Professional Documents

Culture Documents

Fire Water Make Up Pump

Uploaded by

Alvin SmithCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fire Water Make Up Pump

Uploaded by

Alvin SmithCopyright:

Available Formats

OWNER

LSTK

PMC

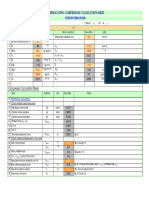

CENTRIFUGAL PUMP DATA SHEET

PROJECT : New Fire Water Network at ONGC, Hazira CLIENT : ONGC, Hazira PMC : IOT D & E LSTK CONTRACTOR : SAVAIR ENERGY LIMITED A 1 2 3 4 B 1 2 3 4 5 6 C 1 2 D 1 E 1 1 2 3 4 5 5a 5b 6 7 8 9 10 11 12 13 14 15 16 GENERAL Applicable To Location Service Quantity OPERATING CONDITIONS Liquid Handled Pumping Temperature (oC) Liquid Density at Pumping Temperature (Kg/m3) Vapour Pressure @ 20 oC (Kg/cm2 A) Viscosity @ 20 C (CST) Corrosion / Errosion CAPACITY CONTROL FOR VOLUMETRIC PUMPS Method of Control Type of Control MECHANICAL DATA Design Pressure (Kg/cm2 A) MANUFACTURER'S SPECIFICATIONS Pump Manufacturer CONSTRUCTION Casing Mount Split Type Casing Connection (Vent / Drain / Gauge) Nozzles : Suction (Size / Rating / Facing / Location) Discharge (Size / Rating / Facing / Location) Impeller Type Impeller Dia mm (Rated / Max / Min) Bearings (Type / No.) Coupling (Make / Type) Guard Non Sparking Driver Half Mounted By (Pump Mfg. / Driver Mfg.) Packing (Make / Type / Size / No. of Rings) Mech Seal (Make / Model / API Class Code) Base Plate Drain Rim Type Foundation Bolts Throat Bushing * / 150# / * / * * / 150# / * / * * * * * Yes / No * * * Yes / No Yes / No Yes / No * * HORIZONTAL CENTRIFUGAL */* / * /* 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 Proposal Curve No. No. Stages NPSH Required (Water) m Speed (RPM) Hydraulic Power (kW) Efficiency (%) Rated Power (kW) Max. Head Rated Impeller (kW) Max. Head Rated Imp (m) Min Cont. Flow (m3/hr) MAWP (kg/cm2 A) Hydrostatic Test Pressure (kg/cm2 g) Rotation Viewed from Coupling End Flushing Packing Lantern Ring Connection Seal Flush Piping (Plan / Material) Ext Seal Flush Fluid LPM / (Kg/cm2g) CW Piping (Plan / Material) * 2 Size and Type PERFORMANCE * * * * * * * * * * * * CW / CCW Self / External Yes / No */* */* */* * 13.5 2 Design Temperature ( oC) 65 As per P & ID As per P & ID 3 4 Control Range Precision at Minimum Range As per P & ID As per P & ID

o

DOC. NO. : REV. NO. : A PAGE NO. : 1 OF 2 REF. P & ID NO. : IOTDE-MM-04-032 REV.2

Purchase Hazira Fire Water 2 x 100%

5 6 7 8

Tag No. Driver Pump Model No. Applicable Standard / Code

47-PD-007A/B Diesel Engine Driven * NFPA

Water AMB 1000 0.04 1 NO

7 8 9 10 11 12

Capacity @ PT (m3/hr) (Min / Normal / Max) Discharge Pressure (Kg/cm2 abs) Suction Pressure (Kg/cm2 abs) Differential Pressure (Kg/cm2 abs) Differential Head (m) NPSH Available (m)

* / 610 / * 6 Flooded

Flooded

OWNER

LSTK

PMC

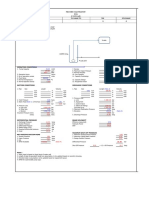

CENTRIFUGAL PUMP DATA SHEET

PROJECT : New Fire Water Network at ONGC, Hazira CLIENT : ONGC, Hazira PMC : IOT D & E LSTK CONTRACTOR : SAVAIR ENERGY LIMITED 17 Balance Device Yes / No 19 DOC. NO. : REV. NO. : A PAGE NO. : 1 OF 2 REF. P & ID NO. : IOTDE-MM-04-032 REV.2 CW Required LPM / (Kg/cm2g) / oC */* /*

OWNER

LSTK

PMC

CENTRIFUGAL PUMP DATA SHEET

PROJECT : New Fire Water Network at ONGC, Hazira CLIENT : ONGC, Hazira PMC : IOT D & E LSTK CONTRACTOR : SAVAIR ENERGY LIMITED F 1 2 3 4 5 G 1 2 3 4 5 H 1 2 3 MATERIAL OF CONSTRUCTION Casing Impeller Inner Case Parts Sleeve Shaft Casing Ring DIESEL ENGINE (BY VENDOR) Manufacturer Model Diesel day Tank (L) with Magnetic Level Gauge Type Power (kW) WEIGHTS Weight of Pump (Kg) Weight of Baseplate (Kg) Weight of Controller (Kg) * * * 4 5 6 Weight of Engine (Kg) Weight of Diesel Day Tank (Kg) Total Weight (Kg) * * * * * * * * 6 7 8 9 10 Revs. (Rpm) No. of Strokes / Cycle No. of Cylinders Bearings Lube * * * * * CI Bronze * * * 6 7 8 9 Impeller Ring Shaft Throttle Bush Mounting Plate * * * * DOC. NO. : REV. NO. : A PAGE NO. : 1 OF 2 REF. P & ID NO. : IOTDE-MM-04-032 REV.2

NOTES: 1. * denotes data to be furnished / confirmed by pump vendor. 2.The Pump shall be supplied with Drive. 3.Discharge matching flanges along with Nuts Bolts Gaskets shall be provided along with Pumps. 4.Pumps shall be capable of furnishing not less than 150% of Rated capacity at a head of not less than 65% of rated head and shut off head shall not exceed 120% of rated head for horizontal centrifugal. 5. Pumps shall be approved by TAC acrediated agency not involved as owner, vendor, contractor, consultant etc.

A

Rev. No.

19/11/2012 Date

ISSUED FOR REVIEW Purpose

AC Prepared By

RP Reviewed By

MD Approved By

OWNER

LSTK

PMC

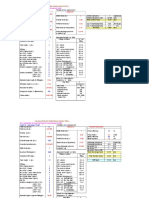

DIESEL ENGINE DRIVER DATA SHEET

PROJECT : New Fire Water Network at ONGC, Hazira CLIENT : ONGC, Hazira PMC : IOT D & E LSTK CONTRACTOR : SAVAIR ENERGY LIMITED A 1 2 3 4 5 6 B 1 a i ii 2 a 3 a C 1 2 D 1 2 3 4 5 6 7 E 1 2 3 4 5 6 F 1 2 3 4 5 6 SITE CONDITION Barometric pressure(mbar)A Mean sea level (m) Ambient Temp ( C) Ambient At Temp around the engine ( C) Water vapour pressure @ ambient Temp. (kg.cm2)A Wet Bulb Temp (C) UTILITY Cooling Water Cooling Water Temp (C) : Supply (Max/Nor/Min.) Return (MAX) Electric Power Electric Supply (Volts/HZ) Fuel Oil Type of Fuel oil APPLICABLE CODES & STANDERDS Noise level (Max) Approval of Engine Required from DRIVEN EQUIPMENT Driven Equipment Type Drive Probable period For Continuous Running Duration of Max Load Duration of Min Load Pump Direct Coupled * * * 8 9 10 11 12 Type Duty Type Startup Minimum BKW of the driven Eqpt KW @ RPM Rated BKW of the driven Eqpt KW @ RPM Maximum BKW of the driven Eqpt KW @ RPM Emergency Automatic */* */* */* * TAC 3 4 Acoustics Housing Standard for Shell & Tube Heat exchanger Yes / No Manfg. Std. * b Lower Calorific Value(KJ/Kg) * 415-440 V / 50 Hz b Avail during (Starting/Operation/Engine not operating) / / / * * b i ii Cooling water Pressure (Kg/cm2g) : Supply (Max/Nor/Min.) Return(MAX) * *

o o

DOC. NO. : REV. NO. : A PAGE NO. : 2 OF 2 REF. P & ID NO. : IOTDE-MM-04-002 REV.2

10 11 Max. 50 Min. 02 12 13 13a

Dry bulb Temp. (C) Location Under roof Electrical Area Classification Class Non Hazardous Indoor

13b Group / Division

Direction of Rotation of driven equipment CW CCW viewed from coupling end For Mech. Drive Application : Minimum site rating of the engine required Kw @ RPM (with 10 % overload provision for one Hour with in a period of 12 hours of Operatio)

kW: _*____ @RPM: ___*___

CONSTRUCTION FEATURES Manufacturer Mounting Engine Cooling (Air / Water Cooled) Type of Engine (2 Stroke / 4 Stroke) No. Of Cylinders Cylinder Arrangement PERFORMANCE Rated Engine Power at Standard Operating condition as per ISO 3046/BS5514(ISO Std. Power): kW: __*__ @ RPM: _*___ * * * * * * 7 8 9 10 11 Engine Model Compression Ratio Bore/Stroke (mm/mm) Speed (RPM) Mean Piston speed (m/sec) * * * * *

(Using only Essential dependent auxiliaries and with 10% Overload provision for one Hour with in a period of 12 Hours of operation.) Rate Engine power at site conditions (service std. power) Guaranteed, No Negative Tolerance): Min. Engine site power at which Engine can be Operated Continuously. Min. Engine speed & corresponding site power at which Engine can be Operated Continuously. Starting time required for full load operation (seconds) kW: ___*__ @ RPM: __*__ kW: __*___ @ RPM: _*__ RPM: ___*__ @ kW: __*___ *

OWNER

LSTK

PMC

DIESEL ENGINE DRIVER DATA SHEET

PROJECT : New Fire Water Network at ONGC, Hazira CLIENT : ONGC, Hazira PMC : IOT D & E LSTK CONTRACTOR : SAVAIR ENERGY LIMITED 7 Specific Fuel Consumption Fuel consumption, gm/kW-hr @ reference condition* ISO 3046 a b c d 8 a b c d G 1 2 3 H 1 2 3 Guaranteed Engine Rated Power(100% continuous Rating) 75% of (a) 50% of (a) 110% of (a) * Standard Reference condition: Total Barometric pressure pr1, kg/cm2A Relative humidity r1% Atmospheric Temp t r1, C Charge Air coolant Temp. t cr1 C SPEED GOVERNING SYSTEM Type Class of accuracy (A0/A1/A2/B1/B2) Governor control Mechanism STARTING SYSTEM Method of starting Method of stopping Startup Time (sec) Battery Starting System a b c h i j Battery Bank Number AH Capacity Regulator and cut-out * * n e f g Voltage Make Dynamo (Make /Rating) * * * n n n * * * 4 5 Type of cold starting Aid Type of Starting System * Battery Starting * * * 4 5 6 Governor Type Governor Make Governor Model * * * 100 Kpa 30 25 (298 oK) 25 (298 oK) Mnfg's Std Site Mnfg's Shop DOC. NO. : REV. NO. : A PAGE NO. : 2 OF 2 REF. P & ID NO. : IOTDE-MM-04-002 REV.2

Battery Charging equipment including transformer, static Rectifier, D.C. Ammeter, D.C. Voltmeter, Charge Rate selector Switch and charging meter. Inter connected cable leads between battery charger & battery Interconnecting cable leads between battery & engine starters. Note: Each Battery bank shall be sized to provide minimum __ consecutive starts.

I a b c d i j J 1 2

COOLING SYSTEM Type of cooling Heat exchanger with Anchor / Foundation Bolts By pass valve Heat exchanger Temp. C (Primary circuit) : Inlet /outlet * n n * e f g h Water pump driven by : Driver rating/speed (kW / Rpm) Check valve Heat exchanger Temp. C (Secondary circuit ): Inlet /outlet * * n *

Primary (soft) circuit piping with Temp. Control and Make Tank Secondary (FW from pumps discharge) circuit piping with FRAME LUBRICATION SYSTEM Type of Lubrication (Splash / Force Feed) Oil cooler Type * * 6 7 Oil Filters (Self cleaning/Duplex/Paper cartridge) Pre-Lube Oil pump driven By * * n strainer; n PR regulating valve

OWNER

LSTK

PMC

DIESEL ENGINE DRIVER DATA SHEET

PROJECT : New Fire Water Network at ONGC, Hazira CLIENT : ONGC, Hazira PMC : IOT D & E LSTK CONTRACTOR : SAVAIR ENERGY LIMITED 3 4 5 K 1 2 3 4 5 6 7 L 1 2 3 M 1 2 3 N 1 a b 2 a b c d e Type / Grade of Lube oil : Pre-Lubrication (Manual / Automatic at intervals of ------hours) Oil cooler testing pressure(kg/cm2g) FUEL SYSTEM TYPE (Gravity Feed system/Fuel Lift Pump) Fuel Injection Pump (Make/Model) Capacity of Daily Service Tank (liters) (for 6 hrs continuous operation@ full load/ for 24 hrs@full load.) Fuel Float Tank Motor Driven fuel transfer pump Over flow pipe Shielded Level gauge for Fuel tank AIR INLET SYSTEM Suction Air Filter Expansion Bellows Air Inlet Ducting / Piping/ Manifolds ENGINE EXHAUST SYSTEM Exhaust manifolds/Ducting/ Piping terminated at safe height outside of the Engine room Expansion Below Exhaust silencer CONTROL AND INSTRUMENTATION Hazardous Area Classification : NEC: ____*___ ISO: ____*___ Electric Supply : Lamps : + ___*__ V; ___*____ AC/DC; ___*____ AC/DC; ___*____ AC/DC; ___*____ AC/DC; ___*____ AC/DC; _____*___ Phase; ____*____ HZ _____*___ Phase; ____*____ HZ _____*___ Phase; ____*____ HZ _____*___ Phase; ____*____ HZ _____*___ Phase; ____*____ HZ Class: ___*____ Zone: ___*_____ Div.: __*___ Group: ___*__ n n Residential Type 4 5 6 Exhaust Stack / Chimney Thermal Insulation for complete Exhaust Flame Arrestor n n n n n n 4 5 All Supports / Hangers Inlet Silencer n n * * * Ground Mounting With Base Plate n n n 8 9 10 11 12 13 14 Fuel filters (/Duplex/Paper cartridge) Fuel Tank Engine Mounting Vent connection for fuel tank with flame arrester Inspection and cleaning Hole for fuel tank (min 150mm) Drain Valve for Fuel tank Fill connection for Fuel tank Float valve in fill connection * * n * * * 8 9 10 DOC. NO. : REV. NO. : A PAGE NO. : 2 OF 2 REF. P & ID NO. : IOTDE-MM-04-002 REV.2 Oil Sump Capacity (Litres) Oil consumption (lph) Expansion Relief valve for crankcase * * *

n n n n

Gas Group: ____*____

Alarm Circuit : + ___*__ V; Trip Circuit : + ___*__ V;

Control Circuit : + ___*__ V; Solenoid Valves: + ___*__ V;

Notes : 01. Pre-alarms to preceed Trips. 02. Instruments to be connected to Junction boxes on skid and consoles 03. All Switching devices (hardware / software) for pre-alarms, trips, trip alarm and interlockingshall be vendor's scope O a b c d MATERIAL Charge Air Cooler Water Cooler Air Cooler Shell : ____*______ Shell : ____*______ Shell : ____*______ Fuel Tank : MS Tubes: ____*________ Tubes: ____*________ Tubes: ____*________

Air Reciever : ____*_______

OWNER

LSTK

PMC

DIESEL ENGINE DRIVER DATA SHEET

PROJECT : New Fire Water Network at ONGC, Hazira CLIENT : ONGC, Hazira PMC : IOT D & E LSTK CONTRACTOR : SAVAIR ENERGY LIMITED P 1 2 3 4 5 Q 1 2 3 4 5 6 7 MAINTENANCE DATA Expected period of Running between Top Overhauls (Hours) Expected period of Running between Main Overhauls (Hours) The Type and Grade of Lubricating Oil Recommended Lube Oil Consumption (Kg/hr) / (Litres/hr) Change of Lubrication Oil Filters (Hours) ACCESSORIES Flywheel with Barring Device Guards for Moving Parts Coupling for Engine - Alternator / Pump Common Base Plate for Engine - Alternator / Pump Foundation / Anchor Bolts Anti Vibration Pads First Fill of Lubrication Oil and Fuel. REMARKS 1 2 3 4 5 6 * denotes data to be furnished / confirmed by pump vendor. The Engine shall be suitable for starting the pump against open discharge valve conditions. The Engine shall be provided with an adjustable governor to control engine speed within 10% of its rated speed. The material of construction of water (FW) wetted parts of the heat exchanger in the secondary cooling water circuit shall suitable for specified water quality. The Engine shall be provided with safety against low lube oil pressure, high water temperature and over speed. Vendor has to comply with the latest norms issued vide notification by Ministry of Environment and Forest ( with all amendments ) on noise limit for D.G.Sets and emission norms for Diesel Engines for D.G.Sets. 19/11/2012 Date ISSUED FOR REVIEW Purpose AC Prepared By DN Reviewed By MD Approved By n n n n n n n * * * * * DOC. NO. : REV. NO. : A PAGE NO. : 2 OF 2 REF. P & ID NO. : IOTDE-MM-04-002 REV.2

A

Rev. No.

You might also like

- MPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013Document2 pagesMPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013zohaib_farooqNo ratings yet

- Technical Bid Evaluation Sheet For Fuel Gas ScrubberDocument3 pagesTechnical Bid Evaluation Sheet For Fuel Gas ScrubberSiva baalanNo ratings yet

- PUMP CALCULATION SHEETDocument4 pagesPUMP CALCULATION SHEETMuhammad BilalNo ratings yet

- Pipe Size For Cooling Water SystemDocument5 pagesPipe Size For Cooling Water Systemnagu108No ratings yet

- Kaybob Gas Plant Piping and Instrumentation DiagramDocument7 pagesKaybob Gas Plant Piping and Instrumentation DiagrampavanNo ratings yet

- Calculation Sheet For Pump Hydraulic (Fps Unit)Document1 pageCalculation Sheet For Pump Hydraulic (Fps Unit)chemical todiNo ratings yet

- TEC NPSH Calculation PUMP SelectionDocument1 pageTEC NPSH Calculation PUMP SelectionphibetNo ratings yet

- N2 Purging Demand Calculation Shutdown - Flare SystemDocument54 pagesN2 Purging Demand Calculation Shutdown - Flare SystemMoch FaridNo ratings yet

- Rho v2Document1 pageRho v2Myung Ho SynNo ratings yet

- Hydraulic Caluculation ReportDocument16 pagesHydraulic Caluculation ReportbecpavanNo ratings yet

- LP Gas Amine Contactor Process DataDocument6 pagesLP Gas Amine Contactor Process DataEddy RainNo ratings yet

- Line Sizing For Liquid, (DO IT OWN)Document11 pagesLine Sizing For Liquid, (DO IT OWN)sumitNo ratings yet

- Condensate Line SizingDocument2 pagesCondensate Line SizingAnonymous oVRvsdWzfBNo ratings yet

- Centrifugal Pump Calculation Summary Sheet: ConfidentialDocument3 pagesCentrifugal Pump Calculation Summary Sheet: ConfidentialPrafitri KurniawanNo ratings yet

- Claus Process CalculationDocument105 pagesClaus Process CalculationDaniel SetyadiNo ratings yet

- Air Consumption Rev 1Document1 pageAir Consumption Rev 1Cahyadi YadiNo ratings yet

- Sphere Design and Thickness Calculation (Div 2)Document6 pagesSphere Design and Thickness Calculation (Div 2)Asad KhanNo ratings yet

- Gas Properties, Flowrate and Conditions: Reciprocating Compressor Calculation SheetDocument5 pagesGas Properties, Flowrate and Conditions: Reciprocating Compressor Calculation SheetNaqqash Sajid0% (2)

- Filter Vessel Shell VelocityDocument12 pagesFilter Vessel Shell VelocityAye KyweNo ratings yet

- Air Cooler-Example 8-2Document3 pagesAir Cooler-Example 8-2citramuaraNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument21 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- Valve Sizing Calculation8Document2 pagesValve Sizing Calculation8PIDNo ratings yet

- Mechanical Data Sheet - Air Filter (031-GN-002AB)Document5 pagesMechanical Data Sheet - Air Filter (031-GN-002AB)Gaurav PandeyNo ratings yet

- Design Conditions Datasheet: Unit Tag Qty Model No Net Cooling Capacity (Ton.r) Nominal Voltage Refrigerant TypeDocument2 pagesDesign Conditions Datasheet: Unit Tag Qty Model No Net Cooling Capacity (Ton.r) Nominal Voltage Refrigerant TypeFernando CabreraNo ratings yet

- Phase1 Hassi Bir Rekaiz Field DevelopmentDocument4 pagesPhase1 Hassi Bir Rekaiz Field Developmentahmed.njahNo ratings yet

- Flame ArresterDocument2 pagesFlame ArresterAariz KhanNo ratings yet

- NSPHa CalculationDocument3 pagesNSPHa CalculationYakubuNo ratings yet

- vs1 DatasheetDocument22 pagesvs1 DatasheetMojtabaNo ratings yet

- Fluid Handling Engineers: U S Agency - Taco DivDocument5 pagesFluid Handling Engineers: U S Agency - Taco DivsitehabNo ratings yet

- 20120507091359 (1)Document6 pages20120507091359 (1)Noman Abu-FarhaNo ratings yet

- Skid Weight Calculation HHI-RAR-SD-SCAL-004. REV.CDocument8 pagesSkid Weight Calculation HHI-RAR-SD-SCAL-004. REV.CAgus MarpaungNo ratings yet

- Process Flow DiagramDocument29 pagesProcess Flow DiagramrohitkushNo ratings yet

- Orifice Plate DatasheetDocument29 pagesOrifice Plate DatasheetshayabajNo ratings yet

- Pipe Sizing Calculation DumaiDocument39 pagesPipe Sizing Calculation DumaiKemas Muhandis M.100% (3)

- Datasheet For Vent ScrubberDocument5 pagesDatasheet For Vent ScrubbercliffrajjoelNo ratings yet

- TDS For Basket StrainerDocument2 pagesTDS For Basket StrainerRAGHVENDRA PRATAP SINGHNo ratings yet

- Fire Jockey Pump. Rev B1Document3 pagesFire Jockey Pump. Rev B1Pump SpesialistNo ratings yet

- Pump (English) TemplateDocument1 pagePump (English) TemplateMichael HaiseNo ratings yet

- SME Air Calculation and Makeup Air Analysis by ZoneDocument33 pagesSME Air Calculation and Makeup Air Analysis by ZoneAshiq NishmaNo ratings yet

- Pressure Drop Calc - STDDocument25 pagesPressure Drop Calc - STDhardik5818No ratings yet

- Mucog 1910502 Mec DS 055Document12 pagesMucog 1910502 Mec DS 055vinodNo ratings yet

- API 610 DatasheetDocument7 pagesAPI 610 DatasheetagusnnnNo ratings yet

- Pump Sizing SpreadsheetDocument2 pagesPump Sizing Spreadsheetandrew rachmanNo ratings yet

- Prepd. by - Dhananjay Thorat Blue: Ref.-Introduction To Chemical Engg. by Ghosal, Sanyal & DattaDocument2 pagesPrepd. by - Dhananjay Thorat Blue: Ref.-Introduction To Chemical Engg. by Ghosal, Sanyal & DattaJojolasNo ratings yet

- Docl Dep Pro CalDocument23 pagesDocl Dep Pro CalIBIKUNLE100% (1)

- Filter Separator Revised Feb 19 2004Document1 pageFilter Separator Revised Feb 19 2004motalebyNo ratings yet

- Sizing Calculation of General Service PumpsDocument193 pagesSizing Calculation of General Service Pumpsmkha87No ratings yet

- Wastewater Treatment Plant Design PDFDocument68 pagesWastewater Treatment Plant Design PDFmostafa1alaahobaNo ratings yet

- Trunnion CalculationDocument92 pagesTrunnion CalculationkarunaNo ratings yet

- RFQ Miscellaneous PumpDocument6 pagesRFQ Miscellaneous PumpGunturMudaAliAkbarNo ratings yet

- Thumb Rules Xls For Chemical EngineerDocument44 pagesThumb Rules Xls For Chemical EngineershashibagewadiNo ratings yet

- Mott-Brown K ValuesDocument13 pagesMott-Brown K Valueslutfi awnNo ratings yet

- Plate Heat ExchangersDocument4 pagesPlate Heat Exchangersamini_mohiNo ratings yet

- Gas Pipe SizingDocument10 pagesGas Pipe SizingSanthosh Kumar100% (1)

- Expansion Tank SizingDocument1 pageExpansion Tank Sizinghaysam0% (2)

- Datasheet For Nitrogen Bottle Rack 4B.4300 SAI S0003 ISGP U48000 MS 2105...Document10 pagesDatasheet For Nitrogen Bottle Rack 4B.4300 SAI S0003 ISGP U48000 MS 2105...vydaniNo ratings yet

- PSV Sizing Report (Fire Case)Document7 pagesPSV Sizing Report (Fire Case)Elias EliasNo ratings yet

- 2009 02 M HD 319 0Document5 pages2009 02 M HD 319 0ZoebairNo ratings yet

- W13018-YT01-GDF-457110 Rev 5-APVDocument8 pagesW13018-YT01-GDF-457110 Rev 5-APVJosé santanaNo ratings yet

- Data Sheet: LPG Filling Pump P-001/002/003/004/005/006Document5 pagesData Sheet: LPG Filling Pump P-001/002/003/004/005/006Denstar Ricardo Silalahi100% (1)

- 09 Job Procedure For Fire ProofingDocument4 pages09 Job Procedure For Fire ProofingAlvin Smith100% (2)

- WRC Check List CriteriaDocument1 pageWRC Check List CriteriaAlvin Smith100% (1)

- Wall Thickness Calculation of Offshore PipelinesDocument1 pageWall Thickness Calculation of Offshore PipelinesAlvin SmithNo ratings yet

- Wall Thickness Calculation of Offshore PipelinesDocument1 pageWall Thickness Calculation of Offshore PipelinesAlvin SmithNo ratings yet

- Comments On GAD Ball ValveDocument2 pagesComments On GAD Ball ValveAlvin SmithNo ratings yet

- Anchor Bolt Design GuideDocument55 pagesAnchor Bolt Design GuideAlvin SmithNo ratings yet

- Carbon Equivalent of RGPPL PipesDocument1 pageCarbon Equivalent of RGPPL PipesAlvin SmithNo ratings yet

- Strain Induced Due To Seismic Wave PropagationDocument4 pagesStrain Induced Due To Seismic Wave PropagationAlvin SmithNo ratings yet

- Specification For Painting-Piping & EquipmentDocument21 pagesSpecification For Painting-Piping & EquipmentAlvin Smith100% (2)

- Datasheet of Deluge ValveDocument2 pagesDatasheet of Deluge ValveAlvin SmithNo ratings yet

- Comments On GAD Ball ValveDocument2 pagesComments On GAD Ball ValveAlvin SmithNo ratings yet

- Piping Needlist PMDDocument6 pagesPiping Needlist PMDAlvin SmithNo ratings yet

- Pressure Instruments: Engineers India LimitedDocument2 pagesPressure Instruments: Engineers India LimitedAlvin SmithNo ratings yet

- New Piping Flexibility Rules in ASME B31.3 AppendixP - Becht & Diehl - ASME - 2006Document5 pagesNew Piping Flexibility Rules in ASME B31.3 AppendixP - Becht & Diehl - ASME - 2006Alvin SmithNo ratings yet

- Anurudh - Hazira FWNDocument2 pagesAnurudh - Hazira FWNAlvin SmithNo ratings yet

- ESREDA WG - Example Conceptual Firefighting DocumentDocument15 pagesESREDA WG - Example Conceptual Firefighting DocumentAlvin SmithNo ratings yet

- Jsa For Piping and Erection RevisedDocument1 pageJsa For Piping and Erection RevisedAlvin Smith77% (26)

- Painting SpecDocument54 pagesPainting Specashim_scribd100% (4)

- Orifice Sizing CalculationDocument24 pagesOrifice Sizing Calculationjamestpp67% (3)

- 3-1643-0408 - Rev - 1 Support Legend IBRDocument1 page3-1643-0408 - Rev - 1 Support Legend IBRAlvin SmithNo ratings yet

- ISOMETRIC LINE INDEXDocument1 pageISOMETRIC LINE INDEXAlvin SmithNo ratings yet

- Pump Power and CurrentDocument2 pagesPump Power and CurrentAlvin SmithNo ratings yet

- 3-1643-0717A - Rev - 1 Spring Support TypeDocument1 page3-1643-0717A - Rev - 1 Spring Support TypeAlvin SmithNo ratings yet

- 3-1643-0402 - Rev - 2 Index of IBR DocumentsDocument1 page3-1643-0402 - Rev - 2 Index of IBR DocumentsAlvin SmithNo ratings yet

- Engineers India Limited: Specification REV Plant: 003 Ongc, MehsanaDocument1 pageEngineers India Limited: Specification REV Plant: 003 Ongc, MehsanaAlvin SmithNo ratings yet

- TGDocument2 pagesTGAlvin SmithNo ratings yet

- 3-1643-0706 Rev 1 Nozzle LoadingDocument1 page3-1643-0706 Rev 1 Nozzle LoadingAlvin SmithNo ratings yet

- Solenoid ValveDocument1 pageSolenoid ValveAlvin SmithNo ratings yet

- Tutorial of WRC 107 For TrunnionDocument9 pagesTutorial of WRC 107 For TrunnionAlvin SmithNo ratings yet

- Perry S Chemical Engineers HandbookDocument1 pagePerry S Chemical Engineers HandbookdatinjacabNo ratings yet

- (I Part) Proceeding of International Conference On Manufacturing Excellence MANFEX 2012Document228 pages(I Part) Proceeding of International Conference On Manufacturing Excellence MANFEX 2012mklohumi1100% (3)

- Sulfinert Treated Sample CylinderDocument4 pagesSulfinert Treated Sample Cylindervipequi50No ratings yet

- 1014 BKTNG ME SP 0017 - Rev0 Specification For EDG PackageDocument1 page1014 BKTNG ME SP 0017 - Rev0 Specification For EDG Packagesondk2No ratings yet

- Book - 2 - Energy Efficiency in Thermal UtilitiesDocument274 pagesBook - 2 - Energy Efficiency in Thermal Utilitiesarkadjyothiprakash67% (9)

- Lecture Filtration 1Document20 pagesLecture Filtration 1LeeGonzaLgo0% (2)

- SG Cryogenic TestingDocument8 pagesSG Cryogenic TestingshahganNo ratings yet

- STIHL HS 45t ManualDocument72 pagesSTIHL HS 45t ManualDamian FulgoniNo ratings yet

- Carburetion Julus VodounnouDocument11 pagesCarburetion Julus VodounnouVodounnouNo ratings yet

- Is.437.1979 SIZE ANALYSIS of Coal and Coke For MarketingDocument16 pagesIs.437.1979 SIZE ANALYSIS of Coal and Coke For Marketingak_thimiriNo ratings yet

- Famous inventions and inventorsDocument3 pagesFamous inventions and inventorsSekolah Kebangsaan Lubuk SirehNo ratings yet

- Motor Caterpillar 3044ctDocument2 pagesMotor Caterpillar 3044ctOscar Pardo Pardo67% (3)

- ROCD5D7Document4 pagesROCD5D7EVCYNo ratings yet

- SnubbingDocument40 pagesSnubbingFranky Alexander Siregar100% (2)

- Commercial Vehicle Transmission Lubricant GuideDocument14 pagesCommercial Vehicle Transmission Lubricant GuideJason KozminskaNo ratings yet

- Bankim Ghosh CVDocument7 pagesBankim Ghosh CVBankim GhoshNo ratings yet

- Camless Engine PDFDocument2 pagesCamless Engine PDFAnusha YadavNo ratings yet

- TJC Chemistry H2 Y1 2009Document21 pagesTJC Chemistry H2 Y1 2009OccamsRazor100% (1)

- MISSION OS Broch Steam BoilerDocument4 pagesMISSION OS Broch Steam Boilerdomagoj17No ratings yet

- @perkins: 3000 Series 3012TAG3ADocument2 pages@perkins: 3000 Series 3012TAG3AHuseyin Taskin100% (4)

- Allocation MeasurementDocument17 pagesAllocation MeasurementdevsysNo ratings yet

- Operating Instructions Hydraulic Hammers HM 350 Eco V and HM 580 Eco (V)Document44 pagesOperating Instructions Hydraulic Hammers HM 350 Eco V and HM 580 Eco (V)Eng-Mohammed SalemNo ratings yet

- TRAIN THE TRAINER COURSE ENERGY EFFICIENT SHIP OPERATIONDocument5 pagesTRAIN THE TRAINER COURSE ENERGY EFFICIENT SHIP OPERATIONOdumoduChigozieUzomaNo ratings yet

- 1000 HP mechanical drilling rig specificationsDocument3 pages1000 HP mechanical drilling rig specificationsdvdv vdvdzvNo ratings yet

- Oil and Gas Directory 2009Document684 pagesOil and Gas Directory 2009Erik Hoover33% (3)

- Design Practice For Piping Arangement (Pipe Rack)Document53 pagesDesign Practice For Piping Arangement (Pipe Rack)Chairul Anwar100% (2)

- Instruction Manual For MIKUNI VM26 Carburetor Kit: Please Read The Following Instructions Carefully Before InstallationDocument4 pagesInstruction Manual For MIKUNI VM26 Carburetor Kit: Please Read The Following Instructions Carefully Before InstallationandreNo ratings yet

- Transportation Cost and Benefit Analysis II - Literature ReviewDocument26 pagesTransportation Cost and Benefit Analysis II - Literature ReviewJeyamony ANo ratings yet

- Why Cable PercussionDocument2 pagesWhy Cable PercussionShaiyid DoorsonNo ratings yet

- Sites Default Files Technip Publications Attachments Skandi Achiever WEBDocument4 pagesSites Default Files Technip Publications Attachments Skandi Achiever WEBimperitusNo ratings yet

- 1 Mbe4000 06aDocument38 pages1 Mbe4000 06azahar222No ratings yet