Professional Documents

Culture Documents

1747-L40C PLC To PC Communication Manual

Uploaded by

rapozaazulOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1747-L40C PLC To PC Communication Manual

Uploaded by

rapozaazulCopyright:

Available Formats

239-9986

Data Sheet

Data Pack D Issued March 1997

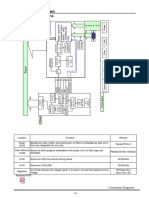

Allen-Bradley SLC 500

programmable logic controllers

The RS Allen-Bradley SLC 500 product

line

The SLC 500 family of small logic controllers surpass simple

machine control. A powerful instruction set, advanced

programming tools, and expanded product capabilities give

you all of the right reasons to apply the SLC 500 solution to

your next control application.

The SLC 500 product line is a growing family of small

programmable controllers built around two hardware

options; a fixed controller with an option to expand using a 2-

slot chassis, or a modular I/O controller. The programming

tools and most I/O modules are compatible between the two

hardware options, so you can cost effectively solve a broad

range of applications.

The SLC 500 product line offers a variety of discrete I/O

modules that enable you to cost-effectively configure your

control system. All of the discrete I/O modules are UL and

CSA certified for industrial applications and the majority are

approved for Class I, Division 2 hazardous environments.

Section index

1. When to choose fixed vs modular?

2. System overview

3. Performance specification comparison of fixed

and modular systems

4. Overview

4.1 System configuration

4.2 Programming

5. System selection guide

5.1 Configuring a fixed system

5.1.1 Tabular method

5.1.2 Charting method

5.2 Configuring a modular system

6. Typical SLC system

7. Technical specifications

7.1 Processors

7.2 Power supply modules

7.3 Input modules

7.4 Output modules

7.5 Specialty modules

7.5.1 Analogue modules

7.5.2 High-speed counter module

7.5.3 DH-485/RS-232C interface module

7.6 Programmers and operator interface

7.6.1 APS

7.6.2 HHT

7.6.3 DTAM

7.7 Chassis and cables

7.7.1 Chassis

7.7.2 Cable

7.8 Memory modules and accessories

7.8.1 Memory modules for fixed SLC 5/01 and

SLC 5/02

7.8.2 Card slot filler

7.8.3 Battery

8. SLC application examples

8.1 Application: High-speed position sensing

8.2 Application: Remote dial-up of an SLC

8.3 Application: PID temperature control

9. General installation requirements

9.1 Loading and installation

9.1.1 Considerations for safety

9.1.2 Considerations for power

9.2 Installation environment

9.3 Calculation of heat

9.4 Mounting instructions

9.4.1 Mounting the fixed style

9.4.2 Mounting the modular style

9.5 Wiring instructions

9.5.1 Wiring of power supply

9.5.2 Wiring of I/O equipment

9.5.3 Grounding

10. Dimensions

10.1 Fixed controller

10.2 Expansion chassis

10.3 Modular controller (with power supply)

11. Programming

11.1 Basics

11.2 Ladder logic representation

11.3 SLC memory organisation

12. Programming instructions

12.1 Bit instructions

12.2 Comparison instructions

12.3 Timer and counter instructions

12.4 Communication instructions

12.5 I/O and interrupt instructions

12.6 File copy and file fill instructions

12.7 Math instructions

12.8 Proportional integral derivative instructions

12.9 Move and logical instructions

12.10 Bit shift, FIFO and LIFO instructions

12.11Sequencer instructions

12.12Control instructions

12.13ASCII instructions (applies to SLC 5/03

OS301 processors only)

13. List of instructions

SLC, SLC 500, SLC 5/01, SLC 5/02, SLC 5/03 and DTAM

are trademarks of Allen-Bradley Company, Inc.

1. When to choose fixed vs modular?

There are two hardware styles to choose from - the fixed

hardware style and the modular hardware style.

Fixed hardware style

The SLC 500 fixed style includes a processor with 1K

instruction capacity, a power supply and a fixed number of

I/O in one complete package. The 20, 30, and 40 I/O

versions accept a 2-slot expansion chassis. All fixed I/O units

are panel mountable. The fixed hardware style is

expandable to 72 I/O points.

Modular Hardware Style

For applications requiring more flexibility, the modular style

offers a wide variety of I/O options. Modular style chassis

are available in 4, 7, and 10-slot versions. The chassis can be

connected together to form a system of up to 30 slots.

Choose from 3 power supplies, 3 processors, and a dozen

I/O cards to tailor a system exactly for the application. The

modular hardware style is expandable to 480 I/O points.

SLC 5/ 01

Modular I/O systems that include an SLC 5/01 processor can

be configured with a maximum of three chassis (30 total

slots) from 4 I/O points to a maximum of 256 I/O points. Two

SLC 5/01 processors (CPUs) are available for the modular

I/O system.

B 1K instruction capacity version with capacitor-backed

RAM memory. An optional battery can be used to retain

RAM memory contents for a longer period of time when

power is removed from the processor.

B 4K instruction capacity version with battery-backed

RAM as standard.

Optional EEPROM and UVPROM memory modules are

available for use with the 5/01 processor.

SLC 5/ 02

The SLC 5/02 processor provides enhanced

communications, faster scan times, advanced instructions,

and extensive diagnostics that allow it to work in more

complex applications. It has 4K instruction capacity, with

battery-backed RAM included. Modular I/O systems, which

include an SLC 5/02 processor, can be configured with a

maximum of 3 chassis (30 total slots) from 4 I/O points to a

maximum of 480 I/O points. Optional EEPROM and UVPROM

memory modules are available for use with the SLC 5/02

processor.

239-9986

2

SLC 5/ 03

The SLC 5/03 processor introduces 32-bit technology. It has

a 3-position key switch on the front panel of the module that

allows you to select the mode of operation. It also provides

built-in RS-232 and DH-485 communications for SCADA and

direct programming as well as on-line program editing and

improved system throughput. The SLC 5/03 has battery-

backed RAM included and accommodates real-time

applications. The SLC 5/03 has 12K instruction capacity.

SLC 5/ 04

The SLC 5/04 processors incorporate all of the functionality

of the SLC 5/03 processor and add increased

communications capabilities, more memory, and faster

throughput. The standard DH-485 port has been placed with

a DH+ port, providing high-speed SLC 5/04-to-SLC 5/04

communications and direct connection to PLC-5

S. The

available memory options are 12K, 28K, or 60K user

instructions, all with 4K additional data words.

Modular I/O systems that include an SLC 5/03 or SLC 5/04

processor can be configured with a maximum of three

chassis (30 total slots) from 4 I/O points to a maximum of 960

local I/O points. I/O capacity is expandable via Remote I/O

and DeviceNet.

An optional memory module is available for use with SLC

5/03 or SLC 5/04 processor. It provides UVPROM and

EEPROM functionality.

SLC 500 I/O modules are available with 4, 8, 16, or 32 points.

Combination modules with 2 inputs / 2 outputs, 4 inputs / 4

outputs, and 6 inputs / 6 outputs are also available.

A wide variety of I/O voltages (including ac, dc, and TTL),

analog I/O and speciality modules are available to help you

create a close fit for your application.

Output Terminals

Input Terminals

Power Supply

Processor (CPU)

slot 0

SLC 500 Fixed Controller

Power Supply

Processor

Input Modules

Output Module

slot 0 1 2 3

SLC 500 Modular Controller

239-9986

3

2. System overview

Product RS stock no. Allen-Bradley no. Description and features

817-886 1747-L20C 20 I/O Fixed Hardware Style (12) dc sink in w/HSC &

(8) relay out, ac line power

817-892 1747-L30C 30 I/O Fixed Hardware Style (18) dc sink in w/HSC &

(12) relay out, ac line power

817-909 1747-L40C 40 I/O Fixed Hardware Style (24) dc sink in w/HSC &

(16) relay out, ac line power

Processor 817-634 1747-L511 SLC 5/ 01Central Processor Unit (processor)

Program memory - 1K instructions

817-640 1747-L514 SLC 5/ 01Central Processor Unit (processor)

Program memory - 4K instructions

817-656 1747-L524 SLC 5/ 02Central Processor Unit (processor)

Program memory - 4K instructions

157-5173 1747-L532 SLC 5/03 Central Processor Unit (processor)

Program memory - 12K words

216-2469 1747-L541 SLC 5/04 Central Processor Unit (processor)

Program memory - 12K words

817-690 1746-P1 Power Supply chassis mount (120/240Vac 2 Amps with

user power)

Power 817-707 1746-P2 Power Supply chassis mount (120/240Vac 5 Amps with

supply user power)

817-713 1746-P3 Power Supply chassis mount (240Vdc 3.6 Amps with

user power)

817-741 1746-IA16 ac Input Module (16) inputs 100/120Vac

Input

817-729 1746-IB16 dc Input Module (16) inputs sink 24Vdc

module

817-735 1746-IV16 dc Input Module (16) inputs source 24Vdc

157-5230 1746-IB32 dc Input Module (32) inputs sink 24Vdc

817-763 1746-OA16 ac Output Module (16) triac 120/240Vac

Output

817-757 1746-OB16 dc Output Module (16) transistor source 10-50Vdc

module

817-779 1746-OW16 Relay Output Module (16) outputs 10-250 Vac/10-125Vdc

157-5202 1746-OX8 Relay Output Module (8) outputs 5-265Vac/5-125Vac

216-2447 1746-OB32 dc Output Module (32) transistor source 10-50Vdc

817-785 1746-NI4 (4) Analogue Inputs, each selectable to accept either

current or voltage

Analogue

817-791 1746-NO4I Analogue Module (4) current outputs, 020mA

module 817-808 1746-NO4V Analogue Module (4) voltage outputs 10Vdc to + 10Vac

157-5218 1746-NIO4I (2) Analogue Inputs, each selectable to accept either

current or voltage

(2) current outputs - 020mA

216-2453 1746-NIO4V (2) High Resolution Analogue Inputs, each selectable to accept

either current or voltage

(2) Analogue Voltage outputs

216-2532 1746-NT4 Thermocouple/mV input module

216-2548 1746-NR4 RTD/Resistance input module

817-814 1746-HSCE High-Speed Counter Encoder Module

Specialty

817-820 1747-KE DH-485/RS-232C Interface Module

module

817-937 1747-PIC Converter RS-232/DH-485

239-9986

4

Product RS stock no. Allen-Bradley no. Description and features

817-921 1747-PA2E Advanced Programming Software English

- 1747-PA2F Advanced Programming Software French

- 1747-PA2G Advanced Programming Software German

- 1747-PA2I Advanced Programming Software Italian

Program-

- 1747-PA2J Advanced Programming Software Japanese

ming

817-959 1747-PTA1E Memory Pak English

software

- 1747-PTA1F Memory Pak French

- 1747-PTA1G Memory Pak German

- 1747-PTA1I Memory Pak Italian

Hand-Held Terminal

817-943 1747-PT1 Note: Does not include battery or Memory Pak. (A

Memory Pak must be ordered with each Hand-Held

Terminal.)

Operator 817-836 1747-DTAM-E Data Table Access Module with English Users

interface Manual

817-965 1746-A4 4-slot Chassis Modular Hardware Style

817-662 1746-A7 7-slot Chassis Modular Hardware Style

Chassis

817-678 1746-A10 10-slot Chassis Modular Hardware Style

216-2431 1746-A13 13 slot Chassis Modular Hardware Style

817-915 1746-A2 2-slot Expansion Chassis for Fixed Hardware Style

817-684 1746-C9 36-inch Chassis Interconnect Cable

Cable 157-5195 1747-CP3 SLC 5/03 RS-232 Program Cable

216-2510 1784-CP13 Programming cable I784-KTX to SLC 5/04

Memory

817-842 1747-M1 EEPROM with 1K User Instructions (SLC 5/01 & 5/02)

module

817-858 1747-M2 EEPROM with 4K User Instructions (SLC 5/01 & 5/02)

216-2481 1747-M11 EEPROM with 20K Words (SLC 5/03 & 5/04)

817-864 1746-N2 Modular Card Slot Fillers Orders must be for

two fillers or multiples of two.

Accessory

817-870 1747-BA Battery (For RAM memory retention)

157-5189 1747-AIC Isolated Link Coupler for DH-485 Connection

- D1746-6.4 Analogue User's Manual

- D1746-6.5 High-Speed Counter Encoder Users Manual

- D1747-ND013 DTAM Users Manual

- D1747-NI001 Fixed Hardware Style Installation and Operation

Manual

845-948 D1747-6.2 Modular Hardware Style Installation and Operation

Manual

845-932 D1747-6.3 APS Getting Started Guide

- 9399-APSUM APS User Manual

- 9339-APSIE APS Import/Export Users Manual

- D1747-NM009 HHT Getting Started Guide

- D1747-NP002 HHT User Manual

845-926 D1747-6.15 APS Reference Manual

- D1747-6.12 DH-485/RS-232C Module Manual (for 1747-KE)

Manual

(shipped

with product

and

available

separately)

239-9986

5

3. Performance specification comparison

of fixed and modular systems

The following table describes the general specifications for

the SLC fixed, SLC 5/01 and the SLC 5/02 processors.

' Fixed style and the 1K version SLC 5/01 only The

capacitor back-up is rated at 35C (95F).

^ Lithium battery is optional for the fixed style and the 1K

version SLC 5/01; standard for the 4K version SLC 5/01.

The scan times are typical for a 1K ladder logic program

consisting of simple ladder logic and communication

servicing. Actual scan times depend on your program

size, instructions used, and communication to the

programming device.

* The SLC 5/03 and 5/04 flash EPROM memory module

cannot be erased with UV light. It must be

reprogrammed or erased with a Prom Programmer

using the Memory Module Adaptor.

Specification Fixed SLC 5/ 01 SLC 5/ 02 SLC 5/ 03 SLC 5/ 04

Program memory 1K instructions 1K or 4K instructions 4K instructions 12K words 12K words

Additional data storage 0 0 0 up to 4K words up to 4K words

I/O capacity 72 Discrete 256 Discrete 480 Discrete 960 Discrete 960 Discrete

Max. chassis/ I/O slots 2-slot chassis 3 chassis, 30 slots 3 chassis, 30 slots 3 chassis, 30 slots 3 chassis, 30 slots

Standard RAM Capacitor -2 weeks Capacitor -2 weeks

'

Lithium Battery - Lithium Battery - Lithium Battery -

Lithium Battery Lithium Battery 2 years 2 years 2 years

-5 years

^

-2 years

^

Memory back-up EEPROM or UVPROM EEPROM or UVPROM EEPROM or UVPROM EEPROM or UVPROM EEPROM or UVPROM

options

LED indicators RUN, CPU FAULT, RUN, FAULT, RUN, FAULT, RUN, FAULT, RUN, FAULT,

FORCED I/O, FORCED I/O, FORCED I/O, FORCED I/O, FORCED I/O,

BATTERY LOW BATTERY LOW BATTERY LOW, COMM. BATTERY LOW, BATTERY LOW,

DH-485, RS-232 DH-485, RS-232

Programming APS or HHT APS or HHT APS or HHT APS APS

Processor instruction 52 52 71 71 71

set

Typical scan time

8 ms/K 8 ms/K 4.8 ms/K 1ms/K 0.9ms/K

Bit execution (XIC) 4 microseconds 4 microseconds 2.4 microseconds 0.4 microseconds 0.37ms

Certification UL listed/CSA UL listed/CSA UL listed/CSA UL listed/CSA UL listed/CSA

approved approved approved approved approved

Class 1, Groups A, B, Class 1, Groups A, B, Class 1, Groups A, B, Class 1, Groups A, B, Class 1, Groups A, B,

C or D, Division 2 C or D, Division 2 C or D, Division 2 C or D, Division 2 C or D, Division 2

CE marked for all CE marked for all CE marked for all CE marked for all CE marked for all

application application application application application

directives directives directives directives directives

4. Overview

4.1 System configuration

The basic fixed controller consists of a processor with 1,024

(1K) instruction capacity, a power supply, and a fixed

number of I/O contained in a single package.

The basic modular controller consists of a chassis, power

supply, processor module (CPU), Input/Output (I/O

modules), and an operator interface device for programming

and monitoring.

239-9986

6

Fixed Hardware Components

Fixed Controller with 2-slot Expansion Chassis

Fixed Hardware Controller

Input Module Output Module

Operator Interface

2-Slot Expansion Chassis

for I/O Modules

Power Supply

Processor

Module

Input Module Output Module Specialty

I/O Module

Operator Interface

Chassis

Modular Hardware Components

Modular Controller

239-9986

7

4.2 Programming

The SLC product line can be programmed using two

different methods, one by using the Hand-Held Terminal

(HHT) and the other using the Advanced Programming

Software (APS), which operates on an IBM-AT/XT or

compatible personal computer.

Both methods have extensive diagnostics, expanded ladder

editors, and are available in several languages. As a result,

either method can be used to configure the SLC processors,

enter or modify an application program, monitor the

execution of the application in real-time, or troubleshoot an

application program.

The HHT can be used to configure the SLC 500 Fixed, SLC

5/01 and SLC 5/02 processors. It accepts programs with a

maximum data table size of 6K. Each rung may contain up to

127 instructions.

APS, on the other hand, has a maximum data table size of 16K

and each rung can contain 128 instructions. It can be used to

configure all SLC 500 family processors.

The instructions include:

B Bit instructions

B Timer and counter instructions

B Math instructions

B Control instructions

B Comparison instructions

B Sequencer instructions

B Bit shift, FIFO, and LIFO instructions

B Move and logical instructions

B File instructions

B Special instructions for the SLC 5/02 and above only such

as PID (Proportional, Integral, Derivative).

5. System selection guide

5.1 Configuring a fixed system

You can use either of two methods to determine whether the

2-slot, fixed I/O expansion chassis will support a specific

combination of modules.

B Tabular method

B Charting method.

The table below represents combinations of modules and

indicates whether or not each combination is valid. The chart

that follows represents the region of operating current that

the fixed I/O expansion chassis supports.

5.1.1 Tabular method

Using the table below, locate both of the modules you plan to

use in the fixed I/O expansion chassis. Follow the top row

across until you find one of the modules. Then follow the

right column down until you find the other module. The

symbol shown in the table cell that marks their intersection

gives you information you must know before installing the

modules.

A dot indicates a valid combination.

No symbol indicates an invalid combination.

A triangle indicates an external 24Vdc power supply

may be required.

B

B B B B B B B + B B B B B B B B

B B + +

B B B B B + B B B B B B B B

B B B B + B B B B B B B B

+ +

B B + + B B B B B B

+ + B

+ + + + + + + + +

+ + + + + +

I

A

1

6

O

A

1

6

I

B

1

6

I

V

1

6

O

W

1

6

N

I

4

H

S

C

E

O

B

1

6

N

O

4

I

N

O

4

V

K

E

N

I

0

4

I

I

B

3

2

O

X

8

N

I

0

4

V

N

T

4

N

R

4

O

B

3

2

IA16

OA16

IB16

IV16

OW16

NI4

HSCE

OB16

NO4I

NO4V

KE

NI04I

IB32

OX8

NI04V

NT4

NR4

OB32

B B

+

B B B B B B

B B

B B B B B B

B B B

B B

B B

B

Y

Y

5.1.2 Charting method

The following chart depicts the range of current

combinations supported by the fixed I/O expansion chassis.

To use it, you must first determine the backplane current

draw and operating voltage for both of the modules you plan

to use in the chassis. You can get these specifications from

the table alongside the chart. Next, plot each of the currents

on the chart below. If the point of intersection falls within the

operating region, your combination is valid. If not, your

combination cannot be used in a 2-slot, fixed I/O chassis.

1. Add current draws of both modules.

2. Plot this point on the chart above.

3. Plot current draw.

4. Note the point of intersection.

Important: The NO4I and NO4V analogue output modules

may require an external power supply. Refer to

the analogue user manual.

5Vdc Amps 24Vdc Amps

1A16 0.085 -

OA16 0.370 -

IB16 0.085 -

IV16 0.085 -

OW16 0.170 0.180

N14 0.025 0.085

HS 0.300 -

OB16 0.280 -

NO41 0.055 0.195

NO4V 0.055 0.145

KE 0.150 0.040

NIO4I 0.055 0.145

IB32 0.104 -

OX8 0.085 0.090

OB32 0.452 -

NI04V 0.055 0.115

NR4 0.050 0.050

NT4 0.060 0.040

450

350

400

300

250

200

150

100

50

200 150 100 50

5 V dc

Current

(mA)

24 V dc Current (mA)

Valid Operating Region

239-9986

8

5.2 Configuring a modular system

1. Estimate the total amount of memory this system

requires:

a) Add up the number of discrete I/O points and place it

in (a).

b) Add up the number of analogue I/O points and place

it in (b).

c) Add up the number of specialty I/O modules and

place it in (c).

d) Multiply a, b, and c by the number indicated.

e) Total those numbers to give you a memory estimate.

2. Select a processor:

Place your choice into slot 0 of chassis 1 on the worksheet.

3. Select the I/O:

a) If multiple chassis system, make copies for each

chassis.

b) Write in the chassis number.

c) Write in the appropriate slot numbers.

d) Select your discrete I/O.

e) Select your specialty and analogue I/O.

f) Using the worksheet, list each I/O module in the slot

you desire.

g) List the power consumption of each module in the

esignated columns. Be sure to account for future

expansion.

h) When the chassis is complete, add up each power

consumption column.

4. Select the correct power supply:

a) Compare the Power Consumption totals with each

power supply.

b) Choose the smallest power supply that provides

sufficient power.

Note: The current shown is rated at 55C.

5. Select the chassis:

a) Add up the number of slots used.

b) Select the smallest chassis which can hold your I/O.

Be sure to account for future expansion.

6. Select the miscellaneous devices:

To complete your system, include devices such as:

cables, communication interfaces, operator interface

devices, and memory modules.

Required memory Required I/ O Processor

0 to 1K Less than 256 SLC 5/01

1K to 4K Less than 256 SLC 5/01

1K to 4K Greater than 256 SLC 5/02

Greater than 4K Greater than 256 SLC 5/03-5/04

239-9986

9

SLC 500 Chassis configuration worksheet

1. To estimate your memory requirements, count the number of discrete and analogue I/O points, plus the number of

specialty I/O.

a) discrete I/O points a) _____ 3 10 = ______ Instruction Words

b) analog input and output points b) _____ 3 25 = ______ Instruction Words

c) specialty I/O points c) _____ 3 100 = ______ Instruction Words

Estimated Total Memory Required ______ Instruction Words

2. Select the Processor

Catalogue Number 1747-L511 SLC 5/01 1K Instructions

Catalogue Number 1747-L514 SLC 5/01 4K Instructions

Catalogue Number 1747-L524 SLC 5/02 4K Instructions

Catalogue Number 1747-L532 SLC 5/03 12K Words

Catalogue Number I747-L541 SLC 5/04 12K Words

3. Select I/O

Chassis Number ___ Catalogue Number Power Consumption Price

5V 24V

Slot ______ ______ ____________ ______ (Slot 0 Reserved

Slot ______ ______ ____________ ______ or processor in

Slot ______ ______ ____________ ______ chassis)

Slot ______ ______ ____________ ______

Slot ______ ______ ____________ ______

Slot ______ ______ ____________ ______

Slot ______ ______ ____________ ______

Slot ______ ______ ____________ ______

Slot ______ ______ ____________ ______

Slot ______ ______ ____________ ______

Slot ______ ______ ____________ ______

Slot ______ ______ ____________ ______

Slot ______ ______ ____________ ______

Total Current ____________

4. Select the Power Supply (55C rating)

Catalogue Number 1746-P1 2A 46A ______

Catalogue Number 1746-P2 5A 96A ______

Catalogue Number 1746-P3 3.6A 87A ______

5. Select the Chassis

Catalogue Number 1746-A4 4 slots ______

Catalogue Number 1746-A7 7 slots ______

Catalogue Number 1746-A10 10 slots ______

Catalogue Number I746-A13 13 slots ______

6. Select Miscellaneous Devices

__________ ______

__________ ______

__________ ______

__________ ______

Total System Cost ______

' Includes power requirements for the DTAM, PIC, and the HHT.

Power Consumption (Amps)'

5Vdc 24Vdc

0.35 0.105

0.35 0.105

0.35 0.105

0.50 0.175

1.00 0.2

6. Typical SLC system

The figure below consists of some components that make up

a typical installation.

7. Technical specifications

7.1 Processors

The SLC 500 processor product line offers a fixed processor

and two types of chassis-based processors.

The SLC fixed controller is a pre-packaged system

consisting of a processor, power supply, network port, and

I/O points. The fixed controller offers you a comprehensive

ladder logic instruction set including math, compare, move,

and sequencing instructions.

The SLC 5/01 processor offers the instruction set of the SLC

500 fixed controller in a modular hardware configuration.

The SLC 5/01 processor provides:

B Two choices of program memory size 1K or 4K

instructions

B Optional battery back-up for the -L511; standard for the

-L514

B Addressing of up to 256 I/O

B Powerful ladder logic programming instruction set

B Subroutines.

B Built-in DH-485 communication channel (peer-to-peer

communication response to message commands only).

The SLC 5/02 processor expands beyond the SLC 5/01

processor capabilities by offering additional instructions and

increased diagnostics. The SLC 5/02 processor provides:

B Program memory size of 4K instructions

B Ability to handle 32-bit signed math functions

B Addressing of up to 480 I/O

B User fault routines

B Interrupt capability

B PID used to provide closed loop control

B Indexed addressing

B Built-in DH-485 communication channel (initiation of

peer-to-peer communication).

239-9986

10

Main features

B Supports I/O configurations of up to 3 chassis (30 slots)

of I/O. Provides you with the flexibility to expand I/O

capacity as required.

B Supports a variety of input and output modules.

B Provides user selectable program security. The wide

range of system protection capabilities allow you to

secure user data and program files from changes.

B Provides superior system throughput. SLC 500 modular

processors deliver fast overall system throughput times

in addition to fast program scan times.

B Supports user memory sizes from 1 to 12K. By offering

a wide range of user memory, SLC 500 modular

processors can be used in a realm of applications.

The SLC 5/03 processor significantly increases performance

by supplying system throughput times less than 1ms for a

typical 1K user program. Now applications such as high-

speed packaging, sorting, and material handling become

more affordable. With the addition of on-line editing, the SLC

5/03 processor presents a positive solution for your

continuous process application. The SLC 5/03 processor

provides:

B Program memory size of 12K, plus 4K additional data

space

B Addressing of up to 960 I/O

B On-line programming (includes runtime editing)

B Built-in RS-232 channel supporting:

- DFI Full-Duplex for remote or point-to-point

communication, or direct connection to IBM compatible

programming devices

- DFI-Half-Duplex Slave for remote communication to a

master device

- DH-485 (serves as a second DH-485 channel using a

1747-PLC or direct connection to IBM compatible

programming devices)

- ASCII for connection to other ASCII devices, such as

barcode readers, printers and weigh scales

B Built-in DH-485 channel

B Built-in real-time clock/calendar

B 1ms Selectable Timed Interrupt (STI)

B 0.50ms Discrete Input Interrupt (DII)

B Advanced math features - PID and floating point

IEC or NEMA rated enclosure suitable for your

application and

environment that shields your controller from electrical

Disconnect, to remove power from the system

Fused isolation transformer or a constant voltage

transformer, as your application requires

Master control relay/emergency-stop circuit

Terminal blocks or wiring ducts

Suppression devices for limiting EMI (electromagnetic

interference) generation

1

2

3

4

5

6

1

4

3

2

6

5

MCR

Disconnect

Isolation

Transformer

SLC 500 Controller

239-9986

11

B Flash PROM provides firmware upgrades without

physically changing EPROMs

B Keyswitch - RUN, REMote, PROGram (clear faults).

The SLC 5/04 processor provides the baseline funcionality of

the SLC 5/03 processor plus DH+ communication.

Communication via DH+ takes place three times faster than

DH-485 communication, providing you with increased

performance levels. In addition, the SLC 5/04 processor runs

approximately 15% faster than the SLC 5/03 processor,

yielding system thru-put times of 0.90ms for a typical 1K user

program.

The SLC 5/04 processor provides :

B program memory sizes of 12K, plus 4K additional data

space

B high-speed performance - 0.90ms/K typical

B control of up to 960 local I/O, expandable via Remote I/O

and DeviceNet

B online programming (includes runtime editing)

B built-in DH+ channel, supporting :

- high-speed SLC 5/04 to SLC 5/04 communication

- mesaging capability between PLCs

and SLCs

- monitoring capabilities to PLC-2

, PLC-3

,

PLC-5

and PLC-5/250 processors

B built-in RS-232 channel, supporting:

- DF1 Full-Duplex for remote or point-to-point

communication, or direct connection to IBM

compatible programming devices

- DF1 Half-Duplex Master/Slave for SCADA type

communication

- DH-485 (serves as a second DH-485 channel using

a 1747-PIC or direct connection to IBM compatible

programming devices)

- ASCII for connection to other ASCII devices, such

as bar code readers, printers and weigh scales

B passthru capability to panelView 550 and PanelView

900

B remote I/O passthru

B built-in real-time clock/calander

B 1ms Selectable Timed Interrupt (STI)

B 0.50ms Discrete Input Interrupt (DII)

B advanced math features - PID and floating point

B flash PROM provides firmware upgrades without

physically changing EPROMS

B keyswitch - RUN, REMote, PROGram (clear faults).

' Fixed style and the 1K version SLC 5/01 only the capacitor back-up is rated at 35C (95F).

^ Lithium battery is optional for the fixed style.

The scan times are typical for a 1K ladder logic program consisting of simple ladder logic and communication servicing.

Actual scan times depend on your program size, instructions used, and communication to the programming device.

Specification Fixed

Program memory 1K Instruction

Additional data storage 0

I/O capacity 72 Discrete

Max. chassis/ I/O slots 2-slot chassis

Standard RAM Capacitor2 weeks' Lithium Battery5 years^

Memory back-up options EEPROM or UVPROM

LED indicators RUN, CPU FAULT, FORCED I/O, BATTERY LOW

Programming APS or HHT

Typical scan time 8 ms/K

Processor instruction set 52

Bit execution (XIC) 4 microseconds

Packaged shipping weights 1747-L20 2.40 Kg (5 lb 6 ozs)

1747-L30 2.80 Kg (6 lb 4 ozs)

1747-L40 3.08 Kg (6 lb 14 ozs)

Noise immunity NEMA Standard ICS 2-230

Ambient temperature rating Operating: 0C to +60C (+32F to +140F)

Storage:40C to +85C (40F to +185F)

Humidity 5 to 95% without condensation

Vibration Displacement: .015 inch, peak-to-peak @ 5-57Hz

Acceleration: 2.5 Gs @ 57-2000Hz

Duration: 1hr per axis (x, y, z)

Certification UL listed, CSA approved

PC RUN

CPU FAULT

FORCED I/O

BATTERY LOW

POWER

' Fixed style and the 1K version SLC 5/01 only The capacitor back-up is rated at 35C (95F).

^ Lithium battery is optional for the fixed style and the 1K version SLC 5/01; standard for the 4K version SLC 5/01.

The scan times are typical for a 1K ladder logic program consisting of simple ladder logic and communication servicing.

Actual scan times depend on your program size, instructions used, and communication to the programming device.

* The SLC 5/03 & 5/04 flash EPROM memory module cannot be erased with UV light. It must be reprogrammed or erased

with a PROM programmer using the memory module adaptor.

239-9986

12

PC RUN

CPU FAULT

FORCED I/O

BATTERY LOW

SLC 5/01 CPU

RUN COMM

CPU FAULT

FORCED I/O

BATTERY LOW

SLC 5/02 CPU

RUN

FLT

BATT

SLC 5/03 CPU

OR OR

FORCE

DH485

RS232

RUN REM PROG

Slot 0

Specification SLC 5/ 01 SLC 5/ 02 SLC 5/ 03 SLC 5/ 04

Program memory 1K or 4K instructions 4K instructions 12K words 12K words

Additional data storage 0 0 Up to 4K words Up to 4K words

I/O capacity 256 Discrete 480 Discrete 960 Discrete 960 Discrete

Max. chassis/ I/O slots 3 chassis, 30 slots 3 chassis, 30 slots 3 chassis, 30 slots 3 chassis, 30 slots

Standard RAM Capacitor2 weeks' Lithium Battery2 years Lithium Battery - 2 years Lithium Battery - 2 years

Lithium Battery2 years^

Memory back-up options EEPROM or UVPROM EEPROM or UVPROM EEPROM or UVPROM* EEPROM or UVPROM*

LED indicators RUN, FAULT, FORCED I/O, RUN, FAULT, FORCED I/O, RUN, FAULT, FORCED I/O, RUN, FAULT, FORCED I/O,

BATTERY LOW BATTERY LOW, COMM. BATTERY LOW, DH-485, BATTERY LOW, DH-485,

RS-232 RS-232

Programming APS or HHT APS or HHT APS APS

Processor instruction set 52 71 71 71

Typical scan time 8 ms/K 4.8 ms/K 1 ms/K 1 ms/K

Bit execution (XIC) 4 microseconds 2.4 microseconds 0.4 microseconds 0.37 microseconds

Noise immunity NEMA Standard ICS 2-230

Ambient temperature rating Operating: 0C to +60C (+32F to +140F)

Storage: 40C to +85C (40F to +185F)

Humidity 5 to 95% without condensation

Vibration Displacement: .015 inch, peak-to-peak @ 557Hz

Acceleration: 2.5 Gs @ 57-2000Hz

Certification UL listed/CSA approved

Class 1, Groups A, B, C or D, Division 2

CE marked for all applicable directives

SLC 5/04 CPU

FORCE

DH+

RS232 BATT

FLT

RUN

RUN REM PR OG

OR

239-9986

13

Selecting chasis

The chassis houses the processor and I/O modules. The

power supply mounts on the left side of the chassis. All

components easily slide into the chassis along guides formed

in the chassis. No tools are required to insert or remove the

processor or I/O modules. A maximum of three chassis (30

I/O slots) may be connected in an SLC system.

There are four sizes of chassis that you can choose; 4-slot; 7-

slot; 10-slot and 13-slot.

Selecting modular processors

The processor always occupies the first slot of the first

chassis (slot 0). The SLC 5/01 processor is available with a

memory range of 1K or 4K of user instructions. The SLC

5/02 is available with 4K of user instructions. The SLC

5/03 processor is available with 12K of user instructions

and 4K of additional data words. The SLC 5/04 processor is

available with 20K of user instructions and 4K of additional

data words. These processors operate in an environment up

to +60C (+140F).

The 1K processor is supplied with a 2-week capacitor back-

up as standard and an optional 5-year battery back-up in the

event of power interuption. The 4K, 12K and 20K processors

are supplied with 2-year battery back-up as standard.

Optional memory modules are also available for the SLC

5/01, 5/02, 5/03 and 5/04 processors. For more details on

memory modules, see pages 1-12.

We designed the SLC 500 processors to operate in an

industrial environment, To keep the processor running as

reliably as possible, install all processors in a manner that

provides protection from various corrosive agents such as

dirt, grease, and falling debris, particularly electrically

conducting material.

7.2 Power supply modules

Allen-Bradley offers three different power supplies, two ac

and one 24Vdc. The ac supplies can be configured to

operate using 120 or 240Vac.

Features

B All power supplies have an LED that indicates proper

supply power.

B Supplies have a hold-up time (the time the system is

operational during a brief power loss) typically

between 20 milliseconds and 3 seconds.

B On ac power supplies, you can select either 120V or 240V

operation by setting a jumper.

B ac supplies have an external 24Vdc terminal that can be

used to power I/O devices.

100/120 Volts 200/240 Volts

Fuse

POWER

1746-P1 and -P2 1746-P3

Fuse

POWER

Specification 1746-P1 1746-P2 1746-P3

Line voltage 85-132/170-265Vac 85-132/170-265Vac 19.2-28.8Vdc

47/63Hz 47/63Hz

Typical line power 135VA 180VA 90VA

requirement

Backplane current 2.0A at 5Vdc 5.0A at 5Vdc 3.6A at 5Vdc

capacity (derated by 0.46A at 24Vdc 0.96A at 24Vdc 0.87A at 24Vdc

5% at +60C)

24Vdc user power 200mA 200mA NA

output current

Hold-up time 20 ms to 3000 ms 20 ms to 3000 ms 20 ms to 3000 ms

(load dependent)

Fuse protection 3.0A 3.0A 5.0A

Inrush current 20.0A (max.)

Temperature range 0 to +60C (+32 to + 140F)

Wiring Two #14 AWG wires per terminal (max.)

7.3 Input modules

The 1746 I/O platform is a modular hardware design that

uses a cost and space effective means to add I/O modules to

your control system. I/O modules can interface to ac and dc.

Features

B LEDs indicate the status of each I/O point. Assisting you in

troubleshooting, LEDs illuminate when the proper signal

is received at an input terminal, or when the processor

commands an output channel to turn on.

B Select I/O modules to exactly match your application.

B Expand the I/O capacity of your fixed controller system.

Two discrete I/O modules can be added to the fixed

controllers 2-slot expansion chassis increasing the

flexibility of the system.

B Digital and field circuits are isolated. All modules feature

optical isolation between digital and field circuits resulting

in increased noise immunity, and limited damage to your

system due to an electrical malfunction of the field

wiring.

B Self-lifting field-wire pressure plates cut installation time.

Wiring terminals have self-lifting pressure plates to

secure two #14 AWG field wires.

B Removable terminal blocks help ease the wiring task.

Removable terminal blocks allow you to replace the

module without rewiring it.

B Removable terminal blocks are colour coded for quick

identification. A matching colour band is also provided on

the front of the module to assist in matching the terminal

block to the module.

B Barrier type terminal blocks provided on all modules.

Each terminal block features a barrier on three sides of

each terminal to help prevent accidental shorting of field

wiring.

B Self-locking tabs secure the module in the chassis. No

tools are necessary to install or remove a module from the

chassis. To install a module, you slide it into the chassis

until it latches in place.

239-9986

14

Backplane

current Offstate

Voltage Operating No. of Points per Catalogue draw (A) Signal delay current

category voltage inputs common number 5V 24V (ms. max.) (max.)

100/120Vac 85-132 16 16 1746-IA16 0.085 0 on = 35 2mA

off = 45

10-30 sink 16 16 1746-IB16 0.085 0 on = 8 1mA

12/24Vdc

off = 8

10-30 source 16 16 1746-IV16 0.085 0 on = 8 1mA

off = 8

24Vdc 18-30 at 50C 32 8 1746-IB32 0.106 0 on = 3 1mA

18-26.4 at 60C off = 3

sink

Terminal Identification

Diagrams on Each Module

LEDs indicate the status

of each I/O point

INPUT

IN 0

IN 1

IN 2

IN 3

IN 4

IN 5

IN 6

IN 7

IN 8

IN 9

IN 10

IN 11

IN 12

IN 13

IN 14

IN 15

AC COM

AC COM

239-9986

15

7.4 Output modules

ac/dc relay, ac triac, and dc transistor output modules are

available.

Features

B LEDs indicate the status of each I/O point. Assisting you in

troubleshooting, LEDs illuminate when the proper signal

is received at an input terminal, or when the processor

commands an output channel to turn on.

B All relay contacts are Silver Cadmium with Gold overlay.

Cold plating resists oxidation and tarnishing resulting

from non-use. Silver Cadmium acts as an excellent

conductor.

B Select I/O modules to exactly match your application.

B Expand the I/O capacity of your fixed controller system.

Two discrete I/O modules can be added to the fixed

controllers 2-slot expansion chassis increasing the

flexibility of the system.

B Digital and field circuits are isolated. All modules feature

optical isolation between digital and field circuits

resulting in increased noise immunity, and limited

damage to your system due to an electrical

malfunction of the field wiring.

B Self-lifting field-wire pressure plates cut installation time.

Wiring terminals have self-lifting pressure plates to

secure two #14 AWG field wires.

B Removable terminal blocks help ease the wiring task.

Removable terminal blocks allow you to replace the

module without rewiring it.

B Removable terminal blocks are colour coded for quick

identification. A matching colour band is also provided on

the front of the module to assist in matching the terminal

block to the module.

B Barrier type terminal blocks provided on all modules.

Each terminal block features a barrier on three sides of

each terminal to help prevent accidental shorting of field

wiring.

B Self-locking tabs secure the module in the chassis. No

tools are necessary to install or remove a module from

the chassis. To install a module, you slide it into the

chassis until it latches in place.

Signal Surge

Backplane delay Continuous Continuous On-state current

Points current (max.) Off-state Load current per current per voltage per

Voltage No. of per draw (resistive leakage current point module drop point

category outputs common Catalogue 5V 24V load) (max.)

^ (min.) (max.)

(max.) (max.) (max.)

'

24Vdc 16 16 1746-OB16 0.280 0.0A on = 0.10ms 1mA 1mA 0.50A at 30C 8A at 30C 1.20V at 3.0A for

(operating A off = 1.0ms 0.25A at 60C 4A at 60C 0.50A 10ms

voltage

10-50Vdc)

120-240Vac 16 8 1746-OA16 0.370 0.0A on = 0.10ms 2mA 10mA 0.50A at 30C 8A at 30 C 1.50V at 10.0A

(operating A off = 11.0ms 0.25A at 60C 4A at 60 C 0.50A for

Voltage 25ms

85-265Vac)

ac/dc 16 8 1746-OW16 0.170 0.180 on = 10.0ms 0mA 10mA See the chart 16.0A ac Not See the

Relay A A off = 10.0ms that follows 8.0A applicable chart

(operating common that

voltage follows

5-265Vac

5-125Vdc)

ac/dc 8 Individually 1746-OX8 0.085 0.090 on = 10.0ms mA 1mA See the chart Must be Not See the

Relay isolated (removable A A off = 10.0ms that follows limited so applicable chart

(operating terminal the module that

voltage block) power does follows

5-265Vac not exceed

5-125Vdc) 1440Vac

24Vdc 32 16 1746-OB32 0.452 0.0A on = 0.1ms 1mA 1mA 0.1A at 60C 3.2A at 60C 1.2V at 1A for

(operating A off = 1ms 0.1A 10ms

voltage

5-50V dc)

Terminal Identification

Diagrams on Each Module

LEDs indicate the status

of each I/O point.

OUTPUT

IN 0

IN 1

IN 2

IN 3

IN 4

IN 5

IN 6

IN 7

IN 8

IN 9

IN 10

IN 11

IN 12

IN 13

IN 14

IN 15

AC COM

AC COM

' Frequency = 47 to 63Hz

^ Triac outputs turn on at any point in the ac line cycle and turn off at ac line zero cross. Recommended surge suppression

for triac outputs when switching 120Vac inductive loads is Harris MOV part number V220 MA2A or equivalent.

To limit the effects of leakage current through triac outputs, a loading resistor can be connected in parallel with your load.

For typical 120Vac applications, use a 15KW, 2 Watt resistor, for typical 240Vac applications, use a 15KW, 5 Watt resistor.

Repeatability is once every 1 second at 30C. Repeatability is once every 2 seconds at 60C.

~

7.5 Specialty modules

7.5.1 Analogue modules

The SLC 500 family offers these I/O analogue modules for

your control applications.

B NI4 input module

B NIO4I & NIO4V analogue I/O combination module

B NO4I output module

B NO4V output module

B NR4 RTD/resistance input module

B NT4 thermocouple/mV input module.

Features

B High resolution 16-bit input and 14-bit output converters

provide accurate control capabilities.

B Outputs are backplane powered no external power

supply required, reducing system cost.

B User selectable inputs that are configured per channel

for current or voltage inputs.

B Input channel filtering rejects high-frequency noise that

couples into an analogue input signal.

B Image maps directly into the SLC image, saving

memory usage and time.

Important: All analogue modules are isolated from each

other and from the backplane. If the NO4I or the

NO4V is externally powered, the 24Vdc

backplane current draw is 0mA.

239-9986

16

Specification

SLC communication format ________________ 16-bit twos

complement binary

Field wiring to backplane isolation ______________ 500Vdc

Conversion time ________ 512s for all channels in parallel

Current/voltage ranges

NI4 ____ 10Vdc or 20mA (current and voltage input)

NO4I ____________________ 0 to 21mA (current output)

NO4V ______________________ 10V (voltage output)

Step response

Input ________________________________ 60ms at 95%

Output ______________________________ 2.5ms at 95%

Maximum wire size ________________________ #14AWG

Terminal block ____________________________ removable

Noise immunity______________ NEMA Standard ICS 2-230

Environmental conditions

Operating temperature __________________ 0 to +60C

(+32 to +140F)

Storage temperature ________________ -40C to +85C

(-40 to +185F)

Humidity rating __________ 5 to 95% (non-condensing)

Recommended cable____________________ Belden #8761

Certification ______ UL 508 listed, CSA 22.2 142 approved

Hazardous Environment Classification __________ Class I,

Division 2 Hazardous Environment

Maximum Amperes

'

Amperes Voltamperes

Relay Contact Ratings Volts Make Break Continuous Make Break

For OW16 240Vac 7.5A 0.75A

2.5A 1800VA 180VA

120Vac 15A 1.5A

125Vdc

^

0.22A

'

1.0A 28VA

24Vdc

^

1.2A

'

2.0A 28VA

For OX8 240Vac 15A 1.5A

5.0A 3600VA 360VA

120Vac 30A 3.0A

125Vdc

^

0.22A

'

1.0A 28VA

24Vdc

^

1.2A

'

2.0A 28VA

' Connecting surge suppressors across your external load will extend the life of SLC 500 relay contacts. For recommended

surge suppressors when switching ac inductive loads, consult the SLC 500 Installation and Operation Users Manual

(Catalogue Number 1747-N1002). Recommended surge suppression for switching 24Vdc inductive loads is a 1N4004

diode that is reverse wired across the load.

^ For dc voltage applications, the make/break ampere rating for relay contacts can be determined by dividing 28VA by the

applied dc voltage.

For example, 28VA/48Vdc = 0.58A.

For dc voltage applications less than 48V, the make/break ratings for relay contacts cannot exceed 2A.

For dc voltage applications greater than 48V, the make/break ratings for relay contacts cannot exceed 1A.

The continuous current per module must be limited so the module power does not exceed 1440VA.

Specification 1746-NI4 1746-NIO4I 1746-NO4I 1746-NO4V 1746-NIO4

Input channels 4 differential, voltage 2 differential, voltage Not applicable Not applicable 2 differential

per module or current selectable or current selectable voltage or

per channel not per channel current

individually isolated selectable

per channel

Output channels Not applicable 2 current outputs, not 4 current outputs, not 4 voltage outputs, not 2 current outputs, not

per module individually isolated individually isolated individually isolated individually isolated

Backplane current 25mA at 5Vdc 55mA at 5Vdc 55mA at 5Vdc 55mA at 5Vdc 55mA at 5Vdc

draw 88mA at 24Vdc 145mA at 24Vdc 195mA at 24Vdc 145mA at 24Vdc 115mA at 24Vdc

External 24Vdc Not applicable Not applicable 24 10% at 195mA 24 10% at 145mA -

power supply (21.6 to 26.4Vdc) (21.6 to 26.4Vdc)

tolerance

239-9986

17

1746-NT4 Thermocouple / mV module

The thermocouple/mV module receives and stores digitally

converted thermocouple and/or dc millivolt (mV) analog

data into its image table for retrieval by all fixed and modular

SLC 500 processors.

The 1746-NT4 module converts input signals from the

following input types.

Features

Cold-junction

compensation and

linearization

Four selectable filters

Individual channel

configuration

Benefits

Provides accurate process

digital temperature

readings

Allows you to tailor system

response to your

environment

Allows you to mix millivolt

and thermopcouple types

Thermocouple temperature ranges

dc millivolt input ranges

Millivolt Range Accuracy

input type (Max. error at 25C/77F)

50mV -50mVdc to +50mVdc 50V

100mV -100mV to +100mVdc 50V

Type of C Temperature F Temperature Accuracy

thermocouple range range (Max. error at

input 25C/ 77F)

Type J -210C to 760C -346F to 1400F 1.06C

Type K -270C to 1370C -454F to 2489F 1.72C

Type T -270C to 400C -454F to 752F 1.43C

Type E -210C to 1000C -454F to 1832F 0.72C

Type N 0C to 1300C 32F to 2372F 1.39C

Type R 0C to 1768C 32F to 3214F 3.59C

Type S 0C to 1768C 32F to 3214F 3.61C

Type B 300C to 1820C 572F to 3308F 3.12C

(0) IN 0+

(1) IN 0-

(2) ANL COM

(3) IN 1+

(4) IN 1-

(5) ANL COM

(6) IN 2+

(7) IN 2-

(8) ANL COM

(9) IN 3+

(10) IN 3-

(11) ANL COM

INPUT

POWER

ANALOG

(0) IN 0+

(1) IN 0-

(2) ANL COM

(3) IN 1+

(4) IN 1-

(5) ANL COM

(6) NOT USED

(7) OUT 0

(8) ANL COM

(9) NOT USED

(10) OUT 1

(11) ANL COM

OUTPUT INPUT

POWER

ANALOG

(0) +24Vdc

(1) DC COM

(0) IN 1+

(1) IN 1-

(2) ANL COM

(3) NOT USED

(4) OUT 0

(5) ANL COM

(6) NOT USED

(7) OUT 1

OUTPUT

POWER

ANALOG

INPUT

CHANNEL

STATUS 1 3

0 2

CJC A+

DO NOT

REMOVE

CJC A-

DO NOT

REMOVE

SHIELD

SHIELD

SHIELD

SHIELD

SHIELD

CJC B-

DO NOT

REMOVE

CJC B+

DO NOT

REMOVE

CHLD+

CHLD-

CHLD1+

CHLD1-

CHLD2+

CHLD2-

CHLD3+

CHLD3-

ANALOG

COM

CJC A+

DO NOT

REMOVE

INPUT

CHANNEL

STATUS 1 3

0 2

CJC A+

DO NOT

REMOVE

CHL 0

RTD

SHIELD

SHIELD

CHL 0

SENSE

CHL 0

RETRN

CHL 2

RTD

CHL 2

SENSE

CHL 2

RETRN

SHIELD

CHL 1

RTD

SHIELD

SHIELD

CHL 1

SENSE

CHL 1

RETRN

CHL 3

RTD

CHL 3

SENSE

CHL 3

RETRN

SHIELD

1746-NI4 1746-NIO4I 1746-NO4I-NO4V 1746-NT4 1746-NR4

Thermocouple specifications

Specification Description

Backplane current draw

5Vdc 60mA

24Vdc 40mA

Temperature scale resolution

(selectable)

C of F and 0.1C or 0.1F

Millivolt scale resolution

(selectable)

0.1 millivolt and 0.01 millivolt (mV)

Open circuit method Upscale

Input step response 300ms at 10Hz

60ms at 50Hz

50ms at 60Hz

12ms at 250Hz

Thermocouple linearization IPTS-68 standard, NBS MN-125,

NBS MN-161

Maximum cable impedance 25Ohms max. loop impedance for

<1LSB error

Calibration Autocalibration at power-up and when

a channel is enabled

Isolation 500Vdc continuous between inputs

and chassis ground, and between

inputs and backplane

Isolation between channels None

Maximum channel-to-channel 2V amximum between any two

common-mode seperation channels (series B)

1

Recommended cable

for thermocouple inputs Appropriate shielded thermocouple

extension wire

2

for mV inputs Belden #8761 or equivalent

(shielded twisted pair)

Maximum wire size Two 14 AWG wires per terminal

239-9986

1

Allows use with a single or multiple grounded thermocouples as long as

the grounds are withim 2V of each other. Series A modules offer zero

volts separation and can be used with a single grounded thermocouple.

Both series A or B can be used with multiple ungrounded themselves.

2

Refer to the thermocouple manufacturer for the correct extension wire.

1746-NR4 RTD/ resistance input module

The RTD/resistance input module enhances the present

temperature control capabilities of your SLC 500 fixed or

modular system by providing the capability to interface with

12 different RTDs and 4 different direct resistance ranges.

RTDs are known for their accuracy, repeatability, linearity,

and long-term stability.

Features

Module interface

capability with a number

of different RTDs

Two selectable excitation

current levels (0.5 and

2mA)

Four selectable filters

Individual channel

configuration

Benefits

Allows you to choose the

best RTD for your

temperature application

Provides capability to limit

RTD self heating and to

provide greater

temperature accuracy

Allows you to tailor system

response to your

environment

Allows you to mix RTD and

resistance device types

RTD temperature ranges, resolution and repeatability

1

The temperature range for the 1000 RTD is dependant on the excitation current.

2

The digits following the RTD type represent the temperature coefficient of resistance (), which is defined as the resistance change per Ohm per C. For

instance, platinum 385 refers to a platinum RTD with = 0.00385 Ohms/Ohm =C or simply 0.00385/C.

3

Actual value at 0C (32F) is 19.042 per SAMA standard RC21-4-1966

4

To maximise the relatively small RTD signal, only 2mA excitation current is allowed.

5

Actual value at 0C (32F) is 100 per DIN standard.

6

Minco Type NA and Minco Type FA (Nickle-Iron).

RTD Type Temp. Range Temp.Range Resolution Repeatability

(0.5mA Excitation)

1

(2.0mA Excitation)

1

100

-200C to +850C -200C to +850C 0.1C 0.2C

(-328F to +1562F) (-328F to +1562F) (0.2F) (0.4F)

200

-200C to +850C -200C to +850C 0.1C 0.2C

(-328F to +1562F) (-328F to +1562F) (0.2F) (0.4F)

Platinum (385)

^

500

-200C to +850C -200C to +850C 0.1C 0.2C

(-328F to +1562F) (-328F to +1562F) (0.2F) (0.4F)

1000

-200C to +850C -200C to +240C 0.1C 0.2C

(-328F to +1562F) (-328F to +464F) (0.2F) (0.4F)

100

-200C to +630C -200C to +630C 0.1C 0.2C

(-328F to +1166F) (-328F to +1166F) (0.2F) (0.4F)

200

-200C to +630C -200C to +630C 0.1C 0.2C

(-328F to +1166F) (-328F to +1166F) (0.2F) (0.4F)

Platinum (3916)

^

500

-200C to +630C -200C to +630C 0.1C 0.2C

(-328F to +1166F) (-328F to +1166F) (0.2F) (0.4F)

1000

-200C to +630C -200C to +630C 0.1C 0.2C

(-328F to +1166F) (-328F to +1166F) (0.2F) (0.4F)

Copper (426)

^

10 Not allowed

-100C to +260C 0.1C 0.2C

(-148F to +500F) (0.2F) (0.4F)

Nickel (618)

^ I

120

-100C to +260C -100C to +260C 0.1C 0.1C

(-148F to +500F) (-148F to +500F) (0.2F) (0.2F)

Nickel (672)

^ I

120

-80C to +260C -80C to +260C 0.1C 0.1C

(-112F to +500F) (-112F to +500F) (0.2F) (0.2F)

Nickel Iron (518)

^ I

604

-100C to +200C -100C to +200C 0.1C 0.1C

(-148F to +392F) (-148F to +392F) (0.2F) (0.2F)

18

239-9986

19

RTD accuracy and temperature drift specifications

1

The accuracy values assume that the module was calibrated within the specified temperature range of 0C to 60C (32F to 140F).

2

The temperature drift specifications apply to a module that has not been calibrated.

3

Module accuracy, using 100 or 200 platinum RTDs with 0.5mA excitation current, depends on the following criteria:

(a) Module accuracy is 0.6C after you apply power to the module or perform an autocalibration at 25C (77F) ambient with module operating temperature

between 0C to 60C (32F to 140F).

(b)Module accuracy is (0.6C + T X 0.034C/C) after you apply power to the module or perform an autocalibration at 25C (77F) ambient with the

module operating temperature between 0C to 60C (32F to 140F).

- where T is the temperature difference between the actual operating temperature of the module and 25C (77F) and 0.034C/C is the temperature drift

shown in the table above for 100 or 200 platinum RTDs.

(c) Module accuracy is 1.0C after you apply power to the module or perform an autocalibration at 60C (140F) ambient with module operating

temperature at 60 C.

4

The digits following the RTD type represent the temperature coefficient of resistance (), which is defined as the resistance change per Ohm per C. For

instance, Platinum 385 refers to a platinum RTD with + 0.00385 Ohms/Ohm - C or simply 0.00385 / C.

5

Actual value at 0C (32F) is 9.042 per SAMA standard RC21-4-1966.

6

To maximise the relatively small RTD signal, only 2mA excitation current is allowed.

7

Actual value at 0C (32F) is 100 per DIN standard.

Resistance input specifications

1

The accuracy values assume that the module was calibrated within the specified temperature range of 0C to 60C (32F to 140F).

2

The accuracy for 150 is dependant on the excitation current: 0.2 at 0.5mA, 0.15 at 2.0mA.

3

The temperature drift for 150 is dependant on the excitation current: 0.006/C at 0.5mA, 0.004 at 2.0mA.

Input type Resistance range Resistance range Accuracy

1

Temperature drift Resolution Repeatability

(0.5mA Excitation) (2.0mA Excitation)

150 0 to 150 0 to 150

2 3

0.01 0.04

500 0 to 500 0 to 500 0.5

0.014/C 0.1 0.2

(0.025/F)

Resistance

1000 0 to 1000 0 to 1000 1.0

0.029/C 0.1 0.2

(0.52/F)

3000 0 to 3000 0 to 1900 1.5

0.043/C 0.1 0.2

(0.077/F)

RTD Type Accuracy

'

Accuracy

'

Temperature drift

^

Temperature drift

^

(0.5mA Excitation) (2.0mA Excitation) (0.5mA Excitation) (2.0mA Excitation)

100

1.0C

0.5C 0.34C/C 0.014C/C

(2.0F) (0.9F) (0.061F/F) (0.025F/F)

200

1.0C

0.5C 0.34C/C 0.014C/C

(2.0F) (0.9F) (0.061F/F) (0.025F/F)

Platinum (385)

2

500

0.6C 0.5C 0.017C/C 0.014C/C

(1.1F) (0.9F) (0.031F/F) (0.025F/F)

1000

0.6C 0.5C 0.017C/C 0.014C/C

(1.1F) (0.9F) (0.031F/F) (0.025F/F)

100

1.0C

0.4C 0.034C/C 0.011C/C

(2.0F) (0.7F) (0.061F/F) (0.020F/F)

200

1.0C

0.4C 0.034C/C 0.011C/C

(2.0F) (0.7F) (0.061F/F) (0.020F/F)

Platinum (3916)

500

0.5C 0.4C 0.014C/C 0.011C/C

(0.9F) (0.7F) (0.025F/F) (0.020F/F)

1000

0.5C 0.4C 0.014C/C 0.011C/C

(0.9F) (0.7F) (0.025F/F) (0.020F/F)

Copper (426)

I

10

Not allowed

I

0.6C

Not allowed

I

0.017C/C

(1.1F) (0.031F/F)

Nickel (618)

I

120

0.2C 0.2C 0.008C/C 0.005C/C

(0.4F) (0.4F) (0.014F/F) (0.014F/F)

Nickel (672)

120

0.2C 0.2C 0.008C/C 0.005C/C

(0.4F) (0.4F) (0.014F/F) (0.014F/F)

Nickel Iron (518)

604

0.3C 0.3C 0.010C/C 0.010C/C

(0.5F) (0.5F) (0.018F/F) (0.018F/F)

RTD Specifications

Backplane current draw

5Vdc____________________________________ 50mA

24Vdc __________________________________ 50mA

Temperature scale resolution

(selectable)________________ 1C or 1F and 0.1C or 0.1F

Resistance scale resolution

(selectable) __________ 1 or 0.1 for all resistance ranges

In addition, 0.01 for 150 range

RTD excitation current____________ Two current values are

user-selectable (0.5mA and 2.0mA)

1

Open circuit or short

circuit method ______________ Zero, upscale or downscale

Input step response:

________________________________ 300ms at 10Hz

_________________________________ 60ms at 50Hz

_________________________________ 50ms at 60Hz

________________________________ 12ms at 250Hz

Cable impedance (max.) ________________ 25 maximum

per 1000 feet

Wire size (max.) ________ Two 24 AWG wires per terminal

Calibration ________________ Autocalibration at power-up

and when a channel is enabled

Isolation between channels ______________________ None

Isolation______________ 500Vdc continuous between inputs

and chassis ground, and between

inputs and backplane

Common mode voltage seperation ______________ 1 volt

1

Refer to the current recommendations of the RTD

manufacturer to determine the best current source for

your application.

7.5.2 High-speed counter module

The high-speed counter module provides bidirectional

counting of high-speed inputs from quadrature encoders and

various high-speed switches. This single channel accepts

input pulse frequencies of up to 50 kHz, allowing precise

control of fast motions. This module is compatible with the

SLC 5/02 processor.

In addition to providing an Accumulated Count, the module

provides the Rate Measurement indicating the pulse

frequency in Hertz (Hz). The Rate Measurement is

determined by accumulating input pulses over a fixed period

of time. The dynamically configurable Rate Period ranges

from 10 milliseconds to 2.55 seconds.

Input and Output Terminals

Hinged Wiring Terminal

Door with Label

OUTPUT INPUT

VDC

OUT 0

OUT 1

OUT 2

OUT 3

DC COM

A+

B+

A-

B-

Z+

LS/24VDC

Z-

LS/12VDC

LS COM

LS/5VDC

FAULT

HSCE

Color-coded Removable

Terminal Block

I/O Status Indicators

Terminal Block

Release Screws

0

1

2

3

4

5

6

7

A

B

Z

LS

239-9986

20

Features

B Three modes of operation (Range, Rate, and Sequencer)

that allow you to select the best mode to fit your

application.

B Four on-board open collector outputs that allow control

independent of the SLC processor scan by the module.

Specification

Backplane current draw

5Vdc __________________________________ 320mA

24Vdc _________________________________ 0.0mA

Noise immunity ______________ NEMA Standard ICS 2-230

Environmental conditions

Operating temp. ____ -0 to +60C (+32 to +140F)

Storage temp. ______ -40 to +85C (-40 to +185F)

Humidity rating________ 5 to 95% (non-condensing)

Max. input frequency

Sequencer and range ____________________ 50kHz

Rate ________________________________ 32.767kHz

7.5.3 DH-485/ RS-232C interface module

The DH-485/RS-232C interface module provides a bridge

between the DH-485 communication network and RS-232

using DFI communication protocol. When used in a SLC 500

chassis with a modem, you can:

B Remotely program and troubleshoot any single SLC 500

processor

B Remotely collect data directly from the data table of any

SLC 500 processor

B Use the SLC 500 as a remote terminal unit.

Features

B It can provide you with local or remote access to examine

ladder programs, monitor program operation, and make

changes if necessary

B By providing a modem connection into your

DH-485 network, it makes troubleshooting installations

over the telephone lines possible!

B It is ideally suited for SCADA/RTU applications where

point-to-point communications is required

B It has a configuration and a DFI serial port that each

accommodate RS-232/423, RS-422, and RS-485

communications

B It is easily configured using either backplane

communication or an ASCII terminal, and it installs

directly into the SLC 500 chassis

B It has a real time clock that can be used by the SLC

processor in conjunction with normal operation

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

CONFIG

DF1

DH485

Configuration

Port

DF1

Port

DH-485

Port

LEDs

DH-485/RS-232C

Door Label

239-9986

21

B It allows connection from a DH-485 network device to a

single DFI device.

Specification

Operating temp. __________ -0 to +60C (+32 to +140F)

Environmental conditions

Storage temp. ______ -40 to +85C (-40 to +185F)

Relative humidity ______ 5 to 95% (non-condensing)

Power consumption ________ 5Vdc voltage requires .150A

24Vdc voltage requires .040A

Important: The 1747-KE module requires both 5Vdc and

24Vdc power from the SLC backplane. The

power consumption of the module must be taken

into consideration when planning your SLC 500

system. Refer to the documentation supplied with

your SLC 500 fixed or modular controller for

additional information on power supplies and

current requirements.

7.6 Programmers and operator interface

The following section describes two types of programming

options available for the SLC 500. The first is the Advanced

Programming Software (APS) and the second is the Hand-

Held Terminal (HHT).

7.6.1 APS

The Advanced Programming Software (APS) v5.01 and later,

enables you to program the SLC 500 family processors

using an IBM-AT/XT or compatible personal computer.

Included in the APS software is the APS Import/Export Utility

(APSIE). This software utility allows you to convert APS

archive files and program documentation into ASCII text files

and vice versa.

Features

Full-line processor support to program any SLC 500 fixed,

SLC 5/01, SLC 5/02, SLC 5/03 and SLC504 modular

processors

B Command line entry of instructions and parameters

provides time-saving key strokes

B On-line context-sensitive help provides quick access to

instructions and status file information

B Cut, copy, and paste editor permits ladder logic to be re-

used

B Search and replace allows quick modification of ladder

logic to match unforeseen hardware changes

B DH-485 and DFI support provides a variety of

communication options to meet your application

requirements

B Runtime online editing allowing entry of programs and

data while online in Run mode when using a SLC 5/03 or

later processor

B System autoconfiguration automatically reads system

configuration information (including I/O and chassis

data), saving you valuable save time.

Specification

Computer ________________ 3.0Mbyte of hard drive space

Hardware 640Kbyte RAM, min. 550 Kbyte free at

execution. Extended or expanded

memory recommended,

but not required

Operating system __________________ DOS 3.1 and higher

Printer interface ______________Parallel or serial 80, 132 or

255 columns

SLC-500 ADVANCED PROGRAMMING SOFTWARE RELEASE 3.00

Allen-Bradley Company, Copyright 1991

1747-PA2E

All Rights Reserved

This software is licensed to: Your name

Your company name

000000000000

Display Area

Message

Prompt Press a function key

Data Entry

Status

Main Functions

ONLINE

CONFIG

ONLINE OFFLINE

CONFIG

WHO SYSTEM

CONFIGR

FILE

OPTIONS

PRINT

REPORTS

SYSTEM

UTILS

EXIT

SYSTEM

OFFLINE

PRG/DOC

F1 F2 F3 F4 F5 F6 F7 F8 F9 F10

Tue Jul 24, 1991 Current Offline File: 09 11:03:09 am

Terminal Address: 0 Current Device: 1747-PIC (DH-485) Proc Address:1

Example of software screen for APS Versiopn 3.00

Additional features for APS Version 6.00

B 640Kbytes of RAM (a minimum of 2Mb of extended

memory is required; 3Mb are required for programming

a 1747-L543 processor.)

B 10Mb fixed-disk drive (APS requires 7.5Mb of free disk

space).

B MS DOS version 3.3 or higher (INTERCHANGE

requires MS DOS version 5.0 or higher).

B For operation using Microsoft

Windows : Windows

version 3.1 or Windows for Workgroups version 3.11.

APS 6.0 is not supported on the following operating systems:

B Windows 95

1

B Microsoft Windows NT 351

B IBM OS/2

B IBM OS/2 WARP

239-9986

22

1

Rockwell Software does not recommend the use of APS 6.0 in the

Windows 95 operating system. APS 6.0 was not designed for specific

Windows 95 compatibility, nor has a complete set of tests within this

operating system been completed at the time of the APS 6.0 release.

However, if you still want to attempt to operate in the Windows 95

operating system, there is some background information provided for

you in the APS ReadMe file.

The amount of free conventional RAM that APS requires

depends on what communication drivers you want to load.

If you want to load :

Only the stand alone

communications drivers

300Kb

Microsoft Windows drivers

(INTERCHANGE software)

369Kb

SLC-500 ADVANCED PROGRAMMING SOFTWARE RELEASE 6.00

Rockwell Software Incorporated, Copyright 1989-1995

9323-PA2E

All Rights Reserved

This software is licensed to: Your name

Your company name

000000000000

Press a function key

ONLINE

CONFIG

ONLINE OFFLINE

CONFIG

WHO SYSTEM

CONFIGR

FILE

OPTIONS

PRINT

REPORTS

SYSTEM

UTILS

EXIT

SYSTEM

OFFLINE

PRG/DOC

F1 F2 F3 F4 F5 F6 F7 F8 F9 F10

Fri Nov 24, 1995 Current Offline File: DEFAULT 11:03:09 am

Terminal Address: 0 Current Device: 1747-PIC (DH-485) Proc Address:1

Example of software screen for APS Version 3.00

Exiting the system : You can exit APS software snd return to Windows by accessing the APS

menu and pressing

EXIT

SYSTEM

If you want to load You need

239-9986

23

7.6.2 HHT

The Hand-Held Terminal (HHT) v2.03 is a powerful portable

programming platform used to configure the SLC 500 fixed,

SLC 5/01, and the SLC 5/02 processors, enter or modify an

application program, monitor the execution of the

application program in real-time, or troubleshoot an

application program. The HHT accepts programs with a

maximum data table size of 6K. Each rung may contain up to

127 instructions. This differs from APS which has a maximum

data table size of 16K and each rung can contain 128

instructions.

The programming memory pack is interchangeable and

available in four languages. Note that the HHT does not

support nested branching or conditional output branches.

Features

B Rugged construction designed for a variety of industrial

environments

B Menu-driven firmware displays step-by-step directions

B LCD display shows up to five rungs of ladder logic at one

time

B ZOOM function displays detailed instruction information

B Formatted display shows PID and MSG instructions.

Specification

Display 8 line 3 40 character super-twist

nematic LCD

Keyboard____________________________________ 30 keys

Operating power ______________ 0.105A (max.) at 24Vdc

Environmental conditions

Operating temp. __________ 0 to +40C (+32 to +104F)

Storage temp. __________ -20 to +65C (-4 to +149F)

Humidity range __________ 5 to 95% (non-condensing)

Display Area

Calculator-style, Color-coded Keyboard

7.6.3 DTAM

The Data Table Access Module (DTAM) aids in accessing

information and monitoring an SLC 500 control system at the

plant floor level. Designed to mount in an enclosure door, the

DTAM allows you to access data file information, change

operating modes, monitor and clear processor faults, and

transfer memory from or to a EEPROM on any SLC 500, or

SLC 5/01, SLC 5/02 or SLC 5/03 processor. Interactive

messaging is also supported between the DTAM and the

SLC 5/02 or SLC 5/03 processor.

Features

B DH-485 network compatible communicating with up to 31

controllers, one at a time, up to 1219m (4000ft).

B Data monitor or modify permitting data values to be