Professional Documents

Culture Documents

OTE Outotec Sintering Technologies Eng Web

Uploaded by

Sunil Kumar DwivediOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OTE Outotec Sintering Technologies Eng Web

Uploaded by

Sunil Kumar DwivediCopyright:

Available Formats

Outotec Sintering technologies

40% of the worlds sintering Iron ore sintering has stood at the heart of the ferrous metallurgical processes for over half a century. Outotec has solid experience in agglomeration of fine-grained iron ores. We have built over 400 sintering plants with capacities ranging from 600 to 20,000 tons per day since 1920. Today, 40% of the worlds sinter is produced by our technology. Besides iron ores, it can also be applied for sintering of manganese ore fines. Over the years, we have developed a number of innovative technologies that increase the performance and reduce the capital and operating costs. Longterm research and testing with raw materials of different origins and process parameters, coupled with continuous development and improvements in mechanical design and process automation have made us an unparalleled technology partner.

002 Sintering technologies

Tata Iron and Steel Co., India, has already three Outotec sintering plants in operation.

Outotec Sintering Process

Outotec sintering process begins with the preparation of raw mix from iron ores, fluxes, in-plant dust and spillage fines, solid fuel and return fines. These materials are mixed and granulated in one or more stages. Water is added in order to assist the raw mix in obtaining optimum permeability for lower electricity consumption, maintained by conveying the raw mix carefully onto the sinter machine. Its surface is then ignited, air being induced through the ignited layer and sintering proceeding in the vertical direction in the sinter strands material bed. Subsequently, the sinter is cooled, usually in a separate sinter cooler, located at the sinter machines discharge outlet. The cooled sinter is crushed to a pre-determined maximum particle size. Undersized sinter that is not suitable for the blast furnace is recycled to the return fines bin. A certain quantity, usually 1020 mm, is screened out and recirculated to the sinter machine, where it serves as a hearth layer, protecting the grate bars of the pallets during the sintering process. The product obtained from the process is a blast furnace feed of superior quality. Sintering is the agglomeration of fine-grained iron ores for blast furnace burden preparation. Manganese ores can also be sintered before smelting in the electric arc furnace. Sintering produces a feed of extremely consistent quality in terms of its: n Chemical composition n Grain size distribution n Reducibility n Sinter strength Why sinter?

Environmental safety

Outotec sinter plants are designed to meet the most stringent environmental regulations. For effective dust collection, electrostatic precipitators and/or bag filters dedust the sinter waste gas and air from the plant dedusting system. We provide processes for limiting dioxin, SOx and NOx emissions, while incorporating noise attenuation equipment to meet local regulations.

Sintering technologies 003

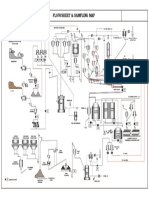

Outotec EOS Emission optimized sintering for lower costs Iron ore sintering creates substantial off-gas volumes, and treating these in order to meet increasingly stringent environmental standards is expensive. That is why we have developed the emission optimized sintering process. EOS uses recycling technology

Energy savings and reduced emissions What is more, CO and pollutants like SO x , NO x , dust and dioxins/furans are passed through the sinter layer together with the recirculated gas. While CO is postcombusted, substantially saving on solid fuel, the pollutants are partially retained in the sinter layer and/ or thermically decomposed. In integrated steel plants about 75% of the CO 2 emissions are generated in the blast furnace and about 12% in the sintering process. When following the international CO 2 policy, the Kyoto protocol, and as there is only a minimum technical margin for CO 2 reduction measures in the blast furnace, EOS brings significant benefits for all steel plant operators.

to reduce off-gas volumes by 40 to 50%, resulting in smaller secondary gas treatment systems. This means: n Lower capital investment n Reduced operating costs Conventional sintering uses ambient air to transport heat within the sinter bed, requiring a high air flow rate. However, EOS takes advantage of the fact that only a part of the oxygen in the air is consumed for coke combustion. Therefore a part stream of the off-gas is recycled via the hood, enriched with ambient air to an oxygen content of 1314% and used as intake process air. This reduces off-gas volumes by about 4050% without affecting the sintering process.

Bleed in

Recirculation gas system

Fresh air supply system

Typical flow sheet of a sinter plant with EOS system.

004 Sintering technologies

Proprietary equipment for control, quality, economy and safety

High intensity mixing and nodulizing Mixing and granulation is performed in two separate high intensity mixers, which have the advantage of minor investment costs and space requirements, combined with an excellent mixing and granulation effect, especially for fine grained ores. The required amount of process water will be added to the two mixers in predetermined ratios by means of spray nozzles, in order to adjust the optimum moisture/ permeability of the feed mix. Ignition furnace for optimum maintenance and operation Outotec ignition furnaces consist of standardized segments, each with straight refractory lined vertical side walls and a laterally-arranged special combustion chamber on each side. This design offers the optimum solution in terms of maintenance and operation: n Uniform ignition n Highly flexible operation in response to fluctuations in material bed permeability n Possibility of operation with a high rate of excess air n High safety standards Lurgi traveling grate Our solution for sinter machine is a Lurgi traveling grate consisting of an endless chain of pallets. Its feeding station ensures a continuous supply of hearth layer and feed mix to the sinter machine. Both the feed bins for hearth layer and for feed mix are level controlled. Furthermore, the hearth layer bin is equipped with an adjustable gate, providing a hearth layer of a predetermined height. n n n n n Since our pallets only come into contact with one another on the horizontal section of the upper and lower track, wear is minimized. Durability is also enhanced through the separation of each pallet from the chain by a lifting and lowering sprocket at each station. Longer lasting pallets The roll feeder discharges the material onto a segregation plate. This is an inclined plate across the pallet width. Its inclination and positioning in relation to the material flow from the roll feeder is adjustable for: n Improved feed mix permeability,lowering power consumption n Optimum segregation of fine and coarse particles n Optimum formation of the material layer on the pallets The variable speed roll feeder is mounted on a separate support with rails and wheels to permit roll-in and rollout for maintenance purposes. The feed mix hopper outlet is equipped with motorized gates for adjusting the amount of material to be discharged via a variable speed roll feeder. Ultrasonic sensors control the bed height level of the individually motorized gates.

Each pallet comprises

n A cast pallet body, as a single unit or in three pieces Exchangeable front plates Four roller sets, each set containing one running roller and one pressure roller, both arranged on the same shaft Grate bars made from high alloyed cast steel Side walls of cast material Insulating sections to protect the pallet body

Sintering technologies 005

Discharge station for long service life The sinter strand discharges the sinter onto a crash deck, specially designed and equipped with wearresistant material, from where it slides into a spiked roll crusher whose crushing arms grind it to a maximum size of 200 mm. A movable grizzly carrier is also featured. Direct charging to cooler improves cooling efficiency and reduces emissions The material discharged from the sinter machine enters a chute with a round opening. A concave material layer is built up on the sides of the chute. While passing through the opening, the entire fraction is mixed. This mixed material falls onto a radially adjustable saddle, where the material is re-segregated, the coarse material being deposited on the rear part of the lower chute section while the fine material is deposited in the center. As the cooler moves, the material accumulates on it to form a sloping material layer, whose height is determined by the inner angle of repose of the sinter. Upon the withdrawal of the material, a core flow develops, large lumps from the rear settling on the bottom of the cooler, fine material in the middle and medium sized on top. Efficient sinter cooling While hot sinter is best cooled in a separate cooler, on-strand cooling can be applied in particular appli-cations. Our cooler features all of the essential attributes: n Annular arrangement of troughs n Cooling air pressed through the sinter n A bed height of 1.4 to 1.6 m, minimizing the cooling air volume n Horizontal movement of the cooler trough, with the trough bottoms following a dip rail at the discharge station The cooler trough wheels run on a circular rail supported by a concrete sub-base, which also serves as a wind channel for cooling air. While the cooler is driven by friction drive units via a segmented friction

ring, cooling air fans are arranged outside the cooler. Spillage collecting plates underneath each cooler trough bottom plate retain all sinter spillage and discharge it to the collecting hopper. Special seal bars, individually supported on flat spring plates, minimize cooling air leakages. Height-adjustable wheels provide equalized, uniform wheel loads, while temperature optimized side wall clamping allows for thermo-expansions without stressing the cooler. Natural segregation with the maintenance-free cascade classifier Outotec's new cascade classifier, separating coarse from fine size iron ore sinter stream material, replaces the scalping screen in front of double roll crushers. It functions based on: n Natural segregation by dropping or pouring material n Adjustable start-up saddles phase), (adjusted once the during of guaranteeing removal

inadmissible coarse material from the separated fines The cascade classifier is almost maintenance-free, since it runs on stone box type saddles which do not touch the side walls. Coarse particles separated at the saddle front side are fed into the cold sinter double roll crusher, while fine material separated at the saddle far side by-passes the crusher and is mixed again with the crushed material underneath.

Energy savings together with reduced emissions:

n Optimum permeability of the sinter layer on the cooler n n Optimal use of the cooling air Minimum spillage since sinter fines are held off the trough bottom n Minimum dust emission since sinter fines are covered by the middle size sinter fraction, acting as a filtration layer

006 Sintering technologies

Sinter plant in Middlesbrough, U.K.

State-of-the-art control systems

Outotec sinter plant control systems include: n Return fines balance control n Material mixture computing and control with individual moisture control n Burn through-point control/sinter capacity control n Ignition furnace control with permeability measurement Such an architecture supports the addition of an operational layer above DCS/OCS for process management (level 3) including monitoring, analyzing, optimizing, simulating and pre-tuning level 2 controllers (process management) based on a dynamic computer sinter model. Flexibility brings extra benefits Our sinter plants are designed to cater for fluctuating production requirements. To enable high production rates, some plants are designed for a specific output of up to 45 t/24 h/m. For lower rates, plants can be operated with maximum energy savings and superior sinter quality. These enable extensive supervisory control functions using standard distributed or open control systems (DCS/OCS).

Sintering technologies 007

Facts about Outotec sinter plants

Traveling grate dimensions n 36600 m reaction area n 25 m machine width Capacity n 0.156.5 million tpy in single units n Availability 330345 days/year n Specific production rates up to 45 t/24 h/m Consumption figures (per ton of product sinter) n Solid and gaseous fuel: 12501400 MJ n Electrical energy: 2832 KWh n Process water: 0.030.05 m n 1620 men per day Process parameters n Basicity CaO/SiO 2 : 1.22.9 n Bed height: 500730 mm n Suction: 130190 mbar n Return fines rate: 1825% Product qualities n ISO-strength (+ 6.3 mm) 7580% n RDI (-3 mm) 2832% n FeO 58% Sinter plant modernization a made-to-fit process Our solutions are not only valid for new plants but also revamps, retrofits and capacity increases. To improve the efficiency of existing plants we provide a number of alternatives, ranging from individual equipment replacement to extensive plant rehabilitations, tailored to each customers specific needs.

3

R&D facilities providing economy and innovative technology Outotecs long research pedigree, based on our own facilities in Frankfurt, Germany, forms the basis for the successful design and construction of sinter plants. While test series yield specific data for the optimum technical and economical design of commercial plants, pot tests determine the key ore mix parameters (specific sinter output as a function of the applied suction and required sinter quality) for use together with the flux and solid fuel. These parameters form the basis of sinter plant design. Our full range of R&D facilities test sinter properties to meet international standards such as ISO, ASTM, JIS and DIN.

Operational manpower (4-shift basis):

Plant modernization can include:

n n n Replacement of obsolete equipment Upgrading of sinter plants Construction of plant units and new sinter plants with maximum leverage of the existing infrastructure

Outotec develops and provides technology solutions for the sustainable use of Earths natural resources. As the global leader in minerals and metals processing technology, Outotec has developed over decades several breakthrough technologies. The company also offers innovative solutions for the chemical industry, industrial water treatment and the utilization of alternative energy sources. Outotec shares are listed on the NASDAQ OMX Helsinki.

ferrous@outotec.com www.outotec.com Copyright 2011 Outotec Oyj. All rights reserved.

Finland, December 2011.

You might also like

- OTE Outotec Pallet Cars For Sintering and PelletizDocument4 pagesOTE Outotec Pallet Cars For Sintering and PelletizShukla SuyashNo ratings yet

- Circular Pelletizing enDocument8 pagesCircular Pelletizing enShukla SuyashNo ratings yet

- SinteringDocument5 pagesSinteringdfhhjjjNo ratings yet

- Advanced Pulverized Coal Injection Technology and Blast Furnace OperationFrom EverandAdvanced Pulverized Coal Injection Technology and Blast Furnace OperationK. IshiiNo ratings yet

- Sintering of Iron Ore PDFDocument32 pagesSintering of Iron Ore PDFDhiraj KadheNo ratings yet

- Effect of Mill Scale on Iron Ore Sinter PhasesDocument13 pagesEffect of Mill Scale on Iron Ore Sinter PhasesDrTrinath TalapaneniNo ratings yet

- Iron Ore Pelletizing: Metso Grate-Kiln SystemsDocument2 pagesIron Ore Pelletizing: Metso Grate-Kiln Systemsmbamarketing54No ratings yet

- Optimal Operation of Coal-Based Rotary KilnDocument9 pagesOptimal Operation of Coal-Based Rotary KilnParesh SaksenaNo ratings yet

- Sintering Plant at A GlanceDocument72 pagesSintering Plant at A GlanceShailesh Kumar100% (1)

- Bulk Density PDFDocument2 pagesBulk Density PDFLOPA THANDARNo ratings yet

- Micro Pellet Sintering Method-CIE 20150414Document10 pagesMicro Pellet Sintering Method-CIE 20150414honeygupta121No ratings yet

- Sinter Plant JSPL, RaigarhDocument14 pagesSinter Plant JSPL, RaigarhJatin BangaliNo ratings yet

- Presentation On Accretion Removal in BF2 at JSW SalemDocument33 pagesPresentation On Accretion Removal in BF2 at JSW SalemNishant BandaruNo ratings yet

- Dynamic Simulation of Pellet Induration Process in Straight-Grate SystemDocument10 pagesDynamic Simulation of Pellet Induration Process in Straight-Grate Systemdavibraga8041100% (1)

- Low Sulphur and Low Si in Hot Metal PDFDocument13 pagesLow Sulphur and Low Si in Hot Metal PDFB V S KumarNo ratings yet

- Laboratory Procedures For Mining Pelletizing Characterization of Iron Ore ConcentrationDocument9 pagesLaboratory Procedures For Mining Pelletizing Characterization of Iron Ore ConcentrationgeodasNo ratings yet

- Iron Ore Sintering: Quality Indices: ArticleDocument13 pagesIron Ore Sintering: Quality Indices: ArticleROWHEITNo ratings yet

- Sinter Plant Single Toothed Roll Crusher PDFDocument14 pagesSinter Plant Single Toothed Roll Crusher PDFrmsh301No ratings yet

- RG-04 Blast FurnaceDocument8 pagesRG-04 Blast FurnaceAnubhav SarafNo ratings yet

- Lime in Iron OreDocument14 pagesLime in Iron Oreranjeet_nismNo ratings yet

- BF Reline ProjectDocument32 pagesBF Reline ProjectAnaruzzaman SheikhNo ratings yet

- Presentation PDFDocument25 pagesPresentation PDFAmit PattanayakNo ratings yet

- Lime and Dolomite For The Steel IndustryDocument8 pagesLime and Dolomite For The Steel IndustrychmsarfrazNo ratings yet

- Environmental Issues Management: C P C BDocument79 pagesEnvironmental Issues Management: C P C BGanesh N KNo ratings yet

- Sintering PlantDocument24 pagesSintering PlantB R Manikyala Rao100% (1)

- Iron Making2Document54 pagesIron Making2richa_msmeNo ratings yet

- Iron Ore Pellets and Pelletizing ProcessesDocument5 pagesIron Ore Pellets and Pelletizing ProcessesNirad SinhaNo ratings yet

- Vocational Training Report at Bokaro Steel PlantDocument34 pagesVocational Training Report at Bokaro Steel PlantRavi kumarNo ratings yet

- 1 Introduction of The Blast Furnace ProcessDocument9 pages1 Introduction of The Blast Furnace Processhemant patilNo ratings yet

- Mine Rajhara DetailsDocument331 pagesMine Rajhara DetailsAditya PrakashNo ratings yet

- Steel Slag JSPLDocument43 pagesSteel Slag JSPLKalai SelvanNo ratings yet

- What Is Furnace ?Document21 pagesWhat Is Furnace ?BARUN BIKASH DENo ratings yet

- Bee - Hive Metallurgical CokeDocument4 pagesBee - Hive Metallurgical Coke124swadeshiNo ratings yet

- Sponge Iron PlantDocument11 pagesSponge Iron PlantLi GaryNo ratings yet

- Stainless Steel AOD Operation and Slag Optimisation PDFDocument41 pagesStainless Steel AOD Operation and Slag Optimisation PDFPrakash MishraNo ratings yet

- Laboratory Study of An Organic Binder For Palletization of A Magnetite ConcentrateDocument8 pagesLaboratory Study of An Organic Binder For Palletization of A Magnetite ConcentrateMaya CiamikNo ratings yet

- Iron Ore Final Grinding by HPGR and Air ClassificationDocument20 pagesIron Ore Final Grinding by HPGR and Air ClassificationW ZuoNo ratings yet

- Fluxes For MetallurgyDocument15 pagesFluxes For Metallurgyramau619No ratings yet

- DSP Overview 10-07-2017Document46 pagesDSP Overview 10-07-2017Binod Kumar Padhi0% (1)

- Optimized Sponge Iron Making ProcessDocument10 pagesOptimized Sponge Iron Making Processawneet_semc100% (1)

- Pelletizing ذكيDocument8 pagesPelletizing ذكييوسف عادل حسانينNo ratings yet

- Standard Operating Procedures for BF Blowing-InDocument18 pagesStandard Operating Procedures for BF Blowing-InTheleapInoblivionNo ratings yet

- Flow sheet & sampling map cement plant processesDocument1 pageFlow sheet & sampling map cement plant processesOkta RiaNo ratings yet

- Cupola Furnace Project ReportDocument32 pagesCupola Furnace Project Reportadelina ednandaNo ratings yet

- Sponge Iron PlantDocument23 pagesSponge Iron Plantashu_update100% (2)

- Grate KilnDocument8 pagesGrate KilnAnggiet HerdayantiNo ratings yet

- Cdi - AliDocument34 pagesCdi - AliNKSNo ratings yet

- Refractory Solutions Improve Steel CleanlinessDocument9 pagesRefractory Solutions Improve Steel CleanlinessBagas Prasetyawan Adi NugrohoNo ratings yet

- 021-Integration of Midrex Technologies in North America Steel Plants - Evaluation of Economical and CO2 ImpactsDocument10 pages021-Integration of Midrex Technologies in North America Steel Plants - Evaluation of Economical and CO2 ImpactscornNo ratings yet

- Different Shaft Kiln For Lime ManufacturerDocument13 pagesDifferent Shaft Kiln For Lime ManufactureranjnaNo ratings yet

- Tecnored Process - High Potential in Using Different Kinds of Solid FuelsDocument5 pagesTecnored Process - High Potential in Using Different Kinds of Solid FuelsRogerio CannoniNo ratings yet

- Coke properties at tuyere level with pulverized coal injectionDocument7 pagesCoke properties at tuyere level with pulverized coal injectionsinghbasant12100% (1)

- FEECO Seal OptionsDocument1 pageFEECO Seal OptionsFernando MilmanNo ratings yet

- Flash Outokumpu Continuous Converting ProcessDocument15 pagesFlash Outokumpu Continuous Converting ProcessSimón BaezaNo ratings yet

- Up Wear ResistantDocument14 pagesUp Wear ResistantIrshad HussainNo ratings yet

- FLS - Ball Mill Liners Brochure - DIGITALDocument9 pagesFLS - Ball Mill Liners Brochure - DIGITALaliNo ratings yet

- Calcination and Reduction of Laterite Nickel OresDocument10 pagesCalcination and Reduction of Laterite Nickel OresrikocahyopNo ratings yet

- Cold Bonding of Iron Ore Concentrate PelletsDocument7 pagesCold Bonding of Iron Ore Concentrate PelletsJaq Plin PlinNo ratings yet

- If-CC-TMT Consumption Factor - Gupta JiDocument18 pagesIf-CC-TMT Consumption Factor - Gupta JiSunil Kumar DwivediNo ratings yet

- State-of-the-Art of An Induction Furnace: Design, Construction and ControlDocument7 pagesState-of-the-Art of An Induction Furnace: Design, Construction and ControlSunil Kumar DwivediNo ratings yet

- State-of-the-Art of An Induction Furnace: Design, Construction and ControlDocument7 pagesState-of-the-Art of An Induction Furnace: Design, Construction and ControlSunil Kumar DwivediNo ratings yet

- Induction Furnace - A ReviewDocument9 pagesInduction Furnace - A ReviewUZAIR.KZNo ratings yet

- Five Point Someone1 PDFDocument153 pagesFive Point Someone1 PDFIonut MihaiNo ratings yet

- Developing A Minerals Processing Project - Thomas W. Hedrick P.E.Document16 pagesDeveloping A Minerals Processing Project - Thomas W. Hedrick P.E.Sunil Kumar DwivediNo ratings yet

- Csna14828enc 001Document72 pagesCsna14828enc 001Sunil Kumar DwivediNo ratings yet

- Induction Furnace - A ReviewDocument9 pagesInduction Furnace - A ReviewUZAIR.KZNo ratings yet

- State-of-the-Art of An Induction Furnace: Design, Construction and ControlDocument7 pagesState-of-the-Art of An Induction Furnace: Design, Construction and ControlSunil Kumar DwivediNo ratings yet

- 1924 January The Adventure of The Sussex VampireDocument11 pages1924 January The Adventure of The Sussex VampireSunil Kumar DwivediNo ratings yet

- Chetan Bhagat - Three Mistakes of My LifeDocument144 pagesChetan Bhagat - Three Mistakes of My LifeGayathri ParthasarathyNo ratings yet

- Chetan Bhagat - Three Mistakes of My LifeDocument144 pagesChetan Bhagat - Three Mistakes of My LifeGayathri ParthasarathyNo ratings yet

- Bill For Engineering and DesignDocument1 pageBill For Engineering and DesignSunil Kumar DwivediNo ratings yet

- Five Point Someone1 PDFDocument153 pagesFive Point Someone1 PDFIonut MihaiNo ratings yet

- Project - Report Libre UreaDocument65 pagesProject - Report Libre UreaSunil Kumar DwivediNo ratings yet

- 96 10 30Document38 pages96 10 30Sunil Kumar DwivediNo ratings yet

- Affidavit by The Student GuardianDocument4 pagesAffidavit by The Student GuardianSunil Kumar DwivediNo ratings yet

- Dps Talent Exam Papers 2013-2014Document16 pagesDps Talent Exam Papers 2013-2014Sunil Kumar DwivediNo ratings yet

- 96 10 30Document38 pages96 10 30Sunil Kumar DwivediNo ratings yet

- APP Booklet of Cement TechnologyDocument232 pagesAPP Booklet of Cement TechnologySunil Kumar DwivediNo ratings yet

- 05.cement Market PeruDocument34 pages05.cement Market PeruSunil Kumar DwivediNo ratings yet

- Pre-Feasibility Study For The Development of A Mini Cement Plant in ColombiaDocument158 pagesPre-Feasibility Study For The Development of A Mini Cement Plant in ColombiaSunil Kumar Dwivedi100% (3)

- Ratio Analysis PROJECT in Steel PlantDocument89 pagesRatio Analysis PROJECT in Steel PlantSunil Kumar DwivediNo ratings yet

- Break Even Analysis of Mining ProjectsDocument60 pagesBreak Even Analysis of Mining ProjectsAnil Kumar100% (1)

- 09 Ironmaking MM BF Burden CalculationDocument1 page09 Ironmaking MM BF Burden CalculationSunil Kumar Dwivedi100% (1)

- Cement Formula BookDocument47 pagesCement Formula Bookgvrr195482% (11)

- TATA BFG Operator Training R1Document56 pagesTATA BFG Operator Training R1Rupesh VermaNo ratings yet

- TATA BFG Operator Training R1Document56 pagesTATA BFG Operator Training R1Rupesh VermaNo ratings yet

- GATE Electrical Engineering - 2008Document24 pagesGATE Electrical Engineering - 2008Pramod ReddyNo ratings yet

- Basic Mechanical Engineering (Draw The PV Diagram in Each Problem)Document2 pagesBasic Mechanical Engineering (Draw The PV Diagram in Each Problem)nidhul07No ratings yet

- Flocculation Dewatering ProcessDocument5 pagesFlocculation Dewatering ProcessRuth LimboNo ratings yet

- AP Final Exam IIDocument21 pagesAP Final Exam IIRobert JonesNo ratings yet

- Lab MektanDocument75 pagesLab MektanbaboNo ratings yet

- EEE-435 Lecture 1: Industrial SafetyDocument20 pagesEEE-435 Lecture 1: Industrial SafetyShah SyedNo ratings yet

- VTU Exam ScheduleDocument46 pagesVTU Exam ScheduleKrisNo ratings yet

- Logistic Growth PDFDocument6 pagesLogistic Growth PDFHongYu HuiNo ratings yet

- Ball and BeamDocument8 pagesBall and BeamIonel MunteanuNo ratings yet

- Gaussian Observation HMM For EEGDocument9 pagesGaussian Observation HMM For EEGDeetovNo ratings yet

- 3 FTP - 2-WT PDFDocument34 pages3 FTP - 2-WT PDFMohama KarimiNo ratings yet

- Thermosense: Occupancy Thermal Based Sensing For Hvac ControlDocument8 pagesThermosense: Occupancy Thermal Based Sensing For Hvac ControledgardoboieroNo ratings yet

- Breasting, Mooring Dolphin, & Main Jetty (Version 1) PDFDocument48 pagesBreasting, Mooring Dolphin, & Main Jetty (Version 1) PDFjuraganiwal100% (10)

- TDS3218 September 2016 B - KITE Technical Datasheet ENDocument4 pagesTDS3218 September 2016 B - KITE Technical Datasheet ENAnonymous srwHCpANo ratings yet

- PDS A4 DDXDocument2 pagesPDS A4 DDXRahadianLabigaAmidarmo100% (1)

- Lab 2: Estimating Avogadro's NumberDocument4 pagesLab 2: Estimating Avogadro's NumbersabrinaNo ratings yet

- 00hydr Fundamentals PDFDocument298 pages00hydr Fundamentals PDFpcalver2000No ratings yet

- Guide To Reading DeleuzeDocument40 pagesGuide To Reading DeleuzeAndrés Upegui JiménezNo ratings yet

- Hollow Section Connection Using BoltDocument4 pagesHollow Section Connection Using Boltikanyu79No ratings yet

- Chapter 9Document23 pagesChapter 9Ayush ChopraNo ratings yet

- L5 MU EE1ME - Differentiation - STDDocument25 pagesL5 MU EE1ME - Differentiation - STDDinNo ratings yet

- Silt TrapDocument6 pagesSilt Trapmtrego9441No ratings yet

- Stepper Catalog PDFDocument36 pagesStepper Catalog PDFCano VoyNo ratings yet

- Influence of The Clinker SO3 On The Cement CharacteristicsDocument1 pageInfluence of The Clinker SO3 On The Cement Characteristicsroshan_geo078896No ratings yet

- Design and Manufacturing of Pneumatic Pipe Bending MachineDocument5 pagesDesign and Manufacturing of Pneumatic Pipe Bending MachineSriram MuruganNo ratings yet

- Ijest NG Vol2 No2 Complete IssueDocument204 pagesIjest NG Vol2 No2 Complete IssueUkemebookieNo ratings yet

- ELEK Cable HV ReportDocument6 pagesELEK Cable HV ReportJayson PatrickNo ratings yet

- 3 - BC 2017-18 5.-6.3 FTC To Sketch and Find Total ChangeDocument6 pages3 - BC 2017-18 5.-6.3 FTC To Sketch and Find Total ChangeSamNo ratings yet

- Black Body RadiationDocument46 pagesBlack Body RadiationKryptosNo ratings yet

- Telpro Data Sheets 2014 PDFDocument26 pagesTelpro Data Sheets 2014 PDFrakacyuNo ratings yet

- Great Circle Sailing Notes PDFDocument88 pagesGreat Circle Sailing Notes PDFAsdNo ratings yet