Professional Documents

Culture Documents

Technical Specifications of HDPE Pipes As Per Indian Standards Institute

Uploaded by

Zacharia JohnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Specifications of HDPE Pipes As Per Indian Standards Institute

Uploaded by

Zacharia JohnCopyright:

Available Formats

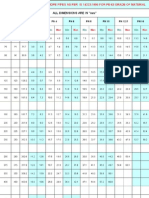

Technical Specifications of HDPE PIPES, IS:4984 & IS:14333

Test Results 1 Raw Material & Test Results 1 Density Melt Flow 2 Rate (MFI) 2 Visual Appearance a) Surface finish Satisfactory. IS:4984:1995 The internal & external surface of the IS:14333:1996 pipes are smooth and free from grooving & other defects. As per relevant BIS Standards IS:4984:1995 IS:14333:1996 0.940 to 0.958 G/CC 0.2 to 1.1 Mins. IS:4984:1995 IS:14333:1996 Acceptance Norms Reference

a. b. c. d. e.

Dimensions & Tolerances Outside Diameter Wall Thickness, of Pipe Ovality Length: Pipe/Coil

3 Performance Requirement a. Heat Reversion b. Hydrostatic Pressure Resistance Test 3% (Max.) Longitudinal Reversion No failure or leakage during the specified period Acceptance Test: Duration 48 Hrs at 80 Cat specified stress value. Type Test: Duration 165 Hrs at 80 C at specified Stress value. 10 Mg/dm2 2.5 + 0.5% Satisfactory 940.0 to 958.0 KG/M3 0.2 to 1.1 Gms/ 10 Mins Color: Black. A pipe is marked in white color by hot embossed or by indelible ink/paint by screening as mentioned below at every mater or on the either end of pipes. Each Pipe has three equi-spaced longitudinal stripes in Blue color a) Manufacturer's Name b) Designation of Pipe c) Batch Number. IS:4984:1995 IS:14333:1996 IS:4984:1995 IS:14333:1996

c. Overall Migration Test d. Carbon Black Content e. Carbon Black Dispersion f. Density g. Melt Flow Rate

4 Identification Marking & Color

You might also like

- Jis g3456 Grade STPT 410 Pipes PDFDocument1 pageJis g3456 Grade STPT 410 Pipes PDFMitul MehtaNo ratings yet

- Asme Sec X 2017Document3 pagesAsme Sec X 2017SARSAN NDTNo ratings yet

- Astm A529 1972Document5 pagesAstm A529 1972dharlanuctcom0% (1)

- E1 Technical Data Sheet - ShortDocument2 pagesE1 Technical Data Sheet - ShortOmaiyio M. SaginiNo ratings yet

- Comparing ASME Code Fatigue Evaluation Methods for Nuclear PipingDocument65 pagesComparing ASME Code Fatigue Evaluation Methods for Nuclear PipingOtso Cronvall100% (1)

- Increase Allowable Stress CodeDocument9 pagesIncrease Allowable Stress Codewenny_tpdNo ratings yet

- ANSI-B16.47 Ser B Blind and Welding Neck FlangesDocument7 pagesANSI-B16.47 Ser B Blind and Welding Neck FlangesRicelles Silveira MartinsNo ratings yet

- Pig ValvesDocument3 pagesPig ValvesteacgNo ratings yet

- Flange Leakage 6Document2 pagesFlange Leakage 6hamid sobirinNo ratings yet

- Rock Shield Material Data SheetDocument1 pageRock Shield Material Data SheetR.S.No ratings yet

- F1685 PDFDocument10 pagesF1685 PDFDaniel LodiNo ratings yet

- VKVC Launcher-Receiver PDFDocument3 pagesVKVC Launcher-Receiver PDFKRUNAL SHAHNo ratings yet

- Hydrogen Compressor Flange Bolts FailureDocument8 pagesHydrogen Compressor Flange Bolts FailurePablo ScottNo ratings yet

- Technical Bid Evaluation SheetDocument3 pagesTechnical Bid Evaluation SheetPer Bagus HandokoNo ratings yet

- Pig Handling EquipmentDocument2 pagesPig Handling Equipmentehsan_baheriNo ratings yet

- Bentley Autopipe v8 CrackDocument3 pagesBentley Autopipe v8 CrackAdi M. Mutawali100% (2)

- PEP Onshore PipelineDocument76 pagesPEP Onshore PipelineYudha MaulanaNo ratings yet

- Lesson 0.1 - Precalculus - Math MedicDocument2 pagesLesson 0.1 - Precalculus - Math Medicfeng yanNo ratings yet

- Tank Construction: Hydrotec Cs GuideDocument100 pagesTank Construction: Hydrotec Cs GuideEvert valencia sebastian100% (2)

- PIP-Vessel S and T Heat Exchanger Design Criteria ASME Code Section VIII, Div 1 and 2Document74 pagesPIP-Vessel S and T Heat Exchanger Design Criteria ASME Code Section VIII, Div 1 and 2rizaNo ratings yet

- FRP Repair of Corrosion-Damaged Concrete BeamsDocument13 pagesFRP Repair of Corrosion-Damaged Concrete BeamsahmadlieNo ratings yet

- API 5L-2007 Specification For Line PipeDocument153 pagesAPI 5L-2007 Specification For Line Pipetom787485100% (1)

- Hot Tapping Split Tee SpecificationDocument19 pagesHot Tapping Split Tee SpecificationAli ClubistNo ratings yet

- Diaphragm Elimination Using Taper-Lok - NPRADocument11 pagesDiaphragm Elimination Using Taper-Lok - NPRAN. S. PanditNo ratings yet

- Woc Hse Manual Standards: Woc LP EP DepartmentDocument12 pagesWoc Hse Manual Standards: Woc LP EP DepartmentAkram AlhaddadNo ratings yet

- Conpipe - CementlingDocument43 pagesConpipe - Cementlingויליאם סן מרמיגיוס50% (2)

- Coating or hydrotestingDocument4 pagesCoating or hydrotestinggigiphi1No ratings yet

- ASME B16 - Gasket Color CodeDocument2 pagesASME B16 - Gasket Color CodeGonçalo CortezNo ratings yet

- CN Scrubber Dn3500 Rev04Document58 pagesCN Scrubber Dn3500 Rev04becemNo ratings yet

- QCDC - Hydraulic and Manual Quick Connect/Disconnect Couplers For Marine Loading ArmsDocument2 pagesQCDC - Hydraulic and Manual Quick Connect/Disconnect Couplers For Marine Loading ArmsVasudev ShanmughanNo ratings yet

- Sootblower SpecsDocument4 pagesSootblower SpecsParthosarothy K MukherjiNo ratings yet

- Garlock Metal - Gaskets TorqueDocument48 pagesGarlock Metal - Gaskets TorqueakenathorNo ratings yet

- Book 2: Chapter 4 - Fluid Flow: Application LimitationsDocument20 pagesBook 2: Chapter 4 - Fluid Flow: Application LimitationsVaniya GoelNo ratings yet

- Pttep Painitng of Offshore FacilitiesDocument66 pagesPttep Painitng of Offshore FacilitiesSufianNo ratings yet

- (509869149) Leak DetectionDocument12 pages(509869149) Leak Detectionsathish_iyengarNo ratings yet

- Subsea Pipeline Design Engineering MethodologyDocument11 pagesSubsea Pipeline Design Engineering MethodologyKumarJR86100% (1)

- Theoretical External Collapsing Pressure For Pipelines (Method Is Not Per ASME.)Document1 pageTheoretical External Collapsing Pressure For Pipelines (Method Is Not Per ASME.)NakkolopNo ratings yet

- Car Washer CatalogueDocument24 pagesCar Washer Cataloguesra electricalsNo ratings yet

- Oil and Gas Offshore Pipeline Leak Detection System: A Feasibility StudyDocument8 pagesOil and Gas Offshore Pipeline Leak Detection System: A Feasibility StudycbqucbquNo ratings yet

- Assembly Instructions For Taper JointsDocument12 pagesAssembly Instructions For Taper JointsmohdNo ratings yet

- TBE-Pressure Vessel Standard TemplateDocument4 pagesTBE-Pressure Vessel Standard TemplateSiva baalanNo ratings yet

- Asme b31. 8 Latest EditionDocument2 pagesAsme b31. 8 Latest EditionAhsan AliNo ratings yet

- Lesson Learnt From SNC On Stress AnalysisDocument3 pagesLesson Learnt From SNC On Stress AnalysiszahoorNo ratings yet

- Bolt Tightening Procedure GuideDocument6 pagesBolt Tightening Procedure Guideal arabiNo ratings yet

- Compipe BrochureDocument48 pagesCompipe Brochureninju1No ratings yet

- API 17K Production Hoses PDFDocument4 pagesAPI 17K Production Hoses PDFShayan Hasan KhanNo ratings yet

- Title: WQ 482 Welding Procedure Specification (WPS) : SupersedesDocument1 pageTitle: WQ 482 Welding Procedure Specification (WPS) : SupersedesdethamrnNo ratings yet

- D 5448 - D 5448M - 93 Rdu0ndgtotmDocument12 pagesD 5448 - D 5448M - 93 Rdu0ndgtotmJuanNo ratings yet

- Storage and HandlingDocument6 pagesStorage and HandlingalagurmNo ratings yet

- Gasket Catalog - 3starDocument14 pagesGasket Catalog - 3startaufik singgih100% (1)

- 6 MFL Tool Spec Rev 3.5Document1 page6 MFL Tool Spec Rev 3.5fadialkasrawiNo ratings yet

- QuillsDocument4 pagesQuillsajostosNo ratings yet

- Jacobs: Equipment Inspection Code: ADocument2 pagesJacobs: Equipment Inspection Code: ASigit BintanNo ratings yet

- Vendor data for diesel generator safety testsDocument2 pagesVendor data for diesel generator safety testsSEPIRTUSNo ratings yet

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionFrom EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionNo ratings yet

- Fatigue Design Procedures: Proceedings of the 4th Symposium of the International Committee on Aeronautical Fatigue held in Munich, 16–18 June 1965From EverandFatigue Design Procedures: Proceedings of the 4th Symposium of the International Committee on Aeronautical Fatigue held in Munich, 16–18 June 1965E. GassnerNo ratings yet

- Thickness Chart For HDPE PipesDocument1 pageThickness Chart For HDPE PipesZacharia JohnNo ratings yet

- Welding Techniques For HDPE PipesDocument1 pageWelding Techniques For HDPE PipesZacharia JohnNo ratings yet

- A Quick Microsoft Access 2007 TutorialDocument44 pagesA Quick Microsoft Access 2007 Tutorialnarinder_sagarNo ratings yet

- Swagelok CatalogueDocument16 pagesSwagelok CatalogueZacharia JohnNo ratings yet

- FEED Screen Whitepaper PlantDocument10 pagesFEED Screen Whitepaper PlantazamshafiqNo ratings yet