Professional Documents

Culture Documents

BDC148790 5

Uploaded by

clahu66Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BDC148790 5

Uploaded by

clahu66Copyright:

Available Formats

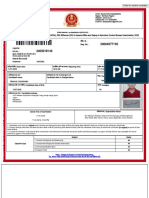

Ironwood Hall, Scottsdale Community College

Scottsdale, Arizona

COMMUNITY

COLLEGES

How to Win More Work

22

ARCHITECTURAL METALS

45

AIA/CES DISCOVERY COURSE

BUILDING ENCLOSURES

55

March 2013

www.BDCnetwork.com

Marchh 2013 3

www.BDCnetwork.com www.BDCuniversity.com

Project: Dallas City Performance Hall

Location: Dallas, TX

Architect: Skidmore, Owings & Merrill LLP

and Corgan Associates

Product: SteelBuilt Curtainwall Infinity System

and SteelBuilt Window & Door Systems

2012 Technical Glass Products. SteelBuilt Curtainwall Infinity and Where Strength Meets Design are trademarks of Technical Glass Products. SteelBuilt Window & Door, Technical Glass Products, One Source. Many

Solutions., and TGP America are registered trademarks of Technical Glass Products.

Where Strength Meets Design

Build your supporting cast without the

limitations of traditional aluminum frames.

Open with taller free spans and larger

lites of glass. The unobstructed views,

smaller frame profiles and thinner profile

depths of steel deliver an artistic vision

that blends the indoors and outdoors. Set

the stage with durable steel curtain walls

and window & door systems.

VISIT TGPAMERICA.COM FOR A CHANCE TO WIN A

NIKON D3100 DIGITAL CAMERA PACKAGE

THE NEW tgpamerica.com | 800.426.0279

Circle 751

Modernizing your facility, and ensuring its prepared for

tomorrow, is simpler than you may think with Siemens

wireless devices. Wireless components eliminate the need for

interconnecting wiring, require no AC power, and utilize low-

power designs, so installations are faster and less disruptive.

Youll use significantly less wire and materials, saving money

and resources whenever you reconfigure a space.

Answers for infrastructure.

usa.siemens.com/wireless

The unlimited flexibility of wireless enables them to be optimally

located for tight temperature control and greater indoor air quality.

This allows you to quickly achieve the delicate balance of a more

comfortable, more energy-efficient environment, no matter the

occupancy demands. Now and in the future, wireless devices are

a smart solution for creating a high-performing building.

Technology that moves as

quickly as their thoughts.

APOGEE wireless devices let you easily and affordably adapt to

changing building needs.

Circle 752

The nations thousand-plus community college districts can be a steady source

of income for your Building Teamprovided you appreciate the special needs of

this important sector of the higher education market.

37 CANADAS ENERMODAL

ENGINEERING: GREEN TO THE CORE

At Enermodal Engineering, theres only one

kind of buildinga sustainable one.

43 REPLACEMENT ESCALATORS GIVE

COBO CENTER A LIFT

New technology enables Detroits Cobo

Center to replace its escalators without

disrupting its convention business.

45 5 NOVEL APPLICATIONS FOR

MESH SCREEN SYSTEMS

From folding faades to colorful LED

displays, these fantastical projects show off

the architectural possibilities of wire mesh

and perforated metal panel technology.

50 HOSPITAL PROJECT BENEFITS

FROM BIM/VDC AND IPD

How BIM/VDC enabled a Building Team to

deliver a truly integrated healthcare project.

AIA CONTINUING

EDUCATION

55 CODES AND COSTS

PUSH TEAMS TOWARD

SUSTAINABLE ENCLOSURES

Earn 1.0 AIA/CES learning units by

studying this article and successfully

completing the online exam.

FEATURES

22

COVER STORY

VOLUME 54, NO. 03

MARCH

How to win more work

from community colleges

ON THE COVER

Ironwood Hall, Chandler-Gilbert Com-

munity College, Chandler, Ariz., part of

the Maricopa County Community College

District. Building Team: Architekton

(architect); Energy Systems Design (MEP);

Arcadia (building envelope); Paragon

Structural Design (SE); Hess-Rountree

(CE); Lord, Aeck & Sargent (laboratory

planner, LEED coordinator); Ecological

Environments (LEED consultant); RC Lurie

(lighting); RAMM (geotechnical); Terrano

Design (landscape architect); Caliente

Construction (CM at risk).

PHOTO: TIMMERMAN PHOTOGRAPHY, INC.

ABOVE

The 46,000-sf Natural Sciences Building,

Scottsdale (Ariz.) Community College, one

of the Maricopa Community Colleges.

Building Team: richrd+bauer (architect);

Energy Systems Design (MEP); Paragon

Design (SE); PK Kland Consulting Civil

Engineers (CE); Research Facilities Design

(lab planner); CF Shuler (landscape archi-

tect); Barton Malow Co. (CM at risk).

M

A

R

K

B

O

I

S

C

L

A

I

R

/

M

A

R

K

B

O

I

S

C

L

A

I

R

P

H

O

T

O

G

R

A

P

H

Y

,

I

N

C

.

www.BDCuniversity.com BUILDING DESIGN+CONSTRUCTION MARCH 2013 5

Circle 753

CALL FOR ENTRIES: BUILDING TEAM AWARDS

Building Design+Constructions Building Team Awards is the industrys only recognition

program to honor new construction projects that exhibit both architectural/construction

excellence and collaboration of all Building Team members. The winners of our 16th annual

program will be featured in the June AIA issue of BD+C. Deadline for entries: March 15,

2013. www.BDCnetwork.com/2013bta

SAVE THE DATE UNDER 40 LEADERSHIP SUMMIT III

Youre invited to join an elite group of the industrys most energetic young professionals

October 9-11, 2013, in San Francisco for an intensive 2-day event aimed at stimulating

your creativity, clarifying your strategic thinking, and networking with other generation lead-

ers in the design and construction industry. www.BDCnetwork.com/U40SF2013

BUILDINGCHICAGO CONFERENCE AND EXPO

Jerry Yudelson, PE, LEED Fellow, author of 13 books on green buildings and a Contributing

Editor to BD+C, will be the featured speaker Wednesday, September 11, at BUILDINGChi-

cago, the new conference and expo set for September 10-12, 2013, in Chicago. Also

on the agenda: Robert Ivy, FAIA, CEO of the American Institute of Architects, who will be

keynoter on Tuesday, September 10. Co-located with BUILDINGChicago is the USGBCs

Midwest conference, Greening the Heartland. www.buildingchicagoexpo.com

APP OF THE MONTH: PLANGRID

A common problem with online project collaboration is keeping tabs on the

latest versions of plans, project details, and documentation. PlanGrid, a free

app, lets you simultaneously view, share, annotate, and sync blueprints on

the iPad and in the cloud. Building Teams can take progress photos and

instantly pin them to the plans, as well as view past versions of drawings

and documents. Up to 10 photos can be uploaded at once from an iPads image library.

Download at: www.BDCnetwork.com/appcenter/plangrid

09 EDITORIAL

Obama on climate change: Four years

too late, or a new tomorrow?

10 NEWS

CURT/FMI study indicates owners still

worried about project capital; BOMA says

yes to benchmarking but no to mandates

18 ON THE DRAWING BOARD

B Resort hotel in Orlando; Rockville,

Md., cancer center; marina hotel in

West Palm Beach; supertall skyscraper

and corporate HQ in China; mixed-use

project for Dallas Design District

62 NEW PROJECTS PORTFOLIO

Houston sports complex; off-campus

community at UCF; suburban Chicago

pharma HQ; police driver training

facility; wine bar in North Naples; three

schools under one roof; Texas junior

high; Dress for Success afliate

66 PRODUCTS AT WORK

Metal ceiling panels, cladding, roof;

translucent transit canopies; standby

power at hospital; curtain wall system;

resilient ooring for childrens hospital

72 ADVERTISER INDEX

74 PRODUCT SOLUTIONS

Accessible bathroom equipment;

re vent plus daylighting; combo

daylighting/LED system

DEPARTMENTS

e-Contents

BD+Cnetwork.com

LIKE BD+C ON FACEBOOK

FOLLOW BD+C ON TWITTER & LINKEDIN

TM

Made in USA

888. 653. 3333

www.saf ti .com/bdc

Circle 754

Icynene has established an international reputation as a leader in spray foam

insulation research and development and sustainable construction technology.

Energy-saving performance is assured with Icynene, with highly innovative

products from water-blown low density open-cell to high R-value medium

density closed-cell and a global pioneer you can count on for premium

quality insulation, service and technical support.

t#VJMEJOH4DJFODF

t%FQFOEBCMF"SDIJUFDUVSBM3FTPVSDFT

t*O)PVTF&YQFSUJTF

4LZIJHIJOOPWBUJPOJO

JOTVMBUJPOTDJFODF

Paul Duffy, M.A.Sc., P. Eng

Icynene Principal Building Scientist

VP Engineering

The Evolution of Insulation

Circle 755

OBAMA ON CLIMATE CHANGE:

four years too late, or a new tomorrow?

F

or hard-core environmentalists, including

many in the greener portions of the design

and construction sector, it was about time.

Many were frustrated with Obama for reneging on

his pledge, made shortly after the 2008 election,

to reduce carbon emissions 80% by 2050.

But like so many others who whined about

how disappointed they were with Obamas rst

termthe healthcare law caved in to the insur-

ance industry, the recovery act was anemic,

and whatever happened to immigration reform

and gay marriage rights?in the end they came

around to his side last November.

So it was something of a surprise to hear the

newly reelected President dare to talk openly

about climate change. Superstorm Sandy

provided a convenient cover for him to call for

a bipartisan, market-based solution to climate

change, reinforcing his case by citing several

ominous data pointsthe most severe drought

in decades, the worst wildres some states

have ever seen, and the 12 hottest years [of

the last 15] on record.

In the very next breath, however, he practi-

cally conceded that such a solution was unlikely,

given the Republican control of the House and

a less-than-super Democratic majority in the

Senate. If Congress wont act soon to protect

future generations, I will, he said.

His plan: a promise to take executive action

to reduce carbon emissions, help communities

prepare for climate change, and speed the

transition to more sustainable sources of ener-

gy, notably more wind energy and natural gas,

both of which come with their own problems.

As for homes and buildings, which account

for a huge 40% share of energy use and carbon

emissions in the U.S., Obama issued a new

goal for America, proposing a 50% cut in ener-

gy wasted by our homes and businesses over

the next 20 years. Apparently forgetting that the

Energy Department alone has 16,000 employ-

ees, he threw it back to the states to come up

with the best ideas to achieve this goal.

We think a lot of the answers are already

available. After the 2008 election, BD+C issued

a set of recommendations to the new Adminis-

tration for reducing greenhouse gas emissions,

based on our earlier 40,000-word White Paper,

Green Buildings + Climate Change (www.

BDCnetwork.com/WhitePaper2008).

In our editorial (www.BDCnetwork.com/

ClimateRecs), we recommended that the new

Administration: 1) focus on conserving energy

in existing buildings and homes; 2) concentrate

on basic building technologies like insulation

and efcient lighting; and 3) consider near-zero,

energy-ready buildings and homes.

We even followed up with two more White

Papers on these topics: Net-Zero Energy

Buildings + Homes (www.BDCnetwork.com/

WhitePaper2011) and High-Performance Re-

constructed Buildings: The 99% Solution (www.

BDCnetwork.com/WhitePaper2012).

We think many of our recommendations are

still validin fact, theyre even more practical

now, given that net-zero energy buildings and

technologies like LEDs are becoming routine.

So, no more ducking the issue, Mr. President.

Future generations are counting on you.

It took him four years to get up the nerve to say it

in public, but President Obama, in his State of the

Union Address on January 21, nally used the phrase

climate change. For the sake of our children and

our future, he told the Congress and the nation, we

must do more to combat climate change.

editorial

3030 W. Salt Creek Lane, Suite 201

Arlington Heights, IL 60005-5025

847.391.1000 Fax: 847.390.0408

STAFF

EDITORIAL DIRECTOR

Robert Cassidy

847.391.1040; rcassidy@sgcmail.com

EDITOR-IN-CHIEF

David Barista

847.954.7929; dbarista@sgcmail.com

SENIOR EDITOR

Julie S. HIgginbotham

847.954.7920; jhigginbotham@sgcmail.com

ASSOCIATE EDITORS

Amy McIntosh, Raissa Rocha

CONTRIBUTING EDITORS

Ted Agres, Susan Bady, Peter Fabris

Barbara Horwitz-Bennett, Pamela Dittmer

McKuen, C.C. Sullivan, Jeff Yoders,

Jerry Yudelson, PE, LEED Fellow

DESIGNER

Elena Mengarelli

DESIGN RESIDENT

Sarah Davidson

WEB DESIGNER

Agnes Smolen

EDITORIAL ADVISERS

David P. Callan, PE, CEM, LEED AP, HBDP

SVP, Environmental Systems Design

Vincent J. DAmbrosio

SVP, Hill International, Inc.

Peter Davoren

CEO, Turner Construction Company

John E. Kemper

Chairman and CEO, KLMK Group

Laurin McCracken, AIA

Marketing Consultant, Jacobs

Philip Tobey, FAIA, FACHA

Senior Vice President, SmithGroupJJR

Randolph Tucker, PE

Associate Principal, ccrd

Peter Weingarten, AIA, LEED AP

Director of the Architectural Practice, Gensler

GROUP DIRECTOR - PRINCIPAL

Tony Mancini

610.688.5553; tmancini@sgcmail.com

EVENTS MANAGER

Judy Brociek

847.954.7943; jbrociek@sgcmail.com

DIRECTOR OF AUDIENCE DEVELOPMENT

Doug Riemer

For list rental information, contact Geffrey Gardner at

845.201.5331; geffrey.gardner@reachmarketing.com

DIRECTOR, CREATIVE SERVICES & PROMOTION

Sandi Stevenson

SUBSCRIPTION INQUIRIES

Circulation Department

Building Design+Construction

3030 W. Salt Creek Lane, Suite 201

Arlington Heights, IL 60005-5025

CORPORATE

Chairman Emeritus (1922-2003)

H.S. Gillette

Chairperson

K.A. Gillette

President/CEO

E.S. Gillette

Senior Vice Presidents

Ann ONeill

Rick Schwer

Senior Vice President/CFO

David Shreiner

Vice President of Custom Media

and Content Management

Diane Vojcanin

Vice President of Events

Harry Urban

For advertising contacts, see page 72.

BUILDING DESIGN+CONSTRUCTION MARCH 2013 9

JAIL COURTHOUSE, 2-3 STORIES POLICE STATION POST OFFICE

13 12 % chg. 13 12 % chg. 13 12 % chg. 13 12 % chg.

Atlanta 267.24 261.96 2.0 186.56 186.34 0.1 217.74 214.97 1.3 125.10 123.55 1.3

Baltimore 281.92 276.17 2.1 196.81 196.44 0.2 229.70 226.63 1.4 131.98 130.25 1.3

Boston 358.62 347.80 3.1 250.35 247.40 1.2 292.19 285.41 2.4 167.88 164.03 2.3

Chicago 355.63 345.14 3.0 248.26 245.50 1.1 289.75 283.22 2.3 166.48 162.77 2.3

Cleveland 301.10 292.15 3.1 210.20 207.81 1.1 245.32 239.74 2.3 140.95 137.79 2.3

Dallas 257.66 251.60 2.4 179.87 178.97 0.5 209.93 206.47 1.7 120.62 118.66 1.6

Denver 284.02 278.83 1.9 198.27 198.34 0.0 231.41 228.81 1.1 132.96 131.50 1.1

Detroit 312.78 304.88 2.6 218.35 216.87 0.7 254.84 250.19 1.9 146.42 143.79 1.8

Houston 260.65 255.15 2.2 181.96 181.49 0.3 212.37 209.38 1.4 122.02 120.34 1.4

Kansas City, Mo. 315.18 306.66 2.8 220.03 218.13 0.9 256.79 251.64 2.0 147.54 144.63 2.0

Los Angeles 324.47 316.42 2.5 226.51 225.08 0.6 264.36 259.66 1.8 151.89 149.23 1.8

Miami 270.54 265.22 2.0 188.86 188.65 0.1 220.42 217.64 1.3 126.65 125.08 1.3

Minneapolis 335.85 329.45 1.9 234.46 234.34 0.0 273.64 270.35 1.2 157.22 155.37 1.2

New Orleans 266.64 261.37 2.0 186.14 185.92 0.1 217.25 214.48 1.3 124.82 123.27 1.3

New York City 399.37 391.31 2.1 278.80 278.35 0.2 325.39 321.11 1.3 186.95 184.55 1.3

Philadelphia 268.14 261.96 2.4 187.19 186.34 0.5 218.47 214.97 1.6 125.52 123.55 1.6

Phoenix 252.81 249.63 1.3 179.54 177.91 0.9 207.76 204.58 1.6 118.37 115.78 2.2

Pittsburgh 310.09 300.44 3.2 216.47 213.71 1.3 252.64 246.54 2.5 145.16 141.69 2.4

Portland, Ore. 301.10 294.52 2.2 210.20 209.50 0.3 245.32 241.69 1.5 140.95 138.90 1.5

St. Louis 311.58 303.40 2.7 217.52 215.81 0.8 253.86 248.97 2.0 145.86 143.09 1.9

San Diego 312.78 304.88 2.6 218.35 216.87 0.7 254.84 250.19 1.9 146.42 143.79 1.8

San Francisco 373.30 365.26 2.2 260.60 259.82 0.3 304.15 299.74 1.5 174.75 172.27 1.4

Seattle 314.58 308.43 2.0 219.61 219.39 0.1 256.31 253.10 1.3 147.26 145.46 1.2

Washington, D.C. 296.30 290.67 1.9 206.85 206.76 0.0 241.41 238.53 1.2 138.71 137.09 1.2

Winston-Salem, N.C. 236.98 224.66 5.5 165.44 159.81 3.5 193.08 184.36 4.7 110.94 105.96 4.7

RSMEANS COSTS COMPARISONS: Jails, courthouses, police stations, post ofces

COSTS IN DOLLARS PER SQUARE FOOT FOR MORE DATA, VISIT RSMEANS AT WWW.RSMEANS.COM, OR CALL (800) 448-8182.

BUILDING OWNERS SAY FUNDING, STAFFING ISSUES

STILL AFFECTING CAPITAL CONSTRUCTION

BY JULIE S. HIGGINBOTHAM, SENIOR EDITOR

news

P

rivate- and public-sector owners of

large capital programs remain con-

cerned about the availability of project

funding, as well as regulatory issues and

internal stafng. The 2012 CURT/FMI Owner

Study, a joint project of consultant FMI

and the Construction Users Roundtable,

projected that construction put-in-place

volumes for 2012 will be 5% higher than

in 2011a hopeful sign, considering that

the industry has contracted by roughly

30% since 2006. A large percentage of

owners said they lack condence in their

ability to devise effective responses, ac-

cording to the report.

Availability of project funding re-

mains the top concern, with 50% of

respondents saying the issue is having

a moderate to high impact on capital

programs. Owners are also fretting about

the talent pool, with 40% saying that

internal stafng is a signicant current

issue. Twenty percent of respondents

report difculty nding qualied planning,

design, or construction partners. Regulatory

compliance and permitting are a signicant

concern for 36%.

Economic issues continue to plague

projects, especially in terms of scope changes

(reported by 58% of respondents) and delays

(reported by 83%). Outright cancellations are

also occurring (41%). Nearly all respondents

(93%) say they have resorted to regular use of

Availability of project funding and internal stafng led capital-program owners list of signicant issues.

CAPITAL FUNDING LEADS OWNER CONCERNS

SOURCE: 2012 FMI/CURT OWNER STUDY

10 MARCH 2013 BUILDING DESIGN+CONSTRUCTION www.BDCnetwork.com

STANDS UP TO YOUR

TOUGHEST STUDENTS.

AND YOUR

TOUGHEST DEMANDS.

2013 Masco Corporation of Indiana

H2Optics

EDUCATION. YOU LIVE IT. WE GET IT.

From vandal-resistance to water-efciency, we understand the

challenges of todays educational facilities. And we deliver solutions

that stand the test of time. Visit deltafaucet.com/education or scan

the code to download our Education Solutions brochure.

Laboratory Flush Valves H

2

Okinetic

Technology

Circle 756

The power of possibilities

forget ber cement as you know it,

this is the Element of Surprise

Ks

KuraStone

12

Fiber

Cement

Ab

Architectural

Block

8

Fiber

Cement

Vw

VintageWood

16

Fiber

Cement

Ss

Sandstone

10

Fiber

Cement

Is

Illumination

Series

6

Fiber

Cement

Pb

PlymouthBrick

18

Fiber

Cement

Vb

VintageBrick

18

Fiber

Cement

Fs

FieldStone

14

Fiber

Cement

Eb

EmpireBlock

16

Fiber

Cement

Weve taken ber cement way beyond lap siding. The common perceptions of

ber cement have been far too limited for far too long...were determined to change those

perceptions. Nichiha offers a true ber cement drained and back ventilated rainscreen system

engineered to stand up to the rigors of a commercial application. Our hidden fasteners, varied

textures and virtually limitless color palette has people believing that Nichiha ber cement is

more than a building material...its an element of surprise.

Golden Gate Pavillion

Architectural Firm: Project Frog

Product: Illumination Series

nichiha.com/elementofsurprise

Qs

QuarryStone

Panels

14

Fiber

Cement

Cb

CanyonBrick

18

Fiber

Cement

2013 NICHIHA USA, INC.

Fiber Cement

Circle 757

fireglass.com

FireLite

Family of Products

Build a LTR with TGP and get

unmatched service and support, plus

the very best products like FireLite.

This fire-rated glazings unique

ultraHD Technology delivers a clearly

superior product. Take a closer look

at how the clarity and sharpness

compares to the competition at

fireglass.com/hd.

Fire ratings up to 3 hours

High impact safety ratings

UL listed and labeled

Seeking long-term relationship

with secure, polished single with

a clear view of the world. Not

into labels (except the fire-rated

kind). Must be beautiful on the

inside and out. Can you take the

pressure? Dont reply if you are

looking for the dull or wired type.

Email me sales@fireglass.com.

Circle 758

www.BDCuniversity.com

Robert Ivy, FAIA, CEO of the American Insti-

tute of Architects, will be the keynote speaker

at BUILDINGChicago on Tuesday, September

10, 2013. Jerry Yudelson, PE, LEED Fellow,

the author of 13 books on sustainable design,

will deliver the Wednesday, September 11,

keynote address.

Ivy served as Vice President/Editorial

Director of McGraw-Hill Construction and

Editor-in-Chief of Architectural Record. Under

his tenure, Record received the National

Magazine Award for General Excellence. In

2009, Ivy received the G.D. Crain Award for

lifetime contributions to editorial excellence in

business media.

Ivy, who started his architectural career as

a principal at Dean, Dale, Dean, & Ivy, Jack-

son, Miss., will discuss Current and Future

Trends in the AEC Industry.

Yudelson, one

of the rst group

of professionals to

be named a LEED

Fellow, has written

13 books on green

building, most

recently The Worlds

Greenest Buildings:

Promise vs. Perfor-

mance in Sustainable

Design (with Ulf Meyer). In the past ve years

he has keynoted nearly 100 green building

conferences in 14 countries.

Yudelsons topic, What Do They Know that

We Dont? Lessons from Beyond the U.S., is

based on the research for his latest book.

For conference details: www.buildingchica-

goexpo.com.

ROBERT IVY, JERRY YUDELSON ANNOUNCED

AS KEYNOTERS FOR BUILDINGCHICAGO

N

O

A

H

K

A

L

I

N

Robert Ivy, FAIA

self-funding due to the capital crunch.

Owners express cautious optimism

about growth in 2013, but expect to face a

tight commercial lending market for years

to come. Look for continued migration of

capital-projects talent across the indus-

try, as owners of large programs work to

recruit appropriate staff in market sectors

and regions where economic recovery is

taking hold.

The American Institute of Architects has

elevated 122 members to its College of

Fellows: an honor recognizing signicant con-

tributions to the profession. Only about 3,100

members have achieved the designation, out

of a total membership of more than 83,000.

Fellows must have been AIA members for at

least 10 years, and must have distinguished

themselves by making a signicant contribu-

tion to architecture and society and achieving

a standard of excellence in the profession.

The AIA also conferred Honorary FAIA sta-

tus on seven international architects for their

distinguished achievements.

The 2013 Jury of Fellows included Linda

Searl, FAIA, Searl Lemaster Howe Architects;

John Castellana, FAIA, TMP Architecture;

Brian Dougherty, FAIA, Dougherty + Dough-

erty Architects; Leevi Kiil, FAIA, Leevi Kiil

Architect; Susan Maxman, FAIA, SMP Archi-

tects; Craig Rafferty, FAIA, Rafferty Rafferty

Tollefson Lindeke Architects; and Raymond

Yeh, FAIA, Yeh Studio. For a complete list of

the 2013 honorees: www.bdcnetwork.com/

AIA2013Fellows.

AIA HONORS 2013 CLASS OF FELLOWS

SmithGroupJJR Vice President Gregory A.

Mella, FAIA, LEED AP, was recently elevated to

the AIA College of Fellows. Mella was one of

BD+Cs 40 Under 40 honorees in 2010.

Edge To Edge & Deck To Sky

800-248-0280

www.duro-last.com / Twitter: @durolast

Duro-Last,EXCEPTIONAL, and the Worlds Best Roof

are registered marks owned by Duro-Last Roofing, Inc.

EXCEPTIONAL Metals is a division of Duro-Last Roofing, Inc.

EXCEPTIONAL

Metals

Edge Details

& Accessories

Duro-Guard

Insulation

Best PVC

Membranes

Duro-Last

is your single-source for complete

roofing systems, engineered to provide long-term

edge to edge and deck to sky

protection.

Installed by authorized contractor, then

inspected and warranted by the industrys

largest and best-trained quality assurance team.

CONTACT DURO-LAST ROOFING, INC.

FOR THE WORLDS BEST ROOF

Custom Prefabricated

Flashings

The Industrys Best

Warranties

news

Circle 759

14 MARCH 2013 BUILDING DESIGN+CONSTRUCTION www.BDCnetwork.com

BOMA, the Building Owners and Manag-

ers Association International, has released

a position statement supporting voluntary

energy benchmarking but opposing state and

BOMA ENDORSES BENCHMARKING, OPPOSES MANDATES

municipal mandates. The organization encour-

ages members to benchmark their projects at

least annually, using Portfolio Manager from the

Environmental Protection Agency or a similar

program. However, state and municipal rules

for mandatory energy benchmarking are

creating a patchwork of varied and unwieldy

requirements, says BOMA.

Instead, the group supports the creation

of a national model building energy perfor-

mance program, based on the Portfolio Man-

ager platform. Utilities should be required to

provide whole-building benchmarking data to

owners and managers, with disclosure limited

to parties involved in a sale, lease, or nanc-

ing transaction. BOMA also favors more

federal funding for improving the Commercial

Buildings Energy Consumption Survey and

supporting EPA Energy Star.

More info: www.BDCnetwork.com/

BOMA.

Julie S. Higginbotham

is the new Senior

Editor of BD+C. She

was most recently

Editor of Laboratory

Design newsletter at

Advantage Business

Media, where she

also supervised the

companys annual

Laboratory Design Conference and its

prestigious Laboratory of the Year

awards program.

A graduate of Southern Illinois Univer-

sity, she was formerly Managing Editor of

School Planning & Management, College

Planning & Management, and Building Sup-

ply Home Centers, and Editor of American

Nurseryman. Her professional honors in-

clude the Jesse H. Neal National Business

Journalism Award and multiple regional and

national awards from the American Society

of Business Publication Editors.

Higginbotham can be reached at jhiggin-

botham@sgcmail.com; 847-954-7920.

HIGGINBOTHAM

JOINS BD+C

AS SENIOR EDITOR

Circle 760

FOR MORE INFORMATION, VISIT WWW.INSULATEDMETALPANELS.ORG

s(IGHEST26ALUEPERINCH

s#ONSISTENTINSULATION

s%XCEEDENERGYCODEREQUIREMENTS

s6IRTUALLYENDLESSDESIGNOPTIONS

s1UICKINSTALLATIONLOWMAINTENANCE

Insulated Metal Panels

6" Traditional Stud Insulated Wall

R-7.4

3" Insulated Metal Wall Panel

R-21

Traditional stud insulated walls

reduce the R-Value as much as

65% (according to ASHRAE 90.1).

IMPRESSIVE

THERMAL PERFORMANCE

news

Circle 761

16 MARCH 2013 BUILDING DESIGN+CONSTRUCTION www.BDCnetwork.com

NEWS BRIEFS

JONES LANG LASALLE predicts an uptick

in HOTEL TRANSACTION ACTIVITY in

the Americas during the next ve years.

Hotels should remain a favored asset class

among lenders and investors, according

to the forecast. www.BDCnetwork.com/

JonesLangHotels

NEW JERSEY has passed two bills that

would require installation of GREEN AND

BLUE ROOFS on new government build-

ings with roofs of at least 15,000 sf.

www.BDCnetwork.com/JerseyGreenRoof

The FEDERAL RESERVE BOARD and

UCLA PROFESSOR STEPHEN OLINER

have collaborated on a study indicating that

PLANNING TIME FOR COMMERCIAL

CONSTRUCTION varies widely across the

U.S. The average is ~17 months, but large

projects and those in highly regulated areas

like the Northeast and California average

much longer. www.BDCnetwork.com/

ConstructionPlanmap.

PHILADELPHIA has joined the ranks of

U.S. cities requiring large buildings to use

Portfolio Manager, the free ENERGY MAN-

AGEMENT TOOL offered by the ENVI-

RONMENTAL PROTECTION AGENCY,

to measure and report energy performance.

www.BDCnetwork.com/PortfolioManager

Insurance expert MORY KATZ, Vice

President at VERISEK Insurance Solutions

Commercial Property, Jersey City, N.J., says

the growing probability of more storms with

HIGH WINDS should prompt widespread

re-examination of BUILDING CODES.

www.BDCnetwork.com/windstorm

The Products at Work item Restroom

Partitions Stand Up to Thousands of

DC Theater Patrons (February, page

60) included an incorrect photo. The

correct image, shown here, features an

installation of Scranton Products Hiny

Hiders bathroom partitions at the Louis

Converse Cramton Auditorium in Wash-

ington, D.C. BD+C regrets the error.

CORRECTION

Alucobond Spectra Colors dress up your projects by breaking light into a luminous spectrum of colors that change based on the viewing angle.

Or, choose Alucobond NaturAL with fnely textured surfaces that accentuate the sophisticated beauty and style of aluminum.

To learn more about the worlds favorite ACM for over 40 years, visit AlucobondUSA.com or call 800.626.3365.

ACCESSORIZE YOUR DESIGNS.

alucobondusa.com

Alucobond

is a registered trademark of 3A Composites USA, Inc.

3A Composites USA, Inc. 2013. All rights reserved.

3A Composites USA Inc.

800.626.3365

Circle 762

BY RAISSA ROCHA, ASSOCIATE EDITOR

1

RENOVATION TRANSFORMS HOTEL INTO

NEWEST B RESORT PROPERTY

VOA Associates is serving as design architect, planner, and

interior designer for a renovation that will turn a Royal Plaza Hotel

into the B in the Walt Disney World Resort. The Orlando, Fla.,

project is the fourth new hotel associated with the B Hotels &

Resorts brand in less than 18 months. The existing 394-room

hotel, which will operate throughout the renovation, was acquired

by a joint venture between InSite Group and Cube Capital. The

new resort is slated to debut this fall.

2

COMMUNITY CANCER CENTER

COMING SOON TO ROCKVILLE

Construction is under way at the $12 million, 51,000-sf Aquilino

Cancer Center, located on the Shady Grove Adventist Hospital

campus in Rockville, Md. Scheduled for completion this summer,

the community-based freestanding comprehensive cancer center

is the rst of its kind in Montgomery County and will include two

linear accelerator vaults for radiation equipment. Services range

from diagnostics to radiation and chemotherapy, as well as pain

and symptom management, multidisciplinary clinics, and clinical

trials. Local rm Forrester Construction is building the facility,

which was designed by AECOM.

ON THE

drawing board

11111

22

33333333

18 MARCH 2013 BUILDING DESIGN+CONSTRUCTION www.BDCnetwork.com

3

FLORIDA HOTEL WILL OFFER VIEWS

OF PALM HARBOR MARINA

Adache Group Architects of Fort Lauderdale, Fla., is designing

a new marina hotel in downtown West Palm Beach. The Palm

Harbor Marina Hotel will take advantage of waterfront views and

provide guests with a rooftop pool, terrace, and patio bar. The

150-suite hotel will also feature 5,500 sf of space for conference

facilities, a tness and lifestyle center, and a lobby lounge with

exterior seating. Construction is anticipated to begin this summer,

with completion slated for summer 2015. The hotel is owned by

Chase Enterprises.

4

SUPERTALL SKYSCRAPER PLANNED FOR

CAPITAL OF GUANGXI PROVINCE

John Portman & Associates has been selected by developer

Guangxi Wei Zhuang Real Estate Co. to design Tian Long

Fortune Center, the rst supertall skyscraper in Nanning,

China. With a height of 1,312 feet, the building will provide new

headquarters for member companies of ASEAN (Association

of Southeast Asian Nations) and is envisioned as a nance and

trade center. The upper portion of the tower will include an atrium

hotel with a tness center, pool, executive club, and restaurants.

The building also will contain a public observation complex,

providing a 360-degree view.

44444

www.BDCuniversity.com BUILDING DESIGN+CONSTRUCTION MARCH 2013 19

555555555

66666666666666666666 888888888888888888888888888888888888888888888

77777777777777

5

CORPORATE HEADQUARTERS

IN THE WORKS IN XIAOSHAN DISTRICT

A 52-story ofce building is currently in development in the

Xiaoshan District in Hangzhou, China. Designed by Chicagos

Turner + DeCelles for the Zhejiang Hengyi Group, the tower

will provide ofce space for ~2,000 employees. A below-grade

transit superstation will house conference facilities, retail

shops, and parking. Approximately half of the ofce space will

be held for future growth but leased to tenants on an interim

basis. Also on the Building Team: BMP Project Consulting

(program manager) and Tongji Architectural Design of Shanghai

(local design rm).

6

NEW HOSPITAL COMPLEX IN FLORIDA TO

INCLUDE INPATIENT, OUTPATIENT CARE

St. Josephs Hospital-South in Riverview, Fla., is a new

325,000-sf acute care hospital and 80,000-sf physicians

ofce building complex. The $224 million, 112-bed hospital is

designed for both inpatient and outpatient care, with facilities

for a variety of medical specialties and surgeries, diagnostic

imaging, emergency, and intensive care units. The Building

Team includes Gresham Smith and Partners (lead architect),

Smith Seckman Reid (MEP), Stantec (civil/landscape engineer),

and Barton Malow (CM).

7

MIXED-USE PROJECT IN DALLAS WILL ADD

RETAIL, RESIDENTIAL SPACE TO

DESIGN DISTRICT NEIGHBORHOOD

District 1444: The Design Village is the newest development for

Harwood International and will be located in Dallass historic Design

District. The ve-story urban development will replace an old

showroom building, and will offer 224 apartment units, a rooftop

pool, and more than 46,000 sf of retail space. The apartments will

be set above a variety of ground-level gardens, shops, cafes, and

restaurants. The project is being designed by Harwood Design

Factory and will break ground this spring.

8

HISTORIC LOS ANGELES APARTMENT COMPLEX

RECEIVES RESTORATION, FACELIFT

A $140 million redevelopment by Denver-based building owner

Aimco and commercial builder Bernards is under way at a landmark

apartment complex in Los Angeless Venice district. Built between

1949 and 1951, Lincoln Place is listed on both the National and

California Registers of Historic Places, and was designed by Heth

Wharton and Ralph A. Vaughn. The complex, which consists of

45 buildings with 696 units, will be restored and modernized in

accordance with the Secretary of Interiors historic preservation

standards. New amenities include a pool, rooftop social deck,

tness center, Internet caf, and open green space.

20 MARCH 2013 BUILDING DESIGN+CONSTRUCTION www.BDCnetwork.com

When performance goes up, so do reputations. Thats why you should specify enhanced DensDeck

Prime Roof Boards.

In adhered, single ply membrane testing, enhanced DensDeck Prime demonstrated an average of 24% better bond

strength than original DensDeck Prime when using solvent-based adhesives.* This leads to an overall stronger assembly

and a better performing roof. Georgia-Pacifc Gypsum and you.

Building Reputations Together

Learn more at www.DensDeck.com.

*Actual results may vary. Average based on 60 sq. ft./gal. coverage rates. Check manufacturers recommended application rates.

2013 Georgia-Pacifc Gypsum LLC. All rights reserved. DENSDECK, the color GOLD, BUILDING REPUTATIONS TOGETHER and the Georgia-Pacifc logo

are trademarks owned by or licensed to Georgia-Pacifc Gypsum LLC.

BOOST PERFORMANCE WITH NEW DENSDECK

PRIME.

Circle 763

22 MARCH 2013 BUILDING DESIGN+CONSTRUCTION www.BDCnetwork.com

community

HOW TO WIN

MORE WORK

FROM

SECOND IN A SERIES

Higher Education Facilities

2013

www.BDCuniversity.com BUILDING DESIGN+CONSTRUCTION MARCH 2013 23

The editors wish to thank Arlen Solochek, AIA, District Director of

Facilities Planning and Development, Maricopa County (Ariz.) Com-

munity College District, for serving as Special Technical Consultant

for this report.

N

o capital development manager or facilities planner in

higher education faces more difcult budgetary decisions

than those serving the nations 1,132 community col-

leges. The recession of 2008-09 led to reduced funding

to two-year colleges in all but a few states, while at the same time

prompting a massive inux of unemployed civilian workers in search

of career retraining.

Thirteen million students enrolled in for-credit and noncredit

courses at community colleges in 2009, representing 44% of all un-

dergraduates in the U.S. A substantial percentage (42%) are the rst

in their family to go to college, according to the American Associa-

tion of Community Colleges.

Keeping their programs affordable for a broad range of students

is central to the mission and appeal of community colleges. Tuition

accounted for only 16% of revenues in 2008-09, according to the

AACC, compared with about 50% for public four-year universities.

Many community college students have to hold down jobs to make

that tuition. Twenty-one percent of full-time community college stu-

dents hold full-time jobs, another 59% of full-timers hold part-time

jobs, and 87% of part-time students are employed.

Less than half of these students (46%) get nancial aid. Many are

raising young families, 13% of them on their own. Three percent are

returning veterans looking to upgrade their skills in order to re-enter

a less-than-welcoming job market.

The 51,605-sf South Mountain Community Library, a joint venture of Mari-

copa Community Colleges and the city of Phoenix, contains a 200-seat

meeting room. Design rm richrd+bauer led the Building Team of Energy

Systems Design (MEP); Rudow + Berry (SE); Dibble Engineering (CE);

McKay Conant Hoover (acoustical); Roger Smith Lighting Design; Kimley-

Horn & Associates (landscape architect); Drew Harrington Associates

(library design consultant); and Haydon Building Corp. (CM at risk).

BY PETER FABRIS, CONTRIBUTING EDITOR

The nations thousand-plus community college

districts can be a steady source of income for

your Building Teamprovided you appreciate

the special needs of this important sector of the

higher education market.

trends analysis report

HIGHER EDUCATION FACILITIES

colleges

M

A

R

K

B

O

I

S

C

L

A

I

R

/

B

O

I

S

C

L

A

I

R

P

H

O

T

O

G

R

A

P

H

Y

/

C

O

U

R

T

E

S

Y

R

I

C

H

R

D

+

B

A

U

E

R

M

I

C

H

A

E

L

T

.

M

A

S

E

N

G

A

R

B

/

C

O

U

R

T

E

S

Y

A

R

C

H

I

T

E

K

T

O

N

Maricopa Community Colleges teamed with

Valley of the Sun YMCA and Foothills Com-

munity Foundation to construct a recreation

center (left), which Paradise Valley Communi-

ty College at Black Mountain uses for tness/

health courses. The college and the founda-

tions Holland Community Center share a

separate building (below). Building Team:

Architekton (architect); Zak Heidman and

Associates (MEP); Rudow + Berry (SE); David

Evans & Associates (CE); URS Archeological.

24 MARCH 2013 BUILDING DESIGN+CONSTRUCTION www.BDCnetwork.com

The result, says Arlen Solochek, AIA,

District Director of Facilities Planning and

Development, Maricopa County (Ariz.)

Community College District, is that many

community college students are one car

breakdown from dropping out. Raising

tuition and fees signicantly is not an option

for most community college districts, which

rely heavily on funding from their states

(34%), local governments (20%), and the

federal government (16%).

Twenty years ago, we got 17% of our

budget from the state; today, its $8 million,

less than 1% of our $1.6 billion total, says

Solochek. Our chancellorRufus Glasper,

PhDrecently said, We used to be state-

funded, then we became state-supported,

and now were state-located.

Adding to the woes of community col-

leges: Many of their buildings are 40 or 50

years old and sorely in need of upgrades

and renovations, not to mention daily main-

tenance. A report last May in The Chronicle

of Higher Education showed community

colleges nationally facing a maintenance

backlog of at least $120/sf, versus $79/

sf for all higher-ed institutions. At 5.8 mil-

lion sf, our district alone would need $700

million just to maintain current conditions,

says Solochek. No way I could ask for that

kind of money.

The upshot of all this is that community

colleges are looking to you, their Building

Team partners, for cost-effective solutions

to these problems. Weve got to squeeze a

dime out of every seven cents, says Solo-

chek. Though funds are short, community

colleges are managing to take on new proj-

ects, albeit with long waits to secure nanc-

ing. Capital planners and facilities directors

in this arena must be highly resourceful and

innovative, and they need Building Teams

who understand their plight and are eager

to share the burden of responsibility.

START WITH THE CLASSIC

QUESTON: RENOVATE OR

BUILD NEW?

Lets begin in California, home to 110 com-

munity colleges. Historically, the Golden State

has been generous to higher education, but

over the past four years, amid massive state

budget decits, funding to community col-

leges statewide has been cut by $809 million,

or 12%. Many have had to trim their class of-

ferings, increase class size, and lay off faculty

and staff. As for new money for constructing

facilities, thats way down the list of priorities.

A lot of districts have held off on new

buildings, says Frank Gornick, PhD, Chan-

cellor of West Hills Community College Dis-

trict in central California. Several buildings

at its Coalinga campusone of two in the

West Hills districtare over 50 years old,

and a major earthquake that hit Coalinga

in the 1980s is still taking a toll on campus

infrastructure, says Gornick.

The districts deferred maintenance

backlog has grown signicantly since the

start of the recession. Weve had to focus

our capital funds on maintenance, says

Weve got to squeeze a dime

out of every seven cents.

Arlen Solochek, Maricopa County

Community College District

M

I

C

H

A

E

L

T

.

M

A

S

E

N

G

A

R

B

/

C

O

U

R

T

E

S

Y

A

R

C

H

I

T

E

K

T

O

N

Gornick. Although West Hills has been able

to pass bond referenda for capital con-

struction, the district has had to dip into

cash reserves and direct some of that bond

money toward maintenance.

Well aware that a reactive strategy would

not be cost-effective over the long run, Gor-

nick has put the college on course for a major

redesign of the Coalinga campus, including

replacement of all buildings. Bakerseld-

based AP Architects is leading the master

plan effort. These new buildings are going to

cost much less to operate over the long haul,

because they will be more efcient, he says.

Gornick, who serves as Chair of the

Board of Directors of the California Com-

munity College Facility Coalition, says that

many member systems face the same

perplexing renovate-or-build-new decision.

Building Teams need to be ready to offer

such clients comprehensive services, in-

cluding master planning, to help them think

through this critical decision.

SEEK CREATIVE ROUTES

TO PROJECT FINANCING

Community colleges are nding innovative

ways to pay for new capital projects. West

Hills used a little-known federal tax credit

program to fund a $20 million, 52,000-sf

multi-use sports/entertainment structure.

The New Markets Tax Credit program, ad-

ministered by the U.S. Treasury Department,

is aimed at revitalizing low-income communi-

ties. In return for signicant tax breaks, the

program allows private investors to nance

projects in qualifying regions. According to

Gornick, this was the rst time this program

was used by a California community college.

West Hills is among a number of commu-

nity college districts that are forging partner-

ships with public high schools. The college

will be paying for upgrades at Riverdale High

School to bring its science labs up to the

colleges standards. West Hills students will

have access to the labs weekday evenings

and all day on weekends; the high school

will be responsible for maintenance.

Maricopa Community Colleges teamed up

with the city of Phoenix to build the joint-use

South Mountain Community Library, designed

by Phoenix rm richrd+bauer. If it was

strictly a community college library, it would

have been just 35,000 sf, says Solochek. A

city branch or regional library would normally

be 15,000 sf to 20,000 sf. The new fusion

library is 51,605 sf. The colleges 69% share of

construction costs, site work, and equipment

came to $15.9 million, for a much more func-

tional spaceincluding a meeting room

than it could have afforded on its own.

A more complicated scenario involved

Maricopa and two nonprot partnersthe

YMCA, which wanted to build a new recre-

ation center in the county; and the Foothills

Community Foundation, a civic/education/

cultural group that was looking for a new

permanent location.

According to Solochek, the college pur-

chased a site in Scottsdale in the mid-1990s

C

O

U

R

T

E

S

Y

A

P

A

R

C

H

I

T

E

C

T

S

The 52,000-sf West HIlls College LeMoore (Calif.) Multi-Use Sports Complex, home of the Golden Eagles, can accommodate 2,400, using telescopic

seating. The $20 million facility, nanced through federal tax credits and general obligation bonds, can be used for concerts and community events.

trends analysis report

HIGHER EDUCATION FACILITIES

26 MARCH 2013 BUILDING DESIGN+CONSTRUCTION www.BDCnetwork.com

with the intent of developing an early-phase

campus there in the latter part of its 10-year

2004 bond program. In 2005, the Y ap-

proached the community college district to

see about a possible partnership. The easy

route would have been for the college sim-

ply to donate the land to the Y, but Arizona

law prohibited such gifts.

Over the next two years, the Y and

Foothills formed a separate nonprot

entity to become, in effect, the buyer;

the new entity and Maricopa hammered

out a memorandum of understanding

that covered general objectives and roles,

development agreements for the design

and construction process, an operating

agreement delineating each of the parties

responsibilities, cost sharing, and numer-

ous other details.

The project, designed by Architekton,

was completed in the fall of 2009. The Y

got its own 27,800-sf facility; the college

and the foundation share a 20,650-sf build-

ing. We had to do some things so that we

werent duplicating restrooms and so on,

says Solochek. We created a legal prop-

erty line down the middle because the foun-

dation could not build on our property. Even

though the city had never done anything

like this before, they were very helpful.

Solochek says it was a good deal for all

concerned. Our share of design and con-

struction costs was about $2.9 million, but

we also had the cash from the land sale to

the Y, so we got a nice classroom complex,

plus access to a full recreation facility, a

large meeting room, and a cultural re-

source center for a very reasonable amount

of money, years ahead of what we had

planned, he says. Were now starting to

work on the remaining project development

that will complete the balance of the 2004

bond program plans for the site.

Building Teams involved with such

trends analysis report

HIGHER EDUCATION FACILITIES

The 85,000-sf, LEED Gold Student Services Center at Mesa College, part of the San Diego Com-

munity College District, unites Admissions, Financial Aid, Evaluation/Testing, Counseling, Disability

Support Programs and Services, Information/Outreach, and student government under one roof.

FOUR WAYS TO WOW

community college clients

1. HELP YOUR CLIENT FIND COST SAVINGS.

Treat our projects as if you were spending your

own money, says Arlen Solochek, AIA, District

Director of Facilities Planning and Development,

Maricopa Community Colleges. We know what

you are used to spending on private-sector jobs.

A pet peeve I have is when contractors dont

hold down overhead costs: Do you really need

that second work-site trailer?

Sally Grans-Korsh, FAIA, LEED AP, former

Director of Facilities Planning for the architect

of the Minnesota state college system, recalls a

renovation project where the contractor asked

the college to change the curriculum so that the

lab would not be needed for the next semester;

this enabled the contractor to finish the job

months sooner than planned. He would have

made more money with a longer construction

schedule, but he realized it was not in the best

interest of the college, says Grans-Korsh, Prin-

cipal Consultant/Owner of Minneapolis-based

ArchiStudio. We were impressed.

2. MAINTAIN CLOSE COLLABORATION

BETWEEN OWNER AND ARCHITECT, espe-

cially on design-build projects. Solochek says

theres a reason he seldom uses design-build

project delivery: I dont want the contractor

between me and the architect. He recalls

a project from bygone years. We said the

HVAC system plan wasnt going to work, and

the contractor went to the engineer and they

insisted that it would work. Sure enough, it

didnt work, and we had a big fight over it.

3. SHOW HOW YOU WOULD MANAGE

PROCESSES in projects with multiple client

partners. Building Teams are going to have to

demonstrate in their RFP responses and inter-

views how the would deal with multi-client proj-

ectsor how they have done so in the pastto

give me confidence that they can manage these

processes on my project, says Solochek.

4. ADVOCATE FOR THE COLLEGES BEST

OPTIONS when dealing with design planning

committees. Use your professional perspec-

tive to help enlighten people that have a

more limited perspective, says Grans-Korsh.

The worst examples are projects where the

designers did exactly what the college offi-

cials said they wanted, even though that is

not what the college needed.

Peter Fabris

B

R

Y

A

N

W

A

Y

N

E

,

G

A

F

C

O

N

/

C

O

U

R

T

E

S

Y

S

A

N

D

I

E

G

O

C

O

M

M

U

N

I

T

Y

C

O

L

L

E

G

E

D

I

S

T

R

I

C

T

WEVE LEARNED A LOT

ABOUT EDUCATIONAL

FLOORING SOLUTIONS.

From you.

Designing for education is all about collaboration.

Engaging you early in the design process has

often inspired flooring solutions that bring a sense

of purpose and energy to your project.

These colorful, durable, sustainable solutions are

ideal for classrooms, corridors, laboratories, cafeterias

and more. Designed for the challenges of learning

environments, nora

rubber flooring is long lasting,

requires less maintenance, and contributes to better

indoor air quality.

It all starts with you.

You and your challenges.

You and your world.

You and nora.

800-332-NORA

www.nora.com/us/education41

Follow us: @noraflooring

Circle 764

partnerships need to be aware that they can

be complicated and time-consuming. The

Maricopa-YMCA-Foothills cost-sharing deal

took nearly two years to work out. If youre

working with multiple user groups, you have

to keep in mind that each of them has its

own processes, expectations, and personal-

ity, says Solochek. Its going to take more

work to get everyone rowing in unison.

Building Teams involved in future multi-

partner projects must also actively engage

in the negotiations and use their expertise

in codes, zoning ordinances, planning,

and cost-effective design and construc-

tion to help move the process toward a

successful outcome.

INNOVATE TO STRETCH

MAINTENANCE DOLLARS

About 12 years ago, Minnesota took action

to reduce the maintenance backlog in state-

funded higher education facilities. A key

element of this plan was to give preference

to proposals for new projects that dedicated

a percentage of funds to removing deferred

maintenance items on campus. For ex-

ample, a $4-5 million classroom remodeling

and expansion might include $2 million for a

campuswide HVAC system upgrade.

As a result of this initiative, the Facility

Conditions Indexthe sum of deferred main-

tenance divided by the current replacement

valuedeclined from 0.15 to 0.11 in eight

years, according to Sally Grans-Korsh, FAIA,

LEED AP, former Director of Facilities Planning

for the Minnesota state college systems ar-

chitects ofce and now Principal Consultant/

Owner of Minneapolis-based ArchiStudio.

San Diego Community College District,

the nations sixth-largest, with three two-

year institutions and six satellite Continu-

ing Education campuses serving 130,000

students, saw its annual operating budget

cut by $50 million. This put enormous pres-

sure on the SDCCDs ability to maintain its

2 million square feet under roofwhich,

28 MARCH 2013 BUILDING DESIGN+CONSTRUCTION www.BDCnetwork.com

U

R

S

U

L

A

K

R

O

E

M

E

R

,

G

A

F

C

O

N

I

N

C

.

/

C

O

U

R

T

E

S

Y

S

A

N

D

I

E

G

O

C

C

D

Gafcon (PM), Joseph Wong Design Associates,

and Balfour Beatty Construction used BIM to

model San Diego CCDs North City campus.

Mesa College Student Services Center. Gafcon (PM) led the team of Hanna Gabriel Wells (architect);

McParlane and Associates (mechanical); Michael Wall Engineers (electrical); KPFF Consulting Engi-

neers (SE); Snipes-Dye Engineering (CE); PCL Construction (CM); and Multi-Prime (GC).

thanks to a successful bond program, will

grow another 80% in new buildings.

Five years ago, the SDCCD began look-

ing into Toyotas Lean improvement process

as a means to address the escalating main-

tenance problem. Aided by a Lean sensei,

the college spent nearly two years shap-

ing the Toyota system to its needs. The

sensei helped us sort fact from anecdote,

so we could carry out data-driven decision

making, recalls David Umstot, PE, Vice

Chancellor of Facilities Management.

The data showed that maintenance staff

were wasting a lot of time on small tasks,

while serious problems were sometimes de-

layed. That led to the creation of a ve-tiered

service level agreement, with a specied

response time for each tier. A centralized call

center whose staff was trained to triage ser-

vice requests based on the tier system was

put in place. Instead of having eld personnel

return to the main ofce after each job, they

now get their work orders via smartphones

with 4G connections and larger screens and

keyboardssomething they requested.

Other problems were unearthed. It was

learned that painters were wasting time

running from campus to campus to do

work; instead, painters were assigned to a

campus for a few months at a time to com-

plete their work. Their efciency doubled.

A nighttime custodial shift was moved

to create a second daytime shift, allowing

C

O

U

R

T

E

S

Y

G

A

F

C

O

N

,

I

N

C

.

www.BDCuniversity.com BUILDING DESIGN+CONSTRUCTION MARCH 2013 29

custodians to keep up with tasks like

refreshing restrooms. SDCCD custodians

were cleaning an average 13,500 sf each,

with maintenance costs at $3.93/sf; more

recently, theyre cleaning 21,225 sf each,

at a cost of $2.31/sf.

District ofcials say the Lean process

saved $4.5 million in FY2012 and will save

$26 million over eight years. All O&M super-

visors must now complete Lean Enterprise

certication, on district time. Its fantastic

to watch the light bulbs come on as they

inculcate these techniques into the organi-

zation, says Umstot.

The next step, he says, is to maximize

the districts investment in building informa-

tion modeling, which it has required on new

projects for the past ve years. The estab-

lishment of BIM standards put us in a great

position to translate BIM for operations and

maintenance, says Umstot. On projects

where BIM has been the common denomi-

nator, he says, the change order rate has

gone down to 2.3%. When a $1.6 billion

capital development program is completed

in 2019, the district will have BIM models

for about 60% of its built environment for

use by maintenance personnel.

Umstot recognizes that a big hurdle to

realizing that vision is technological. How

do you translate large BIM les for easy

wireless accessibility so workers can pull

them up on an iPad? he asks. Down the

line, the ability to roll out robust, campus-

wide wireless accessibility will be crucial to

the success of such a program.

With maintenance a constant concern,

community college administrators are

scrutinizing future buildings and grounds

operating costs as closely as construc-

tion costs. In working with community

colleges, Building Teams will need to put

much greater thought into the long-term

O&M impacts of their designs and the

materials they specify. Firms that can show

how their concepts will save these clients

money over the total life cycle of their

buildings will win their business.

HELP COMMUNITY COLLEGE

CLIENTS FIND WAYS TO

IMPROVE STUDENT SUCCESS

Community colleges have always been the

gateway to higher education for millions of

students who could not afford a four-year

college or dont have the grades to get into

one. According to the AACC, community

colleges account for 51% of Hispanic stu-

dents, 44% of African-American students,

54% of Native American students, and 45%

of Asian/Pacic Island students.

These institutions are providing more

support services to help at-risk students

learn more effectively or brush up on basic

skills. In the past, we were 100% focused

on providing access to higher education,

says David Agazzi, Vice President of Ad-

ministrative Affairs, College of Lake County,

Grayslake, Ill. Now, were also removing

barriers to student success.

One way the college is trying to improve

the graduation rate is through the design of

its facilities. The northern Illinois institution is

schul er shook. com

Chicago Minneapolis Dallas

Marquette University Law School - Milwaukee, Wisconsin

APPEAL-ING ILLUMINATION

Circle 765

trends analysis report

HIGHER EDUCATION FACILITIES

In the past, we were 100%

focused on providing

access to higher education.

Now, were also removing

barriers to student success.

David Agazzi, College of Lake County

30 MARCH 2013 BUILDING DESIGN+CONSTRUCTION www.BDCnetwork.com

planning to consolidate numerous student

services that are currently scattered in

multiple buildings around campus, including

admissions, nancial aid, testing, advising,

and the bookstore, into one building. The

new layout will allow students to meet with

their advisers, take placement tests, and

register for classesin effect, one-stop

shopping. Putting these functions under

one roof will save students time and allow

them to focus on their studies, says Agazzi.

San Diego Community College District

is taking another route to aiding student

success. The district has built Academic

Success Centers that provide specialized

services to help what the college terms

historically disadvantaged students, says

Chancellor Umstot.

The Academic Success Center at San

Diego City College is housed in a converted

two-story, 28,700-sf building, designed by

Hanna Gabriel Wells under program man-

ager Gafcon Inc. There, the college offers

tutoring; assessment and advising; special

programs for African-American and Chi-

cano/Latino students; TRIO/ASPIRE, a U.S.

Department of Education-funded program

that targets full-time students who hope to

go on to four-year colleges; and Extended

Opportunity Programs and Services, a

state-funded effort.

The centers were built with funds from

two bond propositions that voters approved

in 2002 and 2006a total $1.555 billion

for new career training facilities, major

renovations, public safety and accessibility

improvements, parking, and infrastructure

upgrades at SDCCDs nine sites.

PROGRAM SPACE NEEDS

FOR ONLINE LEARNING

Community colleges cant jump on the

online learning bandwagon fast enough.

Online courses appeal to many of their stu-

dents, particularly the core constituency of

older, part-time students with families, jobs,

and tear-your-hair-out schedules.

At West Hills Community College, for

example, 20% of courses are held entirely

West Valley College, Saratoga, Calif., serves more than ten thousand students on the

western edge of Silicon Valley, 50 miles south of San Francisco. Its student center

dates to the early 1970sconcrete construction, limited visibility to the outdoors,

not much flexibility to its spaces, and a hard-to-follow circulation plan. To add to the

problem, a new building cut off two nearby plazas from each other, rendering them

largely unused.

The college brought in BFGC-IBI Group, San Luis Obispo, Calif., to address these

problems. The design firm employed folding glass wall partitions (in this case, the

NanaWall SL70 Folding System) to replace the single-glazed storefront windows.

One of the installations links the two previously separated plaza spaces, creating a

new circulation artery and breathing new life into the plazas.

Another installation in the student center has a fully operable wall of glass, which

enables the college to rent the space for weddings and parties, providing a new

source of revenue. An interior partition installation enhanced visibility between pre-

viously obscured areas of the student center.

Single-glazed storefronts in the student center at Californias West Valley College were

replaced with aluminum-framed, thermally broken windows in a bronze nish that emulates

the look of the original building. The operable window system creates exible space options

that enable the college to rent the space for receptions, creating a new revenue stream.

C

O

U

R

T

E

S

Y

N

A

N

A

W

A

L

L

S

Y

S

T

E

M

S

I

N

C

.

FOLDING GLASS WALLS revitalize student center

trends analysis report

HIGHER EDUCATION FACILITIES

COLORATION

IMAGINATION

facebook.com/mbci.metal @MBCImetal

Visit www.mbci.com/bdccolor to learn more!

877.718.O224 info@moci.com

Let your imagination run wild and design the building youve

always dreamed of when using one of the many color and

texture offerings for MBCIs metal roof, wall, fascia and sofft

panels, as well as a complementary line of trim and other

related accessories.

IMAGINE

A plethora of standard colors

Custom colors for any project

Textured fnishes for single skin and

insulated metal wall panels

Cool Roof coatings for roof panels

Industry leading paint & weather

tightness warranties

Superior technical support

Circle 766

32 MARCH 2013 BUILDING DESIGN+CONSTRUCTION www.BDCnetwork.com

online, and 70% have an online component.

Having more online classes could eventually

mean less demand for classroom space,

but how much or how fast online instruction

will replace the in-person classroom experi-

ence is anyones guess.

Adding to the space forecasting puzzle is

competition from for-prot entities like the

University of Phoenix that are also going

after older adult learners: the AACC says

45% of community college students are

aged 22 to 39, and 15% are 40 or older.

New nontraditional venues, such as

Apples iTunes U and massive open online

courses (so-called MOOCs) like edX, are

offering free or inexpensive courses. In

late January, Sebastian Thrun, a research

professor of computer science at Stanford

whose free Web-based course attracted

160,000 students in more than 190

countries, announced he was forming a

new company, Udacity, to offer low-cost

courses online.

Community colleges are justiably con-

cerned that these new competitors may

peel off a chunk of their core market, the

time-constrained student seeking low-cost

career retraining.

Building Teams that want new (or more)

business from brick-and-mortar community

college districts had better be completely

conversant in these online technologies

and how physical design can be used to

enhance online education.

IMPLEMENT FLEXIBLE

SPACE STRATEGIES

With specialized career preparation a core

mission, community colleges must offer

programs focused on rapidly changing

technologies and industries. A program

such as alternative energy might have to be

completely refreshed every 10 years, says

J. Michael Thomson, Campus President for

Cuyahoga Community Colleges Westshore

campus, in Westlake, Ohio.

Cuyahogas new 65,000-sf Westshore

science building emphasizes space exibil-

ity. The LEED Gold-certied facility originally

ADMINISTRATION

CIRCULATION

CLASSROOMS

CONTAINED LABS

FACILITIES OPERATIONS

FACULTY OFFICES

PUBLIC SPACE

SCIENCE LABS

DEPARTMENT LEGEND

F

E

I

N

K

N

O

P

F

/

C

O

U

R

T

E

S

Y

S

T

A

N

T

E

C

F

L

O

O

R

P

L

A

N

C

O

U

R

T

E

S

Y

S

T

A

N

T

E

C

The 65,000-sf Health Careers and Sciences Building on the Westlake, Ohio, campus of Cuyahoga

Community College achieved LEED Gold certication late last year, with 40% reduction in energy

use, 47% savings in water use, 90% stormwater retention on site, and 92% construction waste

diversion from landll. Building Team: Stantec (architect, ME, landscape architect), Thorson Baker &

Associates (SE), CT Consultants (CE), Sandhu & Associates (plumbing/FP engineer), Dynamix Engi-

neering (electrical/technology engineer), Gilbane Building Co. (PM), and Turner Construction (CM).

trends analysis report

HIGHER EDUCATION FACILITIES

2 2 2 2 2 22 2 2 2013 013 013 013 013 013 1 013 13 013 13 013 Gu Gu Gu Gu Gu Gu Gu Gu GGGuard ard ard ard ard ard ar ard ard a ian ian ian ian ian ian ian iian ian ian ian a In In In In In In Inn In In Indus dus dus dus du dus dus dus dus dustri tri tri tri tri tri tri i ttri tr es es es es es es es es es Cor Cor Cor Cor Cor Cor Cor Cor Cor o p. pp. p. p. p. pp

Sun Sun Sun Sun Sun Sun Sun SunnGua Gua Gua Gua Gua Gua Gua Gua Gua Guuu rd rd rd rd rd rd dddd

and and and and and d and nd andBui Bui Bui Bui Bu Bui Bu Bu ld ld ld ld dddd ld Wit Wit Wit Wit Wit Wit Wit Wit WWWi W h L h L h L h L h L h L h L h LL h L h LLigh igh i h igh igh i h igh igh ightttttttt

ar r ar r are r e r e r ee regi egi egi egi egi ee ste ste ste eered redd redd red red r tr tr ttr tr trr tr t ade ade ade ade ade ade ade ade ade demar mar mar mar mar mmar mar marks ks ks ks kks ks ks kk offf of f of ooo Gua Gua Gua Gua Gua Gua a u Gu rdi rdi rdi rdi rd rdi rd rd d an an an aan an an a Ind Ind Ind Ind nd Ind Indust ust uust ust u trie rie rie rie rie rie eee r s C s C s C s C s C s C s C C s C CCorp orp orp orp orp orp or orp orp rp orp rr orp..... Ple Ple Ple Ple PPle le PPPP ase ase ase ase se e or or or oor or or orde der de der der de er der er er rrr gl gl gl gl gl gl ggl ggl gl glass ass ass as ass s ass ass ass ass ass s sa sa sa sa sa sa sa sa sa sa sa sa aaaa sa aaampl mp mpl mpl mpl mpl mpl mpl mpl mpl mpl mpl mpl mp mpl mpl mpl mp mpl mmp es es s ees es es eeeee for for for for or for r for for for or or rr ac ac ac ac ac ac aac aac accur ur cur cur cur cur cur ur u cur c ate ate ate ate ate ate t ate ate at ate ate ate co cco co co co co co co co co co coolor lor lor lor lor o lo or lor lor lor lor lo ev ev ev ev ev ev eev eevalu alu alu alu alu aluu lu uuuati ati ati ati ti ati aa on. on. on. on. nn on. on onn

How Guardian SunGuard

helped build a better school.

With light.

Well-daylighted classrooms enhance student performance. Thats

why TowerPinkster selected Guardian SunGuard SuperNeutral 54

on clear for Linden Grove Middle School in Kalamazoo, Michigan.

With 54% visible light transmission, SuperNeutral 54 allows plenty

of natural light into a building. But with a low 0.28 solar heat gain

coefcient, heat gain is minimal. The result: TowerPinkster achieved

natural daylighting in every classroom while keeping energy costs

down. For complete performance dataand other ways Guardian

SunGuard can help you Build With Lightvisit SunGuardGlass.com.

Or call 1-866-GuardSG (482-7374).

LINDEN GROVE MIDDLE SCHOOL

KALAMAZOO, MI

ARCHITECT: TowerPinkster

GUARDIAN SELECT FABRICATOR:

Trulite Glass & Aluminum Solutions

GLAZIER CONNECTION MEMBER:

Architectural Glass and Metals

GLASS: SunGuard SuperNeutral 54

Circle 767

was to have six labs ranging in size from

1,130 sf to 1,280 sf. In a cost-saving

move, the sixth lab was penciled out; in

its place, three 235-sf prep areas were

constructed adjacent to the labs to give

instructors room to prepare experiments

and equipment on mobile carts. As soon

as one lab session wraps up, the instruc-

tor can roll in the gear and begin the next

lab class in minutes. They dont need

the classroom an hour ahead of time to

set up, says Justin Fliegel, AIA, LEED AP

BD+C, Project Manager with Stantec, the

lead design rm on the job.

Its not unusual for four-year schools to