Professional Documents

Culture Documents

Viscosity Measurements

Uploaded by

Suseel Jai KrishnanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Viscosity Measurements

Uploaded by

Suseel Jai KrishnanCopyright:

Available Formats

International Journal of Engineering Research & Technology (IJERT) ISSN: 2278-0181 Vol.

1 Issue 8, October - 2012

On Prediction Of Viscosity Of Nanofluids For Low Volume Fractions Of Nanoparticles

N. Siva Shanker1,M. Chandra Shekar Reddy2 and V. V. Basava Rao1*

1 2

University College of Technology, Osmania University, Hyderabad-07, India Sreenidhi Institute of Science and Technology, Ghatkesar, Hyderabad, India ABSTRACT

Nanofluid which is consisting of nanoparticles in base fluid has high performance of heating and cooling in an industrial process and may create a saving in energy. The flow behavior of nanofluid plays a vital role in designing of Heat transfer equipment. Therefore, the prediction of viscosity of nanofluid which depends on base fluid properties, type of nanoparticles, temperature and particle volume fraction is now a challenging task. In the present paper, the literature review on viscosity models have been made and presented briefly. The viscosity of nano fluids made with SiO2 (35nm), ZnO (40nm) and Al2O3 (27& 45nm) in base fluid of 70wt% Glycerol and water mixture were measured using Rheometer. The volume fraction(0.001 to 0.1) effect, temperature(30 80oC ) and particle diameter effect on variations of viscosity of nano fluids analyzed and found that the viscosity increases with volume fraction and exponentially decreases with increasing temperature. Finally, the regression analysis was done to correlate a suitable an equation for estimation of viscosity. Keywords: Nano fluid, Volume fraction, Base fluid, 70wt% glycerol and water solution, Viscosity, Rheometer, Correlation 1.0 INTRODUCTION The enhancement of heating or cooling in an industrial process may create a saving in energy, reduce process time, raise thermal rating and lengthen the working life of equipment. Some processes are even affected qualitatively by the action of enhanced heat transfer. The development of high performance thermal systems for heat transfer enhancement has become popular nowadays. Heat transfer can be enhanced using nanofluids, which consisting nanoparticles in base fluid instead of the original pure fluid because the suspended ultrafine particles significantly increase the thermal conductivity of the mixture and improve its capability of energy exchange. The enhancement mainly depends upon factors such as the shape of particles, the particles size, the volume fractions of particles in the suspensions and the thermal properties of particle materials. Flow behaviour of nanofluids is one of the new challenges for thermo-science provided by the nanotechnology. The nanoparticles Al2O3, CuO, TiO2, ZnO and SiO2 are in commonly use for the major research. The base fluid is normally water, mixture of water with ethylene glycol and engine oil as cooling agent, but it is depend on the type of application and use. The viscosity is one of the very important properties of nanofluids which are essential for the

IJE

RT

www.ijert.org

International Journal of Engineering Research & Technology (IJERT) ISSN: 2278-0181 Vol. 1 Issue 8, October - 2012

evaluation of heat transfer coefficient. This may vary with volume fraction & size of the nanoparticles and temperature of the nanofluid. In order to find the variation of viscosity, many theoretical models were available in the literature [1, 2, 3]. The liquid layering, particle size,particle shape, particles interaction, and dispersion techniques are the depending factors for determining the nanofluids viscosity. The classical model equation [4, 5,6, 7]is based on the assumption of dilute, suspended, spherical particles and no interaction between the nanoparticles. It is valid for relatively low particle volume fractions of nanoparticles. Maiga et al [8] proposed a viscosity model equation based on theparticle volume fraction for Al2O3 /water nanofluids and reported the effective viscosity increases when particlevolume fraction is increased.The temperature variation in viscosity for the range of particle volumefraction of 1% - 4%, reported by [4,7,9,10] for mono particle size (36 nm).Chung et al [11] developed an exponential equation based onkinetic gas theories and correlated with the experimentaldata. They considered the base fluid viscosity and particle volume fraction into account and the particle size and interaction between the particles were not considered. This model found to be more useful for two phase flow having with particles size larger than 100nm. Kulkarni et al [12] proposed an equation for CuO/water nanofluid and for a temperature range of 5-50oC. It shows the exponential decrease of viscosity when temperature is increased. Namburu et al [13] developed another equation for various particle volume fractions of Al2O3, for a temperature range of 5-50oC and for 60:40 ethylene glycol & water as base fluids. It is also found that the exponential decreases of viscosity when temperature is raised.Tseng and Lin [14] also suggested an exponential model equation based on the particle volume fraction for TiO2 / water nanofluids. Drew and Passman [15] introduced the well known Einstein model for dilute suspension, small size spherical particles and for two phase mixture at low particle volume fraction. Further, Graham [10] presented a generalized equation by considering the particle radius and inter-particle space for small particle volume fraction. Masoumi et al [15] formulated an equation based on the Brownian motion of the particles and reported that it is applicable for Al2O3/water nanofluids. White [16] developed an equation for Al2O3 / water and ethylene glycol based nanofluids. Many of the investigators ([17], [18], [19] and [20]) used different equations and they underestimate the effective viscosity of the nanofluids. Based on the review, nanofluid viscosity significantly increases when particle volume fraction is increased anddecreases when temperature increases. Also, viscosity of nanofluid depends on many parameters such as base fluids,nanoparticle volume fraction, particle size, particle shape,temperature, surface charge, pH value, base fluid and dispersion techniques. However no theoretical formula is currently available to predict the nanofluid viscosity with good accuracy.

IJE

RT

www.ijert.org

International Journal of Engineering Research & Technology (IJERT) ISSN: 2278-0181 Vol. 1 Issue 8, October - 2012

2.0 EXPERIMENTAL WORK 2.1 Methods of nanofluid preparation SiO2 (35 nm), ZnO (40 nm) and Al2O3 (27 & 45nm) nanoparticlessupplied by Sigma-Aldrich Chemicals Ltd, Germany have been used to prepare the nanofluid with 70wt% glycerol and water solution as the base fluid. One of the major limitations for commercial application of nanofluid is the difficulty of uniform dispersion in the base fluid and the sedimentation of nanoparticles with time. To avoid the sedimentation of nanoparticles with time, small quantities of surfactants are to be added to the base fluid and it helps sustain dispersion of nanoparticles. To achieve uniform dispersion of nanoparticles and sustain the fluid for longer duration from sedimentation, stirring the mixture for 12 to 16 hour duration was adopted. Sodium Dodecyl Benzene Sulfonate (SDBS) was used as surfactant in the preparation of nanofluid. Nanofluid at different volume fractions in the range of 0.001 - 0.01 was prepared for property evaluation. Nanofluid samples were prepared using 70 wt% of Glycerol and water solution as base fluid. To prepare nanofluid of specific volume fraction, samples were first prepared by adding SDBS surfactant in different proportions to Glycerol + water solution and the mixtures stirred in a magnetic bath for 10 minutes. The nanoparticles were then added and stirred continuously for 16 hours and the samples observed for dispersion and stability.It is observed that SDBS weighing one tenth the weight of nanoparticles added to base fluid gives uniform dispersion without sedimentation.

IJE

Volume fraction ()

RT

p p

Wp

Wp Wbf

(1)

bf

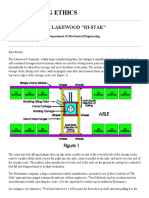

2.2 Evaluation of nanofluid properties The properties of nanofluid such as density, absolute viscosity, were estimated experimentally and compared with relevant equations available in literature. 2.2.1 Density The density of nanofluid at different volume concentrations and temperatures were measured. The values were compared with the calculated values using the equation (2). nf P 1 bf (2) 2.2.2 Absolute viscosity The experimental setup for measurement of viscosity of nanofluids using SiO2 (35 nm), ZnO (40 nm) and Al2O3 (27, 45nm) with 70 wt% Glycerol and water as the base fluid is as shown in Figure1 and it consists of a programmable R/S+ cylindrical rheometer with temperature controlled bath. The rheometer is calibrated using the standard fluids. The spindle type and its speed combinations will produce results with accuracy when the applied torque is in the range of 10% to100% and accordingly the spindle is chosen. Spindle CC45 DIN is used in the rheometer. The nanofluids under test are poured in the sample chamber of the rheometer.

www.ijert.org

International Journal of Engineering Research & Technology (IJERT) ISSN: 2278-0181 Vol. 1 Issue 8, October - 2012

The spindle immersed and rotated in the nanofluids in the speed ranging from 387 to 540 rpm in steps of 12 seconds. A temperature control system is activated to vary the temperature of the test sample. The viscous drag of the fluid against the spindle is measured by the deflection of the calibrated spring. The shear rate, shear strain and viscosity data at room temperature is recorded by a data logger. The Rheometer is having accuracy within 1% of the full scale range of the spindle /speed combination. The reproducibility of test data is found to be within .2%.

Figure 1 Schematic diagram of the viscosity measurement instrument

The Viscosity of nanofluid was also measured using Redwood-1 viscometer at different volume fractions of nanoparticles and temperatures. The equipment was calibrated with water and the absolute viscosity of the nanofluid was then determined.

3.0 RESULTS AND DISCUSSION Masoumi et al [15] and Madhusree & Dey [21] evaluated the viscosity using = +

2

IJE

72

RT

(3)

The correction factor (C) is calculated from 1 = ( + ) (4) The a and b experimental parameters are estimated for all the nanofluids used in the present study. Using equation (3), the viscosities are calculated and it is found that the equation (3) predicts the measured viscosity fairly well. Also Madhusree & Dey [21] show that for low loading of nanoparticles, the nanofluid reveals Newtonian behaviour only at high temperatures. 3.1 Effect of Volume fraction of Nanoparticles on Viscosity Figures 2 and 3show the effect of nanoparticle volume fraction on viscosity of the nanofluid at various temperatures. At all temperatures, nanofluid viscosity increases with increasing

www.ijert.org

International Journal of Engineering Research & Technology (IJERT) ISSN: 2278-0181 Vol. 1 Issue 8, October - 2012

nanopartcle volume fraction. Qualitatively, a similar trend has also been observed in all types of nanofluids used in the present study.

20 18 16

Temperature

30C Series1 40C Series2 50C Series3 60C Series4 70C Series5 80C Series6

Viscosity (cP)

14 12 10 8 6 4 2 0 0 0.005 0.01 0.015

Volume fraction ()

Figure 2: Nanofluid viscosity variation with volume fractions of SiO2 nanoparticles using Glycerol as base fluid

20 18 16 Viscosity (cP) 14 12 10 8 6 4 2 0 0 0.002 0.004

RT IJE

0.006 0.008 0.01 Volume fraction ()

Temperature

Series1

40C Series2

Series3 50C Series4 60C

70C Series5 80C Series6

0.012

Figure 3: Nanofluid viscosity variation with volume fraction of Al2O3 (27nm) Particles: Base fluid as Glycerol 3.2 Effect of Temperature on Viscosity of nanofluid Figures 4 and 5 show the temperature effect on viscosity of nanofluid with various volume fractions. The viscosity of the nanofluid decreases exponentially with temperatures of the

www.ijert.org

International Journal of Engineering Research & Technology (IJERT) ISSN: 2278-0181 Vol. 1 Issue 8, October - 2012

nanofluid and similar trend have also been observed for all the nanofluids used in the present study.

20 18 16 Viscosity (cP) 14 12 10 8 6 4 2 0 0 20 40 60 80 100

Volume fraction

Series1 0.000 Series2 0.002 Series3 0.004

0.006 Series4 0.008 Series5

Series6 0.010

Temperature(C)

Figure 4: Nanofluid Viscosity variations using ZnO nanoparticles and Glycerol

25

RT IJE

0 20 40 60 80 Temperature (C)

20 Viscosity (cP) 15 10 5 0

Volume fraction

0.000 Series1 0.002 Series2

Series3 0.004 Series4 0.006

0.008 Series5 0.010 Series6

100

Figure 5: Nanofluid Viscosity Variations using Al2O3 nanoparticles and Glycerol Further, it can be observed from the figure 6 that the nanofluid prepared by Al2O3 (27 nm) and base fluid of 70 wt% Glycerol and water solution shows the highest viscosity. Whereas remaining nanofluids prepared by SiO2 (35 nm), ZnO (40 nm) and Al2O3 (45nm) in the base fluid of 70 wt% Glycerol and water solution shows decreasing order of viscosities. Since the particle concentration is considerably low (less than 1 vol%), the formation of aggregates are prevented in the nanofluids. Also, figure 6 depicts the decrease in the viscosity when particle size increases irrespective of the type of the nanoparticle. This indicates there can be

www.ijert.org

International Journal of Engineering Research & Technology (IJERT) ISSN: 2278-0181 Vol. 1 Issue 8, October - 2012

generalized equation for low volume fraction of nanoparticles in the nanofluid (less than 1 vol%).

20 18 16 Viscosity (cP) 14 12 10 8 6 4 2 0 0 20 40 60 80 100 Type of Particle Series1 Base Fluid Series2(27nm) Al2O3 0.002 Series3 Si0 (35nm)

2

ZnO (40nm) Series4

Series5 Al2O3 (45nm)

Temerature (C)

Figure 6: Nanofluid Viscosity variations using various nanoparticels and Glycerol as base fluid

nf bf 1 39.11 533.9 2

IJE

3.3Theoretical Models and Correlation for Viscosity The viscosities at different volume fractions of the nanoparticles are also calculated using equation (3) in comparison with the values of Pak and Cho [19] (5)

For temperature dependence of viscosity the following equations have been proposed in the literature; = / = 1 = (6) [22] (7) [12] (8) [13,23]

The present experimental data of nanofluid viscosity show higher deviations with equations (6) and (7). It agrees very closely with equation (8). However, the coefficients of A and B values were evaluated by Namburu et al [23] for each volume fraction of Al2O3 nanoparticles in base fluid of engine coolant as = 225.245 2 + 18.404 + 1.749 = 575.835 3 32.101 2 + 0.148 + 0.011 (9) (10)

However, the above equation is not representing the particle size effect on the viscosity of nanofluids. Therefore, generalized regression equation is developed to include the effect of

RT

www.ijert.org

International Journal of Engineering Research & Technology (IJERT) ISSN: 2278-0181 Vol. 1 Issue 8, October - 2012

temperature, volume concentration and particle diameter in the estimation of nanofluid absolute viscosity given by log = 1.75 + 16.85 + 23.5

2

2

exp 0.015 + 0.15 31.3 2 + 5.65

(11)

Valid in the range 30<T <80C, 27<dp<45 nm, 0.0<<0.01 and obtained with AD of 1.17% and SD of 1.95%. 4.0 CONCLUSION Experimental values of viscosity ofSiO2 (35nm), ZnO (40nm) and A12O3 (27, 45nm) nanofluid at various volume fractions (less than 1 vol%) in base fluid of 70wt% Glycerol and Water are measured. The viscosity of nanofluids were observed to increase with volume fractions of nanoparticles and exponential decrease with increase in temperature. Generalized regression equation is developed to include the effect of temperature, volume concentration and particle diameter in the estimation of nanofluid absolute viscosity given 2 log = 1.75 + 16.85 + 23.5 2 exp 0.015 + 0.15 31.3 2 + 5.65 Valid in the range 30C < T < 80C, 27 < dp <45 nm, 0.0 < < 0.01 5.0 NOMENCLATURE a : Constant in equation (4) A : Constant in equations (6), (7) and (8) b : Constant in equation (4) B : Constant in equation (7) and (8) C : Correction factor in equation (3) dp : Diameter of the Particle (nm) T : Temperature (oC) VB : Volume of the Base Fluid, nm3 Wbf : Weight of Base Fluid, g Wp : Weight of the nanoparticles, g Greek Letters : Thickness of the nanolayer : Volume fraction of the nanoparticles bf : Viscosity of base fluid, cP nf : Viscosity of nanofluid, cP bf : Density of Base Fluid, g/cc nf : Density of nanofluid, g/cc p : Density of Particles, g/cc

IJE

RT

www.ijert.org

International Journal of Engineering Research & Technology (IJERT) ISSN: 2278-0181 Vol. 1 Issue 8, October - 2012

6.0 REFERENCES 1. A,K. Singh, Thermal conductivity of nanofluids, Defense Science J. vol.58. Sep 2008, pp. 600-607. 2. Y, Xuan, and Q. Li, Investigation on convective heat transferand flow features of nanofluids, J. Heat trans,vol.125, 2003,pp.151-155. 3. S. K, Das, N,Putra, P. Thesien, and W. Roetzel, Temperature dependence of thermal conductivity enhancement for nanofluids, J. Heat Trans, vol.125, 2003,pp. 567-574. 4. A. Einstein, EineneueBestimmung der Molekul dimensionen,Annalen der Physik19, 1906,pp. 289-306. 5. I.M. Krieger, and T.J.Dougherty,A mechanism for non-Newtonian flow in suspensions of rigid spheres, Trans .Soc.Rheol, vol.3, 1959. pp.137-152, 6. L.E. Niesen, Generalized equation for the elastic moduli of composite materials, J. Appl.Phy,vol.41, 1970,pp.4626- 4627. 7. G. K. Bachelor, The effect of Brownian motion on the bulkstress in a suspension of spherical particles, J. Fluidmech., vol.83, 1977,pp.97-117. 8. E.B. Maiga, C.T.N guyen, N. Galanis and G. Roy, Heat transfer behaviors of nanofluids in a uniformly heated tube, Superlattices and Microstructures, vol.35,pp. 2004, pp.543 -557. 9. T.S. Lundgren, Slow flow through stationary random beds and suspensions of spheres, J. Fluid Mechanics, vol.51,1972,pp.273 -299. 10. A.L.Graham, On the viscosity of suspensions of solid spheres, Appl. Sci, Res.vol, 37, 1981, pp.275-286. 11. T.H.Chung, L.Lee and K.E.Starling,Applications of kinetic gastheories and multi parameter correlation for prediction of dilutegas viscosity and thermal conductivity .Ind. Eng. Chem. res.vol.27,1998,pp.659-671. 12. D.P.Kulkarni, D. K. Das, G. A. Chukwi, Temperature dependent rheological property of CuO nanoparticles suspension, J. Nanosci. and Nanotech., vol. 6, 2006,pp.1150-1154. 13. D. K.Namburu, N.D.K. Das, K.M.Tanguturi, and K. S. Vijjha,Numerical study of turbulent flow and heat transfer characteristics of nanofluids containing variable properties, .Int.J. thermal sci., .ijthemalsci; 2008.01.001,2008. 14. W. J.Tseng, and K.C.Lin, Rheology and colloidal structure of aqueous TiO2 nanoparticle suspensions, Mat. Sci. and Engg.,vol.355, 2000, pp.186-192,2003. 15. N.Masoumi, N.Sohrabi, and A.Behzadmehr, A new model forcalculating the effective viscosity of nanofluids, J.Appl.Phys.D: vol.42, 2009. 055501. 16. F.White, Viscous Fluid flow,Third ed., McGraw Hill, Newyork,2005. 17. C.T. Nguyen , F. Desgranges , G.Roy, N. Galanis, T.Mare, S.Boucher, and H. AngueMintsa,Temperature and particle size dependent viscosity data for water based nanofluids Hysteresis phenomenon, Int. J. Heat and Fluid flow, vol.28, 2007, pp. 1492-1506. 18. N. A. Frankel, and A. Acrivos, On the viscosity of concentrate suspension of solid spheres, Chem. Eng.sci.vol.22, 1967, pp. 847-853. 19. B.C.Pak, and Y.I. Cho, Hydrodynamic and heat transfer study of dispersed fluids with submicron metallic oxide particles, Exp. heat trans, vol.11, 1998, pp.151-170. 20. M. Chandrasekar, S.Suresh, and A .Chandra Bose, Experimental investigations and theoretical determination of thermal conductivity and viscosity of Al2O3/ water nanofluids, Exp. Thermal and Fluids Sci, vol. 34, 2010, pp.210-216. 21. MadhusreeKole and T.K. Dey, Thermal Conductivity and Viscosity of Al2O3nanofluid based on car engine coolant, J. Phys. D. Appl. Phys., 43, 2010, 315501.

IJE

RT

www.ijert.org

International Journal of Engineering Research & Technology (IJERT) ISSN: 2278-0181 Vol. 1 Issue 8, October - 2012

22. Reid R.C, Prausnitz J M and Sherwood T K, The Properties of Gases and Liquids 4thedn, 1987, McGraw Hill, New York. 23. Namburu PK, Das D K, Tanguturi K M and Vajjha R S, Numerical Studies of turbulent Flow and Heat Transfer Characteristics of Nanofluids Considering Variable Properties, Int. J Therm. Sci., 48, 2009, 290

IJE

RT

www.ijert.org

10

You might also like

- Current AffairsDocument13 pagesCurrent AffairsSuseel Jai KrishnanNo ratings yet

- 2015 May-GE6351Document2 pages2015 May-GE6351Suseel Jai KrishnanNo ratings yet

- Indian Military SSB Interview Screening and Selection ProcessDocument11 pagesIndian Military SSB Interview Screening and Selection ProcessSumeet MittalNo ratings yet

- Anna University Coimbatore PhD Thesis Submission ChecklistDocument1 pageAnna University Coimbatore PhD Thesis Submission ChecklistSuseel Jai KrishnanNo ratings yet

- Triveni Turbines - Quality Checks and Applications for Steam Turbines Up to 100 MWDocument1 pageTriveni Turbines - Quality Checks and Applications for Steam Turbines Up to 100 MWSuseel Jai KrishnanNo ratings yet

- Check List While Submitting ThesisDocument1 pageCheck List While Submitting ThesisSuseel Jai KrishnanNo ratings yet

- Eng-Synthersis and Sturctural Properties of Al2O3-ZrO2 Nano-Raju M. BelekarDocument8 pagesEng-Synthersis and Sturctural Properties of Al2O3-ZrO2 Nano-Raju M. BelekarImpact JournalsNo ratings yet

- GE6351 SyllabusDocument3 pagesGE6351 SyllabusSuseel Jai KrishnanNo ratings yet

- Tocmod 1Document33 pagesTocmod 1Suseel Jai KrishnanNo ratings yet

- Syllabus R2013 PDFDocument105 pagesSyllabus R2013 PDFlogeshboy007No ratings yet

- Hyatt RegencyDocument14 pagesHyatt RegencySuseel Jai Krishnan0% (1)

- Lakewood His TackDocument12 pagesLakewood His TackSuseel Jai KrishnanNo ratings yet

- ME6301 Part A Q&ADocument31 pagesME6301 Part A Q&ASuseel Jai Krishnan100% (1)

- Checklist While Submitting SynopsisDocument1 pageChecklist While Submitting SynopsisSuseel Jai KrishnanNo ratings yet

- ADVANCED IC Unit-2Document34 pagesADVANCED IC Unit-2Suseel Jai KrishnanNo ratings yet

- Internal CombustionDocument26 pagesInternal CombustionakbsrajNo ratings yet

- Advance Ic Me2401Document2 pagesAdvance Ic Me2401Magesh WaranNo ratings yet

- Energy. Syllabus 2009 - Sem 2Document31 pagesEnergy. Syllabus 2009 - Sem 2Suseel Jai KrishnanNo ratings yet

- ME 323 I.C Engines Combustion SlidesDocument89 pagesME 323 I.C Engines Combustion SlidesSuseel Jai KrishnanNo ratings yet

- Leasson Plan UCMDocument6 pagesLeasson Plan UCMSuseel Jai KrishnanNo ratings yet

- Velammal Institute of Technology: Velammal Gardens, Panchetti, Chennai-601204Document5 pagesVelammal Institute of Technology: Velammal Gardens, Panchetti, Chennai-601204Suseel Jai KrishnanNo ratings yet

- Eg QuestionsDocument65 pagesEg QuestionsSuseel Jai KrishnanNo ratings yet

- 2014-2015 4th Sem Time TableDocument1 page2014-2015 4th Sem Time TableSuseel Jai KrishnanNo ratings yet

- BCM Anna University NotesDocument112 pagesBCM Anna University NotesaruchellamNo ratings yet

- Exploded MOM PDFDocument1 pageExploded MOM PDFSuseel Jai KrishnanNo ratings yet

- TOFD Dead Zone CalculatorDocument3 pagesTOFD Dead Zone CalculatorSuseel Jai KrishnanNo ratings yet

- Dynamics of Machines d06Document3 pagesDynamics of Machines d06Suseel Jai KrishnanNo ratings yet

- O Recover The Lost or Deleted Virus Infected Files From A PendriveDocument1 pageO Recover The Lost or Deleted Virus Infected Files From A PendriveSuseel Jai KrishnanNo ratings yet

- GE6351 SyllabusDocument3 pagesGE6351 SyllabusSuseel Jai KrishnanNo ratings yet

- IRCTCDocument1 pageIRCTCSuseel Jai KrishnanNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- A Detailed Lesson Plan in ScienceDocument4 pagesA Detailed Lesson Plan in SciencemarigoldNo ratings yet

- Mathematical Model and Factors of Paste Thickener Rake TorqueDocument5 pagesMathematical Model and Factors of Paste Thickener Rake TorquesaidNo ratings yet

- 01-DSC Method PDFDocument24 pages01-DSC Method PDFDanNo ratings yet

- Astm A184 - A184m-01 STD Specs For Welded Deformed Steel BarDocument4 pagesAstm A184 - A184m-01 STD Specs For Welded Deformed Steel BarCharwin PicaoNo ratings yet

- Chromatography Lab ReportDocument6 pagesChromatography Lab ReportMohamad MerhabiNo ratings yet

- Chapter 5 Design Guidelines Section 5.4 Mechanical Subsection 5.4.2 PlumbingDocument4 pagesChapter 5 Design Guidelines Section 5.4 Mechanical Subsection 5.4.2 PlumbingkapsarcNo ratings yet

- Solid and Liquid Silicone Rubber Product Selection GuideDocument16 pagesSolid and Liquid Silicone Rubber Product Selection GuideD.I. Pablo BoverioNo ratings yet

- Heat Transfer: Conservation of EnergyDocument28 pagesHeat Transfer: Conservation of EnergyAhmadJaffarGulfarazNo ratings yet

- Discussion Exp 2 PicklingDocument2 pagesDiscussion Exp 2 PicklingFarah Izzati100% (6)

- Building The Formula For Calculating The Vapor of The LPG Liquid Generating in The Explosion Risk of LPG TankDocument3 pagesBuilding The Formula For Calculating The Vapor of The LPG Liquid Generating in The Explosion Risk of LPG TankLy Ngoc MinhNo ratings yet

- V0L2 PDFDocument4 pagesV0L2 PDFJohannie Nina ClaridadNo ratings yet

- Rihayat 2018 IOP Conf. Ser. Mater. Sci. Eng. 334 012054Document8 pagesRihayat 2018 IOP Conf. Ser. Mater. Sci. Eng. 334 012054Arina SaukiNo ratings yet

- 8-2 Salt CementDocument23 pages8-2 Salt CementLenin DiazNo ratings yet

- Msds AluminaDocument6 pagesMsds AluminayaderNo ratings yet

- 2011 Exam GeotechnicalDocument9 pages2011 Exam GeotechnicalAhmed AwadallaNo ratings yet

- Chemical SensorsDocument70 pagesChemical SensorsRenu SamuelNo ratings yet

- Performance Materials: Polyurethane SystemsDocument51 pagesPerformance Materials: Polyurethane SystemscaioltbgNo ratings yet

- PulpDocument382 pagesPulpBeerBie100% (1)

- Safety Data Sheet X-CIDE 105: 1. Identification of The Substance/Preparation and The CompanyDocument5 pagesSafety Data Sheet X-CIDE 105: 1. Identification of The Substance/Preparation and The Company123456ccNo ratings yet

- ProcessDocument24 pagesProcessM RajasekaranNo ratings yet

- Sheet 1Document2 pagesSheet 1Mohamed SalahNo ratings yet

- Eee Module 1Document75 pagesEee Module 1Anitha BRNo ratings yet

- Waste Management in JapanDocument45 pagesWaste Management in JapanPrabhu100% (1)

- Properties of Liquid FuelsDocument5 pagesProperties of Liquid FuelsAbigail MonisNo ratings yet

- Dow Science Paper-A Commercially Viable Solution Process To Control Long-Chain Branching in PolyethyleneDocument1 pageDow Science Paper-A Commercially Viable Solution Process To Control Long-Chain Branching in Polyethylenefengshaohua_gmailNo ratings yet

- Is 10500 SpecificationDocument10 pagesIs 10500 SpecificationbrahmishtanNo ratings yet

- Lecture 2Document26 pagesLecture 2alessio8No ratings yet

- Forging a SwordDocument3 pagesForging a Swordglen biazonNo ratings yet

- Plasma SterilizationDocument28 pagesPlasma SterilizationSutan Muhamad SadamNo ratings yet

- The Surface/Bulk Micromachining (SBM) Process: A New Method For Fabricating Released MEMS in Single Crystal SiliconDocument8 pagesThe Surface/Bulk Micromachining (SBM) Process: A New Method For Fabricating Released MEMS in Single Crystal SiliconAnton JohnNo ratings yet