Professional Documents

Culture Documents

New Gen Trunnion Soft Seat Ball Valve

Uploaded by

dirtylsuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

New Gen Trunnion Soft Seat Ball Valve

Uploaded by

dirtylsuCopyright:

Available Formats

New Generation

2 1

trunnion mounted soft seated compact ball valve features (4 through 12)

(ASME 1500, ASME 2500, API 10k)

3 4

6

1 2 3 4 5 6 Spring loaded seats for superb low pressure sealing.

Stem seal seals to body and stem to reduce external seals. Stem retained by body not a bolted bonnet. Retainers threaded to body using stub Acme thread. Makes valve pressure containing without ange installed. Large ange gap allows for 3 part paint system installation to prevent corrosion. Trunnion mounted ball for low torque operation.

Safety Retainer threaded to the body using a Stub Acme thread for durability and strength. This makes the valve fully pressure containing with either end connection removed. Retainers are Xylan coated for corrosion protection and ease of maintenance. Stem is retained by a shoulder in the body, not the bonnet, making the stem fully blow-out proof. New Generation Trunnion Mounted Compact Ball Valves have dedicated, built-in automation mounting locations in the valve bonnet to allow eld installation of automation without loosening any pressure containing fasteners. Many conventional compact valves require removal and reinstallation of bonnet fasteners in order to install actuator mounting hardware. New Generation Trunnion Mounted Compact Ball Valves have double block and bleed capability as standard. Each valve body is tted with a stainless body bleed tting allowing easy bleeding of the body cavity when desired. Compliance New Generation compact ball valves are designed in accordance with API 6A. New Generation compact ball valves are fully compliant with the latest revision of NACE MR0175-2003 which severely limited the use of 17-4 stainless steels for valve stems and eliminated its use for pressure containing components such as bodies, bonnets, and retainers. New Generation compact ball valves incorporate a new zero line spread end connection that is fully compliant with ASME B 31.3 Chapter 9 and ASME B 31.8 New Generation trunnion mounted ball valves have been re tested to API 6FA, API 607, and BS 6755 Part 2. Robust Performance Stronger weldneck end connections allow bending loads up to 50% of pipe yield at full working pressure and up to 100% of pipe yield at no pressure assuming a pipe yield strength of 36,000 psi. Large 1/4 inch gap between the ange face and the body allows improved corrosion protection, eliminating the need for corrosion gaskets. This allows the use of three part paint systems between the ange and valve, and aides in removing the valve from line for maintenance. Incorporates the same bolt pattern on both ends of the valve eliminating assembly issues found in many conventional compact valve designs. Swivel ange fasteners are a different length than weldneck fasteners. Handle incorporates wrench ats to allow the valve to be operated without the extension handle and an integral stop plate that is complete with provisions for installing an FMC Technologies locking device. Automation Interface: stem is round with keyways to simplify adaptation between the actuator and the stem. Stem designed to shear outside of pressure boundary in the event of overload torque. The bonnet is keyed to the body to eliminate rotation when the valve is tted with an actuator. 316 stainless steel nameplates are permanently installed using stainless steel screws. Stem Seal: seals to the body and the stem eliminating the need for a bonnet to body seal - fewer leak paths than conventional compact valves. Trunnion mounted ball reduces actuation torque by as much as 50% compared to conventional compact oating ball valves. Trunnion bearings are self lubricating to ensure long life and low valve torque. Seat assembly incorporates one piece wave springs for ease of maintenance and reliability. Standard PEEK seat insert offers superior chemical and temperature compatibility over other soft seat materials. Valve bore sizes chosen to closely match the most popular pipe bores to minimize ow turbulence in the valve bore.

Trunnion Soft-Seated Ball Valve

A. B. C. C. D. E. F. G. G.

4 through 12

Bore Valve Group Length Overall Length (WNF x WNF) Overall Length (SWF x WNF) B Meter Handle Height Bonnet Height Weldneck Length Nipple Length

4 Through 12 Dimensions (English)

Ball Valve Model Number Nominal Working Weight Bore Pipe Pressure (lbs) (inch) Size (psi) A 3.44 3.83 3.15 3.63 3.06 4.06 4.06 5.19 4.90 4.06 5.13 7.09 7.09 6.09 7.09 9.09 8.50 9.09 7.63 10.75 10.13 10.75 11.40 Valve Group Length B 8.25 9.25 8.88 9.75 10.50 9.00 11.00 11.00 13.00 13.50 16.00 14.25 16.75 19.00 22.25 17.00 20.75 21.25 24.25 20.00 23.00 24.00 21.25 Overall Length

(WNF x WNF)

Overall Length

(SWF x WNF)

Body Outer Diameter D 9.25 10.25 9.50 10.63 10.88 10.63 11.88 12.88 14.63 13.88 16.88 16.13 17.88 20.13 22.75 19.88 21.38 22.63 24.63 23.25 25.13 26.25 24.75

Stem Height

Bonnet Height

Weldneck Nipple Length Length

2B-F0344 2B-F0383 2B-G0315 2B-G0363 2B-K0306 2B-F0406 2B-G0406 2B-F0519 2B-G0490 2B-K0406 2B-K0513 2B-F0709 2B-G0709 2B-K0609 2B-K0709 2B-F0909 2B-G0850 2B-G0909 2B-K0763 2B-F1075 2B-G1013 2B-G1075 2B-F1140

4 4 4 4 4 5 5 6 6 6 6 8 8 8 8 10 10 10 10 12 12 12 12

3750 3750 6250 6250 10000 3750 6250 3750 6250 10000 10000 3750 6250 10000 10000 3750 6250 6250 10000 3750 6250 6250 3750

192 257 230 308 346 291 420 487 766 716 1227 937 1271 1848 2630 1673 2193 2485 3338 2536 3233 3828 3201

C 15.75 17.25 17.13 18.50 19.75 17.50 20.50 20.50 24.50 25.00 28.50 25.75 29.75 33.50 39.75 30.50 36.25 37.75 42.75 36.50 41.00 43.50 40.25

C 16.00 18.00 17.63 18.75 20.25 18.25 21.25 21.50 24.75 25.00 29.00 25.75 30.25 34.00 39.75 31.50 37.25 38.50 42.75 37.50 42.00 44.25 40.25

E 7.27 7.64 7.35 7.79 7.96 7.78 8.46 8.96 10.86 10.47 12.44 11.61 12.95 14.70 16.02 13.98 15.35 15.86 17.18 16.35 17.43 17.92 16.92

F 5.59 6.09 5.72 6.28 6.36 6.26 6.86 7.36 8.73 8.34 9.81 9.48 10.32 11.44 12.76 11.34 12.09 12.72 13.72 13.03 13.97 14.53 13.78

G 3.75 4.00 4.13 4.38 4.63 4.25 4.75 4.75 5.75 5.75 6.25 5.75 6.50 7.25 8.75 6.75 7.75 8.25 9.25 8.25 9.00 9.75 9.50

G 4.00 4.75 4.63 4.63 5.13 5.00 5.00 5.75 6.00 5.75 6.75 5.75 7.00 7.75 8.75 7.75 8.75 9.00 9.25 9.25 10.00 10.50 9.50

4 Through 12 Dimensions (Metric)

Model Number Nominal Working Weight Pipe Pressure (kg) Size (psi) Bore

(mm)

Valve Overall Overall Body Stem Length Length Length Outer Height (WNF x (SWF x (mm) Diameter

WNF) WNF)

Bonnet Weldneck Height Length

Nipple Length

(mm)

2B-F0344 2B-F0383 2B-G0315 2B-G0363 2B-K0306 2B-F0406 2B-G0406 2B-F0519 2B-G0490 2B-K0406 2B-K0513

4 4 4 4 4 5 5 6 6 6 6

3750 3750 6250 6250 10000 3750 6250 3750 6250 10000 10000

87.09 116.57 104.33 139.71 156.94 132.00 190.51 220.90 347.46 324.78 556.56

A 87 97 80 92 78 103 103 132 124. 103 130

B 203 235 225 248 267 229 279 279 330 343 406

C 400 438 435 470 502 445 521 521 622 635 724

C 406 457 448 476 514 464 540 546 629 635 737

D 235 260 241 270 276 270 302 327 371 352 429

E 185 194 187 198 202 198 215 228 276 266 316

F 142 155 125 160 162 159 174 187 222 212 249

G 95 102 105 111 117 108 121 121 146 146 159

G 102 121 118 118 130 127 127 146 152 146 171

21

4 Through 12 Dimensions (Metric) -- continued

Model Number Nominal Working Pipe Pressure Size (psi) Weight (kg) Bore

(mm)

Valve Length (mm) B 362 425 483 565 432 527 540 616 508 584 610 540

Overall Overall Length Length

(WNF x WNF) (SWF x WNF)

Body Stem Bonnet Weldneck Outer Height Height Length Diameter

(mm)

Nipple Length

2B-F0709 2B-G0709 2B-K0609 2B-K0709 2B-F0909 2B-G0850 2B-G0909 2B-K0763 2B-F1075 2B-G1013 2B-G1075 2B-F1140

8 8 8 8 10 10 10 10 12 12 12 12

3750 6250 10000 10000 3750 6250 6250 10000 3750 6250 6250 3750

425.02 576.52 838.25 1192.96 758.87 994.74 1127.19 1514.11 1150.32 1466.48 1736.37 1451.96

A 180 180 155 180 231 216 231 194 273 257 273 290

C 654 756 851 1010 775 921 959 1086 927 1041 1105 1022

C 654 768 864 1010 800 946 978 1086 953 1067 1124 1022

D 410 454 511 578 505 543 575 625 591 638 667 629

E 295 329 373 407 355 390 403 436 415 443 455 430

F 241 262 291 324 288 307 323 348 331 355 369 350

G 146 165 184 222 171 197 210 235 210 216 248 229

G 146 165 197 222 197 222 229 235 235 254 267 241

Trunnion Soft-Seated Ball Valve

4 through 5

A. B. C. C. D. E. F. G. G. Bore Valve Group Length Overall Length (WNF x WNF) Overall Length (SWF x WNF) Body Outer Diameter Handle Height Bonnet Height Weldneck Length Nipple Length

4 Through 5 with Handles Dimensions (English)

Ball Valve Model Number Nominal Working Weight Bore Pipe Pressure (lbs) (inch) Size (psi) A 3.44 3.83 3.15 3.63 3.06 4.06 4.06 5.19 Valve Group Length B 8.25 9.25 8.88 9.75 10.50 9.00 11.00 11.00 Overall Overall Length Length

(WNF x WNF) (SWF x WNF)

Body Outer Diameter D 9.25 10.25 9.50 10.63 10.88 10.63 11.88 12.88

Handle Height

Bonnet Weldneck Height Length

Nipple Length

2B-F0344 2B-F0383 2B-G0315 2B-G0363 2B-K0306 2B-F0406 2B-G0406 2B-F0519

4 4 4 4 4 5 5 6

3750 3750 6250 6250 10000 3750 6250 3750

192 257 230 308 346 291 420 487

C 15.75 17.25 17.13 18.50 19.75 17.50 20.50 20.50

C 16.00 18.00 17.63 18.75 20.25 18.25 21.25 21.50

E 8.15 8.56 8.27 8.71 8.79 8.69 9.29 9.79

F 5.59 6.09 5.72 6.28 6.36 6.26 6.86 7.36

G 3.75 4.00 4.13 4.38 4.63 4.25 4.75 4.75

G 3.75 4.50 4.38 4.38 4.63 5.00 5.00 5.75

Nipple and weldneck lengths are not necessarily the same. Valves are typically provided with weldneck anges at both ends. Nipples / swivel anges may be used at either end of the valve as an option (except as noted above.) Dimension F reects the standard bonnet provided. Bonnets for close coupling of actuation are available on request. When the close coupling bonnet is provided, dimension F increases 0.250 inches.

Trunnion Soft-Seated Ball Valve

4 through 5

A. B. C. C. D. E. F. G. G.

Bore Valve Group Length Overall Length (WNF x WNF) Overall Length (SWF x WNF) Body Outer Diameter Handle Height Bonnet Height Weldneck Length Nipple Length

4 Through 5 with Handles Dimensions (Metric)

Ball Valve Model Number Nominal Pipe Size Working Pressure (psi) Weight (KG) Bore

(mm)

Valve Group Length

(mm)

Overall Length

(WNF x WNF)

Overall Length

(SWF x WNF)

Body Handle Outer Height Diameter

(mm)

Bonnet Height

Weldneck Length

Nipple Length

2B-F0344 2B-F0383 2B-G0315 2B-G0363 2B-K0306 2B-F0406 2B-G0406 2B-F0519

4 4 4 4 4 5 5 6

3750 3750 6250 6250 10000 3750 6250 3750

87.09 116.57 104.33 139.71 156.94 132.00 190.51 220.90

A 87.33 97.18 80.01 92.08 77.80 103.20 103.20 131.78

B 210 235 225 248 267 229 279 279

C 400 438 435 470 502 445 521 521

C 406 457 448 476 514 464 540 546

D 235 260 241 270 276 270 302 327

E 207 217 210 221 223 221 236 249

F 142 155 145 160 162 159 174 187

G 95 102 105 111 117 108 121 121

G 95 114 111 111 117 127 127 146

Nipple and weldneck lengths are not necessarily the same. Valves are typically provided with weldneck anges at both ends. Nipples / swivel anges may be used at either end of the valve as an option (except as noted above.) Dimension F reects the standard bonnet provided. Bonnets for close coupling of actuation are available on request. When the close coupling bonnet is provided, dimension F increases 0.250 inches.

23

Trunnion Soft-Seated Ball Valve

Body, Bonnet, and Retainer Material Place 1 (Body components) - Standard = 1 1 4130 Body, Bonnet & Retainer 2 4130 Body, Bonnet & Retainer (Xylan Body & Bonnet) A Duplex Body, Bonnet & Retainer B Super Duplex Body, Bonnet & Retainer F 410 SS Body, Bonnet & Retainer N Inconel 625 Body, Bonnet & Retainer P Full Clad 625 Q 4130 / Inconel 625 Partial Clad Body, Bonnet & Retainer Ball Material and Coating Place 2 (Ball Material & Coating) - Standard = 3 or 6 3 4130 - .003 ENP Standard 6 17-4PH - .0004 Chrome 7 410 - .0004 Chrome D Duplex - .0004 Chrome H Super Duplex - .0004 Chrome N Inconel 718 - .0004 Chrome Stem Material and Coating Place 3 (Stem Material & Coating) - Standard = 1 D Duplex 1 4130 - QPQ H Super Duplex M Inconel 625 N Inconel 718 Carrier Material and Coating Place 4 (Carrier Material & Coating) - Standard = 1 or 6 1 4130 Alloy 6 17-4PH D Duplex H Super Duplex N Inconel 625 R 410 Stainless

trim codes

Carrier and Body Seal Material Place 5 (Carrier and Body Seal Material) - Standard = 1 or 5 1 Nitrile 5 Viton A A James Walker Elast-o-Lion 101 B James Walker Elast-o-Lion 985 H Greene Tweed 926 Stem Seal and Backup Material Place 6 (Stem Seal and Backup Material) - Standard = 1 or 2 1 Nitrile Jacket / Nitrile O-spring / PEEK Backup 2 Viton Jacket / Viton O-spring / PEEK Backup R Virgin Teon Jacket / Elgiloy Spring / PEEK Backup Seat Material Place 7 (Seat Material) - Standard = P P PEEK Actuation Style Place 8 (Operator and Locking Device) - Standard = 1 1 Handle or Lever 2 Handle or Lever with Locking Device 6 Bare Stem F Gear Operator with Hand wheel G Gear Operator with Hand wheel and Locking Device Service, Grease, and Bonnet Bolting Material Place 9 (Service, Grease, and Bonnet Bolting) - Standard = 1 1 Standard Grease, B7M / L7M Bonnet Bolting 3 Standard Grease, Grade 660 Bonnet Bolting A Low Temperature Grease, B7M / L7M Bonnet Bolting C Low Temperature Grease, Grade 660 Bonnet Bolting Y Oxygen / Air Service Grease, B7M / L7M Bonnet Bolting Z Oxygen / Air Grease, Grade 660 Bonnet Bolting

You might also like

- Triple-Offset Butterflyvalves PDFDocument8 pagesTriple-Offset Butterflyvalves PDFDiwakar NigamNo ratings yet

- Compact Valves 2016Document32 pagesCompact Valves 2016Tuan BuivietNo ratings yet

- Anti Blow Out StemDocument48 pagesAnti Blow Out StemimthiyazmuhammedNo ratings yet

- Sferova API6 Ball Valve CatalogueDocument27 pagesSferova API6 Ball Valve CatalogueWong JowoNo ratings yet

- Installation, Operation and Maintenance Manual For Model WG-HLA Hydraulic ActuatorDocument15 pagesInstallation, Operation and Maintenance Manual For Model WG-HLA Hydraulic ActuatorNeilton Junior100% (1)

- Double Piston EffectDocument1 pageDouble Piston EffectaiaudcoNo ratings yet

- Brochure For SAE J518 O-Ring Assortment KitsDocument1 pageBrochure For SAE J518 O-Ring Assortment KitsChristopher RuizNo ratings yet

- Importing Nozzle Loads From Autopipe Into Autopipe NozzleDocument3 pagesImporting Nozzle Loads From Autopipe Into Autopipe NozzlegchammaNo ratings yet

- BS en 12560-5 2001Document18 pagesBS en 12560-5 2001Marcelo Pires100% (1)

- Process & Piping Design Section Plug Valves Technical SpecificationDocument14 pagesProcess & Piping Design Section Plug Valves Technical Specificationashish.mathur1100% (1)

- Orbit Parts List and Ordering InstructionsDocument24 pagesOrbit Parts List and Ordering Instructionskeertiraj09No ratings yet

- Testing and Analysis of Pipeline Ball Valves Part 1 PDFDocument3 pagesTesting and Analysis of Pipeline Ball Valves Part 1 PDFNovianto Rachmad100% (1)

- Spiraltec Non-Metallic FillersDocument1 pageSpiraltec Non-Metallic FillersJakir HossainNo ratings yet

- Double Containment EDocument43 pagesDouble Containment EDavid FonsecaNo ratings yet

- Serck Arduco Plug ValvesDocument20 pagesSerck Arduco Plug ValvesRominaNo ratings yet

- Kirloskar Valves Technical Specification CatalogueDocument24 pagesKirloskar Valves Technical Specification CatalogueAbhinay SuratkarNo ratings yet

- BOLTING STRESS-bonnetDocument4 pagesBOLTING STRESS-bonnetAbdullah FahmiNo ratings yet

- Clamp Connections: Bearing Ring Load Ring Nut Washer DetailDocument2 pagesClamp Connections: Bearing Ring Load Ring Nut Washer DetailНикита ПромиснкийNo ratings yet

- OMB BALL ValveDocument44 pagesOMB BALL Valveale_f_79No ratings yet

- Trunnion Mounted Ball Valve Catalog from Walworth ValvesDocument84 pagesTrunnion Mounted Ball Valve Catalog from Walworth ValvesWilmer CelisNo ratings yet

- Oooom Om Om: International StandardDocument32 pagesOooom Om Om: International StandardNizarHamrouniNo ratings yet

- Bidirectional Sealing Ball Valves in Power ApplicationsDocument3 pagesBidirectional Sealing Ball Valves in Power Applicationsxisefengchuang100% (1)

- W-P-10-01 - Design Validation TestProcedure - BALL VALVE PR2 ANNEX FDocument6 pagesW-P-10-01 - Design Validation TestProcedure - BALL VALVE PR2 ANNEX FPalkesh TrivediNo ratings yet

- History, Advantages & Applications of Pressure Seals: What Are Pressure Seals, and How Do They Work?Document2 pagesHistory, Advantages & Applications of Pressure Seals: What Are Pressure Seals, and How Do They Work?JEGANATHANNo ratings yet

- L&T Double Block and Bleed Plug ValvesDocument12 pagesL&T Double Block and Bleed Plug Valvesvijay10484No ratings yet

- Pig Trap End Closure105671465 PDFDocument24 pagesPig Trap End Closure105671465 PDFashishNo ratings yet

- Unicom ValveDocument27 pagesUnicom ValveSandi AslanNo ratings yet

- Flanged Ball Trunnion ValvesDocument24 pagesFlanged Ball Trunnion ValvesMahdi DalyNo ratings yet

- Knife Gate Valve - AVKCMSDocument2 pagesKnife Gate Valve - AVKCMSjuantamad02No ratings yet

- Design and Analysis of Disc Plate in Hot Blast Valve #DN1800Document8 pagesDesign and Analysis of Disc Plate in Hot Blast Valve #DN1800MounicaRasagyaPallaNo ratings yet

- Expanding Gate 2016 2Document56 pagesExpanding Gate 2016 2ramyzottyNo ratings yet

- E91 202006 20orifice 20plate 20 - 20doschDocument6 pagesE91 202006 20orifice 20plate 20 - 20doschiaft100% (1)

- EN 12570 - Sizing Operating ElementDocument7 pagesEN 12570 - Sizing Operating Elementyashif aliNo ratings yet

- Hose&Braid Catalog FlexicraftDocument24 pagesHose&Braid Catalog Flexicraftkutts76No ratings yet

- Trunnion Mounted Ball ValveDocument20 pagesTrunnion Mounted Ball ValveJignesh PandyaNo ratings yet

- Globe Valve PresentationDocument11 pagesGlobe Valve Presentationmayur22785No ratings yet

- Dual-Plate Lug Check Valves - Face To Face Dimensions - API Standard 594Document2 pagesDual-Plate Lug Check Valves - Face To Face Dimensions - API Standard 594unknownNo ratings yet

- Nozzle Check ValvesDocument12 pagesNozzle Check Valvesjshadwan100% (1)

- FlowTek S20Document2 pagesFlowTek S20Gabriel Andrés Barcha AnguloNo ratings yet

- Charpy Impact Test - WikipediaDocument18 pagesCharpy Impact Test - WikipediaAshik Speed YuvanNo ratings yet

- FCA Nozzle Non-Slam Check Valve CatalogueDocument16 pagesFCA Nozzle Non-Slam Check Valve CataloguePatricio AcuñaNo ratings yet

- Product Brochure: Manufacturers and Stockists of High Pressure Pipeline and Drilling EquipmentDocument30 pagesProduct Brochure: Manufacturers and Stockists of High Pressure Pipeline and Drilling EquipmentSaravanan NatesanNo ratings yet

- Tech Manual 1222B: Booster Cylinder Assembly EH34-BC03Document21 pagesTech Manual 1222B: Booster Cylinder Assembly EH34-BC03jose perozoNo ratings yet

- Triple Eccentric Metal Seated ValvesDocument4 pagesTriple Eccentric Metal Seated ValvesFelipe Gamboa GálvezNo ratings yet

- ISO Metric Screw Thread StandardsDocument4 pagesISO Metric Screw Thread StandardsskluxNo ratings yet

- Astm F 541-04Document6 pagesAstm F 541-04Jorge ToribioNo ratings yet

- Taper Thread TorqueDocument1 pageTaper Thread TorqueRichardNo ratings yet

- Hydrogen Compressor Flange Bolts FailureDocument8 pagesHydrogen Compressor Flange Bolts FailurePablo ScottNo ratings yet

- Knife Gate Valve Testing ProceduresDocument2 pagesKnife Gate Valve Testing ProceduresmehtahemalNo ratings yet

- API Flange 6A VersionDocument1 pageAPI Flange 6A Versiongazwang478No ratings yet

- API 600 Overview - Steel Gate Valves - Flanged and Buttwelding Ends, Bolted BonnetsDocument2 pagesAPI 600 Overview - Steel Gate Valves - Flanged and Buttwelding Ends, Bolted BonnetsNilesh MistryNo ratings yet

- Lecture Note 4 (Metallic & Non-Metallic Pipes) PDFDocument20 pagesLecture Note 4 (Metallic & Non-Metallic Pipes) PDFhkaqlqNo ratings yet

- Ball Valve: Zhejiangbeiercontrol Valveco.,LtdDocument16 pagesBall Valve: Zhejiangbeiercontrol Valveco.,LtdSandipan GhoshNo ratings yet

- TICO Pipe SupportsDocument8 pagesTICO Pipe SupportsEjeantengNo ratings yet

- Pipes FittingsDocument37 pagesPipes Fittingsanand bandekarNo ratings yet

- James Walker o Ring Catalogue PDFDocument32 pagesJames Walker o Ring Catalogue PDFVinayNo ratings yet

- Valtek ValdiskDocument8 pagesValtek ValdiskGustavo Garcia100% (1)

- AVT Ball & Butterfly Brochure 05 Latest 12 PageDocument12 pagesAVT Ball & Butterfly Brochure 05 Latest 12 PageshalbyNo ratings yet

- Actuador PCVDocument12 pagesActuador PCVmggz_15No ratings yet

- Combustion Engines: An Introduction to Their Design, Performance, and SelectionFrom EverandCombustion Engines: An Introduction to Their Design, Performance, and SelectionNo ratings yet

- Bolting Information Pertaining To ASTM A193Document25 pagesBolting Information Pertaining To ASTM A193dirtylsu100% (2)

- Excel TipsDocument30 pagesExcel Tipshedda14No ratings yet

- API Flange 6A VersionDocument1 pageAPI Flange 6A Versiongazwang478No ratings yet

- Mechanical DraftingDocument166 pagesMechanical Draftingsunita_cc100% (3)

- Cajun RecipesDocument83 pagesCajun RecipesluliberinaNo ratings yet

- Oilfield flowchart troubleshooting guideDocument1 pageOilfield flowchart troubleshooting guidedirtylsu0% (1)

- Inch and Metric ConversionsDocument1 pageInch and Metric ConversionsdirtylsuNo ratings yet

- LA Deer Hunting Schedule 2011-12Document1 pageLA Deer Hunting Schedule 2011-12dirtylsuNo ratings yet

- Estimators General Construction Manhour ManualDocument143 pagesEstimators General Construction Manhour Manualdirtylsu100% (1)

- Welding Cost Estimator PubDocument8 pagesWelding Cost Estimator Pubrockufool100% (4)

- Template To PlateDocument4 pagesTemplate To PlatedirtylsuNo ratings yet

- Arc Gouging GuideDocument44 pagesArc Gouging Guidedirtylsu0% (1)

- Estimator Equipment Installation Manhour ManualDocument105 pagesEstimator Equipment Installation Manhour Manualdirtylsu100% (8)

- Survival - MCRP 3-02f FM 21-76Document571 pagesSurvival - MCRP 3-02f FM 21-76markdcoco690100% (4)

- PHE Manual 0109Document17 pagesPHE Manual 0109dirtylsuNo ratings yet

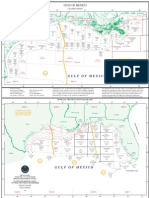

- Gulf Lease MapsDocument1 pageGulf Lease MapsdirtylsuNo ratings yet

- QUANTUM TELEPORTATIONDocument23 pagesQUANTUM TELEPORTATIONalkagabaNo ratings yet

- Reformasi Birokrasi Di AustraliaDocument54 pagesReformasi Birokrasi Di Australiazaky ahmadNo ratings yet

- LGBT Workplace Equality Policy and Customer Satisfaction: The Roles of Marketing Capability and Demand InstabilityDocument20 pagesLGBT Workplace Equality Policy and Customer Satisfaction: The Roles of Marketing Capability and Demand InstabilityFatima ZafarNo ratings yet

- Chowringhee - (Iisco House) Concept Encapsulation Session: The Oldest FIITJEE Centre in KolkataDocument12 pagesChowringhee - (Iisco House) Concept Encapsulation Session: The Oldest FIITJEE Centre in KolkataHemendra PrasannaNo ratings yet

- CED-2021 EnergyTransition ReportDocument75 pagesCED-2021 EnergyTransition ReportCityNewsTorontoNo ratings yet

- Types of EvidenceDocument13 pagesTypes of EvidenceSteven Jan Sab-itNo ratings yet

- Writing Theory DraftDocument18 pagesWriting Theory Draftapi-488391657No ratings yet

- SAP MM Purchase Info Record GuideDocument3 pagesSAP MM Purchase Info Record GuidevikneshNo ratings yet

- Fuzzy Logic Tutorial: What Is, Application & ExampleDocument7 pagesFuzzy Logic Tutorial: What Is, Application & ExampleDe' LufiasNo ratings yet

- Improved Sleep, Cognitive Processing and Enhanced Learning and Memory Task Accuracy With Yoga Nidra Practice in NovicesDocument19 pagesImproved Sleep, Cognitive Processing and Enhanced Learning and Memory Task Accuracy With Yoga Nidra Practice in Novicessankar ganeshNo ratings yet

- Standards List July2019Document8 pagesStandards List July2019Richard PNo ratings yet

- 4 Compass SurveyingDocument10 pages4 Compass SurveyingSuson DhitalNo ratings yet

- American Statistical AssociationDocument7 pagesAmerican Statistical Associationmantu6kumar-17No ratings yet

- Willie Soon, Peter Frick, and Sallie BaliunasDocument4 pagesWillie Soon, Peter Frick, and Sallie BaliunasMiguel CervantesNo ratings yet

- To Signals and SystemsDocument57 pagesTo Signals and SystemsMUHAMMAD HAFIZUDDINNo ratings yet

- DLL - Mathematics 5 - Q1 - W4Document9 pagesDLL - Mathematics 5 - Q1 - W4Avelino Coballes IVNo ratings yet

- 2d3d Opal Card Vending Machine ManualDocument40 pages2d3d Opal Card Vending Machine ManualbsimonopalNo ratings yet

- Brochure GM IM Roller Mill Antares MDDR MDDT en LowDocument8 pagesBrochure GM IM Roller Mill Antares MDDR MDDT en Lowahmed shomanNo ratings yet

- MFS 7104 Quantitative TechniquesDocument2 pagesMFS 7104 Quantitative TechniquesDavid KNo ratings yet

- Pulungmasle High School: Boy Scouts of The Philippines - Pulungmasle High School Chapter Work Plan For S.Y 2018-2019Document3 pagesPulungmasle High School: Boy Scouts of The Philippines - Pulungmasle High School Chapter Work Plan For S.Y 2018-2019Rd DavidNo ratings yet

- Bubble Sort: For (K 0 K X (K + 1) ) Swaparay (X, K, K + 1)Document7 pagesBubble Sort: For (K 0 K X (K + 1) ) Swaparay (X, K, K + 1)Vikas PuniaNo ratings yet

- Hydraulic Vs Mechanical+SnubbersDocument1 pageHydraulic Vs Mechanical+SnubbersJordana VeigaNo ratings yet

- ZEISS CALYPSO 2021 Flyer Action Software Options ENDocument2 pagesZEISS CALYPSO 2021 Flyer Action Software Options ENnaveensirNo ratings yet

- Final AnswersDocument4 pagesFinal AnswersAnshul SinghNo ratings yet

- 4MA1 1H Que 20210304Document28 pages4MA1 1H Que 20210304mo gaNo ratings yet

- BW1114-B2 Bendix Brake CatalogDocument116 pagesBW1114-B2 Bendix Brake Cataloggearhead1100% (1)

- MAG Infinite S 10SC-017XIBDocument3 pagesMAG Infinite S 10SC-017XIBPedro Garcia DiazNo ratings yet

- British Airways Case Study SolutionDocument2 pagesBritish Airways Case Study SolutionHassan ZafarNo ratings yet

- Đề Thi Thử Sở Bình PhướcDocument7 pagesĐề Thi Thử Sở Bình Phướcbinh caoNo ratings yet

- أسئلة شاملة 1Document25 pagesأسئلة شاملة 1ibraheemalabsi99No ratings yet