Professional Documents

Culture Documents

Woolworths (Aus) - Company Summary - Introduction

Uploaded by

Joe HainOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Woolworths (Aus) - Company Summary - Introduction

Uploaded by

Joe HainCopyright:

Available Formats

Woolworths (Aus) Profile

Woolworths (Aus) - Company Summary - Introduction

Company logo

Company websites Corporate www.woolworthslimited.com.au Consumer www.woolworths.com.au and www.woolworths.co.nz

Woolworths Ltd - Company Summary 2011

2010 Group Sales (excl. sales tax) Number of Stores Sales area sq.m (Supermarket Division) AUD 50,283.30 m 3,199 2,452,451 2011 AUD 54,505.7 m 3,241 2,535,894 % change 4.9 1.3 3.4

Source: IGD Research, Woolworths Ltd, 2011 Ownership Woolworths Ltd is a public company listed on the Australian Securities Exchange (ASX). Progressive Enterprises Ltd is its New Zealand subsidiary. It should be noted that Woolworths Ltd has no link with former UK retailer, Woolworths Group plc. Woolworths Ltd - Countries of Operation 2011

South and Central America No Operations

Europe

NAFTA

Asia

Middle East

Africa

Australasia

No Operations

No Operations

No Operations

No Operations

No Operations

Australia New Zealand

Source: IGD Retail Analysis Datacentre, calculated in 2011 Note: Woolworths' consumer electronics division is present in India via a joint venture. Woolworths Ltd - Store Portfolio - By Region 2011

% Change Y-on-Y Stores % Change Y-on-Y Sales

Region

Stores

Sales

IGD Supply Chain Analysis 2011

http://www.supplychainanalysis.igd.com

Woolworths (Aus) Profile

Australasia Total 3,241 3,241 1.3 1.3 AUD 54,505.7 m AUD 54,505.7 m 4.9 4.9

Source: IGD Research, Woolworths Ltd, 2011 Woolworths Ltd - Store Portfolio - By Format 2011

% Change Y-on-Y Stores 2.15 -0.01 4.20 2.20 % Change Y-on-Y Stores -0.01 -0.01 % Change Y-on-Y Sales 3.8 9.9

Formats - Grocery Superstores / Supermarkets Convenience & Forecourt Off-Licence TOTAL Formats - Non Grocery Other - Non grocery TOTAL

Stores 996 592 793 2,381 Stores 860 860

Sales AUD 40,287 m AUD 6,025 m included in Supermarkets AUD 46,312 m Sales AUD 7,831 m AUD 7,831 m

4.6 % Change Y-on-Y Sales 5.7 5.7

Source: IGD Retail Analysis Datacentre, calculated in 2011

Woolworths (Aus) Company Summary Company History

2011

q q

May, Woolworths announces rollout of contactless payment facilities across all brands May, Woolworths announces Masters as the fascia for its new home improvement store; the first outlet (13,500 sqm) will open in Melbourne in September/October to be followed by others in Victoria and Queensland March, Woolworths launches sustainable fish sourcing strategy

2010

q

Acquires Gunns Retail Division in Tasmania, which includes five hardware stores, a timber joinery centre and truss manufacturing plant Finalises acquisition of hardware distributor Danks Holdings Ltd Acquires 25% stake in Gage Roads Brewery Completes acquisition of Macro Wholefoods (seven existing store leases and a development site)

q q q

2009

q

September: Woolworths reveals that it has secured the first site for its hardware business, in Coolaroo, Victoria. The

IGD Supply Chain Analysis 2011

http://www.supplychainanalysis.igd.com

Woolworths (Aus) Profile

site is scheduled to open in late 2011

q

August: Woolworths announces its entry into the hardware market, with the acquisition of Danks. The move comes as a joint venture with US Home Improvement operator Lowe's June: Woolworths is given the green light by the ACCC to complete the acquisition of Macro Wholefoods' eight stores. The retailer will convert the estate to its premium Thomas Dux concept March: Woolworths announces an overhaul of its electrical outlets, and will convert all its Powerhouse and Tandy stores to the Dick Smith banner. The retailer is currently rolling out a fresh look to its Dick Smith stores February: Woolworths announces that it has acquired online wine specialist Langton's Fine Wine Auctions January: Woolworths unveils its new brand identity, aiming to capitalise on its reputation for quality fresh produce. The new logo will be rolled out across the Woolworths estate over the coming year

q q

2008

q

October: Woolworths announces that it is to roll out national unit pricing in all its stores, following completion of a successful trial August: Woolworths opens a new distribution centre in Minchinbury, featuring an element of automation. The distribution facility is linked to the core merchandising systems and store order management, leading to advanced and improved availability of product. The new DC is able to process 5,000 pallets per day May: Woolworths buys a 19.1% stake in Australian pub chain owner, Ale Property Group, for around AUS$57m

2007

q

October: Woolworths decides not to proceed with a request for the competition regulator to review the potential acquisition of some of Coles Group's assets. This follows the ACCC ruling that it will not allow Woolworths to but Coles' Officeworks and Kmart general merchandise chains. It had deferred a decision on whether it could acquire apparel chain Target January: Application submitted to the New Zealand Commerce Commission seeking permission to acquire 100% of The Warehouse Group

2006

q q

September 2006: Acquisition of a 10% stake in The Warehouse Group, New Zealand Announcement of planned market entry into India through a joint venture with the Tata Group

2005

q

Woolworths purchases Progressive Enterprises Ltd in New Zealand

2002

q

Progressive Enterprises Ltd acquires Woolworths NZ from Dairy Farm

2000

q

Chisholm Manufacturing and Rockmans clothing stores are sold as part of renewed focus on core businesses

IGD Supply Chain Analysis 2011

http://www.supplychainanalysis.igd.com

Woolworths (Aus) Profile

1999

q q

The first Ezy Banking service is launched in Queensland Launch of Project Refresh - a company-wide program to reinvigorate its business

1998

q

Launch of HomeShop - Woolworths' internet service

1993

q

Woolworths Ltd floated on the Australian Stock Exchange

1992

q

Formation of an association with United States-based suppliers to serve their customers with counter seasonal produce. Woolworths now exports to Asia, Canada and the USA

1990

q

Divestment of New Zealand operations to Asian retailer Dairy Farm

1983

q

Establishment of the Yennora Distribution Centre - Woolworths first computerised food warehouse

1978

q

LD Nathan and Co Ltd to purchases Woolworths' 40% interest in Woolworths NZ Ltd

1976

q

First BIG W discount store opens

1973

q

Launch of private label line. 200 items launched under five different brand names St Mark, Tania, Grandway, Chevron and Woolworths

1971

q

Market entry into New Zealand with the acquisition of Self Help Supermarkets

IGD Supply Chain Analysis 2011

http://www.supplychainanalysis.igd.com

Woolworths (Aus) Profile

1964

q

Establishment of first shopping centre

1963

q

Formation of the export division and Woolworths is registered in Malaysia, Thailand, Hong Kong and the Philippines

1960

q

First Woolworths supermarket opens in New South Wales, marking the retailer's focus on the food sector

1950s

q

First self-service store opens in Sydney

1930s / 1940s

q

Development of a chain of stores - 31 in Australia and nine in New Zealand

1929

q

Establishment of the London Buying Office and the associated company, Woolworths (New Zealand) Ltd, opening its first store in Wellington

1927

q

First Queensland store opens

1924

q

Establishment of first 'Woolworths Stupendous Bargain Basement' store in Sydney

Woolworths (Aus) Supply Chain Overview Strategy

Woolworths supply chain consists of four main pillars: international logistics, operations, logistics development and replenishment. These pillars are supported by support services including HR, IT systems, Safety and Finance.

IGD Supply Chain Analysis 2011

http://www.supplychainanalysis.igd.com

Woolworths (Aus) Profile

The retailer has been expanding global sourcing and international logistics capabilities delivering substantial benefits with direct buying volume growing more than 46% during the year. The operations side of the supply chain focuses on the day-to-day function of transport, inbound and outbound transport and the distribution centres. So that the supply chain can add value to the business and business objectives, the logistics development function has recently been re-structured to become a shared service for all banners within the group. This means that what the retailer does really well in food and liquor will be rolled out to other fascia. The goal is to look at everything from an end-to-end approach and choose the right flow path from the current practice of multiple ways of getting product to consumer. This will be holistic keeping in mind the flow of goods from supplier to end consumer and across all businesses within the group. The replenishment function in the business is seen as the catalyst between the buying teams and other parts of the supply chain, focusing its efforts on the volume needed to ensure availability in the store. In 2011, the Supply Chain in Woolworths has been delivering financial benefits through a variety of projects including:

q

The intellectual property from Project Refresh, a multifaceted business change program introduced in August 1999, to deliver best practices across its entire group of companies and to improve efficiencies by eliminating waste and duplication, is now being applied across other businesses. Project Galaxy, the third and final phase of this will give Woolworths an even bigger advantage with the use of SAP technology to overhaul merchandising, point-of-sale and retail systems across all Woolworths brands. While the first phase of Project Refresh focused on combining the state-based buying teams into a centrally coordinated national force, the second phase, Project Mercury, focused on rebuilding the supply chain and logistic component. Woolworths also consolidated its distribution centre footprint as part of the refresh, scaling down from 31 centres to nine regional centres and two national centres in 2009. Press reports suggest that these projects have delivered over $6 billion in cost savings. Liquor Distribution Centres (DC) have been enhanced with significant capacity to lower unit costs and the reengineering of Mulgrave National DC has provided increased capacity, improving efficiency and reducing costs Global sourcing and international logistics capabilities have been expanded delivering substantial benefits with direct buying volume growing more than 46% during the year

Lower Costs to deliver cost savings and efficiencies has been a key focus in 2010 and this will continue into 2011.

q

The initiatives under Project Quantum focus on leveraging scale to create cost saving and efficiency synergies across all businesses and support functions including supply chain, IT, Finance, Call Centres, non-trading procurement and global direct sourcing This has resulted in a shared service model with a focus to reduce process waste, duplication and harmonise ways of working across different parts of the business. The benefits realised from this are a lower cost of doing business and increased gross margin to further maximise brand competitiveness in a tough market

IGD Supply Chain Analysis 2011

http://www.supplychainanalysis.igd.com

Woolworths (Aus) Profile

Source: Woolworths Ltd, 2011

Source: Woolworths Ltd, 2011

Woolworths (Aus) Supply Chain Overview Scale of Operations

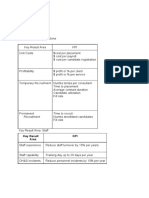

The following table outlines the scale of Woolworths supply chain operations.

Woolworths

IGD Supply Chain Analysis 2011

http://www.supplychainanalysis.igd.com

Woolworths (Aus) Profile

Year ending June 2011 Total Sales (supermarket division) y/e 2011 Total Stores Total Supermarkets (including petrol) Total Sales Space (supermarket division) sqm AU$46,312m 2,381 996 2,535,894

Stores

Supermarkets in Australia

Source: IGD , Woolworths at 04/10/11

Store Formats

Woolworths multi-format strategy means it operates a variety of banners in the markets it is present in. Australia

Formats Supermarkets Liquor General Merchandise Consumer Electronics Fuel Hotels & DIY Banners Woolworths, Thomas Dux Liquor Woolworths, Dan Murphy, Langton, BWS Big W Dick Smith, Tandy Caltex / Woolworths ALH Group, Danks

IGD Supply Chain Analysis 2011

http://www.supplychainanalysis.igd.com

Woolworths (Aus) Profile

New Zealand

Formats Supermarkets Consumer Electronics Banners Woolworths, countdown, Foodtown, fresh choice, supervalue Dick Smith

In addition, the retailer operates the Croma banner in India in partnership with the Tat group, Indias largest private sector group.

Stores

Format Australia Supermarket (Woolworths, Thomas Dux) Petrol/Forecourt (Wow, Caltex, Woolworths) Liquor (BWS, Dan Murphy's, First Estate, Mac's Liquor, The Cheaper Liquor,ALH/MGW) General Merchandise (Big W) Consumer Electronics (Dick Smith Electronics, Dick Smith Powerhouse, Tandy) Hotels & DIY Total Stores Australia 851 581 793 165 394 301 3,085 2011

New Zealand Supermarket (Woolworths, Supervalue, Fresh Choice, Foodtown, Countdown) Total Stores New Zealand Total 156 156 3,241

In addition, the retailer operates 881 wholesale customer stores under the banners of Dick Smith, Progressive, Danks, Statewide Independent Wholesale (Australasia) and Croma in India.

Woolworths (Aus) Supply Chain Overview Management Structure

Woolworth management board is led by CEO Grant OBrien and includes the following executives:

q

Grant OBrien

Managing Director and Chief Executive Officer

IGD Supply Chain Analysis 2011

http://www.supplychainanalysis.igd.com

Woolworths (Aus) Profile

Tom Pockett Julie Coates Andrew Hall Peter Horton Kim Schmidt Steve Greentree

Finance Director Director of Big W Director Corporate and Public Affairs Company Secretary and General Counsel Director Human Resources General Manager Liquor

Woolworths (Aus) Warehousing - Key Initiatives

Australia

Woolworths distribution centres, listed below, are a mix of third-party management and own operations.

Distribution Centre Name Arndell CDC

State New South Wales

Categories Composite Composite produce, ambient,

Street 21 Holbeche road

Suburb/Town Arndell park

New South Wales

Wyong RDC

chilled, fresh and frozen (includes liquour)

Warren road

Warnervale

New South Wales New South Wales

Sydney NDC Wyong RDC

Composite Produce Fresh, ambient, produce, chilled and meat Seafood Bulk beer, ambient, liquor NSW Outside Storage ProduceFrozen, chilled, meat and dairy Produce

Cnr Fairfield & Dursley road 1 Warren road

Yennora Warnervale

New South Wales

Sydney RDC

69 Sargents road

Minchinbury

New South Wales New South Wales

Sydney RDC Sydney LDC

69 Sargents road 29 Sarah Andrews close Building 6, Stockland dist cnr pine

Sydney Erskine park

New South Wales

Yennora

Queensland

Murarrie

51 Alexandra place

Murarrie

Queensland

Townsville Produce D.C.

Jay street

Bohle townsville

IGD Supply Chain Analysis 2011

http://www.supplychainanalysis.igd.com

10

Woolworths (Aus) Profile

Ambient and liquor Bulk, produce, chilled, confectionery, securityaerosols, ambient, fresh Queensland Victoria Victoria Hume RDC Laverton TDC Brisbane P&O Composite Chilled, meat, fresh, events Composite, produce Vic Outside Storage Ambient, Victoria Wodonga RDC produce, chilled, frozen, fresh, liquor, milk Victoria Mulgrave Outside Storage Ambient, bulk Victoria Melbourne LDC beer, cellar, indent storage Frozen Ambient, produce, chilled, frozen, fresh Western Australia South Australia Bunbury Dry Creek Meat Frozen Ambient, liquor, confectionery, bulk beer, produce, chilled, frozen, fresh Tasmania Tasmania Tasmania Derwent Park Devonport Breadalbane Composite Produce Meat 20 Lampton avenue Brooke road 13 Richard street Derwent park East devonport Breadalbane North Boyanup road 6 Bradford way Bunbury Dry creek 40-48 Leakes road Laverton Lot 1, 155 union road Somerton 28 Bilston drive Barnawartha 48 Paradise road 120 Northcorp boulevard 73 Boundary road Acacia ridge Broadmeadows Laverton north

Queensland

Brisbane LDC

28 Quarry road

Stapylton

Queensland

Brisbane RDC

70 Distribution street

Larapinta

Victoria

Melbourne NDC

522 Wellington road

Mulgrave

Victoria

Lot 1, 155 union rd

Somerton

Western Australia

Spearwood

Quarimor road

Spearwood

Western Australia

Perth RDC

20-60 Colquhoun road

Perth international airport

South Australia

Gepps RDC

599 main north road

Gepps cross

IGD Supply Chain Analysis 2011

http://www.supplychainanalysis.igd.com

11

Woolworths (Aus) Profile

Source:www.wowlink.com.au Woolworth's new supply chain was designed following detailed modelling which demonstrated that its optimum supply network should be made up of National Distribution Centres (NDC's) for slow moving lines and Regional Distribution Centres (RDC's) for fast moving goods. The Woolworths network currently comprises two National Distribution Centres (Mulgrave in Melbourne and Yennora in Sydney) and ten Regional Distribution Centres. The network also includes two new Liquor distribution centres, a range of satellite facilities, dedicated sites and 3PL operated DC's.

New Zealand

DC Name Christchurch Temperature Controlled DC Christchurch Dry DC Auckland Temperature Controlled DC Auckland Dry DC Palmerston North Temperature Controlled DC Palmerston North Dry DC Location HORNBY HORNBY SOUTH MANUKAU OTAHUHU PALMERSTON NORTH PALMERSTON NORTH Country NZ NZ NZ NZ NZ NZ

Source: Woolworths WOWLink (2009) Global Location Numbers, www.wowlink.com.au The following diagrams show the NDCs' and RDCs' that Woolworths operates within Australia and New Zealand.

IGD Supply Chain Analysis 2011

http://www.supplychainanalysis.igd.com

12

Woolworths (Aus) Profile

Source: Image 1 Woolworths (2009) Melbourne LDC Vendor Pack, www.woolworths.com.au, Image 2 Wow link, www.woolworths.com.au

Liquor

In 2008 Woolworths began construction on two new dedicated Liquor Distribution Centres, one in Sydney at Erskine Park and another in Melbourne at Laverton. The sites will service Woolworths' liquor stores, BWS and Dan Murphy's with liquor and slower moving lines.

Minchinbury and Hume DC's

Woolworths distributes much of its fast moving dry and non-food categories from two regional distribution centres, Minchinbury, which serves the Sydney area, and Hume/Broadmeadows, serving the Melbourne area. The categories require similar handling allowing the optimum use of automated handling equipment. Both sites were constructed in the late 1990's by Swisslog and include the following features:

q

Goods receiving area for the identification and checking of goods Bulk storage high-bay warehouse Crossdock (transhipment) and flowthru area Automated replenishment to picking area Pick-to-belt module for pick-to-light picking Automated order picking module with robotic picking High-speed sortation and despatch facilities Warehouse management system with material flow control and connection to the Woolworths ERP system.

According to Swisslog the benefits of the sites include: lower stock levels; a good balance between manual and automated processes; the use of up-to-date material handling technology; and the flexibility to operate in an ever-changing environment. Source: Swisslog (accessed August 2009) Case Study, Woolworths Supermarkets Australia, www.swisslog.com/wds-case-

IGD Supply Chain Analysis 2011

http://www.supplychainanalysis.igd.com

13

Woolworths (Aus) Profile

woolworths.pdf

Minchinbury

The 530,000 sq.ft. Minchinbury distribution centre carries around 4000 of the fastest moving grocery items, holds 40,000 pallets (including a high-bay section of 27,600 pallets which is serviced by 10 unmanned stacker/retriever cranes), is capable of receiving 1.5 million cartons per week and has a pick rate of more than 12,000 cartons per hour. The site has 45 receiving and dispatch docks and more than 500 staff operate the depot working two ten hour shifts per day. The warehouse achieves service levels of nearly 98% and services every store in the New South Wales and Australian Capital Territory. Source: Logistics Association Australia (2004) www.laa.asn.au/__data/page/757/NSW_Jun04.pdf. During 2005-2006 Woolworths existing Minchinbury ambient temperature regional distribution facility was expanded to include a new 323,000 sq.ft. cold storage distribution facility, which included new loading and despatch docking facilities, new perimeter hardstand facilities, truck parking, refuelling and washing areas, carparking and office space. The Minchinbury site incorporates a range of features including:

q

Goods receiving area for identification, via mobile RF-Terminals labelling and checking of goods Automated replenishment for picking areas and automated order picking module with robotic picking A pallet conveyor system and monorail system High speed tilt-tray sortation system - capable of handling 12,000 cartons per hour Pallet assembly tables Warehouse management system with material flow control and connection to Woolworths' systems High speed sortation and despatch facilities

The Minchinbury site delivers a number of benefits including:

q

Reduced overall stock levels Lower handling costs per carton (as the throughput of the sites has risen above the system design specification) Reduced lead times from order to supply Improved inventory management and order accuracy Picking accuracy now close to 100% Improved availability Efficient use of available land

Source: IGD Research/Woolworths; Swisslog, 2008

IGD Supply Chain Analysis 2011

http://www.supplychainanalysis.igd.com

14

Woolworths (Aus) Profile

Source Image 1: Hansen Yuncken (2009) Past Projects, www.hansenyuncken.com.au/our-projects/past-projects? sid=1508&id=2381 Source Image 2: TTW (accessed August 2009) Woolworths Distribution Centre, Minchinbury, Sydney and Broadmeadow, Melbourne, www.ttw.com.au

Brisbane

Woolworths Brisbane (Larapinta) distribution centre is one of the retailer's newer sites, which became operational in 2006. The site covers around 800,000 sq.ft. (with room to expand by another third), about three times the size of previous generation warehouses and employs around 1,200 permanent staff. The site is one of the most automated sites in Woolworths network and handles fresh, chilled and frozen products. At the time of construction the site was the largest and the most sophisticated distribution centre in the Southern Hemisphere. A range of high-tech systems play key roles in the maximising the efficiency of the Brisbane site. Radio Frequency (RF) receiving, RF loading, flow-through, cross docking, labour management and integrated voice picking are all key requirements for the retailer. In particular, the cross docking capabilities at the new Brisbane DC are viewed by Woolworths as a critical market advantage. These technology advances allow the RDC to receive 30,000 pallets per week, 2.5 million cases can be picked and 42,000 pallets despatched per week, resulting in 1,200 truck movements in and out of the RDC every day. The goods receipt and management process at the Brisbane site is heavily automated. In a traditional DC a full pallet is unloaded at the dock, picked up and put away by a forklift, whereas at the Brisbane site the full pallet is lifted and positioned by large automated cranes, it then passes through various sensors as it moves from the dock along an infeed conveyor to a stock station. At the stock station the pallet is checked for weight, oversize, integrity, fork tunnels and barcodes before proceeding to a lift and being transported to the Hi-Bay, it is at the station that the pallet will be either accepted or rejected.

Source: Loscam (2005) LOSCAM Leader Issue 8, www.loscam.com A pallet will be rejected if it does not conform to the set criteria, for example, if the pallet is broken, has extruding nails, if the shrink wrap is not applied correctly or if the label is inaccurate, the pallet will be rejected. Only nine pallets can be rejected at

IGD Supply Chain Analysis 2011

http://www.supplychainanalysis.igd.com

15

Woolworths (Aus) Profile

any one time before the automated lift system stops and staff must manually fix the problem. As the system is fullycomputerised the operator can easily identify the cause of the rejection. Once the pallets are stores, the LCS system used at the site knows the location of every pallet, base on the code dates. These are scanned to make use the pallet matches the given information. Source: Woolworths (accessed 2009) and Loscam (2005) LOSCAM Leader Issue 8, www.loscam.com

Melbourne Liquor DC

Woolworths dedicated Liquor distribution centre in Melbourne is located in Laverton, to the south-west of the city, and opened in August 2008. The 759,000 sq.ft. site will employ around 400 people and service approximately 383 stores across Australia. The DC has a manual racking layout with Carton and Pallet live storage, voice picking systems and radio frequency receipt and dispatch systems. Other features of the site include: receiving and dispatch docks on opposite sides, 14 finder and 8 flush docks, 3 container bays and 6 B-Double Bays. The layout of the site is optimal for one-way traffic flow and is designed to support B-double trucks. Source: Woolworths (2009) Melbourne LDC Vendor Pack, www.woolworths.com

New Zealand

Woolworths operates six DCs in New Zealand, located in Auckland, Palmerston North and Christchurch.

Mangere Distribution Centre

Progressive Enterprises Mangere Distribution Centre in Auckland is the largest ambient grocery DC in New Zealand. The 603,000 sq.ft. DC employs more than 300 staff making it the largest ambient grocery DC in New Zealand.

Palmerston North Distribution Centre

The Palmerston North warehouse covers around 125,000 sq.ft. (with extra outside storage available on-demand) and employs more than 100 staff.

Christchurch Composite Distribution Centre

The Christchurch Composite Distribution Centre measures approximately 280,000 sq.ft. and only supplies New Zealand's south island. The CDC consists of two closely located sites, operating as a single Distribution Centre. Primary distribution is from Rotorua to Wellington. Three temperature controlled distribution centres located in Auckland, Wellington and Christchurch supply Woolworths New Zealand supermarkets with produce lines, including fresh fruit and vegetables, flowers and plants. Each distribution centre has Quality Assurance programmes in place to ensure high quality standards. Produce is sourced from New Zealand based suppliers and the retailer encourages local purchasing where possible. All chilled and frozen products are stored and distributed by a 3rd party distributor, P&O Logistics, which operates from 3 sites: Auckland, Palmerston North and Christchurch. Goods are transported using temperature controlled hard-side and curtain side units. Source: Progressive Enterprises Ltd

Key Initiatives

IGD Supply Chain Analysis 2011

http://www.supplychainanalysis.igd.com

16

Woolworths (Aus) Profile

In 2011, Woolworths has maintained a free cash flow of 38% of net profit after tax, contributed to mainly from an increase of 6.2% in the cash from operating activities before interest and tax. Average inventory days in the overall business has increased to 33.8 days, up from 33.3 days in fiscal year 2010. Inventory increased 8.7% primarily due to increased indent stock from direct sourcing, incremental inventory in liquor DCs, the purchase of inventory for new Masters stores and inventory from the acquisition of Cellmasters and retail hardware stores.

Source: www.woolworths.com.au The retailer continues to invest in its distribution centres. For example, in 2011 the capital expenditure on the supply chain includes investment in the new National DC in Auckland, BIG W / Consumer Electronics / Home Improvement DCs in Hoxton Park, re-engineering of the Melbourne National DC and a new meat processing plant in Western Australia. The retailer has invested in a variety of initiatives in its warehouse network in 2010, and these include:

q

Productivity improvement through best-in-class labour planning system. Known as Pyramid, this used technology for effective labour and manpower planning in the supply chain Increased use of outbound fleet for in-bound deliveries (primary freight). This followed the integration of primary freight, secondary freight and NDC linehaul under one banner called Woolworths National Transport in 2009. The concept of primary freight started with transporting ambient goods from supplier premises into Woolworths DCs, and today the retailer also transports temperature controlled, meat and produce categories. Woolworths primary freight contributes close to 50% of the volume in to their distribution centres. Reduced outside storage of imported products Reduced manual pick through layer picking equipment and the use of pool pallet equipment for store delivery. On a weekly basis, pallet composition can be varied to fit store order profiles Woolworths has completed the re-engineering of the national distribution centre located in Mulgrave (Victoria) resulting in increased capacity, pick rate efficiency and reduced costs. The refurbishment of two automated sites at Hume (Victoria) and Minchinbury (New South Wales) is complete which significantly extends the life of these DCs. Construction of the consolidated Tasmanian regional distribution centre for food and liquor has commenced with completion planned in FY12. Development of the Bunbury (western Australia) meat processing and distribution operation is tracking to schedule and is planned to be completed in FY12. This will improve the efficiency of both the meat processing and distribution to supermarkets in western Australia.

q q

IGD Supply Chain Analysis 2011

http://www.supplychainanalysis.igd.com

17

Woolworths (Aus) Profile

Woolworths vendor capability team has been working with suppliers and trade partners to improve DC utilisation, particularly in relation to the number of part-pallets. For a variety of reasons, DCs often receive multiple part-pallets of the same product instead of a single, full pallet of that product and has been identified by the retailer as adding to:

q q q q q

Increased transport charges (and associated environmental impact) Increased receiving / putaway time Greater risks of product damage Wasted DC reserve capacity Increased number of pallet moves

Improving pallet utilisation has been a focus area and the retailer has been addressing improvements in pallet quality, labelling, stabilisation, trade unit packaging and bar coding in this area. Under certain circumstances, the retailer has announced that if the replenishment ream has ordered products from a vendor in less-than-full-layer quantities, suppliers can combine up to four products in one pallet for more efficient transportation (maximum heights of pallets vary depending on if it is third-party operated or Woolworths operated). Further, a change has now been made to the rules regarding mixed code dates for frozen products. Specifically, for frozen products that have 120 days shelf-life or greater, multiple date codes and/or batches can now be combined on the one pallet. For example, if 80 cartons of a product have been ordered, and a supplier has 50 cartons with a Use By Date of X and 30 cartons of Use By Date Y, these 80 cartons can now be combined onto a single pallet. In this case, a single pallet label must be generated (one for each fork-entry side of the pallet) that reflects the earliest Use By/Best Before date, the lowest Batch code, and the total, combined carton quantity. A key initiative for Woolworths in the next 12 months is to use cross-divisional network and the capability across banners to optimise flow-paths. Project Refresh During 2008 Woolworths completed the majority of its end-to-end supply chain improvement programme in Australia. 'Project Refresh' played a key part in Woolworth's strong financial results over recent years and, between 1999 and 2007, delivered cumulative savings of around AU$ 7.3 billion (4.71% of sales). The improvements implemented during the project have led to increased productivity, which has enabled higher levels of "in stock performance" and resulted in greater competitive advantage. The first phase of Project Refresh saw Woolworths reorganise its business from a silo-built state-based business to a national business. The retailer combined the state-based buying teams into a single central operation enabling goods to be purchased nationally. The transformation of its supply chain was driven by the implementation of a range of systems including: a Warehouse Management System; a Transport Management System; StockSmart, a forecast based replenishment system installed in distribution centres; and AutostockR, a store forecast based replenishment system installed in stores. The integration of the store-forecast replenishment system with the distribution centre forecast-based replenishment system has given the business the ability to predict, order and control stock by allowing the retailer to focus more on managing information and less on managing stock which is more cost-efficient and operationally effective. For example, the system allows the retailer to predict how many tins of Golden Circle pineapple slices would be needed by each individual supermarket around the country in two weeks' time. These systems have enabled a range of additional improvements including:

q

Optimization of movement of inventory through the physical supply network to reduce lead times, costs and inventory Rapid re-optimization of replenishment plans for ambient, fresh, chilled and frozen items Supplier to store transportation optimization, planning and management

IGD Supply Chain Analysis 2011

http://www.supplychainanalysis.igd.com

18

Woolworths (Aus) Profile

Better supply chain event monitoring and management Improved management of orders and master data Greater accuracy of reporting and analytics

The re-organisation of the supply chain approached its conclusion in 2008 with the full commissioning of the new Brisbane LDC at Larapinta, which allowed the transition from the previous distribution network of 31 DC's to a more streamlined network comprising nine Regional Distribution Centres, two National Distribution Centres and two Liquor Distribution Centres. Woolworths is confident that the financial benefits of its supply chain restructure will continue to be accrued over future years as the new DC infrastructure reaches optimum efficiency levels. In 2008 the Perth, Adelaide, Wyong and Wodonga sites were already exceeding their initial projected business case. Source: Woolworths Annual Report 2008 (2008) www.woolworths.com Woolworths also now directs its logistics on a national basis. The roll out of the Transport Management System (TMS) has enabled Woolworth's Primary Freight business to better manage inbound volumes into DC's, reducing the cost of its inbound freight and (according to the retailer) outperforming industry benchmarks. In 2008 the retailer also rolled out its outbound Metro Transport Model (MTM) which involves the acquisition of specifically designed trailers and the deployment of industry leading capacity planning, optimisation and freight tracking systems. These will allow Woolworths to optimise transport from DC's to stores, including Backhauling. Woolworths suppliers have also worked with the retailer on primary freight to identify which Distribution Centre is most suitable for each product, have introduced packaging improvements such as shelf-ready-packaging and more customer friendly merchandising, and have focussed on delivering full, high quality orders within the timeslot given. In stores, the project has led to the introduction of time phased replenishment and store re-stocking capabilities and storeready unit load devices including shelf ready trays, roll cages and produce crates, all of which have contributed to reductions in overall costs. Australia's disparate geography creates significant pressure on order pickers and dispatchers to get loads ready on time. Store distances from distribution centres can vary from 4km to 4,000km. Lorries leaving the distribution centre may need to link with other integrated transport such as rail which means that despatching on time can be more important than completing store orders. This practice can have a detrimental impact on store availability. Project Refresh has had a considerable impact on Woolworths' stock holding, days on hand fell by 23% between 2002 - 2006. However, the daily intake capacities of distribution centres has increased significantly, for example the conversion to a national distribution centre in Sydney has enabled an increase of 600 pallets per day to be accepted from 1,000 to 1,600. Woolworths intends to maintain and increase the long-term cost advantages gained as a result of the project and plans to continue to focus on improving its offer and rewarding customers with lower prices, better value, quality, range, freshness, service and convenience. The retailer's long-term objective is for EPS growth to outperform EBIT growth. Source: Woolworths (2007) Annual Report 2007, www.woolworthslimited.com.au New Zealand In New Zealand, Woolworths completed its roll out of StockSmart and AutostockR across its supply chain by late 2008. The retailer has also developed a supply chain strategy designed to improve the service and cost performance of its logistics operations. The retailer aims for this strategy to be fully rolled out by 2011-2012.

Woolworths (Aus) Transport Key Initiatives

IGD Supply Chain Analysis 2011

http://www.supplychainanalysis.igd.com

19

Woolworths (Aus) Profile

Woolworths national transport, as part of its commitment to reduce the environmental impact of its fleet has set a goal to reduce carbon emissions by 25% per carton delivered by Woolworths owned trucks by 2012. Achieving this target will be based on four key areas:

q

Alternate Fuels - Where possible, alternate fuels will be implemented and utilised. The retailer has committed to reduce transportation carbon emissions from their truck fleet. Establishing accurate baseline data in 2008 for all modes is a key element of this. Equipment Design - The equipment used to service Woolworths stores and distribution centres will feature aerodynamic elements to minimise fuel consumption. Improved Prime Mover Emission Technology - Euro IV Prime Movers will be implemented wherever possible, and the potential of hybrid trucks is being reviewed. Supply Chain Efficiency Improvement - Steps are being taken to minimise the effort required by the transport fleet regarding inbound and outbound consolidation.

Source: www.woolworths.com.au The retailers Metro Transport Model is now complete with Brisbane going live in the first half of FY11. This involves Woolworths ownership of specifically designed trailers and the deployment of industry leading capacity planning, optimisation and freight tracking systems. Woolworths new rail strategy has delivered significant benefits following the implementation of the Adelaide to Northern Territory corridor in the last quarter of FY10 and the east west corridor in FY11.

Primary Freight

The concept of primary freight started with transporting ambient goods from supplier premises into Woolworths DCs, and today the retailer also transports temperature controlled, meat and produce categories. Woolworths primary freight contributes close to 50% of the volume in to their distribution centres. An integral part of the Woolworths logistics division, trade partners pay for the primary freight service in the form of a weekly rebate. Primary Freight is made up of four core divisions: Business Development, Business Support, Customer Service and Operations.

Transportation Initiatives

Improved consolidation and optimisation of delivery schedules and route planning will continue to be a focus in 2011. In 2010, emissions reduced a further 3%, bringing the total reduction to 9.4% since 2007.

IGD Supply Chain Analysis 2011

http://www.supplychainanalysis.igd.com

20

Woolworths (Aus) Profile

Effective load building and record management to increase the number of purchase orders on each delivery and the number of pallets on each purchase order at Distribution Centres has delivered an estimated 1517% improvement in primary freight efficiencies. For example, the retailer allows mixed items on a pallet under certain circumstances (see section on warehousing). Other initiatives that have facilitated a more efficient use of transport are:

q

Delivering more pallets per load into Distribution Centres, it is estimated that primary freight has reduced carbon emissions by 14,844 tonnes. Thirty prime movers are to be replaced in 2011 with new safer and more fuel-efficient vehicles. A third party transport company is trialling the use of Liquid Natural Gas (LNG) technology in Western Australia and Woolworths has identified a vehicle released in 2011 which meets their requirements. Successful trial of a B20 biodiesel blend with six vehicles in 2010, confirming no impact to fuel economy or reliability. The trial involved the use of more than 40,000 litres of biodiesel, produced from waste products, which is estimated to have reduced emissions by more than 10 tonnes. The retailers national transport team has developed a trailer that allows the transport of both inbound and outbound freight, maximising integration of primary freight (side loading at supplier depots) and secondary freight (rear loading at Distribution Centres and unloading at stores). This reduces the distances travelled by the fleet and resultant emissions.

q q

Woolworths (Aus) Replenishment - Key Initiatives

Demand planning has been identified as a key requirement to improve on-shelf availability, as supplier deliveries have been identified to constitute 50% of supply issues. In-bound service levels at distribution centres achieve 75% fulfilment, whilst outbound service levels to stores achieve 95% - 96% fulfilment. Woolworths is working with the suppliers to develop communication and improve in-bound service levels in a number of ways:

q

Wow link - data on key measures such as service levels, daily and weekly demand forecasts are communicated via Woolworths' supplier internet portal Inbound Service Level Inbound Service Level is based on the case-fill per line item - delivered 'on time'. It is measured against the original Purchase Order (PO) quantity per line item and the delivery date and time. The quantity delivered is divided by the original PO quantity and is expressed as a percentage. The Guaranteed Purchase Order Acknowledgement quantity provided is not used for Inbound Service Level calculations. For Trade Partners on Woolworths Primary Freight, only the case fill component will be measured. All Primary Freight deliveries are calculated as 'on time'. How the Inbound Service Level is captured Woolworths will record the arrival time at the Distribution Centre (DC) gatehouse for all POs presented. If any POs are not presented via the gatehouse or intercom, these POs will record a 0% Inbound Service Level. If a queue exists outside the DC gatehouse or intercom, where safe and legal to do so, drivers are advised to approach the intercom or gatehouse to provide all PO details. When the PO is registered, this is the arrival time used for calculation of the Inbound Service Level. Case fill definition All quantities per line item delivered are divided by the original PO quantities per line item. The maximum % per line item for the case fill component is 100%. Over delivery of one line item will not compensate for short delivery of another line item. On Time definition

IGD Supply Chain Analysis 2011

http://www.supplychainanalysis.igd.com

21

Woolworths (Aus) Profile

Woolworths requires the PO to be delivered up to 30 minutes early and up to 30 minutes after the time slot, i.e. a one hour window at the discretion of the DC, and with notification deliveries up to one hour early will be considered as on time for Inbound Service Level calculations. Deliveries arriving earlier than one hour before or more than 30 minutes after the scheduled time slot will be considered not on time. This will result in a 0% Inbound Service Level.

q q

Vendor capability team - assist suppliers with transport and logistics arrangements Vendor relationship programme (VRP) - suppliers work within distribution replenishment teams, cooperating with the trading teams to produce demand forecasts; these forecasts are shared with their own organisations. Currently over 50 suppliers are engaged in VRP and represents 50% of the total distribution centre volume. Promotional volumes can cause capacity issues at depots, buyers are challenged to review the cube volume of bulky item promotions

Forecasting

A number of initiatives are in place to improve supply chain forecast accuracy and the impact on the total supply chain:

q

Weather - Woolworths stores span 120 temperature zones. 7 day forecasts are utilised to assess weather impacts Promotions - currently one of the areas where the most improvement can be achieved, c.40% of total demand is promotion driven. Each week 3,000 products are on promotion and promotional volumes can cause depot capacity issues. Buyers are tasked with reviewing the cube volume of bulky item promotions to assess the supply chain impact Demand smoothing - the in-store replenishment system smoothes demand to best utilise back room space and manage peak labour cost periods. This is particularly useful for managing event and weekend volumes

AutostockR

As part of Project Refresh Woolworths has implemented the forecasting system AutostockR to all stores. The objective of AutostockR is to maximise availability and deliver greater visibility of stock requirements and days of supply. AutostockR was initially installed to cover grocery lines, but was latterly rolled-out to cover liquor, general merchandise, fresh food and direct to store supplied lines (Source: Woolworths). AutostockR generates an order using the following components:

q

Forecast sales - based on history and including seasonality Target stock - Minimum presentation level (MPL) is the amount planned prior to the next fill Existing stock - Stock on hand (SOH) + stock in transit (SIT) + stock on order (SOO)

The store is responsible for SOH and MPL of each item. Stores can get baseline forecasts changed only by contacting central AutostockR teams who analyse the availability problem and make necessary changes to the forecast. MPL's are set centrally via the planogram for long life products and in the case of fresh the MPL is set by the store for each of the core range products (Source: Woolworths). New lines use the sales forecast of a similar item when calculating a forecast, as soon as the new item is stocked in stores its own sales start contributing to the forecast. Stores are responsible for ensuring the system orders enough stock for promoted lines. AutostockR provides the store with a suggested uplift as a guide. Stores can adjust their promotional forecast to reflect how an item is expected to sell during the week Additionally, stores can also load in how much stock AutostockR needs to keep in the store for display purposes (Source: Woolworths).

IGD Supply Chain Analysis 2011

http://www.supplychainanalysis.igd.com

22

Woolworths (Aus) Profile

AutostockR - forecasts store item sales based on historical sales, trends and planned inventory levels

Source: IGD, Woolworths

Retail Ready Packaging (RRP)

Project Refresh has re-evaluated the way products are delivered to shelf. Retail Ready Packaging (RRP) has been utilised to improve on-shelf availability. Click here to view the RRP case study

Future Priorities to Further Improve Availability

Woolworths has identified the following key initiatives to further improve on-shelf availability:

q

Unlocking the potential of systems: Development of the Next Generation Replenishment solution is progressing well which will optimise order flow not normally done in replenishment, continue to reduce days inventory as well as save costs in Stores, DCs and Transport. Continuing financial benefits is expected to be achieved as the DC infrastructure reaches greater efficiency levels. Integrate the two replenishment systems (store and depot), AutostockR time horizon to be extended to replace the distribution centre forecast 'One number' to be used through the 'end to end' supply chain. From the buyer through to replenishment, logistics and the supplier

Woolworths (Aus) Environment - Key Initiatives

Woolworths is committed to reducing its environmental footprint through a wide range of initiatives that tackle key areas of energy consumption, waste management, packaging, fuel consumption and hazard management. Initiatives across the supply chain have included the following.

IGD Supply Chain Analysis 2011

http://www.supplychainanalysis.igd.com

23

Woolworths (Aus) Profile

The retailer expects to "mainstream" sustainability initiatives into 'business as usual' having started this process in 2010.

Key Targets CO2-e emissions from fixed assets Transport Emissions Car Emissions Alternative Fuels Biodiesel Reduce emissions by 40% by 2015 (to maintain 2006 levels on projected business growth)

25% reduction in CO2-e emissions per carton delivered by Woolworths owned trucks by 2012 30% reduction on 2006 levels of CO2-e emissions from company car fleets of 3,100 cars by 2010 Trial use of hybrid trucks for home delivery Conduct a study on biodiesel availability in Australia, including quality, vehicle compatibility and cost impacts

Green stores

All new stores from September 2008 will be green stores, using energy efficient building guidelines (Rouse Hill store will be the benchmark)

Water RTI's Low Carbon Strategy

Save a minimum of 200 million litres each year through the WaterWise project Replace single use waxed boxes with 3.4 million reusable crates Establish a forum with major transport suppliers to develop a low carbon strategy for Woolworths third part distribution network

Source: Woolworths Sustainability Strategy 2007-2015 (2007) www.woolworths.com.au

Project Refresh

Project Refresh has delivered cost savings but it has also helped Woolworths become more energy efficient. In New South Wales energy efficiencies generated by the project have allowed the retailer to create tradable NSW Greenhouse Abatement Certificates (NGAC's) as part of the NSW Greenhouse Gas Abatement Scheme that has been in place since the beginning of 2003. One NGAC is equivalent to one tonne of CO2-e that would otherwise have been released into the atmosphere as a result of electricity generation. The retailer's projections show that its energy efficiency measures will create an estimated 16,978 NGAC's per year until 2011. Transport Woolworths aims to reduce the environmental impact of its transport fleet and achieve a 25% reduction in CO2-e emissions per carton delivered by 2012. To achieve this the retailer plans to implement the following measures: improve the design of its fleet (8%); switch to alternative fuels (13%); and reduce the distance travelled by improving efficiency(4%). Improvements to vehicle design include: the use of aerodynamic trailers (-2%) and aerodynamic prime movers (-2%), the introduction of Euro 4 & % engines (-2%),the use of auxiliary power units (-1%) and the use of heavy hybrid vehicles (-1%). Alternative fuels include: LNG (-3% depending on fleet uptake) and Biodiesel (-10% if using B20 blend and depending on fleet uptake). Methods to reduce the distance travelled by improving efficiency include: Reducing delivery frequency (-2%), improving time windows (-2%), maximising vehicle utilisation and better aligning equipment to the freight task. Source: Woolworths (accessed 2009) Sustainability Strategy 2007-2015. www.woolworths.com.

IGD Supply Chain Analysis 2011

http://www.supplychainanalysis.igd.com

24

Woolworths (Aus) Profile

The retailer outsources the majority of its transport and logistics operations to third party road carriers, shipping and air freight operators. However, by improving transport planning and increasing backfilling, to maximise efficiency and minimise empty miles, the retailer has been able to reduce the number of delivery trucks it requires. Woolworths aims to work with its third party carriers to establish accurate baseline information and cutting the environmental impact of the fleet. The retailer has also been able to reduce the number of delivery trucks being used in its business through more efficient planning and backfilling. Woolworths also regularly reviews its logistics planning in order to use its fleet efficiently and cut empty miles. 6.5% reduction in emissions per carton delivered have been achieved by 2009. A 13% reduction in emissions (vis-a-vis 2008) from the company car fleet has been achieved in 2009. Full conversion of the company's car fleet to fuel-efficient cars is expected to be complete in 2010. Source: Woolworths (2008) Parliament of Australia 2008 Enquiry into Coastal shipping policy and regulation, www.aph.gov.au/house/committee/itrdlg/coastalshipping/subs/sub62.pdf Fuel Management Within the Woolworths owned fleet, fuel use is tracked and monitored against distances travelled. This review is designed to provide early warning of vehicles in the fleet that might be using fuel inefficiently resulting in increased emissions. Alternative Fuels Woolworths has conducted a successful biodiesel trial in its Victorian fleet (which the retailer owns) and plans to roll out a biodiesel blend across its whole Victorian fleet by 2012. The retailer has calculated the use of biodiesel could cut emissions by as much as 10% (depending on fleet uptake). In recent years Woolworths has worked with a transport service provider in Western Australia and is using liquid natural gas powered trucks for store deliveries. In order to meet its target of reducing the emissions from its corporate car fleet by 30% by 2010, the retailer has investigated the feasibility of using alternatives to unleaded petrol in its 3000+ corporate car fleet. Alternative fuels could include diesel, LPG (3% reduction in CO2-e emissions) or hybrid vehicles. Woolworths also looked at reducing the size of the cars in its fleet before ordering its new fleet in January 2008. Source: Woolworths (accessed 2009) Sustainability Strategy 2007-2015. www.woolworths.com Disposal of Fleet by-Products Tyres and batteries are disposed of by third party experts and grease traps are used at truck cleaning facilities to prevent oil and waste getting into water systems. Water For Woolworths, a secure water supply is viewed as critical to the sustainability of its business. Around 97% of the fresh fruit and vegetables sold in the retailer's supermarkets its sourced domestically and over recent years droughts have lead to steep rises in fruit, vegetable, dairy and grain-based products. The retailer considers that it has an obligation not to waste water. Woolworths has calculated that its standalone Australian stores use around 2.2 gigalitres per year (2006-2007). In 2009, the retailer used an estimated 1.94 gigalitres in all supermarkets. The retailer aims to reduce its water use by at least 200 million litres per year by 2010. In order to achieve its target the retailer aims to develop a more complete baseline of water usage and roll out the WaterWise project across all its supermarkets at a cost of around AU$975,000. Source: Woolworths (accessed 2009) Sustainability Strategy 2007-2015. www.woolworths.com

IGD Supply Chain Analysis 2011

http://www.supplychainanalysis.igd.com

25

Woolworths (Aus) Profile

WaterWise Woolworths initial WaterWise project was conducted in 2007 and involved 105 supermarkets in Southeast Queensland. The roll-out of a range of water saving initiatives required an investment of AU$115,000, or an average of AU$1,046 per store. The initiatives included: the installation of flow restrictors and water-saving ultra-rinse spray guns and the adjustment of dual and single-flush toilets and urinals to reduce flush volume. Each ultra-rinse spray gun is estimated to save around 100,000 litres per year which, across all stores involved in the project, amounts to around 32.7 megalitres per year. The retailer has also introduced a number of other watersaving initiatives at its sites. For example, at its main support office in Sydney the retailer has installed a 1m litre rainwater tank, to collect stormwater for irrigation, washing and toilet flushing and five of the retailer's distribution centres harvest rainwater. Source: Woolworths (accessed 2009) Sustainability Strategy 2007-2015. www.woolworths.com Packaging Woolworths is a signatory of the Australian National Packaging Covenant and has implemented a range of initiatives over recent years to reduce the volume of packaging and promote greener alternatives. In this context, Woolworths has established a supplier forum to work together on more sustainable packaging. Initiatives introduced by the retailer have included:

q

Cutting the use of HDPE (High Density Polyethylene) plastic bags in its stores and introducing 30% recycled content to Woolworths bags and 15% to Big W bags Making plastic bag recycling facilities available at all supermarkets Introducing reusable bags including green enviro bags, blue chiller bags and wine bags Raising employee awareness about plastic bag stock levels and recycling initiatives through the 'Fill the bag, not the environment' training programme Using roll cages rather than pallets and shrink wrap. Woolworths has progressively introduced roll cages since 2007, beginning with a commission of 104,000 cages which were introduced into 330 stores. Each roll cage replaces 2.125 pallets and about 23 metres of shrink wrap each time it is used. Introducing reusable plastic crates for fresh produce. The crates eliminate the need for waxed cardboard boxes (26 million per year), string nets and Styrofoam plastic boxes. The retailer has over 1.7 million crates (2007) in its pool, and over half a million are issued through Woolworths produce distribution centres each week across Australia. Commissioning the Packaging Alliance to review the packaging of Woolworths private brand products including an audit of all packaged products and the benchmarking and development of key performance indicators and efficiency targets. The exercise will help the retailer to formulate a consumer packaging strategy for its private label. The retailer also plans to use PIQET (Packaging Impact Quick Evaluation Tool) to evaluate 20 private label products by 2010.

In 2008 Woolworths implemented a revised private label procurement policy and supplier guidelines and provided training for 50 of its suppliers. Source: Woolworths (accessed 2009) Sustainability Strategy 2007-2015. www.woolworths.com Crates

IGD Supply Chain Analysis 2011

http://www.supplychainanalysis.igd.com

26

Woolworths (Aus) Profile

Woolworths rolled out its new produce crate system between February 2009 and April 2009. The new crate will be stronger, will provide greater product protection, cut water entrapment, and be designed to stack efficiently on trucks. The crates are also barcoded and have space for and RFID tag. Features of the New Crate

Note: Crate colour will be black Source: Woolworths (2009) Traders Update Presentation

Pallet Labelling

Woolworths is focussed on ensuring pallets are correctly labelled in order to improve the accuracy, safety and efficiency of pallet movement through its depots. Pallets entering Woolworths DC's must:

q

Have a pallet label on each fork-entry side. The label must be minimum A6 size and positioned on the right hand size, 50mm from the edge and 400-800mm high The label must be placed outside the stretch wrap or, if no wrap is used, directly on to the carton Each carry a unique Serial Shipping Container Code (SSCC) barcode which must not be reused for 12 months. The code allows the retailer to receive and track the pallet through the DC and also allows suppliers to track the pallet in their own supply chain

Pallets arriving without a label or incorrectly labelled may be rejected by Woolworths or cause a safety hazard for staff trying to scan an inaccessible label. Example of a Correct SSCC Label

IGD Supply Chain Analysis 2011

http://www.supplychainanalysis.igd.com

27

Woolworths (Aus) Profile

Source: Woolworths (2009) Waste As part of its commitment to sustainability Woolworths aims to achieve zero food waste by 2015. It aims to do this by working with suppliers to develop sustainable initiatives, through smarter in-store practices, educating customers, composting, diverting fit-for-purpose food to local charities and foodbanks, and food not fit-for-human consumption to farmers and zoos. Woolworth views reducing the amount of waste sent to landfill as both environmentally friendly and cost effective. In Australia, the cost of sending waste to landfill is high, and likely to rise in the coming years as government levies and the cost of transport and disposal rise. The retailer has estimated that around 56% of store waste and 28% of distribution centre waste could be diverted away from landfill to another productive use, cutting the greenhouse gas emissions generated by its decomposition. A large proportion of Woolworths waste is organic and the retailer aims to eliminate this from its general waste stream by 2015 and divert it to other uses like the production of electricity. Over 50 of Woolworths Sydney-based stores send their food waste to the EarthPower facility to the west of the city. Here the waste is processed into compost, fertilizer and green electricity. The retailer plans to increase the number of stores diverting waste to facilities such as EarthPower from 53 in 2006-07 to 100 by 2010, however there are barriers including the number of suitable facilities and the long lead-times involved in constructing new sites. Woolworths is also focussed on minimising the amount of recyclable plastics and cardboard being sent to landfill by increasing education and awareness of recycling procedures in stores and DC's, reducing the quantity of plastic wrapping and increasing the use of roll cages. Woolworths aims to cut the amount of plastic and cardboard in the general waste stream to less than 1% (by weight) by 2010. The retailer is also aware of the issue of e-waste, such as computers and televisions, which are difficult to dispose of safely. Source: Woolworths (accessed 2009) Sustainability Strategy 2007-2015. www.woolworths.com Green Stores Woolworths opened its first Green Store at Rouse Hill in Sydney in 2007, followed by another in Victoria Harbour, Melbourne in 2008 and there are more stores in the planning stages as the retailer has committed to ensuring that all stores opened after September 2008 are Green Stores. The retailer aims to achieve a 25% reduction in stores CO2-e emissions by using its new

IGD Supply Chain Analysis 2011

http://www.supplychainanalysis.igd.com

28

Woolworths (Aus) Profile

sustainable store designs compared with previous business-as-usual designs. The retailer aims to minimise the environmental impact of new supermarkets by introducing: energy efficient refrigeration and air conditioning systems, greenhouse-friendly refrigerants, minimising water use, waste and the use of harmful materials, improved lighting technology and management procedures. At the Green Store in Rouse Hill the retailer has installed a cascade refrigeration system which uses carbon dioxide instead of conventional refrigerants, reducing greenhouse gas emissions by 25%. The refrigerators are also fitted with automatic night blinds which trap cold air, cutting energy use by 10% and reducing CO2 emissions by 100 tonnes per year; high-efficiency fans; low heat glass doors and a heat reclaim system that collects waste heat from refrigeration and uses it within the store's air conditioning system. At the Rouse Hill store, the air conditioning system has an economy cycle and uses fresh air pumped in from outside when possible, rather than using the mechanically cooling system. The chiller system uses an innovative water cooling process and the central cooling tower uses recycled water and is estimated to be 50% more energy efficient than typical systems. Improved lighting technology at the Green stores includes the use of light emitting diodes (LED) in signage and in fridges in place of conventional fluorescent tube lighting. LED lighting uses around 70% less energy, produces less heat and last longer than fluorescent tube lighting. Similarly, lighting inside stores will use T5 fluorescent technology which incorporates an automated energy management system and, compared to regular fluorescent lamps, can produce more light with up to 30% less energy use. Woolworths opened 28 supermarkets after 1 September 2008 and 24 were built and fitted to their sustainable guidelines. These guidelines have been adapted for application in Woolworths Liquor group stores with other divisions to follow in 2010. Existing Woolworths stores average energy use per square metre is 920 KWh/m and new stores, with more refrigeration, will have higher energy demand of 1,200 KWh/m. However the retailer's green stores aim to reduce this business-as-usual energy use by around 25%. The Rouse Hill green store uses gas as an alternative to electricity for water heating, chicken cookers and the bakery oven. Gas produces around 40% less CO2-e emissions than electricity. Source: Woolworths (accessed 2009) Sustainability Strategy 2007-2015. www.woolworths.com

Woolworths (Aus) - IT Systems Key Initiatives

The introduction of the SAP merchandising solution to master core data elements is well underway. The Business Release Master Data includes product information, cost, sell, merchandise categories, vendor records and GS1net. Rollout of the master data release is progressing, based on Woolworths Categories (e.g. Tea, Dairy Yoghurt and Cream) for Woolworths Supermarkets, Liquor, Petrol, BWS, Dan Murphys, Thomas Dux Grocer, Homeshop and Progressive Enterprises in New Zealand. This has meant that suppliers can use the suite of product maintenance forms to electronically send product and price information for Woolworths categories that have moved to SAP. The Woolworths New Article Summary (WNAS), Woolworths Article Form (WAF) and Woolworths Price Form (WPF) have introduced a new way of doing business with Woolworths whilst maintaining the existing business practices that suppliers are familiar with.

Wow link

Woolworths began the launch of its wow link data portal in late 2008 and the roll-out has continued into 2009. Wow link is a

IGD Supply Chain Analysis 2011

http://www.supplychainanalysis.igd.com

29

Woolworths (Aus) Profile

replacement for the previous vendor website and has been designed to be a one-stop shop for all the information suppliers need to work with Woolworths. The portal is designed to provide Woolworths trade partners with better access and communication with the retailer, and reports and information about supply chain performance, service levels, days of supply, and promotional activity. The portal also provides access to a range of business applications including Woolworths Transport Management System (TMS) and the product Withdrawal/Recall Management (PWRM) application.

Source: Woolworths (2009)

Woolworths' Project Galaxy Partner Services

Woolworths has embarked on a program to replace its core merchandising systems for Food, Liquor, Petrol divisions labelled as Galaxy, a new way of doing business by leveraging SAP. This will make new forms submission electronic and will enable Woolworths to receive automatic new and existing product and price submissions through GS1 net. This is expected to be implemented between October 2010 and March 2011.

Project Refresh

Woolworths supply chain improvement programme, called Project Refresh has played a key part in Woolworth's strong financial results over recent years. A range of systems have driven the transformation of the retailer's supply chain including: a Warehouse Management System, a Transport Management System and StockSmart, a forecast based replenishment system installed in its distribution centres, and AutostockR, a store forecast based replenishment system installed in its stores. The retailer's new Warehouse Management System, developed by Infor, is designed to improve supply chain management by: providing a clear view of available inventory; allowing work and supply chain resources to be aligned to satisfy store requirements, optimising fulfilment and distribution processes to ensure that orders are delivered on time and in full. Ultimately, Woolworths installed the system to reduce its direct operating costs and increase overall revenue. Capabilities of the WMS include: inventory management, work and task management, labour management, cross-docking, slotting and optimisation of SKU's, organisation of value added services, yard management, the ability to track multiple inventories and multiple customers, voice directed distribution. Source Infor (2009) www.infor.com StockSmart and AutostockR were designed and rolled out to support in-store and warehouse efficiency improvements. The systems have delivered significant improvements in in-store availability and Woolworths aims to further integrate the systems for even greater efficiency gains.

Radio Technology

IGD Supply Chain Analysis 2011

http://www.supplychainanalysis.igd.com

30

Woolworths (Aus) Profile

All new generation Woolworths distribution centres have been enabled with 802.11b/g radio frequency infrastructure. The wireless network allows the warehouse management system (WMS) to share data with ground staff in distribution centres on the location and transporting of pallets. Staff use handheld devices or fork-lift mounted terminals to receive instructions from the WMS. The WMS requests a pallet of stock for an individual store order, and will direct an employee to the desired pallet. The employee will then scan the pallet barcode and verify this over the network with the WMS. The pallet will then be transported.

RFID

Woolworths completed two trials of Radio Frequency Identification (RFID) in 2008. The retailer tested both passive dualfrequency tags and UHF EPC Gen 2 tags at a number of supplier distribution centres and supermarkets to test the viability of the technology. The first trial used the tags to track and trace fresh produce along the supply chain but was halted as it became clear that the cost of the technology remained prohibitive. However the second trial, which involved monitoring temperature levels across certain segments of the distribution network, was extended. The benefits of RFID can include:

q

Improvements in efficiency for tracking fresh produce (this is currently a paper-based process) Reduced errors in accounts, improved documentation and reduced paper use Better visibility and control over stock, reducing wastage

In addition to the high cost of the technology, the retailer has also identified a number of other barriers to its use including the hostile operating environment which includes high levels of water, metals and changes in temperature, all of which can interfere with RFID technology.

Business Activity Monitoring

Woolworths has invested in a business activity monitoring service called webMethods Optimize, which enables real-time insight into supply chain performance. This software solution has proved to be a key element in revolutionising the retailer's logistics operations, underpinning an improved technology platform which is helping to reduce costs and drive efficiencies.

New AU$50 million Datacentre

In June 2009 it was reported that Woolworths has contracted Watpac Construction to build a new AU$50m datacentre in Sydney's Eastern Creek District. The 150,700 sq. ft. site will house three data halls and office space and create around 350 jobs. Construction is scheduled to be completed in 2010.

Optimize Business Activity Monitoring Service and CentraSite

In 2008 it was reported that Woolworths had purchased webMethods Optimize, a business activity monitoring service developed by Software AG, a German solutions provider. The system enables real-time insight into the performance of supply chain processes and Woolworths uses the information produced by the system to bring its process strategies in line with its broader goals. Woolworths has also invested in SoftwareAG's CentraSite system which now underpins its entire IT service-orientated architecture (SOA).

IGD Supply Chain Analysis 2011

http://www.supplychainanalysis.igd.com

31

You might also like

- IkeaDocument3 pagesIkeacauverykNo ratings yet

- Task 1 Finance ManagementDocument17 pagesTask 1 Finance Managementraj ramukNo ratings yet

- Identify and Evaluate A1 BDocument6 pagesIdentify and Evaluate A1 BanushaNo ratings yet

- BBQfun Sales Data Worksheet - ASSESSMENT TASK 2 Part ADocument4 pagesBBQfun Sales Data Worksheet - ASSESSMENT TASK 2 Part AbabluanandNo ratings yet

- BSBMKG501 Identify and Evaluate Marketing Opportunities With Comments With CommentsDocument22 pagesBSBMKG501 Identify and Evaluate Marketing Opportunities With Comments With CommentsRonal JovenNo ratings yet

- Madelyn Isales Rayses TWIMR9339: TAD168 BSBMKG605 Responsibility: Head Trainer © The Wales Institute Pty LTDDocument11 pagesMadelyn Isales Rayses TWIMR9339: TAD168 BSBMKG605 Responsibility: Head Trainer © The Wales Institute Pty LTDMadam BabygirlNo ratings yet

- BSBFIM501 Manage Budgets and Financial Plans Learner Instructions 1 (Plan Financial Management Approaches)Document8 pagesBSBFIM501 Manage Budgets and Financial Plans Learner Instructions 1 (Plan Financial Management Approaches)vipulclasses01 vipulclassNo ratings yet

- JV or Franchise for Cocoa Delights ExpansionDocument5 pagesJV or Franchise for Cocoa Delights ExpansionMina PrajapatiNo ratings yet

- Marketing Objectives and Organisational Review for Cocoa DelightDocument10 pagesMarketing Objectives and Organisational Review for Cocoa DelightMohammed MGNo ratings yet

- Strategic Plans Guide Native Bush SpicesDocument11 pagesStrategic Plans Guide Native Bush SpicesSartika SARTIKANo ratings yet

- BSBMKG502 Assessment V1.0615Document7 pagesBSBMKG502 Assessment V1.0615purva020% (5)

- Anti-Bribery Workshop GuidanceDocument47 pagesAnti-Bribery Workshop Guidancediwa tataNo ratings yet

- BSBMKG608 Task 1 CompletedDocument6 pagesBSBMKG608 Task 1 CompletedCath HalimNo ratings yet

- Implement Workplace Info SystemDocument7 pagesImplement Workplace Info Systemlily100% (1)

- MGT617Document14 pagesMGT617Youtube TheaterNo ratings yet

- BSBMKG502 Task 2Document9 pagesBSBMKG502 Task 2Diana PulidoNo ratings yet

- Bonatelli Wines Is A Premier Wine Company Based in AustraliaDocument6 pagesBonatelli Wines Is A Premier Wine Company Based in AustraliasammyNo ratings yet

- Key Areas of Risk For Woolworths Ltd.Document19 pagesKey Areas of Risk For Woolworths Ltd.Allison BestNo ratings yet

- BSBWHS605 Powerpoint (Draft)Document4 pagesBSBWHS605 Powerpoint (Draft)Madam BabygirlNo ratings yet

- Report SACODocument15 pagesReport SACOMohammed UsmanNo ratings yet

- BSBMKG421 - Assessment Task 1Document17 pagesBSBMKG421 - Assessment Task 1Angelica Corredor MartinNo ratings yet

- RedingtonDocument7 pagesRedingtonapi-3716851No ratings yet

- Private Label's Effect On Distribution ChannelDocument9 pagesPrivate Label's Effect On Distribution ChannelsinmayyinNo ratings yet

- Boonrak 417-Task 1Document4 pagesBoonrak 417-Task 1Teerapol KhoonburanNo ratings yet

- DOCUMENTHOUZIT MARKETING PLANDocument11 pagesDOCUMENTHOUZIT MARKETING PLANTuba MirzaNo ratings yet

- Woolworths Limited - Retail Leader in AustraliaDocument55 pagesWoolworths Limited - Retail Leader in AustraliaMd. Mesbah Uddin100% (6)

- Project Proposal: Installation of Mineral Water PlantDocument2 pagesProject Proposal: Installation of Mineral Water PlantShahrooz Leo QureshiNo ratings yet

- BSBMKG 417Document5 pagesBSBMKG 417Seonho LeeNo ratings yet

- Corporate Social Responsibility in Europe - Rhetoric and RealitiesDocument375 pagesCorporate Social Responsibility in Europe - Rhetoric and Realitieshrabanek2No ratings yet

- Review and Optimize Houzit's Marketing ActivitiesDocument6 pagesReview and Optimize Houzit's Marketing ActivitiesbhshdjnNo ratings yet

- Bsbfia401 Ass3Document3 pagesBsbfia401 Ass3wanyuan gaoNo ratings yet

- BSBMKG 501 Identify and Evaluate Marketing Opportunities PDFDocument27 pagesBSBMKG 501 Identify and Evaluate Marketing Opportunities PDFbabluanandNo ratings yet

- Unit Bsbmkg419 Ass1 Part BDocument12 pagesUnit Bsbmkg419 Ass1 Part BT RexNo ratings yet

- Food Quality Management 650Document7 pagesFood Quality Management 650Waqar Ibrahim100% (1)

- Develop A Marketing PlanDocument11 pagesDevelop A Marketing PlanRupinderNo ratings yet