Professional Documents

Culture Documents

Slip-Form Productivity Analysis For Concrete Silos

Uploaded by

Vinay BabuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Slip-Form Productivity Analysis For Concrete Silos

Uploaded by

Vinay BabuCopyright:

Available Formats

1st International Construction Specialty Conference 1re Confrence internationale spcialise sur le gnie de la construction

Calgary, Alberta, Canada May 23-26, 2006 / 23-26 mai 2006

Slip-Form Productivity Analysis for Concrete Silos

M.R. Sharifi, S. Baciu and T. Zayed Department of Building, Civil, and Environmental Engineering, Concordia University, Montreal, Quebec, Canada

Abstract: Starting from the beginning of the 20-century, slip-forming is widely used in formwork due to fast concrete work. Slip-forming is one of the potential concrete formwork methods that improves speed and productivity of repetitive vertical concrete work. Typical projects that employ this technique are: silos, core of high-rise buildings, telecommunication towers, cooling towers, heavy concrete offshore platforms, etc. Current research aims at assessing slip-form productivity using simulation as well as determining the best slip-form rate and resource combination. A simulation model for slip-forming technique is developed. Data are collected from a case study in slip-forming of concrete silo. The potential control units in the system are described while applying the developed model to the case study. Results show the usefulness of applying the developed simulation model to slip-forming technique with robust results of 99% validation.

1. Introduction Slip-forming is one of the most common methods of construction in concrete silos. Usually, industrial silos such as coal or production line storage silos, which have different heights and diameters are made of concrete using slip-form. Silos are also used to store grains in which they are interconnected as multiple cells (Peurifoy & Oberlender, 1996). Slip-forming construction technology has also become very important in high-rise concrete structures (Risser, 1995). It differs from conventional concrete formwork because it moves semi-continuously with respect to the concrete surface being formed and form ties are not used (Risser, 1995). Recent improvements in larger yoke capacities and better laser guidance result in more efficient and faster slipping rates (Risser, 1995). Jaafari et al. (1989) reported that there are many forming methods that can be used to construct a highrise building or concrete silo, such as slip-form, climb-form, jump-form, super-shafter, and conventional forming methods. It has been shown that for buildings of less than 15 stories high or silo less than 15 m high, none of the alternative methods can compete with the conventional forming method. This study further stated that for tall structures (greater than 30 stories), the alternative methods could potentially reduce the costs by up to 30-40%. In addition, slip-forms showed cost advantages for more than 20 stories and larger than 600 m2 formed area per floor. For silos higher than 15 meters, slipforming method is the best economically and time wise (Jaafari et al., 1989). Slip-forms were extensively used in concrete silos and tall structures in the last few decades (Risser, 1995; Hurd, 1990; Jaafari et al., 1989; and Anon, 1987). Simulation technique can be applied to the modeling of slip-form operations in order to study different combinations of resources. MicroCYCLONE modeling and programming technique can be used to simulate this process. The elements of MicroCYCLONE, originally developed by Halpin in 1973, are used to model and simulate slip-form operations. MicroCYCLONE is a simple and powerful tool for construction process planning, as demonstrated by many researchers (Zayed and Halpin, 2001).

CT-070-1

Therefore, due to lack of research in modeling slip-form productivity, current research will design a concrete silo construction productivity model for slip-forms using simulation. It will determine the best slipping (jacking) rate and resource combination. It further accommodates limitations of concrete property and construction difficulties, such as stoppages, technological problems, concrete setting time, and their effect on productivity.

2. Slip-Form Background Few decades ago, for the first time, a wooden rising form using wooden screw jacks and wooden yokes was operated, and six years later, in Tennessee, USA, the first apartment building was constructed using slip-forming (Ratary, 1980). In 1974, slip-form method was used to construct the concrete shaft of CN tower in Toronto, with 335 m height, within eight months. Slip-forming is a technique used to build structures quickly, in which the wet concrete is extruded, rather than retained in forms until it has hardened (Anon, 1978 & 1987). In slip-forming, the concrete is poured at a pre-determined rate on top of a traveling form and emerges in a hardened state from the bottom. Concrete is shaped to the desired profile during the travel of the form. Slip-forming is economical for structures with uniform cross-section, but it is adopted for structures that vary in cross-section and shape through their height as well. Slipping speed has a fixed rate in which the form will leave the concrete after being strong enough to retain its shape while it can carry the load of its weight. Therefore, careful planning is essential to establish a suitable concrete mix well before starting the work. With the reductions in construction time and labor cost, slip-forms prove more economical in the long run in spite of their high initial investment (Anon, 1978 & 1987). Slip-forms have many advantages over other techniques: high operational speed, economical, accurate operations, high quality finished surfaces, and a continuous moving monolithic structure. It can be used to construct special structures: telecommunication and cooling towers, silos, heavy concrete offshore platforms, etc. Many challenges face slip-form usage in the construction industry. Continuous work needs high-level management of resources and convenient work environment. In addition, weather conditions and labor union restrictions might add to these challenges. It requires many accompanied equipments that have to work continuously parallel to the slip-forms. This will increase the initial investment as well as assembling and disassembling expenses of such method (Betterham, 1980). In addition, any changes in the operational information during constriction cost a lot of time and money. The number of boxes and embedded parts in the height of the structure influences greatly the cost and time as well. The basic criteria for selecting slip-form as a formwork method will be project time; required speed; cross section uniformity and height; number of openings; and necessary stoppages in the height. The risk of modifying operational information and having mistakes should be eleminated (Hanna, 1999). Therefore, the speed of slip-form is a function of concrete properties, number of stoppages, weather conditions, and management capabilities. The slipping rate depends on how fast horizontal reinforcements and anchor plates can be placed. In addition, concrete setting time greatly influences the slipping rate. The slip-form can move whenever concrete can carry the load of its weight in lowest parts of form sheet; therefore, slipping rate is directly related to the concrete setting time. Because setting time is influenced by weather conditions (temperature, humidity, etc), cement ratio, type of cement, slump, and admixtures (Hurd. 1995), the best slipping rate will be chosen based upon job conditions. Slip-form speed should not be so fast to cause collapses, where soft concrete falls out from under the form, nor so slow to cause stick, where concrete sticks to the slip-form and parts will rip away from the wall.

3. Slip-Form Simulation Model Development To build the simulation model of constructing concrete silo using slip-form technique, the construction phases (algorithm) have to be identified. Slip-form passes through several steps in order to build one meter of the concrete silo as shown in Figure 1: Step 1: Slip-form considers to be started from specific level in the high of silo. In this step, tower-crane lifts reinforcements and embedded plates to the platform.

CT-070-2

Step 2: One-step jacking is done where the slip-form is driven up one jacking step ( = 2 in = 5.08 cm). Step 3: Then, concrete will be poured to fill the empty form. Concrete will be cured and finished in order to be ready for the next step. Step 4: Repeat step 2 four times to raise the form 20 cm. Rebar will be installed for the next 20 cm. Step 5: Repeat the above four steps until the completion of one meter of concrete silo. Step 6: Repeat the above five steps until the completion of the concrete silo. These steps are better explained through Figure 2, which shows the elevation of the constructed silo with its important levels. In addition, Figure 3 shows the details of the above construction algorithm. After identifying the construction algorithm, simulation model can be designed. The MicroCYCLONE (Halpin and Riggs, 1992) elements that are used in modeling the simulation model are shown in Figure 4. Based on these elements, a model is developed as shown in Figure 7.

Figure 1. Construction steps for concrete core using slip-forms.

4. Case Study Hormozghan cement factory project (Bandar Abbas, Iran) was chosen as a case study in current research. It included Raw Meal Silos and towers with 6000-ton cement production per day. All silos and towers of the cement factory were constructed using slip-form lifting system as shown in Figure 5. The silo was designed to store row material to feed a pre-heater tower that was used as a reserve for production line. Row materials were transported from the Row Mill to the uppermost part of the silo. From there the row material flowed down a concerte cone, which distributed material to all outlets. Samarah Construction Co. (general civil contractor) performed the slip-forming part of this project. Silo has 16 meter- inner diameter, 50 cm thickness and 50 meters-height. Concrete was poured using bucket and crane with a rate of approximately 8 m3/hr; rebar and material were lift to the platform by the same crane. Slip-forming took place through 24 working hours per day through shifts. Table 1 shows general project information that is considered in the simulation model. On the other hand, the duration of simulation activities are shown in Table 2. Figure 6 shows the construction steps of concrete silo from foundation to the project close out. Table 1. General Project Data Item Considered Silo height Wall thickness Silo inner diameter Information 1.0 m 0.5 m 16.0 m Table 2. Activities Duration (Triangular Distribution) Activity Jacking Concrete Pouring Rebar installation Material lifting Duration (Min) 5 4,4.8,5 7,8,9 5,6,7

CT-070-3

Figure 2. Construction process of Raw Meal Silo by slip forming

Figure 3. Construction algorithm of slip-form application to concrete silo.

5. Simulation Model Application to Case Study Activity durations are estimated and embedded into the MicroCYCLONE model to start simulation. The input data include: maximum possible jacking rate according to the mechanical capability of the form, mix design and concrete property, concrete pouring, rebar installation, and material lifting. Rebar installation time is determined based on a crew of 8 rebar workers (rodmen). Concrete pouring time is determined based on crane and bucket rates. Material lifting time is based on average crane lifting speed. The MicroCYCLONE package is used to simulate with the developed model in Figure 7. Sensitivity analysis is used to estimate productivity based upon various maximum potential jacking rate, silo diameter and thickness, and concrete pouring method. Jacking rates depend mainly on various concrete setting times and jacks power. Jacking rates changes from 10 cm/hr up to the 60 cm /hr. However, the rate can be increased, but concrete requires extra admixtures, such as setting time accelerators. Concrete pouring method is also alternated between two systems: pump system (average pouring rate = 3 minutes/m3) versus crane-buckets system (pouring rate = 10 minutes/m3). The results of simulation as well as sensitivity analysis are shown in Tables 3, 4 and 5. Table 3 and Figure 8 show jacking rates and their associated productivity in case study silo. It further shows that productivity with 30 cm/hr jacking rate using crane-buckets system to pour concrete is 0.151 m/hr (assuming 24 working hours per day). The cross-section area of the silo: diameter and thickness are the factors that affect productivity of slipform system. Therefore, two charts have been developed to predict productivity (m/hr) considering silo diameter, and jacking rate, as shown in Figures 9, and 10. For example, Figure 9 shows that a project of 12m-diameter silo using 40 cm/hr jacking rate, and using crane-buckets system to pour concrete will produce 0.2m/hr productivity. Similarly, the productivity different silos, using pump to pour concrete can be predicted using Figures 10. It is obvious that the developed curves for pump and crane-buckets systems are deemed beneficial to practitioners in the slip-form industry. These curves can further be used to plan slip-form projects efficiently. They enable experts to optimally schedule slip-form operation in a specific project and within various projects.

CT-070-4

Name

Symbol

Function

This element is always preceded by Queue Nodes. Before it can commence, units must be available at each of the preceding Queue Nodes. If units are available, they are combined and processed through the activity. If units are available at some but not all of the preceding Queue Nodes, these units are delayed until the condition for combination is met. This is and activity similar to the COMBI. However, units arriving at this element begin processing immediately and are not delayed.

Combination (COMBI) Activity

Normal Activity

Queue Node

This element precedes all COMI activities and provides a location at which units are delayed pending combination. Delay statistics are measured at this element. It is inserted into the model to perform special function such as counting, consolidation, marking, and statistic collection.

Function Node

Accumulator

It is used to define the number of times of the system cycles.

Arc

Indicates the logical structure of the model and direction of entity flow.

Figure 4. Basic MicroCYCLONE Modeling Elements (Halpin and Riggs, 1992)

Figure 5. Two Production Lines of Hormozghan Cement Factory Under the Construction

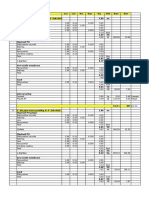

Tables 3. Different productivity values using crane-buckets and pump for concrete pouring in the case study silo (16 m diameter and 0.5 m thickness). Jacking Rate (Cm/h) 10 20 30 40 50 60 Productivity Using Bucket (M/h) 0.075 0.121 0.151 0.173 0.189 0.202 Productivity Using Pump (M/h) 0.088 0.158 0.214 0.260 0.299 0.332

CT-070-5

Figure 6. Complete construction process of Row Meal Silo.

CT-070-6

3. STEEL AND EMBEDDED CREW IDLE

.

\

21. STEEL AT PLATFORM GEN 4

QUA 1

22. 5. CON 5

4. EMBEDDED PARTS INSTALLATIO N

\

20. CON 4

STEEL WORKING CYCLE

1. READY TO EMBEDDED PARTS AND STEEL WORKING

\

19. STEEL LIFTING

18. STEEL AVAILABLE

6. JACKS READY TO LIFT GEN 60

15. CON 20

8. 5 CM JACKING

9. GEN 2

16. READY TO STEEL LIFTING

\

11. CRANE IDLE

.\

\

\

Figure 7. MicroCYCLONE Model for Slip-form Application to Concrete Silo.

Tables 4. Different productivity values using crane-buckets for concrete pouring Silo diameter and thickness ft (m) 8 (0.40) 10 (0.40) 12 (0.50) 16 (0.50) 18 (0.60) 20 (0.60) 22 (0.70) 25 (0.70) 28 (0.80) 30 (0.80) 10 0.088 0.086 0.080 0.075 0.069 0.067 0.062 0.059 0.052 0.051 20 0.158 0.150 0.134 0.121 0.106 0.101 0.089 0.088 0.071 0.068 Jacking rate (cm/hr) 30 40 50 0.214 0.261 0.300 0.201 0.241 0.274 0.172 0.201 0.223 0.151 0.173 0.189 0.129 0.145 0.156 0.122 0.136 0.145 0.105 0.114 0.121 0.096 0.104 0.110 0.081 0.087 0.090 0.077 0.082 0.086 60 0.333 0.301 0.241 0.202 0.165 0.153 0.127 0.114 0.093 0.088

\

7. COMMAND TO JACKING FROM CONCRETE CREW

.

12. CONCRETE CREW

\

10. CONCRETE AVAILABLE

CONCRETE POURING CYCLE

13. CONCRETE POURING

14. CON 2

.\

CT-070-7

Tables 5. Different productivity values using pump for concrete pouring Silo diameter and thickness ft (m) 8 (0.40) 10(0.40) 12(0.50) 16(0.50) 18(0.60) 20(0.60) 22(0.70) 25(0.70) 28(0.80) 30(0.80) 10 0.095 0.093 0.090 0.088 0.085 0.083 0.080 0.078 0.073 0.072 20 0.179 0.174 0.164 0.158 0.147 0.143 0.133 0.128 0.116 0.113 Jacking rate (cm/hr) 30 40 0.255 0.324 0.245 0.308 0.225 0.277 0.214 0.260 0.195 0.232 0.188 0.222 0.171 0.200 0.162 0.188 0.144 0.163 0.139 0.157 50 0.387 0.365 0.321 0.299 0.263 0.250 0.222 0.207 0.178 0.170 60 0.444 0.415 0.360 0.332 0.288 0.273 0.240 0.222 0.189 0.181

Productivity (M/hr)

Jacking Rate (Cm/hr) Figure 8. Slip-forming productivity using crane-buckets vs. pump system to pour concrete for case study silo (24 working hrs/day)

CT-070-8

Silo Inner Diameter (Thickness in Meters)

Productivity (M/hr)

Jacking Rate (Cm/hr) Figure 9. Slip-forming productivity vs. silo diameter using bucket and crane in concrete pouring (24 working hrs/day) Silo Inner Diameter (Thickness in Meters)

Productivity (M/hr)

Jacking Rate (Cm/hr) Figure 10. Slip-forming productivity vs. silo diameter using pump in concrete pouring (24 working hrs/day)

CT-070-9

6. Simulation Model Validation Hormozghan Cement Project had more than twenty towers and silos that were constructed using slipforming technique. Out of these twenty, four Row Meal and four Cement silos were identical; therefore, slip-forming system that was used in these eight silos was identical too. Data was collected from these silos considering jacking rates and productivity in meter per hour. Average maximum capable jacking rate was 30 cm/hr, average productivity was 0 .15 m/hr in which concrete pouring used crane and bucket. By applying the developed model in current research to this case study results in average productivity of 0.15121 m/hr (Standard deviation of 0.00034 and 95% confidence interval limits are 0.15113 and 0.15127) as shown in Table 3 and Figure 8. Based on this case study, the developed model shows robust results with 99% validation.

7. Conclusion and Further Studies Current research designs a productivity model for slip-form application to concrete silos using simulation. This model considers several factors that affect productivity, such as jacking rates, pouring method, silo diameter and thickness, and concrete setting time. Several charts are developed to determine productivity of slip-forms considering different silo diameter, and concrete pouring methods. The model is validated and shows robust results. The developed model is essential to practitioners and researchers because it provides practitioners with a planning and scheduling tool for their slip-form operation in concrete silos. It can further be used in bid estimating process. On the other hand, it provides researchers with a simulation model that is flexible enough to modify and add more features to it in order to enhance its capabilities.

8. Acknowledgment The authors would like to extend their appreciation to Samarah Construction Co., particularly Mr. Ahmad Keshavarz (project engineer), Project manager and construction manager of Hormozghan cement factory project for his great help and professional advice in current research.

9. References Anon 1978. Key to Courthouse Puzzle. Engineering News-Record, May 25, 200(21): 26-27. Anon 1987. Concrete. Indian Concrete Journal, April, 61(4): 85-86. Betterham, R.G. 1980. Slip-form Concrete. New York: Longman publisher,. Biswas, A. 1976. Vertical Slip-form. Indian Concrete Journal, December, 50(12): 360-362. Elazouni, A. M.; Nosair, I. A.; Mohieldin, Y. A.; and Mohamed, A. G. 1997. Estimating Resource Requirements at Conceptual Design Stage Using Neural Networks. J. of Computing in Civil Engineering, October, 11(4): 217-223. Hanna 1998. Concrete Formwork Systems. New York: Marcel Dekker. Halpin, D. W., and Riggs, L. S. 1992. Planning and analysis of construction operations. New York: Wiley. Hurd, M. K. 1990. Self-lifting forms shape building cores. Concrete Construction, Feb., 35(2): 215 -219. Hurd, M. K. 1995. Formwork for Concrete. Special Publication no. 4, American Concrete Institute. Jaafari, A.; Kew, Y. C.; and Yeoh, C. K. 1989. Alternative Methods for Construction of Vertically-Formed Concrete Structures. Institution of Engineers, Australia, Civil Engineering Transactions, May, CE31(1): 54-62. Peurifoy, R., Oberlander, G. 1996. Formwork for Concrete structures. 3rd Ed. New York: McGraw- Hill. Pruitt, J. D. 1987. Slip-forming of Atlanta's IBM Tower. Concrete Construction, April, 32(4):345-349. Ratary, R. T. 1980. Handbook of Temporary Structures in Construction. New York: McGraw-Hill. Risser, B. 1995. Advances in Vertical Slip-Form Construction. Aberdeen's Concrete Construction, October, 40(10): 4. Zayed, T. and Halpin, D. 2001. Simulation Of Concrete Batch Plant Production. J. Of Construction Engineering. And Management, ASCE, April, 127(2): 132-141.

CT-070-10

You might also like

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Assembly Transmission Volvo A40GDocument52 pagesAssembly Transmission Volvo A40GNanang SetiawanNo ratings yet

- Precast Concrete Frame Buildings Design GuideDocument91 pagesPrecast Concrete Frame Buildings Design GuideAmiruddin Bin Mishad50% (2)

- Driven Cast in Situ PilesDocument17 pagesDriven Cast in Situ PilesSonu KumawatNo ratings yet

- Print Rate AnalysisDocument124 pagesPrint Rate Analysisfelix sowah-laryeaNo ratings yet

- Concrete Formwork SystemsDocument318 pagesConcrete Formwork Systemscdnaveen100% (14)

- Jupiter - The Giant Planet That Destroys CometsDocument2 pagesJupiter - The Giant Planet That Destroys Cometsmaiche amarNo ratings yet

- Methodology For Convreting WorksDocument7 pagesMethodology For Convreting WorksLokesh SaranNo ratings yet

- PT DetailingDocument52 pagesPT Detailingcuongnguyen100% (4)

- Hemispherical Head Design ToolDocument1 pageHemispherical Head Design Toolnaveen_86No ratings yet

- Tunnel Form Construction Technique and ProcessDocument4 pagesTunnel Form Construction Technique and Processvenkateswara rao PothinaNo ratings yet

- Rigid PavementDocument55 pagesRigid PavementRamakrishna Ramakrishna100% (1)

- b25d b30d Mkiii HydraulicsDocument28 pagesb25d b30d Mkiii HydraulicsErmias100% (3)

- Sky Greens Residential Building ConstructionDocument53 pagesSky Greens Residential Building ConstructionRakshit Gp Goyal100% (1)

- Earthwork Operations & EquipmentsDocument20 pagesEarthwork Operations & EquipmentsSavitha Pradeep0% (1)

- Foundation Design for Tall BuildingsDocument25 pagesFoundation Design for Tall BuildingsRajan Kc Pramod100% (1)

- List of Electronics Manufacturing Companies in Noida - ElectronicsmediaDocument2 pagesList of Electronics Manufacturing Companies in Noida - ElectronicsmediaBlue Oceon50% (4)

- DAR Vol 1Document1,107 pagesDAR Vol 1Ramachandra SahuNo ratings yet

- Construction and Quality Control For Concrete Structures by D.v.bhavanna RaoDocument150 pagesConstruction and Quality Control For Concrete Structures by D.v.bhavanna Raoapncrmptpqa100% (2)

- Flat Concrete Floor Work Method - FindotekDocument16 pagesFlat Concrete Floor Work Method - FindotekTAHER AMMARNo ratings yet

- Precast Construction: Prepared By: Parth S. Patel SD1510Document55 pagesPrecast Construction: Prepared By: Parth S. Patel SD1510Gireesh Gowda GiriNo ratings yet

- 4-1 - FormworkDocument55 pages4-1 - FormworkFahmi NazriNo ratings yet

- Road Constuction MethodDocument62 pagesRoad Constuction MethodPRADEEP100% (1)

- Productivity Rate AnalysisDocument6 pagesProductivity Rate AnalysismhdfhmNo ratings yet

- Seminar PPT On Slip ForworkDocument24 pagesSeminar PPT On Slip ForworkAkashViratM100% (2)

- 100% Fly Ash in ConcreteDocument19 pages100% Fly Ash in ConcreteVinay BabuNo ratings yet

- Rustomjee Realtors waterproofing rate analysisDocument4 pagesRustomjee Realtors waterproofing rate analysisAnis MushrifNo ratings yet

- Working of MivanDocument5 pagesWorking of MivanAnuja JadhavNo ratings yet

- Construction Quality Control & Odit ProposelDocument7 pagesConstruction Quality Control & Odit ProposelHamayet RaselNo ratings yet

- Steel Quantity by Thumb RuleDocument15 pagesSteel Quantity by Thumb RuleSheikh Nouman Mohsin RamziNo ratings yet

- MivanDocument101 pagesMivanDipak KaleNo ratings yet

- Katja Kruckeberg, Wolfgang Amann, Mike Green-Leadership and Personal Development - A Toolbox For The 21st Century Professional-Information Age Publishing (2011)Document383 pagesKatja Kruckeberg, Wolfgang Amann, Mike Green-Leadership and Personal Development - A Toolbox For The 21st Century Professional-Information Age Publishing (2011)MariaIoanaTelecan100% (1)

- Slip Form ConstructionDocument10 pagesSlip Form ConstructionAkshay JangidNo ratings yet

- PPSC Test Questions For Irrigation Department - Civil Engineers PKDocument5 pagesPPSC Test Questions For Irrigation Department - Civil Engineers PKAli naveedNo ratings yet

- Field Density FDT FormDocument3 pagesField Density FDT FormPedjaNo ratings yet

- Lecture 1 Concrete TechnologyDocument24 pagesLecture 1 Concrete TechnologyadamNo ratings yet

- Detailed Estimate of Stree Shakti BhavanDocument9 pagesDetailed Estimate of Stree Shakti BhavanObuladas MNo ratings yet

- AAC Block Cost ComparisonDocument5 pagesAAC Block Cost ComparisonVikas Singh100% (1)

- Methodology For Laying of Kerb Concrete: - 1 - VKLR - QmeDocument5 pagesMethodology For Laying of Kerb Concrete: - 1 - VKLR - QmevaideehNo ratings yet

- Concrete Overlay Options for Pavement RehabilitationDocument69 pagesConcrete Overlay Options for Pavement RehabilitationSunil BoseNo ratings yet

- Construction MethodolgyDocument2 pagesConstruction MethodolgystarscrawlNo ratings yet

- Methodology ConstructionDocument35 pagesMethodology ConstructionAnurag KumarNo ratings yet

- Basics of post-installed rebar connectionsDocument33 pagesBasics of post-installed rebar connectionsHaitham KayyaliNo ratings yet

- Utilizing Shotcrete and Gunite For Infrastructure RehabilitationDocument30 pagesUtilizing Shotcrete and Gunite For Infrastructure RehabilitationMurali CkNo ratings yet

- Concrete in High-Rise BuildingsDocument6 pagesConcrete in High-Rise BuildingsxeryhoneyNo ratings yet

- Ready Mix Concrete EssentialsDocument3 pagesReady Mix Concrete EssentialsYoga Raj0% (1)

- Adamson University explores rigid pavementsDocument16 pagesAdamson University explores rigid pavementsJohnrick LasquetyNo ratings yet

- Quality FormetDocument20 pagesQuality FormetVishal TiwariNo ratings yet

- Marble Chips in ConcreteDocument6 pagesMarble Chips in ConcreteMidhun JosephNo ratings yet

- Gfa HandbookDocument132 pagesGfa HandbookLim Lion YeeNo ratings yet

- MAINI Aluminium Formwork SystemDocument1 pageMAINI Aluminium Formwork SystemVanshaj MainiNo ratings yet

- Schedule of Rates BarisalDocument138 pagesSchedule of Rates Barisal00152100% (3)

- 275 MTR Chimney ScheduleDocument3 pages275 MTR Chimney Scheduleharpreetresearch0% (1)

- Gantt chart for ground and first floor finishing worksDocument10 pagesGantt chart for ground and first floor finishing worksIbrahim AliNo ratings yet

- Chemical Water Proofing Rate Ana As Per SunandaDocument5 pagesChemical Water Proofing Rate Ana As Per SunandaVinodPotphodeNo ratings yet

- Material Supplier or Certifier Type/Gradation Astm Date S.G. Quantity %Document1 pageMaterial Supplier or Certifier Type/Gradation Astm Date S.G. Quantity %Waqas SadiqNo ratings yet

- Specifications: FoundationDocument6 pagesSpecifications: FoundationRichu PaliNo ratings yet

- Final Year Project Chapter 2Document7 pagesFinal Year Project Chapter 2MohamadMuqhrisNo ratings yet

- Hollow Blocks Trial Mix Design.S1, S2, S3, S4, S5,&S6-FINAL REPEATDocument8 pagesHollow Blocks Trial Mix Design.S1, S2, S3, S4, S5,&S6-FINAL REPEATGaneshNo ratings yet

- Fresh ConcreteDocument28 pagesFresh ConcreteAmar WadoodNo ratings yet

- 04-Filling Foundation Concrete Work PlumDocument4 pages04-Filling Foundation Concrete Work PlumBijay Krishna DasNo ratings yet

- Building Vertical Steel Tank FoundationsDocument12 pagesBuilding Vertical Steel Tank Foundationskaushik arunexcelloNo ratings yet

- Pipe Jacking & Microtunnelling GuideDocument48 pagesPipe Jacking & Microtunnelling GuideHizbar ArsjadNo ratings yet

- 6B Day in Life Segmental Precast Yard P MontermerloDocument48 pages6B Day in Life Segmental Precast Yard P MontermerloSuresh DevarajanNo ratings yet

- Acotec Walls BrochureDocument4 pagesAcotec Walls BrochuretharazainNo ratings yet

- Construction EquipmentDocument8 pagesConstruction EquipmentElenduJuniorOgbonnaNo ratings yet

- Civil Engineering EstimationDocument6 pagesCivil Engineering EstimationcivilsadiqNo ratings yet

- Quantity Survey Methods in Buildings: by V.R.K.MurtyDocument101 pagesQuantity Survey Methods in Buildings: by V.R.K.MurtyRatnesh PatelNo ratings yet

- Feasibility of ProjectDocument5 pagesFeasibility of ProjectzaraNo ratings yet

- High-Rise TowersDocument12 pagesHigh-Rise TowersRicardo AzocarNo ratings yet

- Mix Design and Fresh Properties For HPPC (A Relire)Document25 pagesMix Design and Fresh Properties For HPPC (A Relire)Mounia Ait Ben HamouNo ratings yet

- Artifician Ice Skating RinksDocument2 pagesArtifician Ice Skating RinksVinay BabuNo ratings yet

- Chloride Content Limits Recommended by ACI CommitteeDocument4 pagesChloride Content Limits Recommended by ACI CommitteeJiravit PeungnoiNo ratings yet

- Equations For Mix Design of Structural Lightweight ConcreteDocument10 pagesEquations For Mix Design of Structural Lightweight ConcreteNicola TomasiNo ratings yet

- Concrete Technology Workshop 2010 Lecture 1a - MaterialsDocument6 pagesConcrete Technology Workshop 2010 Lecture 1a - MaterialsJohn ChandaNo ratings yet

- A Critique of The ACI 318 Chloride LimitDocument4 pagesA Critique of The ACI 318 Chloride LimitVinay BabuNo ratings yet

- Concrete Durability in A Marine EnvironmentDocument17 pagesConcrete Durability in A Marine EnvironmentAnonymous mcHqIfbnV1No ratings yet

- Evaluation of Concrete Mix Designs To Mitigate Early-AgeDocument158 pagesEvaluation of Concrete Mix Designs To Mitigate Early-AgeVinay BabuNo ratings yet

- 1408Document6 pages1408Andi CxfriendsNo ratings yet

- Plastic ViscosityDocument13 pagesPlastic ViscosityVinay BabuNo ratings yet

- Creep & Stress RK DHIRDocument9 pagesCreep & Stress RK DHIRVinay BabuNo ratings yet

- Evaluation of Self-Curing Admixture in Fly Ash ConcreteDocument10 pagesEvaluation of Self-Curing Admixture in Fly Ash ConcreteVinay BabuNo ratings yet

- Maturity Calculation - in SituDocument14 pagesMaturity Calculation - in SituVinay BabuNo ratings yet

- Various Test On WorkabilityDocument93 pagesVarious Test On WorkabilityParul SinghNo ratings yet

- Chloride Pen It Ration of ConcreteDocument33 pagesChloride Pen It Ration of ConcreteSamitha JayawardaneNo ratings yet

- Measuring Workability and Rheology of Fresh ConcreteDocument23 pagesMeasuring Workability and Rheology of Fresh ConcreteVinay BabuNo ratings yet

- Degree of Hydration and Gel Space Ratio of High Vol Fly Ash Cement SystemsDocument10 pagesDegree of Hydration and Gel Space Ratio of High Vol Fly Ash Cement SystemsVinay BabuNo ratings yet

- Admixture EffectDocument2 pagesAdmixture EffectVinay BabuNo ratings yet

- Low rank tensor product smooths for GAMMsDocument24 pagesLow rank tensor product smooths for GAMMsDiego SotoNo ratings yet

- A Study To Assess The Effectiveness of PDocument9 pagesA Study To Assess The Effectiveness of PKamal JindalNo ratings yet

- Toaz - Info Interchange 2 Quiz Units 5 Ampamp 6 Revision Del Intento PRDocument5 pagesToaz - Info Interchange 2 Quiz Units 5 Ampamp 6 Revision Del Intento PRMarco Antonio Gonzalez CastilloNo ratings yet

- Sist-En-6101-2016 .Document9 pagesSist-En-6101-2016 .lokelooksNo ratings yet

- Gmail LogoDocument12 pagesGmail Logovinodram993480No ratings yet

- Caring Seedlings TLE Weekly PlanDocument3 pagesCaring Seedlings TLE Weekly PlanMarjorie RaymundoNo ratings yet

- Physics Semiconductor Device MCQDocument3 pagesPhysics Semiconductor Device MCQAsim Ali0% (1)

- Instruction Manual Series 854 XTG Level GaugeDocument60 pagesInstruction Manual Series 854 XTG Level GaugeJandri JacobNo ratings yet

- 5e Lesson Plan s16 - MagnetsDocument6 pages5e Lesson Plan s16 - Magnetsapi-317126609No ratings yet

- BS (English) Dept of English University of SargodhaDocument36 pagesBS (English) Dept of English University of SargodhaFEROZ KHANNo ratings yet

- Basf Masteremaco Application GuideDocument15 pagesBasf Masteremaco Application GuideSolomon AhimbisibweNo ratings yet

- List of SDAsDocument4 pagesList of SDAsAthouba SagolsemNo ratings yet

- Strategic Investment Plan ForDocument78 pagesStrategic Investment Plan Forapi-3833112No ratings yet

- NCP 1014Document24 pagesNCP 1014rodricaldasNo ratings yet

- Module II Lecture 4Document19 pagesModule II Lecture 4Prateek NayakNo ratings yet

- Handy 2010 Case StudyDocument6 pagesHandy 2010 Case Studycancer6No ratings yet

- Section 3.4 The Conditional and Related StatementsDocument11 pagesSection 3.4 The Conditional and Related Statementsmister sparklesNo ratings yet

- CanReg5 InstructionsDocument150 pagesCanReg5 InstructionsdiyafersanNo ratings yet

- Chapter 1 Optical Fiber Transmission Media PDFDocument46 pagesChapter 1 Optical Fiber Transmission Media PDFGilang AnandaNo ratings yet

- 13 Nilufer-CaliskanDocument7 pages13 Nilufer-Caliskanab theproNo ratings yet

- Optimization Module For Abaqus/CAE Based On Genetic AlgorithmDocument1 pageOptimization Module For Abaqus/CAE Based On Genetic AlgorithmSIMULIACorpNo ratings yet

- Innovations in Drill Stem Safety Valve TechnologyDocument22 pagesInnovations in Drill Stem Safety Valve Technologymiguel mendoza0% (1)

- Lesson Plan 2 Sine Rule and Cosine RuleDocument8 pagesLesson Plan 2 Sine Rule and Cosine Ruleapi-280114661No ratings yet

- The Chair As Health Hazard Part II J of PDFDocument11 pagesThe Chair As Health Hazard Part II J of PDFPablo BuniakNo ratings yet