Professional Documents

Culture Documents

Eng Tech

Uploaded by

shivmech12Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Eng Tech

Uploaded by

shivmech12Copyright:

Available Formats

cc_eng_tech.

fm Page 43 Monday, March 21, 2005 4:46 PM

DYNA-SYNC

ENGINEERING/TECHNICAL

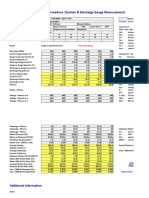

Horsepower and Belt Tension for Simple Conveyors *

Table 1 HP Required to Operate Loaded Conveyor on the Level

350

400

500

600

700

800

900

1000

3.0

3.6

4.1

4.5

5.0

5.5

6.0

6.4

6.8

7.5

8.4

9.2

10.2

11.1

12.2

3.3

3.9

4.5

4.9

5.4

5.9

6.5

7.0

7.3

8.0

9.0

10.0

11.0

12.0

13.2

3.5

4.2

4.8

5.3

5.8

6.3

7.0

7.5

8.0

8.8

9.8

10.7

11.9

13.0

14.3

4.0

4.8

5.5

6.0

6.6

7.2

8.0

8.6

9.2

10.1

11.2

12.2

13.6

14.9

16.4

4.5

5.4

6.2

6.8

7.4

8.1

9.0

9.7

10.4

11.4

12.6

13.7

15.3

16.8

18.5

5.0

6.0

6.9

7.5

8.2

9.0

10.0

10.8

11.6

12.7

14.0

15.2

17.0

18.7

20.6

5.5

6.6

7.6

8.3

9.0

9.9

11.0

11.9

12.8

14.0

15.4

16.7

18.7

20.6

22.7

6.0

7.2

8.3

9.0

9.8

10.8

12.0

13.0

14.0

15.3

16.8

18.2

20.4

22.5

24.8

6.5

7.8

9.0

9.8

10.6

11.5

13.0

14.1

15.2

16.6

18.2

19.7

22.1

24.4

26.9

to Lift Load on Belt Conveyor

150

200

250

300

350

400

500

600

700

800

900

1000

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

10.0

1.5

3.0

4.5

6.0

7.5

9.0

10.5

12.0

13.5

15.0

2.0

4.0

6.0

8.0

10.0

12.0

14.0

16.0

18.0

20.0

2.5

5.0

7.5

10.0

12.5

15.0

17.5

20.0

22.5

25.0

3.0

6.0

9.0

12.0

15.0

18.0

21.0

24.0

27.0

30.0

3.5

7.0

10.5

14.0

17.5

21.0

24.5

28.0

31.5

35.0

4.0

8.0

12.0

16.0

20.0

24.0

28.0

32.0

36.0

40.0

5.0

10.0

15.0

20.0

25.0

30.0

35.0

40.0

45.0

50.0

6.0

12.0

18.0

24.0

30.0

36.0

42.0

48.0

54.0

60.0

7.0

14.0

21.0

28.0

35.0

42.0

49.0

56.0

63.0

70.0

8.0

16.0

24.0

32.0

40.0

48.0

56.0

64.0

72.0

80.0

9.0

18.0

27.0

36.0

45.0

54.0

63.0

72.0

81.0

90.0

10.0

20.0

30.0

40.0

50.0

60.0

70.0

80.0

90.0

100.0

Where:

The belt tensions developed in a belt conveyor depend on the

following:

1. Motor horsepower

2. Belt speed in feet per minute

3. Drive configuration

To determine tight side (T1) and slack side (T2) operating tensions,

first determine the effective tension (difference between T1 and T2)

from: Te = 33,000 x HP/FPM

Where: Te = Effective tension

HP = Motor horsepower

FPM = Belt speed

The slack side belt tension is calculated from Te and the drive factor

Cw (from Table 7) by: T2 = Te x Cw

Where: T2 = Slack side tension

Te = Effective tension

Cw = Drive factor from Table 7

Table 7 Drive Factor

0

Wrap

180

200

210

220

240

T1 = Tight side tension

Te = Effective tension

T2 = Slack side tension

Example: Horsepower and Tension calculation

Calculate horsepower and belt tensions for a conveyor given:

1. Capacity of 300 tons per hour

2. 300 ft. conveyor length

3. 20 ft. conveyor lift

4. Belt speed of 450 feet per minute

5. Screw take-up system

6. 1805 arc of contact on drive pulley

7. Lagged drive pulley

Horsepower:

From Table 5 the horsepower required to operate the belt on the

level is 8.4. From Table 6 the horsepower required for lift is 6.0. The

total horsepower required is 8.4 + 6.0 = 14.4. (A 15 HP motor would

be selected.)

Tension:

Automatic takeup

Bare

Lagged

Pulley

Pulley

0.84

0.50

0.72

0.42

0.66

0.38

0.62

0.35

0.54

0.30

Manual takeup

Bare

Lagged

Pulley

Pulley

1.2

0.8

1.0

0.7

1.0

0.7

0.9

0.6

0.8

0.6

The tight side tension is calculated from Te and T2 by:

T1 = Te + T2

FEATURES/BENEFITS

PAGES PT13-2 - PT13-3

Sprockets

Short Tons Per Hour (2000 lbs.)

100

Belt Tension:

Type of

pulley

drive

Single no snub

Single with snub

300

2.7

3.3

3.8

4.2

4.6

5.0

5.5

5.8

6.2

6.8

7.6

8.4

9.2

10.2

11.1

Conveyor Components

in

Feet

10

20

30

40

50

60

70

80

90

100

250

HT Synchrous Belts

Short Tons Per Hour (2000 lbs.)

Length of

The horsepower required to operate a

Conveyor

100 150 200

belt conveyor depends on the following:

in feet

1. Maximum tonnage to be handled

25

2.0

2.3

2.5

50

2.4

2.7

3.0

2. Length of the conveyor

75

2.8

3.1

3.5

3. Vertical lift of the conveyor

100

3.0

3.4

3.8

125

3.4

3.8

4.2

To determine horsepower required for a

150

3.7

4.1

4.6

horizontal conveyor, use Table 1 only.

175

4.0

4.5

5.0

To determine horsepower required for an

200

4.3

4.8

5.3

inclined conveyor, use Table 1 and Table 2.

225

4.6

5.1

5.7

Figure each table separately and sum the

250

4.9

5.5

6.2

results to determine total horsepower

300

5.6

6.2

7.0

required.

350

6.2

6.9

7.7

400

6.8

7.6

8.5

Note: Other factors, such as conveyor

450

7.3

8.3

9.2

plows, scrappers, and skirt boards over

500

8.0

9.0

10.1

12 feet, will require additional factors

for horsepower. See conveyor design

Table 2 HP Required

program or call conveyor component

Lift

engineering for assistance.

First calculate effective tension from:

33000 x HP

33000 x 15

Te =

Te =

= 1100 lbs.

FPM

450

Calculate T2 from Te and drive factor Cw (From Table 7 Cw = .8)

T2=Cw x Te

T2=.8 x 1100 = 880 lbs.

Finally calculate T1 from T2 and Te

T1=880+1100=1980 lbs.

T1=T2+Te

* These calculations are limited to level or uphill conveyors with

single drive pulley and a maximum length of 500 ft. For other

systems, consult DODGE.

SELECTION/DIMENSIONS

PAGE PT13-10

MODIFICATIONS/ACCESSORIES

PAGE PT13-35

PT13-43

RELATED PRODUCTS

PAGE PT13-40

Engineering

Horsepower

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ACCA Friction Rate Reference ChartDocument31 pagesACCA Friction Rate Reference ChartMark Mach Allen100% (1)

- Separator SizingDocument16 pagesSeparator SizingMichael J. BaneNo ratings yet

- 3403 OrigDocument8 pages3403 OrigMichael J. BaneNo ratings yet

- Wire To Water Energy Calculator: Required Data Pump 1 Pump 2Document2 pagesWire To Water Energy Calculator: Required Data Pump 1 Pump 2Michael J. BaneNo ratings yet

- Flare and Disposal System DG-3575Document25 pagesFlare and Disposal System DG-3575Michael J. BaneNo ratings yet

- CPSA Instructions: Click On The Feet and PSI Tabs To View The ResultsDocument6 pagesCPSA Instructions: Click On The Feet and PSI Tabs To View The ResultsJOHNKNo ratings yet

- IndustrialVentilation MachineRoom PDFDocument4 pagesIndustrialVentilation MachineRoom PDFHassan KhanNo ratings yet

- SMH MTR Calc IiDocument6 pagesSMH MTR Calc IiMichael J. BaneNo ratings yet

- Utility Summary Sheet Design DetailsDocument1 pageUtility Summary Sheet Design DetailsMichael J. BaneNo ratings yet

- Control of The Environment in Elec - Equip.roomsDocument15 pagesControl of The Environment in Elec - Equip.roomsMichael J. BaneNo ratings yet

- Pump Test CurveDocument34 pagesPump Test CurveMichael J. Bane100% (1)

- City Utilities Design Standards Manual CADD Standards Chapter CADD 6 LayersDocument5 pagesCity Utilities Design Standards Manual CADD Standards Chapter CADD 6 LayersMichael J. BaneNo ratings yet

- Buried Pipe Design HDPEDocument8 pagesBuried Pipe Design HDPEMichael J. BaneNo ratings yet

- Pump Cycle Calculator: Input DataDocument2 pagesPump Cycle Calculator: Input DataMichael J. BaneNo ratings yet

- Buried Pipe Design M-1Document12 pagesBuried Pipe Design M-1Michael J. BaneNo ratings yet

- Buried Pipe Design for Deep Rock Petroleum TerminalDocument12 pagesBuried Pipe Design for Deep Rock Petroleum TerminalMichael J. BaneNo ratings yet

- Traffic Loading CalculatorDocument13 pagesTraffic Loading CalculatorMichael J. Bane100% (1)

- Buried Pipe Design for Deep Rock Petroleum TerminalDocument12 pagesBuried Pipe Design for Deep Rock Petroleum TerminalMichael J. BaneNo ratings yet

- Suction Pipeline DesignDocument64 pagesSuction Pipeline DesignMichael J. BaneNo ratings yet

- Underground Petroleum Piping Systems PDFDocument21 pagesUnderground Petroleum Piping Systems PDFMichael J. BaneNo ratings yet

- Graphical Symbols For Piping PlantDocument10 pagesGraphical Symbols For Piping Plantamory23No ratings yet

- Suction PipelineDocument4 pagesSuction PipelinemhsalihNo ratings yet

- Supplementary Documentation of GF SSP Version 605Document71 pagesSupplementary Documentation of GF SSP Version 605Michael J. BaneNo ratings yet

- Process Diagrams ManualDocument1 pageProcess Diagrams ManualMichael J. BaneNo ratings yet

- 11-4080 HYSYS Relief Valve Sizing Demo Guide FinalDocument18 pages11-4080 HYSYS Relief Valve Sizing Demo Guide FinalNoman Abu-FarhaNo ratings yet

- Uniflux Heater Brochure PDFDocument8 pagesUniflux Heater Brochure PDFMichael J. BaneNo ratings yet

- STDRD Details & Typical Drawings PipingDocument55 pagesSTDRD Details & Typical Drawings Pipingarisan47No ratings yet

- South Pars Gas Field Development Phase 13 Identification and NumberingDocument44 pagesSouth Pars Gas Field Development Phase 13 Identification and NumberingMichael J. BaneNo ratings yet

- Pickup and Saltation Velocitiesin Pneumatic ConveyingDocument720 pagesPickup and Saltation Velocitiesin Pneumatic ConveyingMichael J. BaneNo ratings yet

- 05 PDFDocument12 pages05 PDFmos3ad2006No ratings yet