Professional Documents

Culture Documents

11 - 819EN Rev B

Uploaded by

vinodk335Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

11 - 819EN Rev B

Uploaded by

vinodk335Copyright:

Available Formats

Data Sheet

10/11-8.19 EN

Head mounted Temperature Transmitter TH02/TH02-Ex

HART programmable, Pt 100 (RTD), thermocouples, electrical isolation

Input Resistance thermometer (2-, 3-, 4-wire circuit) Thermocouples Resistance remote signalling unit (0...5000 ) Voltages, mV (-125...+1200 mV) Output 2 wire technique 4...20 mA, HART signal Electrical isolation (I/O) Measured error 0.1 K Customer-specific linearization 32 tie points Continuous sensor and self-monitoring Parameter saved permanently in EEPROM Monitoring of data integrety every 10 s Wire break monitoring in acc. with NAMUR NE 89 Substitution strategy in case of error (NE 43) Approvals for explosion protection Intrinsically safe II 2 (1) G EEx [ia] ib IIC T6, mount in zone 1 II 3 G EEx n A II T6, mount in zone 2 Input functionality (absolute, differential, average value) EMC acc. to EN 50082-2 and NE 21 Parameterization Device Management Tool: DSV4xx (SMART VISION) Hand held terminals: DHH691 (691 HT), STT04, HC275, FC375 CoMeter (HART configurator/LC display)

Excellent long term stability Temperature linear output signal Enhanced self diagnostics

Head mounted Temperature Transmitter TH02/TH02-Ex HART programmable, Pt 100 (RTD), thermocouples, electrical isolation

10/11-8.19 EN

Technical data

Output

Output signal (temperature linear) 4...20 mA Residual ripple (peak-to-peak) < 0.3 % Current consumption < 3.6 mA Maximum output current 23.6 mA Parameterizable current error signal Underranging 3.6 mA Overranging 22 mA Default value 3.6...23.6 mA Damping t63 = 0...30 s

Sensor short-circuit < 5 (for RTD) Sensor break (temperature/resistance measurement 2, 3, 4 wire) Measuring range 0... 500 > 530 Measuring range 0...5000 > 5.3 k Sensor wire break monitoring in accordance with NAMUR NE 89 Sensor wire break detection 3 wire resistance measurement > 35 4 wire resistance measurement > 3.7 k Input filter 50/60 Hz

Thermocouples/Voltages

Types B, E, J, K, L, N, R, S, T, U Voltages -125 mV...+ 125 mV -125 mV...+1200 mV Minimum measuring span 2 mV/50 mV Sensor wire break monitoring in accordance with NAMUR NE 89 Pulsed with 1 A outside of the measuring interval Monitoring disconnectible Thermocouple measurement > 5 k Voltage measurement > 5 k Input filter 50/60 Hz Internal reference junction Pt 100, via software switchable (no jumper necessary)

Input

Resistance

Resistance thermometer (IEC 751, JIS, SAMA) n Pt 100/Ni 100 to Pt 1000/Ni 1000; Cu (n = 0.1, 0.2, 0.5, 1, 1.2, 2, 3...10) Min. measuring span 15 K/50 K Resistance 0...500 /0...5000 Min. measuring span 5 /50 Maximum line resistance (Rw) per core 2, 3, 4 wire 7.5 , 10 , 50 Measuring current 300 A

Input element Standard IEC 584-1 Sensor Thermocouple type B Thermocouple type E Thermocouple type J Thermocouple type K Thermocouple type R Thermocouple type S Thermocouple type T Thermocouple type N Thermocouple type L Thermocouple type U Resistance thermometer Pt 100 Resistance thermometer Pt 1000 Resistance thermometer Ni 100 Resistance thermometer Ni 500 mV

Measuring range 250...+1820 C 250...+1000 C 210...+1200 C 250...+1372 C 50...+1768 C 50...+1768 C 200...+ 400 C 200...+1350 C (+482...+3308 F) (418...+1832 F) (346...+2192 F) (418...+2502 F) ( 58...+3215 F) ( 58...+3215 F) (328...+ 752 F) (328...+2462 F)

Min. measuring span 235 C 30 C 37 C 54 C 171 C 193 C 50 C 60 C 36 C 40 C 15 C 50 C 8 C 15 C 5 /50 2 mV 50 mV (423 F) ( 54 F) ( 67 F) ( 98 F) (308 F) (348 F) ( 90 F) (108 F) ( 65 F) ( 72 F) ( 28 F) ( 90 F) ( 15 F) ( 28 F)

DIN 43710 IEC 751; JIS; SAMA1) 2, 3 and 4 wire DIN 43760 2, 3 and 4 wire Resistance Voltage

1)

200...+ 900 C ( 76...+ 482 F) 200...+ 600 C (328...+1112 F) 200...+ 850 C (328...+1562 F) 200...+ 850 C (328...+1562 F) 60...+ 250 C ( 76...+ 482 F) 60...+ 250 C ( 76...+ 482 F) 0...500 /0...5000 125 mV...+ 125 mV 125 mV...+1200 mV

IEC 751 a = 0.00385, JIS a = 0.003916, SAMA a = 0.003902

Head mounted Temperature Transmitter TH02/TH02-Ex HART programmable, Pt 100 (RTD), thermocouples, electrical isolation

10/11-8.19 EN

Power supply (poling protected)

Supply voltage Non-Ex-application Us = 8.5...30 V DC For Ex-Application, max. Ui = 8.5...29.4 V DC 2 wire methode: power supply wires = signal wires Influence of supply voltage < 0.05 %/10 V maximum residual ripple 1 % US (< 500 Hz)

Mechanical construction

Dimensions Confer dimensional drawing Weight 55 g Housing material Polycarbonat black (Non-Ex-type) blue (Ex-type)

Power demand of indicators (only with AGLHD head) (Power demand of transmitter and indicator have to be added)

Digital indicator Usd = 2 V DC CoMeter (HART configutor/LC display) Usd = 2.9 V DC

Electrical connection

Terminals, pluggable 2.5 mm2, screw terminals (stainless steel screws)

Characteristics at rated conditions

According to IEC 770 (related to 25 C)1) Digital measured error Pt 100 Thermocouples Linear resistance 500 /5000 Linear voltage 120 mV/1200 mV D/A measured error 0.05 % of measuring span Additional influence of the internal reference junction Pt 100 DIN IEC 751 Kl. B

io n n ra ge

Maximum load

( U smax U smin ) R ( k ) = --------------------------------------23.6

0.1 K 20 V 40 m/200 m 20 V/50 V

910

Maximum permissible load R

788

With CoMeter

250

(HC)

at er

Influences

Influence of ambient temperature acc. to IEC 68-2-2 Pt 100/resistance measurement2)

30

0 8,5 11,4 14,4 17,3

Z-20160

V DC Power supply Us

ME ( ) < ( 0.05 % + -------------------- 0.008 % ) 10 K MS ( ) Thermocouple/mV3)

General characteristics

Output signal refreshment rate Pt 100 0.4 s (Input signal change < 0.25 K/s) Thermocouples 0.2 s (Input signal change < 2.5 K/s) Vibration resistance Vibration in operation Resistance to shock Electrical isolation (I/O) 1.5 kV AC (60 s) Long-term drift 0.02 % per annum (ambient temperature < 60 C) 0.05 % per annum (ambient temperature < 85 C) 2 g acc. to DIN IEC 68T.2-6 acc. to DIN IEC 68T.2-27

ME ( mV ) 0.14 K < ( 0.05 % + ------------------------ 0.01 % + ------------------ 100 % ) 10 K MS ( mV ) MS ( K ) Percentage related to measuring span MS = ME MA MA = lower range value, ME = upper range value

1) 2)

Percentage related to set measuring span Specified values corresponds to 3 (Gaussian normal distribution) Pt 100 (0...400 C): Influence of ambient temperature < (0.05 % + 0.013 %)/10 K = 0.063 %/10 K 3) Type K (0...1000 C): Influence of ambient temperature < (0.05 % + 0.01 % + 0.014 %)/10 K = 0.074 %/10 K

Environment conditions

Ambient temperature range -40...85 C Transport and storage temperature -40...100 C Relative humidity < 100 % (100 % humidity with isolated terminals only) Condensation: Permitted

Head mounted Temperature Transmitter TH02/TH02-Ex HART programmable, Pt 100 (RTD), thermocouples, electrical isolation

10/11-8.19 EN

Explosion protection

Intrinsically safe

Zone 1 Marking EC-Type-Examination certificate Temperature class T6/T5/T4 Supply circuit Max. voltage Short-circuit current Max. power Internal inductance Internal capacitance

4)

Electromagnetic compatibility (EMC)

Pt 100: measuring range 0...100 C, span 100 K Type of test Burst to signal/ data lines Static discharge Contact plate (indirect) Terminals for supply1) Terminals for sensors1) Radiated field 80 MHz...1 GHz Coupling 150 kHz - 80 MHz Surge: asymmetrisch symmetrisch

5)

II 2 (1) G EEx [ia] ib IIC T6 PTB 99 ATEX 2139 X 50 C/65 C/85 C Input [ia] Uo = 5.6 V Io = 1.5 mA4) Po = 20 mW Lo = 1 mH Co = 1.55 F

Degree 3 kV

Influence < 0.1 %

IEC 1000-4-4 1000-4-2

Output [ib] Ui = 29.4 V Ii = 130 mA Pi = 0.8 W Li = 220 H Ci = 15 nF

8 kV 6 kV 4 kV 10 V/m 10 V 1 kV 0.5 kV

no influence no influence no influence 1000-4-3 < 1.0 % 1000-4-6 < 1.0 % 1000-4-5 <1% <1%

See 1. supplement PTB 99 ATEX 2139 X

Air discharge (at 1 mm distance)

Zone 2 Marking Conformity statement Temperature class T6/T5/T4

II 3 G EEx n A II T6 PTB 99 ATEX 2216 X 50 C/65 C/85 C

According to NAMUR NE 21 recommendation. In case of an input signal change > 0.25 K/s for Pt100 or > 2.5 K/s for thermocouples a measured value plausibility check is performed.

Canadian Standards Association and Factory Mutual

Intrinsically Safe FM CSA Class I, Div. 1, Groups A, B, C, D T6 Class I, Zone 0, Group IIC T6 Class I, Div. 1 and Div. 2, Groups A, B, C, D T6 Class I, Zone 0, Group IIC T6 (Class II Groups E, F, G; Class III if build in BUZH -, AGL- or AGLH head) Class I, Div. 2, Groups A, B, C, D, T6 Class I, Div. 2, Groups A,B,C,D T6 (Class II, Groups E, F, G; Class III if build in BUZH-, AGL- or AGLH head)

Communication/parameterization

Hand held terminal HHT DHH691 (691 HT), STT04, HC275, FC375 CoMeter Hart conigurator and LC display Device Management Tool DSV4xx (SMART VISION) FDT/DTM technology Software connection AMS (from version 5 without additional drivers) Parameter Sensor type, error signalling, measuring range, general characteristics (i. e. TAG number), damping, signal simulation of output

Nonincendive FM CSA

CoMeter

Processinterface Line resistance

+

(250 min.)*

or Isolators Controller Recorders

DHH691 (691 HT), STT04, HC275, FC375

Z-20162d

GND

or

(optional) FSK Modem

or FDT/DTM technology *if necessary

Head mounted Temperature Transmitter TH02/TH02-Ex HART programmable, Pt 100 (RTD), thermocouples, electrical isolation

10/11-8.19 EN

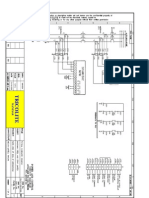

Connection diagram

Resistance sensors/Potentiometer

Microprocessor

Thermocouples/Voltages

1 1 1 1 1

1

Input

+

Us = 8,5...30 V DC

Output

K1

3 3 3 3

K1

3 3 3

4...20 mA

Reference junction

4 4

K2

4

4 4 4

K2

4 4

2

2 2 2 2 2 2 2

V DC

V DC

a)

b)

c)

d)

e)

f)

g)

h)

i)

j)

k)

a) b) c) d)

Resistance thermometer, 2 wire circuit Resistance thermometer, 3 wire circuit Resistance thermometer, 4 wire circuit Double resistance thermometer, 2 wire circuit (average value or differential temperature measurement)

f) Thermocouple g) Double thermocouple (average value or differential temperature measurement) Voltages: -125 mV...+125 mV or -125 mV...+1200 mV h) Voltage measurement i) 2-fold voltage measurement (average value or differential temperature measurement)

Potentiometer: 0...500 or 0...5000 e) Potentiometer input, 2 wire circuit f) Potentiometer input, 3 wire circuit g) Potentiometer input, 4 wire circuit

Dimensional diagram (dimensions im mm)

44/1,73

Hat rail mounting

23

5,

9/

0,

M4 x 23

Automation Products

TH02

35/1,38

7, 4/ 0, 29

M4

22,5/0,87

Automation Products

TH02

Messumformer/Transmitter/Transducteur

50/1,94

5,50/2,2

14/0,55

5,50/2,2

33/1,3

Messumformer/Transmitter/Transducteur

Z-20165

1

5, 2/ 0, 20

Head mounted Temperature Transmitter TH02/TH02-Ex HART programmable, Pt 100 (RTD), thermocouples, electrical isolation

10/11-8.19 EN

Displays (option in conjunction with AGLHD head)

ProMeter Programmable LC indicator loop-powered (4...20 mA) LC display: 5 digits ( 1999), digit height 7,6 mm, 7 segments sign and variable decimal place 10 segment bargraph (heading of measuring range) 7 digits alphanumeric characters 6 mm, 14 segments Programmable display variables: process value, sensor value, loop current, percentage Password-protected programming acces CoMeter Dual function (HART configurator and programmable LC display) Programmable LC indicator as ProMeter HART configurator HART transmitter programming unit (all HART functions except for freely configurable characteristic curve and TAG Number)

ESC key

Request function Process variable, analog and display value, description of measuring point, serial number, error behaviour, lower/upper measuring range limit Change function Sensor type, sensor circuit, measuring range, damping, mains filter, error signalling Special function Zero point adjustment, simulation of output signal, adjustment of output signal, wet calibration

Display Response time Measuring error Maximum current EMC Temperature operating range Humidity ProMeter 1.3 s 0.15 % 130 mA 215 mA EN 50082-2 -20...+70 C (-40...-20 C without function) 0...100 %, condensating permitted CoMeter

ENTER key

12.000 *

0% / - - - - / 100%

Display HART communication

Bargraph for analog output indication

mA

ProMeter/CoMeter NEXT key PREV key

ProMeter configuration menu

Display

*

NEXT PREV

ESC NEXT PREV

ESC

ESC NEXT PREV

ESC NEXT PREV

ConF MANUAL

ESC ENTER NEXT PREV

ConF CURRENT

ESC ENTER

ConF PERCENT

ESC ENTER

ConF PASSWD

ESC

NEXT PREV

NEXT PREV

ESC

ENTER

ESC

ENTER

ESC

ENTER

ESC

ENTER ENTER

SET 4...20 mA INDICATION

NEXT PREV

ESC

ESC

LINEAR SQR

ENTER

NEXT PREV

04000 04000 04000 00000 00000 ZERO

ENTER

20000 20000 20000 20000 20000 FULL SC

ENTER

ESC

ENTER

ENTER

KPA TORR ATM MPA IN H2O

ENTER

ConF UPDATE?

ESC

OUTPUT

LINEAR SQR

ESC

ENTER

ENTER

SET 0...100% INDICATION (WITH OR WITHOUT SQUARE ROOT)

UPDATE?

* Simult. press and hold the Next key and the Prev key for approx. 5 s ** The 4 and 20 mA ProMeter signal for zero and full scale configuration

can be produced by using the THx02 simulation function in the DSV4xx program (SMART VISION)

KG / CM2

ENTER

ENTER

UPDATE NEW PASSWORD

Note: 1. When using the ProMeter for process value or sensor value indication, its zero and full scale configuration must be in accordance with the transmitter temperature range or sensor range.

2. CoMeter configuration menu see 3KDE115040R4501

ENTER

4000 ZERO

NEXT PREV

20000 FULL SC

NEXT PREV

NEXT PREV

NEXT PREV

**

**

ENTER

UNITS

ConF UPDATE?

00000 01000 01200 01230 01234 PASSWD

Head mounted Temperature Transmitter TH02/TH02-Ex HART programmable, Pt 100 (RTD), thermocouples, electrical isolation

10/11-8.19 EN

Ordering information

Catalog No. TH02/TH02-Ex V11518(without Ex) 1 TH02 Type of protection: intrinsically safe ATEX Zone 1: II 2 (1) G EEx [ia]ib IIC T6 5 TH02-Ex ATEX Zone 2: II 3 G EEx n A II T6 N TH02-Ex N FM 7 TH02-Ex IS Class I, Div. 1, Groups A, B, C, D T6 IS Class I, Zone 0, Group IIC T6 CSA IS Class I, Div.1 and Div. 2, Groups A, B, C, D T6 9 TH02-Ex (Class II Groups E, F, G; Class III If build in BUZH head, AGL head or AGLH head) Nonincendive, Class I, Div. 2, Groups A, B, C, D T6, (Class II, Groups E, F, G; Class III if built in BUZH head, AGL head or AGLH head) FM M TH02-Ex N nonincendive, Class I, Div. 2, Groups A, B, C, D T6 Construction / display Module (h = 22.5 mm) Module (h = 22.5 mm) with sensor connecting line Module (h = 22.5 mm) with snap-on fixing Module (h = 27.5 mm) for mounting on measuring module Module built into connection head or cover with sensor connecting line BUZH head BUSH head BUKH-Ex head Raised B-head cover B head (complete head with raised cover) AUZH head AUSH head AGL head without display 1) AGLHD head with digital display (ProMeter) 1) AGLHD head with digital display/HART configurator (CoMeter) 1) Attention: The sensor connecting lines correspond to the order for the type of sensor or its type of circuitry Module built into field housing: Aluminum field housing 80 x 75 x 57 mm, IP 65; 2 x M16 x 1.5 Polyester field housing 75 x 80 x 55 mm, IP 65; 2 x M16 x 1.5 Aluminum field housing 80x175x57 mm, IP 65; 1 x M16 x 1.5; 1 x M20 x 1.5, with seperate terminal block Polyester field housing 75x190x55 mm, IP 65; 1 x M16 x 1.5; 1 x M20 x 1.5, with seperate terminal block Note: Other field housings with several transmitters or especially for pipe mounting on request Programming Factory standard parameter Pt 100, 0...100 C, 4 wire circuit, damping off, direct action characteristic overranging at sensor or device error (22 mA) Customer specific parameter settings EUR Deliv. time 3 wks. 234,00 * 263,00 * 263,00 * 263,00 * 263,00 *

263,00 * 3 1 4 Z R P N L K V U X D C 7,85 * 10,30 * 5,73 * 42,50 43,10 34,60 20,40 24,30 56,90 58,10 82,50 270,00 316,00 * * * * * * * * * *

A 9 F E

74,70 * 77,50 * 91,70 * 100,00 *

22,80 *

Continued on next page 1) Standard: Aluminum, metal-cable-screw-connection M20 x 1.5 EEx e; protective pipe connection M24 x 1.5 (optional M20 x 1.5; 1/2" NPT; 3/4" NPT); (do not use for EEx d applications, see data sheet 10/10-3.28 EN for EEx d details)

Head mounted Temperature Transmitter TH02/TH02-Ex HART programmable, Pt 100 (RTD), thermocouples, electrical isolation

10/11-8.19 EN

Ordering information (continued)

TH02/TH02-Ex Calibration certificates without 2 point 9 point Certificates without SIL2 - Declaration of conformity Catalog No. V115180 1 2 0 2 EUR Deliv. time 3 wks.

80,20 * 113,00 * 46,10 *

Accessories

ABB FSK modem [EEx ib] IIC (parameter setting in the installation) Device Management Tool DSV4xx (SMART VISION) see Data Sheet 10/63-6.71 EN see Data Sheet 10/63-1.20 EN

Note: For a local programming on the desk the universal FSK programming set can be used as Hardware (see Data Sheet 10/63-6.71 EN: ordering information)

ABB has Sales & Customer Support expertise in over 100 countries worldwide. www.abb.com/instrumentation

The Companys policy is one of continuous product improvement and the right is reserved to modify the information contained herein without notice. Printed in the Fed. Rep. of Germany (03.05) ABB 2005

ABB Ltd. Salterbeck Trading Estate Workington, Cumbria, CA14 5DS UK Tel: +44(0)1946-830-611 Fax: +44(0)1946-832-661

ABB Inc. 125 E. County Line Road Warminster, PA 18974 USA Tel: +1 215-674-6000 Fax: +1 215-674-7183

ABB Automation Products GmbH Borsigstr. 2 63755 Alzenau Germany Tel: +49 551 905-534 Fax: +49 551 905-555 CCC-support.deapr@de.abb.com

10/11-8.19 EN Rev. B

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Cable Size Calculation for 125 KW LT and 350 KW HT MotorsDocument5 pagesCable Size Calculation for 125 KW LT and 350 KW HT MotorsJay Rameshbhai ParikhNo ratings yet

- CAAB 2008 EEE Question BankDocument2 pagesCAAB 2008 EEE Question Bankrajshahieee100% (10)

- Motor Technical Brochure PDFDocument24 pagesMotor Technical Brochure PDFvinodk335100% (1)

- Motor Technical Brochure PDFDocument24 pagesMotor Technical Brochure PDFvinodk335100% (1)

- PT-100 RTD 4 Wire Sensor RosemountDocument8 pagesPT-100 RTD 4 Wire Sensor RosemountVictor de JesusNo ratings yet

- III 1 Electrification 1 28Document35 pagesIII 1 Electrification 1 28SannyBombeoJomoc100% (1)

- Itemp TMT111, DIN Rail: Technical InformationDocument10 pagesItemp TMT111, DIN Rail: Technical InformationAntonio DjelicNo ratings yet

- ITXPlus Datasheet 120108Document4 pagesITXPlus Datasheet 120108alltheloveintheworldNo ratings yet

- 11 819TH02Document8 pages11 819TH02Yves KORENo ratings yet

- TTF300 DatasheetDocument20 pagesTTF300 DatasheetRaja Prathap SinghNo ratings yet

- Head Mounted Temperature Transmitter TH02/TH02-Ex: Data SheetDocument8 pagesHead Mounted Temperature Transmitter TH02/TH02-Ex: Data SheetSibin K MathewNo ratings yet

- Abb TH202Document8 pagesAbb TH202Ruben Checalla RamosNo ratings yet

- Itemp Hart TMT 182: Temperature Head TransmitterDocument10 pagesItemp Hart TMT 182: Temperature Head TransmitterAG OscarNo ratings yet

- Gefran 600 Pidcontroler ManualDocument30 pagesGefran 600 Pidcontroler ManualOrlando David Zeña SandovalNo ratings yet

- DSe IB KFD2-UT2-Ex1 PDFDocument3 pagesDSe IB KFD2-UT2-Ex1 PDFRaj ChavanNo ratings yet

- ABB Make TTF200 Basic TransmitterDocument10 pagesABB Make TTF200 Basic TransmitterRushil H SevakNo ratings yet

- Micromann AR SeriesDocument8 pagesMicromann AR SeriesSocaciu VioricaNo ratings yet

- Transmitter For Pressure and Temperature Atm/T: Features Typical ApplicationsDocument4 pagesTransmitter For Pressure and Temperature Atm/T: Features Typical ApplicationsJoseph TaylorNo ratings yet

- TMT 181Document10 pagesTMT 181Boris MirandaNo ratings yet

- Specifications Specifications Specifications: Thermocouple Input Module Analog Input Module RTD Input ModuleDocument1 pageSpecifications Specifications Specifications: Thermocouple Input Module Analog Input Module RTD Input ModulesadrianocNo ratings yet

- EDS11 173 PXE Temperature ControllerDocument4 pagesEDS11 173 PXE Temperature ControllerR NandakumarNo ratings yet

- Sitranst th300 Fi01enDocument7 pagesSitranst th300 Fi01enLuis GuillermoNo ratings yet

- Data Sheet HB03PBT7KDocument2 pagesData Sheet HB03PBT7Kasipahi6116No ratings yet

- Omron E5CWL PDFDocument12 pagesOmron E5CWL PDFmaloyNo ratings yet

- YTA70PDocument3 pagesYTA70PjamesrickynNo ratings yet

- stt650 Brochure 34-tt-03-15 0Document18 pagesstt650 Brochure 34-tt-03-15 0R NandakumarNo ratings yet

- Memograph rsg40 Ti133ren - 0707Document20 pagesMemograph rsg40 Ti133ren - 0707cristianmihaiNo ratings yet

- Atm Ii: Features Typical ApplicationsDocument4 pagesAtm Ii: Features Typical ApplicationsJoseph TaylorNo ratings yet

- TTH300 DatasheetDocument16 pagesTTH300 DatasheetAzriq BahariNo ratings yet

- Omron K3MA-L DatasheetDocument16 pagesOmron K3MA-L DatasheetEdwin IxtinNo ratings yet

- DP25Document4 pagesDP25Fabián HerreraNo ratings yet

- Temperature Transmitters: SEM203 PDocument2 pagesTemperature Transmitters: SEM203 PMandark0009No ratings yet

- DT3P1GBDocument2 pagesDT3P1GBAkoKhalediNo ratings yet

- Sitranst th100 Fi01enDocument4 pagesSitranst th100 Fi01enGhassan Al HaririNo ratings yet

- Rt420 Datasheet enDocument11 pagesRt420 Datasheet enxandebarataNo ratings yet

- 331-1KF01 - AI 8x13bit - Technical Data: Chapter 6 Analog Input ModulesDocument5 pages331-1KF01 - AI 8x13bit - Technical Data: Chapter 6 Analog Input ModulesIgor TusjakNo ratings yet

- Digital Controller: E5AK/E5EKDocument36 pagesDigital Controller: E5AK/E5EKcangianoaNo ratings yet

- Digital Temperature Transmitter For Resistance Sensors, Head-And Rail-Mounted Version Models T15.H, T15.RDocument11 pagesDigital Temperature Transmitter For Resistance Sensors, Head-And Rail-Mounted Version Models T15.H, T15.RGerardo SánchezNo ratings yet

- Контроллер Е5СВ (GB) PDFDocument12 pagesКонтроллер Е5СВ (GB) PDFyadelekNo ratings yet

- Yokogawa Transmisor 4 20 HartDocument3 pagesYokogawa Transmisor 4 20 HartÁngel Méndez GödelNo ratings yet

- Programmable TransmittersDocument8 pagesProgrammable Transmittersjose cruzNo ratings yet

- Temperature ControllerDocument8 pagesTemperature ControllerWai Ee YapNo ratings yet

- D2440-01-01 Sem203p Data SheetDocument2 pagesD2440-01-01 Sem203p Data SheetbrusarpNo ratings yet

- ET1103Document11 pagesET1103fredy arias duranNo ratings yet

- YTA70Document4 pagesYTA70jamesrickynNo ratings yet

- Shimaden Digital Controller: Shimaden, Temperature and Humidity Control SpecialistsDocument8 pagesShimaden Digital Controller: Shimaden, Temperature and Humidity Control SpecialistsGeta IvanNo ratings yet

- EL3202 - 2-Channel Input Terminal PT100 (RTD) For 2-Or 3-Wire ConnectionDocument2 pagesEL3202 - 2-Channel Input Terminal PT100 (RTD) For 2-Or 3-Wire ConnectionmostroyaNo ratings yet

- Shimaden Digital Controller: SR1 / SR3 / SR4Document2 pagesShimaden Digital Controller: SR1 / SR3 / SR4Ferni_6028No ratings yet

- TEMATEC Temperature Head Transmitter Data SheetDocument5 pagesTEMATEC Temperature Head Transmitter Data SheetPaulius TranavičiusNo ratings yet

- Ds Te3204 en CoDocument18 pagesDs Te3204 en CoHamed YadegariNo ratings yet

- Data Sheet Optris CT 3M PDFDocument2 pagesData Sheet Optris CT 3M PDFVEbrey SevenNo ratings yet

- Ecograph T: Technical InformationDocument16 pagesEcograph T: Technical InformationLuis RamirezNo ratings yet

- Panel Meters and Controllers Controller For Pulse Signals Type MDI 40 TFDocument4 pagesPanel Meters and Controllers Controller For Pulse Signals Type MDI 40 TFheroes11No ratings yet

- Hart Field Temperature Transmitter Models TIF50, TIF52, TIF62Document9 pagesHart Field Temperature Transmitter Models TIF50, TIF52, TIF62jmenesesmNo ratings yet

- General Specifications: Model YT200 Temperature TransmitterDocument4 pagesGeneral Specifications: Model YT200 Temperature TransmitterJorge GuerreroNo ratings yet

- EL3204Document1 pageEL3204leexsanoNo ratings yet

- Data Sheet OPT104Document2 pagesData Sheet OPT104vitezixNo ratings yet

- IEC-Compliant Electricity Meter Technical SpecsDocument6 pagesIEC-Compliant Electricity Meter Technical Specsroadkill7No ratings yet

- Smart Universal Temperature Transmitter SEM210Document2 pagesSmart Universal Temperature Transmitter SEM210Nórida Pájaro GómezNo ratings yet

- RT9 Temperature Recorder - ControllerDocument26 pagesRT9 Temperature Recorder - ControllerjglunaNo ratings yet

- Tongyu TMADocument3 pagesTongyu TMARogersNo ratings yet

- E5cn User ManualDocument25 pagesE5cn User ManualDragan MarkovicNo ratings yet

- Advt Combined Sub Engg Test 2012Document2 pagesAdvt Combined Sub Engg Test 2012Neha SinghalNo ratings yet

- Travelling Exp FormDocument2 pagesTravelling Exp Formvinodk335No ratings yet

- Advt Combined Sub Engg Test 2012Document2 pagesAdvt Combined Sub Engg Test 2012Neha SinghalNo ratings yet

- TGE 5, TGE 5-Ex, TGM 5, TGM 5-Ex, TGU 5, TGU 5-Ex: Transmitter For Angular PositionDocument10 pagesTGE 5, TGE 5-Ex, TGM 5, TGM 5-Ex, TGU 5, TGU 5-Ex: Transmitter For Angular Positionvinodk335No ratings yet

- Full Scope 120 R SeriesDocument4 pagesFull Scope 120 R Seriesvinodk335No ratings yet

- Account SummaryDocument1 pageAccount Summaryvinodk335No ratings yet

- TGE 5, TGE 5-Ex, TGM 5, TGM 5-Ex, TGU 5, TGU 5-Ex: Transmitter For Angular PositionDocument10 pagesTGE 5, TGE 5-Ex, TGM 5, TGM 5-Ex, TGU 5, TGU 5-Ex: Transmitter For Angular Positionvinodk335No ratings yet

- Full Scope 120 R SeriesDocument4 pagesFull Scope 120 R Seriesvinodk335No ratings yet

- Sse264xc 4Document28 pagesSse264xc 4vinodk335No ratings yet

- TGE 5, TGE 5-Ex, TGM 5, TGM 5-Ex, TGU 5, TGU 5-Ex: Transmitter For Angular PositionDocument10 pagesTGE 5, TGE 5-Ex, TGM 5, TGM 5-Ex, TGU 5, TGU 5-Ex: Transmitter For Angular Positionvinodk335No ratings yet

- MOD30 XL+ControllerDocument6 pagesMOD30 XL+Controllervinodk335No ratings yet

- Tricoloite Drawings1Document1 pageTricoloite Drawings1vinodk335No ratings yet

- 11 - 864EN Rev BDocument8 pages11 - 864EN Rev Bvinodk335No ratings yet

- 14 - 684EN Rev ADocument17 pages14 - 684EN Rev Avinodk3350% (1)

- Balance Spare Motors RequiredDocument1 pageBalance Spare Motors Requiredvinodk335No ratings yet

- Spau 130 C Three-Phase Overvoltage and Undervoltage Relay: User S Manual and Technical DescriptionDocument52 pagesSpau 130 C Three-Phase Overvoltage and Undervoltage Relay: User S Manual and Technical Descriptionvinodk335No ratings yet

- Spau 130 C Three-Phase Overvoltage and Undervoltage Relay: User S Manual and Technical DescriptionDocument52 pagesSpau 130 C Three-Phase Overvoltage and Undervoltage Relay: User S Manual and Technical Descriptionvinodk335No ratings yet

- SPAM 150 Users ManualDocument64 pagesSPAM 150 Users ManualPhilip Watts100% (1)

- Spaj 140CDocument68 pagesSpaj 140CTiago Marques PereiraNo ratings yet

- WL WL: Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Document2 pagesWL WL: Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)vinodk335No ratings yet

- FM Spae01 en BDocument12 pagesFM Spae01 en BSudhakar YsNo ratings yet

- Safe Grid EarthingDocument11 pagesSafe Grid EarthingYusuf BhikhapurwalaNo ratings yet

- Uc 3Document15 pagesUc 3Osama shrf shrf2No ratings yet

- SN75189NDocument10 pagesSN75189NJonatan Sovero BozaNo ratings yet

- Rumus ConvertDocument14 pagesRumus ConvertIrlan MalikNo ratings yet

- Lesson 2: LO 1. Select Measuring Tools and Instruments and LO 2. Carry Out Measurements and CalculationsDocument56 pagesLesson 2: LO 1. Select Measuring Tools and Instruments and LO 2. Carry Out Measurements and CalculationsarielNo ratings yet

- Resistance Formula ExplainedDocument3 pagesResistance Formula ExplaineddljbNo ratings yet

- Dynatel 965t ManualDocument99 pagesDynatel 965t ManualhjstamNo ratings yet

- 24 Circuits ResistanceDocument6 pages24 Circuits ResistanceeltytanNo ratings yet

- Board Label Qty Manufacturer Part NumberDocument6 pagesBoard Label Qty Manufacturer Part NumberestrallatorNo ratings yet

- Electrical Sciences (EEE A 102) : Dr. Rajiv Ranjan SinghDocument34 pagesElectrical Sciences (EEE A 102) : Dr. Rajiv Ranjan SinghSharmila KrishnaswamyNo ratings yet

- Tech2 Gr9 LBDocument168 pagesTech2 Gr9 LBPride Shayne MwakNo ratings yet

- Module 3 BDocument48 pagesModule 3 BBu DakNo ratings yet

- RTD and thermocouple calculations worksheetDocument18 pagesRTD and thermocouple calculations worksheetnjc6151No ratings yet

- Math 115 HW #9 Solutions PDFDocument7 pagesMath 115 HW #9 Solutions PDFHyan Gontijo0% (1)

- ElecrDocument11 pagesElecrRaji GoprajuNo ratings yet

- CSE209 (Lab Report 1)Document6 pagesCSE209 (Lab Report 1)Tasnim Saima RaitaNo ratings yet

- Latestnews Kei4z091xhz9sth8 1644584032Document97 pagesLatestnews Kei4z091xhz9sth8 1644584032FlowealthNo ratings yet

- University Physics Chapter 10 PDFDocument62 pagesUniversity Physics Chapter 10 PDFAnmol DasNo ratings yet

- 3254 IEC ACCC Spec Sheets HelsinkiDocument1 page3254 IEC ACCC Spec Sheets HelsinkiRicardo Hernandez MoralesNo ratings yet

- QSC Amp Spa2-60 PDFDocument2 pagesQSC Amp Spa2-60 PDFAnthony Marin De FreitasNo ratings yet

- XII Phy Past PprsDocument46 pagesXII Phy Past PprsHashim Raza Siyal100% (1)

- Model 3940: Temperature Transmitter With Hart CommunicationsDocument4 pagesModel 3940: Temperature Transmitter With Hart Communicationswhisnu hyerlambangNo ratings yet

- Problems: Circuitos Eléctricos Avanzados Ingeniería MecatrónicaDocument18 pagesProblems: Circuitos Eléctricos Avanzados Ingeniería MecatrónicaGonzalo Daniel Ramos MenaNo ratings yet

- Czujniki Temperatury MOTOMETERDocument7 pagesCzujniki Temperatury MOTOMETERhelp3rNo ratings yet

- RezistenteDocument15 pagesRezistenteMariusPlesaNo ratings yet

- MasterBook 1 Eng PDFDocument64 pagesMasterBook 1 Eng PDFDaniel CîrsteaNo ratings yet

- Arduino For Tangible Human InteractionDocument153 pagesArduino For Tangible Human InteractionBrent Michel FarmerNo ratings yet