Professional Documents

Culture Documents

Welcome To International Journal of Engineering Research and Development (IJERD)

Uploaded by

IJERDOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welcome To International Journal of Engineering Research and Development (IJERD)

Uploaded by

IJERDCopyright:

Available Formats

International Journal of Engineering Research and Development e-ISSN: 2278-067X, p-ISSN: 2278-800X, www.ijerd.

com Volume 6, Issue 8 (April 2013), PP. 46-52

Data Acquisition System Using Master Slave Communication through ATmega32A Microcontroller

Yadav Raghvendra Satyanarayan1, Yadav Satyendra Satyanarayan2

M.Tech, Instrumentation & Control Engineering, Faculty of Technology Dharmsinh Desai University, Nadiad, Gujarat, India

1, 2

Abstract:- This paper presents a data acquisition system using master slave communication using ATmega32A microcontroller. In this system, we can do the analog to digital conversion using slave microcontrollers. Then by using SPI (Serial Peripheral Interface) protocol we can get that slave microcontrollers data to the master microcontroller and save that analog to digital convertor data to the master microcontroller memory. We can use those data for further processing. Keywords:- ATmega32A microcontroller, Data Acquisition System, Analog to Digital Converter, Master Slave Communication, SPI (Serial Peripheral Interface) Protocol,

I.

INTRODUCTION

As we know that this project is based on the data acquisition system so, it is necessary to understand the data acquisition system first.[6] In data acquisition system there are number of stages involved as shown below:

Fig.1: Block diagram of Data Acquisition System Each stages of this Data Acquisition system described below: A. Sensor Sensor is a device which provides a usable output in response to a specified measurand. [1] B. Signal Conditioning This is a stage of data acquisition system which converts the analog signal coming from the sensors into appropriate range of analog signal which is used for the analog to digital converter. C. Analog Multiplexer Multiplexer selects one of channel of analog signal from multiple analog signal channels. D. Sample & Hold Circuit

46

Data Acquisition System Using Master Slave Communication through.

This circuit simply doing the sampling of the analog signal and holding that analog signal at a constant value for a specified period of time up to completion of the conversion of analog signal into digital, or we can say it holds on to its last sampled value until the input is sampled again.[2] E. Program Sequencer This controls the timing of the selection of analog channel of multiplexer and timing of sample hold circuit and maintaining the perfect synchronization between these two circuits. F. Analog to Digital Converter This converts the analog signal into digital form. I have used ATmega32A (AVR Family) microcontroller because it have in-built analog to digital converter and it also supports the SPI protocol for communication. In SPI protocol, when the communication will establish between two microcontrollers at that time one will work as master microcontroller and second as slave microcontroller. In the microcontroller we can easily select one microcontroller as master and other as slave microcontroller. SPI (Serial Peripheral Interface) is a synchronous serial data link that operates in full duplex mode. SPI is four pins communication protocol which are MISO (Master In Slave Out), MOSI (Master Out Slave In), SCK (Serial Clock) and SS (Slave Select) pins. [3] We can add maximum 26 no. Of slaves for single master, but the circuitry becomes more complex so we can use fewer slaves to communicate with the master microcontroller. The selection of slave is done by the master by simply pull down (at zero voltage level) the pin PB4 (Active low Slave Select pin of ATmega32A) of slave microcontroller. Each microcontroller has eight channel in-built analog to digital converter. Every slave microcontrollers continuously do the analog to digital conversion of analog signals of different sensors. Sensors includes such as temperature sensor, pressure sensor, motion sensor, displacement sensor or any other sensors. Then each slave will store the A/D data into their individual memory. Then from the request of master the slave will send that data using SPI protocol to the master.

II.

HARDWARE

We have used ATmega32A microcontroller. It has advanced RISC (Reduced Instruction Set Computing) architecture. It has 131 single cycle execution instructions. It has 32 KB of flash program memory, 1024 bytes EEPROM and 2 KB of SRAM. It has eight channel 10-bit ADC (Analog to Digital Converter) and SPI interface for communication. The SFRs (Special Function Register) related for the in-built ADC and SPI are explained below: A. ADC related SFRs The ADC related SFRs are listed below: [4] i) ADMUX ADC Multiplexer Selection Register :

Bit 7:6 REFS1:0 (Reference Selection) Bits: Select the voltage reference for the ADC, as shown in table. If these bits are changed during a conversion, the change will not go in effect until this conversion is complete (ADIF in ADCSRA is set). TABLE I Voltage Reference Selections for ADC REFS1 REFS0 Voltage Reference Selection 0 0 Aref, Internal Vref turned off 0 1 AVCC with external capacitor at Aref pin 1 0 Reserved 1 1 Internal 2.56V Voltage Reference at Aref pin Bit 5 ADLAR (ADC Left Adjust Result): This bit affects the presentation of the ADC conversion result in the ADC Data Register. Write one to ADLAR to left adjust the result. Otherwise, the result is right adjusted. Bits 4:0 MUX4:0 (Analog Channel and Gain Selection Bits): The value of these bits selects, which combination of analog inputs are connected to the ADC. These bits also select the gain for the differential channels. If these bits are changed during a conversion, the change will not go in effect until this conversion is complete (ADIF in ADCSRA is set). ii) ADCSRA ADC Control and Status Register :

47

Data Acquisition System Using Master Slave Communication through.

Bit 7 ADEN (ADC Enable): Writing this bit to one enables the ADC. By writing it to zero, the ADC is turned off. Turning the ADC off while a conversion is in progress will terminate this conversion. Bit 6 ADSC (ADC Start Conversion): In Single Conversion mode, write this bit to one to start each conversion. In Free Running Mode, write this bit to one to start the first conversion. ADSC will read as one as long as a conversion is in progress. When the conversion is complete, it returns to zero. Writing zero to this bit has no effect. Bit 5 ADATE (ADC Auto Trigger Enable): When this bit is written to one, Auto Triggering of the ADC is enabled. Bit 4 ADIF (ADC Interrupt Flag): This bit is set when an ADC conversion completes and the Data Registers are updated. The ADC Conversion Complete Interrupt is executed if the ADIE bit and the I-bit in SREG are set. Bit 3 ADIE (ADC Interrupt Enable): When this bit is written to one, the ADC Conversion Complete Interrupt is activated. Bits 2:0 ADPS2:0 (ADC Pre-scalar Select Bits): These bits determine the division factor between the XTAL frequency and the input clock to the ADC. iii) ADCL and ADCH The ADC Data Register iv) SFIOR Special Function IO Register :

Bit 7:5 ADTS2:0 (ADC Auto Trigger Source): If ADATE in ADCSRA is written to one, the value of these bits selects which source will trigger an ADC conversion. If ADATE is cleared, the ADTS2:0 settings will have no effect. A conversion will be triggered by the rising edge of the selected Interrupt Flag. Note that switching from a trigger source that is cleared to a trigger source that is set will generate a positive edge on the trigger signal. B. SPI related SFRs The SPI related SFRs are listed below: [5] i) SPDR SPI Data Register: The SPI Data Register is a read/write register used for data transfer between the Register File and the SPI Shift Register. Writing to the register initiates data transmission. Reading the register causes the Shift Register Receive buffer to be read. ii) SPCR - SPI Control Register:

Bit 7 SPIE (SPI Interrupt Enable): This bit causes the SPI interrupt to be executed if SPIF bit in the SPSR Register is set and if the global interrupt enable bit in SREG is set. Bit 6 SPE (SPI Enable): When the SPE bit is written to one, the SPI is enabled. This bit must be set to enable any SPI operations. Bit 5 DORD (Data Order): When the DORD bit is written to one, the LSB of the data word is transmitted first. When the DORD bit is written to zero, the MSB of the data word is transmitted first. Bit 4 MSTR (Master/Slave Select): This bit selects Master SPI mode when written to one and Slave SPI mode when written logic zero. If SS is configured as an input and is driven low while MSTR is set, MSTR will be cleared, and SPIF in SPSR will become set. The user will then have to set MSTR to re-enable SPI Master mode. Bit 3 CPOL (Clock Polarity): When this bit is written to one, SCK is high when idle. When CPOL is written to zero, SCK is low when idle.

48

Data Acquisition System Using Master Slave Communication through.

Bit 2 CPHA (Clock Phase): The settings of the Clock Phase bit (CPHA) determine if data is sampled on the leading (first) or trailing (last) edge of SCK. Bits 1,0 SPR1,SPR0 (SPI Clock Rate Select 1 and 0): These two bits control the SCK rate of the device configured as a Master. SPR1 and SPR0 have no effect on the Slave. The relationship between SCK and the Oscillator Clock frequency fosc is shown in the TABLE II. This SPI clock is also controlled by another bit of SPSR (SPI Status Register) which controls the speed of the SPI. That bit named as SPI2X, which increase the SPI speed doubles. TABLE II Relationship between SCK and the Oscillator Frequency SCK Frequency SPI2X SPR1 0 0 Fosc/4 0 0 Fosc/16 0 1 Fosc/64 0 1 Fosc/128 1 0 Fosc/2 1 0 Fosc/8 1 1 Fosc/32 1 1 Fosc/64 iii) SPSR SPI Status Register :

SPR0 0 1 0 1 0 1 0 1

Bit 7 SPIF (SPI Interrupt Flag): When a serial transfer is complete, the SPIF Flag is set. An interrupt is generated if SPIE in SPCR is set and global interrupts are enabled. If SS is an input and is driven low when the SPI is in Master mode, this will also set the SPIF Flag. SPIF is cleared by hardware when executing the corresponding interrupt handling vector. Alternatively, the SPIF bit is cleared by first reading the SPI Status Register with SPIF set, then accessing the SPI Data Register (SPDR). Bit 6 WCOL (Write Collision Flag): The WCOL bit is set if the SPI Data Register (SPDR) is written during a data transfer. The WCOL bit (and the SPIF bit) is cleared by first reading the SPI Status Register with WCOL set, and then accessing the SPI Data Register. Bit 5:1 Reserved Bits: These bits are reserved bits in the ATmega32A and will always read as zero. Bit 0 SPI2X (Double SPI Speed Bit): When this bit is written logic one the SPI speed (SCK Frequency) will be doubled when the SPI is in Master mode (see Table II). This means that the minimum SCK period will be two CPU clock periods. When the SPI is configured as Slave, the SPI is only guaranteed to work at fosc/4 or lower.

III.

SYSTEM DEVELOPMENT

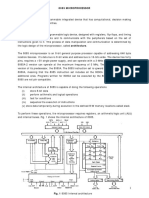

As we have already discussed that using SPI protocol this system has been developed. From the block diagram of system we can understand that what is happening in the system. As shown in figure the master as well as slave we have used same chip ATmega32A microcontroller. In this system we have used only two slaves which are doing the ADC of analog signals and then transfer that ADC data to the master using SPI protocol. In this system we have used LCD for display of A/D converted data. We can also use the RS232 communication using USART communication between master and a PC and we can directly log the data to the PC and we can store it also. We can also connect the master with other interfaces I Cs using SPI protocol such as external ADC ICs such as MCP3202, DS1307 real time clock IC etc. For this we have developed PCB for this project. In which, single PCB can use as master as well as slave also. Means a single design of PCB we can use for both master as well as slave. To develop the PCB we have used ARES Professional software which is very easy for developing the PCB layout as well as PCB schematic for any microcontroller based project or other small projects. We have developed single layer as well as double layer PCB for this project. After developing the PCB and mounting all the components the next stage of this project is to develop the programming for the master as well as slave microcontroller.

49

Data Acquisition System Using Master Slave Communication through.

Fig.2: Block diagram of Data Acquisition system using Master-Slave Communication The above figure is block diagram of the project. As we have already discussed above in this one controller works as master and others are works as slave. From above figure we can say that analog signals are given to the slaves in-built A/D converter that transfers those data to the master using SPI protocol. For that we must have to do the programming for master as well as for slave microcontroller also. For that, we have used AVR Studio 4 assembler to do the programming of the microcontrollers. We have used Sunroms ICSP (In Circuit Serial Programmer) for programming of microcontroller. That programmer is also based on the SPI protocol and according to that it selects a microcontroller as slave and loads the program into microcontrollers flash memory. This programmer we can use for the most of AVR Family of the Atmel microcontrollers. It is available with the USB connector so we can use it with our laptops easily and anywhere. For developing of this project we have used as hardwares are ATmega32A microcontroller, ICSP programmer as well as different types of sensors, which are generating electrical signal according to the change in measurand. Basically power supply is basic need of any project so, we have also used the +5V power supply to power up the microcontroller. We have used temperature sensor (LM35) as sensor to get the analog signal according to the temperature of its surrounding area. After developing of system, the next objective is programming and for that the flow chart of programming is necessary.

IV.

FLOW CHART

Flowchart is the first requirement for developing the programming for any application for any microcontroller. As shown in Fig.3 the flowchart indicates the way or direction of the program. For this project the first requirement is initialization of LCD using program. We can connect the LCD with master or with slave as per our requirement. We have connected the LCD with the master controller. After that we have to select the controller as master or slave, for that we have to write 1 at the bit of MSTR of SPCR SFR of the controller, for other we will write zero so that controller will selects as slave. As we have informed above that the programming for master as well as slave are different that we can see from the flowchart of programming. By using programming skills we can easily make a program which is suitable for every slave controller. In that, master will simply polling all slaves one by one to get the ADC data of each slave. At that time each slave other than that slave (which is connected with the master using SPI protocol) will do the A/D conversion and store that A/D conversion data into their individual memory. Then master will select a slave for getting that ADC data, that time the slave will transmit that data to the master. If we use the RS232 communication using USART port of microcontroller we can directly get that data to the screen of PC and we can also do some further processing according to our requirement. We can also add the programming for the RS232 communication. We have only use the LCD for data display of the ADC of slave controllers.

50

Data Acquisition System Using Master Slave Communication through.

Fig.3: Flowchart of programming of Data acquisition System using Master Slave communication

V.

CONCLUSIONS

This system is useful for the data acquisition process. We can use this system into home automation field as well as into building automation application. As this is based on SPI protocol we can also use Zig-Bee as slave and we can develop a wireless network using multiple Zig-Bees as slave of the master microcontroller. This is very useful for the less number of analog inputs, instead of plc for the same process. We can communicate with microcontroller or log the digital data of the microcontroller using Ethernet module. Using this module we can see the data of the process as well as we can control the process using internet connection. For complex number of analog inputs this system requires more programming of the master microcontroller, which requires more time as well as more knowledge and management of the programming.

51

Data Acquisition System Using Master Slave Communication through. REFERENCES

[1]. [2]. [3]. D. Patranabis, Sensors and Transducers, 2nd Edition, Prentice Hall of India (PHI) Publication, New Delhi, 2007. Ramakant A. Gayakwad, Op-Amps and Linear Integrated Circuits, 4th Edition, Prentice Hall of India (PHI) Publication, New Delhi,2007. Archana Ramesh R, M.S.R.Sekhar, Design and Verification of Serial Peripheral Interface using OVM, International Journal of Electronics Communication and Computer Technology (IJECCT), Volume 2, Issue 6 (November 2012), pp. 267-269. Datasheet of ATmega32A Microcontroller, Analog to Digital Converter, www.alldatasheet.com and www.atmel.com, pp.209-227. Datasheet of ATmega32A Microcontroller, Serial Peripheral Interface, www.alldatasheet.com and www.atmel.com, pp.138-146. Shaikh Yusuf H., Khan A. R and Behere S. H, AVR Microcontroller Based Data Acquisition System for Laboratory Experiments, Advances in Applied Science Research, 2012, 3 (1) , pp. 208-215.

[4]. [5]. [6].

52

You might also like

- Self-Coached Climber - The Guide To Movem - Dan M (1) HagueDocument376 pagesSelf-Coached Climber - The Guide To Movem - Dan M (1) HagueBill Frisch100% (1)

- Heat Combustion Laboratory ReportDocument8 pagesHeat Combustion Laboratory ReportSteven Lee100% (1)

- Catchment YieldDocument7 pagesCatchment YieldBernard PalmerNo ratings yet

- GBE Version 3: API: New API SpecificationDocument44 pagesGBE Version 3: API: New API SpecificationAdi BauNo ratings yet

- Social Media and Loneliness - Why An Instagram Picture May Be Worth More Than A Thousand Twitter WordsDocument13 pagesSocial Media and Loneliness - Why An Instagram Picture May Be Worth More Than A Thousand Twitter WordsCarlos Leite Filho100% (1)

- 2.1 LPC2129 Microcontroller: 2.1.1 FeaturesDocument14 pages2.1 LPC2129 Microcontroller: 2.1.1 FeaturesBhaskar Rao PNo ratings yet

- Using The Mid-Range Enhanced Core PIC16 Devices' MSSP Module For Slave I C CommunicationDocument14 pagesUsing The Mid-Range Enhanced Core PIC16 Devices' MSSP Module For Slave I C CommunicationDario Darius100% (2)

- MC8085Document7 pagesMC8085Bhavani BhavanNo ratings yet

- Notes Unit 1Document25 pagesNotes Unit 1Ashish YadavNo ratings yet

- En - STM32L4 Peripheral I2CDocument29 pagesEn - STM32L4 Peripheral I2CCristian MolanoNo ratings yet

- 1st Experiment ManualDocument5 pages1st Experiment Manualdevonlaratt359No ratings yet

- Block Diagram and Architecture of 8085 MicroprocessorDocument13 pagesBlock Diagram and Architecture of 8085 MicroprocessorShubham SahuNo ratings yet

- Fpga Interface For An Analog Input Module: Volume 2, Issue 4, April 2013Document6 pagesFpga Interface For An Analog Input Module: Volume 2, Issue 4, April 2013International Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Pic MicrocontrollerDocument14 pagesPic Microcontrollermsubashece001No ratings yet

- SpiDocument21 pagesSpirockymaxdeemannNo ratings yet

- 8085 MaterialDocument12 pages8085 MaterialsameerNo ratings yet

- Viva Questions and Answers in MP Lab - 1Document6 pagesViva Questions and Answers in MP Lab - 1Sai KrishnaNo ratings yet

- Pin Description and Signals of 8085 MicroprocessorDocument9 pagesPin Description and Signals of 8085 MicroprocessorKripanand JhaNo ratings yet

- MM Lab ManualDocument53 pagesMM Lab ManualDev SejvaniNo ratings yet

- Dire Dawa University Institute of TechnologyDocument28 pagesDire Dawa University Institute of TechnologyAsed ZakirNo ratings yet

- Exp 1 Induction To 8085 Micro PDocument10 pagesExp 1 Induction To 8085 Micro Phardik ChanderaNo ratings yet

- I2c Bus Contr ReportDocument13 pagesI2c Bus Contr ReportSreeshmith Sreedar100% (2)

- Laboratory Manual Rec 451 - Microprocessors & Microcontrollers LabDocument28 pagesLaboratory Manual Rec 451 - Microprocessors & Microcontrollers Lababhishek singhNo ratings yet

- Programming 8085 Microprocessor ArchitectureDocument34 pagesProgramming 8085 Microprocessor ArchitectureAbhinandan JainNo ratings yet

- 8085 Features, Signal DescriptionDocument13 pages8085 Features, Signal DescriptionRakesh Kumar DNo ratings yet

- SDA - Serial Data, SCL - Serial ClockDocument10 pagesSDA - Serial Data, SCL - Serial ClockPavan Kulkarni100% (3)

- 8 MPLAB ICD & PIC 16F877 Tutorial: CY CY OSC OSCDocument9 pages8 MPLAB ICD & PIC 16F877 Tutorial: CY CY OSC OSCrobotbusterNo ratings yet

- FPGA ADC Peak Detection System GuideDocument3 pagesFPGA ADC Peak Detection System Guidetouseef kalyarNo ratings yet

- SPI EmbeddedDocument16 pagesSPI EmbeddedSrivatsanNo ratings yet

- Microprocessor Lecture Notes 1 10Document202 pagesMicroprocessor Lecture Notes 1 10Ambarish SinghNo ratings yet

- 2.1 LPC2103 Microcontroller: 2.1.1 FeaturesDocument18 pages2.1 LPC2103 Microcontroller: 2.1.1 FeaturesBhaskar Rao PNo ratings yet

- Microprocessor Lab Manual EE0310Document44 pagesMicroprocessor Lab Manual EE0310sathishkumar.vNo ratings yet

- Study of 8085 and Kit STS-85Document10 pagesStudy of 8085 and Kit STS-85Mohammed MansoorNo ratings yet

- Risabh Tyagi Rithik PrakashDocument16 pagesRisabh Tyagi Rithik PrakashSuryadev Kumar SinhaNo ratings yet

- Pic Microcontroller 2.1 Pic It Is A Family of Modified Harvard Architecture Microcontrollers MadeDocument16 pagesPic Microcontroller 2.1 Pic It Is A Family of Modified Harvard Architecture Microcontrollers MadeSuresh KumarNo ratings yet

- Basic Concepts of MicroprocessorsDocument32 pagesBasic Concepts of MicroprocessorsAakrati SharmaNo ratings yet

- Unit-II-ESM-Architecture of PIC Microcontroller 2Document5 pagesUnit-II-ESM-Architecture of PIC Microcontroller 2HarishNo ratings yet

- SPI Pins SPI Clock SPI Master Slave Connection SPI Registers DAC SpecificationsDocument7 pagesSPI Pins SPI Clock SPI Master Slave Connection SPI Registers DAC Specificationspiyushpandey100% (1)

- NEC 022 External Paper SolutionDocument13 pagesNEC 022 External Paper SolutionSachin PalNo ratings yet

- 1-Architecture of 8085Document34 pages1-Architecture of 8085Pinki KumariNo ratings yet

- 8085 Is Pronounced AsDocument9 pages8085 Is Pronounced AsArbaaz khan786No ratings yet

- COMSATS ADC Lab GuideDocument16 pagesCOMSATS ADC Lab GuideBilal HabibNo ratings yet

- Uart, Spi & I2cDocument12 pagesUart, Spi & I2cdeepakacharya424No ratings yet

- Microprocessor System: Session # 7Document13 pagesMicroprocessor System: Session # 7Aamir BhuttoNo ratings yet

- Pic MicrocontrollerDocument5 pagesPic MicrocontrollerFarhat AbbasNo ratings yet

- An Over View of 8085Document12 pagesAn Over View of 8085nskprasad89No ratings yet

- CT1 SolDocument16 pagesCT1 Soln200vermaNo ratings yet

- Lab # 03 I2C WriteDocument4 pagesLab # 03 I2C WriteSOBAN KHANNo ratings yet

- Micro ControllersDocument9 pagesMicro Controllersmiriam.aliceNo ratings yet

- Analog Device Micro ConverterDocument20 pagesAnalog Device Micro ConvertershaileshNo ratings yet

- I2C Interfacing To XC3S400 FPGADocument14 pagesI2C Interfacing To XC3S400 FPGAMahesh BhatkalNo ratings yet

- saha2014Document6 pagessaha2014PoojaNo ratings yet

- MicroprocessorDocument103 pagesMicroprocessorUbaid SaudagarNo ratings yet

- How To Implement DSP Algorithms Using The Xilinx Spartan 3E Starter BoardDocument7 pagesHow To Implement DSP Algorithms Using The Xilinx Spartan 3E Starter BoardShahzad SaleemNo ratings yet

- Using Serial Peripheral InterfaceDocument21 pagesUsing Serial Peripheral InterfaceArton TonoNo ratings yet

- Serial Communication With 8051Document25 pagesSerial Communication With 8051prakriti sankhlaNo ratings yet

- Unit 6 2Document25 pagesUnit 6 2Venkatesh RachaNo ratings yet

- Microprocessor 8085 NotesDocument48 pagesMicroprocessor 8085 NotesDewal ChaturvediNo ratings yet

- STM32L4 ADC OverviewDocument20 pagesSTM32L4 ADC OverviewSTNo ratings yet

- EC8711 Embedded Lab Manual FinalDocument258 pagesEC8711 Embedded Lab Manual FinalbloomeceNo ratings yet

- ARM Cortex M Starter Kit GuideDocument8 pagesARM Cortex M Starter Kit GuideThangaraj KNo ratings yet

- Component DetailsDocument45 pagesComponent DetailsSHARANYANo ratings yet

- MIC 04 - Case Study One 8085 MPUDocument40 pagesMIC 04 - Case Study One 8085 MPUomar hanyNo ratings yet

- Preliminary Specifications: Programmed Data Processor Model Three (PDP-3) October, 1960From EverandPreliminary Specifications: Programmed Data Processor Model Three (PDP-3) October, 1960No ratings yet

- Mitigation of Voltage Sag/Swell With Fuzzy Control Reduced Rating DVRDocument12 pagesMitigation of Voltage Sag/Swell With Fuzzy Control Reduced Rating DVRIJERDNo ratings yet

- Mems Microphone InterfaceDocument4 pagesMems Microphone InterfaceIJERDNo ratings yet

- Influence of Tensile Behaviour of Slab On The Structural Behaviour of Shear Connection in Composite Beam Subjected To Hogging MomentDocument10 pagesInfluence of Tensile Behaviour of Slab On The Structural Behaviour of Shear Connection in Composite Beam Subjected To Hogging MomentIJERDNo ratings yet

- A Novel Method For Prevention of Bandwidth Distributed Denial of Service AttacksDocument8 pagesA Novel Method For Prevention of Bandwidth Distributed Denial of Service AttacksIJERDNo ratings yet

- Gold Prospecting Using Remote Sensing A Case Study of Sudan'Document5 pagesGold Prospecting Using Remote Sensing A Case Study of Sudan'IJERD0% (1)

- Study On The Fused Deposition Modelling in Additive ManufacturingDocument4 pagesStudy On The Fused Deposition Modelling in Additive ManufacturingIJERDNo ratings yet

- Active Power Exchange in Distributed Power-Flow Controller (DPFC) at Third Harmonic FrequencyDocument9 pagesActive Power Exchange in Distributed Power-Flow Controller (DPFC) at Third Harmonic FrequencyIJERDNo ratings yet

- Reducing Corrosion Rate by Welding DesignDocument6 pagesReducing Corrosion Rate by Welding DesignIJERDNo ratings yet

- Router 1X3 - RTL Design and VerificationDocument10 pagesRouter 1X3 - RTL Design and VerificationIJERDNo ratings yet

- Moon-Bounce: A Boon For VHF DxingDocument5 pagesMoon-Bounce: A Boon For VHF DxingIJERDNo ratings yet

- Spyware Triggering System by Particular String ValueDocument5 pagesSpyware Triggering System by Particular String ValueIJERDNo ratings yet

- A Blind Steganalysis On JPEG Gray Level Image Based On Statistical Features and Its Performance AnalysisDocument5 pagesA Blind Steganalysis On JPEG Gray Level Image Based On Statistical Features and Its Performance AnalysisIJERDNo ratings yet

- Secure Image Transmission For Cloud Storage System Using Hybrid SchemeDocument9 pagesSecure Image Transmission For Cloud Storage System Using Hybrid SchemeIJERDNo ratings yet

- Application of Buckley-Leverett Equation in Modeling The Radius of Invasion in A Reservoir Undergoing Microbial Enhanced Oil RecoveryDocument10 pagesApplication of Buckley-Leverett Equation in Modeling The Radius of Invasion in A Reservoir Undergoing Microbial Enhanced Oil RecoveryIJERDNo ratings yet

- Hardware Analysis of Resonant Frequency Converter Using Isolated Circuits and HF Transformer.Document8 pagesHardware Analysis of Resonant Frequency Converter Using Isolated Circuits and HF Transformer.IJERDNo ratings yet

- Gesture Gaming On The World Wide Web Using An Ordinary Web CameraDocument7 pagesGesture Gaming On The World Wide Web Using An Ordinary Web CameraIJERDNo ratings yet

- Simulated Analysis of Resonant Frequency Converter Using Different Tank Circuits.Document6 pagesSimulated Analysis of Resonant Frequency Converter Using Different Tank Circuits.IJERDNo ratings yet

- Intelligent Learning Management System StartersDocument12 pagesIntelligent Learning Management System StartersIJERDNo ratings yet

- MS-Extractor: An Innovative Approach To Extract Microsatellites On Y ChromosomeDocument10 pagesMS-Extractor: An Innovative Approach To Extract Microsatellites On Y ChromosomeIJERDNo ratings yet

- Seismic Drift Consideration in Soft Storied RCC Buildings: A Critical ReviewDocument5 pagesSeismic Drift Consideration in Soft Storied RCC Buildings: A Critical ReviewIJERDNo ratings yet

- Study of Macro Level Properties of SCC Using GGBS and Lime Stone PowderDocument6 pagesStudy of Macro Level Properties of SCC Using GGBS and Lime Stone PowderIJERDNo ratings yet

- Importance of Measurements in Smart GridDocument3 pagesImportance of Measurements in Smart GridIJERDNo ratings yet

- Content Based Video Retrieval Using Integrated Feature Extraction and Personalization of ResultsDocument9 pagesContent Based Video Retrieval Using Integrated Feature Extraction and Personalization of ResultsIJERDNo ratings yet

- Post Processing of SLM Ti-6Al-4V Alloy in Accordance With AMS 4928 StandardsDocument7 pagesPost Processing of SLM Ti-6Al-4V Alloy in Accordance With AMS 4928 StandardsIJERDNo ratings yet

- Planar Internal Antenna Design For Cellular Applications & SAR AnalysisDocument7 pagesPlanar Internal Antenna Design For Cellular Applications & SAR AnalysisIJERDNo ratings yet

- Joint State and Parameter Estimation by Extended Kalman Filter (EKF) TechniqueDocument11 pagesJoint State and Parameter Estimation by Extended Kalman Filter (EKF) TechniqueIJERDNo ratings yet

- Treatment of Waste Water From Organic Fraction Incineration of Municipal Solid Waste (MSW) by Evaporation-Absorption ProcessDocument8 pagesTreatment of Waste Water From Organic Fraction Incineration of Municipal Solid Waste (MSW) by Evaporation-Absorption ProcessIJERDNo ratings yet

- Experimental Study of Material Removal Efficiency in EDM Using Various Types of Dielectric OilDocument8 pagesExperimental Study of Material Removal Efficiency in EDM Using Various Types of Dielectric OilIJERDNo ratings yet

- Analysis of Security Algorithms Used in E-Commerce and ATM TransactionsDocument6 pagesAnalysis of Security Algorithms Used in E-Commerce and ATM TransactionsIJERDNo ratings yet

- Expositions On The Variation of Torsional-Distortional Stresses and Deformations in Box Girder BridgesDocument9 pagesExpositions On The Variation of Torsional-Distortional Stresses and Deformations in Box Girder BridgesIJERDNo ratings yet

- Design of LQR Controller For The Inverted Pendulum: Lili Wan, Juan Lei, Hongxia WuDocument5 pagesDesign of LQR Controller For The Inverted Pendulum: Lili Wan, Juan Lei, Hongxia WuVictor PassosNo ratings yet

- Oracle Database JDBC Developer Guide and ReferenceDocument432 pagesOracle Database JDBC Developer Guide and Referenceapi-25919427100% (1)

- Essay For Villa Savoye AbstractDocument1 pageEssay For Villa Savoye AbstractFrancis PohNo ratings yet

- L - 1 - INTRO - Well LoggingDocument47 pagesL - 1 - INTRO - Well LoggingSaaeed Ali100% (1)

- 03 Correcao Exercicios FixacaoDocument3 pages03 Correcao Exercicios FixacaoRodrigoNo ratings yet

- HP ALM FeaturesDocument51 pagesHP ALM FeaturesSuresh ManthaNo ratings yet

- Rigid PavementDocument100 pagesRigid PavementJAY GANDHI100% (1)

- Design of RivetsDocument20 pagesDesign of RivetsRavishanker BaligaNo ratings yet

- Java 8 Interview QuestionsDocument31 pagesJava 8 Interview QuestionsAmit Sharma100% (2)

- CC5291-Design For Manufacture Assembly and Environments QBDocument11 pagesCC5291-Design For Manufacture Assembly and Environments QBYuvaraj Yuvi0% (1)

- Central Angles and Inscribed Angles GuideDocument22 pagesCentral Angles and Inscribed Angles GuideEric de Guzman100% (1)

- Ch01Document33 pagesCh01sakali aliNo ratings yet

- A Prediction of Water Quality Analysis Using Machine LearningDocument6 pagesA Prediction of Water Quality Analysis Using Machine LearningmonacmicsiaNo ratings yet

- Ws2 PascalDocument3 pagesWs2 PascalsalahadamNo ratings yet

- TM View Software User - S ManualDocument190 pagesTM View Software User - S ManualLuis SánchezNo ratings yet

- SE 2003&2008 Pattern PDFDocument799 pagesSE 2003&2008 Pattern PDFBenigno Tique Jonasse100% (1)

- Cross Taping - A Practical Guide 12Document2 pagesCross Taping - A Practical Guide 12jfjjfjfjjfjfNo ratings yet

- Product Catalogue Chemical IndicatorsDocument28 pagesProduct Catalogue Chemical IndicatorsscribdddcNo ratings yet

- Unit I The Scientific Approach in EducationDocument4 pagesUnit I The Scientific Approach in EducationadesaNo ratings yet

- Rac NotesDocument16 pagesRac NotesJohnRay LominoqueNo ratings yet

- Complete trip-free loop, PFC and PSC testerDocument2 pagesComplete trip-free loop, PFC and PSC testerGermanilloZetaNo ratings yet

- AMCP 706-185, Military Pyrotechnics - Theory and ApplicationDocument270 pagesAMCP 706-185, Military Pyrotechnics - Theory and ApplicationASDAFF ASADNo ratings yet

- QPCR Analysis DifferentlyDocument12 pagesQPCR Analysis DifferentlyIan SaundersNo ratings yet

- Quality Control Analysis of Chlorpheniramine Maleate Marketed in NigeriaDocument7 pagesQuality Control Analysis of Chlorpheniramine Maleate Marketed in Nigeriaحمزة الفنينيNo ratings yet

- Dental Material Final ReportDocument7 pagesDental Material Final ReportAbdullah Muhammed khaleel HassanNo ratings yet