Professional Documents

Culture Documents

Basic Emulsion QC Sheet

Uploaded by

Francheska Caniones LlanesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Basic Emulsion QC Sheet

Uploaded by

Francheska Caniones LlanesCopyright:

Available Formats

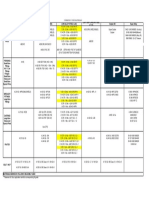

BASIC EMULSION A.

Quality Control Sheet Appearance: creamy, white, thick homogenous mixture Volume: 10 mL pH: Pourability: easily pourable Redispersability: redispersable Particle size-Apperance Relationship: > 1 m, milky Physical Stability: Aggregation, Coalescence, Creaming, Microbial growth, Oxidative decomposition, Phase Inversion, Sedimentation Test Preparation A (w/o) Preparation B (o/w) Dilution Test Dissolves in oil; not dissolved in water Dissolves in water; not dissolved in oil Conductivity Test Does not light the lamp Lights up lamp Dye-Solubility Test Oil-soluble dye colors the solution; water-soluble dye forms colored aggregates Water-soluble dye colors the whole emulsion; oil-soluble dye forms colored aggregates CoCl2/Filter Paper Test CoCl2 paper stays colored blue CoCl2 paper changes from blue to pink Fluorescence Test No dotted pattern Forms dotted pattern Packaging Requirement: Preserve in well-closed containers. Label: Shake well before use Container: 15mL flint bottle Cap: Black plastic screw cap with cap liner B. Label C. Schematic Diagram D. Answers to Guide Questions 1. Official Title: non-official Category: Gastrointestinal Drug Synonyms: None Uses: - Enhances drug stability - Masking of unpleasant odor or taste of drug - Enhanced absorption of drugs & oil because of the reduced particle size of the internal phase - Absorption rate and permeation of medicaments are controlled - Suitability for topical application 2. Review of Basic Concepts: a. Dispersed Systems/ Emulsions Emulsions are dispersions in which the dispersed phase is composed of small globules of a liquid distributed throughout a vehicle in which it is immiscible. Emulsions are two-phase systems of two immiscible liquids. b. Types of Emulsions > Macromolecule emulsion the coarse pharmaceutical macroemulsions appear white and tend to separate on standing * Oil in Water (o/w) emulsion with an oleaginous internal phase and an aqueous external phase an emulsifying agent w/ hydrophilic character will promote an o/w emulsion present in casein, egg yolk, gelatin * Water in Oil (w/o) emulsion with an aqueous internal phase & an oleaginous external phase an emulsifying agent with hydrophobic character will promote w/o emulsion > Multiple emulsion dispersed phase of 3 emulsions which contain even smaller droplets which are miscible with the continuous phase; emulsions within emulsions both hydrophilic & hydrophobic emulsifiers are used & both have an effect on the yield and stability; multiple emulsions are used to separate 2 incompatible substances * Oil in Water (o/w) the aqueous phase is between the two oil phases * Water in Oil (w/o) the internal and external aqueous phases are separated by an oil phase > Microemulsion translucent or transparent, does not separate and has a droplet diameter in the nanometer size range

microemulsion is thermodynamically stable, optically transparent, isotropic mixtures of a biphasic oil-water system stabilized with surfactants Activity To Be Expected from Surfactants with Assigned HLB Numbers HLB Range Activity 0 3 antifoaming 4 6 emulsifiers (w/o) 7 9 wetting agents 8 18 emulsifiers (o/w) 10 18 solubilizers 13 15 detergents c. Basic Components of an Emulsion, with examples > Internal Phase/ Discontinuous Phase / Dispersed Phase o Ex. Water, oil > External Phase/ Continuous Phase / Dispersing Medium o Ex. Water, oil > Emulsifying Agent o (Natural) egg yolk, gelatine, casein, acacia, tragacanth, chondrus o (Synthetic) sodium lauryl sulphate, benzalkonium chloride, polyethylene glycol 400 monostearate, Span, Tween d. Uses of Ingredients * Mineral oil/water solvent * Mineral oil/ water internal phase * Span 80 / Tween 80 emulsifier * Viscosity agents * Preservatives e. RFIS 1. Heat mineral oil to 60oC. To incorporate emulsifier effectively 2. Heat water to 65oC. To incorporate emulsifier effectively 3. Maintain at 70-72oC after mixing the 2 phase. Temperature at which the 2 phases are in maximum contact with each other 4. Constant stirring. To disperse the globules evenly f. Procedure and Specifications for the ff QC tests: 1) Particle Size-Appearance relationship Droplet Size Appearance > 1 m Milky 0.1 1 m Blue-white (Tyndall effect) 0.05 0.1 m Gray, semi-transparent < 0.05 m Transparent 2) Methods of determining emulsion type > Dilution test depends on the fact that an o/w emulsion can be diluted with water and aw/o emulsion, with oil when oil is added to an o/w emulsion or water to a w/o emulsion, the additive is not incorporated into the emulsion and separation is apparent is greatly improved if the addition of water or oil is observed microscopically > Conductivity test higher conductivity is observed in an emulsion in which the continuous phase is aqueous compared to an emulsion with an oleaginous continuous phase usually, if a pair of electrodes, connected to a lamp and an electrical source, is dipped in an o/w emulsion, the lamp will light up due to passage of a current between the two electrodes if the lamp does not light, the emulsion is assumed to be the w/o type > Dye-solubility test basis: a water-soluble dye will dissolve in the aqueous phase of an emulsion while an oil-soluble dye will be taken up by the oil phase o/w emulsion: if microscopic examination shows that a water-soluble dye has been taken up the continous phase

w/o emulsion: water-soluble dye did not stain the continuous phase, but upon addition of oil-soluble dye, coloring of the continuous phase occurs > CoCl2/Filter Paper test filter paper with cobalt chloride will become blue from pink in an o/w emulsion > Flourescence test ultraviolet light thru w/o emulsion will exhibit dot patterns in o/w emulsions, the fluorescence is shown throughout the emulsion From USP 32 EMULSIONS Emulsions are two-phase systems in which one liquid is dispersed throughout another liquid in the form of small droplets. Where oil is the dispersed phase and an aqueous solution is the continuous phase, the system is designated as an oil-in-water emulsion. Conversely, where water or an aqueous solution is the dispersed phase and oil or oleaginous material is the continuous phase, the system is designated as a water-in-oil emulsion. Emulsions are stabilized by emulsifying agents that prevent coalescence, the merging of small droplets into larger droplets and, ultimately, into a single separated phase. Emulsifying agents (surfactants) do this by concentrating in the interface between the droplet and external phase and by providing a physical barrier around the particle to coalescence. Surfactants also reduce the interfacial tension between the phases, thus increasing the ease of emulsification upon mixing. Natural, semisynthetic, and synthetic hydrophilic polymers may be used in conjunction with surfactants in oil-inwater emulsions as they accumulate at interfaces and also increase the viscosity of the aqueous phase, thereby decreasing the rate of formation of aggregates of droplets. Aggregation is generally accompanied by a relatively rapid separation of an emulsion into a droplet-rich and droplet-poor phase. Normally the density of an oil is lower than that of water, in which case the oil droplets and droplet aggregates rise, a process referred to as creaming. The greater the rate of aggregation, the greater the droplet size and the greater the rate of creaming. The water droplets in a water-in-oil emulsion generally sediment because of their greater density. The consistency of emulsions varies widely, ranging from easily pourable liquids to semisolid creams. Generally oilin-water creams are prepared at high temperature, where they are fluid, and cooled to room temperature, whereupon they solidify as a result of solidification of the internal phase. When this is the case, a high internalphase volume to external-phase volume ratio is not necessary for semisolid character, and, for example, stearic acid creams or vanishing creams are semisolid with as little as 15% internal phase. Any semisolid character with water-in-oil emulsions generally is attributable to a semisolid external phase. All emulsions require an antimicrobial agent because the aqueous phase is favorable to the growth of microorganisms. The presence of a preservative is particularly critical in oil-in-water emulsions where contamination of the external phase occurs readily. Since fungi and yeasts are found with greater frequency than bacteria, fungistatic as well as bacteriostatic properties are desirable. Bacteria have been shown to degrade nonionic and anionic emulsifying agents, glycerin, and many natural stabilizers such as tragacanth and guar gum. Complications arise in preserving emulsion systems, as a result of partitioning of the antimicrobial agent out of the aqueous phase where it is most needed, or of complexation with emulsion ingredients that reduce effectiveness. Therefore, the effectiveness of the preservative system should always be tested in the final product. Preservatives commonly used in emulsions include methyl-, ethyl-, propyl-, and butyl-parabens, benzoic acid, and quaternary ammonium compounds.

You might also like

- Emulsions PDFDocument56 pagesEmulsions PDFRebecca Chen100% (2)

- Women Institute of Learning AbbottabadDocument15 pagesWomen Institute of Learning AbbottabadRida syedNo ratings yet

- Herbal Cosmetics Handbook - Chapter 'COSMETIC EMULSIONS'Document54 pagesHerbal Cosmetics Handbook - Chapter 'COSMETIC EMULSIONS'randatagNo ratings yet

- EmulsionDocument53 pagesEmulsionSyifaturrahmah Nurfalah67% (3)

- DemulsifiersDocument3 pagesDemulsifiersAnand ChristyNo ratings yet

- Emulsion Dosage FormDocument11 pagesEmulsion Dosage FormKinza WaqasNo ratings yet

- Emulsion S: By: Hannako Faith NgohayonDocument44 pagesEmulsion S: By: Hannako Faith NgohayonHannako NgohayonNo ratings yet

- Presented By: Bakhtawar WaseemDocument37 pagesPresented By: Bakhtawar WaseemshahzadibakhtawarNo ratings yet

- Formulation of EmulsionDocument8 pagesFormulation of EmulsionSyafiqah ZainoddinNo ratings yet

- Publication 11 16756 6264 PDFDocument8 pagesPublication 11 16756 6264 PDFVikram VermaNo ratings yet

- pdf 20221120 193206 ٠٠٠٠Document68 pagespdf 20221120 193206 ٠٠٠٠asma2002mhNo ratings yet

- EmulsionsDocument26 pagesEmulsionskhelicu517No ratings yet

- Emulsions: Lec 1 Ansel's Pharmaceutical Dosage Forms and Drug Delivery Systems DR Hala SadeqDocument26 pagesEmulsions: Lec 1 Ansel's Pharmaceutical Dosage Forms and Drug Delivery Systems DR Hala SadeqHM A92No ratings yet

- Pharmaceutics I: Emulsions and Emulsifying Agents (o/w, w/oDocument91 pagesPharmaceutics I: Emulsions and Emulsifying Agents (o/w, w/oKausik SenNo ratings yet

- (Pp.401-411) Dry Method-Ex of Magmas and GelsDocument11 pages(Pp.401-411) Dry Method-Ex of Magmas and GelsJicah Mae LumbaoNo ratings yet

- EmulsionDocument10 pagesEmulsionfdt11No ratings yet

- Mineral Oil Emulsion GuideDocument7 pagesMineral Oil Emulsion GuideLlang LleavNo ratings yet

- Emulsion Preparation MethodsDocument12 pagesEmulsion Preparation MethodsMariam BurhanNo ratings yet

- Pharmaceutical EmulsionsDocument28 pagesPharmaceutical EmulsionsEph RemNo ratings yet

- Identify Emulsion Type TestsDocument5 pagesIdentify Emulsion Type Testssterilization100% (1)

- Emulsions ExplainedDocument24 pagesEmulsions Explainedabdullah2020No ratings yet

- EmulsionsDocument24 pagesEmulsionsRohan SinghNo ratings yet

- SPO 2018 EmulsionDocument38 pagesSPO 2018 Emulsionsnow keykkNo ratings yet

- Mr. Saran Kumar Das Ms. Deepika U M.Pharm Department of PharmaceuticsDocument36 pagesMr. Saran Kumar Das Ms. Deepika U M.Pharm Department of PharmaceuticsChilaNo ratings yet

- 634798775670659161Document41 pages634798775670659161Suvin PsNo ratings yet

- EmulsionsDocument24 pagesEmulsionsgkunal991No ratings yet

- Emuslion LabDocument34 pagesEmuslion Labfmousli123No ratings yet

- Surfactants - Emulsifiers Surfactants EmulsifiersDocument62 pagesSurfactants - Emulsifiers Surfactants EmulsifiersUmut Erkılıç100% (1)

- Pharmaceutical EmulsionsDocument55 pagesPharmaceutical EmulsionschandramohanNo ratings yet

- Multiple Emulsions: Complex Systems for Encapsulation and Controlled ReleaseDocument46 pagesMultiple Emulsions: Complex Systems for Encapsulation and Controlled Releaseved.g007No ratings yet

- RDR Emulsions NewDocument7 pagesRDR Emulsions NewCynthia Grace Dela CruzNo ratings yet

- EmulsionsDocument47 pagesEmulsionsmanubaba123No ratings yet

- Understanding EmulsionsDocument86 pagesUnderstanding EmulsionsMusfira KhalidNo ratings yet

- Industrial Pharmaceutics Semester 8 Sir. Talib HussainDocument9 pagesIndustrial Pharmaceutics Semester 8 Sir. Talib HussainMuhammad KafeelNo ratings yet

- EmulsiDocument53 pagesEmulsiYohana KedangNo ratings yet

- EmulsionDocument13 pagesEmulsionPriyanka KushwahaNo ratings yet

- Oil/water separation technologies guideDocument3 pagesOil/water separation technologies guiderohitkushNo ratings yet

- Emulsion ConsistencyDocument23 pagesEmulsion ConsistencyAgista AmaliaFirdausNo ratings yet

- EMULSIFICATIONDocument9 pagesEMULSIFICATIONmukailaridwan1No ratings yet

- EmulsionDocument4 pagesEmulsionAh Rep BeanNo ratings yet

- Industrial Preparation of Demulsifiers: Theory and ApplicationsDocument14 pagesIndustrial Preparation of Demulsifiers: Theory and Applicationswahab aliNo ratings yet

- EMULSIONSDocument10 pagesEMULSIONSsahilarrain0011No ratings yet

- 734 Part2 EmulsionDocument28 pages734 Part2 EmulsionRabiya KhanNo ratings yet

- Emulsions & SunscreensDocument117 pagesEmulsions & SunscreensQuoc Thanh100% (1)

- Emuls KrimDocument66 pagesEmuls KrimPutri Zahra ArdiyanitaNo ratings yet

- EMULSIONSDocument24 pagesEMULSIONSMaria Natalia Tambunan100% (6)

- PHT 312: Pharmaceutics II - EmulsionsDocument55 pagesPHT 312: Pharmaceutics II - EmulsionsMAHALAKSHMI S100% (1)

- مورينيوDocument6 pagesمورينيوaltabym223No ratings yet

- JOHNSON OLAMIDE-WPS OfficeDocument14 pagesJOHNSON OLAMIDE-WPS OfficeMark GalantyNo ratings yet

- Lec. 1 EmulsionDocument13 pagesLec. 1 EmulsionSujitha DineshNo ratings yet

- Pharmaceutical Emulsions ExplainedDocument28 pagesPharmaceutical Emulsions ExplainedSuvin PsNo ratings yet

- PHT 312 EmulsionDocument45 pagesPHT 312 EmulsionChristopher GambleNo ratings yet

- Plant and Animal Bio-Chemistry - Including Information on Amino Acids, Proteins, Pigments and Other Chemical Constituents of Organic MatterFrom EverandPlant and Animal Bio-Chemistry - Including Information on Amino Acids, Proteins, Pigments and Other Chemical Constituents of Organic MatterNo ratings yet

- Soap-Making Manual: A Practical Handbook on the Raw Materials, Their Manipulation, Analysis and Control in the Modern Soap PlantFrom EverandSoap-Making Manual: A Practical Handbook on the Raw Materials, Their Manipulation, Analysis and Control in the Modern Soap PlantNo ratings yet

- Soap-Making Manual. A practical Handbook on the RControl in the modern Soap PlantFrom EverandSoap-Making Manual. A practical Handbook on the RControl in the modern Soap PlantRating: 5 out of 5 stars5/5 (2)

- Simple Homemade Lotion: Easy Homemade Beauty Products For A Silky Soft, Gorgeous And Radiant Looking Skin!From EverandSimple Homemade Lotion: Easy Homemade Beauty Products For A Silky Soft, Gorgeous And Radiant Looking Skin!No ratings yet

- The Chemistry of Dairy Products - A Chemical Analysis of Milk, Cream and ButterFrom EverandThe Chemistry of Dairy Products - A Chemical Analysis of Milk, Cream and ButterNo ratings yet

- Soap Manufacturing TechnologyFrom EverandSoap Manufacturing TechnologyLuis SpitzRating: 4 out of 5 stars4/5 (6)

- List of Pakistani Lubricant PlantsDocument4 pagesList of Pakistani Lubricant Plantschem Khan0% (1)

- Workbook 8Document9 pagesWorkbook 8JenniferNo ratings yet

- ASME P No. and GR PDFDocument2 pagesASME P No. and GR PDFnoell gunawanNo ratings yet

- Homogenous and Hetrogenous SubstancesDocument3 pagesHomogenous and Hetrogenous SubstancesAravindSureshNo ratings yet

- 东欧和独联体国家的合金厂Document1 page东欧和独联体国家的合金厂Nick SiNo ratings yet

- D8-13b Standard Terminology Relating To Materials For Roads and PavementsDocument4 pagesD8-13b Standard Terminology Relating To Materials For Roads and PavementsVag KatsikopoulosNo ratings yet

- Science6 q1 Mod1les5 Colloids and Their Characteristics FINAL08032020Document19 pagesScience6 q1 Mod1les5 Colloids and Their Characteristics FINAL08032020Godgiven Blessing100% (4)

- Compro Shellindo PDFDocument13 pagesCompro Shellindo PDFAndhika Aulia PratamaNo ratings yet

- Steel Grade Equivalency TableDocument2 pagesSteel Grade Equivalency TableBudy GedhaBlackNo ratings yet

- Conductivity of Metals Sorted by Resistivity - Eddy Current TechnologyDocument6 pagesConductivity of Metals Sorted by Resistivity - Eddy Current TechnologyAddi VitryNo ratings yet

- Pet111 Ass 3Document3 pagesPet111 Ass 3mghareebNo ratings yet

- ApagscanDocument14 pagesApagscanSafri IchsanNo ratings yet

- High Temp. Alloy UNS N02200 N07080: Uns No Description Brand/Trp ASTM EquivalentDocument36 pagesHigh Temp. Alloy UNS N02200 N07080: Uns No Description Brand/Trp ASTM Equivalent윤병택No ratings yet

- DESCON HSE Report FromatDocument64 pagesDESCON HSE Report FromatCesar ReyesNo ratings yet

- Consolidated List of CRMs & SRMs IRON PDFDocument3 pagesConsolidated List of CRMs & SRMs IRON PDFearth metallurgical services pvt.ltd.No ratings yet

- Chapter 2, Unit 2, Pharmaceutical Analysis, B Pharmacy 1st Sem, Carewell PharmaDocument7 pagesChapter 2, Unit 2, Pharmaceutical Analysis, B Pharmacy 1st Sem, Carewell Pharmayash08jan01No ratings yet

- Bitumen Fuel Prices Monthly ReportDocument3 pagesBitumen Fuel Prices Monthly Reportkarunamoorthi_p2209No ratings yet

- Theory Hours 08:45-09:35 09:40 - 10:30: Lab Hours 08:45-10:30 Course CodeDocument6 pagesTheory Hours 08:45-09:35 09:40 - 10:30: Lab Hours 08:45-10:30 Course CodeKalyan AlluriNo ratings yet

- Heavy Oil's Production ProblemsDocument22 pagesHeavy Oil's Production Problemsalfredo moran100% (1)

- Marshall Mix DesignDocument2 pagesMarshall Mix DesignTakdir Satria NandaNo ratings yet

- Tipuri de Otel Inoxidabil CalitatiDocument2 pagesTipuri de Otel Inoxidabil CalitatiCorina MarcuNo ratings yet

- Commonly Used MaterialDocument1 pageCommonly Used MaterialJitendra PrasadNo ratings yet

- Summative No.1 Q1 (Eng, Sci, Math, AP, Music)Document13 pagesSummative No.1 Q1 (Eng, Sci, Math, AP, Music)Jhen SalamatNo ratings yet

- Control Sheet RwadDocument9 pagesControl Sheet RwadrawadNo ratings yet

- Petroleum Consumption Analysis April 2019-March 2020Document1 pagePetroleum Consumption Analysis April 2019-March 2020Ayush BishtNo ratings yet

- Crude Oil in SaskatchewanDocument5 pagesCrude Oil in Saskatchewan404 System ErrorNo ratings yet

- Vertical Well All CasesDocument21 pagesVertical Well All CasesbhupenderNo ratings yet

- Amenam Blend: Loading Facilities - Port DataDocument1 pageAmenam Blend: Loading Facilities - Port Datadassi99No ratings yet

- Spartan Carbide CatalogDocument31 pagesSpartan Carbide CatalogAnkit ChawlaNo ratings yet

- Home TrendsDocument29 pagesHome TrendsSHALINI NIGAMNo ratings yet