Professional Documents

Culture Documents

Foundation

Uploaded by

risrizCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Foundation

Uploaded by

risrizCopyright:

Available Formats

3.

0 Foundations

Foundations The function of any foundation is to safely sustain and transmit the combined dead, imposed and wind loads to the ground on which it rests in such a manner as not to cause any settlement or other movement which would impair the stability or cause damage to any part of the building. Foundation Design Principles The main objectives of foundation design are to ensure that the structural loads are transmitted to the subsoil(s) safely, economically and without any unacceptable movement during the construction period and throughout the anticipated life of the building or structure. Basic Design Procedure ~ this can be considered as a series of steps or stages; Assessment of site conditions in the context of the site and soil investigation report. Calculation of anticipated structural loading(s). Choosing the foundation type taking into consideration - Soil conditions, Type of structure, Structural loading(s), Economic factors, Time factors relative to the proposed contract period, & Construction problems. Sizing the chosen foundation in the context of loading(s), ground bearing capacity and any likely future movements of the building or structure. Foundation Types Apart from simple domestic foundations most foundation types are constructed in reinforced concrete and may be considered as being shallow or deep. Shallow Foundations:- pads, strips (spread footing) , rafts (mat foundation) Deep Foundation:- piles 1. Pad Footings Isolated footings, suitable for most subsoils except loose sands, loose gravels and filled areas. Pad foundations are usually constructed of reinforced concrete. 2. Strip Foundations These are suitable for most subsoils and light structural loadings such as those encountered in low to medium rise domestic dwellings where mass concrete can be used. Reinforced concrete is usually required for all other situations.

3. Raft Foundation These are used to spread the load of the superstructure over a large base to reduce the load per unit area being imposed on the ground and this is particularly useful where low bearing capacity soils are encountered and where individual column loads are heavy. Typical Raft foundation types are illustrated below.

4. Pile foundation These can be defined as a series of columns constructed or inserted into the ground to transmit the load(s) of a structure to a lower level of subsoil. Piled foundations can be used when suitable foundation conditions are not present at or near ground level making the use of deep traditional foundations uneconomic. In other words, where the bearing capacity of the soil is poor or imposed loads are very heavy, pile foundations are required. Classification of Piles ~ Piles may be classified by their basic design function (1 & 2) or by their method of construction (3 & 4). 1. End bearing piles: where the pile acts as a column carrying the load down to the bearing strata

2. Friction piles: where the load is gradually transferred along the length of the pile by means of friction between the surface of the pile and the surrounding soil.

3. Replacement Piles ~ These are often called bored piles. The removal of the soil to form the hole for the pile is always carried out by a boring technique. Used primarily in cohesive subsoils for the formation of friction piles & when forming pile foundations close to existing buildings where the allowable amount of noise and/or vibration is limited. Replacement pile types: Percussion bored, Rotary bored, & Flush bored 4. Displacement Piles These are often called driven piles since they are usually driven into the ground displacing the earth around the pile shaft. These piles can be either preformed or partially preformed if they are not cast insitu and are available in a wide variety of types and materials. The pile or forming tube is driven into the required position to a predetermined depth or to the required `set' which is a measure of the subsoils resistance to the penetration of the pile and hence its bearing capacity by noting the amount of penetration obtained by a fixed number of hammer blows. Displacement pile types: Preformed, Partially preformed, Driven insitu, Cast insitu

Pile Caps

piles can be used singly to support the load but often it is more economical to use piles in groups or clusters linked together with a reinforced concrete cap. The pile caps can also be linked together with reinforced concrete ground beams.

Describe common methods used to improve the effectiveness of foundations in low bearing capacity ground. Methods: rolling, injection grouting, vibro flotation, permanent reduction of ground water a) Grouting. b) Freezing. c) Vibro compaction. d) Wellpoints. e) Surcharging If soil investigation reveals a naturally poor subsoil or extensive filling, where soil bearing capacity will be low, the effectiveness of the subsoil need to be improved in order to build the structure on the same ground. There are various soil improvement techniques as discussed below. Remove and Replace The poor ground can be excavated, removed and replaced by compacted fills. Using this method there is a risk of differential settlement and generally for depths over 4m it is uneconomic. Surcharging This involves preloading the poor ground with a surcharge of aggregate or similar material to speed up settlement and thereby improve the soil's bearing capacity. Generally this method is uneconomic due to the time delay before actual building operations can commence which can vary from a few weeks to two or more years. Vibration This is a method of strengthening ground by vibrating a granular soil into compacted stone columns either by using the natural coarse granular soil or by replacement. the objective of this method is to strengthen the existing soil by rearranging and compacting coarse granular particles to form stone columns with the ground. This is carried out by means of a large poker vibrator. On large sites the vibrator is inserted on a regular triangulated grid pattern. Ground vibration is not a piling system but a means of strengthening ground to increase the bearing capacity. Sand Compaction - applied to non-cohesive subsoils where the granular particles are rearranged into a denser condition by poker vibration. The crane-suspended vibrating poker is water-jetted into the ground using a combination of self weight and water displacement of the finer soil particles to penetrate the ground. Under this pressure, the soil granules compact to increase in density as the poker descends. At the appropriate depth, which may be determined by building load calculations or the practical limit of plant (generally 30m max.), jetting ceases and fine aggregates or sand are infilled around the poker. The poker is then gradually withdrawn compacting the granular fill in the process. Compaction continues until sand fill reaches ground level. Spacing of compaction boreholes is relatively close to ensure continuity and an integral ground condition.

Dynamic Compaction This is a method of soil improvement which consists of dropping a heavy weight through a considerable vertical distance to compact the soil and thus improve its bearing capacity and is especially suitable for granular soils. This method of ground improvement consists of dropping a heavy weight from a considerable height and is particularly effective in granular soils. The drop pattern, size of weight and height of drop are selected to suit each individual site

Jet Grouting This method of consolidating ground can be used in all types of subsoil and consists of lowering a monitor probe into a 150mm diameter prebored guide hole. The probe has two jets the upper of which blasts water, concentrated by compressed air to force any loose material up the guide to ground level. The lower jet fills the void with a cement slurry which sets into a solid mass this is a means of consolidating ground by lowering into preformed bore holes a monitor probe. The probe is rotated and the sides of the bore hole are subjected to a jet of pressurised water and air from a single outlet which enlarges and compacts the bore hole sides. At the same time a cement grout is being introduced under pressure to fill the void being created. The water used by the probe and any combined earth is forced up to the surface in the form of a sludge.

If the monitor probe is not rotated grouted panels can be formed. The spacing, depth and layout of the bore holes is subject to specialist design.

You might also like

- Proposal Report Evaluation - May 2020Document1 pageProposal Report Evaluation - May 2020risrizNo ratings yet

- L PDFDocument4 pagesL PDFrisrizNo ratings yet

- FFDocument4 pagesFFrisrizNo ratings yet

- 11Document3 pages11risrizNo ratings yet

- The Hydrologic Cycle: It Plays An Important Role in Moving Chemical Elements Through The EcosphereDocument12 pagesThe Hydrologic Cycle: It Plays An Important Role in Moving Chemical Elements Through The EcosphererisrizNo ratings yet

- E-18 Semester 1 Timetable - FinalDocument1 pageE-18 Semester 1 Timetable - FinalrisrizNo ratings yet

- SurgeDocument2 pagesSurgerisrizNo ratings yet

- 12Document2 pages12risrizNo ratings yet

- HammerDocument2 pagesHammerrisrizNo ratings yet

- 14 PDFDocument2 pages14 PDFrisrizNo ratings yet

- 13Document2 pages13risrizNo ratings yet

- ) ) (SLS) ) ) ) ) ) (MM) /F - Deformed Bars /F - Plain BarsDocument1 page) ) (SLS) ) ) ) ) ) (MM) /F - Deformed Bars /F - Plain BarsrisrizNo ratings yet

- CarriculumDocument2 pagesCarriculumrisrizNo ratings yet

- Responsibility matrix for key staff on water projectDocument1 pageResponsibility matrix for key staff on water projectrisrizNo ratings yet

- Academic Calender Semester 2 (E17)Document1 pageAcademic Calender Semester 2 (E17)risrizNo ratings yet

- Design Calculations1.XlsxsdfDocument1 pageDesign Calculations1.XlsxsdfrisrizNo ratings yet

- Understanding First-Order and Pseudo First-Order Chemical ReactionsDocument1 pageUnderstanding First-Order and Pseudo First-Order Chemical ReactionsrisrizNo ratings yet

- Lake Ecosystem Structure - Physical Factors, Primary Producers & Energy TransferDocument1 pageLake Ecosystem Structure - Physical Factors, Primary Producers & Energy TransferrisrizNo ratings yet

- RJ CalDocument1 pageRJ CalrisrizNo ratings yet

- Environmental EngineeringDocument4 pagesEnvironmental EngineeringrisrizNo ratings yet

- Consumables PDFDocument1 pageConsumables PDFrisrizNo ratings yet

- Models of Population Growth - Mass Balance ApproachDocument1 pageModels of Population Growth - Mass Balance ApproachrisrizNo ratings yet

- SdfdsDocument1 pageSdfdsrisrizNo ratings yet

- Pipe PlanDocument1 pagePipe PlanrisrizNo ratings yet

- Wastewater Disposal SystemDocument1 pageWastewater Disposal SystemrisrizNo ratings yet

- Designed Checked Approved Date: at Serviceability Limit StateDocument1 pageDesigned Checked Approved Date: at Serviceability Limit StaterisrizNo ratings yet

- Calculating water levels in gravity pipesDocument1 pageCalculating water levels in gravity pipesrisrizNo ratings yet

- 253 PDFDocument1 page253 PDFrisrizNo ratings yet

- Wo PDFDocument2 pagesWo PDFrisrizNo ratings yet

- 252Document1 page252risrizNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Synthesis and Characterization of Manganese (II), Cobalt (II) and Nickel (II) Complexes of Phenyl Glycine - O-Carboxylic AcidDocument4 pagesSynthesis and Characterization of Manganese (II), Cobalt (II) and Nickel (II) Complexes of Phenyl Glycine - O-Carboxylic AcidJASH MATHEWNo ratings yet

- M.A.M College of Engineering: Department of Electrical and Electronics EnggDocument16 pagesM.A.M College of Engineering: Department of Electrical and Electronics EnggKrishna ChaitanyaNo ratings yet

- Mcas Magnetism ElectricityDocument27 pagesMcas Magnetism ElectricityBea GonzalesNo ratings yet

- General Relativity: Matthias Bartelmann Institut F Ur Theoretische Astrophysik Universit at HeidelbergDocument196 pagesGeneral Relativity: Matthias Bartelmann Institut F Ur Theoretische Astrophysik Universit at HeidelbergparonimusNo ratings yet

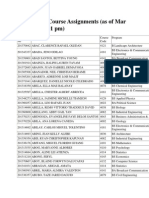

- UP Diliman Course AssignmentsDocument82 pagesUP Diliman Course Assignmentsgamingonly_accountNo ratings yet

- William Liller - Space AstrophysicsDocument290 pagesWilliam Liller - Space Astrophysicsmuhamad dimas arifin a.k.a Ahmd El ArfNo ratings yet

- BX51WI/BX61WI Fixed Stage Upright MicroscopeDocument8 pagesBX51WI/BX61WI Fixed Stage Upright MicroscopestreetcribdealerNo ratings yet

- 6 Pile GroupDocument4 pages6 Pile GroupAnonymous nwByj9LNo ratings yet

- Corrosion Resistance of Surface Treated 42crmo4 Steel: D. Kusmič, V. Hrubý, L. BachárováDocument6 pagesCorrosion Resistance of Surface Treated 42crmo4 Steel: D. Kusmič, V. Hrubý, L. BachárovárachidradouaniNo ratings yet

- IS 1570 Part 5Document18 pagesIS 1570 Part 5Sheetal JindalNo ratings yet

- Summary A PDFDocument3 pagesSummary A PDFAhmad TouqirNo ratings yet

- Turbomachineries School of Mechanical and Industrial Engineering Debre Markos UniversityDocument58 pagesTurbomachineries School of Mechanical and Industrial Engineering Debre Markos UniversitybirlieNo ratings yet

- Eurotherm 2116Document156 pagesEurotherm 2116jessicrmNo ratings yet

- Egyptian FractionsDocument80 pagesEgyptian Fractionsmyasweet22No ratings yet

- 06 - 3D Embankment ConsolidationDocument28 pages06 - 3D Embankment ConsolidationRaynaldo JodistiroNo ratings yet

- Grade 12 English Test Review: Key Terms, Grammar, Reading ComprehensionDocument5 pagesGrade 12 English Test Review: Key Terms, Grammar, Reading ComprehensionLinh HuongNo ratings yet

- Chap3 (D) MillDocument22 pagesChap3 (D) MilljojoNo ratings yet

- Ernest Allen's CVDocument6 pagesErnest Allen's CVernestrallenNo ratings yet

- Design Charts for Bolts with Combined Shear and Tension ForcesDocument4 pagesDesign Charts for Bolts with Combined Shear and Tension ForcescmkohNo ratings yet

- THF Oxidation With Calcium HypochloriteDocument3 pagesTHF Oxidation With Calcium HypochloriteSmokeNo ratings yet

- Horizontal Twin-Shaft Paddle Mixers - The Ultimate in Mixing TechnologyDocument5 pagesHorizontal Twin-Shaft Paddle Mixers - The Ultimate in Mixing TechnologyMilling and Grain magazineNo ratings yet

- The Evolution of Consciousness According to Bhagavad-GitaDocument14 pagesThe Evolution of Consciousness According to Bhagavad-Gitatrabajo mpdNo ratings yet

- Triton X 100Document2 pagesTriton X 100jelaapeNo ratings yet

- (ISRM Book Series) Shunsuke Sakurai - Back Analysis in Rock Engineering-Routledge - CRC Press (2016) PDFDocument241 pages(ISRM Book Series) Shunsuke Sakurai - Back Analysis in Rock Engineering-Routledge - CRC Press (2016) PDFJorge Cortez CampañaNo ratings yet

- Unconfined Compression Test: Experiment No. 3Document6 pagesUnconfined Compression Test: Experiment No. 3Patricia TubangNo ratings yet

- JC 3000s Clamp-On Ultrasonic FlowmeterDocument4 pagesJC 3000s Clamp-On Ultrasonic FlowmeterXu EmilyNo ratings yet

- 11 HW ChemistryDocument6 pages11 HW ChemistryJ BalanNo ratings yet

- Suntech STP225-20 WD 225Wp ENDocument2 pagesSuntech STP225-20 WD 225Wp ENmax2503No ratings yet

- Product Note PD30 en RevA 2011 Anti-Sway Control ProgramDocument2 pagesProduct Note PD30 en RevA 2011 Anti-Sway Control ProgramkumarNo ratings yet

- EE3008 Quiz 1Document5 pagesEE3008 Quiz 1Ricky Kwan Ki KwokNo ratings yet