTH SIDES

19 ANGLE

TYPICAL 4 FRONT AND BACK

TYPICAL 2X 4 SUPPORTING WALL WITH 7/16 ASPENITE SHEETING

BIRDS MOUTH CAREFULLY CUT OUT 4 FOR THE TOP OF THE SUPPORTING WALLS AND THEN CUT DOWN FOR THE SIDE

VISIT OUR FAMILY OF WEB SITES TO GET A FREE MATERIAL LIST FOR ANY OF OUR SHED PLANS

NOTE WHEN CUTTING RAFTERS IT IS BEST TO CUT 1 FIRST AND THEN PLACE IT ON THE WALLS TO BE SURE IT FITS PROPERLY THEN USE IT AS A TEMPLATE TO CUT THE REMAINING RAFTERS NEEDED

RAFTER CUTTING LAYOUT SCALE 3 = 1- 0 SIZE

10X8

PLAN

FREE 12

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16.

17. 18. 19 20 21 22 23 24

THE START-UP Once you have your plans and know where you are going to place your new shed contact your local public utilities. They will inform you about any pipes or cables that are buried in the ground in the area where you want to build. This is usually a FREE service. It can help avoid costly disruptions in the event that you cause damage to their lines. Know or find out exactly where your property lines are. Contact your local building department and inquire about the required distance needed for side and rear yard set backs if any and about any building permits that you may require. Its a good building practice to take the material list that comes with our plans to your local supplier and review the in stock availability of the materials needed. FOUNDATIONS If you choose to build your shed using a foundation that is a concrete pier style (rather than a slab-on-grade) then the height of the pier above grade should not be any higher than 3 times the smallest width of the pier. They should also be placed so they will resist any soil or water pressure that acts against them such as that which may take place when building on the side of a steep hill. When building on a concrete pad (slab-on-grade) place anchor bolts no further than 7-0 apart. All concrete should be at least 1500 P.S.I. in strength. It should be reinforced with wire mesh or re-bar when these plans require or in areas where soil conditions are poor or where earthquakes can occur. Your local building department can advise you on this in your area. Place a moisture barrier (polyethylene plastic sheet; it can be purchased in big rolls or you can use scraps of such plastic if you like) between all concrete and wood or treat that wood with wood preservative. Grade around the shed so that all water drains away from the building to protect it and the contents from water damage. WOOD FRAMING Where termites are known to exist, wood that they can reach should be treated with a recommended chemical that is toxic to termites. The long nails can be 3 1/2 common or 3 1/4spiral Ardox, but must be long enough so that not less than their length penetrates into the second member. Nails should be staggered so as to minimize splitting the wood and kept well in from the edges. Use 2 nails to nail all sheeting, spaced 5 7/8 O.C. along the edges of the sheets and 11 O.C. in-between. Nail structural members as specifically stated on the plans and generally as required in item # 16 of the specifications. Nail framing members using 3 spiral nails so that not less than 2 nails are used for the ends of each wall stud, ceiling joist, each side and at the end of every lintel. Toe nail rafters to the ridge pole if there is one and to the top of the walls using 3 nails at the end of each rafter. Nail the top 2X4 sill plate and/or the walls to the floor joist at 23 O.C. Nail the double studs at openings and in the corners with nails placed 23 O.C. Use 2 nails wherever the 2X5 fascia boards meet the ends of the rafters. Fill all nail holes with nails in the saddle anchors and joist hangers. The double floor joist and the pieces of built up wood beams shall be nailed together with a double row of nails not more than 18 apart. Use only tongue and grove plywood subflooring or support the edges of the sheets with solid backing underneath. Install all floor and roof sheeting at right angles to the rafters and floor joists. ATTIC VENTILATION, ROOFING AND SIDING The proper attic ventilation should be obtained by using only vented soffit and the roof vents as called for on the plans. Roofing and siding should be installed in strict accordance with the manufacturers instructions, including the recommended starter strips and all recommended trim. WINDOWS AND DOORS Using windows and doors other than those called for will not affect the building provided they are the same size, function in the same way and they should have the same appearance and be of equal quality. Quality caulking should be applied around all openings so as to prevent water from coming into your new shed. OPTIONS Owners choosing to add options to their sheds such as heating, plumbing and an electrical service should consult area trades people regarding their needs. GENERAL In spite of these plans, specifications and or advice and construction guides provided by Just Sheds Inc. it becomes by building, the owners sole responsibility to apply for all required permits, to build so that it is in accordance with all required skill, standards and in a safe and skillful manner that suits the intended purpose in that area.

Please Always work safely

2002 Just Sheds Inc. All rights reserved

SPECIFICATIONS PLAN

FREE 13

No.

QUAN

SIZE 6 X 6 X 10 2X 6X 16

DESCRIPTION AND USE

NOTES 1,2,3 1,2,7,3 1,2,7,3 2,7,3 7 7 1,3 1,3,5 3,4

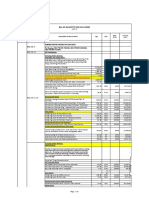

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34

2 8 4 6 11 14 3 9 20 9 4 9 4 24 110 11 1 1 1 12 12 lbs 12 lbs 9 lbs 300 36 4 30 40 22 44 44 6 270

3X 3 2X 8X 10 2X 8X 8 2X 8 4X 8 X 5/8 2X 4X 16 2X 4X 14 4X 8X 7/16 2X 5X 12 2X 4X 10 4X 8X 3/8 3/8 Sq. ft. Linear ft.

Cedar or pressure treated wood (USE ONLY FOR SKID FOUNDATION) Solid bridging, floor and header joists (USE ONLY FOR SKID FOUNDATION) Steel saddle anchors (or 10 anchor bolts if concrete pad is used) 3-pc built up beam at the front and back Single and double floor joist as shown on the plans Single joist hangers (install before plywood) Tongue and groove plywood When cut will give 1 bottom and 2 top plates for all walls plus misc. needs When cut will give the needed studs of various lengths Aspenite wall sheeting Fascia boards all around Roof rafters Spruce plywood roof sheeting H clips or use scrap wood to support roof sheeting edges Asphalt roof shingles (includes starter strip) Metal cap flashing Andersen window NARROLINE # 2046 Therma-tru door # CS210 (outswing is another option) Locking door knob (check with door supplier regarding size, set back etc.) Aspenite sheeting for interior walls and ceiling Ardox or spiral framing nails Ardox or spiral framing nails Roofing nails; use for shingles, asphalt paper, vinyl siding and trim # 15 asphalt paper Vinyl siding starter strip Vinyl siding outside corner post J channel F channel (wall mounted to hold soffit material) Vented soffit Under sill trim; use under window and on the top edge of the vinyl fascia 6 vinyl fascia Vinyl door and window cap Double 4 vinyl siding Misc. caulking and paint for the door

6 6

4X 8X 7/16 3 1/4 2 1 1/4 Sq. ft. Linear ft. X 3X 10 Linear ft. Linear ft. Sq. ft. Linear ft. Linear ft. Linear ft. Sq. ft.

5 5 5

Pride will result when adding labor to the above.

NOTE: PLEASE READ ALL NOTES AND SPECIFICATIONS BEFORE ORDERING ANY MATERIALS OR BUILDING 1 2 3 4 5 6 7 8 9 When cut in two or to the required size one piece will yield the needed amount. Cedar or pressure treated wood is recommended. Use cut end treatment if treated wood is used. Grade numbers 1 and 2 spruce is the specified lumber for this project. 2X 5 lumber is recommended because it suits the 6 vinyl fascia best. Consider ordering a few more of these items or others as it is common to use more because of working style, waste or mistakes. Always confirm the size of the unit and the rough stud opening (R.S.O.) from the supplier before ordering or building. Delete these items and 18 sq. ft. from no. 33 if you choose to build your shed on a concrete pad. Not knowing your site or soil conditions prevents us from estimating any of your concrete needs. It is the owners responsibility to apply for all required permits and to build with the necessary skill and in accordance with all required standards.

MATERIAL LIST SIZE

NOW YOU CAN GET

10X8

PLAN

FREE MATERIAL LISTS FOR ANY OF OUR SHED PLANS

FREE

14

# 1 CUT PAPER TEMPLATE ALONG THIS LINE TO GET THE ANGLES MENTIONED ON THE RAFTER CUTTING LAYOUT PAGE (BOTTOM END)

NOTE

UNSTAPLE IF ATTACHED

ROTATE TURN TO THE LEFT TO GET A HELPFUL AND SIMILAR VIEW AS SHOWN ON THE RAFTER CUTTING LAYOUT PAGE.

FOLLOW THE STEP-BY-STEP INSTRUCTIONS BY NUMBER

TYPICAL RAFTER SEE RAFTER CUTTING LAYOUT PAGE

# 2 CUT PAPER TEMPLATE ALONG THESE 3 SOLID LINES TO GET THE BIRDS MOUTH MENTIONED ON THE RAFTER CUTTING LAYOUT PAGE

# 3 FOLD ALONG THIS LINE THEN LAY IT ON THE RAFTERS EDGE AND MARK THE BIRDS MOUTH AND THE BOTTOM CUTTING ANGLE. USE TEMPLATE 2 OF 2 FOR THE TOP OF THE RAFTER. USE THIS CUT RAFTER AND/ OR RAFTERS AS A TEMPLATE TO MARK AND THEN CUT ALL THE OTHERS LEGEND

RAFTER CUTTING TEMPLATE

SCALE

ACTUAL SIZE

PLAN

FREE

15

# 1 CUT PAPER TEMPLATE ALONG THIS LINE TO GET THE ANGLES MENTIONED ON THE RAFTER CUTTING LAYOUT PAGE (TOP END)

NOTE UNSTAPLE IF ATTACHED ROTATE TURN TO THE RIGHT TO GET A HELPFUL AND SIMILAR VIEW AS SHOWN ON THE RAFTER CUTTING LAYOUT PAGE.

TYPICAL RAFTER SEE RAFTER CUTTING LAYOUT PAGE

FOLLOW THE STEP-BY-STEP INSTRUCTIONS BY NUMBER

# 3 FOLD ALONG THIS LINE THEN LAY IT ON THE RAFTERS EDGE AND MARK THE BIRDS MOUTH AND THE TOP CUTTING ANGLE AT THE LENGTH MENTIONED ON THE RAFTER CUTTING LAYOUT PAGE USE TEMPLATE 1 OF 2 FOR THE BOTTOM OF THE RAFTER. USE THIS CUT RAFTER AND/ OR RAFTERS AS A TEMPLATE TO MARK AND THEN CUT ALL THE OTHERS

# 2 CUT PAPER TEMPLATE ALONG THESE 3 SOLID LINES TO GET THE BIRDS MOUTH MENTIONED ON THE RAFTER CUTTING LAYOUT PAGE

LEGEND

RAFTER CUTTING TEMPLATE

SCALE

ACTUAL SIZE

PLAN

FREE

MATERIAL LIST

16

You might also like

- FH01JUN CraftsmanShedDocument27 pagesFH01JUN CraftsmanShedjuan100% (3)

- Building Plans For ShedsDocument24 pagesBuilding Plans For ShedsArik Seo100% (1)

- Easy DIY Garden Shed Plans - 1Document4 pagesEasy DIY Garden Shed Plans - 1Fred Mirtz100% (1)

- Free 12 X 8 Shed Plan: Click Here To Download 12,000 Shed PlansDocument24 pagesFree 12 X 8 Shed Plan: Click Here To Download 12,000 Shed PlansRamón Baró100% (1)

- Building A Garden Shed Step By Step Instructions and PlansFrom EverandBuilding A Garden Shed Step By Step Instructions and PlansRating: 2 out of 5 stars2/5 (1)

- Shed Storage2Document9 pagesShed Storage2Bob Pouliot88% (8)

- Shed PlansDocument1 pageShed PlansFrancis Wolfgang Urban50% (2)

- Shed PlansDocument1 pageShed PlansFrancis Wolfgang UrbanNo ratings yet

- Build a Basic 12' x 8' ShedDocument22 pagesBuild a Basic 12' x 8' ShedEric Blanchard100% (3)

- Just ShedsDocument16 pagesJust Sheds- yAy3e -100% (2)

- Storage Shed Blueprints and DesignsDocument25 pagesStorage Shed Blueprints and Designsapi-236974610100% (1)

- 50 Contractor Garage Plans ConstructionDocument90 pages50 Contractor Garage Plans Constructionapsaraso100% (4)

- Guide To Building Your First ShedDocument10 pagesGuide To Building Your First Shedpatience peters100% (1)

- Multipurpose Garden ShedDocument5 pagesMultipurpose Garden ShedEloy Rodriguez100% (1)

- Garden ShedDocument1 pageGarden ShedWayne HenryNo ratings yet

- Diy - Woodwork - Plans - Shed Framing PDFDocument0 pagesDiy - Woodwork - Plans - Shed Framing PDFSignora LofaroNo ratings yet

- The Family Handyman-2011!07!08 520 Garden ShedDocument63 pagesThe Family Handyman-2011!07!08 520 Garden ShedVermontique100% (9)

- Download 12,000 Shed PlansDocument27 pagesDownload 12,000 Shed PlansRadu_IS100% (2)

- Typical Garage / Storage Shed / Shop DetailsDocument28 pagesTypical Garage / Storage Shed / Shop DetailskennypetersNo ratings yet

- Lean To PlanDocument7 pagesLean To PlandimfoNo ratings yet

- The Shed January-February 2018 PDFDocument132 pagesThe Shed January-February 2018 PDFtony445100% (2)

- GHD PlansDocument4 pagesGHD PlansRyan BezzNo ratings yet

- Off Grid Shed Final PDFDocument35 pagesOff Grid Shed Final PDFExpendedoras Corrientes100% (3)

- Shed 10x16 PlansDocument8 pagesShed 10x16 PlansLory Dena Heath100% (1)

- Wall and roof framing diagramsDocument13 pagesWall and roof framing diagramsAnonymous QKAsdVIeKr100% (1)

- Lakewoods Cottage & Cabin PlansDocument5 pagesLakewoods Cottage & Cabin PlansFrances Sullivan Mayhall67% (3)

- How To Build A Shed With A Slanted Roof Step-by-Step GuideDocument39 pagesHow To Build A Shed With A Slanted Roof Step-by-Step GuideFederico BarberisNo ratings yet

- DIY Cabin Building Plans PDFDocument6 pagesDIY Cabin Building Plans PDFRoberto Landa100% (5)

- Shednew PM1Document1 pageShednew PM1Olin StejNo ratings yet

- 18 Best Free Shed Plans That Will Help You DIY A Shed PDFDocument12 pages18 Best Free Shed Plans That Will Help You DIY A Shed PDFUdu Ogah0% (2)

- 00 Folding Picnic Table DIY Out of 2x4 LumberDocument48 pages00 Folding Picnic Table DIY Out of 2x4 Lumberbf100% (2)

- Black & Decker The Complete Guide To Contemporary ShedsDocument242 pagesBlack & Decker The Complete Guide To Contemporary Shedsjbonvier100% (27)

- The Family Handyman - August 2015Document94 pagesThe Family Handyman - August 2015gaposto83% (6)

- Ultimate List of 28 DIY Playset PlansDocument45 pagesUltimate List of 28 DIY Playset PlansMikeMeisner67% (3)

- FH03JAu GardenShed PDFDocument17 pagesFH03JAu GardenShed PDFMax Popp80% (5)

- DIY Outdoor Chair - Angela Marie MadeDocument10 pagesDIY Outdoor Chair - Angela Marie MademrcongamanNo ratings yet

- Ana White Tiny House Free PlansDocument20 pagesAna White Tiny House Free PlansAnonymous MmhbgdX8a100% (2)

- Installing a Garage Door and Opener- Special Bundle: Cake Decorating for BeginnersFrom EverandInstalling a Garage Door and Opener- Special Bundle: Cake Decorating for BeginnersNo ratings yet

- Handy Simple ShedDocument6 pagesHandy Simple ShedMiguel Angel Rodríguez Zenteno100% (1)

- Lean To Shed Plan: Free Streamlined VersionDocument9 pagesLean To Shed Plan: Free Streamlined VersionjesusdoliNo ratings yet

- Tool Shed PlansDocument26 pagesTool Shed PlansWinnie Mandela100% (2)

- Ana White - Clubhouse BedDocument32 pagesAna White - Clubhouse Bedcmuniz13No ratings yet

- How To Turn Your Shed Into A Workshop - A Free Guide From WaltonsDocument18 pagesHow To Turn Your Shed Into A Workshop - A Free Guide From WaltonsWaltons Garden Buildings100% (2)

- Pavilion MareDocument16 pagesPavilion MarenicnicnicNo ratings yet

- Kreg Tool - Innovative Solutions For All of Your Woodworking and DIY Project NeedsDocument5 pagesKreg Tool - Innovative Solutions For All of Your Woodworking and DIY Project NeedsFernandoNo ratings yet

- Wichita Cabin Coop2Document81 pagesWichita Cabin Coop2caapromo67% (3)

- Patios (UK Only): Designing, building, improving and maintaining patios, paths and stepsFrom EverandPatios (UK Only): Designing, building, improving and maintaining patios, paths and stepsNo ratings yet

- Framing Guidelines PDFDocument9 pagesFraming Guidelines PDFJase72HR100% (3)

- The Family Handyman - January 2015 USADocument94 pagesThe Family Handyman - January 2015 USALawrence Ngari100% (7)

- Entertaining Easy ShedDocument10 pagesEntertaining Easy ShedRaidx2No ratings yet

- Deck Construction GuideDocument13 pagesDeck Construction Guidefaxtackley100% (2)

- Cabin PlanDocument17 pagesCabin PlanMacMac Nisperos67% (3)

- FH04JAU RusticYardShed PDFDocument13 pagesFH04JAU RusticYardShed PDFjuan83% (6)

- FREE DIY 16X24 Gable Shed PlanDocument9 pagesFREE DIY 16X24 Gable Shed PlanJacob RossNo ratings yet

- Outdoor Kitchen Design BriefDocument18 pagesOutdoor Kitchen Design BriefBuzatu RazvanNo ratings yet

- DIY 8x10 6ft Short Shed Plans Under 40 CharactersDocument6 pagesDIY 8x10 6ft Short Shed Plans Under 40 CharactersElba Roark100% (1)

- A Complete Guide To Building Your Own DeckDocument16 pagesA Complete Guide To Building Your Own DeckAdrian Berna100% (5)

- 12x24 Homesteader's Cabin v1Document21 pages12x24 Homesteader's Cabin v1Mihajlo Talevski100% (6)

- Build Your Own Sheds & Outdoor Projects Manual, Fifth Edition: Over 200 Plans InsideFrom EverandBuild Your Own Sheds & Outdoor Projects Manual, Fifth Edition: Over 200 Plans InsideRating: 5 out of 5 stars5/5 (1)

- Shed Material List Part (1 of 9)Document2 pagesShed Material List Part (1 of 9)nwright_besterNo ratings yet

- Shed PlansDocument1 pageShed PlansFrancis Wolfgang UrbanNo ratings yet

- Shed PlansDocument1 pageShed PlansFrancis Wolfgang UrbanNo ratings yet

- Shed PlansDocument1 pageShed PlansFrancis Wolfgang UrbanNo ratings yet

- Shed PlansDocument1 pageShed PlansFrancis Wolfgang UrbanNo ratings yet

- Figure E Small Roof: 2x4 Nailers 2x4 Rafter 2x4 Subfascia 1x2 Fascia Trim 24" 32" 29-3/4"Document1 pageFigure E Small Roof: 2x4 Nailers 2x4 Rafter 2x4 Subfascia 1x2 Fascia Trim 24" 32" 29-3/4"Francis Wolfgang UrbanNo ratings yet

- Shed PlansDocument1 pageShed PlansFrancis Wolfgang Urban50% (2)

- 25 Foot CabinDocument28 pages25 Foot Cabinapi-3708365100% (1)

- 3inchrefractorDocument6 pages3inchrefractorGianluca SalvatoNo ratings yet

- 10 Dollar Telescope PlansDocument9 pages10 Dollar Telescope Planssandhi88No ratings yet

- Figure A Trusses: Inner (Common) Truss (9 Req'd)Document1 pageFigure A Trusses: Inner (Common) Truss (9 Req'd)Francis Wolfgang UrbanNo ratings yet

- 3 Wheel Dune BuggyDocument5 pages3 Wheel Dune BuggyyukitadaNo ratings yet

- 6 Inch Reflector PlansDocument12 pages6 Inch Reflector PlansSektordrNo ratings yet

- 15 Foot SailDocument4 pages15 Foot SailjdogheadNo ratings yet

- Build and Use Small Electric MotorsDocument5 pagesBuild and Use Small Electric MotorsdarkquinkNo ratings yet

- IRS Publication Form Instructions 8829Document4 pagesIRS Publication Form Instructions 8829Francis Wolfgang UrbanNo ratings yet

- Build a DIY Motorized Mountain BuggyDocument5 pagesBuild a DIY Motorized Mountain Buggyjii_907001No ratings yet

- IRS Publication Form Instructions w-2/w-3Document13 pagesIRS Publication Form Instructions w-2/w-3Francis Wolfgang UrbanNo ratings yet

- IRS Publication Form Instructions 2106Document8 pagesIRS Publication Form Instructions 2106Francis Wolfgang UrbanNo ratings yet

- IRS Publication Form Instructions 8941Document10 pagesIRS Publication Form Instructions 8941Francis Wolfgang UrbanNo ratings yet

- IRS Publication Form Instructions 8867Document2 pagesIRS Publication Form Instructions 8867Francis Wolfgang UrbanNo ratings yet

- Instructions for Form 1099-MISCDocument10 pagesInstructions for Form 1099-MISCFrancis Wolfgang UrbanNo ratings yet

- IRS Publication Form Instructions 5405Document6 pagesIRS Publication Form Instructions 5405Francis Wolfgang UrbanNo ratings yet

- Form 8853 InstructionsDocument8 pagesForm 8853 InstructionsFrancis Wolfgang UrbanNo ratings yet

- IRS Publication Form Instructions 8594Document3 pagesIRS Publication Form Instructions 8594Francis Wolfgang UrbanNo ratings yet

- IRS Publication Form Instructions 8283Document7 pagesIRS Publication Form Instructions 8283Francis Wolfgang UrbanNo ratings yet

- IRS Publication Form Instructions 4797Document10 pagesIRS Publication Form Instructions 4797Francis Wolfgang UrbanNo ratings yet

- IRS Publication Form Instructions SseDocument6 pagesIRS Publication Form Instructions SseFrancis Wolfgang UrbanNo ratings yet

- IRS Publication Form Instructions 1120sDocument42 pagesIRS Publication Form Instructions 1120sFrancis Wolfgang UrbanNo ratings yet

- NRA Repair and Retrofitting Manual For Masonry Structure - 181122Document171 pagesNRA Repair and Retrofitting Manual For Masonry Structure - 181122Dinesh Poudel100% (1)

- Water Heating Renewables Air Conditioning Central Heating Solar Thermal System Flat-Plate CollectorDocument68 pagesWater Heating Renewables Air Conditioning Central Heating Solar Thermal System Flat-Plate CollectorsanitermNo ratings yet

- Ivil Ngineering Rawing: Vayu Education of IndiaDocument16 pagesIvil Ngineering Rawing: Vayu Education of IndiaMaheshreddy YenamNo ratings yet

- Literature Review TOP CoatingDocument57 pagesLiterature Review TOP CoatingWo Ai NiNo ratings yet

- Building Construct PDFDocument10 pagesBuilding Construct PDFchristableNo ratings yet

- 04 DM BLDG Glazed+Schedule V01+Document1 page04 DM BLDG Glazed+Schedule V01+Saahil KhaanNo ratings yet

- OMG31532 - Roof Edge ProtectionDocument2 pagesOMG31532 - Roof Edge ProtectionSasi Samhitha KNo ratings yet

- ProTherm Quantum Pure BBA Certificate 1Document12 pagesProTherm Quantum Pure BBA Certificate 1PauloRobertoLiñanFigueiredoNo ratings yet

- National Archives of Australia storage standard protects archival recordsDocument17 pagesNational Archives of Australia storage standard protects archival recordsickoNo ratings yet

- Roofing Product Catalogue-File044006 PDFDocument64 pagesRoofing Product Catalogue-File044006 PDFHenry Thokozani Ndlovu SibandaNo ratings yet

- Guidelines for Calculating Roof Zones and Maximum Field Sizes for Solar PV InstallationsDocument14 pagesGuidelines for Calculating Roof Zones and Maximum Field Sizes for Solar PV InstallationsFinaru FlorinNo ratings yet

- Climate Design Buildings Hot HumidDocument6 pagesClimate Design Buildings Hot Humidrekha vivekNo ratings yet

- Unit 1 Properties and ShapeDocument9 pagesUnit 1 Properties and ShapePrita Devi WidiyaniNo ratings yet

- Manchester City Stadium - Structural Case StudyDocument20 pagesManchester City Stadium - Structural Case StudyYuvan SethNo ratings yet

- Kerala Architecture Guide: Traditional Nalukettu Home DesignDocument10 pagesKerala Architecture Guide: Traditional Nalukettu Home DesignRula FiryalNo ratings yet

- BCCA BIDCENTRAL RULES FOR SUBCONTRACTORSDocument85 pagesBCCA BIDCENTRAL RULES FOR SUBCONTRACTORSautocadplease6213No ratings yet

- The Complete Guide To Greenhouses & Garden Projects PDFDocument241 pagesThe Complete Guide To Greenhouses & Garden Projects PDFGregy Joe Batin100% (4)

- Yuens CatalogueDocument23 pagesYuens CatalogueDora PopNo ratings yet

- Annexure I - Bill of Quantities - PricedDocument16 pagesAnnexure I - Bill of Quantities - PricedjatinNo ratings yet

- Ce325 PDFDocument7 pagesCe325 PDFmttaibNo ratings yet

- Super Cast Fosroc AdmixturesDocument10 pagesSuper Cast Fosroc AdmixturesVedachalam ManiNo ratings yet

- SIKAPLAN G, Trocal S Prezentacija - EngDocument30 pagesSIKAPLAN G, Trocal S Prezentacija - EngStatybosproduktai100% (1)

- Polyboard: Bitumen Impregnated Compressible Fibre Filler BoardDocument2 pagesPolyboard: Bitumen Impregnated Compressible Fibre Filler Boardmpandy1984No ratings yet

- Building Foundation Design GuideDocument14 pagesBuilding Foundation Design GuideAhmed KassemNo ratings yet

- Salvador Pires On Sustainable Architecture and BuildingDocument37 pagesSalvador Pires On Sustainable Architecture and BuildingPapers and Powerpoints from UNTL-VU Joint Conferenes in Dili100% (7)

- Unit 2: Specification WritingDocument9 pagesUnit 2: Specification WritingHastala vistaNo ratings yet

- IlunaDocument11 pagesIlunaanon_301507253No ratings yet

- Roof-Plan Lay OutDocument33 pagesRoof-Plan Lay OutEugen GacheNo ratings yet

- Detail 2006 10Document28 pagesDetail 2006 10filipgavrilNo ratings yet

- Electric Bird Shock TapeDocument3 pagesElectric Bird Shock TapeShock-TapeNo ratings yet