Professional Documents

Culture Documents

Improving Water Use in Distillery Case Study

Uploaded by

vinteshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Improving Water Use in Distillery Case Study

Uploaded by

vinteshCopyright:

Available Formats

Resources, Conservation and Recycling 43 (2005) 163174

Improving industrial water use: case study for an Indian distillery

N.K. Saha, M. Balakrishnan , V.S. Batra

TERI School of Advanced Studies, Darbari Seth Block, India Habitat Center, Lodhi Road, New Delhi 110003, India Received 17 November 2003; accepted 3 April 2004

Abstract Alcohol distilleries are highly water intensive units generating large volumes of high strength wastewater that poses a serious environmental concern. This study aimed at identifying options for improved water use in this sector through a case study in a local distillery. It emerged that optimization of cooling tower operation, innovative ways to reuse wastewater streams like spent lees and spentwash and employing semi-continuous/continuous fermentation could reduce water use in distilleries. 2004 Published by Elsevier B.V.

Keywords: Distillery; Water use; Conservation; Wastewater; Recycling; Reuse

1. Introduction Alcohol distilleries are one of the most polluting industries generating an average of 815 L efuent (spentwash) per liter of alcohol produced. India has around 295 distilleries with a total installed capacity of 3198 million liters per annum and a current yearly production of 1587 million liters alcohol (Ali, 2002). The manufacturing process (Fig. 1) involves fermentation of diluted sugarcane molasses with yeast. The fermentation lasts about 80h and the resulting product contains 68% alcohol. The yeast cells are separated by settling and the cell free broth is steam distilled and rectied to obtain 9495% alcohol. Fresh water is consumed at various stages of the alcohol manufacturing process namely yeast preparation, molasses dilution, bottle washing, adjusting the alcohol to the required strength for potable purpose and occasionally, dilution of the treated efuent, prior to discharge. The efuent generated is acidic in nature, has a high BOD and COD value and

Corresponding author. Tel.: +91 11 2468 2100/2468 2111; fax: +91 11 2468 2144/2468 2145. E-mail address: malinib@teri.res.in (M. Balakrishnan).

0921-3449/$ see front matter 2004 Published by Elsevier B.V. doi:10.1016/j.resconrec.2004.04.016

164

N.K. Saha et al. / Resources, Conservation and Recycling 43 (2005) 163174

Fig. 1. Schematic of alcohol manufacturing process.

poses an aesthetic problem due to its color and odor (Table 1). Consequently, extensive treatment is required before the treated wastewater can meet the stipulated environmental norms (Table 2). Further, a maximum of 15 m3 of efuent can be generated per kilolitre of alcohol produced as per the Water (Prevention and Control of Pollution) Cess Rule, 1978 specied by the Government of India. In this context, improved water use in distilleries can contribute to: better operational efciency; improved economic competitiveness through reduced water demand combined with savings in water and wastewater treatment costs; low environmental impact due to decrease in surface and subsurface withdrawals as well as less groundwater contaminant intrusion; also, such measures will mitigate the effects of water stress (Sinha, 2002). This work aims to identify possible strategies that can improve water use in Indian distilleries. This was achieved through a preliminary questionnaire survey of select local distilleries in Northern India, followed by a detailed study in one unit.

N.K. Saha et al. / Resources, Conservation and Recycling 43 (2005) 163174 Table 1 Typical characteristics of distillery spentwash (Goyal et al., 1996) Parameter pH Total solids (mg/L) Total suspended solids (mg/L) Total dissolved solids (mg/L) Total volatile solids (mg/L) Chemical oxygen demand (mg/L) Biological oxygen demand (for 5 days at 20 C) (mg/L) Total nitrogen as N (mg/L) Potash as K2 O (mg/L) Phosphate as PO4 (mg/L) Sodium as Na (mg/L) Chlorides as Cl (mg/L) Sulfates as SO4 (mg/L) Acidity as CaCO3 (mg/L) Temperature (after heat exchanger) ( C) Range

165

3.84.4 6000090000 200014000 5800076000 4500065000 7000098000 4500060000 10001200 500012000 5001500 150200 50008000 20005000 800016000 7080

Table 2 Comparison of treated spentwash and efuent quality standards prescribed by Central Pollution Control Board (CPCB) Parameter Spentwash characteristics after primary treatment (Ali, 2002) 37 C 7.08.5 40005000 2500030000 1.01.5 700800 25004500 20003000 300500 15002500 CPCB discharge standards (CPCB, 1998) Into surface water, Indian Standards: 2490 (1974) Shall not exceed 40 C 5.59.0 30 250 100b 2100 10 2 1000 1000 1.0 On land for irrigation, Indian Standards: 3307 (1974) Shall not exceed 40 C 5.59.0 100a 200b 2100 10 1000 600 600

Temperature ( C) pH BOD5 20 C (mg/L) COD (mg/L) Suspended solids (%) Total dissolved solids (inorganic) (mg/L) Oil and grease (mg/L) Sulde (S2 ) (mg/L) Sulfates (SO4 2 ) (mg/L) Chlorides as Cl (mg/L) Total residual chlorine (mg/L) Sodium (Na+ ) (mg/L) Potassium (K+ ) (mg/L)

a b

When land is used for secondary treatment, BOD up to 500 mg/L is permissible. Absolute values in mg/L.

2. Approaches towards water conservation in industries Monitoring of water use in industries is gaining importance due to increasing competition and stringent environment norms. Water is no longer perceived as a free commodity; further,

166

N.K. Saha et al. / Resources, Conservation and Recycling 43 (2005) 163174

innovative technologies, along with modication of existing technologies are commercially available to reduce process water consumption. In general, reduction in industrial wastewater can be achieved through one or a combination of the following measures: process modication or change in raw materials to reduce water consumption; direct reuse of wastewater; in-plant reuse of reclaimed wastewater; use of treated wastewater for non-industrial purposes.

The nal choice of the measures adopted are dictated by the availability of substitute raw material and technology, nature of pollutants, purity requirement of water for reuse, competing water demands and overall treatment cost. Table 3 summarizes some key initiatives implemented for improved water use in different industrial sectors.

3. Methods A questionnaire survey on water use in distilleries was conducted through the All India Distillers Association. The survey was limited to distilleries in Northern India, located near Delhi. Based on the results of the survey, a distillery unit located in the state of Uttar Pradesh was chosen for further study. The detailed water balance was examined and water/wastewater samples were collected from different points in the plant. The water characteristics were determined in the laboratory following standard methods (APHA, 1989). Data on volumes of water consumed and efuent generated was obtained from the distillery records.

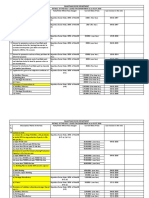

4. Results and discussions 4.1. Summary of questionnaire survey The questionnaire was administered to a total of seven distilleries, of which four distilleries provided responses. The survey results are collated in Table 4. The following salient points emerged from this exercise. 1. Ground water is the main water source. Water is pumped out of deep wells and distributed to the various points of water utilization. 2. Signicant volume of water is consumed for molasses dilution, bottle washing and inoculum (yeast) preparation. 3. Water consumption for potable alcohol preparation is dependent upon the total potable alcohol production as well as the product mix in terms of country liquor and Indian made foreign liquor (IMFL). 4. The primary efuent treatment step involves anaerobic treatment with biogas generation. This is sometimes followed by aerobic treatment; alternatively, the primary treated efuent is used for biocomposting, or stored in lagoons for several months before nal discharge in the rainy season. Ferti-irrigation is also practiced in some areas, after diluting with water.

Table 3 Water conservation possibilities and technological availability for different industries Industry Distillery Interventions Spentwash recycling Technology adopted Modication in existing process Remarks N.K. Saha et al. / Resources, Conservation and Recycling 43 (2005) 163174 Successful trials with 40% spentwash recycling for molasses dilution and fermentation at Fermpro, Malaysia (Yeoh et al., 2001) 25% spentwash recycle for fermentation being used at SSK Distillery, Akluj, India (Waste Minimization Circle) Semi-continuous process reduced water consumption up to 70% in Sarina distillery, Australia (EnviroNet Australia) 93% water savings, payback just above 24 months in San Francisco Ameca Plant Jalisco, Mexico (EMCENTRE, 1999; UNEP-WBCSD, 1998) Reduced water use by 30,000 m3 /year in a dairy in Tartu, Estonia (UNEP-WBCSD, 1998) Trials in a mill at Jmsnkoski, Finland displayed (UNEP-WBCSD, 1998) 75% reduction in freshwater consumption by changing feedstock Zero efuent pulp and paper mill

Sugar

Recycling of process water from the barometric column Recycling of boiler condenser water Recycling wash water used in chimney cleaning Reduced water for washing Recirculation of water with cleaning solution in cleaning area Change in feedstock Regeneration of water from the wastewater stream Recycle of paper machine white water, decker and screen white water, condenser cooling water

Developed system for cooling and collecting water

Dairy

Improved hose with shut-off nozzle High pressure washing Screening Clarication Evaporation Close monitoring of operation conditions Combined ultraltration and reverse osmosis

Pulp and paper

Board

Regeneration of process water from secondary treated efuent

Successful pilot scale study in Turkey (Yalcin et al., 1999) showed high quality of treated water 167

168

Table 3 (Continued ) Industry Tannery Interventions Reuse of main soak for dirt soak Drum soaking instead of pit soaking Reuse of limed water Deliming of water for subsequent usesoaking Regeneration, use of dyeing and fulling wastewater Use of rejected water from deionizing unit as cooling water make-up Recycling of process water Metal industries Treatment of heavy metal polluted acidic water Technology adopted Chemical treatment Little modication in existing facilities Remarks Recommended by Central Pollution Control Board, India expected to result in signicant reduction in water consumption (CPCB, 1999) N.K. Saha et al. / Resources, Conservation and Recycling 43 (2005) 163174

Textiles Semiconductor

Combined ultraltration and reverse osmosis Chemical treatment

Tested on pilot scale in Italy (Ciardelli et al., 2000) with estimated treatment cost 1 /m3 Practical experience in SGS-Thomson Microelectronics, Malta (UNEP-WBCSD, 1998) Case study in Chungli, Taiwan (You et al., 2001) Research experience in South Africa (Van Hille et al., 1999) shows Signicant reduction in metal ion concentration when tested in a bench scale reactor Tannery or saline water can be used as nutrient for algae

Microltration Ion-exchange resin treatment Biological treatment with alkali producing algae (Spirulina sp.) followed by anaerobic polishing

Petroleum rening

Use of tertiary treated municipal wastewater as process water

Ultraltration and reverse osmosis

Signicant savings in freshwater consumption through combined ultraltration and reverse osmosis of secondary treated municipal sewage in Chennai Petroleum Company Limited, Chennai, India Treatment cost is estimated to be Rs. 28/kL and is economically feasible (Viswanathan and Sethi, 2002)

Table 4 Survey results Parameter Distillery 1 Plant capacity (kL/day) Molasses consumed (kg) Water source Water use (kL/day) Molasses dilution Inoculum preparation Washing Potable alcohol preparation Spentwash dilution Recycling/reuse 45 180000 Ground 430 3.5 81 22 30 Recirculation of condenser and fermenter cooling water; fermenter washing using spentlees; wash water from bottling plant for gardening Biomethanation 2 25 110000 Ground 250 16 20 45 75 None 3 180 8000,000 Ground 1300 30 50 50 Cooling water 4 25 1100000 Ground 160 30 40a 5b 1050 For diluting treated efuent

N.K. Saha et al. / Resources, Conservation and Recycling 43 (2005) 163174

Efuent treatment

Biomethanation & aerobic treatment Ferti-irrigation and discharge into drain

End use of treated efuent

a b

Biocomposting

Biomethanation, anaerobic lagooning and aerobic treatment Discharged in rainy season

Biomethanation and aerobic treatment Limited ferti-irrigation

For one chain (8 h/day). For 200,000 B.L. country liquor/month.

169

170

N.K. Saha et al. / Resources, Conservation and Recycling 43 (2005) 163174

Table 5 Background of test unit Location Total production capacity (kL/day) Potable alcohol (kL/day) Rectied spirit (kL/day) Molasses consumption (quintal) Molasses concentration for fermentation (Brix) Total water consumption (kL/day) Number of fermenters Fermenter type Efuent treatment Reactor and capacity (kL/day) Operational Installed End use of treated efuent

a b

Uttar Pradesh, India 45 25 20 1800 3840 1133.5 9 Batch SMAGa 350 650 Bio-composting with sugarcane press-mud UASBRb 150 375

Submerged media attached growth. Up ow anaerobic sludge blanket reactor.

5. Concentration and incineration of the efuent is another option that is being examined. This recovers the water from the efuent and the concentrated mass can be burnt in the boiler for steam generation. The ash produced is rich in inorganics and can nd application as fertilizer. Even though local rms are supplying the technology, it is still under testing. 6. There is considerable interest in water conservation among local distilleries because of strict environmental norms. In this context, cooling water recycling is a commonly practiced measure. Of the units that responded, distillery 1 was proactively exploring water conservation and reuse. Thus, this unit was chosen for the detailed study. 4.2. Case study The background of the chosen unit is summarized in Table 5. Fig. 2 shows the water balance and Table 6 provides the distribution of water use. Analysis of the various water/wastewater samples is listed in Table 7.

Table 6 Distribution of fresh water consumption in test unit Activity Inoculum preparation Molasses dilution Fermenter washing Boiler Cooling water make-up Bottle washing Potable alcohol preparation Efuent treatment Consumption (kL/day) 3.5 430 18 187 388 30 15 30

N.K. Saha et al. / Resources, Conservation and Recycling 43 (2005) 163174

171

Fig. 2. Water balance diagram.

The unit uses 1133.5 kL water/day and generates around 668 kL/day of efuent. The efuent volume has been calculated on the basis of contributions from water used for molasses dilution, yeast preparation, steam generation, fermenter washing and efuent treatment. It has been assumed that other processes do not contribute to efuent generation. Molasses dilution, cooling requirement and steam generation in the boiler are the most water intensive processes. Thirty-four percent of total daily water input to the distillery is in the form of cooling tower make-up volume that is a consequence of evaporative loss, drift loss and blowdown. Optimization of the cooling tower operation and maintenance

172

N.K. Saha et al. / Resources, Conservation and Recycling 43 (2005) 163174

Table 7 Characteristics of water/wastewater in different distillery processes pH Fresh water Demineralized water Bottle washing wastewater Cooling water Spent lees Spentwash 8.10 5.70 7.94 7.65 2.90 3.90 Temperature ( C) 8085 8590 Total solids (g/L) 8.3 8.9 17 7.9 7.6 63.8 Total suspended solids (g/L) 0.5 0.3 0.5 0.7 1.8 13.8 Dissolved solids (g/L) 7.8 8.6 16.5 7.2 5.8 50 Chloride (mg/L) 34.8 17.4 78.4 87.2 69.7 8720 COD (mg/L) 504 1080 72 2088 8640 388800

can contribute signicantly to makeup water requirement (NCDENR).1 Possible measures include energy balance to justify the evaporative loss of water, use of drift eliminator to control drift loss and marginal increase in concentration ratio to minimize the blowdown. For instance, an increase in concentration ratio from 1.5 to 2% can result in 33% savings in makeup water (NCDENR). Further, treated wastewater can also be explored as an alternative source of makeup water. At present, the unit uses the wash water from the bottling plant for gardening. Further, for efuent dilution, fresh water is used. The characteristics of the water generated after bottle washing are comparable to fresh water (Table 7) since the bottles, which are pre-washed, are simply rinsed without using any detergent. Thus, this wash water can replace the freshwater used for efuent dilution thereby saving about another 3% of total water input to the plant. Simultaneously, water requirement for gardening can be reduced by choosing appropriate plant species such as Bryophyllum, Agave, Casuarina equisetifolia, Aloe vera etc. that require less water for their growth. Appropriate wastewater streams can be partially substituted for fresh water in fermenter washing. For instance, this distillery unit has successfully attempted partial reuse of spent lees for fermenter washing. This is in spite of the fact that the spent lees is typically at 8085 C and has a pH and COD signicantly different from that of fresh water. This intervention contributes to a 2.7% saving in overall freshwater requirement. Modifying the fermentation process can result in the control of both water consumption and efuent generation. In Malaysia 40% reduction in freshwater consumption has been achieved by reusing the spentwash in molasses dilution and fermentation steps (Yeoh et al., 2001). In another study, M/s S S K Distillery, Akluj, Maharashtra, India reported recycling 25% of the spentwash from the distillation column directly to the fermenter to reduce water utilization (Waste Minimization Circle).2 The same unit also employed a modied fermentation process (dual biofermcen process) resulting in a 40% reduction in spent wash generation (Waste Minimization Circle). In another study, CSRs Sarina distillery

1 NCDENR, NCDENR (North Carolina Department of Environment and Natural Resources), Division of Pollution Prevention and Environmental Assistance. Water EfciencyWater Management Options Cooling and Heating. http://www.p2pays.org/ref/04/03101.pdf. 2 Waste Minimization Circle, National Productivity Council of India. Waste minimization case study in WMC distillery unit conversion of BAT process http://wmc.nic.in/case-studies3.asp.

N.K. Saha et al. / Resources, Conservation and Recycling 43 (2005) 163174

173

in Queensland, Australia tested a semi-continuous fermentation process (Biostil) that reportedly cut down water consumption by 70% (EnviroNet Australia).3 Though continuous fermentation has been successfully employed in Indian distilleries in the southern state of Maharashtra, extreme variations in the ambient temperature in the state of Uttar Pradesh may limit its efciency.

5. Conclusion There is signicant scope to improve water utilization in Indian distilleries through conservation and reuse. Though good housekeeping measures such as proper metering of water ow in individual units and maintenance of piping contribute to water savings, specic interventions should also be targeted. Our study identied optimization of cooling tower operation, innovative ways to reuse segregated wastewater streams and replacing batch with semi-continuous/continuous fermentation to be appropriate interventions to reduce water use in distilleries.

Acknowledgements The authors acknowledge the All India Distillers Association (AIDA) and the distilleries that participated in this study.

References

Ali, S. Move towards a zero liquid discharge distillery. In: Proceedings of the Second FICCI-TERI Global Conference: Green2002 Agenda for Industry. 78 February 2002, New Delhi, India. APHA. Standard methods for the examination of water and wastewater. 17th ed. Washington, DC: American Public Health Association; 1989. Ciardelli G, Corsi L, Marcucci M. Membrane separation for wastewater reuse in the textile industry. Resources Conserv Recycl 2000;31:18997. CPCB (Central Pollution Control Board). Pollution Control Acts, Rules, Notications issued thereunder, vol. I. New Delhi: Central Pollution Control Board, Ministry of Environment and Forests; 1998. p. 3112, 501. CPCB (Central Pollution Control Board). Parivesh Newsletter, 1999;6:1920. EMCENTRE (Environmental Management Centre); 1999. http://www.emcentre.com/unepweb/tec case/food 15/ house/casename.shtml. Goyal SK, Seth R, Handa BK. Diphasic xed-lm biomethanation of distillery spentwash. Bioresource Technol 1996;56:23944. Sinha AK. Sustainability of the Indias water resources: challenges and perspectives. Sustainable Development International 2002;4:12933. http://www.sustdev.org/explore/water res man/articles/edition4.shtml. UNEP-WBCSD, 1998. Industry, fresh water, and sustainable development. United Nations Environmental Programme and World Business Council for Sustainable Development. Van Hille RP, Boshoff GA, Rose PD, Duncan JR. A continuous process for the biological treatment of heavy metal contaminated acid mine water. Resources Conserv Recycl 1999;27:15767.

3 EnviroNet Australia. Recycling Waste Products from Molasses Fermentation, CSR Distilleries. http://www.p2pays.org/ref/04/03358.htm.

174

N.K. Saha et al. / Resources, Conservation and Recycling 43 (2005) 163174

Viswanathan S, Sethi N. Down to Earth 2002;11. Yalcin F, Koyuncu I, Oztrk I, Topacik D. Pilot scale UF and RO studies on water reuse in corrugated board industry. Water Sci Technol 1999;40(45):30310. Yeoh BG, Chen SS, Aziz AA, Nee TY, Chong TC, van de Graaff R, van de Graaff H. Cleaner production in the distillery industrythe Malaysia experience. In: Proceedings of the Third Asia Pacic Roundtable Conference for Cleaner Production. February 28March 2, 2001, Manila, Philippines. http://www.aprcp.org/articles/papers/yeoh.htm. You S-H, Tseng D-H, Guo G-L. A case study on the wastewater reclamation and reuse in the semiconductor industry. Resources Conserv Recycl 2001;32:7381.

You might also like

- Brewery Effluent Treatment Plant (ETP) PerformanceDocument7 pagesBrewery Effluent Treatment Plant (ETP) PerformanceMohan P100% (1)

- Application of Chemical Biological and MDocument14 pagesApplication of Chemical Biological and MAfan MirajNo ratings yet

- Biogas Generation From Distillery Spent Wash by Using An OPUR Western Biotechnology Process: A Case StudyDocument9 pagesBiogas Generation From Distillery Spent Wash by Using An OPUR Western Biotechnology Process: A Case Studyali aqdasNo ratings yet

- Anaerobic Reactor For Waste Water TreatmentDocument7 pagesAnaerobic Reactor For Waste Water TreatmentJermaine PinedaNo ratings yet

- Polymeric Cellulose Derivative Carboxymethyl Cellulose As Useful Organic Flocculant Against Industrial Waste WatersDocument7 pagesPolymeric Cellulose Derivative Carboxymethyl Cellulose As Useful Organic Flocculant Against Industrial Waste WatersJR NilNo ratings yet

- Pilot Scale Study of Horizontal Anaerobic Digester For Biogas Production Using Food WasteDocument4 pagesPilot Scale Study of Horizontal Anaerobic Digester For Biogas Production Using Food WasteAl AkilNo ratings yet

- 42 JMES 486 2013 BerradiDocument6 pages42 JMES 486 2013 BerradiAhmed AliNo ratings yet

- Chemically Enhanced Primary Wastewater Treatment (CEPT) in Conjunction With H O /UV Technology in Controlled AtmosphereDocument7 pagesChemically Enhanced Primary Wastewater Treatment (CEPT) in Conjunction With H O /UV Technology in Controlled Atmospherejmrozo3No ratings yet

- Quality Water Drinking Irrigation Contaminants: Chapters 21 IntroductionDocument10 pagesQuality Water Drinking Irrigation Contaminants: Chapters 21 IntroductionMohd ShakoorNo ratings yet

- Effect of Hydrogen Peroxide On Industrial Waste WaDocument9 pagesEffect of Hydrogen Peroxide On Industrial Waste WaBeant SinghNo ratings yet

- علي غانم خضير PDFDocument29 pagesعلي غانم خضير PDFAli AlibrahimiNo ratings yet

- Biogas Production From SludgeDocument4 pagesBiogas Production From Sludgeravi1214No ratings yet

- Dairy Wastewater Use in Concrete ConstructionDocument50 pagesDairy Wastewater Use in Concrete ConstructionMegha ProjectsNo ratings yet

- Envirmonement Source ReportDocument19 pagesEnvirmonement Source Reportمهيمن الابراهيميNo ratings yet

- Potable Water From Industrial Wastewater: M. S. AliDocument4 pagesPotable Water From Industrial Wastewater: M. S. AliEr Omkar Ravindra MhatreNo ratings yet

- Desalination: Marcel Melo, Helga Schluter, Jailton Ferreira, Rosana Magda, Agenor Júnior, Oswaldo de AquinoDocument3 pagesDesalination: Marcel Melo, Helga Schluter, Jailton Ferreira, Rosana Magda, Agenor Júnior, Oswaldo de AquinoAhmed AliNo ratings yet

- Fermentaion Water TreatmentDocument11 pagesFermentaion Water TreatmentBernard GanzwaNo ratings yet

- SubhDocument10 pagesSubhsunilsubhranshu28No ratings yet

- Master Thesis: Moving Biofiles in Sequential Discharge Reactor (SBR)Document88 pagesMaster Thesis: Moving Biofiles in Sequential Discharge Reactor (SBR)DianerNo ratings yet

- Treatment of Distillery Spent Wash by AnaerobicDocument4 pagesTreatment of Distillery Spent Wash by AnaerobicInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Reduction of Cod and Bod by Oxidation: A Cetp Case Study: Prashant K. Lalwani, Malu D. DevadasanDocument5 pagesReduction of Cod and Bod by Oxidation: A Cetp Case Study: Prashant K. Lalwani, Malu D. Devadasanjmrozo3No ratings yet

- Application of Uasbr in Treatment of Dairy Waste Water: 1, PG Student, 2, Assistant ProfessorDocument9 pagesApplication of Uasbr in Treatment of Dairy Waste Water: 1, PG Student, 2, Assistant Professorvk100No ratings yet

- Resources, Conservation and Recycling Volume 44 Issue 2 2005 (Doi 10.1016/j.resconrec.2004.11.002) S. Å Ostar-Turk I. Petrinić M. Simonič - Laundry Wastewater Treatment Using Coagulation and MembrDocument12 pagesResources, Conservation and Recycling Volume 44 Issue 2 2005 (Doi 10.1016/j.resconrec.2004.11.002) S. Å Ostar-Turk I. Petrinić M. Simonič - Laundry Wastewater Treatment Using Coagulation and MembrIpungNo ratings yet

- 1.IJAEST Vol No 8 Issue No 1 "Biomethanation of Dairy Waste Water Through UASB at Mesophilic Temperature Range" 001 009Document9 pages1.IJAEST Vol No 8 Issue No 1 "Biomethanation of Dairy Waste Water Through UASB at Mesophilic Temperature Range" 001 009helpdesk9532No ratings yet

- Plant Trial For Scale InhibitorsDocument15 pagesPlant Trial For Scale InhibitorsOladimejiNo ratings yet

- COD Reduction in Coffe Wastewater Through Flocculation An AOP PDFDocument6 pagesCOD Reduction in Coffe Wastewater Through Flocculation An AOP PDFJesus SerranoNo ratings yet

- Proses Produksi EtanolDocument8 pagesProses Produksi Etanollarasaticandra104No ratings yet

- Environmental Impact in Brewery: Master Programme Kaho Sint - LievenDocument26 pagesEnvironmental Impact in Brewery: Master Programme Kaho Sint - LievenisabeljaramillogNo ratings yet

- Performance Evaluation of Petroleum Refinery Wastewater Treatment PlantDocument6 pagesPerformance Evaluation of Petroleum Refinery Wastewater Treatment PlantInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Bio Degradation of Distillery Spent WashDocument20 pagesBio Degradation of Distillery Spent Wash9219561870No ratings yet

- Waste Water TreatmentDocument3 pagesWaste Water TreatmentSana Saleem100% (1)

- Waste WaterDocument60 pagesWaste Waterbarhooom100% (1)

- Refining WaterDocument60 pagesRefining WaterSohail MalikNo ratings yet

- 37 April 649Document6 pages37 April 649Anju KumariNo ratings yet

- Integrated Management of Potato Starch WastesDocument0 pagesIntegrated Management of Potato Starch WastesMihir DakwalaNo ratings yet

- Li 2012Document7 pagesLi 2012singhdhatri25No ratings yet

- 1 PBDocument7 pages1 PBleonlovebernardNo ratings yet

- Anaerobic Ponds Treatment of Starch Wastewater Case Study in ThailandDocument9 pagesAnaerobic Ponds Treatment of Starch Wastewater Case Study in ThailandPurnama Muhlis KaimunNo ratings yet

- IOSRJEN (WWW - Iosrjen.org) IOSR Journal of EngineeringDocument9 pagesIOSRJEN (WWW - Iosrjen.org) IOSR Journal of EngineeringIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNo ratings yet

- Improvement of Condition of Date Juice Industry Wastewater Treatment ProcessDocument7 pagesImprovement of Condition of Date Juice Industry Wastewater Treatment Processjerliman manaluNo ratings yet

- Sustainable Reclamation and Reuse of Industrial Wastewater Including Membrane Bioreactor TechnologiesDocument7 pagesSustainable Reclamation and Reuse of Industrial Wastewater Including Membrane Bioreactor TechnologiesadrianqNo ratings yet

- Parametric Study of Brewery Wastewater Effluent Treatment Using Chlorella Vulgaris MicroalgaeDocument8 pagesParametric Study of Brewery Wastewater Effluent Treatment Using Chlorella Vulgaris MicroalgaeAA0809No ratings yet

- Munir 2018Document8 pagesMunir 2018Jesús BarónNo ratings yet

- Coagulation/ Occulation Process and Sludge Conditioning in Beverage Industrial Wastewater TreatmentDocument7 pagesCoagulation/ Occulation Process and Sludge Conditioning in Beverage Industrial Wastewater TreatmentAJITH SNo ratings yet

- Greywater Reuse System For Toilet FlushingDocument10 pagesGreywater Reuse System For Toilet FlushingPatel KalingaNo ratings yet

- Contribution of Activated Carbon Based On Cacao Peels (Theobroma Cacao L.) To Improve The Well Water Quality (COLOR, BOD, and COD)Document9 pagesContribution of Activated Carbon Based On Cacao Peels (Theobroma Cacao L.) To Improve The Well Water Quality (COLOR, BOD, and COD)Van AlifNo ratings yet

- Coagulation Flocculation Process and Slu PDFDocument6 pagesCoagulation Flocculation Process and Slu PDFJaberNo ratings yet

- COD and BOD reduction from coffee wastewater using avocado peel carbonDocument8 pagesCOD and BOD reduction from coffee wastewater using avocado peel carbonTom MOt'sNo ratings yet

- 1459-Article Text-3727-1-10-20161213Document6 pages1459-Article Text-3727-1-10-20161213Ha Cao TheNo ratings yet

- Journal of Semipermeable Membrane andDocument8 pagesJournal of Semipermeable Membrane andMichael Bryan PrajogoNo ratings yet

- Reverse Osmosis Applied To Metal Finishing WastewaterDocument6 pagesReverse Osmosis Applied To Metal Finishing WastewaterBarbara RicciNo ratings yet

- Possibility of Reuse of Waste Water in DairysDocument12 pagesPossibility of Reuse of Waste Water in DairyscufuzavarNo ratings yet

- Kotra WTPDocument5 pagesKotra WTPrinkyNo ratings yet

- Imp Distillery Industry Wastewater TreatmentDocument21 pagesImp Distillery Industry Wastewater Treatmentteddybir100% (1)

- Kano Textile IndustriesDocument34 pagesKano Textile IndustriesMuhammad Umar NasirNo ratings yet

- Cost-Benefit Analysis of Wastewater Recycling Plant For Textile Wet ProcessingDocument5 pagesCost-Benefit Analysis of Wastewater Recycling Plant For Textile Wet ProcessingInternational Journal of computational Engineering research (IJCER)No ratings yet

- Constructed Wetlands for Industrial Wastewater TreatmentFrom EverandConstructed Wetlands for Industrial Wastewater TreatmentAlexandros I. StefanakisNo ratings yet

- Biological Sludge Minimization and Biomaterials/Bioenergy Recovery TechnologiesFrom EverandBiological Sludge Minimization and Biomaterials/Bioenergy Recovery TechnologiesEtienne PaulNo ratings yet

- Steam Turbine ManualDocument239 pagesSteam Turbine Manualvintesh80% (5)

- Boiler Blowdown Heat ExchangeerDocument2 pagesBoiler Blowdown Heat ExchangeerJayaraman_mNo ratings yet

- PGM Distilling Part1Document21 pagesPGM Distilling Part1vinteshNo ratings yet

- Socio DemoDocument5 pagesSocio DemovinteshNo ratings yet

- Antojitos Mexicanos PlatillosDocument2 pagesAntojitos Mexicanos Platillosapi-242872308No ratings yet

- Alm Scotch Cigar EtiquetteDocument12 pagesAlm Scotch Cigar Etiquetteapi-241601435No ratings yet

- 105759056!Document3 pages105759056!Jan juel langoyNo ratings yet

- Community Walk: DialogueDocument43 pagesCommunity Walk: Dialogueangel.quintero100% (1)

- FrootoDocument25 pagesFrootorifatNo ratings yet

- Present Simple X Present ContinuousDocument5 pagesPresent Simple X Present ContinuousAndreia SimõesNo ratings yet

- Segmentation, Targeting, Positioning of Coca Cola: BrandDocument5 pagesSegmentation, Targeting, Positioning of Coca Cola: BrandTalha SohailNo ratings yet

- Interesting Cases HbsDocument12 pagesInteresting Cases Hbshus2020No ratings yet

- Levis EsDocument12 pagesLevis EsArjyadeepNo ratings yet

- Low Carb Desserts Decadent - Guilt Free Low Carb Cookie and Dessert Recipes For Low Carb Baking - Nodrm PDFDocument111 pagesLow Carb Desserts Decadent - Guilt Free Low Carb Cookie and Dessert Recipes For Low Carb Baking - Nodrm PDFAndreeaNo ratings yet

- Adventure Inn PDFDocument7 pagesAdventure Inn PDFZachary YorkNo ratings yet

- "Ten Restaurants That Changed America" ExerptDocument8 pages"Ten Restaurants That Changed America" ExerptMarketplaceNo ratings yet

- Analysis of Lebui Nutrition Content and Preference in Processed Vegetable ProductsDocument5 pagesAnalysis of Lebui Nutrition Content and Preference in Processed Vegetable ProductsAgus Dwi AnantoNo ratings yet

- The Dismal Depths, Level 1a: Tunnels of The Mole-Men: Wandering MonstersDocument1 pageThe Dismal Depths, Level 1a: Tunnels of The Mole-Men: Wandering MonstersCrusssDaddyNo ratings yet

- How Can The Kellogg Do Better in IndiaDocument5 pagesHow Can The Kellogg Do Better in IndiaraptorsidNo ratings yet

- Grammar Review for Rodrigo in 1oESODocument4 pagesGrammar Review for Rodrigo in 1oESOCarmen Maria Tebar PlazaNo ratings yet

- LPJ MRDocument14 pagesLPJ MRBagas AudiNo ratings yet

- Creative Media Evaluation 2Document11 pagesCreative Media Evaluation 2api-237720244No ratings yet

- Biscuit Industry Analysis and Applied Family Brand StrategiesDocument28 pagesBiscuit Industry Analysis and Applied Family Brand StrategiessachipmNo ratings yet

- Carta KuskoDocument9 pagesCarta KuskoPara LosNo ratings yet

- Sidewalk Lounge & Bar MenuDocument16 pagesSidewalk Lounge & Bar MenuTobi Dele-SafaNo ratings yet

- 10 de HSG 10Document102 pages10 de HSG 10Nguyễn Khánh LinhNo ratings yet

- Wicker Park Press Catalogue For Winter 2011Document12 pagesWicker Park Press Catalogue For Winter 2011Michael ArnzenNo ratings yet

- Notting Hill 1999 FinalDocument98 pagesNotting Hill 1999 FinalwammaNo ratings yet

- Energies 05 00243Document15 pagesEnergies 05 00243Adam WilsonNo ratings yet

- By-Group J Rewat Sachdeva (2K19/ME/189) Sharad Awasthi (2K19/ME/226)Document10 pagesBy-Group J Rewat Sachdeva (2K19/ME/189) Sharad Awasthi (2K19/ME/226)Rewat SachdevaNo ratings yet

- Goethe's Faust adapted for the stage by GounodDocument62 pagesGoethe's Faust adapted for the stage by Gounodjavp4691No ratings yet

- The Glorious Heresies by Lisa McInerney (Extract)Document12 pagesThe Glorious Heresies by Lisa McInerney (Extract)Hodder Stoughton100% (1)

- Lifestyles Catering and WeddingsDocument26 pagesLifestyles Catering and Weddingsapi-251538037No ratings yet

- Hacking for Food RescueDocument21 pagesHacking for Food RescueLaura VillarrealNo ratings yet