Professional Documents

Culture Documents

9 - TENDERIZING - A New Process To Improve Beef Tenderness

Uploaded by

DougOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

9 - TENDERIZING - A New Process To Improve Beef Tenderness

Uploaded by

DougCopyright:

Available Formats

The hydrodyne: a new process to improve beef tenderness. M B Solomon, J B Long and J S Eastridge J ANIM SCI 1997, 75:1534-1537.

The online version of this article, along with updated information and services, is located on the World Wide Web at: http://www.journalofanimalscience.org/content/75/6/1534

www.asas.org

Downloaded from www.journalofanimalscience.org by guest on January 28, 2013

The Hydrodyne: A New Process to Improve Beef Tenderness1

M. B. Solomon*, J. B. Long, and J. S. Eastridge*

*Meat Science Research Laboratory, USDA, ARS, Beltsville, MD 20705 and Hydrodyne, Inc., San Juan, PR 00936

ABSTRACT: The organoleptic trait most affecting consumer acceptance of beef is tenderness. The Hydrodyne process uses a small amount of explosive to generate a shock wave in water. The shock wave passes through (in fractions of a millisecond) objects in the water that are an acoustic match with water. Four beef muscles (longissimus, semimembranosus, biceps femoris, and semitendinosus) exposed to either 50, 75, or 100 g of explosives were significantly

tenderized compared with controls. As much as a 72% reduction in shear force was observed for the longissimus muscle using 100 g of explosives. Reductions in shear force with magnitudes of 30 to 59% improvements were observed for the other three muscle types. Results suggest that tenderizing beef with the Hydrodyne process presents a potentially novel opportunity in the way the meat industry can tenderize meat.

Key Words: Tenderizing, Tenderness, Beef J. Anim. Sci. 1997. 75:15341537

Introduction

Tenderness is one of the most important sensory characteristics of meat. Research during the past 50 yr has been devoted to improving tenderness of meats. A variety of techniques have been introduced for tenderizing meat. Techniques, applied individually or in combination, include mechanical, chemical, conditioning, aging, electrical stimulation, pressure-heat treatment, and alternative carcass positioning. A number of these techniques require additional holding periods, space, and labor. The Hydrodyne process (patent numbers 5,273,766 and 5,328,403), which is different from any currently used or described method(s) for meat/carcass tenderization, uses a small amount of explosive to generate a hydrodynamic shock wave in liquid medium (water). The shock wave, which occurs in fractions of a millisecond, passes through objects in the water that are an acoustical match with the water (Kolsky, 1980). Meat (muscle), which compositionally is approximately 75% water, depending on the amount of intramuscular fat and connective tissue present (Price and Schweigert, 1978), is a close acoustical match.

The shock wave reflects off any object in the water that is not an acoustic match (Kolsky, 1980). Experiments were conducted to 1 ) determine the amount of explosive required to achieve significant tenderization, 2 ) determine the effectiveness of the Hydrodyne process on tenderizing beef from the USDA Select grade, and 3 ) determine the effectiveness of the Hydrodyne process for tenderizing intentionally coldshortened meat from a variety of muscles.

Experimental Procedures

In the Hydrodyne process for experimental purposes, the meat was encapsulated twice, first in a polyolefin resin (Cryovac) bag followed by encapsulation in a polymer of isoprene (rubber) bag. Both bags were evacuated. Meat samples were supported against the floor of plastic containers (208-L capacity and 51-cm diameter), each fitted with a steel plate (2cm thick) so the ensuing wave reflected back through the meat to intersect the incoming wave. The containers were situated below ground level and filled to the top with water. The explosive used was composed of a liquid (nitromethane) and a solid (ammonium nitrate), which were not explosive until combined. The explosive was submerged in the water to a distance of 30.5 cm away from the front surface of the meat and was wired to a detonating device. The detonating device triggered the detonation of the explosive. In the first set of three experiments, 12 longissimus ( LM) steaks (3.2 cm in thickness) were removed

1The USDA neither guarantees nor warrants the standard of the product, and the use of the name by USDA implies no approval of the product to the exclusion other products that may also be suitable. Received July 30, 1996. Accepted February 5, 1997.

1534

Downloaded from www.journalofanimalscience.org by guest on January 28, 2013

POSTMORTEM MEAT TENDERIZATION

1535

from the loins (both sides) of five 2-yr-old Holstein cows at 24 h postmortem. Two steaks served as controls from each loin. Six steaks per loin (two for each treatment) were exposed to the Hydrodyne process using either 50, 75, or 100 g of explosive in a single load. An additional two steaks per loin were exposed to the Hydrodyne process using two individual loads of 50 g of explosive each, the first detonation followed by a second. The remaining two steaks per loin were frozen and treated frozen using a single 75-g load of explosive. The two steaks per treatment were vacuumed-packaged in Cryovac bags, and all steaks designated for a specific quantity of explosive were encapsulated in the same rubber bag. In the second set of experiments, three fresh, whole (USDA Select grade) biceps femoris ( BF) were purchased from a local grocery store. Eight steaks per biceps femoris were removed (3.2 cm in thickness). Two steaks per individual muscle served as controls. Six steaks per muscle (two/treatment) were exposed to the Hydrodyne process using either 50, 75, or 100 g of explosive in a single load. The two steaks per treatment were vacuumed-packaged in Cryovac bags, and all steaks designated for a specific quantity of explosive were encapsulated in the same rubber bag. In the last set of experiments, portions of ( n = 8 ) boneless LM, BF, semimembranosus ( SM) , and semitendinosus ( ST) from four 2-yr-old Holstein cows were hot-boned within 1.5 h postmortem, vacuumpackaged, and stored for 1 d at 2 to 4C, after which they were frozen at 34C. All muscles were thawed prior to sampling and treating with the Hydrodyne process. Each muscle was divided into two equal portions (20 cm in length), one portion (random) from each muscle was exposed to the Hydrodyne process (100 g explosive), and the remaining portion from the same muscle served as the control. Individual muscle sections representing the different muscles were individually vacuumed-packaged in Cryovac bags and these individual muscle samples were individually encapsulated in a rubber bag. Steaks (3.2 cm in thickness) were cut from the muscle sections after being treated. In all three sets of experiments, the control and Hydrodyne samples were held or transported on ice to the testing site, and the duration of time that elapsed from the time of Hydrodyning to the time the samples were cooked was less than 2 h. All steaks were broiled to an internal temperature of 71C (AMSA, 1995) using Farberware Open-Hearth broilers (Model 350A, Walter Kidde and Co., Bronx, NY). Internal temperature was monitored using iron-constantan thermocouples attached to a Speedomax multipoint recording potentiometer (Model 1650, Leeds and Northrup, North Wales, PA). After cooking, all steaks were allowed to cool to room temperature (25 C ) before coring. A minimum of eight cores (1.27 cm diameter) were removed from each steak parallel to the musclefiber orientation for shear force determination using a

Warner-Bratzler shear device mounted on a Food Texture Corp. Texture measurement system (Model TMS-90, FTC, Chantilly, VA). Data were analyzed using analysis of variance and F-tests (SAS, 1994) to determine the significance of variation. Least squares means and linear contrasts were generated using SAS (1994). The Duncans Multiple Range test (SAS, 1994) was used to compare treatments at the a = .05 level.

Results

In our initial set of experiments, three loads of explosives (50, 75, and 100 g ) were used to evaluate their effectiveness at tenderizing LM. Results are presented in Table 1. Shear force was improved 49 to 72% in all of the fresh LM samples using the Hydrodyne process. However, the magnitude of improvement depended on the quantity of explosive used or the number of detonations performed on each meat sample. Exposing pieces of meat to two independent loads of 50 g each resulted in the greatest improvement in shear force (7.8 vs 2.2 kg) followed by the single 100 g load (7.8 vs 2.6 kg). However, successful reductions in shear force (56 and 49%) were also achieved using single loads of either 50 or 75 g of explosives, respectively. Shear force for frozen LM steaks was improved 24% (7.8 vs 5.9 kg) using the Hydrodyne process on frozen pieces of meat compared with controls (Table 1). These findings suggest that although the Hydrodyne process is effective at tenderizing frozen pieces of meat, it is much more effective for tenderizing fresh pieces of meat. In the second set of experiments (Table 2), as much as a 19 to 30% improvement in BF shear force was observed compared to controls when BF steaks were treated with the Hydrodyne process. Initial shear force for the controls in this sample group was 4.3 kg, which was considerably less than the shear force for the controls (7.8 kg) representing the LM samples in the first set of experiments. Even though these locally

Table 1. Effect of quantity of explosive on tenderization of beef longissimus muscle as measured by shear force

No. of detonations 0 1 2 1 1 1 Shear force, kg 7.8a 3.4cd 2.2d 4.0c 2.6d 5.9b .3

Quantity of explosive, g Control 50; fresh steak 50; fresh steak 75; fresh steak 100; fresh steak 75; frozen steak SEM

a,b,c,dMeans within a column lacking a common superscript letter differ ( P < .05).

Downloaded from www.journalofanimalscience.org by guest on January 28, 2013

1536

SOLOMON ET AL.

Table 2. Effect of quantity of explosive on tenderization of beef biceps femoris muscle as measured by shear force

No. of detonations 0 1 1 1 Shear force, kg 4.3a 3.3b 3.5ab 3.0b .2

Quantity of explosive, g Control 50; fresh steak 75; fresh steak 100; fresh steak SEM

a,bMeans within a column lacking a common superscript letter differ ( P < .05).

purchased USDA Select grade BF samples had initial shear values of 4.3 kg, the Hydrodyne process was effective at further reducing shear values by as much as 30%. The Hydrodyne steaks did not appear to be over tenderized (i.e., mushy; visual and physical appearance), nor were there any visual signs of differences in meat color after treatment (personal observations). In the last set of experiments (Table 3), shear force (kilograms) was improved 66% (8.3 vs 2.8) in the LM, 59% (10.5 vs 4.3) in the SM, 53% (7.8 vs 3.7) in the BF, and 56% (12.9 vs 5.7) in the ST after treating with the Hydrodyne process (100 g of explosive). Hotboning the intact muscles and holding them for 1 d at 2 to 4C before freezing resulted in high shear values that would suggest that cold shortening of the muscles occurred (Locker and Hagyard, 1963). If the high shear values were a result of the cold-shortening phenomenon, results indicate that the Hydrodyne process was effective at significantly tenderizing coldshortened meat, regardless of muscle origin.

Discussion

To be an acoustic match with water, the object, in this case meat, must possess a ratio of E/D similar to water, where E is the bulk modulus of elasticity and D is the density (Kolsky, 1980). The high proportion of water in meat (75%) provides an excellent acoustic match with the liquid medium (water) in the

container. The shock wave is generated and transmitted through the water. The relationship between the wave velocity and the wave period of the ensuing shock wave is such that the front surface of the wave, when reflected by the steel plate fitted at the bottom of the container, intersects the remaining portions of the incoming wave. The pressures within the meat at this time are the sum of the incoming pressure and the reflected pressures at each point in the meat. The result is an increased pressure within the meat (doubling effect) and a nearly uniform pressure exposure within the meat from the front surface to the bottom surface. Pressure fronts were measured (not in tabular form) using transducers designed to capture pressure transmissions. One problem we encountered in recording pressure fronts is that the transducers that are available are designed to measure pressure fronts with a longer time duration than the fraction of a millisecond we encounter in the Hydrodyne process. The pressure fronts were measured in the last set of experiments, which used 100 g of explosives. Shock pressures in the range of 6.05 106 to 7.03 106 kg/ m2 were observed at the front contact surface of the meat where the transducers were attached. Uniformity of shock pressure transmission is achieved by supporting the meat against a steel surface and reflecting the shock wave back to intersect the incoming wave. MacFarlane (1973) was the first to report that prerigor pressurization (hydrostatic pressure) significantly tenderized beef and sheep muscle. Hydrostatic pressure alone (MacFarlane, 1973; Elgasim and Kennick, 1980; Kennick et al., 1980) or in combination with heat (Bouton et al., 1977, 1978) has been shown to have a significant tenderizing effect on beef and sheep muscle. MacFarlane (1973) reported that a hydrostatic pressure of 1.05 107 kg/m2 at 30 to 35C for a 2 min duration was effective at increasing meat tenderness. Kennick et al. (1980) demonstrated that high hydrostatic pressure tenderized meat and(or) accelerated meat aging. The Hydrodyne system uses a hydrodynamic shock wave to tenderize meat. Hydrodynamics, which occurs instantaneously, is the motion of fluids and the forces acting on solid bodies immersed in these fluids. Hydrostatics, which is not instantaneous, is the characteristics of liquids at rest

Table 3. Effect of the Hydrodyne process on beef longissimus, semimembranosus, biceps femoris, and semitendinosus muscle shear force

Shear force, kg Muscle Longissimus Semimembranosus Biceps femoris Semitendinosus Control 8.3 10.5 7.8 12.9 100 g explosive 2.8 4.3 3.7 5.7 SEM .4 .5 .3 .6 Significance, P < .01 .01 .01 .01

Downloaded from www.journalofanimalscience.org by guest on January 28, 2013

POSTMORTEM MEAT TENDERIZATION

1537

and the pressure in a liquid or exerted by a liquid on an immersed object. Shackelford et al. (1991) reported that WarnerBratzler shear force values of top loin steaks should not exceed 3.2 kg for a 95% confidence level, 3.9 kg for a 68% confidence level or 4.6 kg for a 50% confidence level to assure overall tenderness ratings of slightly tender or greater from a trained sensory panel. Results for Hydrodyned loin muscle samples in the present study indicated that the resulting shear values of 2.6 and 2.8 kg after detonation of 100 g of explosive were well within the 95% confidence level described by Shackelford et al. (1991). In fact, the 50 and 75 g of explosives used to tenderize fresh LM samples were sufficient quantities to produce shear values comparable to the 68% confidence level described by Shackelford et al. (1991). Extrapolating the results for the BF, SM, and ST samples in Table 3 that were Hydrodyned using 100 g of explosive and using the shear force value thresholds reported by Shackelford et al. (1991), it can be deduced that the Hydrodyne process was, in most instances, successful at improving meat tenderness and provided meat that was considered to be tender, regardless of muscle origin or type.

Hydrodyne process presents a potentially new and alternative method for tenderizing meat. The process presently is designed as a batch system and research is currently underway at evaluating a Hydrodyne unit with a capacity of 1,060 L of water that would accommodate approximately 272 to 363 kg of meat per detonation.

Literature Cited

AMSA. 1995. Research Guidelines for Cookery, Sensory Evaluation and Instrumental Tenderness Measurements of Fresh Meat. Am. Meat Science Assoc., Chicago, IL. Bouton, P. E., P. V. Harris, J. J. MacFarlane, and J. M. OShea. 1977. Effect of pressure treatments on the mechanical properties of pre-and post-rigor meat. Meat Sci. 1:307. Bouton, P. E., P. V. Harris, J. J. MacFarlane, and J. M. OShea. 1978. Pressure heat treatment of meat: Effect on connective tissue. J. Food Sci. 43:301. Elgasim, E. A., and W. H. Kennick. 1980. Effect of pressurization of pre-rigor beef muscles on protein quality. J. Food Sci. 45:1122. Kennick, W. H., E. A. Elgasim, Z. A. Holmes, and P. F. Meyer. 1980. The effect of pressurization of pre-rigor muscle on post rigor meat characteristics. Meat Sci. 4:33. Kolsky, H. 1980. Stress Waves in Solids. Dover Publishing, New York. Locker, R. H., and C. J. Hagyard. 1963. A cold shortening effect in beef muscles. J. Sci. Food Agric. 14:787. MacFarlane, J. J. 1973. Pre-rigor pressurization of muscle: Effects on pH, shear value and taste panel assessment. J. Food Sci. 38: 294. Price, J. F., and B. S. Schweigert. 1978. The Science of Meat and Meat Products. Food and Nutrition Press, Westport, CT. SAS. 1994. SAS/STAT Users Guide (Version 6 Ed.). SAS Inst. Inc., Cary, NC. Shackelford, S. D., J. B. Morgan, H. R. Cross and J. W. Savell. 1991. Identification of threshold levels for warner-bratzler shear force in beef top loin steaks. J. Muscle Foods 2:289.

Implications

The findings reported in this paper indicate that the Hydrodyne process was effective in reducing shear force values and improving meat tenderness in beef. Furthermore, the Hydrodyne process was an effective technique for tenderizing cold-shortened muscle. The

Downloaded from www.journalofanimalscience.org by guest on January 28, 2013

Citations

This article has been cited by 1 HighWire-hosted articles: http://www.journalofanimalscience.org/content/75/6/1534#otherarticles

Downloaded from www.journalofanimalscience.org by guest on January 28, 2013

You might also like

- VBI-SciVac Merger Conference Call - Nov 5 2015Document17 pagesVBI-SciVac Merger Conference Call - Nov 5 2015DougNo ratings yet

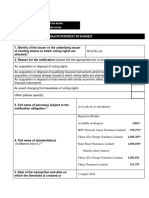

- TR1 Notification - August 2016 - 2Document4 pagesTR1 Notification - August 2016 - 2DougNo ratings yet

- TR1 Notification - August 2016Document4 pagesTR1 Notification - August 2016DougNo ratings yet

- Amphion Pledge August 22 2016Document2 pagesAmphion Pledge August 22 2016DougNo ratings yet

- TheraBond Material Safety Data SheetDocument6 pagesTheraBond Material Safety Data SheetDougNo ratings yet

- SilverSeal MSDSDocument3 pagesSilverSeal MSDSDougNo ratings yet

- BioSig Corporate Presentation - November 2015Document26 pagesBioSig Corporate Presentation - November 2015DougNo ratings yet

- Notification of Major Interest in Shares - MotifBioDocument3 pagesNotification of Major Interest in Shares - MotifBioDougNo ratings yet

- Innovations in EP - Interview With Greg CashDocument1 pageInnovations in EP - Interview With Greg CashDougNo ratings yet

- Cardax Corporate PresentationDocument56 pagesCardax Corporate PresentationDougNo ratings yet

- Fellsmere Housing Group PresentationDocument12 pagesFellsmere Housing Group PresentationDougNo ratings yet

- ContraVir Code of Business Conduct and EthicsDocument6 pagesContraVir Code of Business Conduct and EthicsDougNo ratings yet

- VBI Vaccines - ICAAC Presentation 2014Document12 pagesVBI Vaccines - ICAAC Presentation 2014DougNo ratings yet

- Utah CMV Public Health InitiativeDocument4 pagesUtah CMV Public Health InitiativeDougNo ratings yet

- DGCV - Fact Book Design Sample 2 - 24 PagesDocument24 pagesDGCV - Fact Book Design Sample 2 - 24 PagesDougNo ratings yet

- Enveloped Virus-Like Particle Expression of Human Cytomegalovirus Glycoprotein B Antigen Induces Antibodies With Potent and Broad Neutralizing ActivityDocument8 pagesEnveloped Virus-Like Particle Expression of Human Cytomegalovirus Glycoprotein B Antigen Induces Antibodies With Potent and Broad Neutralizing ActivityDougNo ratings yet

- DGCV - Fact Book Design Sample - 24 PagesDocument24 pagesDGCV - Fact Book Design Sample - 24 PagesDougNo ratings yet

- Bactericidal SAWC2013l Pstr-FinalDocument1 pageBactericidal SAWC2013l Pstr-FinalDougNo ratings yet

- Final Hydress SellSheet 9 13Document2 pagesFinal Hydress SellSheet 9 13DougNo ratings yet

- Utilization of Silver Hydrogel Sheet Dressing On Post-Surgical Incisions: A Pilot Study in Foot and Ankle SurgeryDocument1 pageUtilization of Silver Hydrogel Sheet Dressing On Post-Surgical Incisions: A Pilot Study in Foot and Ankle SurgeryDougNo ratings yet

- SachetDocument2 pagesSachetDougNo ratings yet

- SanaDocument4 pagesSanaDougNo ratings yet

- SilverIon SAWC2013 Pstr-Final PDFDocument1 pageSilverIon SAWC2013 Pstr-Final PDFDougNo ratings yet

- Lap Evolution ChartDocument2 pagesLap Evolution ChartDougNo ratings yet

- Alliqua SilverSeal Sell SheetDocument2 pagesAlliqua SilverSeal Sell SheetDougNo ratings yet

- Alliqua Investor Presentation ALQADocument20 pagesAlliqua Investor Presentation ALQADougNo ratings yet

- Clinical Assessment of The KeyHole CupDocument2 pagesClinical Assessment of The KeyHole CupDougNo ratings yet

- ESRI Investor PresentationDocument39 pagesESRI Investor PresentationDougNo ratings yet

- 8 - TENDERIZING - Tenderization of Beef Lions Using A High Efficiency SparkerDocument7 pages8 - TENDERIZING - Tenderization of Beef Lions Using A High Efficiency SparkerDougNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Lec-1b - Types of StructuresDocument23 pagesLec-1b - Types of StructuresNouman AhmadNo ratings yet

- Matlab HW PDFDocument3 pagesMatlab HW PDFMohammed AbdulnaserNo ratings yet

- SCSS1 Midterm Exam OutlineDocument5 pagesSCSS1 Midterm Exam OutlineRezy ElegueNo ratings yet

- Bay of BengalDocument18 pagesBay of BengalKarl GustavNo ratings yet

- General Specifications: Ph/redox and Temperature Sensor Model PH20 and FU20Document8 pagesGeneral Specifications: Ph/redox and Temperature Sensor Model PH20 and FU20HolicsNo ratings yet

- Seepage and Flow NetsDocument60 pagesSeepage and Flow NetsMavenNo ratings yet

- Microcontroller Control Thermoelectric Heating and Cooling System Using TEC1 12706Document5 pagesMicrocontroller Control Thermoelectric Heating and Cooling System Using TEC1 12706Editor IJTSRDNo ratings yet

- Question Bank (Unit I) Cs6402-Design and Analysis of Algorithms Part - ADocument12 pagesQuestion Bank (Unit I) Cs6402-Design and Analysis of Algorithms Part - Aviju001No ratings yet

- National Workshop On NEP Institute Industry LinkagesDocument2 pagesNational Workshop On NEP Institute Industry Linkagesasiya bagwanNo ratings yet

- man 3025 final paper keskyDocument10 pagesman 3025 final paper keskyapi-737247135No ratings yet

- General FileDocument15 pagesGeneral FileMayega BrianNo ratings yet

- Chapter QuestionDocument5 pagesChapter Questionsn nNo ratings yet

- Numerical Differentiation and Integration: By: Habtamu GaromaDocument53 pagesNumerical Differentiation and Integration: By: Habtamu GaromaAmiin HirphoNo ratings yet

- Science: Quarter 3, Week 6 - 7 Module 5Document27 pagesScience: Quarter 3, Week 6 - 7 Module 5NRIZA MAE CACHONo ratings yet

- Marriage Builders Emotional Needs Questionnaire PDFDocument12 pagesMarriage Builders Emotional Needs Questionnaire PDFPrarthanaRavikumarNo ratings yet

- A Course of Theoretical Physics Volume 1 Fundamental Laws Mechanics Electrodynamics Quantum Mechanics-A.S. Kompaneyets PDFDocument574 pagesA Course of Theoretical Physics Volume 1 Fundamental Laws Mechanics Electrodynamics Quantum Mechanics-A.S. Kompaneyets PDFRoberto Pomares100% (1)

- gepIII Overview ArxivDocument20 pagesgepIII Overview Arxivuma_poppyNo ratings yet

- BWG CalculatorDocument10 pagesBWG CalculatorELIECER SANCHEZNo ratings yet

- Failure Case Studies in Civil EngineeringDocument135 pagesFailure Case Studies in Civil Engineeringpratip_b100% (2)

- Trading Using Harmonic PatternsDocument1 pageTrading Using Harmonic PatternsBiantoroKunartoNo ratings yet

- Risk Management Plan - Philippine-Specific AnnexDocument2 pagesRisk Management Plan - Philippine-Specific Annexultimate_2226252No ratings yet

- Pedroso Probset 1Document11 pagesPedroso Probset 1Princess Niña B. PedrosoNo ratings yet

- 1w5q Chapter 3 Dynamics of Linear MotionDocument2 pages1w5q Chapter 3 Dynamics of Linear MotionKHOO YI XIAN MoeNo ratings yet

- Scientific Method ReviewDocument2 pagesScientific Method ReviewHaneen QamarNo ratings yet

- Molecular Technique For Gender Identification: A Boon in Forensic OdontologyDocument12 pagesMolecular Technique For Gender Identification: A Boon in Forensic OdontologyBOHR International Journal of Current research in Dentistry (BIJCRID)No ratings yet

- Words: WilburnDocument88 pagesWords: WilburnDaisy lazyNo ratings yet

- Mothly Supervisory PlanDocument6 pagesMothly Supervisory Planclaire alcantaraNo ratings yet

- Zoning Color Code Chart for Land Use ZonesDocument2 pagesZoning Color Code Chart for Land Use Zonesmervin escribaNo ratings yet

- Ways of CopingDocument5 pagesWays of Copingteena jobNo ratings yet

- A Primer in Research Methodology and BiostatisticsDocument163 pagesA Primer in Research Methodology and BiostatisticsAdriana Villarreal100% (3)