Professional Documents

Culture Documents

Example Risk Assessment For A Woodworking Company Updated 15-02-11

Uploaded by

garry1979Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Example Risk Assessment For A Woodworking Company Updated 15-02-11

Uploaded by

garry1979Copyright:

Available Formats

Example Risk Assessment for a Woodworking Company

Setting the Scene

The owner / manager did the risk assessment at this company, which manufactures furniture and uses a variety of woods and a range of machinery. Six people are employed and two of them work part-time. The business is located on a small industrial estate, in a spacious premises built in 2002 which does not have asbestos-containing materials. There is sufficient space in the yard for loading and unloading vehicles. The company has a toilet and washing facilities and a mess room where staff can take their breaks, prepare drinks and eat food. A first-aid kit is kept there and is regularly checked to make sure all necessary items are maintained.

How was the risk assessment done?

The manager followed the guidance in Five Steps to Risk Assessment (www.healthandsafetyworksni.gov.uk/riskassessment) 1. To identify the hazards, the manager: Looked at Health and Safety Works NIs (HSWNI) woodworking and construction web pages for free advice and to learn where hazards can occur; Walked around the premises, inside and out, noting what might pose as a risk, taking into consideration what was learned from HSWNIs guidance; Talked to staff to learn from their knowledge and experience of areas and activities, and listen to their concerns and opinions about health and safety issues in the workplace; and Looked at the accident book, to understand what had previously resulted in incidents. 2. The manager wrote down who could be harmed by the hazards and how.

Page 1 of 7

Example Risk Assessment for a Woodworking Company

3. For each hazard, the manager wrote down what controls, if any, were in place to manage these hazards. These controls were then compared to the good practice guidance on the Health and Safety Works NI website. Were existing controls were not considered good enough, the manager wrote down what else needed to be done to control the risk. 4. Putting the risk assessment into practice, the manager decided and recorded who was responsible for implementing the further actions and when they should be done. When each action was completed, it was ticked off and the date recorded. The risk assessment was then displayed in the mess room for all staff to see. 5. The manager discussed the findings with the staff. A decision was made to review and update the risk assessment every year or straightaway if any major changes in the workplace happened.

Important Reminder

This example risk assessment shows what kind of approach a small business might take. Use it as a rough guide to think through some of the hazards in your business and the steps you need to take to control the risks. Please note that this is not a generic risk assessment that you can just put your company name on and adopt wholesale without any thought. This would not satisfy the law and would not be effective in protecting people. Every business is different you need to think through the hazards and controls required in your business for yourself.

Page 2 of 7

Example Risk Assessment for a Woodworking Company

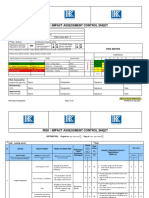

Company name: A Woodworking Company Assessment carried out by: A. Joiner

What are the hazards? Exposure to Wood Dust Who might be harmed and how? Staff risk lung diseases, such as asthma, from inhaling wood dust. Hardwood dust can cause cancer, particularly of the nose. What are you already doing?

Date assessment was carried out: 01/08/10 Date of next review: 01/08/11

What further action do you need to take? Remind staff of the risks of wood dust, and why these controls are necessary. Who needs to carry out the action? Manager When is the action needed by? 02/08/10 Done

Local exhaust ventilation (LEV) provided at machines and staff are trained in using it properly. LEV maintained to keep it in good condition and working effectively. LEV inspected every 14 months by a competent person. Wood dust cleared up using a suitable vacuum cleaner, fitted with an appropriate filter. Suitable respiratory protective equipment (RPE) as well as LEV for very dusty jobs, and staff trained in how to use it. Staff do health surveillance questionnaire before starting, then annually. Any affected staff referred to a medical professional.

02/08/10

Remind staff never to dry sweep wood dust, which just spreads dust around.

Manager

02/08/10

02/08/10

Page 3 of 7

What are the hazards? Machinery

Who might be harmed and how? Staff risk serious and possibly fatal cut injuries following contact with moving parts of machinery, particularly saw blades.

What are you already doing?

What further action do you need to take? Download information sheets on the safe use of machines from the Health and Safety Works NI website and pin them up in the mess room.

Who needs to carry out the action? Manager

When is the action needed by? 04/08/10

Done

All machines guarded according to manufacturers instructions. Guards inspected regularly and maintained as necessary to ensure their good condition. Staff have sufficient space at machines to work safely. Staff monitored by manager to ensure guards always used. All staff trained in safe use of machines by a competent person. All machines braked and fitted with necessary safety features, eg chip limited tooling etc.

03/08/10

Manual Handling

Staff may suffer musculoskeletal disorders, such as back pain, from handling heavy / bulky objects, eg timber boards and machinery parts. Also risk cuts when handling tooling, or splinters when handling pallets.

Staff trained in manual handling. Workbenches and machine tables set at a comfortable height. Strong, thick gloves provided for handling tooling and pallets. Panel trolley and lifting hooks available for moving boards. Systems of work in place for the safe and careful handling of assembled furniture.

Where possible, store tooling next to the machine to reduce carrying distance. Remind staff to ask for a new set of gloves when old ones show wear and tear, and not to try and lift objects that appear too heavy.

Manager

05/08/10

05/08/10

Manager

07/08/10

04/08/10

Page 4 of 7

What are the hazards? Noise

Who might be harmed and how? Staff and others may suffer temporary or permanent hearing damage from exposure to noise from woodworking machinery.

What are you already doing?

What further action do you need to take? Consider if certain machines could be safely mounted on antivibration mountings.

Who needs to carry out the action? Manager

When is the action needed by? 20/08/10

Done

Noise enclosures used where practicable, and maintained in good condition. Low-noise tooling used where possible. Planned maintenance programme for machinery and LEV systems. Suitable hearing protectors provided for all staff and staff trained how to use them. Check and maintain them according to advice given by supplier. Staff trained in risks of noise exposure. Staff trained in systems of work to reduce noise exposure (eg suitable feed rates for certain jobs, timber control etc.)

04/08/10

Include noise emission in specification for new vertical spindle moulder, to be purchased next year.

Manager

20/08/10

08/08/10

Work at Height

Falls from any height can cause bruising and fractures.

Strong stepladder in good condition provided. Only trained, authorised staff allowed to work at height.

Condition of stepladder to be check periodically.

Manager

20/08/10

As required

Page 5 of 7

What are the hazards? Vehicles

Who might be harmed and how? Staff may suffer serious, possibly fatal, injuries if struck by a vehicle such as a lift truck or a delivery lorry. Staff could suffer serious injuries such as bruising or fractures if they trip over objects, or slip, eg on spillages, and fall.

What are you already doing?

What further action do you need to take? Ensure drivers get out of their vehicle and stand in a safe area while it is being loaded / unloaded.

Who needs to carry out the action? Manager and all staff

When is the action needed by? 06/08/10

Done

Fork-lift truck maintained and inspected as per lease contract. Lift truck operated only by staff who have been trained to use it. Pedestrian walkways marked. Only authorised people allowed in yard for deliveries / dispatch. Generally good housekeeping off-cuts cleared away promptly, dust cleared regularly etc. Staff wear strong safety shoes that have a good grip. Good lighting in all areas. Residual current device (RCD) built into main switchboard. Staff trained to spot and report any defective plugs, discoloured sockets or damaged cable / equipment to manager. No personal electrical appliances, eg toasters or fans, allowed.

04/08/10

Slips, trips and falls

Remind all staff to clear up spillages of wax or polish immediately, even very minor spillages.

Manager

05/08/10

03/08/10

Electrical

Staff could get electrical burns from using faulty electrical equipment, eg machinery, or a faulty installation. Electrical faults can also lead to fires.

Ask landlord when the next safety check of the electrical installation will be done. Confirm with landlord the system for making safe any damage to building installation electrics, eg broken light switches or sockets.

Manager

05/08/10

04/08/10

Manager

03/08/10

02/08/10

Page 6 of 7

What are the hazards? Fire

Who might be harmed and how? If trapped, staff could suffer fatal injuries from smoke inhalation / burns.

What are you already doing?

What further action do you need to take? Ensure the actions identified as necessary by the fire risk assessment are completed.

Who needs to carry out the action? Manager

When is the action needed by? From now on

Done

----

Fire risk assessment done and necessary action taken

Assessment Review Date: 01/08/2011

Example Risk Assessment for a Woodworking Company published by HSWNI, 08/10. Health and Safety Executive gratefully acknowledged as source . Page 7 of 7

You might also like

- Example Risk Assessment For A Motor Vehicle ShowroomDocument4 pagesExample Risk Assessment For A Motor Vehicle Showroomdogankku100% (1)

- HSE Risk Assessment WarehouseDocument6 pagesHSE Risk Assessment WarehouseSean Clark100% (1)

- Hazard Identification Risk Assessment AND Control: Department of Health and Safety ServicesDocument14 pagesHazard Identification Risk Assessment AND Control: Department of Health and Safety ServicesRi OzNo ratings yet

- Risk assessment for contract bricklayersDocument16 pagesRisk assessment for contract bricklayersWeei Zhee70No ratings yet

- HSE-RA-063 Erecting and Dismantling of Placing Boom - Rev 0Document15 pagesHSE-RA-063 Erecting and Dismantling of Placing Boom - Rev 0عمروNo ratings yet

- Inherent V Residual RiskDocument2 pagesInherent V Residual RiskAlephNo ratings yet

- Procedure For Identification of Environmental Aspects, Hazards, Evaluation of Impacts, Risks and Determination of Control MeasuresDocument10 pagesProcedure For Identification of Environmental Aspects, Hazards, Evaluation of Impacts, Risks and Determination of Control MeasuresradhouaneNo ratings yet

- Project Baseline Risk Assessment REF DIA61362019RFPDocument26 pagesProject Baseline Risk Assessment REF DIA61362019RFPThandabantu Magengelele100% (1)

- Topic 2 Job Safety Analysis & HirarcDocument65 pagesTopic 2 Job Safety Analysis & HirarcrieNo ratings yet

- Risk Assessment 2 PDFDocument15 pagesRisk Assessment 2 PDFarunNo ratings yet

- ISO-OHSMS guideDocument10 pagesISO-OHSMS guidesanjeev kumar0% (1)

- Al Majal QMS - 2018Document19 pagesAl Majal QMS - 2018Adam DeviatteyNo ratings yet

- Heat Stress ProcedureDocument13 pagesHeat Stress ProcedureKneekEy CastleNo ratings yet

- Training Program: By: Rahul AhujaDocument17 pagesTraining Program: By: Rahul Ahujakei HoinaNo ratings yet

- HSE Safety AuditsDocument3 pagesHSE Safety Auditsvlad100% (1)

- Safety MNGT Sys Audit ReportDocument10 pagesSafety MNGT Sys Audit Reportrashid zamanNo ratings yet

- 4 August 2021 ExamDocument5 pages4 August 2021 ExamRafa'eel BickooNo ratings yet

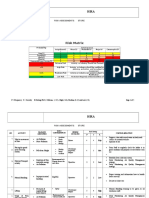

- Without Controls With Controls: High LOWDocument5 pagesWithout Controls With Controls: High LOWZameer Basha Navzath AliNo ratings yet

- HIRA risk assessments: StoreDocument5 pagesHIRA risk assessments: Storederwaishjee1100% (1)

- HIRAC - Work at Height TemplateDocument8 pagesHIRAC - Work at Height Templateputra2azanNo ratings yet

- Job Hazard and Risk AssessmentDocument5 pagesJob Hazard and Risk Assessmentasponce2003No ratings yet

- Health Safety Environmental Manager in Houston TX Resume Fabian Gregory WomacDocument2 pagesHealth Safety Environmental Manager in Houston TX Resume Fabian Gregory WomacFabianGregoryWomacNo ratings yet

- Risk Assessment For 4600002029Document213 pagesRisk Assessment For 4600002029Ows Anish50% (2)

- Risk AssessmentDocument5 pagesRisk Assessmentapi-409852619No ratings yet

- Electrical Safe Work PracticesDocument1 pageElectrical Safe Work PracticesjesusbarajasNo ratings yet

- CoP - 15.0 - Electrical SafetyDocument16 pagesCoP - 15.0 - Electrical SafetyBaskaran NarayanamoorthyNo ratings yet

- 06-F02 Training Needs AnalysisDocument36 pages06-F02 Training Needs AnalysisSn AhsanNo ratings yet

- Risk Assessment FormDocument3 pagesRisk Assessment FormThomas100% (1)

- Risk Assessment: Pick & Carry CranesDocument36 pagesRisk Assessment: Pick & Carry CranesAbd Ennacer100% (2)

- NVQ Level 6 Diploma Course SyllabusDocument1 pageNVQ Level 6 Diploma Course SyllabusNaeem AbbasNo ratings yet

- Health & Safety Handouts ComDocument52 pagesHealth & Safety Handouts ComTyra GeorgesNo ratings yet

- PPE Risk Assessment DocumentDocument5 pagesPPE Risk Assessment DocumentFarzanaNo ratings yet

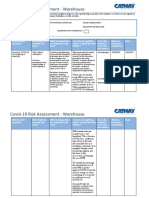

- Covid-19 RiskAssessmentWarehouseDocument11 pagesCovid-19 RiskAssessmentWarehouseBalgo BalgobinNo ratings yet

- Example Hs PolicyDocument2 pagesExample Hs PolicyellyusanaNo ratings yet

- Warehouse Risk AssessmentsDocument4 pagesWarehouse Risk AssessmentsHilario AlinabonNo ratings yet

- Ergonomics Risk MatrixDocument31 pagesErgonomics Risk Matrixvacky77No ratings yet

- Scaffolding-Fixed and Mobile: Safety Operating ProceduresDocument1 pageScaffolding-Fixed and Mobile: Safety Operating Proceduresmohammed muzammilNo ratings yet

- RISK ASSESSMENT FOR ANTIFOULING COATING WORKSDocument19 pagesRISK ASSESSMENT FOR ANTIFOULING COATING WORKSeDtutors. inNo ratings yet

- Safety Monitoring Plan (OGF-HSE-035)Document1 pageSafety Monitoring Plan (OGF-HSE-035)sarge18No ratings yet

- Health Safety Risk Assessment Template 1Document4 pagesHealth Safety Risk Assessment Template 1alokcNo ratings yet

- Warehouse Risk AssessmentDocument8 pagesWarehouse Risk AssessmentBISHAL ROY100% (2)

- 162 Accident Investigation Basic 1 HourDocument34 pages162 Accident Investigation Basic 1 HourHassanNo ratings yet

- Managing Safety and HealthDocument6 pagesManaging Safety and HealthLexter CEmpronNo ratings yet

- Tip Safety PlanDocument28 pagesTip Safety PlanTC Nihal AlcansoyNo ratings yet

- Ohs Consultation 2Document11 pagesOhs Consultation 2Franco Buitrago GarciaNo ratings yet

- PN3-PRO-HSE-010 Work Permit System - Rev 04Document23 pagesPN3-PRO-HSE-010 Work Permit System - Rev 04aymenmoatazNo ratings yet

- 9 Hazard Identification Risk AssessmentDocument10 pages9 Hazard Identification Risk Assessmentvasanth pugazhendhiNo ratings yet

- Sample SOP For PPEs ManagementDocument3 pagesSample SOP For PPEs ManagementAamir ShamasNo ratings yet

- Working at Height Rescue Plan SampleDocument7 pagesWorking at Height Rescue Plan SampleAnvarsha SharafudheenNo ratings yet

- SOP For Use of Grinder Machines in WorkshopDocument8 pagesSOP For Use of Grinder Machines in WorkshopFaisal RajaNo ratings yet

- AJCI Hazard Identification ProcedureDocument4 pagesAJCI Hazard Identification ProcedureEldhose Varghese100% (1)

- Trade Area: Construction Industry-PaintingDocument3 pagesTrade Area: Construction Industry-PaintingRam-tech Jackolito FernandezNo ratings yet

- Additional Guidance Unit 2Document7 pagesAdditional Guidance Unit 2haya100% (1)

- Health and Safety Risk AssessmentDocument2 pagesHealth and Safety Risk AssessmentShahil IslamNo ratings yet

- Incident Investigation: AMEC Earth & Environmental Monthly Safety Training Program March 2009Document42 pagesIncident Investigation: AMEC Earth & Environmental Monthly Safety Training Program March 2009Nikkolai Kirril Gementiza UguisNo ratings yet

- Safety Violation Notice1Document1 pageSafety Violation Notice1rahul kavirajNo ratings yet

- Contract Risk Assessment DeliveryDocument8 pagesContract Risk Assessment DeliverySagar BhavsarNo ratings yet

- Operational Risk Management Plan A Complete Guide - 2020 EditionFrom EverandOperational Risk Management Plan A Complete Guide - 2020 EditionNo ratings yet

- Abdominal Trauma: Fatin Amirah KamaruddinDocument29 pagesAbdominal Trauma: Fatin Amirah Kamaruddinvirz23No ratings yet

- CD - 29. Far Eastern Shipping Company vs. Court of Appeals, 297 Scra 30Document2 pagesCD - 29. Far Eastern Shipping Company vs. Court of Appeals, 297 Scra 30MykaNo ratings yet

- Getting To Grips With Hoisting People: HSE Information SheetDocument8 pagesGetting To Grips With Hoisting People: HSE Information Sheetsmishra2222No ratings yet

- DNB Papers Topic WiseDocument116 pagesDNB Papers Topic WiseMohit RakhechaNo ratings yet

- MVP-50T Ii 1211061DDocument79 pagesMVP-50T Ii 1211061DvnNo ratings yet

- Sudden Makes War - 1942 - PDFDocument197 pagesSudden Makes War - 1942 - PDFSreenath Chary80% (5)

- Musculoskeletal XXXXXXXXXDocument25 pagesMusculoskeletal XXXXXXXXXIgnatius Erik Dwi WahyudiNo ratings yet

- Chapter 69 Nursing Management EmergencyDocument6 pagesChapter 69 Nursing Management EmergencyMeganNo ratings yet

- Junior B Semi Final ReportDocument1 pageJunior B Semi Final ReportMoynaltyNo ratings yet

- 3 Diagnosis of Acute Groin Injuries A Prospective Study of 110 Athletes 3757147577Document9 pages3 Diagnosis of Acute Groin Injuries A Prospective Study of 110 Athletes 3757147577César ArveláezNo ratings yet

- Plastic - Surgery - 6 - Volume - Set - 4e Head and NeckDocument1,198 pagesPlastic - Surgery - 6 - Volume - Set - 4e Head and NeckАнтон Коновалов83% (12)

- Markel H - The Stethoscope and The Art of Listening 2006Document3 pagesMarkel H - The Stethoscope and The Art of Listening 2006GeorgianaRamonaNo ratings yet

- Simple Klatt Test Detects Lower Body ImbalancesDocument3 pagesSimple Klatt Test Detects Lower Body Imbalancessale18100% (1)

- Hemostasis: Written By: Fayzah Alshammari Date: 06-11-2021Document4 pagesHemostasis: Written By: Fayzah Alshammari Date: 06-11-2021fayzah alshammariNo ratings yet

- Surgical InstrumentDocument27 pagesSurgical InstrumentMila Diciano YangoNo ratings yet

- SUN2000 - (50KTL-ZHM3, 50KTL-M3) User ManualDocument126 pagesSUN2000 - (50KTL-ZHM3, 50KTL-M3) User ManualMuresan AlinaNo ratings yet

- Checklist For Turning The PatientDocument4 pagesChecklist For Turning The PatientCord Covie Niluag HonculadaNo ratings yet

- MTP3055Document9 pagesMTP3055lisandroantonNo ratings yet

- CA upholds conviction of 2 men for attempted murderDocument9 pagesCA upholds conviction of 2 men for attempted murderabo8008No ratings yet

- CDCR Medal of Valor Awards 2010Document16 pagesCDCR Medal of Valor Awards 2010Marissa KayNo ratings yet

- Risk Assessment Ig2 Passing 003Document20 pagesRisk Assessment Ig2 Passing 003Qasim Ibrar75% (4)

- SpasticityDocument57 pagesSpasticityheena solankiNo ratings yet

- MAPEH ReportingDocument18 pagesMAPEH ReportingKurt Dela PenaNo ratings yet

- Life Assessment of Turbine Components Based On Deterministic and Probabilistic ProcedurDocument5 pagesLife Assessment of Turbine Components Based On Deterministic and Probabilistic ProcedurPeerasak ArunNo ratings yet

- Module 1 - Lesson 1 Introduction To Movement Analysis and Musculoskeletal SystemDocument8 pagesModule 1 - Lesson 1 Introduction To Movement Analysis and Musculoskeletal Systemapi-583268741No ratings yet

- Thoracic Veins and Arteries.Document14 pagesThoracic Veins and Arteries.Shimmering MoonNo ratings yet

- Department of Labor: USDOL OALJ LHWCA BENCHBOOK TOPIC 2 (2002)Document108 pagesDepartment of Labor: USDOL OALJ LHWCA BENCHBOOK TOPIC 2 (2002)USA_DepartmentOfLabor100% (1)

- Car Crashes With Polytrauma in Southern Germany: January 2009Document12 pagesCar Crashes With Polytrauma in Southern Germany: January 2009bgdNo ratings yet

- FMEA analysis optimizes Quad Torc vehicle safetyDocument3 pagesFMEA analysis optimizes Quad Torc vehicle safetyVishnu RoyNo ratings yet