Professional Documents

Culture Documents

CSL 1034

Uploaded by

oscar horacio floresOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CSL 1034

Uploaded by

oscar horacio floresCopyright:

Available Formats

250-C20 CSL-1034

COMMERCIAL

Indianapolis.Indiana 46206

SERVICE

LETTER

Page 1 of 8 January 16, 1975 FAA-DER Approved

Oetmit Diesel Allison

Subject:

CEO0 Fuel Control Flushing Procedure to Remove Suspected Internal Contamination

Internal contamination in the fuel control can lead to an array of performance problems: hung starts, no start, erratic operation, uncontrollable acceleraAs a result, the unit is prematurely tion with no response to adjustment. removed and returned to the distributor for corrective action. In many cases, investigations of prematurely removed fuel controls revealed that contamination may have been sufficient to affect performance. After ques is to after from may reviewing the different operating environments and fuel handling techniemployed by 250 operators, the most practical approach to the problem flush the fuel control with clean, filtered calibrating fluid or engine fuel overhaul or removal from storage. In the event of premature removal the aircraft/engine for one of the aforementioned problems, operators elect to flush the unit or return it to the distributor for corrective action, therefore, is recommended at

The following flushing procedure, .

Operator maintenance facilities or distributor facilities on all model MC-40 Fuel Controls, P/L 104000, removed from service for suspected contamination or performance problems of hung starts, no start, erratic operation, uncontrollable acceleration or hot start with no response to adjustment. Distributor facilities on all controls processed for overhaul or after removal from storage. Purging should be completed prior to preset calibration. It is estimated that approximately required to flush one unit. 0.5 man-hour will be

MANPOWER: TOOLING:

A test/flushing stand or other fluid supply capable of delivering Calibrating Fluid, MIL-F-7024 Type Il, or engine fuel at 100 psig with a fuel delivery of 350 pounds per hour (phr). Filtration of 10 microns is required. Use holding fixture STD67180 (or equivalent) mounted to flushing stand or equivalent, and Speed Rotor Wrench, STD67229, or equivalent.

Rolls-Royce Proprietary Data Uncontrolled Printed Copy

250-C20 (XL-1034 Page 2

COMMERCIAL

ACCOMPLISHMENT A.

SERVICE

LETTER

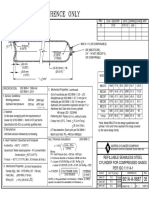

Refer to Figure 1 for port

INSTRUCTIONS:

Prepare the fuel control forflushing. identification.

1.

Mount control on STD67180 Holding Fixture (or equivalent) secured to flushing stand, plug or cap all open ports and thoroughly wash all external surfaces with calibrating fluid or engine fuel. Blow dry with filtered compressed air. Remove the following pressure FG, AF, BR, AR and Bypass. and SS restriction. NOTE: port plugs or fittings: Pl, BF, SS, Remove speed sense rotor group and

2.

Do not remove O-rings from port plugs, fittings, speed sense rotor group unless damaged.

3. 4.

Connect a line (as short as possible) between the Fuel-out to PTG and Fuel-in from PTG ports (see Figure 2). Connect the fluid supply line to the Fuel Control inlet port (see Figure 2). Put test stand spray shield in place if applicable. NOTE: Calibrating fluid or engine fuel that is flushed through the fuel control shall not be recirculated or reused for flushing unless it is filtered to 10 microns.

5.

On field returned units and units removed from storage, note the location of the clip or stop screw in the Start Derichment Adjustment and position of Light-Off Adjustment (see Figure 3). Temporarily mark the casting boss with the location of the clip or screw on the Derichment Adjustment. Also, put a temprorary scribe mark on the Light-Off Adjustment and Start Flow Adjustment. CAUTION

B.

Flush the fuel control as follows: BESURE THATTHEFUELOUTLETANDBYPASSAREOPEN. COVER THE FUEL CONTROL WITH A CLEAN PLASTIC BAG TO PROTECT AGAINST FLUID SPRAY. 1. Supply calibrating fluid or engine fuel to the fuel control inlet as required to obtain a steady flow from the open pressure ports (approximately 100 psig at a flow of 325 pounds per hour (phr).

Rolls-Royce Proprietary Data Uncontrolled Printed Copy

250-c20 CSL-1034 Page 3

COMMERCIAL

2.

SERVICE

LETTER

Allow each port to purge lo-20 seconds. Install one plug or fitting at a time in the following order, purging between installations., a. b. c. Install Pl pressure port plug. Install the SS Restriction and Rotor Group.

During flushing of the BR and AR ports cycle the start Derichment Adjustment back and forth through its limit of travel, as restricted by clip or stopscrew. Cycle the Light-Off Adjustment clockwise and counterclockwise approximately l/4 turn and cycle the Power Lever from Max. to 10 degrees. Install BR pressure port plug. NOTE: Return the Start Derichment Adjustment and LightOff Adjustment to the previously marked positions (refer to paragraph A. 5). Jnstall AR pressure Install BF pressure port plug. port plug.

d. e. f. g. h.

1.

Install SS pressure port plug. Install FG pressure port plug. Cycle PC pressure port plug. NOTE: ambient to 80 psia. and install AF pressure

Purge through Bypass port. Whenever possible, position the fuel control and holding fixture in such a way as to have purging fluid directed to test stand sink.

C.

Completion 1.

2.

Disconnect the Fuel Control Inlet Port from the flushing stand supply. Install aircraft/engine fittings. Torque all plugs and fittings to the required specification and lockwire as required.

Rolls-Royce Proprietary Data Uncontrolled Printed Copy

250-C20 CSL-1034 Page 4

COMMERCIAL

3.

SERVICE

LETTER

Remove the fuel control from the flushing stand. a. b. Maintenance units are ready for reinstallation. Overhaul units (1) If unit is in process of overhaul, Preset Calibration. the unit is now ready for recheck

(2) If overhaul has been completed, final calibration is suggested if practical.

L. 0. Davidson Service Manager Aircraft Engines MJK/bsc

Rolls-Royce Proprietary Data Uncontrolled Printed Copy

COMMERCIAL

SERVICE

LETTEgqe

250-C20 CSL-1034 5

FUEL

INLET

BY-PA: PORT Pi 3RT 10 IN.- -LB!

AR P t-6

(5-10

IN.-LB)

PORTLOCATIONS FrGuRE1 (SIIEET~

0~ 2)

Rolls-Royce Proprietary Data Uncontrolled Printed Copy

250-C20 CSL-1034 Page6 COMMERCIAL SERVICE LETTER

FUEL OUT TO POWER TURBINE GOVERNOR

LIGHT-OFF ADJUSTMENT /

P 15

FG PI3RT (5-10 IN.-L FUEL <FROM

IN

PTG

IENT IENT BR (5-

ROTOR GROlJ6 (20-30 AND SS RESTRICTION (20 IN.-LB MAX) (SEE FIGURE 2-2)

IN.-LB)

PORTLOCATIONS mx~m i (SHEET 2 0~ 2)

Rolls-Royce Proprietary Data Uncontrolled Printed Copy

250-C20 CSL-1034 Page7

COMMERCIAL

SERVICE

LETTER

FLUID SUPPLY LINE

PTG BY-PASS LINE

HOLDING FIXTURE STD67 180

SS RE5TRICTION

-SPEED

SENSE ROTORGROUP

FLUIDCONNECTIONS FIGURE 2

Rolls-Royce Proprietary Data Uncontrolled Printed Copy

250-C20 Page 8

CSL-1034

COMMERCIAL

SERVICE

LETTER

LIGHT-OFF ADJUSTMEN

CLIP

STOP SCREW

ADJUSTMENTS FIGURE 3

Rolls-Royce Proprietary Data Uncontrolled Printed Copy

You might also like

- QRH Rev 43DDocument294 pagesQRH Rev 43Doscar horacio floresNo ratings yet

- DR6000 MK2 Diversity Receiver Manual, Installation & OperationDocument39 pagesDR6000 MK2 Diversity Receiver Manual, Installation & Operationoscar horacio floresNo ratings yet

- Apu B 767Document103 pagesApu B 767gm&oNo ratings yet

- TM-9-2320-280-20-2 HMMWV Unit Maintnance Vol 2Document945 pagesTM-9-2320-280-20-2 HMMWV Unit Maintnance Vol 2AUGieDogie1100% (4)

- CEB1113Document1 pageCEB1113oscar horacio floresNo ratings yet

- TM 9 2320 280 10 Operators Manual HMMWVDocument407 pagesTM 9 2320 280 10 Operators Manual HMMWVAUGieDogie1100% (16)

- MCDP Remote Panel WireDocument6 pagesMCDP Remote Panel Wireoscar horacio floresNo ratings yet

- Introduction To Aircraft Performance, Selection and Design PDFDocument168 pagesIntroduction To Aircraft Performance, Selection and Design PDFAnres Anres DictadorNo ratings yet

- Sketch A320Document33 pagesSketch A320oscar horacio floresNo ratings yet

- TM-9-2320-280-20-3 HMMWV Unit Maintnance Vol 3Document1,151 pagesTM-9-2320-280-20-3 HMMWV Unit Maintnance Vol 3AUGieDogie1100% (5)

- Detroit Diesel AllisonDocument1 pageDetroit Diesel Allisonoscar horacio floresNo ratings yet

- CEB1112Document5 pagesCEB1112oscar horacio floresNo ratings yet

- TM-9-2320-280-20-1 HMMWV Unit Maintnance Vol 1Document883 pagesTM-9-2320-280-20-1 HMMWV Unit Maintnance Vol 1AUGieDogie1100% (6)

- CEB1115Document6 pagesCEB1115oscar horacio floresNo ratings yet

- LeitholdDocument1,383 pagesLeitholdsethokiba67% (3)

- CEB1110Document4 pagesCEB1110oscar horacio floresNo ratings yet

- CEB1108Document5 pagesCEB1108oscar horacio floresNo ratings yet

- CEB1111Document5 pagesCEB1111oscar horacio floresNo ratings yet

- CEB1109Document6 pagesCEB1109oscar horacio floresNo ratings yet

- CEB1104Document8 pagesCEB1104oscar horacio floresNo ratings yet

- HKMN Gas Turbine Division: Rolls-Royce Proprietary Data - Uncontrolled PrintedDocument10 pagesHKMN Gas Turbine Division: Rolls-Royce Proprietary Data - Uncontrolled Printedoscar horacio floresNo ratings yet

- CEB1107Document5 pagesCEB1107oscar horacio floresNo ratings yet

- CEB1103Document31 pagesCEB1103oscar horacio floresNo ratings yet

- CEB1106Document4 pagesCEB1106oscar horacio floresNo ratings yet

- CEB1099Document6 pagesCEB1099oscar horacio floresNo ratings yet

- CEB1100Document4 pagesCEB1100oscar horacio floresNo ratings yet

- CEB1102Document1 pageCEB1102oscar horacio floresNo ratings yet

- CEB1101Document5 pagesCEB1101oscar horacio floresNo ratings yet

- CEB1097Document5 pagesCEB1097oscar horacio floresNo ratings yet

- CEB1098Document8 pagesCEB1098oscar horacio floresNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Cement ProcessDocument14 pagesCement ProcessChristian RuedaNo ratings yet

- 9 Pipeline TransportationDocument4 pages9 Pipeline TransportationMhiaBuenafeNo ratings yet

- Hyundai E I20 EuropeDocument7 pagesHyundai E I20 EuropeAmit KumarNo ratings yet

- Fire Fighting CesDocument7 pagesFire Fighting Cesissam elmoharir100% (1)

- Pump GDDocument2 pagesPump GDdelcololalunaNo ratings yet

- Gas Screw Compressor Bearing BasicsDocument5 pagesGas Screw Compressor Bearing BasicsDayo IdowuNo ratings yet

- De ReportDocument28 pagesDe ReportAdityaraj Rathore100% (1)

- Pyrolysis PlasticDocument16 pagesPyrolysis Plasticdiego NNo ratings yet

- Agency Approvals Braided 2651 - LRDocument2 pagesAgency Approvals Braided 2651 - LRMohamed ElmakkyNo ratings yet

- PFDDocument19 pagesPFDCyril JohnsonNo ratings yet

- Refillable Seamless Steel Cylinder For Compressed Gases PER ISO 11114-1Document1 pageRefillable Seamless Steel Cylinder For Compressed Gases PER ISO 11114-1bkprodhNo ratings yet

- DODGE STRATUS CHRYSLER SEBRING 2002 Service Repair Manual PDFDocument16 pagesDODGE STRATUS CHRYSLER SEBRING 2002 Service Repair Manual PDFjfjkkskemmdm67% (3)

- Air Independent Power SystemsDocument14 pagesAir Independent Power Systemsknowme73No ratings yet

- West Tower Condominium vs. First Philippine Industrial CorporationDocument30 pagesWest Tower Condominium vs. First Philippine Industrial CorporationPMVNo ratings yet

- Bernoulli S PrincipleDocument13 pagesBernoulli S PrincipleElla ZainuddinNo ratings yet

- Resume - Gaurav Maheshwari - Lead Process EngineerDocument3 pagesResume - Gaurav Maheshwari - Lead Process Engineergauravtech1988No ratings yet

- PTQ Q4 2004 - Foam Control in Crude Units PDFDocument8 pagesPTQ Q4 2004 - Foam Control in Crude Units PDFWong Yee SunNo ratings yet

- Planning and Calculation en LowDocument24 pagesPlanning and Calculation en Lowcarloscareca1100% (1)

- PDFDocument32 pagesPDFgharsallah mouna100% (1)

- Encounter Technology Magazine 2/2014Document62 pagesEncounter Technology Magazine 2/2014AUDI AG100% (2)

- TCD 7.8 Agriculture enDocument2 pagesTCD 7.8 Agriculture enVăn Tuấn NguyễnNo ratings yet

- BS en 682-2002 Elastomeric Seals-Materials Requirements For Seals Used in PipesDocument22 pagesBS en 682-2002 Elastomeric Seals-Materials Requirements For Seals Used in PipesM Alim Ur RahmanNo ratings yet

- Presentation On Oil & Gas LegistationDocument15 pagesPresentation On Oil & Gas Legistationtanzim mehdiNo ratings yet

- GB Navod K Obsluze A Instalaci VIADRUS GRAND G36!16!2013Document60 pagesGB Navod K Obsluze A Instalaci VIADRUS GRAND G36!16!2013ben_hamidNo ratings yet

- Replacing Damaged Cam on B&W Slow Speed EngineDocument3 pagesReplacing Damaged Cam on B&W Slow Speed EngineArun SNo ratings yet

- Fault Codes MID128Document174 pagesFault Codes MID128Izz Bahar67% (3)

- Transmission Control ValveDocument12 pagesTransmission Control ValveEdwar Julian100% (5)

- Phase I ESA QuestionnaireDocument13 pagesPhase I ESA QuestionnaireredhousecatNo ratings yet

- HSE Unloading Petrol From Road TankersDocument24 pagesHSE Unloading Petrol From Road Tankersgjbishopgmail100% (2)

- IRJET Modeling and Analysis of A 100ccDocument6 pagesIRJET Modeling and Analysis of A 100ccDamianCurcanNo ratings yet