Professional Documents

Culture Documents

Example Risk Assessment For A Motor Vehicle Showroom

Uploaded by

dogankkuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Example Risk Assessment For A Motor Vehicle Showroom

Uploaded by

dogankkuCopyright:

Available Formats

Health and Safety Executive

Example risk assessment for a motor vehicle showroom

Setting the scene

The owner carried out the risk assessment at this company, which sells motor vehicles from a small showroom and forecourt on a high street. Opening hours are 10.00 am to 6.00 pm, 7 days a week. Ten staff work at the company, five full-time and five part-time. Apart from the showroom and forecourt, there are two offices (one for closing sales and completing documentation, one for the manager and the company secretary), a designated car wash/valet area behind the showroom, a small kitchen and toilet and washing facilities. Vehicle servicing and repair is done off-site, by a different company. The premises are cleaned every day, between 5.30 pm and 6.30 pm, by staff from a contract cleaning company. The same company also cleans the showroom and office windows, and supplies staff for car valeting and washing. The premises were built in 2003 and do not contain any asbestos.

talked to the cleaning staff, and the manager of the contract cleaning company, to ensure that their work did not pose a risk to others, and vice-versa; and looked at the accident book, to gain an understanding of what has previously resulted in incidents.

2 The manager then wrote down who could be harmed by the hazards and how. 3 For each hazard, the manager wrote down what controls, if any, were in place to manage these hazards. They then compared these controls to the good practice guidance on the HSE website. Where existing controls were not considered good enough, the manager wrote down what else needed to be done. 4 Putting the risk assessment into practice, the manager decided and wrote down who was responsible for implementing the actions identified and when they should be done. When each action was completed, it was ticked off and the date recorded. He discussed the findings of the risk assessment with staff, put a copy up in the staff kitchen for all staff to see and made it part of the induction process for new staff. 5 The manager decided to review and update the risk assessment every year, or straightaway if any major changes in the workplace happened.

Important reminder

This example risk assessment shows the kind of approach a small business might take. Use it as a guide to think through some of the hazards in your business and the steps you need to take to control the risks. Please note that it is not a generic risk assessment that you can just put your company name on and adopt wholesale without any thought. This would not satisfy the law and would not be effective in protecting people. Every business is different you need to think through the hazards and controls required in your business for yourself.

How was the risk assessment done?

The manager followed the guidance in Five steps to risk assessment (www.hse.gov.uk/pubns/indg163.pdf). 1 To identify the hazards, the manager:

looked at HSEs web pages for small businesses (www.hse.gov.uk/smallbusinesses/index.htm), to learn where hazards can occur; walked around the premises, inside and out, noting things that might pose a risk, and taking into consideration what was learnt from HSEs guidance; talked to staff to learn from their knowledge and experience of areas and activities, and to get their concerns and opinions about health and safety issues in the workplace;

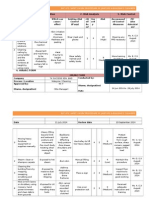

Example risk assessment: Motor vehicle showroom

1 of 4 pages

Health and Safety Executive

Company name: Smiths Motor Sales

Date of risk assessment: 28/09/07

What are the hazards? Slips and trips

Who might be harmed and how? Staff and visitors may be injured if they trip over objects or slip on spillages.

What are you already doing? Staff see it and sort it, eg all spillages trailed in water, dried up immediately with a dry mop. Premises cleaned every evening. Showroom floor machine cleaned and polished only after the showroom is closed. All areas well lit. Floor surfaces, inside and out, in good condition. No trailing leads or cables. Door mats put at showroom entrance in wet/icy weather, and replaced when they get very wet. Staff cars are parked at the back, away from customer area. Vehicles are moved very slowly. All staff that are expected to move vehicles hold a full driving licence. Staff ensure that cars being manually pushed always have a person seated at the wheel, to keep the vehicle under control. All cleaning products stored in a secure, cool and dry area. Staff are trained in safe storage, handling and use of products, eg only use small quantities at a time, keep lid on containers, keep doors/sun roof open when working inside vehicles, spills procedure, etc. Staff wear the right personal protective equipment, as recommended by supplier. Staff instructed to dry their hands thoroughly after washing cars, and to use skin cream provided as necessary.

What further action is necessary? Loose carpet tile in managers office to be repaired/ replaced. Remind staff to put warning cones around spillages during cleaning and drying.

Action by whom? Company secretary to arrange Manager

Action by when? 30/10/07

Done 21/10/07

01/10/07

01/10/07

Movement of vehicles

Staff and others risk potentially serious injury if struck by a moving vehicle.

Only authorised staff allowed to handle high performance vehicles.

Manager

04/10/07

01/01/07

Contact with cleaning chemicals

Valeting staff risk skin problems such as dermatitis, and eye damage, from direct contact with cleaning chemicals. Vapour from cleaning products may cause breathing problems.

Investigate replacing irritant cleaning products with milder alternatives. Remind staff to read the safety information on the product before use, and to follow the instructions. Remind staff to report any health problems they think may come from cleaning, and to regularly check for dry, red and itchy skin on their hands.

Company secretary Manager Manager

30/10/07 04/10/07 04/10/07

30/10/07 04/10/07 04/10/07

Manager to appoint someone to regularly check skin Manager on hands of valeting staff.

04/10/07

04/10/07

Example risk assessment: Motor vehicle showroom

2 of 4 pages

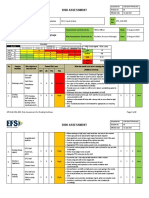

Health and Safety Executive

What are the hazards? Manual handling Moving cars, handling office equipment etc. Display screen equipment

Who might be harmed and how? Staff risk injuries or back pain from handling heavy/bulky objects, such as moving cars. Staff risk posture problems and pain, discomfort or injuries, eg to hands/ arms, from overuse, improper use or from poorly designed workstations or work environments. Headaches or sore eyes can also occur, eg if the lighting is poor.

What are you already doing? Staff trained in how to safely push cars, eg ensure sufficient people available to do so etc. Trolley used to transport boxes of paper and other heavy items when collecting deliveries etc. High shelves for storing light items only. Staff do not use computers for long and continuous periods. DSE training and assessments of workstation from CD ROM carried out by all new starters early on in induction. Any actions to be carried out ASAP. Reassessment to be carried out at any change to work feature, eg equipment, furniture or the work environment such as lighting. Workstation and equipment set to ensure good posture and to avoid glare and reflections on the screen. Shared workstations are assessed for all users. Lighting and temperature suitably controlled. Venetian blinds at office windows to control natural light on screen. Noise levels controlled. Eye tests provided for those who need them, dutyholder to pay for basic spectacles specific for VDU use (or portion of cost in other cases). Residual Current Device (RCD) built into main switchboard. RCD tested by valeting staff before using the pressure washer. Staff trained in safe use of pressure washer. Staff trained to spot and report to office administrator any defective plugs, discoloured sockets or damaged cable/equipment. Defective equipment taken out of use safely and replaced promptly. All appliances brought onto site (toasters, fans etc) must first be tested for electrical safety.

What further action is necessary? Remind staff not to try to lift objects that appear too heavy to handle.

Action by whom? Manager

Action by when? 30/10/07

Done 04/10/07

Manager to ensure that any actions arising from the self-assessments are followed up ASAP. Remind staff to tell the company secretary if they have any pain that may be linked to computer use.

Manager 30/10/07 Manager 30/10/07 04/10/07 04/10/07

Electrical

Staff could get electrical shocks or burns from using faulty electrical equipment, such as pressure washers, or a faulty installation. Electrical faults can also lead to fires.

Ask landlord when the next safety check of the electrical installation will be done. Confirm with landlord the system for making safe any damage to building installation electrics, eg broken light switches or sockets.

Company secretary Company secretary

30/10/07 30/10/07

20/10/07 20/10/07

Example risk assessment: Motor vehicle showroom

3 of 4 pages

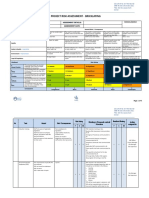

Health and Safety Executive

What are the hazards? Work at height Changing light bulbs, putting up decorations etc. Plate glass

Who might be harmed and how? Falls from any height can cause bruising and fractures. Staff/customers risk injury from walking into plate glass windows. If trapped staff could suffer fatal injuries from smoke inhalation/burns.

What are you already doing? Strong stepladder, in good condition, provided. Only trained, authorised staff allowed to work at height.

What further action is necessary?

Action by whom?

Action by when? 4/10/07

Done 4/10/07

Print and pin up in kitchen HSE leaflet on safe use of Company stepladders (www.hse.gov.uk/falls/stepladders.htm). secretary

Safety glass used. Promotional displays and other markings on showroom windows to show it is glass. Working with landlord, fire risk assessment done, see www. communities.gov.uk/fire and necessary action taken.

No further action at this stage.

Fire

Ensure the actions identified as necessary by the fire Manager risk assessment are done.

From now on

Assessment review date: 28/9/08

Example risk assessment: Motor vehicle showroom Published by the Health and Safety Executive 11/10

4 of 4 pages

You might also like

- Office Cleaning Risk AssessmentDocument3 pagesOffice Cleaning Risk Assessmentisak23No ratings yet

- Example Risk Assessment For A Poultry Farm: Setting The Scene How Was The Risk Assessment Done?Document4 pagesExample Risk Assessment For A Poultry Farm: Setting The Scene How Was The Risk Assessment Done?Olivera NovkovicNo ratings yet

- Motor Vehicle Repair Work. Example Risk Assess.Document6 pagesMotor Vehicle Repair Work. Example Risk Assess.dogankkuNo ratings yet

- Office Cleaning RiskDocument3 pagesOffice Cleaning RiskR Chandra Jaya Listiandoko100% (3)

- Butcher Shop Risk AssessmentDocument4 pagesButcher Shop Risk AssessmentSrikanth BammhideNo ratings yet

- Health and Safety Risk AssessmentDocument4 pagesHealth and Safety Risk Assessmenthello3232No ratings yet

- Example Risk Assessment For A Woodworking Company Updated 15-02-11Document7 pagesExample Risk Assessment For A Woodworking Company Updated 15-02-11garry1979No ratings yet

- Risk Assessment for Earth WorkDocument14 pagesRisk Assessment for Earth Worksamer8saifNo ratings yet

- Risk Assessment for Interlock Concrete Paver ProjectDocument11 pagesRisk Assessment for Interlock Concrete Paver ProjectZubair Khan100% (1)

- 2.4 Attachments - Risk Assessment and Method StatementDocument10 pages2.4 Attachments - Risk Assessment and Method StatementFahad MaqsoodNo ratings yet

- Incident Accident ProceduresDocument3 pagesIncident Accident ProceduresmpriceatccusaNo ratings yet

- Kitchen Risk AssessmentDocument4 pagesKitchen Risk Assessmentamnaakram996100% (1)

- Contact NoDocument3 pagesContact NovictorNo ratings yet

- Clean Tank WaterDocument1 pageClean Tank Waterblahblah100% (1)

- Risk Assessment MasonryDocument1 pageRisk Assessment Masonrymohamed ghalyNo ratings yet

- Iaslc Ra 013 Working Under Direct Sun LightDocument4 pagesIaslc Ra 013 Working Under Direct Sun LightJoe PsNo ratings yet

- RISK ASSESSMENT - Tower Crane DraftDocument12 pagesRISK ASSESSMENT - Tower Crane Draftloveson70933% (3)

- Heat Stress Assessment Checklist: Section IDocument3 pagesHeat Stress Assessment Checklist: Section IninisaisNo ratings yet

- Working Heights Risk Assessment TemplateDocument8 pagesWorking Heights Risk Assessment TemplatePanchdev KumarNo ratings yet

- HSE Auditing HSE ProfessionlasDocument20 pagesHSE Auditing HSE ProfessionlasSantanu DasNo ratings yet

- EFS-SLB-SRA-006 Risk Assessment For General Waste CollectionDocument2 pagesEFS-SLB-SRA-006 Risk Assessment For General Waste Collectionmohammed ayazNo ratings yet

- Risk AssessmntDocument5 pagesRisk Assessmntapi-456358200No ratings yet

- Injury Prevention for Bathroom CleaningDocument1 pageInjury Prevention for Bathroom CleaningSajid HussainNo ratings yet

- First Aid Record Form TemplateDocument1 pageFirst Aid Record Form Templatepuput utomoNo ratings yet

- Safe Lifting Procedure 2Document6 pagesSafe Lifting Procedure 2angelaNo ratings yet

- Risk Assessment New Site Lifting Operations 07-06-2015Document3 pagesRisk Assessment New Site Lifting Operations 07-06-2015ANAND MLNo ratings yet

- Task /activity: Installation of Abseil HooksDocument10 pagesTask /activity: Installation of Abseil HooksfrancisbautistaNo ratings yet

- Risk Assessment DrivingDocument3 pagesRisk Assessment Drivingghada gattouch100% (2)

- Risk Assessment Excavation For Trenches, Duct Bank, Pole Foundations and Back-FillingDocument3 pagesRisk Assessment Excavation For Trenches, Duct Bank, Pole Foundations and Back-FillingSafety Professional0% (1)

- RA 26 - Spray PaintingDocument2 pagesRA 26 - Spray PaintingkazishahNo ratings yet

- Reporting and investigating HSE incidents flow chartDocument2 pagesReporting and investigating HSE incidents flow chartzam110No ratings yet

- Safe Operational Procedure: Excavator: Personal Protective Equipment (PPE)Document2 pagesSafe Operational Procedure: Excavator: Personal Protective Equipment (PPE)JamesNo ratings yet

- Safe Work at Heights ProceduresDocument1 pageSafe Work at Heights ProceduresOws AnishNo ratings yet

- Covid-19 RiskAssessmentWarehouseDocument11 pagesCovid-19 RiskAssessmentWarehouseBalgo BalgobinNo ratings yet

- Sample Swms Heights Mobile ScaffoldDocument7 pagesSample Swms Heights Mobile Scaffoldmani narayananNo ratings yet

- Alnajim Alzahir Co. - Emergency Evacuation Drill On 10-May-2022Document12 pagesAlnajim Alzahir Co. - Emergency Evacuation Drill On 10-May-2022Abdullah TwfeeqNo ratings yet

- Composite Works at Manglore For Hpclproject: Project No. W-488 Rev. 01 Page1 0f 2Document2 pagesComposite Works at Manglore For Hpclproject: Project No. W-488 Rev. 01 Page1 0f 2Bhargav BbvsNo ratings yet

- EVT471Document3 pagesEVT471Nurul AqielaNo ratings yet

- Working AloneDocument3 pagesWorking Aloneanon_803215984100% (1)

- Comprehensive Safety and Health Program ConstructionDocument15 pagesComprehensive Safety and Health Program ConstructionNina CaliwagNo ratings yet

- Diesel Filling JSADocument6 pagesDiesel Filling JSAMohammed Ali QaziNo ratings yet

- Job Hazard AssessmentDocument26 pagesJob Hazard AssessmentGeherson AbustanNo ratings yet

- A. 3 HirarcDocument29 pagesA. 3 HirarcJeny MulyaNo ratings yet

- Soil and Penetrometer Risk AssessmentDocument5 pagesSoil and Penetrometer Risk AssessmentDapo OmoladeNo ratings yet

- Final Risk AssessmentDocument8 pagesFinal Risk Assessmentapi-514194726No ratings yet

- Risk Assessment Ground Collapse 8Document5 pagesRisk Assessment Ground Collapse 8Ali Almarshad100% (1)

- Drilling Work by MCDocument1 pageDrilling Work by MCChandruNo ratings yet

- Fire Risk Assessment For Site Office and SiteDocument11 pagesFire Risk Assessment For Site Office and SiteSajid Shah100% (1)

- Risk Assessment Steel FixingDocument1 pageRisk Assessment Steel Fixingmohamed ghalyNo ratings yet

- EFS-SLB-SRA-005 Risk Assessment For Dusting Surfaces of SignagesDocument2 pagesEFS-SLB-SRA-005 Risk Assessment For Dusting Surfaces of Signagesmohammed ayazNo ratings yet

- Chisels Risk AssessmentDocument1 pageChisels Risk AssessmentTawfik Mohamed Abu Zaid100% (1)

- Example Hs PolicyDocument2 pagesExample Hs PolicyellyusanaNo ratings yet

- SOP Workplace InspectionsDocument5 pagesSOP Workplace InspectionskafilussNo ratings yet

- Risk Assessment for Canal Construction WorksDocument9 pagesRisk Assessment for Canal Construction WorksAshoka Indunil WickramapalaNo ratings yet

- Tower Scaffolds: What You Need To DoDocument3 pagesTower Scaffolds: What You Need To DoMario Marasigan100% (1)

- Risk Assessment - Site Establishment - 2021Document6 pagesRisk Assessment - Site Establishment - 2021Asakundwi MukhwaNo ratings yet

- AsdssssDocument1 pageAsdssssAviects Avie JaroNo ratings yet

- Risk Assessment Form-2Document2 pagesRisk Assessment Form-2Badar AlsiyabiNo ratings yet

- Manufacturing Risk AssessmentDocument4 pagesManufacturing Risk AssessmentVijayakumar Karunanidhi100% (1)

- Motor Vehicle Repair Body Shop: Example Risk Assessment For ADocument6 pagesMotor Vehicle Repair Body Shop: Example Risk Assessment For AIvan BaraćNo ratings yet

- ASME B16.5 Flanges PDFDocument50 pagesASME B16.5 Flanges PDFPedro De Mesquita Soares CamposNo ratings yet

- Auto Repair Man HazardsDocument4 pagesAuto Repair Man HazardsdogankkuNo ratings yet

- Floor Tech FB Primer DataDocument2 pagesFloor Tech FB Primer DatadogankkuNo ratings yet

- Flexi Tech 60rg DataDocument2 pagesFlexi Tech 60rg DatadogankkuNo ratings yet

- Documents StackDocument1 pageDocuments StackDan MNo ratings yet

- Quality Management System (ISO 9001) and Environmental Quality Management System (ISO 14001) : Towards An Integrated ModelDocument12 pagesQuality Management System (ISO 9001) and Environmental Quality Management System (ISO 14001) : Towards An Integrated ModelAtul EknathNo ratings yet

- A320 CBT Navigation: Table of ContentDocument40 pagesA320 CBT Navigation: Table of ContentAman VermaNo ratings yet

- Rubia Fleet HD 200 PDFDocument2 pagesRubia Fleet HD 200 PDFdnoaisapsNo ratings yet

- Universal Remote Instruction Manual: RM24918 RM84918Document16 pagesUniversal Remote Instruction Manual: RM24918 RM84918Antonio GonçalvesNo ratings yet

- Green IT Project Outline and Practical ApplicationsDocument29 pagesGreen IT Project Outline and Practical ApplicationsRahul Yadav100% (1)

- Saudi Aramco Inspection Checklist: Visual Inspection of Pneumatic Test SAIC-A-2021 25-May-05 MechDocument1 pageSaudi Aramco Inspection Checklist: Visual Inspection of Pneumatic Test SAIC-A-2021 25-May-05 MechphilipyapNo ratings yet

- 2021-12-Clamp Proximity Sensor TestingDocument4 pages2021-12-Clamp Proximity Sensor TestingSARET respaldoNo ratings yet

- Es100 114 Zise20Document48 pagesEs100 114 Zise20Matias CzarnotaNo ratings yet

- B.tech. (Mechanical Engineering), 5th SemesterDocument70 pagesB.tech. (Mechanical Engineering), 5th SemesterGurdeep SinghNo ratings yet

- Manual CX600 X8Document261 pagesManual CX600 X8volicon voliconNo ratings yet

- Vba Codes ExcelDocument46 pagesVba Codes ExcelKen Matsuda100% (1)

- 08 - Installation and Maintenance of Health IT Systems - Unit 9 - Creating Fault-Tolerant Systems, Backups, and Decommissioning - Lecture CDocument15 pages08 - Installation and Maintenance of Health IT Systems - Unit 9 - Creating Fault-Tolerant Systems, Backups, and Decommissioning - Lecture CHealth IT Workforce Curriculum - 2012No ratings yet

- BPB31103 Production & Operations Management ch7Document60 pagesBPB31103 Production & Operations Management ch7Anis TajuldinNo ratings yet

- Coc: A Unified Distributed Ledger Based Supply Chain Management SystemDocument12 pagesCoc: A Unified Distributed Ledger Based Supply Chain Management SystemLove GolaNo ratings yet

- Lahan GATIBIDI 80 Asar Text Press FinalDocument89 pagesLahan GATIBIDI 80 Asar Text Press FinalRajan Kumar DahalNo ratings yet

- ANALYSISTABS Sample Dashboard Sales DataDocument232 pagesANALYSISTABS Sample Dashboard Sales Datapuran1234567890No ratings yet

- dgtww201311 DL PDFDocument60 pagesdgtww201311 DL PDFvrider81No ratings yet

- Digital Circuits and Logic Design Lecture OverviewDocument42 pagesDigital Circuits and Logic Design Lecture Overviewramanaidu1No ratings yet

- TH L47E5S Panasonic+ (TNPH0993)Document60 pagesTH L47E5S Panasonic+ (TNPH0993)Luiz Gustavo SantosNo ratings yet

- V Series: User'S Manual SetupDocument109 pagesV Series: User'S Manual SetupTFNo ratings yet

- Arnold S. Berger - Embedded Systems Design - An Introduction To Processes, Tools, and Techniques-CMP Books (2001)Document1 pageArnold S. Berger - Embedded Systems Design - An Introduction To Processes, Tools, and Techniques-CMP Books (2001)Anonymous 6WoK61sYpyNo ratings yet

- Kirloskar Technologies P. LTD.: Appraisal FormDocument4 pagesKirloskar Technologies P. LTD.: Appraisal Formdihudi.prasantaNo ratings yet

- Errer Code List Konica 7145Document16 pagesErrer Code List Konica 7145Pamela MitchellNo ratings yet

- 67 Jbiet Civil R14 Syllabus PDFDocument161 pages67 Jbiet Civil R14 Syllabus PDFGaddam SudheerNo ratings yet

- Electronic Hand Control MH 2000Document3 pagesElectronic Hand Control MH 2000Christian ChumpitazNo ratings yet

- A Survey of VPN Performance EvaluationDocument5 pagesA Survey of VPN Performance EvaluationEditor IJRITCCNo ratings yet

- Telefone IP 8002 - 80012Document3 pagesTelefone IP 8002 - 80012Ronaldo JoseNo ratings yet

- 18CS202J Object Oriented Design and Programming: Unit - 1Document103 pages18CS202J Object Oriented Design and Programming: Unit - 1vasu buchingariNo ratings yet

- SPPC OperatorManual V100 EN 03 PDFDocument26 pagesSPPC OperatorManual V100 EN 03 PDFhaitan981No ratings yet

- Ahmad RaqibDocument3 pagesAhmad RaqibMohamad IkhwanNo ratings yet