Professional Documents

Culture Documents

Romi Journal Editon 4 Machine Tools PDF

Uploaded by

Mustafa AlHalfawiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Romi Journal Editon 4 Machine Tools PDF

Uploaded by

Mustafa AlHalfawiCopyright:

Available Formats

4

Machine Tools

www.romi.com

Romi C Series

CNC Lathes and Heavy Duty CNC Lathes

| Romi C 420 | Romi C 510 | Romi C 620 | Romi C 680 | Romi C 830 | Romi C 1000 | Romi C 850H | Romi C 1100H | Romi

A wide range of CNC lathes for several manufacturing segments, for parts up to 2.580 mm.

The ROMI C Series consists of several models that offer power, robustness and flexibility for multiple applications, with several configurations of headstocks and toolholders. The heavy duty CNC lathes are extremely robust machines for heavy machining processes providing high efficiency and productivity. Suitable for machining large parts in the industries of steel & sugar mills, energy, oil & gas and others.

Mill rool assembly for ethanol plant.

www.romi.com

High technology, reliability and productivity for manufacturing and repair of heavy duty parts.

C 1290H | Romi C 1300H | Romi C 1600H | Romi C 1800H | Romi C 2100H | Romi C 2200H | Romi C 2600H

1 Component of oil extraction equipment. 2 Oil tube machining. 1 2 3 3 Component of wind power generation equipment.

All photos are illustrative. / Machines equipped with optional.

Romi GL Series

| Romi GL 350Y | Romi GL 350B

Turning Centers

ROMI GL SERIES offer more creative and effective solutions for machining processes.

Left headstock: built-in motor headstock (FANUC), high technology and high performance

Equipped with M type tool turret for fixed tools, driven tools and Y axis capability. This allows for turning, drilling and tapping operations to be performed on the same machine. In addition, the ROMI GL 350B, equipped with left and right headstock (B axis), provides greater efficiency in machining operations for increased productivity.

M type Tool Turret, with BMT-65 tool disk and Y axis.

Right headstock (B axis): built-in motor headstock (FANUC), supported on linear guides and driven by servomotor and ball screw.

| Romi GL 170G | Romi GL 240 | Romi GL 240M | Romi GL 280 | Romi GL 280M | Romi GL 350 | Romi GL 350M | Romi GL 350Y | Romi GL 350B

Operator friendly graphic display for part program verification. High-Speed Machining. Canned cycles and Custom Macro B for simplified part programming.

Series 0i model D

Standard Nano-Interpolation and Ethernet interface. Advanced functionalities like Jerk Control, Nano Smoothing and AI Contour Control II. Integrated Safety with Dual Check Safety.

1-888-FANUC-US (888-326-8287)

www.fanucfa.com

FA AMERICA

www.romi.com

Robust structure for machining operations at full power, with high accelerations, rigidity and precision.

Romi G Series

| | | |

Turning Centers

Romi G 30 Romi G 30M Romi G 550 Romi G 550M

12-station tool turret with boring bar support (optional)

Hydraulic steady rest (optional)

Excellent power and torque, fast displacement and high machining precision

Designed to operate in high production environments, the ROMI G Series allows for a significant increase in productivity and profitability.

All photos are illustrative. / Machines equipped with optional.

Romi D Series

Vertical Machining Centers

Flexibility for multiple applications with a significant increase in productivity and profitability

Ideal for high production, tool rooms and simple to complex part geometry.

| Romi D 600

| Romi D 800

| Romi D 1000

SINUMERIK 828D

Compact, strong, simply perfect!

The SINUMERIK 828D is a panel-based CNC, tailor-made for use in milling and turning machines. The product combines CNC, PLC, operating and axis control functions for six CNC measuring circuits into one compact unit, which is designed to fit any operator panel housing in both its horizontal and vertical version. Despite its compact dimensions, the SINUMERIK 828D is a real powerhouse. Equipped with premium CNC functions such as the ability to execute kinematic transformations or powerful tool management makes it perfect for the jobshop. Compact, strong, simple... simply perfect!

800 333 7421 www.siemens.com/sinumerik

www.romi.com

High chip removal capacity and high accuracy for increased productivity

The ROMI D Series are extremely versatile machines for a wide range of applications, in high production environments as well as in tool rooms. Equipped with a robust structure, which ensures speed, high acceleration, stiffness, thermal and geometric stability, as well as high performance and reliability.

1 Machined part example. 2 Machined part example. 1 3 High technology controls, excellent performance and reliability, Siemens or Fanuc versions.

Direct Drive Headstock 25 hp / 18,5 kW Roller type linear guide (X,Y and Z)

15.000 rpm

Rapid traverse up to 40 m/min

| Romi D 1250

| Romi D 1500

1 Broad framework, extremely robust, designed for high loads, absorbs cutting forces and vibrations under the most adverse machining conditions. 2 Spindle cartridge with ISO 40 or 50 spindle, supported by ultra-precision roller bearings. Allows for high speeds, ensuring performance even under most heavy cutting conditions. 3 Double arm automatic tool changer: Allows for speed, accuracy and reliable to increase productivity and efficiency in the machining processes. 4 Rotary table: optional equipment that allows for machining of parts at any angle with interpolations.

All photos are illustrative. / Machines equipped with optional.

Romi VT Series

Versatility for machining several kinds of large chuck parts for the energy, oil and gas segments.

Vertical CNC Lathes

Machining resources for turning, drilling, milling and tapping operations.

1 C axis and driven tool. 2 Vertical RAM system with 12-tools magazine capacity 1

ROMI VT 5000 The largest vertical lathe manufactured in South America

Capacity for turning parts up to 6.000 mm and up to 90 tons

Faster return on investment

This is a real find.

Visit the Sandvik Coromant Smart Hub, booth W-1500 and register to WIN one of 12 $1000 tooling certificates!*

*Offer valid in the U.S. during IMTS only.

Choosing the right tooling, right from the start, can help you pay off a new machine investment a full year faster. Make the Sandvik Coromant Smart Hub your first stop at IMTS and well show you how to make your machine investment start paying you back from day one.

What will you discover?

www.sandvik.coromant.com/discovery

ROMI ad 2.indd 1

7/17/2012 4:29:28 PM

www.romi.com

Vertical Turning Centers

|

Romi VT 1400

Romi VTL 500R Romi VTL 500MR

The best cost benefit in this machine category. Technology, reliability and high productivity for chuck parts machining up to 500 mm.

The ROMI VTL 500R and ROMI VTL 500MR turning centers were designed to operate in medium and high production environments, offering high torque, excellent dimensional accuracy and great efficiency. Incorporating a robust structure, which is ideal for machining at full power, providing rigidity, stability, accuracy and versatility in machining processes for a wide range of chuck parts.

Romi VT 2000

Romi VT 2500

Romi VT 3000

Romi VT 5000

Romi VT 6000

1 T type turret, servo driven with hydraulic locking and ROMI standard disk for 12 fixed tools (ROMI VTL 500R). M type turret servo driven with hydraulic locking and BMT-65 standard disk for 12 fixed or driven tools, for milling, drilling and tapping operations (ROMI VTL 500MR). 2 ASA A2-8 headstock, for 315 or 390 mm hydraulic chucks.

All photos are illustrative. / Machines equipped with optional.

10

Romi DCM 620-5X

B axis C axis 1

Vertical Machining Center - 5 Axis

High technology for complex geometries and machining strategies

The ROMI DCM-620-5X is a powerful vertical machining center designed for complex geometric machining at high speeds. The 5 axis configuration allows for machining of complex parts in a single setup, significantly reducing the machining time, with efficiency, precision and productivity.

The NC rotary / tilt table offers high rigidity, ensuring accuracy in 5-axis simultaneous machining with positioning at any angle for highly complex parts. 1 Table: rotary axis (B axis) and tilt axis (C axis) 2 Table at position -50 3 Table at position -0 4 Table at position +110

Romi DCM 560DP

Suitable for high and medium production of parts with predominance of holes and threads.

Vertical Tapping Center

Automatic pallets changer

Automatic tool changer with 24 tools magazine

Ergonomic design which offers great flexibility for multiple drilling and tapping applications at high speed and high feed rates, as well as small milling operations, with significant increased productivity.

Machined parts example

www.romi.com

Romi DCM 3000

Simple, effective, reliable ensuring high productivity

Suitable for high and medium production of parts with multiple holes and threads. Flexibility for machining long and heavy parts demanding high geometric accuracy

Moving Column Vertical Machining Center

Machining of heavy and large parts

Pendular mode, with fixed part and rotary table

Pendular mode, enabling parts loading and unloading while the machining is in progress

Long parts machining using a rotary table and tailstock

Machining of various parts

Machining of long workpieces

A new generation of Horizontal Machining Centers

Romi PH Series

| Romi PH 400 | Romi PH 630

Sturdy structure designed for high load machining

1 Pallet Changer: integrated mechanism at monoblock base. Allows easy access to the user for parts loading and unloading, as well as a quick setup for clamping parts system preparation. 2 Double arm automatic tool changer: magazine prepared for BT / BBT type tool holder, with 40 tools capacity (ROMI PH 400) or 60 tools capacity (ROMI PH 630).

Horizontal Machining Centers

Romi Lazzati

| Romi Lazzati HBM 130T

NC rotary table (B axis), which allows the positioning of parts at any angle, allowing the machining of complex parts with interpolations. Large surface with 1,500 x 2,000 mm for parts up to 12,000 kg, prepared for heavy duty machining with excellent assembly stability. 130 mm nitrited quill, prepared for BBT type tooling (Big Plus) with increased clamping rigidity.

High Performance Boring Mill

All photos are illustrative. / Machines equipped with optional.

12

Romi ES-40 Series

| Romi ES-40 | Romi ES-40A | Romi ES-40B

Engine Lathes

ROMI T SERIES

| Romi T 240 | Romi T 500 | Romi T 350

Engine Lathes

Engine lathes for toolroom, production, maintenance and training

ROMI UT Series

| Romi UTR 800 | Romi UT 1000 | Romi UT 1500 | Romi UT 1700 | Romi UT 2000

Extra-Heavy Duty CNC Lathes

The robust structure, designed with a monoblock bed, offers higher rigidity and stability for extra-heavy duty machining operations.

www.romi.com

Technology and tradition for high performance machine tools manufacturing

ROMI & Burkhardt+Weber

Acquired in February 2012 the Burkhardt + Weber Fertigungssysteme GmbH (Burkhardt + Weber) is now part of Romi group, offering high quality machine tools. Burkhardt + Weber founded in 1888 has headquarters in Reutlingen, Baden-Wurttemberg, Germany. Machining Centers of premium quality Building efficient and highly precise machining center for working on pieces of steel and casting up to a 40 ton load capacity. In addition, B + W develops and produces fully automatic manufacturing systems for production with minimal operator input for several sectors: General Engineering, Driving Technology, Power Generation Parts, Wood and Plastic Processing Machines, Hydraulics / Compressors, Diesel Engines and Systems, Commercial Vehicles, Rolling Mills and Mining, Machine Tools and many others. The combination of Burkhardt + Weber and Romi has strengthened both companies. Romi has added Burkhardt + Webers product line to its machine tools product range in order to better supply premium machines produced in Germany to the customers of North, Central and South Americas. www.burkhardt-weber.de

All photos are illustrative. / Machines equipped with optional.

14

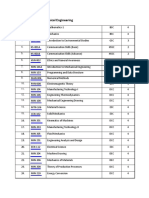

ROMI. A wide range of machine tools for several manufacturing segments.

Engine Lathes Centers height Distance between centers Spindle nose Speed range Power Engine Lathes Centers height Distance between centers Spindle nose Speed range Power CNC Lathes Distance between centers Swing over bed Spindle nose Speed range Power m mm ASA rpm hp / kW A2-5 mm m ASA rpm hp / kW mm m ASA rpm hp / kW

ROMI T 240 220 0,5 / 1,5 L0 45 ~ 2.240 7,5 / 5,5 ROMI ES-40 250 1,5 / 2,0 L1 32 ~ 2.360 15 / 11,2 ROMI C 420 0,5 / 1,0 430 A2-6 3 ~ 3.000 10 / 7,5 ROMI C 680 A2-6

ROMI T 350 268 1,5 L0 40 ~ 2.000 7,5 / 5,5 ROMI ES-40A 325 2,0 / 3,0 L1 23 ~ 1.700 15 / 11,2 ROMI C 510 1,5 520 A2-8 2 ~ 2.200 15 / 11

ROMI T 500 342 2,25 / 3,25 L0 35 ~ 1.800 7,5 / 5,5 ROMI ES-40B 420 3,0 / 4,0 / 5,0 L1 16 ~ 1.180 15 / 11 ROMI C 620 1,0 / 2,0 620 A2-8 (geared) 1 ~ 667 (range 1) 2 ~ 2.500 (range 2) 25 / 18,5 ROMI C 830 2,0 / 3,0 / 4,0 / 5,0 850 A2-8 (direct drive) 1 ~ 1.800

4 ~ 4.000

3 ~ 3.000

Distance between centers Swing over bed Spindle nose Speed range Power

m mm ASA rpm hp / kW A2-8 1 ~ 450 (range 1) 1 ~ 1.800 (range 2)

2,0 / 3,0 680 A2-11 1 ~ 250 (range 1) 1 ~ 1.000 (range 2) 40 / 30 ROMI C 1000 A2-11

A2-15 1 ~ 198 (range 1) 1 ~ 755 (range 2) 40 / 30

1 ~ 250 (range 1) 1 ~ 1.000 (range 2)

ROMI C 1000 (Big Bore) 3,0 1.000 A2-20 A2-20 1 ~ 125 (range 1) 1 ~ 400 (range 2) 40 / 30 ROMI C 1100H 2,0 / 3,5 / 5,0 / 6,5 / 8,0 / 9,5 1.110 A2-15" 1 ~ 750 15.000 72 / 53 ROMI C 1800H / C 2100H 4 / 5,5 / 7 / 8,5 / 10 1.800 A2-20" 1 ~ 500 30.000 114 84 ROMI UT 1700 8 / 10 / 12 1.700 40.000 Especial 1 ~ 188 / 1 ~ 300 200 / 150 155 1 ~ 300 1 ~ 500 50.000 114 ROMI UT 2000 8 / 10 / 12 2.020 100.000 Especial 1 ~ 188 / 1 ~ 300 300 / 220 2.150 A2-20 1 ~ 500 ROMI C 1290H 3,5 / 5,0 1.330 A2-20 1 ~ 500 15.000 72 / 53 ROMI C 2200H / C 2600H 4 / 6 / 8 / 10 / 12 2.210 A2-20" 1 ~ 300 2.580

Distance between centers Swing over bed Spindle nose Speed range Power Heavy Duty CNC Lathes Distance between centers Swing over bed Spindle nose Speed range Max. admissible weigth between centers at 50 rpm Power

m mm ASA rpm hp / kW A2-11

2,0 / 3,0 / 4,0 / 5,0 1.000 1 ~ 250 (range 1) 1 ~ 1.000 (range 2) 40 / 30 ROMI C 850H 1 ~ 125 (range 1) 1 ~ 500 (range 2)

m mm ASA rpm kg hp / kW

2,0 / 3,5 / 5,0 950 A2-15 1 ~ 750 15.000 72 / 53 ROMI C 1300H / C 1600H

Distance between centers Swing over bed Spindle nose Speed range s Max. admissible weigth between centers at 50 rpm Power Extra Heavy Duty CNC Lathes Distance between centers Swing over bed Max. admissible weigth between centers at 50 rpm Spindle nose Speed range Power Vertical CNC Lathes Maximum cutting diameter Maximum swing diameter Chuck diameter Speed range Max. admissible weight Power m mm kg ASA rpm hp / kW

m mm ASA rpm kg hp / kW

3,5 / 5 / 6,5 / 8 / 9,5 / 11 / 12,5 1.300 A2-15" 1 ~ 1.000 15.000 114 ROMI UT 1000 1.600 A2-20 1 ~ 500 22.000 84

ROMI UT 1500 4 / 6 / 8 / 10 / 12 1.500 50.000 Especial 1 ~ 300 200 / 150 ROMI VT 2500 2.700 2.800 2.500 1 ~ 180 25.000 114 / 84

m mm kg ASA rpm hp / kW

4 / 5,5 / 7 / 8,5 / 10 1.060 30.000 Especial 1 ~ 300 100 / 75 ROMI VT 1400 1.600 1.800 1.400 1 ~ 335 12.000 114 / 84 ROMI VT 2000 2.200 2.300 2.000 1 ~ 248 18.000 114 / 84

ROMI VT 3000 (*) ROMI VT 5000 (*) ROMI VT 6000 (*) 3.400 3.500 3.000 1 ~ 100 25.000 114 / 84 6.000 6.000 5.000 1 ~ 60 90.000 145 / 108 7.000 7.000 6.000 1 ~ 50 90.000 145 / 108

www.romi.com

Turning Centers Maximum cutting diameter Maximum cutting length Spindle nose Speed ranges Power mm mm ASA rpm hp / kW

ROMI GL 170G 170 A2-5 6 ~ 6.000 15 / 11 ROMI GL 350 / GL 350M

ROMI GL 240 / GL 240M 300 / 260 400 A2-5" / A2-6" 6 ~ 6.000 / 4 ~ 4.500 20 / 15 ROMI GL 350Y 350 740 A2-6" / A2-8" 5 ~ 5.000 / 4 ~ 4.000 33 / 25 ROMI G 30M 320 1.020 A2-8" A-2 8 2 ~ 2.000

ROMI GL 280 / GL 280M 340 / 280 540 A2-6" / A2-8 4 ~ 4.500 / 3 ~ 3.500 25 / 18,5 ROMI GL 350B 350 740 A2-6" / A2-8 5 ~ 5.000 / 4 ~ 4.000 33 / 25 A2-5" 6 ~ 6.000 29 / 22 ROMI G 550 / G 550M 550 1.300 A2-11" ( ZF gearbox) 6 ~ 630 (range 1) 2 ~ 2.000 (range 2) 50 / 37 A2-15" (ZF gearbox) 4 ~ 473 (range 1) 1 ~ 1.500 (range 2)

Maximum cutting diameter Maximum cutting length Spindle nose (left headstock) Speed ranges (left headstock) Power (left headstock) Spindle nose (right headstock) Speed ranges (right headstock) Power (right headstock) Turning Centers Maximum cutting diameter Maximum cutting length Spindle nose Speed ranges Power Vertical Machining Centers Spindle taper Table longitudinal travel (X axis) Table traverse travel (Y axis) Headstock travel (Z axis) Speed ranges Power

mm mm ASA rpm cv / kW ASA rpm hp / kW

400 / 390 1.140 A2-6" / A2-8" 4 ~ 4.500 / 3 ~ 3.500 25 / 18,5 ROMI G 30

mm mm ASA rpm hp / kW

320 1.020 A2-8" 3 ~ 3.000 / 2 ~ 2.500 30 / 22 ROMI D 600

3 ~ 3.000 / 2 ~ 2.500 30 / 22 ROMI D 800 40 800 530 580 7 ~ 7.500 / 10 ~ 10.000 20 / 15

ROMI D 1000 40 1.020 610 640 6 ~ 6.000 / 10 ~ 10.000 25 / 18,5 ROMI D 1500 40 / 50 1.530 760 760

ROMI D 1000AP DD 40 1.020 610 640 15 ~ 15.000 25 / 18,5 ROMI D 2000 (*) 40 / 50 2.000 900 800 6 ~ 6.000 / 8 ~ 8.000 / 12 ~ 12.000 25 / 18,5 Vertical Tapping Center Spindle taper X axis travel Y axis travel Z axis travel Speed ranges Power ISO mm mm mm rpm hp / kW ROMI DCM 560DP (*) 40 560 400 400 15.000 15 / 11

ISO mm mm mm rpm hp / kW

40 600 530 580 8 ~ 8.000 / 10 ~ 10.000 20 / 15 ROMI D 1250

Spindle taper Table longitudinal travel (X axis) Table traverse travel (Y axis) Headstock travel (Z axis) Speed ranges Power Vertical Turning Centers Maximum cutting diameter Maximum admissible diameter Maximum cutting height Max. admissible height Spindle nose Speed ranges Power Vertical Machining Center - 5 axis Spindle taper X axis travel Y axis travel Z axis travel Speed ranges Power

ISO mm mm mm rpm hp / kW

1.270 610 640 6 ~ 6.000 / 10 ~ 10.000 20 / 15 20 / 15 ROMI VTL 500R (*) ROMI VTL 500MR (*) 500 620 620 620 A2-8" 2 ~ 2.500 28 / 21

8 ~ 8.000 / 10 ~ 10.000 / 12 ~ 12.000 30 / 22

mm mm mm mm ASA rpm hp / kW

500 620 668 668 A2-8" 2 ~ 2.500 28 / 21

ROMI DCM 620-5X (*) ISO mm mm mm rpm hp / kW 40 620 520 460 12.000 24 / 18

Moving Column Vertical Machining Center Spindle taper X axis travel Y axis travel Z axis travel Speed ranges Power ISO mm mm mm rpm hp / kW

ROMI DCM 3000 (*) 40 3.000 840 600 10 ~ 10.000 30 / 22 HBM 130T (*) ISO mm mm mm mm mm rpm hp / kW 50 130 2.000 4.000 1.800 800 5 ~ 3.000 79 / 58

Horizontal Machining Center Spindle taper Column travel (X axis) Headstock travel (Y axis) Table travel (Z axis) Speed ranges Power mm mm mm mm ASA hp / kW

ROMI PH 400 (*) 40 630 630 630 10 ~ 10.000 30 / 22

ROMI PH 630 (*) 50 1.050 900 1.000 6 ~ 6.000 (ZF gearbox) 10 ~ 10.000 48 / 36

High Performance Boring Mill Spindle taper Quill diameter Headstock vertical travel (Y axis) Table travel (X axis) Column longitudinal travel (Z axis) Quill travel (W axis) Speed ranges Power

(*) Avaliable for brazilian market.

All photos are illustrative. / Machines equipped with optional.

Plant 16 internal view

Brazil

Germany - B+W

USA

Germany

Italy

France

UK

Spain

A tradition of innovation

www.romi.com

Indstrias ROMI SA Headquarter Av. Prola Byington 56 Santa Brbara dOeste SP 13453 900 Brasil Phone +55 (19) 3455 9000 Fax +55 (19) 3455 2499 Industrial Site Rod. SP-304, Km 141,5 Santa Brbara dOeste SP 13453 900 Brasil Phone +55 (19) 3455 9000 Fax +55 (19) 3455 2499

Burkhardt+Weber Fertigungssysteme GmbH Burkhardt+Weber-Strasse 57 72760 Reutlingen Phone +49 7121 315-0 Fax +49 7121 315-104 info@burkhardt-weber.de www.burkhardt-weber.de ROMI Machine Tools, Ltd 1845 Airport Exchange Blvd Erlanger KY 41018 EUA Phone +1 (859) 647 7566 Fax +1 (859) 647 9122 sales@romiusa.com

ROMI Europa GmbH Wasserweg 19 D 64521 Gross Gerau Alemanha Phone +49 (6152) 8055 0 Fax +49 (6152) 8055 50 sales@romi-europa.de

ROMI in France Sandretto Industrie SAS Parc de Genve, 240 Rue Ferdinand Perrier 69800 St Priest Phone 00 334 37 25 60 70 Fax 00 334 37 25 60 71 infos@sandretto.fr ROMI in UK Sandretto UK Limited Leigh Road Swift Valley Industrial Estate Rugby CV21 1DS Phone +441788 544221 Fax +441788 542195 sales@sandretto.co.uk

ROMI in Spain Italprensas Sandretto S.A. Calle Comadrn, 15 Pol. Ind. Can Salvatela C.P. 08210 Barber del Valls Phone 34 93 848 4954 Fax 34 93 718 7932 info@italprensas.com ROMI in Mexico Sandretto Mexico, S de RL de CV Moliere 13, piso 10-B Col. Chapultepec Polanco, C.P. 11560 ventasmx@romi.com

ROMI Italia SRL Via Primo Levi 4 10095 Grugliasco TO Itlia Phone +39 (011) 410 1441 Fax +39 (011) 411 7049 sandretto@romi.com

For additional and updated information visit our site: www.romi.com CE safety regulation compliance available only for the European Community or under request. Consult availability of the products / features with your Romi representantive. Specifications are subject to change without prior notice.

Informativo MF / IN / 4 / 082012

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- CNC Machining The Complete Engineering GuideDocument41 pagesCNC Machining The Complete Engineering GuideHarry0% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- CKE6150-Operation Manual (MAQCHIN)Document65 pagesCKE6150-Operation Manual (MAQCHIN)Vanessa Rivera100% (1)

- Estimating and CostingDocument135 pagesEstimating and CostingShamim AkhtarNo ratings yet

- CNCDocument99 pagesCNCSree Raj91% (11)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Quorn: Tool and Cutter GrinderDocument5 pagesQuorn: Tool and Cutter GrinderDan HendersonNo ratings yet

- Tools and PatternsDocument472 pagesTools and PatternsTaliaNara100% (2)

- Mechnical CNC Machines Report PDFDocument27 pagesMechnical CNC Machines Report PDFsatya pNo ratings yet

- Leblond Lathe Manual 3934Document82 pagesLeblond Lathe Manual 3934cl10171% (7)

- Quality Manual for Ames Research CenterDocument27 pagesQuality Manual for Ames Research CenterMustafa AlHalfawiNo ratings yet

- Lathe Machine Project Semester 2Document11 pagesLathe Machine Project Semester 2Ye Chonn79% (34)

- Lab Exp Manual Workshop 2018 19Document32 pagesLab Exp Manual Workshop 2018 19Babeet JaatNo ratings yet

- Lathe setup checklist for aluminum bar machiningDocument1 pageLathe setup checklist for aluminum bar machiningBrayan Blanco MontesNo ratings yet

- Wrenches & Torque WrenchesDocument21 pagesWrenches & Torque WrenchesMustafa AlHalfawiNo ratings yet

- LowDocument2 pagesLowMustafa AlHalfawiNo ratings yet

- Screwdrivers Bits & Power BitsDocument16 pagesScrewdrivers Bits & Power BitsMustafa AlHalfawiNo ratings yet

- Other ToolsDocument14 pagesOther ToolsMustafa AlHalfawiNo ratings yet

- Hexagon & Star KeysDocument6 pagesHexagon & Star KeysMustafa AlHalfawiNo ratings yet

- Ytg C 0712Document24 pagesYtg C 0712Mustafa AlHalfawiNo ratings yet

- Hexagon & Star KeysDocument6 pagesHexagon & Star KeysMustafa AlHalfawiNo ratings yet

- Hand Sockets. Bit Sockets. AccessoriesDocument35 pagesHand Sockets. Bit Sockets. AccessoriesMustafa AlHalfawiNo ratings yet

- Ytg B 0811Document24 pagesYtg B 0811Mustafa AlHalfawiNo ratings yet

- Uum A 1011Document6 pagesUum A 1011Mustafa AlHalfawiNo ratings yet

- Ytg C 0712Document24 pagesYtg C 0712Mustafa AlHalfawiNo ratings yet

- Me PDFDocument340 pagesMe PDFShyam ChoudharyNo ratings yet

- MFT 2 TWO Marks With AnswersDocument28 pagesMFT 2 TWO Marks With AnswersThulasi RamNo ratings yet

- Mounting, Removing, and Aligning Lathe Centers: Session 8Document17 pagesMounting, Removing, and Aligning Lathe Centers: Session 8adhiabhi100% (1)

- 2Document77 pages2Pothuri SuneeldathNo ratings yet

- Unit 8 PDFDocument43 pagesUnit 8 PDFAnurag RanaNo ratings yet

- Setup Sheet Report: Lathe DefaultDocument22 pagesSetup Sheet Report: Lathe Defaultjamesbond1212No ratings yet

- Fundamentals of Welding: Review QuestionsDocument10 pagesFundamentals of Welding: Review QuestionsKhaled ShaabanNo ratings yet

- Bench Lathe: Operation ManualDocument14 pagesBench Lathe: Operation ManualEdson Gordiano100% (1)

- V9.1 Lathe Tutorial Change Pages (Inch)Document39 pagesV9.1 Lathe Tutorial Change Pages (Inch)Andrew TNo ratings yet

- CON3130 Module NotesDocument8 pagesCON3130 Module NotesEd PawliwNo ratings yet

- Tooling Form A Zak SDocument11 pagesTooling Form A Zak Salecandro_90No ratings yet

- MC - RSCQ4502 (CPCQ0204) - MO Plastic Injection Moulding - V1.0 - 24.09.2019Document21 pagesMC - RSCQ4502 (CPCQ0204) - MO Plastic Injection Moulding - V1.0 - 24.09.2019ashish goyalNo ratings yet

- Sobha CatalogueDocument20 pagesSobha CatalogueErshad Shafi AhmedNo ratings yet

- Workshop ReportDocument8 pagesWorkshop ReportspdNo ratings yet

- Model EngineeringDocument5 pagesModel Engineering8inlinea0% (1)

- CATALOG OF STANDARD CLAMPING TOOLSDocument80 pagesCATALOG OF STANDARD CLAMPING TOOLSJosip ZrilićNo ratings yet

- Positioning and Locating Workpieces for MachiningDocument79 pagesPositioning and Locating Workpieces for MachiningRajyalakshmiNo ratings yet

- Productivity Improvement I N MM540 Steering BoxDocument42 pagesProductivity Improvement I N MM540 Steering BoxVijay JNo ratings yet

- Ace Internship ReportDocument23 pagesAce Internship Reportsoumya100% (7)