Professional Documents

Culture Documents

Is 18001

Uploaded by

shivajireturnsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Is 18001

Uploaded by

shivajireturnsCopyright:

Available Formats

Disclosure to Promote the Right To Information

Whereas the Parliament of India has set out to provide a practical regime of right to

information for citizens to secure access to information under the control of public authorities,

in order to promote transparency and accountability in the working of every public authority,

and whereas the attached publication of the Bureau of Indian Standards is of particular interest

to the public, particularly disadvantaged communities and those engaged in the pursuit of

education and knowledge, the attached public safety standard is made available to promote the

timely dissemination of this information in an accurate manner to the public.

! $ ' +-

Satyanarayan Gangaram Pitroda

Invent a New India Using Knowledge

01 ' 5

Jawaharlal Nehru

Step Out From the Old to the New

1 +, 1 +

Mazdoor Kisan Shakti Sangathan

The Right to Information, The Right to Live

! > 0 B

BharthariNtiatakam

Knowledge is such a treasure which cannot be stolen

IS 18001 (2007): Occupational Health and Safety Management

Systems--Requirements with Guidance for Use (First

Revision). ICS 13.100

IS 18001 : 2007

Clfcl'{il[f -if

cB xif"5C1

( q5MI )

Inc/ianStandard

OCCUPATIONAL HEALTH AND SAFETY

MANAGEMENT SYSTEM - REQUIREMENTS WITH

GUIDANCE FOR USE

S'eptember 2007

( First Revision)

ICS 13.100

BIS 2007

BUREAU OF INDIAN STANDARDS

MANAK BHAVAN. 9 RAHADUR SHAH ZAFAR MARG

NEW DELHI 110002

Price Group 11

Occupational Safety and Health and Chemical Hazards Sectional COlnmittee, CHD 8

FOREWORD

This Indian Standard (First Revision) was adopted by the Bureau of Indian Standards, after the draft finalized by

Occupational Safety and Health and Chemical Hazards Sectional Committee had been approved by the Chemical

Division Council

Health and safety is one of the most important aspects of an organization's smooth and effective functioning.

Good health and safety performance ensures an accident free industrial environment. With the continuous and

untiring effort of various legislative authorities as well as NGOs, the awareness of occupational health and safety

(OH&S) has improved in India considerably. Organizations have started attaching the same importance to achieve

high OH&S performance as they do to other key aspects of their business activities. Considering this fact and a

great demand from the industry for a comprehensive framework for OH&S, the Committee formulated IS 18001

in the year 2000 taking considerable assistance from BS 8800 : 1996 'Guide to occupational health and safety

management system'; and ASINZS 4804 : 1997 'Occupational health and safety management systems - General

guidance and principles, assessment and supporting techniques'.

There is no ISO Standard on the subject. Based on the experiences gained since last 5 years, and the revision of

I SO 14001 : 1996 'Environmental management systems - Requirement guidance for use' as well as both the

hase standards, the Committee felt to revise the standard to make it more compatible/with latest ISO 14001

keeping in mind the interest of the users for integrating with other management system.

This standard intends to assist the organizations to develop a systematic approach to management ofOH&S in

such a way as to protect their employees and others whose health and safety may be affected by the organizations'

activities. This standard also intends to improve OH&S performance of organizations by providing the requirements

and guidance for use. The OH&S management systems may be integrated with the management of other aspects

of business performance in order to:

a) minimize risk to employees and others,

b) improve business performance, and

c) assist organizations to establish a responsible image at the marketplace.

The requirements of OH&S n1anagement systems have been prescribed iIi this standard. Annex A provides the

guidance for use and correct interpretation. Annex B gives a comparison of requirements of this standard with

those of IS/ISO 9001 : 2000 and ISIISO 14001 : 2004. It is expected that this comparative chart will help the

llsers in understanding the standard in a better way. Identification of hazard and assessment and control of risks

form a major and important part of OH&S management systems. A general guideline describing the principles,

approach and procedure of hazard identification and assessment and control of risks has been given- in Annex C

though the Committee also developed a separate Indian Standard IS 15656 : 2006 'Hazard identification and risk

nnalysis - Code of practice'.

Compliance with this standard by an organization does not confer its immunity from its legal obligations.

The composition of the Committee responsible for formulation of this standard is given at Annex D.

IS 18001 : 2007

Indian Standard

OCCUPATIONAL HEALTH AND SAFETY

MANAGEMENT SYSTEM - REQUIREMENTS WITH

GUIDANCE FOR USE

( First Revision)

I SCOPE

This standard prescrihes requirements for an

occupational health and safety (OH&S) management

-;ystem, to enable an organization to formulate a policy

and objectives, taking into account legislative

requirements and information abollt significant hazards

and which the organization can control and over

which it can he expected to have an intluence, to protect

its employees and others. whose health and safety may

be affected by the activities of the organization. It does

not itself state specific safety performance criteria. This

.'itandard is applicahle to any organization that wishes

to:

a) Implement, maintain and continually improve

an OH&S management system;

b) Assure itself of its confomlance with its stated

OH&S policy;

c) Demonstrate such conformance to others;

d) Seek certification/registration of its OH&S

m'lnagement systems by an external

organization; and

e) Make a self-determination and self-

declLlfation of conformance with standard.

All the requirements in this standard are intended to

he incorporated into any OH&S management system.

The extent of application will depend on such factors

as the OH&S policy of the organization, the nature of

its activities and the conditions in which it operates.

This Indian Standard also provides informative

guidance on the use of the requirements in Annex A.

NOTES

1 for case of use, the sub-clauses of this specification and Annex

A have related numbers; thus. for example, 4.3.3 and A-3.3 hoth

deal with 'Legal and other requirements'.

2 Tlh' guidance has been provided to ensure that managers

who have already invested in learning to opaale within the

framework l)f cither Quality Managemcnt Syqems or

Environmental Management Systems standards can readily

understand the requirements of this standard and thereby

improvt." OH&S management in their organization.

2 REFERENCES

The standards listed below contain provisions, which

through reference in this text, constitute provisions of

this standard. At the time of publication, the editions

indicated were valid. All standards are subject to

revision. and parties to agreements based on this

standard are encouraged to investigate the possibility

of applying the most recent editions of the standards

indicated below:

IS No.

3786: 1983

ISIlSO 14001 :

2004

Title

Method of computation of frequency

and severity rates for industrial injuries

and classification of industrial

accidents (jin;t revision)

Environmental management systems

- Requirements with guidance for

use

IS 14489 : 1998 Code of practice on occupational

safety and health audit

3 TERMINOLOGY

For the purpose of this standard, the definitions given in

IS/ISO 14001, IS 14489 and the following shall apply.

3.1 Accident - UnpJannedlUndesired event giving rise

to death, ill health, injury, damage or other losses to

personnel or property.

3.2 Audit - A systematic, independent and a documented

process for obtaining evidence and evaluating it

objectively to determine the extent to which defined

criteria are f uHilled.

NOTE - The word 'independent' here docs not necessarily

mean external to the organiz;ltion.

3.3 Continual Improvement - Recurring process of

enhancing the OH&S management system, to achieve

improvements in overall OHS performance

3.4 Hazard - A source or a situation with a potential

to cause harm in terms of human injury or ill health,

damage to property, damage to the environment or a

combination of these.

3.5 Hazard Identification - The process of recognizing

a hazard in existence and defining its characteristic!

impact.

3.6 Incident - Event that give rise to an accident or

IS 1 SOO I : 2007

ha.;; the potential to lead to an accident.

'lUTE - An incident whne no ;11 health, injury, daJll<lge or

!llher loss occurs is also referred to as 'near-miss', The term

'incident' im:ludt:s 'near-misses',

3.7 Interested Party - Individual or group concerned

with or affected by the OH&S performance of an

organization,

3.8 !'ion-conformity - of a requirement

[ISIlSO 9000: 2000,3.6.21

3.9 Occupational III Health - III health that is judged

to hJve been caused by or made worse by a person's

work activity or environment.

3.10 Occupational Health and Safety

System - A set of interrelated or interacting elements

to establish OH&S Policy and objectives, and to

achieve those objectives.

3.1 J Occupational Health and Safety

Objectives -Overall goals in terms of OH&S

performance, arising from the OH&S policy that an

organization sets itself to achieve. and \vhich is

quantified where practicable.

3.12 Occupational Health and Safety Policy -

Overall intentions and direction of an organization in

relation to its overall OH&S performance as formally

expressed hy top management.

:'\OTE - The OH&S Policy provides a frarncv"ork tor ils duillll

for setting its OH&S ohjectives and targets,

3.13 Occupational Health and Safety Professional --

A person, with expertise and qualifications in the

assessment, evaluation and prevention or control of

occupational risks, hazards or occupational ill health,

3.14 Occupational Health and Safety Target-- A

detailed performance requirement quantified \vhcrcver

practicable pertaining to the organization, that arises

from the health and safety objectives and that needs [0

be met in order to achieve those objectives.

.l15 Occupational Health Surveillance-

Monitoring the health of people to detect signs or

symptoms of work related ill health so that steps can

he taken to eliminate, or reduce the probahility of

further deterioration.

3.16 Rehabilitation - The managed process of

maintaining injureu or ill employees in, or returning

them Lo suitable employment.

3.17 Risk - The combination of frequency, or

probability of occurrence and consequence of a

specified hazardous event.

3.18 Risk Analysis - A systematic lise of available

information 10 determine how often specified events

may occur and magnitude of their likely

3.19 Risk Assessment - The overall process of

estimating the magnitude of risk and deciding whether

the risk is tolerable.

3.20 Safety - State in which the risk of harm to

persons or damage to property is limited to a tolerable

leveL

3.21 Tolerable Risk - Risk that has been reduced to

a level that can be endured by the organization having

regards to its legal obligations and its own OH&S

Policy.

4 OH&S MANAGEMENT SYSTEMS

REQUIREMENTS

4.1 General Requirements

The organization shall establish, document, implement,

maintain and continually improve an OH&S

management sy:'itcm. in accordancc with the

requirements of this standard. The organization shall

define and document the scope of its OH&S

management system.

4.2 OH&S Policy

Top management shall define, document and endorse

its OH&S policy, The policy shall:

a) be appropriate to the nature. scale and the

hazards and risks of its activities and facilities;

b) includes a commitment to continual

improvement in its OH&S performance;

c) include a commitment to comply with the

applicable OH&S legislations and with other

requirements to which the organizations

suhscribe;

d) be implemented, maintained, communicated

to all employees and understood within the

organization;

c) provide a framework for establishing,

maintaining and periodically reviewing

OH&S ohjectives and targets;

t) be reviewed periodically to ensure that it

remains relevant and appropriate to the

organization; and

g) be available to the public.

4.3 Planning

4.3.11Ilitial OH&S Review

The organization shall carry out an initial review of

their existing arrangements for managing OH&S, The

current position of an organization with regard to

OH&S shall be estahlished by means of an initial

review of its current OH&S arrangements to:

a) Identify the gaps between any existing

systems in place and the requirements of this

standard;

b) Identify all hazards and risks with

the organization's activity and factlities;

c) Assess the level of know ledge and compliance

with all OH&S standards and legislation;

d) Compare current arrangement'i with best

practice and performance in the organization's

employment sector and other appropriate

e) Review past experience with incidents and

results of any previous assessments.

compensation experience, disruption, etc,

associated with OH&S; and

f) Assess efficiency and effectiveness of existing

resources devoted to OH&S management.

The organization shall document this information and

shall plan .the progressive implementation of the

elements of the system based on this information.

4.3.2 Hazard Identification. Risk Assessment and Risk

Control

The organization shall estahlish, implement and

maintain procedures for the ongoing identification of

hazards, assessment of associated risks and necessary

control measures related to its activities and facilities

over which it has control or influence, in order to

determine those which have or can have significant

impact over OH&S. This shall include:

a) Routine and non-routine activities;

b) Activities of all personnel having access to

the workplace (including sub-contractors and

visitors); and

c) Facilities at the work place, whether provided

by the organizations or others.

The organization shall ensure that the results of these

assessments and the effects of these controls are

considered while setting its OH&S objectives. The

organization shall document this information and keep

it uptodate.

4.3.3 Legal and Other Requirements

The organization shall establish, implement and

maintain a procedure(s):

a) to identify and have access to all legal and

other requirements to which the organization

subscribes and that are attributable to the

OH&S hazards and risks of its activities and

facilhies.

b) to determine how these requirements apply

to its OH&S hazards and risks.

The organization shall also keep track oflegal and other

3

IS t 8001 : 2007

requirements as well as the changes to these to maintain

regulatory compliance. It shall ensure communication

of relevant information on legal and other requirements

to its employees at all times.

4.3.4 Objectives, Targets, Performance Indicators and

Programme(s)

The organization shall establish, implement and

maintain documented OH&S objectives and targets at

relevant functions and levels within the organization.

When establishing and reviewing its objectives, an

organization shall consider the legal and other

requirements, its significant hazards and risks, its

technological options and its financial, operational and

husiness requirements and views of the interested

parties. The objectives and targets shall be measurable

where practicable and consistent with the OH&S

policy, including the commitment to health and safety

at workplace, to compliance with applicable legal

requirements and to continual improvement.

Objectives, targets and programme(s) shall be regularly

reviewed at planned intervals and revised, if necessary.

The organization shall establish. implement and

maintain programme(s) for achieving its objectives and

targets. It shall include:

a) Designation of responsibility for achievement

of objectives and targets at relevant functions

and levels of the organization, and

h) Means and timeframe by which they are to

be achieved.

I f a project relates to new developments and new or

modified activities and services, programme(s) shall

be amended appropriately, where relevant, to ensure

that OH&S management applies to Stich projects.

When the objectives and targets are set. the organization

shall consider establishing measurable OH&S

performance indicators. These indicators shall be used

as a basis for an OH&S performance evaluation system

and to provide information on both OH&S

management and operation systems.

4.4 Implementation and Operation

4.4.1 Resources. Roles. Responsibility and Authority

Roles, responsibilities and authorities of the personnel

who manage, perform and verify activities having an

effect on the OH&S risks of the organization's

activities, facilities, processes and services, shall be

defined, documented and communicated to facilitate

effective OH&S management. OH&S responsibilities,

accountabilities and authorities to act and reporting

relationships or all levels of functionaries including

sub-contractors and visitors shall be defined,

documented and communicated.

IS ISOOt: 20U7

Ult!mate responsibility for 01-l&S shall rest with the

top management. The organizatlon shall define,

designate, document and communicate OH&S

and authority to act and reporting

relationships for all levels of functionaries including

suh-contractors and visitors. The organization shall also

estahlish and maintain procedure that monitors and

communicate any changes in designated

resronsibilities and authorities and the organization

shall be able to respond in a timely and effective manner

to ,-'hanging or unusual circumstances or events.

The organization's top management shall appoint at

tht' senior management level specific management

rcpresentative(s), with executive powers, who,

irrc<.;pectivc of other responsihilities, shall have defined

role:-., responsibilities and authority for:

<1) Ensuring Chat OH&S management system

rC(luircments ::Irc establishcd, implemented

and maintained in accordance with this Indian

Standard; and

b) Reponing on the performance of OH&S

management system to top management for

n:vicw anJ a:-,; a for improvemt:nt of the

OH&S management system.

Management shall provide adequate resources essential

to e'itahlish, implement, maintain/control and

i mprovcmcnt of the OH&S management system.

Resources include human resources including

specialized skills, organizational infrastructure,

technology and fillancial resources.

4.4.2 Competenc(', Trailling and Awareness

The organization shall ensure that any person(s)

performing tasks for it or 011 its behalf whose work/

\\iorkplace involves significant hazard, identified by

the organization is(are) c'ompetent on the basis of

appropriate education, training or experience, and shall

retain Jssociateu records. The organization shall also

implement and maintain a procedure(s) to

identify the competency standards and to meet them.

fhe organizJtion shall identify training needs for all

personnel, whose work/workplace involves significant

hazard associated with its OH&S management system.

It shall provide training or take other action to meet

lhese needs, evaluate its effectiveness. and shall retain

associated records.

It shall establish and maintain procedures to make its

or members at each relevant function and

level <l\V3re of:

<I) The importance of conformance with the

OH&S policy and procedures and with

requirements of the OH&S management

system;

4

b) The significant hazards and risks actual or

potential, of their work activities and the

benefits of improved OH&S performance;

c) Their roles and responsibilities \n achieving

conformance with OH&S policy and

procedures and with the requirements of

OH&S management systems; and

d) The potential consequences of departure from

specified operating procedures.

4.4.3 Communication and Reporting

4.4.3.1 Commu.nication

Organization shall establish, implement and maintain

procedure(s) to ensure that pertinent OH&S

information including significant risks and hazards are

communicated and from employees and other

interested parties. The organization shall ensure:

a) Communicating the results from management

systems monitoring, audit and management

reviews to those within the organization who

are responsib1e for and have a stake in the

organization's performance;

b) Receiving, documenting and responding to

relevant communication on OH&S from

external interested and

c) Communicating the relevant information to

people outside organization who are likely to

be affected.

4.4.3.2 Reporting

The organization shall establish, implement and

maintain documented procedures for relevant and

timely reporting of information required for monitoring

and continual improvement of OH&S performance.

Internal reporting procedures shall cover:

a) Incident occurring reporting,

b) Non-conformance reporting,

c) Health and safety performance reporting, and

d) Hazard identification reporting.

External reporting procedures shall cover:

a) Statutory reporting requirements, and

b) Stakeholder reporting,

4.4.4 Documentatioll

The OH&S Management System documentation shall

indude:

a) OH&S Policy, objectives and targets;

b) Description of the scope of the OH&S

management system;

c) Description of the main elements of the

OH&S management systems and their

interaction, and reference to related

documentation;

d) Documents, including records, required hy

this Indian Standard; and

e) Documents. including records, determined by

the organization to ensure the dft.':ctive

implementation of OH&S management

system.

NOTE-- It is important that documented procedures alld \vork

instructions are treated with productivity in mind and with

health & safety matter integrated into each step and the design

and review of such procedures are developed by competent

people together with involvement from 1110',(' required [0

perform the task(s). Such documented procedures and work

instructions are commonly known as systems of work or

standard operation procedure.

4.4.5 Conlml of Documents

The organization shall establish, implement and

maintain a procedure(s) for controlling all documents

required by the OH&S management sysler .. s and hy

this standard:

a) Documents are approved for adequacy prior

to issues;

b) Dm;urnenls are periodically reviewed, revised

as and when necessary and re-approved for

adequacy by authorized personnel;

c) Changes and the current revision status of

documents are identified;

d) The current versions of relevant documents

arc available at all locations;

e) Obsolete documents are promptly removed

from all points of issue and points of LIse, or

otherwise assured against unintended use;

n Any obsolete documents retained for legal

and/or knowledge preservation purposes arc

suitably identified;

g) Documents remain legible, dated (with dates

of revision) and readily identified: and

h) Documents of external origin determined by

the organization to be for the

planning and operation of the OH&S

management systems arc identified and their

distribution controlled.

Records are special type of documents :lI1d shall be

controlled in accordance with the requirement given

In 4.5.4.

4.4.6 Operational Control

The organization shall identify those operations and

activities that arc associated with the identified

significant hazards and risks in line with its policy,

objectives and targets. The organization shall plan these

activities, including maintenance, in order to ensure

that they arc carried out under specified conditions by:

5

IS 18001: 2007

<1) Establishing, implementing and maintaining

documented procedure(s) to control situations

where their ahsence could lead to deviations

from the OH&S policy and the objectives and

targets;

b) StipUlating operating criteria in the

procedures; and

c) Establishing and maintaining procedure(s)

related to the identified significant hazards

and risks of goods and services lIsed by the

organization and communicating relevant

procedures and requirements to suppliers and

sub-contractors.

4.4.6.1 Design and engineering

The organization shall establish, implement and

maintain procedure(s) to ensure that health and safety

is considered at the initial design and planning phase

to build risk controls at this point. To ensure this, each

stage of design cycle (development, review verification.

validation and change) should incorporate hazard

identification, risk assessment and risk control

procedures. Appropriately competent people shall be

allocated clear responsibilities to meet and verify health

and safety requirements. Where the newly evaluated

hazard cannot be eliminated or substituted for one that

presents lower risks, engineering controls shall he

adopted. When the product. process or workplace is

redesigned this experience shall be considered in the

design process.

4.4.6.2 Purchasing

The organization shall establish, implement and

maintain procedure(s) for purchasing of goods and

services including maintenance procedures under

contract to others to ensure that purchased goods,

services, and products and suh-contractors conform to

the organization's OH&S requirements.

4.4.7 Emergency Preparedness and Response

The organization shall establish, implement and

maintain procedure(s) for emergency preparedness and

response, to plan for contingency in advance and to

periodically test these plans to allow an adequate

response to occur during the actual emergency. While

planning the proccdure for emcrgency preparedness it

shall consider significant events such as fire, explosion,

toxic release or natural disasters that threaten the

viability of the organization. On-site and off-site

emergency plans and procedures shall be developed

and periodically tested. reviewed and revised, where

necessary by the appropriate authority. Emergency

plans of large installations should be prepared in

consultation with municipal or state disaster planning

authorities.

interaction. and reference to related

documentation:

d) Documents, including records, required hy

this Indian Standard: and

e) Documents, including records, determined hy

the organization to ensure the effective

implementation of OH&S mJTlagemcm

system.

NOTE - It is important that dOl:umcntetl procedures and work

Instrul:tions nrc treated with productivity ill mind and with

health & safety matter integratcu into e ~ K h step and the design

and reviev,: of such procedures are developed hy cUlllpt'tt'nt

people together with involvclllC'Jlt from tho';l' required to

perform the task(s). Such documented proCl'dilfc'; and work

instructions arc commonly known as :iystems of work or

standard operation procedure.

4.4.S Control o/DocUfnenls

The organization shall establish, impJernellt and

maintain a procedure(s) for controlling all documents

required by the OH&S management SYSlcr,-,s and hy

this stalldard:

cl) Documents are approved for adequacy prior

to issues;

b) Documents are periodically reviewed, revised

as and when necessary and fe-approved for

adequacy by authorized personnel;

c) Changes and the current revision status of

documents are identified;

d) The current versions of relevant documents

are available at all locations;

t') Obsolete documents are promptly removed

from all points of issue and points of lise, or

otherwise assured against unintended usc;

n Any obsolete documents retained for legal

and/or knowledge preservation purposes are

suitably identified:

g) Documents remain legible, dated (with dates

of revision) and readily identified; and

Ii) Documents of external origin dekrmined by

the organization to be necessary for the

planning and operation of the OH&S

management systems are identifieu and their

distrihution controlled.

Records Clrc special type of documents :lnd shall bc

controlled in accordance with the requirement given

in 4.5.4.

4.4.6 Operational Control

The organization shall identify those operations and

activities that are associated with the identified

significant hazards and risks in line with its policy,

objectives and targets. The organization shall plan these

,lCtivities, including maintenance, in order to ensure

that they are carried out under specified c(inditions by:

5

IS 18001: 2007

;1) Establishing, implementing and maintaining

documented procedure(s) to control situations

where their absence could lead to deviations

from the OH&S policy and the objectives and

targets;

b) Stipulating operating criteria in the

procedures; and

C) Establishing and maintaining procedure(s)

related to the identified significant hazards

and risks of goods and services lIsed by the

organization and communicating relevant

procedures and requirements to suppliers and

sub-contractors.

4.4.6.1 Design and engineering

The organization shall establish, implement and

maintain procedure(s) to ensure that health and safety

is considered at the initial design and planning phase

to build risk controls at this point. To ensure this, each

"tage of design cycle (development, review verification,

validation and change) should incorporate hazard

identification, risk assessment and risk control

procedures. Appropriately competent people shall be

allocated clear responsibilities to meet and verify health

and safety requirements. Where the newly evaluated

hazard cannot be eliminated or substituted for one that

presents lower risks, engineering controls shall he

adopted. When the product, process or workplace is

redesigned this experience shall be considered in the

design process.

4.4.6.2 Purchasing

The organization shall establish, implement and

maintain procedure(s) for purchasing of goods and

services including maintenance procedures under

contract to others to ensure that purchased goods,

services, and products and suh-contractors conform to

the organization's OH&S requirements.

4.4.7 EmergencJ' Preparedness and Response

The organization shall establish, implement and

maintain procedure( s) for emergency preparedness and

response, to plan for contingency in advance and to

periodically test these plans to allow an adequate

response to occur during the actual emergency. While

planning the procedure for emergency preparedness it

shall consider significant events such as fire, explosion,

toxic release or natural disasters that threaten the

viability of the organization. On-site and off-site

emergency plans and procedures shall be developed

and periodically tested, reviewed and revised, where

necessary by the appropriate authority. Emergency

plans of large installations should be prepared in

consultation with municipal or state disaster planning

authorities.

[S lHOOl: 2007

fhe organization shall also establish and maintain

procedure(s) to mitigate the effects of such incidents

on those directly suffering injury. These procedures

shall include:

a) Establishment of appropriate first aid facilities

that are matched to the site hazards and

availahility of further assistance. Sites remote

from medical assistance shall have first aid

appropriate to stabilize any injury until

transported to such medical assistance; and

/l) Process to rehabilitate injured employees hy

providing appropriate rehabilitation as soon

as practicable after the injury occurs, so that

recovery from the injury is expedited.

4.4.8 Critical Incident Recovery Plan

The organization shall establish, implement and

maintain procedures for Critical Incident Recovery

Plan (CIRP) to aid in-plant employee re,ovcry as soon

as possible after the cessation of the event. Only

suitably qualified counsellors shall be used to assist

victims associated with a traumatic event.

NOTE - The CIRP allows the plant to minimile the time

rcquirrt! to return to normal nperatiufls alllllll a s ~ i S ! elllployees

who are not IIljured but who have, for example, wItnessed an

incident. to cope up with the trauma.

4.5 Checking

4.5.1 Monitoring and Measurement

The organization shall establish, implement and

maintain procedures to monitor and measure OH&S

performance on a regular basis the key characteristics

of its operations and activities that can have significant

hazards and risks. These procedures shall provide for:

a) both qualitative and quantitative measures,

appropriate to the needs of the organization:

b) monitoring of the extent to which the

organization's OH&S objectives arc met;

c) proactive measures of performance that

monitor compliance with the OH&S

management programme, operational criteria

and applicable legislation and regulatory

requirements:

d) reactive measures of performance to monitor

accidents, i II heal th incl ud ing heal th

surveillance, incidents (including near-

misses) and other historical evidence of

deficient OH&S performance; and

e) recording of data and results of monitoring

and measurements sufficient to facilitate

subsequent corrective and preventive action

analysis.

The organization shall establish, implement and

maintain procedures for the calibration and

6

maintenance of monitoring equipments used for

performance measurement and monitoring. Records

of calibration and maintenance activities and results

shall be retained according to the organization'S

procedure.

4.5.2 Evaluation of Compliance

4.5.2.1 The organization shall establish, implement

and maintain a procedure(s) for periodically

evaluating compliance with legal requirements. The

organization shall keep records of results of the

periodic evaluation.

4.5.2.2 The organization shall establish, implement

and maintain a procedure(s) for periodically evaluating

compliance with other requirements to which

organization subscribes. The organization shall keep

records of results of the periodic evaluation.

4.5.3 Accident. Incident. Non-conformance. Corrective

and Preventive Action

The organization shall establish and maintain

procedures for defining responsibility and authority for:

a) The handling and investigation of:

I) Accidents,

2) Incidents, and

3) Non-conformances;

b) Taking action to mitigate any consequences

arising from accidents, incidents or non-

conformance;

c) Initiation and completion of corrective and

preventive action; and

d) Confirmation of the effectiveqess of con-ective

and preventive action taken.

These procedures shall require that all proposed

corrective and preventive actions shall be reviewed

through the risk assessment process prior to

implementation.

Any corrective and preventive action taken to eliminate

the causes of actual and potential non-conformances

shall be appropriate to the magnitude of prnhlcms and

commensurate with the OH&S hazards and risks

encountered.

The organization shall implement and record any

changes in the documented procedures resulting from

corrective and preventive actions taken.

4.5.4 Control of Records

The organization shall establish and maintain records

as necessary to demonstrate conformity to the

requirements of its OH&S management system and of

this International Standard, and the results achieved.

The organization shall establ ish, implement and

maintain a procedure(s) for the identification,

-;torage, protection, retrieval. retention and disposal

of records.

Records shall be and remain legible, identifiable and

traceable.

4.5.5 Internal Audit

The organization shall ensure that internal audits of

the OH&S management system are conducted at

planned intervals to:

a) Determine whether the OH&S management

system,

I) conforms to planned <lrrangements for

OH&S management including the

requirements of this standard,

2) has been properly implemented and is

maintained; and

b) Provide information on the results of audits

to management.

Audit programmes shall be planned, established,

implemented and maintained by the organization,

laking into consideration the OIl&S importance ofthe

operation(s) concerned and the results of previous

audits. Audit procedure(s) shall be established,

implemented and maintained that address:

a) the responsibilities and requirements for

planning and conducting audits, reporting

results and retaining associu(ed records, and

b) the determination of audit criteria, scope,

frequency and methods.

Selection of auditors and conduct of audits shall ensure

ohjectivity and the impartiality of the audit process.

7

IS 18001: 2007

4.6 Management Review

The organization's lOp management shall at intervals,

that it determines, review the OH&S management

system to ensure its continuing suitability, adequacy and

effectiveness. The management review process shall

ensure that the necessary information is' collected to

allow management to carry out this evaluation. Reviews

shall include assessing opportunities for improvement

and the need for changes to the OH&S management

system, including the OH&S policy, objectives and

targets. Records of the management review shall be

retained. The management review shall consider:

a) Results of internal audits and evaluations of

compliance with legal requirements and with

other requirements to which the organization

subscribes;

b) Communication(s) from external interested

parties, including complaints;

c) The OH&S performance of the organization,

d) Extent to which ohjectives and targets have

been m c t ~

e) Status of corrective and preventive actions,

t) Follow-up actions from previous management

reviews;

g) Changing circumstances, including

developments in legal and other requirements

related to its health and safety; and

h) Recommendations for improvement.

The output from management reviews shall include

any decisions and actions related to possible changes

to OH&S policy, objectives, targets and other elements

of the OH&S management system, consistent with the

commitment to continual improvement.

IS 18001: 2007

ANNEXA

(ForeH'ord, and Clause 1)

GUIDANCE FOR USE OF THE SPECIFICATION

;\-1 GENERAL REQUIREMENTS

This Annex gives additional information on the

requirements and is intended to avoid misinterpretation

of the specification. This Annex only addrc __ scs the

OH&S management system requirements contained

1n 4. The introduction of Occupational health and safety

(OH&S) management into the existing overall

management system should be considered within a

general management system model that incorporates

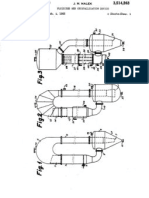

the following principles (see Fig. I):

a) Principle 1 Commitment and Policy - An

urganization should define its OH&S policy

and ensure commitment to its OH&S

management systems.

b) Principle 2 Planning - An organization

should plan to fulfil its OI-l&S policy.

objectives and targets.

e) Principle 3 Implementation and Operation .-

For effective implementation, an organization

shuuld develop the capabilities and support

mechanism necessary to achieve i t ~ OH&S

policy, objectives and targets.

d) Principle 4 Measurement and Em/uatioll -

An organization should measure, monitor and

evaluate its OH&S performance and take

preventive and corrective action.

e) Principle 5 Management Review - An

organization should regularly review and

continually improve its OH&S management

system, with the objective of improving its

OH&S performance.

In carrying out its OH&S commitment, an organization

should aim at:

a) Developing the capability to balance and

resolve conflicts between OH&S and other

organizational objectives and priorities, and

b) Alignment/integration of OH&S into the

overall business management process.

Keeping this in mind, the management system is best

viewed as an organizing framework that should be

continually monitored and periodically reviewed, to

provide effective direction for an organization's OH&S

activities in response to changing internal and external

factors.

As organizations grow in experience, procedures,

programmes and technologies can be put in place to

further improve OH&S performance. As OH&S

management system matures, OH&S considerations

should be integrated into all its business decisions.

Commitment

and Policy

Planning

FIG. 1 ELEMENTS OF HEALTH AND SAFETY MANAGEMENT

8

A-2 OH&8 POLICY

The organization's OH&S policy is a public statement

signed by top management declaring its commitment

and intent to manage its OH&S responsibilities. In

publishing the policy the organization is sending a clear

message that it has a vision for OH&S management

within the whole organization.

The policy should be relevant to the organization's

overall vision and objectives. It should be dynamic and

sct the framework for continual improvement,

especially in decision making. It should set out a

programme of action for the whole organization,

ensuring accountability and linking OI-l&S to the

overall organizational values, objectives and processes.

The policy is implemented through planning.

This policy is intended to clearly tell employees.

customers and interested parties that OH&S

is an integral part of all operations. Management being

actively involved in the review and continual

iIlJprovement of OH&S perfomlance fUl1her reinforces

Ihis commitment.

Evnyonc :ihould he aware of the influence thal their

actions and inaction can have. on the effectiveness of

t he system. They can also participate in the

esrablishment and maintenance of the OH&S controls,

as well as ;lssisting in the planning.

Successful change can be accomplished by effective

leadership in the areas of:

a) Determining the organization's current

position on OIl&S;

b) Resource allocation induding setting budgets,

responsibilities, authority and accountability;

c) Coordinated management planning and

agreed delegations; and

d) Decisions followed through and performance

assessed.

Regular review of OH&S at senior management level

reinforces its importance to the organizatinn's success

in meeting its commercial and legal obligations.

A-2.t The following questions can aid in establishing

ur rewriting an organization's OH&S policy:

a) Integration and Relevance - Is the policy

integral and relevant to the organi7ation's:

I) mission statement, vision, core values

and beliefs;

2) overall management system; and

3) activities, products and services.

b) Accountability - Docs the OH&S policy

address accountability in terms of:

9

IS 18001: 2007

1) capacity to assign/delegate, deliver, and

review the policy's commitments;

2) inclusion of OH&S accountability in all

duty statements (reflecting the degree of

legaJ responsibility);

3) setting of objectives and targets to

minimize incidents, injury, illness and

incidents; and

4) allocation of adequate resources to fulfil

the aims of the policy.

c) Consultation - Does the policy enable

consultation with:

1) employees;

2) line managers;

3) sub-contractors; and

4) suppliers;

A-3 PLANNING

The initial OH&S review (see 4.3.1) of the

organization's position provides a planning framework

for the impJementation of the OH&S management

system. While during initial review all the hazards and

risks are identified, in the process of planning the

significant hazards and risks are recognized.

Objectives, targets and performance indicators are

established and plans are also made to achieve them.

Planning needs to address schedules, resources and

responsibilities for achieving the organization;s OH&S

objectives and targets. Such planning (and resulted

plans) can cover a number of areas. For ex.ample:

a) Plans to manage and control the initial

implementation of an OH&S management

system;

h) Specific OH&S plans required for managing

OH&S risks;

c) Contingency plans required as part of the

organization's emergency preparedness to

meet foreseeable emergencies as well as plans

to mitigate their effects (that is critical incident

recovery, first aid and clean-up);

d) Plans required to meet objectives and targets

in measuring performance, undertaking audits

and reviewing the system; and

e) Response plans for dealing with corrective

action identified as part of the incident

investigation process or following the

identification of non-conformances.

The level and complexity of planning should

commensurate with the size, complexity and nature of

the organization and the risks it has to manage. In

smaller organizations many of these types of plans may

be combined.

IS 18001: 2007

A-3.1 Initial OH&S Review

Every organization will find that it has some elements

of ;)n OH&S management system in place. What is

less common is the linking of these elements into a

coordinated overall system for improvement.

A useful starting point is to critically compare the basic

intent of each element in this standard with

management practices and procedures, vvhich are

currently being used in the organization. Many

organizations have obsolete procedures and need to

compare the requirements of this standard with what

actually occurs in order to obtain a realistic assessment

or the implementation task.

A-3.1.1 Core elements which could be initially focused

on:

a) Clear management responsibility fm OH&S;

b) Identification of all applicahle legal

requirements and their compliance;

c) Hazard identification and risk assessment, and

what is being done about them;

d) Documentation of critical procedures;

c) OH&S inspections of critical procedures and

plant; and

f) Training.

Other elements can be progressively implemented in

accordance with organizational needs and priorities.

A-3.1.2 Some common techniques for initial review

include:

a) Questionnaires,

h) Interviews with employees,

c) Checklists,

d) Direct inspection and measurement,

e) Assessments (internal and external),

f) Review of records, and

g) Comparison with similar organizations.

A-3.1.3 External sources which may be able to help

include:

a) Government agencies in relation to laws and

permits,

b) Local or regional libraries or databases,

c) Other organizations for exchange of

information,

d) Industry associations,

c) Larger customer organizations,

f) Suppliers of equipment, and

g) Professional help.

A-3.1.4 Many organizations do not have a complete

understanding of their legal responsibilities in relation

iO

to the many OH&S statutes. regulations, standards.

codes of practice and guidance documents, which cover

their area of operations.

A-3.1.5 Useful sources of information include:

a) Disease. incident and first aid records kept by

the organization or by industry associations,

governments and the like;

b) Workers compensation experience. Insurance

companies are often ahle to provide feedback

on an organization's claims experience and

the breakdown of the components of the

insurance premium and how these compare

within an industry group; and

c) Other data an organization may hold on

absenteeism, sick leave, industrial disputes

and the like may provide indirect pointers to

i l r e i l ~ of poor OH&S management.

A-3.2 Hazard Identification, Risk Assessment and

Risk Control

Hazard identification, risk assessment and risk control

should be taken into account when plans are formulated

to meet an organization's OH&S policy. All identified

hazards are assessed to determine the level of risk,

which is a measurement of the probability and possible

consequence of injury and illness resulting from

exposure to hazard. The final step involves risk control

where risk is treated to reduce its level (see Fig. 2).

FIG. 2 HAZARD IDENTIFICATION ASSESSMENT AND

CONTROL Of RISK

A-3.2.1 Hazard Identijlcl1liof1

Tools used to assist in the identification of hazards

include:

a) Consultation - People who may have

experience in aspects of the job that they like

least and may lead to hazardous activities.

h) Inspcctiol1- A physical inspection of the

work environment.

c) Illness and injury records- Records of past

incidents involving injury ;l!1d illness

highlight sources of potential harm.

d) Information/specialist advice- The

identification of some h;lZards will require

specialist advice, research and information.

e) Task analysis- By breaking a task down into

its individual elements hazards associated

with the task can be identified.

/) Formal hazard analysis systems. for example

HAZOPfHAZAN.

NOTE -- IS 37g6 prescribes !!lcttw<.is of computaliun of

frequency and severity rales for inuustrial injuries ilnd

of industrial accidents, This Indian Standard may

Jlso be useful in the process of ilienlificalion i)f hazard,

A-3.2.2 Risk Assessment and Control

In order to carry out risk assessment, the level of risk

is determined first. Establishing the level of a risk

requires clear specification of the actual components

of the risk being considered, for example, the specific

scenario of sequence of events including the nature of

consequences to be considered, the exposure to the

chosen hazard, finally the probability or likelihood of

that scenario taking place. (In doing so the existing

controls are determined when exposure is assessed.)

Any scenario involving particular hazard can lead to

different consequences depending on the sequence of

exposure events. Hence any risk level needs to be

assessed separately for each choscn sequence of events.

To combine the following three components of any

risk in assessing its leveL

a) Choose a specific consequence or outcome

severity for one possible sequence of events

involving the hazard under consideration. Other

possihle sequences with different possible

consequences need to he assessed separately.

The number of persons hamled and the nature

of their injurieslillness affects the estimation of

the consequence or outcome severity;

b) Determine the exposure for the chosen

'icquence, that is how often (frequency): how

long duration of the affected persons exposed

to the particular hazard; and

c) Estimate the probability, likelihood or chance

that the chosen scenario will lead to the

specific consequences being consi(iL'red,

Every scenario that is considered for any

particular hazard has its own specific risk

level. The integrity and effectiveness of any

11

IS 18001: 2007

existing risk control measures will need to be

included in estimating probability.

Elimination/substitution is a permanent solution and

should be attempted in the first instance. The hazard is

either eliminated altogether or substituted by one that

presents a lower risk. This could involve the elimination

of a hazardous process or substance or the substitution

of a toxic substance with a less toxic substance.

NOTE - For the purpost! of idt!lltification of hazard and

and control of risks a guideline has been giwn in

Annex C.

Risk= Consequence x Exposure x Probability

Level The outcome Frequency and Likelihood or

severity duration of chance that

(injurylillness) exposure of the chosen

of one scenario persons to the sequence and

chosen hazard consequence

will occur

Elimination/substitution is a permanent solution and

should be attempted in the first instance. The hazard is

either eliminated altogether or substituted by one that

presents a lower risk. This could involve the elimination

of a hazardous process or substance or the substitution

of a toxic substance with a less toxic substance.

NOTE - For the purpose of identification of hazard and

assessment and control of risks a guideline has been given in

Annex C of this slandard.

A-3.3 Legal and Other Re(IUirements

In maintaining regulatory compliance, an organization

should identify and understand regulatory requirements

applicable to its activities, products or services.

Regulations cover several aspects such as:

a) Those specific to the activity (for example

confined spaces regulations);

b) Those specific to the organization's products

or services;

c) Those specific to the organization'S industry;

d) General OH&S laws; and

c) Authorizations, licences and permits.

Several sources can be used to identify OH&S

regulations and ongoing changes, including:

a) All levels of government;

h) Industry associations or groups;

c) Commercial databases; and

d) Professional services.

To facilitate keeping track of legal requirements, an

organization can establish and maintain a list of all

laws and regulations pertaining to its activities,

products or services and the same should be updated

on a regular basis.

IS IROOl: 2007

A-3.4 Objectives, Targets, Performance Indicators

and Pogramme(s)

Objectives state what is intended to he accomplished

and targets define a performance level timcframc.

Ohjectives should be aimed at broad level

improvements in the OH&S performance and the

targets should be qualified wherever practicahle in the

following terms:

a) Attrihutes - things which are major (handling

injuries and adequately guarded machine);

b) Scale -- against which the altribures can be

measured;

c) Goal - describing what is to he achieved;

and

d \ Time scale - in which it is to be achieved.

Performance indicators are the means by which it is

fllcasured whether expected outcomes meet ohjectives.

There are measures such as rates, ratios or indices

which reflect how well the OH&S management system

or its elements are performing.

Comhining targets and performance indicators

produces objectives that are specific, measurable,

achievable, realistic and time-bound.

For example:

Objective Implement an OH&S management system

T ~ l r g ~ l Full implementation within six month'i

I ndicator Percentage of departmental meeting audit

criteria

(Objective: All business units to fully meet system

audit criteria within six months.)

or

Objective Reduce injuries associated with manual

handling

Target 20 percent reduction from previous year

lndicator Percentage of manual handling injuries

per year

(Ohjective: Reduce the percentage of manual

handling injuries by 20 percent from the

previous year in the next 12 ml)nths.)

When considering their technological options, an

organization may consider the use of the best available

technology where economically viable, cost effective

and judged appropriate. Review of objectives and

targets should be based on past performance and in

consultation with workplace personnel, OH&S

professionals, insurers and other appropriate persons

(ll t:roups. When the objectives and targets arc set, the

12

organization should consider estublishing measurable

OH&S performance indicators. These indicators

should be used as a I?asis for an OH&S performance

evaluation system and to provide information on both

the OH&S management and operation systems.

The creation and lise of one or more programmes is a

key clement to the successful implementation of an

OH&S management system. The programme should

describe how the organization's objectives and targets

will be achieved, including time, skill and personnel

responsible for implementing the organization's OH&S

policy. This programme may be subdivided to address

specific elements of the organization's operations. The

programme should include an OH&S review for new

activities.

The programme may include, where appropriate and

practical, consideration of planning, design,

production, marketing and disposal stages. This may

he undertaken for both current and new activities.

product or services. Por products this may address

design, materials, production processes, use and

ultimate disposal. For new installation or significant

modification of processes this may address planning.

design, construction, commissioning operation and at

the appropriate time as determined by the organization,

de-commissioning.

A-4 Il\1PLEMENTATION AND OPERATION

A-4.1 Resources, Roles, Responsibility and Authority

A-4.Ll In organizing the implementation and effective

management of its OH&S policy an organization

should:

a) Allocate adequate resources commensurate

with its size and nature;

b) Identify the competencies required at all levels

within the organization and organize any

necessary training;

c) Make arrangements for the effective

communication of OH&S information;

d) Make effective arrangements for the

provisions of specialist advice and services;

e) Make effective arrangements for

handicapped, Clged, visitors and foreign

employees and/or special category of

employees; and

f) Make effective arrangements for employee

concentration and active involvement.

A-4.1.2 The resource base, structure, and size of

organizations may impose constraints on

implementation. In order to overcome these constraints

external health and safety resources may need to be

utilized. Such resources might include:

a) Shared technology and experience from larger

client

b) Cooperative approaches to develop industry

specific guidance material and strategic,,;

c) Support from industry and L'Jl1ployec

associations or principal sub-contractors and

d) Assistance from government health and safety

organizations;

c) Use of consultants and the collective

engagement of consullants;

f) Provision of advice and lra;lning from

suppliers;

g) Assistance provided by workers'

compensation insurance agents;

h) Attendance at health and safety seminars; and

j) Manually support from universities

and other research centers.

Organizations should focus on utilizing cooperative

strategies to implement and maintain an effective

OH&S management system.

A4.1.3 Improving health and safety is most effective

when people from all levels of the organization are

encouraged to participate in the development and

implementation of the programme. People are more

likely to embrace change ifit is not imposed upon them.

At all levels of the organizations, people should be:

a) Responsible for the health and safety of those

they manage, themselves and others with

whom they work;

b) Aware of the responsibility for the health and

safety of people who may be affected hy the

activities they control, for example suh-

contractors and puhlic; and

c) Aware of the influence that action or

inaction can have on the effectiveness of the

OH&S management systems.

A-4.1.4 Senior management should demonstrate, their

commitment being actively involved in lhe continual

improvement of OH&S performance. \Vhile ultimate

responsibility for OH&S rests with the employer, [he

following also need to be ensured:

a) A person at the senior management level

should be assigned particular responsihility

for ensuring that the OH&S management

system is implemented and performs to

expectations, in all location:; within the

organizations;

b) To recognize that knowledge <.md experience

throughout the workforce a valuable

resource and it should actIo and

13

IS 18001 : 2007

delegate responsibilities and authorities for the

development and implementation of the

OH&S management system for all key

functional areas; and

c) A defined system of implementing and

communicating any change of responsibility

and authority.

It should be recognized that effective management of

OH&S requires the support and commitment of the

employees, and that the knowledge and experience of

the workforce can be a valuable resource in the

development and operation of the OH&S management

system.

A-4.2 Competence, Training and Awareness

The effective implementation and maintenance of an

OH&S management system is dependent on (he

competencies and training of an organization's people.

A-4.2.2.1 The top management of an organization

should demonstrate its commitment to OH&S through

consultation with and where appropriate, its employees

and other relevant individual(s) or grQups in the

development, implementation, and maintenance of its

OH&S management systems. The objectives and

targets should be understood and supported by the

organization's employees and they should be

encouraged to accept the importance of their

achievements both in terms of the organization's

OH&S performance and the benefits, to the

environment in which they work. Employees should.

be made aware of exposure to possible harm ()r injury

in their work environment including physical,

chemical, ergonomic, radiation, biological and

psychological hazards. They should have an

understanding of these hazards as they relate to their

work environment and be able to recognize and take

action to prevent work practices or activities likely to

leave to incidents.

A-4.2.2.2 OH&S competency standards should be

developed by:

a) Using existing industry competency standard,

b) Examining job or position descriptions,

Analysing work tasks, c)

d) Inspection and audits of hazards identification

and risk analysis, and

t) Reviewing incident reports.

The organization should develop training programme

after the assessment of current capability against the

required competency profile. An organization should

also establish and maintain documented procedures for

evaluation of training provided to its workers and its

effectiveness.

IS tR001: 2007

A -4.2.2.3 Generally a health and safet) i ng

programme should cover hut are not limited to the

fc>llowing aspects:

a) Health and safety policy of the organization.

h) Way in which health and safety is urganized

in the workplace.

C) Health and safety procedures il1 the

()rgani7ation,

d) Specific hazards and risk controls,

c \ OH&S legislation. and

f) Emergency procedures.

A-4.2.2.4 A training programme may need to address

a Ilumncr of target groups including:

a) Senior management;

h) Line

c} Employees;

d) Those with specific (first aid,

fire. elected health and safety representatives);

Sub-contractors;

n Operators who require certificates under

legislation; and

g) Site visitors.

A-4.2.2.S Training records should normally include:

a) Information about those who have heen

trained.

b) What the training course covered,

c) When the training took place.

d) Who provided the training, and

e) Feedback from trainees.

A-4.2.2.6 OH&S training is typically prl.wiLled at

certain key tlmes in an operational cycle including:

a) At induction for new employees,

h) When employees are transferred to new johs.

c) On movement into managerial or supervisory

positions,

dl On engagement of suh-contractors.

C I When modification in the system is l'arricd

out. anu

f) After a time gap as a refresh.

A-4.3 Communication and Reporting

A-4.3.1 Commllnic(l{iOfl

Organizations should implement a procedure for

receiving documenting and responding to relevant

inf(lfll1ation anu requests from interested parties. The

procedure may include a dialogue with interested

part ics and consideration of their relevant concern, In

S(\l1lC circumstances. response to interested parties'

may include relevant information ahout the

14

hazards and risks associated with the organization's

operations. These procedures should also address

necessary communication with public authorities

regarding emergency planning and other relevant

issues. Organizations should also have a system to

communicate relevant OH&S information including

objectives and targets and any change in delegation of

responsibility to its own employees.

A-4.3.1.1 Commonly used methods of internal

communication include:

a) Bulletins,

b) News letters,

c) Notice boards;

d) Signage,

c) Videos,

f) Minutes/action notes of the meetings,

g) Team briefings, and

h) Hard copy or electronic mail.

A-4.3.1.2 Commonly used methods of external

communication includes:

a) Annual reports,

b) Publications,

c) [nserts in industry publications.

d) Paid advertising,

e) Telephone inquiry services,

f) Submissions to government, and

g) Websites.

A-4.3.2 Reportinf?

Traditionally reporting has focused on lost-time injuries

and nol the management system established to control

risks. Effective reporting should cover the positive steps

the organization is taking to identify hazards and

control risks and can include reports:

a) of levels of conformance with procedures,

b) on performance against targets,

c) on improvements made,

d) on underlying reasons for incident

occurrences,

e) on results of safety inspections and audits;

f) on health monitoring, and

g) of workplaces monitoring.

A-4.4 Documentation

Documentation is an important element in enabling

an or8anization to implement a successful OH&S

management system. It is also important in assembling

and retaining OH&S knowledge, but it is important

that documentation is kept to the minimum required

for effectiveness and efficiency.

A-4.4.1 Organizations should ensure tbat sufficient

documentation is available to enable OH&S plans to

be fully implemented and is propOJtional II) their needs.

A4.4.2 Operational processes and procedures should

he defined and appropriately documented and updated

as necessary. The organization should clearly define

the various types of documents, which establish and

effective operational procedures control.

A-4.4.3 Thc existence of OH&S managclIlent systems

documentation supports employee awarenes<.:, of what

is required to achieve the organization's OH&S

ohjectives and enables the evaluation of the "y"tcm and

OH&S performance.

A-4.4.4 The degree and quality of the documentation

\vill vary depending on the sile and complexity of the

organization. Where elements of the OH&S

!l1ill1ilgcmcllt ilrc integrated with itn

oq;anization's overall management system the OH&S

documentation should be integrated into existing:

documentation. The organizations should consider

organizing and maintaining a summary of the

documcntution to;

a) Collate the OH&S policy, objectives and

targets;

b) Describe the means of achieving OH&S

objectives and targets:

c) Document the key roles, responsibilities and

procedures;

d) Provide direction to related d()cumentation

and describe other elements of the

organization's management system, where

appropriate; and

e) Demonstrate that the OH&S management

system elements appropriate For the

organization are implemented.

A4.5 Control of Documents

OH&S documents communicate and regulate

action. They should be current, compn:hensive and

issued by an authoritative source. The organization

should ensure that:

a) Documents can he identified \vith appropriate

organization, division. functioll, activity or

contact person;

b) Documents are periodically revised

as necessary and approved by authorized

personnel prior to issue;

c) The CUlTent version of relevant documents are

available at all locations where operations

essential to the effective fUl1ctlOning of the

system are performed; and

d) Obsolete documents are promptly n .. 'movcd

from all points of issue.

15

IS 18001 : 2007

Documents can be in any medium as long as they arc

accessible, useful and easily understood.

A-4.6 Operational Control

It is important that OH&S, in its broadest sense, is fully

integrated across the organization and into all its

activities, whatever the size or nature of its work. In

organizing for the implementation of the policy and

the effective management of OH&S, the organization

should make arrangements to ensure that activities are

carried out safely and in accordance with alTangements

and should:

a) Define the allocation of responsibilities and

accountabilities in the management structure,

b) Ensure people have the necessary authority

to carry out their responsibilities, and

c) Allocate adequate resources commensurate

with its size and naturc.

Some typical activities, which arc covered under

operational control are:

3) Production,

b) Maintenance,

c) Storage,

d) Handling,

e) Packaging, :!nd

t) Transportation.

However this list is not an exhaustive list and may be

... suitably modified depending upon the activities of the

organization. Some examples of arcas in which risks

typically arise, and some examples of control measures

against them are given below:

a) Hazardous tasks

This includes the following:

1) Identification of hazardous tasks,

2) Pre-determination and approval of

working methods,

3) Pre-qualification of personnel for

hazardous tasks, and

4) systems, and procedures

controlling the entry and exist of

personnel to hazardous work sites ..

b) Hazardous 11l1lteria/s

This includes the following:

I) Identification of inventories, and storage

locations;

2) Safe storage provisions and control of

access; and

3) Provision and access to material safety

data and other relevant information.

IS 1 ROO 1 : 2007

A1([inrel1(lIlce ofs(lle plant alld equipment

This includes the following:

1) Provision. control and maintenance of the

organization's plant and equipment;

2) Provision, control and maintenance of

PPE;

J) Segregation and control of access; and

4) Inspection and testing of OH&S related

equipment and high integrity systems

such as:

i} operator protection systems:

ii) guarding and physical protection:

iii) shutdown systems;

iv) fire detection and suppression

equipment;

v) handling equipment (cranes.

forklifts, hoists and lifting

devices);

vi) radiological sources and safeguards;

vii) essemial monitoring devices:

viii) IO(dl exhaust ventilation systems;

and

ix) medical facilities and prov isions.

:\-4.6.1 Design and EllgineerinR

EngineL'ring controls involve some structural change

to the work environment or work process to place a

harrier to, or interrupt the transmission path between

the worker and the hazard. This may include machine

l':uarLis, isolation or enclosure for hazards. the lise of

ventilation and manual handling deviccs.

hazard involving processes or services.may

he at the design stage in consultation with

various professionals, for example, engineers,

architects, doctor'i or health and safety profc'isionals.

The risk associated wilh these hazards may he

,,:olllrolled hy appropriate design, sitting and selection

i)f premises including:

a) Proposed use, foreseeable uses and future

maintenance:

b) Construction in a manner incorporating best

health and safety practices; and

c) Checking compliance to contract

specifications.

\-4.6.2 Purchasing

rhe organization needs to ensure that a policy has becll

,Ievcloped for the employment of sub-contractors who

undertake work on the employer's premises or .assets,