Professional Documents

Culture Documents

Control of Document

Uploaded by

Looi Kok HuaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Control of Document

Uploaded by

Looi Kok HuaCopyright:

Available Formats

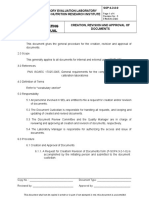

STANDARD OPERATING PROCEDURE CONTROL OF DOCUMENT

1.0 OBJECTIVES To define the controls needed

Doc. No. Rev. No. Date Page

: : : : 1 of 7

1.1 To approve documents for adequacy prior to issue, 1.2 To review and update as necessary and re-approve documents, 1.3 To ensure that changes and the current revision status of documents are identified, 1.4 To ensure that relevant versions of applicable documents are available at points of use, 1.5 To ensure that documents remain legible and readily identifiable, 1.6 To ensure that documents of external original are identified and their distribution controlled, and 1.7 To prevent the unintended use of obsolete documents, and to apply suitable identification to them if they are retained for any purposes. 2.0 SCOPE Applicable to all documents established for the Quality Management System of ABC International Berhad as follows. 2.1 Quality Manual 2.2 Standard Operating Procedures 2.3 Work Instructions, and 2.4 Forms / Records 3.0 RESPONSIBILITIES The Quality Management Representative is responsible to establish, document, implement and maintain this procedure. 4.0 REFERENCES 4.1 ISO 9001:2000 / 4.2.3 4.2 Quality Manual of ABC International Berhad 5.0 ACRONYM 5.1 Quality Management System 5.2 Quality Management Representative 5.3 Quality Manual 5.4 Standard Operating Procedure 5.5 Work Instruction 5.6 Job Description 5.7 Head Of Department - QMS - QMR - QM - SOP - WI - JD - HOD 1st level document 2nd level documents - 3rd level documents 4th level documents

STANDARD OPERATING PROCEDURE CONTROL OF DOCUMENT

6.0 PROCEDURE 6.1 Preparation and validation of New Document 6.1.1 6.1.2 6.1.3 6.1.4

Doc. No. Rev. No. Date Page

: : : : 2 of 7

The Originator to prepare the draft of the document with white A4 papers and provide an appropriate document name. Submit the draft of the document to the respective Head Of Department for review and approval. Forward this approved draft to the QMR to prepare for an Official Draft. QMR to prepare the Official Draft and indicate all the relevant approval parties needed on the front page of draft using the DRAFT COPY APPROVAL format as shown in the sample below. DRAFT COPY APPROVAL

Position Name Signature Date

CEO AS Tan

GM

Engineering

Quality

HOD

HOD of Doc. Owner.

Originator

6.1.5 6.1.6 6.1.7

6.1.8

QMR to return the prepared Official Draft to the originator for review and approval prior to obtain the approval of HOD of document owner. QMR will then forward this approved and duly signed Official Draft to the HOD of other department affected for review and approval. All the parties concerned to review the completeness and adequacy of the Official Draft document and its compliance with the requirements of ISO 9001:2000 Standard and Quality Manual. Any amendment or disagreement made shall be referred back to the originator and the draft approval process is then repeated. The QMR shall forward the HODs approved Official Draft pertaining any of the following matters to the CEO for his final mandatory approval. 6.1.8.1 Policy change 6.1.8.2 Process change 6.1.8.3 System change and 6.1.8.4 Quality standard change Similarly, any amendment or disagreement made by the CEO shall be referred back to the originator to be rectified and the draft approval process is to be repeated.

6.1.9

After obtaining the approval of CEO, the QMR will prepare the Master Copy of document and its History Page using white A4 papers.

STANDARD OPERATING PROCEDURE CONTROL OF DOCUMENT

Doc. No. Rev. No. Date Page

: : : : 3 of 7

6.1.10 QMR to sign on this History Page and forward to the Executive Director for approval. 6.1.11 The approved Master Copy of document shall be safeguarded and its distribution controlled by QMR. 6.2 Format Of Document 6.2.1 Letterhead of the Master Copy of document shall contain the following informations. 6.2.1.1 Name of the company ABC INTERNATIONAL BERHAD 6.2.1.2 Type of document - e.g. QUALITY MANUAL, STANDARD OPERATING PROCEDURE, WORK INSTRUCTION or FORM. 6.2.1.3 Name of document - e.g. CONTROL OF DOCUMENT 6.2.1.4 Document number - e.g. SOP-12 (refer 6.3 ) 6.2.1.5 Revision number - e.g. 05 (Two-digit number) 6.2.1.6 Effective date - e.g. 08/02/2007 6.2.1.7 Page - e.g. 3 of 48 6.2.1.8 Section - e.g. EHF (if necessary) 6.2.1.9 Line - e.g. Face Line (if necessary) Letterhead sample for Standard Operating Procedure ABC STANDARD OPERATING INTERNATIONAL PROCEDURE BERHAD CONTROL OF DOCUMENT

Doc. No. Revision Date Page : SOP-12 : 05 : 08/02/2007 : 3 OF 48

Letterhead sample for Work Instruction WORK ABC INSTRUCTION INTERNATIONAL BERHAD QC FACE LINE Letterhead sample for Form ABC INTERNATIONAL BERHAD FORM DOCUMENT MASTER LIST

Doc. No. Section Line Revision Date Page Doc. No. Revision Date Page

: WI-QC-01 : : : 05 : 08/02/2007 : 3 OF 48 : F-SOP12-01 : 00 : 08/02/2007 : 3 OF 48

STANDARD OPERATING PROCEDURE CONTROL OF DOCUMENT

6.2.2

Doc. No. Rev. No. Date Page

: : : : 4 of 7

The content of the document shall follow the sample format given below as a guide. 1.0 OBJECTIVE:

2.0 SCOPE:

3.0 RESPONSIBILITY:

4.0 REFERENCE:

5.0 DEFINITION: (If necessary)

6.0 ACRONYM: (If necessary)

7.0 PROCEDURE or INSTRUCTION: 7.1 7.2 7.2.1 7.2.2 a)

STANDARD OPERATING PROCEDURE CONTROL OF DOCUMENT

Doc. No. Rev. No. Date Page

: : : : 5 of 7

8.0 APPENDIX: (If necessary) 8.1 8.2 9.0 RECORD: (If necessary)

10.0

CHART:

STANDARD OPERATING PROCEDURE CONTROL OF DOCUMENT

6.3 Document Number

Doc. No. Rev. No. Date Page

: : : : 6 of 7

All documents shall be categorized and shall be assigned a document number according to type, section / department and content. The method of categorization of document is as follows. a) Quality Manual: QM Where QM is the acronym for Quality Manual. b) Standard Operating Procedure: SOP-XX Where SOP is the acronym for Standard Operating Procedure and XX is the serial number of the Standard Operating Procedure. c) Work Instruction: WI YY XX Where WI is the acronym for Work Instruction, YY is the type of Work Instruction and XX is the serial number of the Work Instruction. d) Form / Record: F ZZZZ XX Where F is the acronym for Form / Record, ZZZZ is the type of reference document and XX is the serial number of the Form / Record.

STANDARD OPERATING PROCEDURE CONTROL OF DOCUMENT

6.4 Review And Approval Of Document

Doc. No. Rev. No. Date Page

: : : : 7 of 7

Head Of Department is responsible and empowered to review and up-date the documents of his respective department for adequacy and suitability. All documents shall also subject to the approval of HOD of any other relevant department, section or individual having concern / interest in that document. 6.5 Final Endorsement Of Approved Document

You might also like

- Document ControlDocument11 pagesDocument ControlPRADEEP KUMARNo ratings yet

- GMP Quality Documentation Control Tracking and Distribution QMS-025 SampleDocument13 pagesGMP Quality Documentation Control Tracking and Distribution QMS-025 SampleMostafa FawzyNo ratings yet

- Document Control ProcedureDocument13 pagesDocument Control ProcedureSALES AL ABERNo ratings yet

- VI-401466-PS-1 Example ISO 9001 Document Control ProcedureDocument7 pagesVI-401466-PS-1 Example ISO 9001 Document Control ProcedurevoyyNo ratings yet

- PRC0502Document5 pagesPRC0502John Thompson100% (2)

- Procedure - Control of DocumentsDocument5 pagesProcedure - Control of DocumentsMarjorie Dulay Dumol100% (1)

- (ISO 9001) Procedure For TrainingDocument3 pages(ISO 9001) Procedure For TrainingTuan AnhNo ratings yet

- Quality Management System Master18 February 2014Document27 pagesQuality Management System Master18 February 2014shani5573No ratings yet

- Create & revise lab docsDocument4 pagesCreate & revise lab docsclairealbertiniNo ratings yet

- Q2-760-01-Control of Monitoring and Measuring DevicesDocument5 pagesQ2-760-01-Control of Monitoring and Measuring DevicesAlineNo ratings yet

- 4.0 - Quality Management SystemsDocument6 pages4.0 - Quality Management SystemsDn MldoNo ratings yet

- WI 1 Document ControlDocument7 pagesWI 1 Document ControlPeterNo ratings yet

- Control Records ProcedureDocument4 pagesControl Records ProcedureSaAhRa100% (1)

- Procedure For Design andDocument4 pagesProcedure For Design andSharif KhanNo ratings yet

- QSV 2 Product Release Procedure EN 01Document6 pagesQSV 2 Product Release Procedure EN 01prashanthNo ratings yet

- 1 Internal & Product AuditDocument3 pages1 Internal & Product AuditPrafull BhamareNo ratings yet

- COMP-OPP-02 Procedure For Control and Validation of Service ProvisionDocument6 pagesCOMP-OPP-02 Procedure For Control and Validation of Service ProvisionISODCC DSPINo ratings yet

- Quality Record Procedure Rev-JDocument4 pagesQuality Record Procedure Rev-JherminNo ratings yet

- Product Identification and Traceability: YES NO NADocument1 pageProduct Identification and Traceability: YES NO NAViswaChaitanya NandigamNo ratings yet

- Quality Record Control ProcedureDocument6 pagesQuality Record Control ProcedurePrime CapNo ratings yet

- ISO 13485 2003 Vs FDA QSR 42 69Document28 pagesISO 13485 2003 Vs FDA QSR 42 69Ancuta FeierNo ratings yet

- Supplier Approval ProcedureDocument2 pagesSupplier Approval ProcedureJobaer100% (2)

- Control of Documented Information-4 1Document4 pagesControl of Documented Information-4 1mrawaf balasmehNo ratings yet

- Competency SOPDocument10 pagesCompetency SOPD Tech Dental Technologies100% (1)

- qp-001 Rev5 2011Document13 pagesqp-001 Rev5 2011api-177803962No ratings yet

- Vendor Selection CriteriaDocument2 pagesVendor Selection CriteriaMohammad Faraz AkhterNo ratings yet

- Design Control Quality Assurance ProcedureDocument13 pagesDesign Control Quality Assurance ProcedurePrakash TiwariNo ratings yet

- Procedure For Selection and Supplier DevelopmentDocument5 pagesProcedure For Selection and Supplier DevelopmentQuality Unit 1 Ajay Pandey100% (3)

- PROCESS CONTROL OF NON-COMPLIANT PRODUCTSDocument7 pagesPROCESS CONTROL OF NON-COMPLIANT PRODUCTSambabibabaru100% (1)

- QP-024 Product IdentificationDocument7 pagesQP-024 Product Identificationesraa asemNo ratings yet

- Procedures Manual 8-31-07Document36 pagesProcedures Manual 8-31-07vabimhahNo ratings yet

- CLAUSE 8.5 Production and Service ProvisionDocument10 pagesCLAUSE 8.5 Production and Service ProvisionNavnath TamhaneNo ratings yet

- Non-Conforming Product ProcedureDocument3 pagesNon-Conforming Product ProcedureHamzah Abbass SibaiNo ratings yet

- Quality System Manual: Uncontrolled UncontrolledDocument83 pagesQuality System Manual: Uncontrolled UncontrolledEngr Saeed AnwarNo ratings yet

- ##-QSP-05 Risk Assessment and ManagementDocument11 pages##-QSP-05 Risk Assessment and Managementrajiv100% (1)

- PR-5 - Docuent Control ProcedureDocument7 pagesPR-5 - Docuent Control ProcedureSAMEER JAVEDNo ratings yet

- Procedure For Control of Documents and RecordsDocument3 pagesProcedure For Control of Documents and RecordsmrugeshjNo ratings yet

- Supplier Evaluation and Approval - Disapproval PGP2001ADocument6 pagesSupplier Evaluation and Approval - Disapproval PGP2001ASayed AbbasNo ratings yet

- QAP 5.0 - Document and Data Control PDFDocument4 pagesQAP 5.0 - Document and Data Control PDFRana BiswasNo ratings yet

- Procedure for Purchase SOPDocument6 pagesProcedure for Purchase SOPShakti ShuklaNo ratings yet

- Calibration Policy SOPDocument3 pagesCalibration Policy SOPYousifNo ratings yet

- Document Control ProcedureDocument5 pagesDocument Control ProcedureH. Nazeer Khan100% (1)

- QMS 080 GMP Audit Procedure SampleDocument9 pagesQMS 080 GMP Audit Procedure SampleCarolina TarifNo ratings yet

- Control of RecordsDocument3 pagesControl of Recordschahi100% (1)

- Control of Documents (IMS)Document11 pagesControl of Documents (IMS)Rambir Kaushik0% (1)

- Monitoring and Measurement of QmsDocument3 pagesMonitoring and Measurement of QmsamoNo ratings yet

- QP02 Control of RecordsDocument4 pagesQP02 Control of RecordsDida Wellby100% (2)

- Quality Manual: ISO/TS 16949:2009 Quality Management SystemDocument47 pagesQuality Manual: ISO/TS 16949:2009 Quality Management Systemluismi081300No ratings yet

- HR-2-001, Issue 01, Procedure For Training & DevelopmentDocument2 pagesHR-2-001, Issue 01, Procedure For Training & Developmentsajid waqasNo ratings yet

- 4-04-1 Contract ReviewDocument4 pages4-04-1 Contract Reviewjeric bañaderaNo ratings yet

- SOP - CTR - 01 Contract ReviewDocument3 pagesSOP - CTR - 01 Contract ReviewShahfri ShafNo ratings yet

- ESCL SOP 013, Outsourcing ProcedureDocument7 pagesESCL SOP 013, Outsourcing ProcedureadiqualityconsultNo ratings yet

- QSP 8.3.1 Nonconforming Product - SampleDocument3 pagesQSP 8.3.1 Nonconforming Product - SampleGladys Calvo100% (2)

- Non Conforming ProductDocument2 pagesNon Conforming ProductbomiNo ratings yet

- ISO 9001:2008 Standard Operating Procedures Manual: A P & C, IDocument88 pagesISO 9001:2008 Standard Operating Procedures Manual: A P & C, IBuenoflor GrandeaNo ratings yet

- Master List of Quality Procedures IndexDocument71 pagesMaster List of Quality Procedures IndexLILIANAMAR100% (2)

- APC Inc. Standard Operating Procedures ManualDocument87 pagesAPC Inc. Standard Operating Procedures Manualskynyrd75100% (3)

- Quality System Procedures: AAG Land Survey QSP-First EditionDocument39 pagesQuality System Procedures: AAG Land Survey QSP-First EditionAnkit TomarNo ratings yet

- CM-MA-119 Procedure For Document ControlDocument8 pagesCM-MA-119 Procedure For Document ControlIgnacio Luis Reig MataixNo ratings yet

- Procedure - Control of DocumentsDocument5 pagesProcedure - Control of Documentsjamal nasirNo ratings yet

- 02 Letter of Allegation-MasterDocument1 page02 Letter of Allegation-MasterLooi Kok HuaNo ratings yet

- QQ S006Document1 pageQQ S006Looi Kok HuaNo ratings yet

- Employee Show Cause LetterDocument1 pageEmployee Show Cause LetterLooi Kok HuaNo ratings yet

- 02 Show Cause Letter - 01Document1 page02 Show Cause Letter - 01Looi Kok HuaNo ratings yet

- QQ S005Document1 pageQQ S005Looi Kok HuaNo ratings yet

- QQ S010Document1 pageQQ S010Looi Kok HuaNo ratings yet

- QQ S014Document1 pageQQ S014Looi Kok HuaNo ratings yet

- 02 Letter of Allegation-MasterDocument1 page02 Letter of Allegation-MasterLooi Kok HuaNo ratings yet

- 01 Appointment of Investigating Officer-MasterDocument1 page01 Appointment of Investigating Officer-MasterLooi Kok HuaNo ratings yet

- QQ S009Document1 pageQQ S009Looi Kok HuaNo ratings yet

- QQ S012Document1 pageQQ S012Looi Kok HuaNo ratings yet

- QQ S004Document1 pageQQ S004Looi Kok HuaNo ratings yet

- QQ S013Document1 pageQQ S013Looi Kok HuaNo ratings yet

- QQ S011Document1 pageQQ S011Looi Kok HuaNo ratings yet

- QQ S008Document1 pageQQ S008Looi Kok HuaNo ratings yet

- QQ S007Document1 pageQQ S007Looi Kok HuaNo ratings yet

- Engineering Change NoticeDocument4 pagesEngineering Change NoticeLooi Kok HuaNo ratings yet

- QQ S006Document1 pageQQ S006Looi Kok HuaNo ratings yet

- Create Solutions With Quality Assurance PlansDocument2 pagesCreate Solutions With Quality Assurance PlansLooi Kok HuaNo ratings yet

- Einstein IQ TestDocument1 pageEinstein IQ TestLooi Kok HuaNo ratings yet

- QQ S002Document1 pageQQ S002Looi Kok HuaNo ratings yet

- QQ S003Document1 pageQQ S003Looi Kok HuaNo ratings yet

- QQ S001Document1 pageQQ S001Looi Kok HuaNo ratings yet

- ISO-External Document Master ListDocument2 pagesISO-External Document Master ListLooi Kok HuaNo ratings yet

- ABC Company Flow Chart Symbols GuideDocument3 pagesABC Company Flow Chart Symbols GuideLooi Kok HuaNo ratings yet

- Common Words in MalayDocument3 pagesCommon Words in MalayLooi Kok HuaNo ratings yet

- Employee Monthly Behaviourial Record Rev 00Document2 pagesEmployee Monthly Behaviourial Record Rev 00Looi Kok HuaNo ratings yet

- Quotable Quotes ChineseDocument1 pageQuotable Quotes ChineseLooi Kok HuaNo ratings yet

- ATTITUDE - Charles SwindollDocument2 pagesATTITUDE - Charles SwindollLooi Kok HuaNo ratings yet

- Quotable Quotes - in Alphabetical OrderDocument1 pageQuotable Quotes - in Alphabetical OrderLooi Kok HuaNo ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (241)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (50)

- Control of Power Electronic Converters and Systems: Volume 1From EverandControl of Power Electronic Converters and Systems: Volume 1Rating: 5 out of 5 stars5/5 (1)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- An Architect's Guide to Construction: Tales from the Trenches Book 1From EverandAn Architect's Guide to Construction: Tales from the Trenches Book 1No ratings yet

- The Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsFrom EverandThe Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsRating: 4.5 out of 5 stars4.5/5 (6)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionFrom EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionRating: 4.5 out of 5 stars4.5/5 (3)

- The Laws of Thermodynamics: A Very Short IntroductionFrom EverandThe Laws of Thermodynamics: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (10)

- Introduction to Applied Thermodynamics: The Commonwealth and International Library: Mechanical Engineering DivisionFrom EverandIntroduction to Applied Thermodynamics: The Commonwealth and International Library: Mechanical Engineering DivisionRating: 2.5 out of 5 stars2.5/5 (3)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseFrom EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseRating: 5 out of 5 stars5/5 (3)

- Building Construction Technology: A Useful Guide - Part 1From EverandBuilding Construction Technology: A Useful Guide - Part 1Rating: 4 out of 5 stars4/5 (3)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionFrom EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionRating: 4.5 out of 5 stars4.5/5 (2)

- Building Construction Technology: A Useful Guide - Part 2From EverandBuilding Construction Technology: A Useful Guide - Part 2Rating: 5 out of 5 stars5/5 (1)

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsFrom EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsNo ratings yet

- Quantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationFrom EverandQuantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationRating: 1 out of 5 stars1/5 (1)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Design of Foundations for Offshore Wind TurbinesFrom EverandDesign of Foundations for Offshore Wind TurbinesRating: 5 out of 5 stars5/5 (3)

- Rolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsFrom EverandRolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsNo ratings yet

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet