Professional Documents

Culture Documents

457

Uploaded by

Rajesh ChowhanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

457

Uploaded by

Rajesh ChowhanCopyright:

Available Formats

-1Tender Fee Rs. 1500.00 Earnest Money Rs. 44,155.00 Contractors Name & Address : Time :4:00 P.M.

Date of Opening : 09-02-10 Tender No :- 457 Date of submission : 09-02-10 AHEMDABAD MUNICIPAL CORPORATION SPECIFICATION

MEMORANDUM OF WORK IN BRIEF

1. 2. 3. 5 6. 7. 8. Name of Work Tender Estimated Cost Earnest Money S.D. Time-Limit Validity Period (i) Last Date of Submission of the Tender (ii) Mode of Sending : : :

Development of LALBHAI UDHYAN NR.TIGER FLAT AHMEDABAD Rs. 44,15,388.40

CHAGANBHAI PATEL AT NAWA WADAJ,

1% of the Tender Cost i.e. (Rs. 44,155/-)

: 5% : 8 (Eight) months : 120 Days : : a) In Sealed cover in duplicate copies by Registered Post A.D, or by Courier.or hand delivery b) Tender sent by ordinary post will be rejected out right.

(iii) Description essential to be made on sealed cover (iv) Mode of quoting rates in Schedule of Quantities and Rates Date of Opening Place of Submission & Opening of Tender

a) Name of work, Tender Notice No. & Tender No. b) Date of receiving tender by Corporations. : In Figures as well as in words. : :

9. 1 0

West Zone, 2nd Floor, A.M. Office, Dr. Ramanbhai Patel Bhavan, Usmanpura.Ahmedabad Municipal Corporation, W.Z. Office, Ahmedabad-380013. Rs.500 per day but not more then 10% of bill

1 1

Penalty Due to Delay of work

Signature of contractor Name : Company's Seal : Date :

Add. City Engg.(West Zone) Ahmedabad Municipal Corporation

Date :

-1-

D:\Jigar\Tender Notice 2009-2010\Tender Notice No. 13\LALBHAI CHAGANBHAI PATEL GARDEN TENDER New Vadaj Ward.DOC

-2-

AHMEDABAD MUNI.CORPORATION.. WEST ZONE TENDER

Name of work Development of LALBHAI CHAGANBHAI PATEL UDHYAN NR.TIGER FLAT AT NAWA WADAJ, AHMEDABAD

SR. NO. 1 2 ITEM EARTHWORK - A 1700.00 Excavation for foundation upto 1.5 M. depth in following kind of soil including sorting out, stacking of useful materials and disposing off the excavated stuff upto 50 Mt. lead. 20.00 Excavation for foundation from 1.5 Mt. to 3.00 Mt.depth in following kind of soil including sorting out, stacking of useful materials and disposing off the excavated stuff upto 50 Mt. lead. 10.00 Excavation for foundation from 3.00 Mt. to 5.00 Mt. depth in following kind of soil including sorting out, stacking of useful materials and disposing off the excavated stuff upto 50 Mt. lead. 150.00 Filling available excavated earth (excluding rock) in trenches, plinth, sides of foundations etc. in layers not exceeding 20 cm. in depth, consolidating each deposited layer by ramming and watering. 1700.00 Filling in foundation and plinth with murrum or selected soil in layers of 20 cm. thickness including watering, ramming and consolidating etc. Complete. 50.00 Filling in plinth with sand under floors including watering, ramming, consolidating and dressing etc. completed. 1850.00 Conveyance charge of lime , murrum, building rubbish, earth manure or sludge, and excavated earth and fly ash upto lead of 5.00 Kms. CONCRETE WORK - B 80.00 Providing and laying Brick Bat cement concrete 1:4:8 (1cement:4-coarse sand:8-brick bats) and curing complete excluding cost of formwork in foundation and plinth (A) Foundation and plinth 25.00 Providing & laying Plain cement concrete 1:4:8 (1 cement : 4 coarse sand : 8 stone aggregates 40 mm nominal size) and curing complete excluding cost of form work in Foundation and plinth. Providing & laying cement concrete 1:2:4 (1 cement : 2 coarse sand : 4 graded stone aggregates 20 mm nominal size) and curing complete excluding cost of form work and reinforcement for reinforced concrete work in 10.00 (A) Foundations, footings, base of columns, and mass concrete 5.00 (B) Walls from top of foundations/level up to floor two level. 30.00 (C) Slabs, landing shelves, Balconies, lintels, beams, girders, and cantilever, up to floor two level.( Weather sheds Qty. PER RATE . AMOUNT

Cmt.

57.10

97070.00

Cmt.

61.90

1238.00

Cmt.

66.80

668.00

Cmt. Cmt. Cmt.

28.70

4305.00

5 6 7

187.00 317900.00 241.00 12050.00

Cmt. 88.32 163392.00 TOTAL - ( A ) 596623.00

Cmt.

1367.00 109360.00

Cmt.

1696.00

42400.00

10

Cmt. Cmt. Cmt.

2591.00 2612.00 2612.00

25910.00 13060.00 78360.00

-2-

D:\Jigar\Tender Notice 2009-2010\Tender Notice No. 13\LALBHAI CHAGANBHAI PATEL GARDEN TENDER New Vadaj Ward.DOC

-3-

Inlcuded) 11 12 8.00 (D) Columns, pillars, posts, and struts, up to floor two level. 4000.00 Providing and fixing Thermo mechanically Treated (TMT) bars for RCC works inclduing Bending, binding and placing upto floow two level. Providing form work in ordinary timber planking so as to give a rough finish including centering, shuttering, strutting and propping etc. height of propping and centering below supporting floor to celling not exceeding 4 Mt. & removal of the same for in situ reinforced or plain concrete work in. 50.00 (A) Foundation, footings, bases of columns etc. and mass concrete. 50.00 (B) Flat surface such as soffits of slabs, landing and the like (I) Floors etc. 200 mm in thickness. (II) Floors etc. above 200 mm in thickness. 50.00 (G) Columns, pillars, posts & struts. 50.00 (H) (1) Sides and soffits of beam, haunchings cantilevers, girders, and lintels MASONARY WORKS - C 110.00 Brick work using common burnt clay building bricks having crushing strength not less than 35 kg/Sq. cm. in foundations and plinth in cement mortar 1:6 (1 cement :6 fine sand) 95.00 Brick work using common burnt clay building bricks having crushing strength not less than 35 kg/Sq. cm. in cement mortar 1:6 (1 cement :6 fine sand) for superstructure upto floor three level height. 30.00 Half brick masonry in common burnt clay building bricks having crushing strength note less than 35 Kg/Sq. Cm. in cement mortar 1:4 (1 cement : 4 coarse sand) for super structure upto floor three level height. 5.00 Providing and fixing Porbandar stone dressed stone masonary Cmt. Kgs. 2612.00 20896.00

36.40 145600.00

Smt. Smt. Smt.

77.20 111.30 130.00

3860.00 5565.00 6500.00

Smt. 86.60 4330.00 TOTAL - ( B ) 455841.00

13 14

Cmt.

1416.00 155760.00

Cmt.

1479.00 140505.00

15

Smt.

212.00

6360.00

16

Cmt. 10500.00 52500.00 TOTAL - ( C ) 355125.00

17

18

STEEL WORKS - D Steel work welded in built up sections frame work including cutting, hoisting, fixing in position and applying priming coat of red lead paint. 350.00 (A) In beam and joists, channels, angles, tees, flats with connection plates or Angle cleats as in main & cross beams. Hop and jack rafters, purlins connected to common rafters and like. Kgs. 3.00 Providing & Fixing in position Alluminium doors with frame using approved quality oxodised extruded alluminium section as approved by Engg. In charge. Smt. (a) Frame sections 101.6x44.45 mm ( at 1.31 kg/mt) (b) Shutter bottom vertical & top section 83.5x44.45 (wt. 1.31 kg/mt.) (c ) Shutter bottom section at 114.3 x44.45mm at ( 1.37 kg/mt Shutter middle section at 100x44.3 wt. (1.37 kg/mt ) incl. providing & installing 5 mmth. Clear float glass of approved quality fixed with glazing chips on upper pannel & Laminated sheet on lower pannel (wt. 0.13 kg/ Rmt) etc. comp. as directed

44.07 2600.00

15424.50 7800.00

D:\Jigar\Tender Notice 2009-2010\Tender Notice No. 13\LALBHAI CHAGANBHAI PATEL GARDEN TENDER New Vadaj Ward.DOC

-3-

-4-

19

20

21

22

23

3.00 Providing & Fixing in position Alluminium window with frame using approved oxodised extruded alluminium section as approved by Engg. In charge. (a) Frame sections 65 x 25 mm ( at 0.41 kg/mt) (b)Sliding Frame bottom section of 61.85 x 31.75 mm (at 0.41 Kg/Rmt) Shutter top & bottom section 40 x18 mm ( wt. 0.41 Kg/Rmt ) (d) Shutter interlock vertical section 10 x 18 mm.( 0.41 Kg/ Rmt) (e) Shutter vertical of 40 x 18 mm. (0.41 Kg/Rmt) including P/F installing 5 mm th. Clear float glass & approved quality etc.comp. 3.00 Providing & Fixing in position Alluminium vents with frame using approved oxodised extruded alluminium section as approved by Eng. In charge.units equivalent Frame section of 63.50 x 38.50 mm. (wt. 0.68 Kg/Rmt) incl. Providing & Installing 5 mm. th. Clear float glass & approved quality etc. comp. 5.00 Providing & fixing 30 mm thick Factory made solid panel PVC Door shutter consisting frame made out of M.S. tubes of 19 gauge thickness and size of 19 mm x 19 mm for stiles, and 15 mm x 15 mm for top and bottom rails. M.S. frame shall have a coat of steel primer of approved make and manufacturers. M.S. frame covered with 5 mm thick heat moulded prelam PVC 'C' channel of size 30 mmx 50 mm forming stiles adn 5 mm thcik 75 mm wide PVC sheets for top rail , lock rail and bottom rail on either side and 10 mm (5 mm x 2) thick, 20 mm wide cross PVC sheet as gap insert for top rail and bottom rail, Panelling of 5 stiles and rails with 30 mm wide x 5 mm thick PVC sheet beading on either side, and joined together with solvent cemnet adhesive, an additional 5 mm thick PVC strip of 20 mm width is to be stcuk on the interior side of the 'C' channel usingPVC solvent cement adhesive etc. complete as per directed by Engineer in charge. 8.00 Providing and fixing 35 mm thick shutters for doors, windows, and clear storey windows including Indian teak wood frames 12 cms x 7 cms. Size including anodised aluminum fixtures & fastening including primer coat of approved quality and two coats of oil paint etc. complete. (II) Fully paneled 450.00 Providing and fixing M.S. Ornamental grill of required pattern with M.S. pipes / Flats / Bars/ at required spacing and fixing the same with nuts and bolts and /or welding. Rate also includes necessary accessories such as welding rods, tools, equipments etc fixtures and fasteners required for the same

Smt.

1850.00

5550.00

Smt.

1550.00

4650.00

Smt.

1897.58

9487.90

Smt.

3452.00

27616.00

Kgs. 55.00 TOTAL - ( D )

24750.00 95278.40

24

25

PLASTERING & POINTING - E 1500.00 Providing 15 mm. thick cement plaster in single coat on fair side of brick /concrete walls for interior plastering upto floor two level and finished even and smooth in C: M 1 : 3 ( 1 Cement : 3 Sand) Smt. 250.00 Providing 20 mm. thick sand face cement plaster on walls upto height of 10 mt.. and above ground level consisting of 12 mm. thick backing coating of C.M. 1:3 (1 cement : 3 sand) Smt.

75.00 112500.00 134.00 33500.00

-4-

D:\Jigar\Tender Notice 2009-2010\Tender Notice No. 13\LALBHAI CHAGANBHAI PATEL GARDEN TENDER New Vadaj Ward.DOC

-5-

and 8 mm. thick finishing coat in C.M. 1:1 (1 cement :1 sand) etc. complete TOTAL - ( E ) 146000.00 26 PAVING & FLOOR FINISHES - F 50.00 Providing and laying Polished kota stone slab (Polished, Green colour) flooring over 20 mm. (average) thick base of cement mortar 1:6 (1 cement : 6 coarse sand) joined with grey cement slurry including rubbing and polishing complete. for thickness upto 25 m.m. 10.00 Providing and laying marble stone slab flooring over 20 mm (average) base of cement mortar 1:6( 1 cement : 6 coarse sand) and jointed with grey cement slurry including rubbing and polishing etc. complete for marble slab 25 mm thick. 50.00 Providing and laying Rough chiselled dressed (kota stone green) stone flooring over 20 mm. thick base of cement mortar 1:5 (1 cement : 5 coarse sand) or L.M. 1:1.5 including pointing with cement mortar 1:2 (1 cement : 2 coarse sand) etc. complete.( 40 mm thick) 10.00 Providing kesariyaji Green marble steps of thickness 19 m.m. and width upto 1'-0'' rate includes necesssary cushioning layer of 20 m.m. thickness in C.M. 1:6 and labour required for fixing in good line and level etc. comprate also includes necessary moulding required on front side as per design suggested by engineer-in-charge etc.. comp. 20.00 Providing sandwich type seating platform of kesariyaji green marble having thickness upto 19 m.m. as suggested by architect rate includes necessary vertical supports of marble and base of marble stone rate also includes jesalmer patti upto 1" thickness between sandwitch and labour required for constg. Platform as directed by engineer incharge etc comp. 350.00 Providing and fixing interlocking type paver block of 65mm thickness, & M30 grade rate includes 50 m.m. thick sand bedding and labour required for fixing the same in good line and level as directed by engineer in-charge etc comp. 1200.00 Providing kerbing of size 300 X 300 X 75 m.m. of c.c. 1:2:4 with good finishing rate includes pointing in C.M. (1:1) and fixing in good line, level and plumb etc.. Comp. 20.00 Providing and laying cement concrete flooring (IPS) Indian Pattern Stone in 1:2:4(1 Cement : 2 coarse sand :4 graded aggregrate 20mm nominal size) laid in one layer of 50 mm thickness finished with a floating coat of neat cement on the top. 10.00 Providing and fixing of ' Little glass' or approved make, glass mosaics, 4 mm of thickness. Colour and extra white protective layer are fused at the back surface of this glass mosaics. Mosaics is pasted on a net / paper sheet. The glass mosaic pieces are uniformly mounted on the net / paper sheet. The supply is to made as per the colour shades, combination (plain / random Blend) and design approved by and available with the Engineering / consultant in charge. in different colour combination. 30.00 Providing and laying decorative tiles for wall cladding on walls / column / dado laid on 10 mm. thick cement mortar 1:3 (1 cement : 3 coarse sand) jointed with grey cement slurry including rubbing and polishing etc. complete.(Market Rate)

Smt.

708.00

35400.00

27

Smt.

1418.00

14180.00

28

Smt.

361.00

18050.00

29

Smt.

850.00

8500.00

30

Rmt.

4500.00

90000.00

31

Smt. Rmt.

460.00 161000.00 275.00 330000.00

32 33

Smt.

170.00

3400.00

34

Smt.

2500.00

25000.00

35

Smt.

900.00

27000.00

-5-

D:\Jigar\Tender Notice 2009-2010\Tender Notice No. 13\LALBHAI CHAGANBHAI PATEL GARDEN TENDER New Vadaj Ward.DOC

-6-

36 37

38 39

40 41

50.00 Providing cement vata ( 10 cms. X 10 cms size) quarter round in cement mortar 1:1 including neat cement finishing, watering etc. complete. 30.00 Providing and fixing Duracrete / Eurocon paver tiles 25 mm thick coloured tiles (in different colour combination) of the same make to be used in the parking areas or any areas specified by the engineer in charge ,on cement mortar bedding 1 : 6 ( 1 cement : 6 coarse sand ) including joint filled up with coloured cement to match the shade of tiles as approved by the Consultants. 40.00 Providing & Laying China mosaic clay flooring & skirting dedo on wall salb surface over 20 mm. th. C.m. 1:3 finished with white cement incldg. etc. comp. as directed 25.00 Providing and laying Cement concrete road of atleast 150 mm thickness average. The concrete shall be not less than 1:2:4( 1 Cemetn : 2 Sand : 4 Coarse aggregrates) or as approved by the engineer in charge 25.00 Providing and laying Ceramics flooring tiles in flooring, treads of steps and dado on 12 mm. thick cement plaster 1:3 (1 cement : 3 coarse sand) and jointed with white cement slurry. 40.00 Providing and laying White glazed tiles 5mm. thick in skirting, risers of steps and dado on 10 mm. thick cement plaster 1:3 (1 cement : 3 coarse sand) finished with flush pointing in white cement.

Rmt.

14.00

700.00

Smt. Smt.

815.00 300.00

24450.00 12000.00

Smt. Smt.

500.00 643.00

12500.00 16075.00

Smt. 663.00 26520.00 TOTAL - ( F ) 804775.00

42

43

44

45

46

47

ROOF COVERING - G 20.00 Providing and fixing 2.00 m.m. thick F.R.P sheet of good quality and standard make rate also includes necessary fabrication structure in the grid of 3' X 2' size using hollow pipe of 16 gauge and size 2" X 1" and 1" X 1" rate also inclusive necessary bending, cutting and fabrication charges and priming coat and 2 coats of oil paint of shade approved by engineer in-charge rate also includes washers and silicon paste required for fixing the sheet in good quality as directed. Smt. 1865.00 10.00 Providing 2.00 mm thick F.R.P gutter with necessary supporting brackets. Rmt. 400.00 TOTAL - ( G ) PAINTING - H 600.00 Painting two coats (excl. priming coat) on new steel & other Metal surfacer with enamel paint, brushing, interior to give an even shade incl. cleaning the surface of all dirt, dust and other foreign matter. Smt. 46.80 2500.00 White washing with lime on undecorated wall surfaces (two coats) to give an even shade including thoroughly brooming the surface to remove all dirt, dust mortar drops and other foreign matter.. Smt. 3.00 1500.00 Finishing wall with water proofing cement paint on an undercoated wall surface s(two coat) to given an approved brand and manfacture and of required shape even shade after throughly brushing the surface to remove all dirt and remains of loose powder materials. Smt. 27.10 TOTAL - ( H ) PLUMBING & DRAINAGE - I 6.00 Const. B.P. type catches pit of size0.60x0.60 depth up to 0.75 m including excavation, B.B.C.C. (1:5:10), 23 CMS. Thick brick walls in Cm (1:6) with 40 mm thick IPS flooring in the No. 2594.00

37300.00 4000.00 41300.00

28080.00

7500.00

40650.00 76230.00

15564.00

-6-

D:\Jigar\Tender Notice 2009-2010\Tender Notice No. 13\LALBHAI CHAGANBHAI PATEL GARDEN TENDER New Vadaj Ward.DOC

-7-

48 49 50

51

52

53

54 55

56

57

58

prop M15 at bottom and 20 mm thick cement plaster inside the catchpit in the proportion of CM(1:3) including heavy duty FRC seat and jali etc.comp.as directed. 400.00 Provding and laying 50 mm dia UPVC water supply line. Rate includes necessary excavation and laying pipe including all the necessary accessories for the same. Rmt. 250.00 100000.00 100.00 Provding and laying 32 mm dia UPVC water supply line. Rate includes necessary excavation and laying pipe including all the necessary accessories for the same. Rmt. 200.00 20000.00 1.00 Provding Soakwell of 4.00 Mt. depth and 3.00 Mt. wide. The well shall be having perforated brick works as per the standards, and shall have the RCC top slab of 115 mm thickness. The rates includes all necessary ancillary activities such as excavation, brick work, connection from manhole. etc. complete. Job. 30000.00 30000.00 Provdg. and fixing to wall, ceiling & floor galvanised mild steel tubes(Medium grade) of the following nominal bore, tube fitting and clamps incl. making good the wall, ceiling and floor. 15.00 (A) 15 mm Rmt. 98.80 1482.00 45.00 (B) 20 mm Rmt. 129.00 5805.00 10.00 (D) 32 mm Rmt. 220.00 2200.00 Providing and laying in trenches galvanised mild steel tubes ( Medium. Grade) of the following nominal bore., & tube fittings (Earth works in trenches shall be measured and paid seperately) 15.00 (C) 25 mm Rmt. 142.00 2130.00 100.00 (D) 40 mm Rmt. 204.00 20400.00 Provdg. And fixing to wall ceiling and floor 10.00 kg. F/Sq.Cm working pressure polythelene pipes (PVC pipes) of the following outside diameter, low, density, complete with special flange compression type fittings, wall clips etc. making good wall ceiling and floor. 10.00 (D) 40 mm dia Rmt. 93.70 937.00 5.00 E) 50 mm dia Rmt. 134.00 670.00 15.00 F) 75 mm dia Rmt. 239.00 3585.00 5.00 (G) 100 mm dia Rmt. 413.00 2065.00 Providing & fixing in position PVC crowl to vent pipes 5.00 (i) 75mm dia No. 224.00 1120.00 4.00 Providing and fixing PVC Nahni trap of the following nominal diameter of self cleansing design with incl. cost of sutting & making, good the walls and floors 100 mm inlet and 50 mm outlet. No. 222.00 888.00 2.00 Providing and fixing Water closet squatting pan ( indian type W.C. pan) size 580 mm including Earth work, Bed concrete, foot rest and trap. (1) Long pattern white colour No. 689.00 1378.00 1.00 Providing & fixing wash down Water closet ( European type W.C. Pan) with integral P or S trap incl. jointing the trap with soil pipe in cement mortar1:1 (1 cement : 1 fine sand) including seat and cover . Vitreous china White Color No. 426.00 426.00 2.00 Provdg. & fixing Wash basin with single hole for pillar tap with C.I. or M.S. brackets painted white incl. sutting holes and making good the same but excluding fittings. Flat bank wash Each 706.00 1412.00

-7-

D:\Jigar\Tender Notice 2009-2010\Tender Notice No. 13\LALBHAI CHAGANBHAI PATEL GARDEN TENDER New Vadaj Ward.DOC

-8-

59

60

61

62

63

64

65

66

67 68 69

70

basin of 500 mm x 400 mm x 150 mm size in white colour. Provdg. & fixing C.P. Brass waste for wash basin of Sink. 2.00 (A) 32 mm dia Each 1.00 (B) 40 mm dia Each Provdg. & fixing M.I, fisher union for wash basin or sink. 2.00 (A) 32 mm dia Each 2.00 (B) 40 mm dia Each 1.00 Provdg. & fixing kitchen sink sink C.I. or M.S. brackets, painted white incl. cutting holes in walls and making good the same but excluding fitting. (C) vitreous China sink : (I) 600 mm 450 mm x 150 mm size No. Providing & fixing screw down bib taps of following size. (A) Brass screw down bib tap polished bright 8.00 (I) 15 mm dia No. Providing & fixing pillar tap capstan head, screw down high pressure with screws shanks and back nuts. 2.00 (A) 15 mm dia No. Providing & fixing brass screw down stop tap (SOR Chap. 23 Item No. 30.23.96(A)) 5.00 (A) 15 mm dia No. Providing & fixing gun metal check or nonreturn full wheel valve. 1.00 (A) 15 mm dia No. 1.00 (B) 20 mm dia No. 1.00 (C) 25 mm dia No. 4.00 (D) 32 mm dia No. 1.00 (E) 40 mm dia No. Provdg. & fixing chromium plated brass half turn flush cock of approved qaulity including fixing pipe the etc. complete. 2.00 (I) 20 mm dia No. 2.00 (II) 25 mm dia No. 1.00 (III) 32 mm dia No. 2.00 Providing & fixing chromium plated bottle trap with necessary coupling of approved qaulity for washbasin. No. 2.00 Providing & fixing G.I.rain water spout of 50 mm dia and 30 cm length. No. Providing & fixing S.W. Gully trap with C.I. grating brick masonry chamber & water tight C.I. cover with frame of 300 mm x 300 mm size ( inside) with standard weight. 2.00 (A) 100 mm x 100 mm size P-trap No. 2.00 (B) 150 mm x150 mm size P-Trap No. Providing & Laying & Jointing glazed stoneware pipes incl. excavation up to 2.0 mt.,refilling, trasporting the pipe to work site, unloading, lowering in trenches, laying and jointing the pipes in c.m. 1:1 incl. all jointing materials such as cement, sand, hemp, bitumen as dire. testing the pipe line to a head of 1.5 mt. and hydraulic test as dire incl. watering trenches, spreading , and carting away of surplus earth within 100 mt.lead as dire. etc. comp. 75.00 a) 23 cm dia. Rmt. 2.00 b) 15 cm dia Rmt. 2.00 c) 10 cm dia. Rmt.

53.00 70.40 58.60 70.20

106.00 70.40 117.20 140.40

1326.00

1326.00

104.00

832.00

175.00

350.00

100.00

500.00

210.00 233.00 291.00 379.00 523.00

210.00 233.00 291.00 1516.00 523.00

288.00 301.00 230.00 333.00 74.00

576.00 602.00 230.00 666.00 148.00

610.00 616.00

1220.00 1232.00

220.00 110.00 80.00

16500.00 220.00 160.00

-8-

D:\Jigar\Tender Notice 2009-2010\Tender Notice No. 13\LALBHAI CHAGANBHAI PATEL GARDEN TENDER New Vadaj Ward.DOC

-9-

71

72 73

74 75

76

77

2.00 d) 30 cm dia. Rmt. 270.00 540.00 Constg. brick masonry chamber for underground C.I. inspection chamber and bends with brick having crushing strength not less than 35 Kg./Cm. in C.I. 1 : 5 C.M. cover with frame (light duty) 455 x 610 mm. internal dimensions, total weight of cover with frame to be not less than 38 Kg. (Wt. or cover 23 Kg. and Wt. of frame 15 Kg.) R.C.C. top slab with C.C. 1 : 2 : 4 mix (1 cement : 2 coarse sand : 4 graded aggregate 20 mm. size) foundation concrete 1 : 5 : 10 inside plaster 15 mm. thick with C.M. 1 : 3 finished smooth with a finishing coat of neat cement on walls and bed concrete etc. complete. 1.00 (I) Inside Dimensions 455mm x 610 mm & 450 mm deep for single pipe line Each 1241.00 1241.00 6000.00 Providing & Fixing Polytheline over head tank with necessary dia holes for outlet , inlet over flow and washout with necessary washer and checkput etc. complete Ltr. 4.50 27000.00 Constg. Manhole with R.C.C. top slab in 1 : 2 : 4 mix (1 cement : 2 coarse sand : 4 graded stone aggregate 20 mm. nominal size) foundation concrete 1 : 3 : 6 (1 cement : 3 coarse sand : 6 brick bats 40 to 50 mm. size) inside plastering 15 mm. thick with C.M. 1 : 5 (1 cement : 5 coarse sand) finished with floating coat of neat cement and making channels in C.C. 1 : 2 : 4 (1 cement : 2 coarse sand : 4 stone aggregate 20 mm. nominal size) finished smooth complete incl. curing and testing (1) inside size 900 mm. x 120 mm. and 1.5 mm. deep including C.I. cover with frame size. 560 mm diameter total weith of cover & frame to be not less than 128 kg, (Wt. of cover 64 kg. & Wt. of frame 64 kg) (A) with 230 mm th. Walls of brick masonry using brick having crushing strength not less than 356 kg./Sq.cm in cement mortar 1 :5 (1cement : 5 coarse sand) 1.00 (3) C-type depth 2.24 meter for 150 mm diameter sewer No. 10321.00 10321.00 2.00 Providing And Fixing Heavy Duty Fibre Reinforced Seat And cover in line and level in CC 1:2:4 and finishing smooth etc, complete as directed No. 1550.00 3100.00 2.00 Providing and fixing urinal of approved quality including connection with trap and with integral longitudinal flush pipe for: Nos. 794.00 1588.00 (A) Squatting plate patten white eartheware 550 mm x 300 mm TOTAL - ( I ) 281621.00 ELECTRIFICATION - J 25.00 Point wiring for secondary light point with 2-1.0sq.mm & earthwire of 1.0 sq.mm (green) both are of ISI marked FR PVC insulated multistrand copper wires, in existing pipe duly erected complete with earth continuity and necessary connection with primary light with accessories erected on polished wooden block / Metal / PVC box covered with 3 mm thick laminated sheet for concealled wiring (1-1-4) Point 65.00 1625.00 Note:- Maximum up to 6 mtrs length, excess will be considered as Mains for Secondary Point. 25.00 Point wiring for Light/primary Point with 2 No of wires -1.0Sq mm & earthwire of 1.0 sq.mm(green) both are of .ISI marked FR PVC insulated multistrand copper wires,in existing pipe duly erected, complete with 6A Modular type switch & Point 180.00 4500.00

-9-

D:\Jigar\Tender Notice 2009-2010\Tender Notice No. 13\LALBHAI CHAGANBHAI PATEL GARDEN TENDER New Vadaj Ward.DOC

- 10 -

78

79

80

81

82

83

accessories erected on PVC/ Metallic board covered with appropriate modular type front plate erected concealled in wall and ceiling(1-1-3) 2.00 Point wiring for individual plug with 2-1.0 sq mm & earthwire of 1.0 sq mm (green) both are of ISI marked. FR PVC insulated multistrand copper wires in existing pipe duly erected complete with 6 Amp. Modular type switch & 5pin plug erected on PVC/ metallic boxes covered with appropriate front plate modular erected concealled in wall and ceiling with following type of accessoreis(1-2-3) Cat II Point Providing and erecting 1.5 mm thick FIA apprroved and ISI marked (embossed) RIGID PVC pipes of following size complete erected with necessary PVC fittings and junction boxes fixed with adhesive , solution and clamps with following types of erection.(1-4-2) (1) For open execution with clamps erecting on wall or ceiling of following size of diameter 10.00 (i) 25mm Rmt. 10.00 (ii) 32 mm Rmt. (2) For erecting conceal in wall or slab alongwith continuous fish wire to draw mains laid in approved manner with plastering by cement mortar and finishing the surface to match the wall or ceiling.(1-4-2) 10.00 (i) 20 mm Rmt. 50.00 (ii) 25 mm Rmt. 50.00 (iii) 32 mm Rmt. Mains with 1.1KV grade FR PVC insulated ISI marked standard copper conductor wiring in existing pipe erected with 1.5 sq mm copper conductor FR PVC insulated standard wire of green colour for earth continuity of following size. Rate excludes PVC pipes (1-5-1) 100.00 (1) 2 wire 1.5 sq mm Rmt. 50.00 (2) 2 wire 2.5 sq mm Rmt. 15.00 (3) 4 wire 2.5 sq mm Rmt. Mains with 1.1KV grade FR PVC insulated ISI marked standard copper conductor wiring in existing pipe erected with 2.5 sq mm copper conductor FR PVC insulated standard wire of green colour for earth continuity of following size.(1-52) 100.00 (1) 2 wire 4.0 sq mm Rmt. 10.00 (2) 2 wire 6.0 sq mm Rmt. 10.00 (3) 4 wire 4.0 sq mm Rmt. 10.00 (4) 4 wire 6.0 sq mm Rmt. 10.00 (5) 4 wire 10.0 sq mm Rmt. Providing and erecting following shockproof Tissino or approved type accessories on 3 mm thick laminated sheet in wooden / PVC / Metallic box erected on wall or ceiling.(1-7-1) 25.00 1) One No. Single Pole 6 A switch / Bell push Each 5.00 2) One No. 3/5 pin 6 A socket Each 2.00 5) One No, single pole 16 Amp. Switch.and one no. 6/16 A universal socket combined Each Providing and ercting 240 V MCB double pole switch for motor & inductive load ( C Curve) having 10 KA breaking capacity & confirming to IS:8828 in exisitng box having following capacity(3-10-3)

310.00

620.00

25.00 40.00

250.00 400.00

20.00 28.00 43.00

200.00 1400.00 2150.00

21.00 27.00 47.00

2100.00 1350.00 705.00

43.00 58.00 80.00 105.00 380.00

4300.00 580.00 800.00 1050.00 3800.00

17.00 22.00 65.00

425.00 110.00 130.00

D:\Jigar\Tender Notice 2009-2010\Tender Notice No. 13\LALBHAI CHAGANBHAI PATEL GARDEN TENDER New Vadaj Ward.DOC

- 10 -

- 11 -

84

85

86

87 88 89

5.00 A) 6 to 32 Amp.Cat-III Each 2.00 B) 40 Amp Cat-III Each Supply and Laying of XLPE / PVC armored cable of 1100 V grade of Aluminium / Copper conductor of following sizes in ground or in pre-laid RCC hume pipe with necessary cable identification mark to be provided at distance of 10 mt scope includes Excavation and back filling of cable trenches of 1000 mm depth as directed by engineer incharge. 800.00 a) 10 sq. mm x 4 c Al. cable Rmt 2.00 Supplying, unloading at site , shifting to site, assembling , leveling, grouting, erecting, Testing & Commissiononing double compartmentalized Street light control panel with IP 55 protection & should be powder coated fabricated from 10 Guage M.S.sheet & folded channel totally enclosed cubical type with pad lock arrangment. The successful tenderer will have to prepare general arrangement with dimensions & get it approve through Architect/ Consultant. All civil wotk including RCC platform for section pillar should be in scope of Electrical contractor complete in all respect as per detail drawing and directed by engineer incharge. Nos. Incoming : 63 Amp.FP FSU with HRC fuse with RYB indicating lamp Busbar : Set of 63 A FP tinned copper busbars of EC. Grade & adequate capacity , size & insulated with colour tape & should be tined at all joints. Auto/Manual by pass switch with indicating lamp. Adequate size 3 ph contractor with NV coil of 230V 1 No.dual channel Daily dial digital type Timer with 48 Hr. battery back up of L & T mak or equivalent. Outgoing : 4 Nos. per phase S.P.MCB of 6-32 AMP, i.e.12 nos Brass neutral link of 6 way per Phase, i.e. 3 nos. 30.00 Supply and erecting sintex or approved make S.M.C. press moulded composite FRP ( Platic) loop in loop out box with bakelite connector strip 4 way and hinged door having locking arrangement with mounting clamp with nut, bolt and washers suitable for erection on pole with cable gland and earth bolt of following sizes Nos. a) 300 mm x 200mm x 200 mm 1.00 a) Motor rating 2 HP (12 stage) pump having capacity of 50 LPM at 45 Mtr head suitable for 32 mm dia delievery pipe.(Cat.II) Nos. 1.00 b) Motor rating 1.5 HP (16 stage) pump having capacity of 50 LPM at 60 Mtr. Head suitable for 32 mm dia delievery pipe. Nos. Supplying and erecting funnel type earthing having earth plate of following size buried in specifically prepared earth pit 3 Mt. below ground with 150 Kgs. Charcoal & salt with alternate layers of each, 38 mm dia G.I. pipe, with funnel with a wire mesh for watering & bricks masonary block C.I. cover complete as per IS 3043 with necessary length fo double G.I. / copper earth wire No. 6 SWG bolted with lug to the plate and covered in 12 mm dia G.I. Pipe 2.5 mtr. long complete connected to the nearest switch gear with end socket as per the instructions (3-15-12)

340.00 400.00

1700.00 800.00

120.00

96000.00

42000.00

84000.00

1000.00

30000.00

15000.00 12000.00

15000.00 12000.00

D:\Jigar\Tender Notice 2009-2010\Tender Notice No. 13\LALBHAI CHAGANBHAI PATEL GARDEN TENDER New Vadaj Ward.DOC

- 11 -

- 12 -

90 91 92 93

1.00 d) Earthing 60 x 60 x 0.615 cms. Copper earth plate 30.00 Providing of 3Mt. Clear Height GI / M.S. Decorative Pole 30.00 Providing of 70 watt HPSV Fitting with Lamp 30.00 Labour work for fixing of Pole, bracket erecting charges of pole with earth plates fitting etc. 30.00 Providing of 70 watt single arm M.S. Bracket atleast 0.90 Mt. long MISCELLANEOUS - K 7.00 Providing and fixing M.S. fabricated children play area instruments such as swings, sea-saw, slides, marry-go-round etc. made as per the designs and standards approved by the project consultants. 10.00 Providing and fixing PVC benches of approved shade, size and standards. Rate includes necessary fixtures to ensure the safety of the benches etc. complete. 10.00 Providing and fixing PVC dustbins of atleast 1.20 Mts. height in various designs and shapes as per the instructions of the engineer in charge and / or the consultants 1.00 Constructing Gazebo upto 3.50 Mt. Daimeter at ground level, in Ferro cement struture with RCC circular columns, cladded with ferrocement materials to give the look of wood. Rate includes necessary activities like excavation, P.C.C.,RChTworks,Ferrocement works, Sitting arrangement etc. complete as per the requirements laid by the Engg. Incharge. 1.00 Providing and fixing Borewell of atleast 180 feet depth. The rates includes all necessary ancillary activities such as drilling, casing, dewatering, etc. complete and all the fittings and fixtures required for the same.

Nos Nos. Nos. Nos.

5100.00 5100.00 7000.00 210000.00 4500.00 135000.00 1800.00 54000.00

Nos. 850.00 25500.00 TOTAL - ( J ) 695595.00

94

Nos. 12000.00 Nos Nos. 4300.00 4000.00

84000.00 43000.00 40000.00

95 96 97

No. 400000.00 400000.00

98

Job. 300000.00 300000.00 TOTAL - ( K ) 867000.00

D:\Jigar\Tender Notice 2009-2010\Tender Notice No. 13\LALBHAI CHAGANBHAI PATEL GARDEN TENDER New Vadaj Ward.DOC

- 12 -

- 13 -

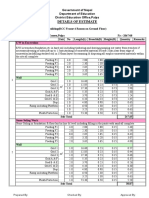

AHMEDABAD MUNICIPAL CORPORATION GARDEN DEPARTMENT - WEST ZONE Development of LALBHAI CHAGANBHAI PATEL UDHYAN NR.TIGER FLAT AT NAWA WADAJ, AHMEDABAD RECAPITULATION SHEET S.NO.

A B C D E F G H I J K EARTH WORK CONCRETE WORK MASONARY WORKS STEEL WORKS PLASTERING & POINTING PAVING & FLOOR FINISHES ROOF COVERING PAINTING PLUMBING & DRAINAGE ELECTRIFICATION MISCELLANEOUS

TOTAL OF CIVIL WORK ( A TO K )

DESCRIPTION

AMOUNT

596623.00 455841.00 355125.00 95278.40 146000.00 804775.00 41300.00 76230.00 281621.00 695595.00 867000.00

Total Amount Rs.

44,15,388.40 44,15,388.40

% ABOVE % LESS

Contractor`s sign.

Add.C.E (W.Z)

D:\Jigar\Tender Notice 2009-2010\Tender Notice No. 13\LALBHAI CHAGANBHAI PATEL GARDEN TENDER New Vadaj Ward.DOC

- 13 -

- 14 -

SPECIFICATIONS OF MATERIALS M-1. 1.1 Water: Water shall not be salty or brackish and shall be clean, reasonably clear and free from objectionable quantities of silt and traces of oil and injurious alkalis, salts, organic matter and other deleterious material which will either weaken the mortar or concrete or cause efflorescence or attack the steel in R.C.C Container for transport, storage and handling of water shall be clean. Water shall conform to the standards specified in I.S.456-1978. If required by the Engineer-in-charge it shall be tested by comparison with distilled water. Comparison shall be made by means of standard cement tests for soundness, time of setting and mortar strength as specified in I.S.269-1976. Any indication of unsoundness, change in time of setting by 30 minutes or more or decrease of more than 10 per cent in strength of mortar prepared with water sample when compared with the results obtained with mortar prepared with distilled water shall be sufficient cause for rejection of water under test. Water for curing mortar, concrete or masonry should not be too acidic or too alkaline. It shall be free of elements which significantly affect the hydration reaction or otherwise interfere with the hardening of concrete during curing or those which produce objectionable stains or other unsightly deposits on concrete or mortar surfaces. Hard and bitter water shall not be used for curing. Portable water will be generally found suitable for curing mortar or concrete. Lime: Lime shall be hydraulic lime as per I.S. 712-1973. Necessary test shall be carried out as per I.S. 6932 (Parts I to X), 1973. The following field tests for limes are to be carried out: A very rough idea can be formed about the type of lime by its visual examination i.e. fat lime bears pure white colour, lime in form of porous lumps of dirty white colour indicates quick lime, and solid lumps are the unburnt lime stone. Acid tests for determining the carbonate content in lime, Excessive amount of impurities and rough determination of class of lime. Storage shall comply with I.S. 712-1973. The slaked lime, if stored, shall be kept in a weather proof and damp-proof shed with impervious floor and sides to protect it against rain, moisture, weather and extraneous materials mixing with it. All lime that has been damaged in any way shall be rejected and all rejected materials shall be removed from site of work. Field testing shall be done according to I.S. 1624-1974 to show the acceptability of materials. Cement : Cement shall be ordinary Portland slag cement as per I.S. 269-1976 or Portland slag cement as per I.S. 455-1976. White Cement : The white cement shall conform to I.S. 80412-E 1978. Coloured Cement: Coloured cement shall be with white or gray Portland cement as specified in the item of the work. The pigments used for Coloured cement shall be of approved quality and shall not exceed 10% of cement used in the Mix. The mixture of pigment shall be properly grounded to have a uniform colour and shade. The pigments shall have such properties to provide for durability under exposure to sunlight and weather. The pigment shall have the property such that it is neither by the cement nor detrimental to it. Sand:

- 14 -

1.2

1.3

1.4 1.5 M-2. 2.1 2.2 (1) (2) 2.3

2.4 M-3. 3.1 M-4. 4.1 M-5. 5.1 5.2

5.3 M-6.

D:\Jigar\Tender Notice 2009-2010\Tender Notice No. 13\LALBHAI CHAGANBHAI PATEL GARDEN TENDER New Vadaj Ward.DOC

- 15 -

6.1

6.2

Sand shall be natural sand, clean, well graded, hard strong durable and gritty particle free from injurious amounts of dust clay, kankar nodules, soft or flaky particles shale, alkali, salts organic matter, loam, mica or another deleterious substance and shall be got approved from the Engineer-in-charge. The sand shall not contain more than 8 percent of silt as determined by field test. If necessary the sand shall be washed to make it clean. Coarse Sand : The fineness modulus of coarse sand shall not be less than 2.5 and shall not exceed 3,0. The sieve analysis of coarse shall be as under: Percentage weight Passing Sieve 100 90 to 100 70-100 by I.S.Sieve Percentage by weight Passing Sieve 30-100 5-70 0-50

I.S.Sieve

Designation Designation 4.75 mm. 600 Micron 2.36 mm. 300 Micron 1.18 mm. 150 Micron 6.3 Fine Sand: The fineness modulus shall not exceed 1.0. The sieve analysis of fine sand shall be as under: I.S.Sieve Percentage by I.S.Sieve Percentage by weight weight Designation Passing Sieve Designation Passing Sieve 4.75 mm. 100 600 Micron 40-85 2.36 mm. 100 300 Micron 5-50 1.18 mm. 70-100 150 Micron 0-10 M-7. Stone Dust : 7.1 This shall be obtained from crushing hard black trap or equivalent. It shall not contain more than 8% of silt as determined by field test with measuring cylinder. The method of determining silt contents by field test is given as under : 7.2 A sample of stone dust to be tested shall be placed without drying in 200 mm. measuring cylinder. The quantity of the sample shall be such that it fills the cylinder upto100 mm. mark. The clean water shall be added upto 150 mm. mark. The mixture shall be stiffed vigorously and the content allowed to settle for 3 hours. 7.3 The height of silt visible as settled layer above the stone dust shall be expressed as percentage of the height of the stone dust below. The stone dust containing more than 8% silt shall be washed so as lowering the silt content within the allowable limit. 7.4 The fineness modulus of stone dust shall not be less than 1.80. M-8. Stone Grit: 8.1 Grit shall consist of crushed or broken stone and be hard strong, dense, durable, clean, of proper gradation and free from skin or coating likely to prevent adhesion of mortar Grit shall generally be cubical in shape and as far as possible flaky elongated pieces shall be avoided. It shall generally comply with the provisions of I.S. 383-1970. Unless special stone of particular quarries is mentioned, grit shall be obtained from the best black trap or equivalent hard stone as approved by the Engineer-in-charge. The grit shall have no deleterious reaction with cement. 8.2 The grit shall conform to the following gradation as per sieve analysis: Percentage by weight through Sieve 0-20% 0-25% concrete in which it is used to used to

- 15 -

Percentage by I.S.Sieve weight Designation through Sieve Designation 12.50 mm. 100% 4.75 mm. 10.00 mm. 85-100% 2.36 mm. 8.3 The crushing strength of grit will be such as to allow the built up the specified strength of concrete.

D:\Jigar\Tender Notice 2009-2010\Tender Notice No. 13\LALBHAI CHAGANBHAI PATEL GARDEN TENDER New Vadaj Ward.DOC

I.S.Sieve

- 16 -

8.4 M-9. 9.1 9.2 9.3

The necessary tests for grit shall carried out as per the requirements of I.S.2386(Parts I to VII) 1963, as per instructions of the Engineer-in-charge. The necessity of test will be decided by the Engineer-in-charge. The necessity of test will be decided by the Engineer-in-charge. Cinder : Cinder is well burnt furnace residue, which has been fused or sintered into lumps of varying sizes. Cinder aggregates shall be well burnt furnace residue obtained from furnace using coal fuel only. it shall be sound clean free from clay, dirt ash or other deleterious matter. The average grading for cinder aggregates shall be as mentioned below : Percentage passing 100 86 I.S.Sieve Designation 4.75 mm. 2.36 mm. Percentage passing 70 52

I.S.Sieve Designation 20 mm. 10 mm. M-10. 10.1 Sand: 10.2

Lime Mortar : Lime shall confirm to specification M-2 Water shall conform to specification M-1. Sand Shall conform to specification M-6. Proportion of Mix : 10.2.1. Mortar shall consist of such proportions of slaked lime and sand as may be specified in the item. The slaked lime and sand be measured by volume. 10.3 Preparation of Mortar : 10.3.1. Lime mortar shall be prepared by wet process as per I.S. 1625-1971. Power driven mill shall be used for preparation of lime mortar. The slaked lime shall be placed in the mill in an even layer and ground for the 180 revolutions with a sufficient water. Water shall be added as required during grinding (care being taken not to add more water) that will bring the mixed material to a consistency of stiff paste. Thoroughly wetted sand shall then be added evenly and the mixture ground for another 180 revolutions. 10.4 Storage : 10.4.1 Mortar shall always be kept damp, protected form sum and rain till used up , covering it by tarpaulin or open sheds. 10.5 Use : 10.5.1 All mortar shall be used as soon as possible after grinding it should be used on the day on which it is prepared. But in no case mortar made earlier than 36 hours shall be permitted for use. M-11. Cement Mortar: 11.1 Water shall conform to specification M 1. Cement : Cement shall conform to specification M3. Sand: Sand shall conform to M-6 11.2 Preparation of Mix :11.2.1 Cement and shall be mixed to specified proportion, sand being measured by measuring boxes. The proportion of cement will be by volume on the basic of 50 kg / Bag of cement being equal to 0.0342 Cu.m. The mortar may be hand mixed or machine mixed as directed. 11.3 Preparation of mortar : 11.3.1 In hand mixed mortar cement and sand in the specified proportions shall be thoroughly mixed dry on a clean impervious platform by turning over at least 3 times or more till a homogenous mixture of uniform colour is obtained., Mixing platform shall be so arranged that no delirious extraneous material shall get mixed with mortar or mortar shall be gradually added and thoroughly mixed to form a stiff plastic mass of uniform colour so that each particle of sand shall be completely covered with a film of wet cement. The water cement ratio shall be adopted as directed. 11.3.1 The mortar so prepared shall be used within 30 minutes of adding water Only such quantity of mortar shall be prepared as can be used within 30 minutes. M-12 Stone Coarse Aggregate For nominal Mix Concrete :

D:\Jigar\Tender Notice 2009-2010\Tender Notice No. 13\LALBHAI CHAGANBHAI PATEL GARDEN TENDER New Vadaj Ward.DOC

- 16 -

- 17 -

12.1 12.2

Coarse aggregate shall be machine crushed stone of black trap or equivalent and be hard, strong m dense, durable clean and free form skin and coating likely to prevent proper adhesion for mortar. The aggregate shall generally be cubical in shape. Unless special stones of particular quarries are mentioned aggregates shall be machine crushed from the best black trap or equivalent hard stone as approved. Aggregate shall have no deleterious reaction with cement. The size of the coarse aggregate for plain cement concrete and ordinary reinforced cement concrete shall generally be as per the table given below. However in case of reinforced cement concrete the maximum limit may be restricted to 6 mm. less than the minimum lateral clear distance between bars or 6 mm. less than the cover, Whichever is smaller. TABLE

percentage passing for single I.S.Sieve Percentage passing for single sized aggregates of nominal Designati aggregates of Nominal size on sized size 80 mm. ---12.5 mm. ---63 mm. 100 --10 mm. 0.5 0.02 0.30 40 mm. 85-100 100 -4.75 mm -0.5 0.5 20 mm. 0-20 85-100 100 2.35 ---mm. 15 mm. --85-100 NOTE: This percentage may be carried some what by Engineer-in-charge when considered necessary for obtaining better density and strength of concrete. 12.3 The grading test shall be taken in the beginning and at the change of source of materials. The necessary test indicated in I.S. 383-1970 and I.S. 456-1978 shall have to be carried out to ensure the acceptability. The aggregates shall be stores separately and handled in such a manner as to prevent the intermixing of different aggregates. If the aggregates. are covered with dust, they shall be washed with water to make them clean. M-13. Black Trap or Equivalent Hard Stone Coarse : 13.1 Aggregate For Design Mix Concrete :Coarse aggregate shall be of machine crushed stone of black trap or equivalent hard stone and be hard strong dense, durable clean and free skin and coating likely to prevent proper adhesion of mortar. 13.2 The aggregates shall generally be cubical in shape. Unless special stones of particular quarries are mentioned, aggregates shall be machine crushed from the best, black trap or equivalent hard stones as approved. Aggregate shall have no deleterious reaction with cement. 13.3 The necessary tests indicated in I.S. 383-1970 and I.S. 456-1978 shall have to be carried out to ensure the acceptability of the material. 13.4 If aggregate is covered with dust it shall be washed with water to make it clean. M-14. Brick Bats Aggregate : 14.1 Brick bat aggregate shall be broken from well burnt or slightly over burnt and dies brick. It shall be homogeneous in texture roughly cubical shape, clean and free from dirt of any other foreign material. The brick bats shall be of 40 mm. to 50 mm. size unless otherwise specified in the item. The unburnt or over burnt brick bats shall not be allowed. 14.2 The brick bats shall be measured by volume by suitable boxes or as directed. M-15 Bricks : 15.1 The bricks shall be hand or machine moulded and made from suitable soils and kiln-burnt. They shall be free from crack and nodules of free lime. They shall have smooth rectangular faces with sharp corers and shall be of uniform colour. The bricks shall be moulded with a frog of 100 mm. X 40 mm. and 10 mm. to 20 mm. deep on one of its flat sides. The bricks shall not break when thrown on the ground from a height of 600 mm. l.s.sieve

D:\Jigar\Tender Notice 2009-2010\Tender Notice No. 13\LALBHAI CHAGANBHAI PATEL GARDEN TENDER New Vadaj Ward.DOC

- 17 -

- 18 -

15.2 15.3 15.4 15.5 M-16 16.1

16.2 16.3

M-17. 17.1

17.2 17.3 17.4 M-18. 18.1 18.2 18.3 1. 2. 3. 4. 5. 6. 7. M-19. 19.1 19.2

The size of modular bricks shall be 190 mm. X 90 mm. X 90 mm. 3 3 The size of the conventional bricks shall be as under : (9x48 x 24 )225 x 110 x 75 mm. Only bricks of one standard size shall be used on one work. The following tolerances shall be permitted in the conventional size adopted in a particular work. Length : 1.8 (3.0 mm.) Width : 1/6 (1.51 mm.) Height : 1/6 1.50 mm.) The crushing strength of the bricks shall not be less than 35 Kg./Sq.Cm. The average water absorbed shall not be more than 20 percent by weight. Necessary tests for crushing strength and water absorption etc. shall be carried out as per I.S. .3493 (Part-I to IV) 1976. Stone : The stone shall be of the specified variety such as Granite/Trap Stone. Quartzite or any other type of good hard stones. The stones shall be obtained only from the approved quarry and shall be hard, sound, durable and free from defects like cavities, cracks, sand holes, flaws, injurious veins, patches of loose or soft materials etc. and weathered portions and other structural defects or imperfections tending to affect their soundness and strength. The stone with round surface shall not be used. The percentage of water absorption shall not be more that 5% of dry weight, When tested in accordance with I.S. 1134-1974. The minimum crushing strength of the stone shall be 200 kg./Sq. Cm. unless otherwise specified. The samples of the stone to be used shall be got approved before the work is started. The Khanki facing stone shall be dressed by chisel as specified in the item for khanki facing in required shape and size. The face of stone shall be so dressed that the bushing on the exposed ace shall not project by more than 40 mm. from the general wall surface and on face to be plastered it shall not project by more than 19 mm. nor shall it have depressions more than 10 mm. from the average wall surface. Laterite Stone : Laterite stone shall be obtained from the approved quarry. It shall be compacted in texture, sound, durable and free from soft patches. It shall have a minimum crushing strength of 100 K.G/S.q. Cm. in its dry condition. It shall not absorb water more than 20% of its own weight, When immersed for 24 hours in water. After quarrying the stone shall be allowed to weather for some time before using in work. The stone shall be dressed into regular rectangular blocks so that all faces are free from waviness and unevenness, edges true and square. Those types of stone in which white clay occur, should not be used. Special corner stones shall be provided where so directed. Mild Steel Bars : Mild steel bars reinforcement for R.C.C work shall conform to I.S. 432(Part-II) 1966 and shall be tested quality. It shall also comply with relevant part of I.S. 456-1978. All the reinforcement shall be clean and free from dirt, paint, grease, mile scale or loose or thick rust at the time of placing. For the purpose of payment, the bar shall be measured correct up to 100 mm. length and weight payable worked out at the rate specified below : 6mm. x 0.22 Kg./Rmt 8. 20mm. x 2.47 Kg./ Rmt 8mm. x 0.39 Kg./Rmt. 9. 22mm. x 2.98 Kg./Rmt 10mm x 0.62 Kg./Rmt 10. 25mm. x 3.85 Kg./Rmt 12mm x 0.89 Kg./Rmt 11. 28mm. x 4.83 Kg./Rmt 14mm x 1.21 Kg./Rmt 12. 32mm. x 6.31 Kg./Rmt 16mm x 1.58 Kg./Rmt 13. 36mm. x 7.99 Kg./Rmt 18mm x 3.00 Kg./Rmt 14. 40mm x 9.86 Kg./Rmt. High yield Strength Steel Deformed Bars : High yield strength steel deformed bars are either cold twisted or hot rolled, shall conform to I.S. 1739-1966 and I.S.1139-1966 respectively. Other provision and requirements shall conform to specification NO. M-18 for Mild steel bars.

- 18 -

D:\Jigar\Tender Notice 2009-2010\Tender Notice No. 13\LALBHAI CHAGANBHAI PATEL GARDEN TENDER New Vadaj Ward.DOC

- 19 -

M-20. High Tensile Steel Wire: 20.1 The high tensile wires for the use in prestressed concrete work shall conform to I.S. 2090-1962. 20.2 The tensile strength of the high tensile steel bars shall be as specified in the item. In absence of the given strength, the minimum strength shall be taken as per para 6.1 of I.S. 1785-1962. Testing shall be done as per I.S. requirements. 20.3 The high tensile steel shall be free from loose mill scale, rust oil, grease, or any other harmful matter, Cleaning of steel bars may be carried out by immersion in solvent solution, wire brushing or passing through a pressure box containing carborundum. 20.4 The high tensile wire shall be obtained from manufactures in coil having diameter not less than 350 times the diameter of wire itself so that wire springs back straight back straight on being uncoiled. M-21. Mild Steel Binding Wire : 21.1 The mild steel wire shall be of 1.63 mm or 1.22 mm. (16 or 18 gauge) diameter and shall conform to I.S. 280-197. 21.2 The use of black wire be permitted for binding reinforcement bars. It shall be free from rust, Oil paint, grease, looser mile scale or any other undesirable coating which may prevent adhesion of cement mortar. M-22. Structural Steel : 22.1 All structural steel shall conform to I.S. 226-1965. The steel shall be free from the defects mentioned in I.S. 226-1975 and shall have a smooth finish. The material shall have a smooth finish. The material shall be free from loose mile scale, rust pits or other defects affecting the strength and durability. Rivet bars shall conform to I.S. 1148-1973. 22.2 When the steel is supplied by the Contractor test certificates of the manufactures shall be obtained according to I.S. 226-1975 and other relevant Indian Standards. M-23. Galvanised Iron Sheets : 23.1 The galvanised iron sheets shall be plain or corrugated sheets of specified in item. The G.I. sheets shall conform it I.S. 217-1977. The sheets shall be undamaged in carriage and handling either by rubbing off of zinc coating or otherwise they shall have clean and bright surface and shall be as directed as per site condition. 23.2 The length and width of G.I. sheet shall be as directed as per site condition. M-23 (A) G.I Valleys gutter ridges : 23.A.1. The G.I.ridges and hips shall be of plain galvanised sheets class-3 of the thickness as specified in item. These shall be 600 mm. in width and properly bent up to shape without damage to the sheets in process of bending. 23.A.2. Valleys gutters and flashings shall also be galvanised sheet of thickness as specified in item. Valleys shall be 900 mm. Wide overall and flashing shall be 380 mm. wide overall. They shall be bent to the required shape without damage to the sheet in the process of bending. M-24. Asbestos Cement Sheets : 24.1 Asbestos cement sheets plain, corrugated or semi corrugated shall conform to I.S. 459-1970. 24.2 Ridges & Hips : 24.2.1 Ridges and hips shall be same thickness at that of A.C.sheets. The types of ridges suitable for the type of sheets and locations. 24.2.2 Other accessories to be used in roof such as flashing pieces, caves filler pieces valley gutters, north light and ventilator curves, barge boards etc. shall be standard manufacture and shall be suitable for the type of sheets and location. M-25. Mangalore Pattern Roof Tiles : 25.1 The Mangalore pattern tiles shall conform to I.S. 654-1972 for Class AA or Class A type as specified in item. Samples of the tiles to be provided shall be got approved from the Engineerin-charge. Necessary tests shall be carried out as directed. M-26. Shuttering :

D:\Jigar\Tender Notice 2009-2010\Tender Notice No. 13\LALBHAI CHAGANBHAI PATEL GARDEN TENDER New Vadaj Ward.DOC

- 19 -

- 20 -

26.1

26.2

26.3

26.4

26.5 26.7

26.8

The shuttering shall be either of widen planking of 30 mm. minimum thickness with or without steel lining roof steel plates stiffened by steel angles. The shuttering shall be supported on battens and beams and props of vertical ballies properly cross braced together so as to make the centering rigid. In places of bully props, brick pillar of adequate section built in mud mortar may be used. The form work shall be sufficiently strong and shall have camber, so that it assumes correct shape after deposition of the concrete and shall be able to resist forces caused by vibration of live load of men working over it and other incidental loads associated with it. The shuttering shall have smooth and even surface and its joints shall not permit leakage of cement grout. If at any stag of work during or after placing concrete in the structure, the form work sags or bulges out beyond the required shape of the structure, the concrete shall be removed and work redone with fresh concrete and adequately rigid form work. The complete from work shall be got inspected by and got approved from the engineer-in-charge, before the reinforcement bars are placed in position. The props shall consist of bullies having 100 mm. minimum diameter measured at mix length and 80 mm, at thin end and shall be placed as per design requirement. These shall rest squarely on wooden sole plates 40 mm. thick and minimum bearing area if 0-10 sq. m. laid on sufficiently hard base. Double wedges shall further be provided between the sole plate and the wooden props so as to facilitate tightening and easing of shuttering without jerking the concrete. The timber used in shuttering shall not be so dry as to absorb water from concrete and swell or bulge nor so green or wet as to shrink after erection. The timber shall be properly sawn and planed on the sides and surface coming in contact with concrete. Wooden from work with metal sheet lining or steel plates stiffened by steel angles shall be permitted. As far as practicable, clamps shall be used to hold the forms together and use of nails and spikes avoided.

26.9 The surface of timber shuttering that would come in contact with concrete shall be well wetted and coated with soap solutions before the concreting is done. Alternatively coat of raw linseed oil or oil of approved manufacturer may be applied in place of soap solution. In case of steel shuttering either soap solution or raw linseed oil shall be applied after thoroughly cleaning the surface. Under no circumstances black or burnt oil shall be permitted.

26.10 The shuttering for beams and slabs shall have camber of 4 mm. per meter (1 to 250) or as directed by the Engineer-in-charge so as to offset the subsequent deflection. For cantilevers, The camber at free end shall be 1/50 of the projected length or as directed by the Engineer-incharge. M-27. Expansion joints-Premoulded filter : 27.1 The item provides for expansion joints in R.C.C frame structures for internal joints, as well as exposed joints, with the use of premoulded bituminous joint filler. 27.2 Premoulded bituminous joint filler, i.e. performed strip of expansion joint filler shall not get deformed or broken by twisting, bending or other handling when exposed to atmospheric condition. Pieces of joint filler that lave been damaged shall be rejected. 27.3 Thickness of the pre-moulded joint filler shall otherwise specified. 27.4 Premoulded bituminous joint filler shall conform to I.S. 1838-1961. M-28 Expansion joints-Copper strips & hold fasts : 28.1 The item provide for expansion joints in R.C.C frame structure for internal joints as well as for exposed joints with the use of necessary copper strip and hold fasts. 28.2 Copper sheet shall be of 1.25 mm. thick and of 1.25 mm. width when the U shape in middle. Copper strips shall have hold fast of 3 mm. diameter copper rod fixed to the plate soldered on strip at intervals of about 30 cm. or as shown in the drawing or as directed. The width of each

D:\Jigar\Tender Notice 2009-2010\Tender Notice No. 13\LALBHAI CHAGANBHAI PATEL GARDEN TENDER New Vadaj Ward.DOC

- 20 -

- 21 -

flange (horizontal side) of the copper plate to be embedded in the concrete work shall be 25 mm. Depth of U to be provide in the expansion joint, in the copper plate shall be of 25 mm. M-29. Teak wood : 29.1 The teak wood shall be of good quality as required for the item to be executed. When the kind of wood is not specifically mentioned, good Indian teak wood as approved shall be used. 29.2 Teak wood shall generally be free from large, loose, dead or cluster knots, flaws, shakes, warps, twists bends or any other defects. It shall generally be uniform in substance and of straight fibres as far as possible. It shall be free from rot, decay, harmful fungi and other defects of harmful nature which will affect the strength durability of its usefulness for the purpose for which it is required. The colour shall be uniform as far as possible. Any effort like painting, using any adhesive or resins materials made to hide the defects shall render the pieces liable to rejection by the Engineer-in-charge. 29.3 All scantlings, planks etc. shall be sawn in straight lines and planes in the direction of grains and of uniform thickness. 29.4 The tolerances in the dimensions shall be allowed at the rate of 1.5 m.m. per face to be planed. 29.5 First class teak wood : 29.5.1. First class teak wood shall have no individual hard and sound knots, more than 6 sq. cm. size and the aggregate area of such knots shall not be more than 1% of area of piece. The timber shall be closed grained. 29.6 Second Class Teak Wood : 29.6.1. No individual hard and sound knots shall be more than 15 Sq. cms. in size and aggregate area of such knots shall not-exceed 2% of the area of piece. M-29. (A) Non-teak wood : The non teak-wood shall be chemically treated, seasoned as per IS Specifications and of good quality. The type of wood shall be got approved before collecting the same on site. Fabrication of wooden members shall be started only after approval. For this purpose wood of Bio, Kalali, Siras, Behda, Jamun, Sisoo will be used for door frames where as only Kalali, Siras,Halda,Kalam etc. will be permitted for shutters after proper seasoning and chemical treatment. The non-teak wood shall be free from large, loose, dead of cluster knots, flows, shakes warps bends or any other defect. It shall be uniform in substance and of straight fibers as far as possible. It shall be free rots, decay harmful fungi and other defects of nature which effect the strength, durability or its usefulness for the purpose for which it is required. The colour of wood shall be uniform as far as possible. The scantlings planks etc. shall be sawn in straight lines and planes in the direction of grain and uniform thickness. The department will use the Agency to produce certificate from forest Department in event of Disputes and the decision of the Department shall be final and binding to the contractor. The tolerance in the dimension shall be allowed as 1.5 mm. per face to be planed. M-30. Wooden flush door shutters (solid core) : 30.1 The solid core type flush door shutters shall be decorative or non-decorative type as specified in the drawing. The size and thickness of the shutter shall be as specified in drawings or as directed. The timber species for core shall be used as per I.S. 2202- (Part-I) 1980. The timber shall be free from decay and insect attack. Knots and knot holes less than half the width of cross-section of the members in which they occur may be permitted. Pitch pockets, Pitch streaks and harmless pin holes shall be permissible except in the exposed edges of the core members. The commercial plywood, cross-bands shall conform to I.S. 303-1275. 30.2 The face panel of the shutters shall be formed by gluing by the hot press process on both faces of the core with either plywood or cross-bands and face veneers. The hopping rebating opening of glazing, Venetian etc. shall be provided if specified in the drawing. 30.3 All edges of the door shutters shall be square. The shutters shall be free twist or warp in its plane. Both faces of the shutters shall be sand papered to smooth even texture. 30.4 The shutters shall be tested for

D:\Jigar\Tender Notice 2009-2010\Tender Notice No. 13\LALBHAI CHAGANBHAI PATEL GARDEN TENDER New Vadaj Ward.DOC

- 21 -

- 22 -

(1) End immersion test : The test shall be carried out as per I.S. 2202 (part-I) 1980. There shall be no delamination at the end of the test. (2) Knife test : The face panel when tested in accordance with I.S. 1659-1979 shall pass the test. (3) Glue adhesion Test : The flush door shall be tested for glue adhesive test in accordance with I.S. 2202 (Part-I) 1980. The shutters shall be considered to have passed the test if no delamination occurs in the glue lines in the plywood and if no single declamination more than 80 mm. in length and more than 3 mm. in depth has occurred in the assembly glue lines between the plywood face and the style and rail. Delamination at the corner shall be measured continuously around the corner. Delamination at the knots, knots holes and other permissible wood defects shall not be considered in assessing the sample. 30.5 The tolerance in size of solid core type flush door shall be as under :

In Normal thickness + 1.2 mm. In Normal height + 3 mm.

The thick of the shutters shall be uniform throughout with a permissible variation of not more than 0.8 mm. when measured at any two points. M-31. Aluminum doors, Windows, Ventilators: 31.1 Aluminum alloy used in the manufacture of extruded window sections shall conform to I.S. designation HEA-WP of I.S. :733-1975 and also to I.S. Designation WVG-WP of I.S. 1285-1975. The Section shall be as specified in the drawing and design. The fabrication shall be done as directed. 31.2 The hinges shall be cast or extruded aluminum hinges of same type as in windows but of large size. 31.3 The hinges shall normal be of 50 mm. projecting type. Non-projecting type of hinges may also be used if directed. The handles of door shall be of specified in the drawing and design. The fabrication shall be done as directed. M-32. Rolling Shutters : 32.1 The rolling shutter shall conform to I.S. 6248-1979. Rolling shutters shall be supplied of specified type with accessories. The size of the rolling shutters shall be specified in the drawings. The shutters shall be constructed with interlocking lath sections formed from cold rolled steel strips not less than 0.9 mm. thick and 80 mm. wide for shutters upto 3.5 mm., width not less than 1.25 mm. thick and 80 mm. wide for shutters 3.5 mm in width and above unless otherwise specified. 32.2 Guide channels shall be of mild steel deep channel section and of rolled pressed or built up (fabricated) jointures construction. The thickness of sheet used shall not be less than 3.15 mm. 32.3 Hood covers shall be made of M.S. Sheets not less that 0.92 mm. thickness For shutters having width 3.5 Meter and above the thickness of M.S. Sheet for the hood cover shall be not less than 1.25 mm. 32.4 The spring shall be of best quality and shall be manufactured from tested high tensile spring steel wire or strip of adequate strength to balance the shutters in all position. The spring pipe shaft etc. shall be supported on strong M.S. or malleable C.I. brackets. The brackets shall be fixed on or under the lintel as specified with raw plugs and screws bolts etc. 32.5 The rolling shutters shall be of self rolling type up to 8 Sq.m. clear area without ball bearing and p to 12 Sq.m. clear area with ball bearing. If the rolling shutters are larger, then gear operated type shutters shall be used. 32.6 The locking arrangement shall be provided at the bottom of shutter at both ends. The shutters shall be opened from outside. 32.7 The shutters shall be completed with door suspension shafts, locking arrangements pulling hooks, handles and other accessories. M-33. Collapsible Steel Gate : 33.1 The collapsible steel gate shall be in one or two leaves and size as per approved drawings or as specified. The gate, shall be fabricated from best- quality mild steel channels, flats etc. Either steel pulleys or ball bearing shall be provided in every double channel. Unless otherwise specified the particulars of collapsible gate shall be as under:

D:\Jigar\Tender Notice 2009-2010\Tender Notice No. 13\LALBHAI CHAGANBHAI PATEL GARDEN TENDER New Vadaj Ward.DOC

30.6

- 22 -

- 23 -

(a) (b) (c) (d) M-34. 34.1

M-35. 35.1

35.2 M-36. 36.1

M-37. 37.1

37.2 37.3

37.4

37.5

Pickets : These shall be of 20 mm. M.S., channels of heavy sections unless otherwise shown on drawings. The distance center to center of pickets shall be 12 cms. with an opening of 10 Cms. Pivoted M.S. flats shall be 20 mm x 6 mm. Top and bottom guides shall be from tee or flat iron of approved size. The fittings like stoppers, fixing hold fasts, locking cleats, brass handles and cast iron rollers shall be of approved design and size. Welded Steel Wire Fabric : Welded steel wire fabric for general purpose shall be manufactures from cold drawn steel wire as drawn or galvanised steel conforming to I.S. 226-1975 with longitudinal and transverse wire securw4ely connected at every intersection by a process of electrical resistance welding and conforming to I.S. 4948-1974. It shall be fabricated and finished in workmanlike manner and shall be free from injurious defects and shall be rust proof. The type of mesh shall be oblong or square as directed. The mesh sizes and size of wire for square as well as oblong welded steel wire fabric shall be as directed. The steel wire fabric in panels shall be in one whole piece in each panel as far as stock size permit. Expanded Metal Sheets : The expanded metal sheets shall be free from flaws, joints, broken strands, laminations and other harmful surface Expanded metal steel sheet shall conform to I.S. 412-1975, Except that blank sheets need not be with guaranteed mechanical properties. The size of the diamond mesh of expended metal and dimensions of strands (width and thickness) shall be as specified. The tolerance in nominal weight of expended metal sheets shall be of + 10 percent. Expanded metal in panels shall be in one whole piece panel each as far as stock size permit. The expanded metal sheets shall be coated with suitable protective coating to prevent corrosion. Mild Steel Wire (Wire ) : Mild steel wire may be galvanised, as indicated All finished steel wire shall be well cleanly drawn to the dimensions and size of wire as specified in item. The wire shall be sound, free from splits, surface flaws, rough jagged and imperfect edges and other harmful surface defects and shall conform to I.S. 280-1978. Plywood : The plywood for general purpose shall conform I.S. 303-1975. Plywood is made by cementing together thin boards or sheets of wood into panels. There are always an odd number of layers 3,5,7,9 ply etc. The plies are placed so that grain of each layer is right angle to the grain in the adjacent layer. The Chief advantages of plywood over a signal board of the same thickness is the more uniform strength of the plywood, along the length and width of the plywood and grater resistance to cracking and splitting with change in moisture content. Usually synthetic resins are used for gluing, pherolic resins are usually cured in a hot press which compresses and simultaneously heats the plies between hot plates which maintain a temperature of 90 degrees C. to 140 degrees C. and a pressure of 11 to 14 kg/sq.cm. on the wood. The time of heating may be anything from 2 to 69 minutes depending upon thickness. When water glue are used , the wood absorbs so much water that the finished plywood must be dried carefully. When synthetic resins are used as adhesive finished by plywood must be exposed to an atmosphere of controlled humidity until the proper amount of moisture has been absorbed. According to I.S. 303-1975 the plywood for general purpose shall be of three grades BWR, WWR and CWR, depending upon the adhesives used for bonding and veneers, and it will be further classified into six types namely AA,AB,AC,BB,BC and CC based on the quality of the two faces, each face being of three kinds namely, A,B and C, After pressing, the finished plywood should be reconditioned to a moisture content not less than 8 percent and not more than 16 percent.

- 23 -

D:\Jigar\Tender Notice 2009-2010\Tender Notice No. 13\LALBHAI CHAGANBHAI PATEL GARDEN TENDER New Vadaj Ward.DOC

- 24 -

37.6

Thickness of plywood Boards :

TABLE

Board Thickness Board Thickness Board Thickness Board Thickness

3 ply

3 mm. 4 mm. 5 mm. 6 mm.

5 ply

5 mm. 6 mm. 8 mm. 9 mm.

7 ply. 9 ply.

9 mm. 13 mm. 16 mm. 13 mm.

9 ply. 11 ply.

16 mm. 19 mm. 19 mm. 22 mm. 25 mm.

M-38. Glass : 38.1 All glass shall be of the best quality free from specks, bubbles, smokes, veins, air holes blisters and other defects. The king of glass to be used shall be mentioned in the item or specification or in the special provisions or as shown in detailed drawings. Thickness of glass panes shall be uniform. The specifications or different kinds of glass shall be as under. 38.2 Sheet Glass : 38.2.1 In absence of any specified thickness or weight in the item or detailed specifications of the item of work, sheet glass shall be weighing 7.5 Kg/Sq.m. for panes upto 600 mm x 600 mm. 38.2.2 For panes larger than 600 mm. x 600 mm. and upto 800 m. x 800 mm. the glass weighing not less than 8.75 Kg/Sq.m. shall be used. For bigger panes upto 900 mm. x 900 mm. glass weighing not less than 11.25 Kg/Sq.m. shall be used. 38.2.3 Sheet glass shall be patent flattened glass of best quality and for glazing and framing purposes shall conform to I.S. : 1761-1960. Sheet glass of the specified colours shall be used, if so shown on detailed drawings or so specified. For important buildings and for panes with any dimension over 900 mm. plate glass of specified thickness shall be used. 38.3. Plate Glass. 38.3.1. When plate glass is specified it shall be Polished patent plate glass of best quality. It shall have both the surface ground flat and parallel and polished to obtain clear undisturbed vision and reflection. The plate glass shall be of the thickness mentioned in the item or as shown in the detailed drawing or as specified. In absence of any specified thickness and type of glass shall be as per details on drawings or as specified or as directed. 38.4 Obscured Glass : 38.4.1. This type of glass transmits light so that vision is Partially or almost completely sbscured. Glass shall be plain rolled, figured, ribbed or fluted or frosted glass as may be specified as required. The thickness and type of glass shall be as per details on drawings or as specified or as directed. 38.5 Wired Glass : 38.5.1 Glass shall be with wire netting embedded in a sheet of plate glass electrically welded 13 mm. Georgian square mesh may be used. Thickness of glass shall not be less than 6 mm. Wired glass shall be of type and thickness as specified. M-39. Acrylic Sheets : 39.1 Acrylic sheet be of thickness as specified in the item and of an specified shape and size as the case may be. Panels may be flat or curved . It should be light in weight. It shall be colourless or coloured or opaque as specified in the item. Colourless sheet shall be as transparent as the finest optical glass. Its light transmission rate shall be about 95%. Transparency shall not be affected for the sheets of larger thickness. It shall be extremely resistant to sunlight, weather and low temperatures. It shall not show any significant yellowing or change in physical properties or loss of light transmission over a longer period of use. The sheet shall be impact resistant also. Sheets should be available in complete range of standard transparent,

D:\Jigar\Tender Notice 2009-2010\Tender Notice No. 13\LALBHAI CHAGANBHAI PATEL GARDEN TENDER New Vadaj Ward.DOC

- 24 -

- 25 -