Professional Documents

Culture Documents

Report Styrene Monomer Lyondell

Uploaded by

amiller1987Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Report Styrene Monomer Lyondell

Uploaded by

amiller1987Copyright:

Available Formats

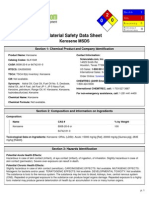

MATERIAL SAFETY DATA SHEET

according to Regulation (EC) No. 1907/2006

STYRENE MONOMER

Version 1.0 Revision Date 11/29/2010

Gen. Variant: SDS_NL Print Date 11/29/2010 MSDS No.: BE645

1. Identification of the substance/mixture and of the company/undertaking

1.1 Product identifier Trade name Substance name Substance No. : STYRENE MONOMER : Styrene : 202-851-5 (EINECS)

1.2 Relevant identified uses of the substance or mixture and uses advised against Use of the Substance/Mixture : Manufacture of substances, Formulation & (re)packing of substance and mixtures, Distribution of substance, Polymer production, Other consumer uses

1.3 Details of the supplier of the safety data sheet

Company Lyondell Chemie Nederland, B.V. Weena 737 3013 AM Rotterdam Netherlands E-mail address Responsible/issuing person Telephone 31 (0) 10 275 55 00 Registration number 01-2119457861-32-0017

1.4 Emergency telephone

Emergency telephone +32 3 575 1235

: product.safety@lyondellbasell.com

2. Hazards identification

2.1 Classification of the substance or mixture Classification (REGULATION (EC) No 1272/2008) Flammable liquids, Category 3 Acute toxicity, Category 4 Skin irritation, Category 2 Eye irritation, Category 2 Aspiration hazard, Category 1 Specific target organ systemic toxicity single exposure, Category 3 Specific target organ systemic toxicity repeated exposure, Category 1 Classification (67/548/EEC, 1999/45/EC) Harmful. Irritant. R10: Flammable. R20: Harmful by inhalation. R65: Harmful: may cause lung damage if swallowed. R48/20: Harmful: danger of serious damage to health by prolonged exposure through inhalation. 1 / 42 H226: Flammable liquid and vapor. H332: Harmful if inhaled. H315: Causes skin irritation. H319: Causes serious eye irritation. H304: May be fatal if swallowed and enters airways. H335: May cause respiratory irritation. H372: Causes damage to organs through prolonged or repeated exposure if inhaled.

MATERIAL SAFETY DATA SHEET

according to Regulation (EC) No. 1907/2006

STYRENE MONOMER

Version 1.0 Revision Date 11/29/2010

Gen. Variant: SDS_NL Print Date 11/29/2010 MSDS No.: BE645

R36/37/38: Irritating to eyes, respiratory system and skin. 2.2 Label elements Labeling (REGULATION (EC) No 1272/2008) Hazard pictograms :

Signal Word Hazard Statements

: :

Danger H226 H332 H319 H335 H315 H372 H304 Flammable liquid and vapor. Harmful if inhaled. Causes serious eye irritation. May cause respiratory irritation. Causes skin irritation. Causes damage to organs through prolonged or repeated exposure if inhaled. May be fatal if swallowed and enters airways. Keep away from heat/sparks/open flames/hot surfaces. - No smoking. Wear protective gloves/ protective clothing/ eye protection/ face protection. Avoid breathing dust/ fume/ gas/ mist/ vapors/ spray.

Precautionary Statements

Prevention: P210 P280 P261 Response: P302 + P352

IF ON SKIN: Wash with plenty of soap and water. P305 + P351 + P338 IF IN EYES: Rinse cautiously with water for several minutes. Remove contact lenses, if present and easy to do. Continue rinsing. P310 Immediately call a POISON CENTER or doctor/ physician. P331 Do NOT induce vomiting.

2.3 Other hazards Irritating to eyes, respiratory system and skin. This substance is not considered to be persistent, bioaccumulating nor toxic (PBT). This substance is not considered to be very persistent nor very bioaccumulating (vPvB).

3. Composition/information on ingredients

3.1 Substances 2 / 42

MATERIAL SAFETY DATA SHEET

according to Regulation (EC) No. 1907/2006

STYRENE MONOMER

Version 1.0 Chemical nature Chemical Name Styrene Revision Date 11/29/2010 : Substance CAS-No. EINECS-No. / ELINCS No./EC-No. 100-42-5 202-851-5

Gen. Variant: SDS_NL Print Date 11/29/2010 MSDS No.: BE645

Concentration [%] > 99.8

4. First aid measures

4.1 Description of first-aid measures General advice : Harmful by inhalation. Harmful: danger of serious damage to health by prolonged exposure through inhalation. Inhalation of vapors may cause signs of respiratory tract irritation (cough and difficulty breathing), CNS depression (fatigue, dizziness, headache, collapse, coma and death), possible cardiac sensitization, and irritation of the eyes, nose and throat. Aspiration into the lungs during swallowing or vomiting can cause lung damage, possibly leading to chronic lung dysfunction or death. Causes eye and skin irritation. Repeated exposures to very high concentrations of vapor may cause auditory effects. Always observe self-protection methods Wear appropriate personal protective equipment, avoid direct contact. Move out of dangerous area. Remove contaminated shoes and clothing. Get medical attention immediately. Show this material safety data sheet to the doctor in attendance. If inhaled : Remove victim to fresh air and keep at rest in a position comfortable for breathing. Do not leave the victim unattended. Keep patient warm and at rest. Immediately seek medical attention. If breathing is difficult, give oxygen. If unconscious place in recovery position and seek medical advice. In the event of unconsciousness, apnea or cardiac arrest (no pulse) apply cardiopulmonary resuscitation. : Take off contaminated clothing and shoes immediately. In case of contact, immediately flush skin with soap and plenty of water. Seek medical attention if ill effect or irritation develops. Wash contaminated clothing before reuse. : In case of eye contact, remove contact lens and rinse immediately with plenty of water, also under the eyelids, for at 3 / 42

In case of skin contact

In case of eye contact

MATERIAL SAFETY DATA SHEET

according to Regulation (EC) No. 1907/2006

STYRENE MONOMER

Version 1.0 Revision Date 11/29/2010

Gen. Variant: SDS_NL Print Date 11/29/2010 MSDS No.: BE645

least 15 minutes. Get medical attention immediately. If swallowed : Clean mouth with water and drink afterwards plenty of water. DO NOT induce vomiting. If vomiting does occur, have victim lean forward to reduce risk of aspiration. Get medical attention immediately. Do not give milk or alcoholic beverages. Never give anything by mouth to an unconscious person.

4.2 Most important symptoms and effects, both acute and delayed Symptoms : Signs of eye, throat, and respiratory tract irritation (cough and difficulty breathing), CNS depression (fatigue, dizziness, headache, collapse, coma and death) and possible cardiac sensitization may occur after exposure to high vapor concentrations. : Moderate eye irritant. Causes moderate skin irritation. Aspiration may cause pulmonary edema and pneumonitis. Potential danger from aspiration must be weighed against possible oral toxicity when deciding to induce vomiting. May cause hearing loss. 4.3 Indication of immediate medical attention and special treatment needed Treatment : Treat symptomatically. Treatment of overexposure should be directed at the control of symptoms and the clinical condition of the patient. Gastric lavage is indicated in those patients who require decontamination. Be sure that an endotracheal tube is in place prior to lavage; use cuffed tubes in patients over 7 years of age. Epinephrine and other sympathomimetic drugs may initiate cardiac arrhythmias (irregular beating) in persons exposed to this material.

Hazards

5. Fire-fighting measures

5.1 Extinguishing media Suitable extinguishing media : SMALL FIRE: Use dry chemical, CO2, water spray or regular foam. LARGE FIRE: Use water spray, water fog or regular foam. Do not use straight streams.

Unsuitable extinguishing : Do not use solid water stream/may spread fire. media 5.2 Special hazards arising from the substance or mixture Specific hazards during fire fighting : Releases flammable vapors below normal ambient temperatures. May autopolymerize if uninhibited, heated or involved in a fire. Autopolymerization will be accompanied by evolution of heat, 4 / 42

MATERIAL SAFETY DATA SHEET

according to Regulation (EC) No. 1907/2006

STYRENE MONOMER

Version 1.0 Revision Date 11/29/2010

Gen. Variant: SDS_NL Print Date 11/29/2010 MSDS No.: BE645

which may cause release of styrene vapors forming flammable mixtures with air. Liquid normally inhibited but not vapors. Vapors may condense as solids, plugging pressure relief devices, causing overpressure/rupture of storage containers during runaway polymerization. Fight fire from maximum distance or use unmanned hose holders or monitor nozzles. Move containers from fire area if you can do it without risk. Cool containers with flooding quantities of water until well after fire is out. Withdraw immediately in case of rising sound from venting safety devices or discoloration of tank. Always stay away from tanks engulfed in fire. For massive fire, use unmanned hose holders or monitor nozzles; if this is impossible, withdraw from area and let fire burn. Eliminate all sources of ignition. Sustained fire attack on vessels may result in a Boiling Liquid Expanding Vapour Explosion (BLEVE). Fire residues and contaminated fire extinguishing water must be disposed of in accordance with local regulations. 5.3 Precautions for fire-fighters Special protective equipment for fire-fighters : Wear positive pressure self-contained breathing apparatus (SCBA). Structural firefighters protective clothing will only provide limited protection.

6. Accidental release measures

6.1 Personal precautions, protective equipment and emergency procedures Personal precautions : Use personal protective equipment. Ensure adequate ventilation. Eliminate all sources of ignition. Evacuate personnel to safe areas. Beware of vapors accumulating to form explosive concentrations. Vapors can accumulate in low areas. Enter area only if strictly necessary. A combustible gas detector can be used to check for flammable gas or vapors.

6.2 Environmental precautions Environmental precautions : Prevent entry into waterways, sewers, basements or confined areas. Prevent further leakage or spillage if safe to do so. If the product contaminates rivers and lakes or drains inform respective authorities. If necessary, all contaminated waste water must be treated in a municipal or industrial wastewater treatment plant before release to surface water. 5 / 42

MATERIAL SAFETY DATA SHEET

according to Regulation (EC) No. 1907/2006

STYRENE MONOMER

Version 1.0 Revision Date 11/29/2010

Gen. Variant: SDS_NL Print Date 11/29/2010 MSDS No.: BE645

Chemical removal by air and water pollution control devices must meet the minimum efficiency requirements needed to reduce exposures to an acceptable level. The discharge of treatment plant effluent to rivers and oceans must achieve the dilution ratio needed to reduce exposures to an acceptable level. The size and capacity of wastewater treatment plants must meet the minimum requirements needed to reduce exposures to an acceptable level. Waste management practices such as incineration, recycling, reuse must be enforced as needed to reduce exposures to an acceptable level. External treatment and disposal of waste should comply with applicable local and/or national regulations. The maximum allowable site tonnage and the days of use should be below the number needed to maintain exposures at an acceptable level. 6.3 Methods and materials for containment and cleaning up Methods for cleaning up : Flammable liquid. Release will cause immediate fire/explosion. Eliminate all sources of ignition. All equipment used when handling this product must be grounded. Do not touch or walk through spilled material. Stop leak if you can do it without risk. Prevent entry into waterways, sewers, basements or confined areas. A vapor suppressing foam may be used to reduce vapors. Absorb or cover with dry earth, sand or other non-combustible material and transfer to containers. Use clean non-sparking tools to collect absorbed material.

7. Handling and storage

7.1 Precautions for safe handling Advice on safe handling : May autopolymerize if uninhibited, heated or involved in a fire. Autopolymerization will be accompanied by evolution of heat, which may cause release of styrene vapors forming flammable mixtures with air. Do not handle near heat, sparks, or flame. Avoid contact with incompatible agents. Use only with adequate ventilation/personal protection. Avoid contact with eyes, skin and clothing. Do not enter storage area unless adequately ventilated. Metal containers involved in the transfer of this material should be grounded and bonded. Containers that have held styrene monomer must be thoroughly cleaned, drained and dried to prevent fire hazard from residue. Keep container tightly closed when not in use. Take necessary action to avoid static electricity discharge 6 / 42

MATERIAL SAFETY DATA SHEET

according to Regulation (EC) No. 1907/2006

STYRENE MONOMER

Version 1.0 Revision Date 11/29/2010

Gen. Variant: SDS_NL Print Date 11/29/2010 MSDS No.: BE645

(which might cause ignition of organic vapors). Use only non-sparking tools. Fire-fighting class : Flammable liquid.

7.2 Conditions for safe storage, including any incompatibilities Requirements for storage areas and containers : Monitor inhibitor to maintain appropriate concentration. Keep containers tightly closed when not in use and store in a well-ventilated area. Isolate incompatible materials such as oxidizers. Containers should be clearly labeled. Metal containers used to store this material should be grounded. Store below 104F (40C). Empty containers may contain flammable product residues. Do not weld, solder, drill, cut or perform similar operations on or near containers. Ensure that all relevant regulations regarding explosive atmospheres, and handling and storage facilities of flammable products are followed.

7.3 Specific end uses : (Refer to exposure scenario section for specific information).

8. Exposure controls/personal protection

8.1 Control parameters Occupational Exposure Limits

Component Styrene Source US (ACGIH) US (ACGIH) NIOSH STEL TWA IDLH Type: Value 40 ppm 20 ppm 700 ppm Note None. None. None.

DN(M)EL

DN(M)EL

DN(M)EL

End Use: Workers Routes of exposure: Inhalation Potential health effects: Acute effects Value: 289 mg/m3 Systemic effects End Use: Workers Routes of exposure: Inhalation Potential health effects: Acute effects Value: 306 mg/m3 Local effects End Use: Workers Routes of exposure: Skin contact Potential health effects: Long term 7 / 42

MATERIAL SAFETY DATA SHEET

according to Regulation (EC) No. 1907/2006

STYRENE MONOMER

Version 1.0 Revision Date 11/29/2010

Gen. Variant: SDS_NL Print Date 11/29/2010 MSDS No.: BE645

DN(M)EL

DN(M)EL

DN(M)EL

DN(M)EL

DN(M)EL

DN(M)EL

Systemic effects End Use: Workers Routes of exposure: Inhalation Potential health effects: Long term Value: 85 mg/m3 Systemic effects End Use: General Population Routes of exposure: Inhalation Potential health effects: Acute effects Value: 174.25 mg/m3 Systemic effects End Use: General Population Routes of exposure: Inhalation Potential health effects: Acute effects Value: 182.75 mg/m3 Local effects End Use: General Population Routes of exposure: Skin contact Potential health effects: Long term Systemic effects End Use: General Population Routes of exposure: Inhalation Potential health effects: Long term Value: 10.2 mg/m3 Systemic effects End Use: General Population Routes of exposure: Ingestion Potential health effects: Long term Systemic effects Fresh water Value: 0.028 mg/l Assessment factor -10 Sea water Value: 0.0028 mg/l Assessment factor -100 Water Value: 0.04 mg/l Intermittent Releases, Assessment factor -100 Fresh water sediment Value: 0.614 mg/kg dw Sea sediment Value: 0.0614 mg/kg dw Sewage Treatment Plant Value: 5 mg/l Assessment factor -100 Soil Value: 0.2 mg/kg dw 8 / 42

PNEC

PNEC

PNEC

PNEC PNEC PNEC

: : :

PNEC

MATERIAL SAFETY DATA SHEET

according to Regulation (EC) No. 1907/2006

STYRENE MONOMER

Version 1.0 Revision Date 11/29/2010

Gen. Variant: SDS_NL Print Date 11/29/2010 MSDS No.: BE645

8.2 Exposure controls Engineering measures Use process enclosures, local exhaust ventilation, or other engineering controls to keep airborne levels below recommended exposure limits. Personal protective equipment Respiratory protection : When workers are facing concentrations above the exposure limit they must use appropriate certified respirators. Wear a respirator conforming to EN 140 with type A filter or better. : Use chemical resistant gloves appropriate to conditions of use. Wear chemical resistant gloves such as: Glove material fluoroelastomer; material thickness 0.4 mm; break through time 480 min. Gloves must be replaced after 8 hours of wear (GESTIS recommendation). The selected protective gloves have to satisfy the standard EN 374 derived from it. Gloves should be discarded and replaced if there is any indication of degradation or chemical breakthrough. : Eye protection such as chemical splash goggles and/or face shield must be worn when possibility exists for eye contact due to splashing or spraying liquid, airborne particles, or vapor. Safety glasses are the minimum requirements. The selected goggles or glasses must satisfy the European norm standard EN 166. : When skin contact is possible, protective clothing including gloves, apron, sleeves, boots, head and face protection should be worn. The selected protective clothing has to satisfy the standard EN 13034, which describes clothing offering limited 8 hour protection against splashes. Choose body protection according to the amount and concentration of the dangerous substance at the work place. Use PPE that is chemical resistant to the product and prevents skin contact. : Selection of appropriate personal protective equipment should be based on an evaluation of the performance characteristics of the protective equipment relative to the task(s) to be performed, conditions present, duration of use, and the hazards and/or potential hazards that may be encountered during use. Emergency eye wash fountains and safety showers should be available in the immediate vicinity of any potential exposure. Use good personal hygiene practices. Wash hands before eating, drinking, smoking, or using toilet 9 / 42

Hand protection

Eye protection

Skin and body protection

Hygiene measures

MATERIAL SAFETY DATA SHEET

according to Regulation (EC) No. 1907/2006

STYRENE MONOMER

Version 1.0 Revision Date 11/29/2010

Gen. Variant: SDS_NL Print Date 11/29/2010 MSDS No.: BE645

facilities. Take off contaminated clothing and wash before reuse. Environmental exposure controls General advice : See section 6.

9. Physical and chemical properties

9.1 Information on basic physical and chemical properties Appearance Color Odor Flash point : liquid : Colorless to yellow. : Aromatic, sweet odor. : 31 C at 1,013 hPa

Lower explosion limit Upper explosion limit Flammability (solid, gas) Oxidizing properties Autoignition temperature Molecular Weight pH Melting point/range Boiling point/boiling range Vapor pressure Water solubility Partition coefficient: noctanol/water Viscosity, dynamic Relative vapor density

: ~1.1 vol% : ~6.1 vol% : Flammable. : The substance or mixture is not classified as oxidizing. : 490 C at 1,013 hPa

: 104.15 g/mol : Note: Not applicable. : -31 C : 145 C at 1,013 hPa : 6.67 hPa at 20 C : 320 g/l at 25 C : log Pow: 2.96 at 25 C : 0.696 mPa.s at 25 C : ~3.6 at 15 - 20 C Note: (Air = 1.0) 10 / 42

MATERIAL SAFETY DATA SHEET

according to Regulation (EC) No. 1907/2006

STYRENE MONOMER

Version 1.0 Surface tension Explosive properties 9.2 Other information Revision Date 11/29/2010

Gen. Variant: SDS_NL Print Date 11/29/2010 MSDS No.: BE645

: Note: Surface activity is not expected or predicted based on structural considerations. : Not explosive

10. Stability and reactivity

10.1 Reactivity This product is stable with an appropriate level of TBC inhibitor (minimum 10 ppm), but reactive (unstable) without. Contact a company sales representative for information regarding adequate inhibitor levels and methods of making inhibitor level determinations. 10.2 Chemical stability Stable under recommended storage conditions. 10.3 Possibility of hazardous reactions Hazardous reactions : May occur. Note: Reactive (unstable) when uninhibited.

10.4 Conditions to avoid Conditions to avoid : May autopolymerize if uninhibited, heated or involved in a fire. Autopolymerization will be accompanied by evolution of heat, which may cause release of styrene vapors forming flammable mixtures with air. Depleted inhibitor levels. High temperatures and severe oxidizing conditions. Avoid static discharge or other sources of ignition.

10.5 Incompatible materials Materials to avoid : Strong oxidizing agents Peroxides Contaminants and catalysts for vinyl polymers. Alkali metal-graphite compounds. Aluminum chloride. Strong acids. Strong alkalies. Copper Copper alloys Rubber. Brass.

10.6 Hazardous decomposition products Hazardous decomposition products Thermal decomposition : On decomposition, emits acrid fumes. Carbon Monoxide and Carbon dioxide. : Note: Thermal decomposition may produce oxides of carbon and other toxic gases and liberate heat and pressure. 11 / 42

MATERIAL SAFETY DATA SHEET

according to Regulation (EC) No. 1907/2006

STYRENE MONOMER

Version 1.0 Revision Date 11/29/2010

Gen. Variant: SDS_NL Print Date 11/29/2010 MSDS No.: BE645

11. Toxicological information

11.1 Information on toxicological effects Acute toxicity Acute oral toxicity Styrene

: LD50 (Oral): ~ 5,000 mg/kg Species: rat Remarks: This substance is of low acute toxicity when administered orally. Ingestion may cause discomfort and irritation of the gastrointestinal tract, effects on lungs and kidneys, and CNS depression (fatigue, dizziness and possibly loss of concentration, with collapse, coma and death in cases of severe overexposure) Aspiration into the lung may cause fatal chemical pneumonitis. May increase the sensitivity of the heart to endogenous catecholamines leading to potentially fatal cardiac sensitization.

Acute inhalation toxicity Styrene

: LC50 (Inhl): 11.8 mg/l Exposure time: 4 HOURS Species: rat Remarks: Vapors are toxic when inhaled. Vapors may cause irritation of the eyes, nose and throat as well as CNS depression (primarily fatigue, dizziness and loss of concentration, with collapse, coma and death in cases of severe over-exposure) May increase the sensitivity of the heart to endogenous catecholamines leading to potentially fatal cardiac sensitization.

Acute dermal toxicity Styrene

: LD50 (Skin): > 2,000 mg/kg Species: rat Method: OECD Test Guideline 402

Skin corrosion/irritation Skin irritation Styrene

: Classification: Irritating to skin.

Serious eye damage/eye irritation Eye irritation Styrene

: Classification: Irritating to eyes.

Respiratory or skin sensitization 12 / 42

MATERIAL SAFETY DATA SHEET

according to Regulation (EC) No. 1907/2006

STYRENE MONOMER

Version 1.0 Revision Date 11/29/2010

Gen. Variant: SDS_NL Print Date 11/29/2010 MSDS No.: BE645

Sensitization Styrene Germ cell mutagenicity Remarks Styrene

: Classification: Not sensitizing

: Styrene does possess some genotoxic potential in vitro presumably reflecting conversion to styrene oxide. There is no convincing evidence from available animal and human data that styrene possesses significant mutagenic/clastogenic potential in vivo.

Carcinogenicity Remarks Styrene : Chronic inhalation resulted in hyperplasia and fibrosis and an increased incidence of late onset lung tumors in mice, which are believe to have arisen through a non-genotoxic mechanism. Tumor incidence in rats was unaffected after chronic inhalation exposure. there is no convincing evidence that styrene possesses significant carcinogenic potential in humans.

Reproductive toxicity Remarks Styrene

: Results from reproductive toxicity studies in animals exposed via drinking water or inhalation have shown no evidence of selective toxicity to the testis or ovary or adverse effects on fertility.

Teratogenicity Remarks Styrene : Results from animal studies demonstrate that styrene is not a teratogen, nor is it fetotoxic at sub-maternally-toxic treatment levels. No selective effects on nervous system development have been reported. Some indication of developmental delay was observed in pups from dams exposed to high dose levels (500 ppm) however these findings were attributed to decreased pup body weight rather than a selective effect on the offspring.

Target Organ Systemic Toxicant - Repeated exposure Styrene : Remarks: Results from repeat-dose toxicity studies demonstrate that the mouse is highly sensitive to styreneinduced toxicity, with hyperplasia and fibrosis in lung tissue and atrophy and degeneration of nasal olfactory epithelium after chronic exposure. Mild nasal changes were also observed in the rat. Mechanistic studies demonstrate greater formation of locally toxic products in mouse nose and lung, and provide a metabolic basis for these species differences in 13 / 42

MATERIAL SAFETY DATA SHEET

according to Regulation (EC) No. 1907/2006

STYRENE MONOMER

Version 1.0 Revision Date 11/29/2010

Gen. Variant: SDS_NL Print Date 11/29/2010 MSDS No.: BE645

susceptibility (negligible metabolism likely in human respiratory tract). There is clear evidence that styrene causes a specific adverse effect on hearing in laboratory animals after long-term exposure; additionally there is an indication for styrene-induced hearing losses in humans. Minor impairment of color discrimination has been reported in workers occupationally exposed to styrene, however the magnitude of the change is small suggesting it is of negligible toxicological or clinical significance.

12. Ecological information

12.1 Toxicity Toxicity to fish Styrene

: LC50: 4.02 mg/l Exposure time: 96 HOUR Species: Pimephales promelas (fathead minnow) Remarks: Toxic to fish.

Toxicity to daphnia and other aquatic invertebrates. Styrene : EC50: 4.7 mg/l Exposure time: 48 HOUR Species: Daphnia magna. Remarks: This material is toxic to aquatic invertebrates (acute exposure). Toxicity to algae Styrene

: EC50: 4.9 mg/l Exposure time: 72 HOUR Species: Pseudokirchneriella subcapitata

Toxicity to daphnia and other aquatic invertebrates. (Chronic toxicity) Styrene : NOEC: 1.01 mg/l Exposure time: 21 d Species: Daphnia magna (Water flea)

12.2 Persistence and degradability Biodegradability Styrene

: Remarks: Readily biodegradable in aerobic conditions.

12.3 Bioaccumulative potential 14 / 42

MATERIAL SAFETY DATA SHEET

according to Regulation (EC) No. 1907/2006

STYRENE MONOMER

Version 1.0 Revision Date 11/29/2010

Gen. Variant: SDS_NL Print Date 11/29/2010 MSDS No.: BE645

Bioaccumulation Styrene

: Remarks: This material is not expected to bioaccumulate.

12.4 Mobility in soil Surface tension : Note: Surface activity is not expected or predicted based on structural considerations.

Distribution among environmental compartments Styrene : Remarks: The atmosphere is the main environmental compartment for releases of styrene. In water, volatilization will result in substantial losses to the atmosphere with a half-life of approximately 3 hours . A calculated Koc value of 352 indicates no significant potential for geoaccumulation. 12.5 Results of PBT and vPvB assessment Styrene : This substance is not considered to be persistent, bioaccumulating nor toxic (PBT)., This substance is not considered to be very persistent nor very bioaccumulating (vPvB).

12.6 Other adverse effects Additional ecological information Styrene : Toxic to fish, invertebrates and microorganisms, however, substantial aquatic exposure is not expected based on the volatile nature of this material.

13. Disposal considerations

13.1 Waste treatment methods Product : Contaminated product, soil, water, container residues and spill cleanup materials may be hazardous wastes. Comply with applicable local, state or international regulations concerning solid or hazardous waste disposal and/or container disposal. Contaminated product, soil or water should be considered dangerous due to potential evolution of flammable vapor. Proper grounding procedures to avoid static electricity should be followed. The product should not be allowed to enter drains, water courses or the soil.

14. Transport information

15 / 42

MATERIAL SAFETY DATA SHEET

according to Regulation (EC) No. 1907/2006

STYRENE MONOMER

Version 1.0 Revision Date 11/29/2010

Gen. Variant: SDS_NL Print Date 11/29/2010 MSDS No.: BE645

ADR UN-Number UN proper shipping name Transport hazard class(es) Packing group Classification Code Hazard identification No Labels Tunnel restriction code Environmentally hazardous IMDG UN-Number Description of the goods Class Packing group Labels EmS Number 1 EmS Number 2 Marine pollutant RID UN-Number Description of the goods Transport hazard class(es) Packing group Classification Code Hazard identification No Labels Environmentally hazardous

: : : : : : : :

2055 STYRENE MONOMER, STABILIZED 3 III F1 39 3 D/E : no 2055 STYRENE MONOMER, STABILIZED 3 III 3 F-E S-D

: : : : : : :

: no : : : : : : : 2055 STYRENE MONOMER, STABILIZED 3 III F1 39 3 : no

15. Regulatory information

15.1 Safety, health and environmental regulations/legislation specific for the substance or mixture Water contaminating class (Germany) US (ACGIH) International Agency for Research on Cancer : WGK 2 water endangering : Not classifiable as a human carcinogen. : Possibly Carcinogenic to Humans Monograph 82 [2002], Monograph 60 [1994]

Notification status All ingredients are on the following inventories or are exempted from listing

Country Australia Canada China European Union Japan Korea Notification AICS DSL IECS EINECS ENCS/ISHL ECL

16 / 42

MATERIAL SAFETY DATA SHEET

according to Regulation (EC) No. 1907/2006

STYRENE MONOMER

Version 1.0 Revision Date 11/29/2010

Gen. Variant: SDS_NL Print Date 11/29/2010 MSDS No.: BE645

Philippines United States of America New Zealand

PICCS TSCA NZIoC

Contact product.safety@lyondellbasell.com for additional global inventory information.

15.2 Chemical Safety Assessment A Chemical Safety Assessment has been carried out for this substance.

16. Other information

Material safety datasheet sections which have been updated: First Edition Updated with substance registration requirements according to EC 1907/2006 Annex II and (EC) No.1272/2008 CLP. November 29 2010 Full text of R-phrases referred to under sections 2 and 3 R10 R20 R36/37/38 R48/20 R65 Flammable. Harmful by inhalation. Irritating to eyes, respiratory system and skin. Harmful: danger of serious damage to health by prolonged exposure through inhalation. Harmful: may cause lung damage if swallowed.

Full text of H-Statements referred to under sections 2 and 3. H226 H304 H315 H319 H332 H335 H372 Flammable liquid and vapor. May be fatal if swallowed and enters airways. Causes skin irritation. Causes serious eye irritation. Harmful if inhaled. May cause respiratory irritation. Causes damage to organs through prolonged or repeated exposure if inhaled.

Disclaimer Multiple legal entities and registration numbers may be displayed in Section 1. The Recipient shall refer to the shipping documents to identify the legal entity that supplied this product. This document is generated for the purpose of distributing health, safety, and environmental data. Information is correct to the best of our knowledge at the date of the MSDS publication. It is not a specification sheet nor should any displayed data be construed as a specification. The information on this MSDS was obtained from sources which we believe are reliable. However, the information is provided without any warranty, expressed or implied, regarding its correctness. Some information presented and conclusions drawn herein are from sources other than direct test data on the substance itself. The conditions or methods of handling, storage, use and disposal of the product are beyond our control and may be beyond our knowledge. For this and other reasons, we do not assume responsibility and expressly disclaim liability for loss, 17 / 42

MATERIAL SAFETY DATA SHEET

according to Regulation (EC) No. 1907/2006

STYRENE MONOMER

Version 1.0 Revision Date 11/29/2010

Gen. Variant: SDS_NL Print Date 11/29/2010 MSDS No.: BE645

Disclaimer damage, or expense arising out of or in any way connected with handling, storage, use, or disposal of this product. If the product is used as a component in another product, this MSDS information may not be applicable.

18 / 42

MATERIAL SAFETY DATA SHEET

according to Regulation (EC) No. 1907/2006

STYRENE MONOMER

Version 1.0 Annex Section 1 Title Use Descriptor Revision Date 11/29/2010

Gen. Variant: SDS_NL Print Date 11/29/2010 MSDS No.: BE645

Processes, tasks, activities covered

Section 2 Section 2.1 Product characteristics Physical form of product Concentration of substance in product Amounts used Frequency and duration of use Other Operational Conditions affecting worker exposure Contributing Scenarios Number of contributing Scenario Use in contained systems [CS38]. Dehydrogenation Reactor PROC 2 Use in contained systems [CS38]. Condensation of crude styrene - water separation PROC 2 Use in contained systems [CS38]. Vacuum Distillation PROC 2 Additivation and stabilisation [CS69]. Addition of inhibitors or retardants in distillators PROC 8b Process sampling [CS2]. Sampling from reactors/condensors/distillators PROC 8a Laboratory activities [CS36]. Laboratory - Quality Control PROC 15 Material transfers [CS3]. Transfert from distillator to storage tanks via pipelines. PROC 1 Additivation and stabilisation [CS69]. Stabiliser addition for storage and transport

Exposure Scenario Title Manufacturing of styrene CAS: 100-42-5 Sector of Use: SU3, SU8 Process Categories: PROC1, PROC2, PROC8a, PROC8b, PROC15 Environmental Release Categories: ERC1 Manufacture of the substance. Includes recycling/ recovery, material transfers, storage, maintenance and loading (including marine vessel/barge, road/rail car and bulk container), sampling and associated laboratory activities Operational conditions and risk management measures Control of worker exposure Liquid, vapour pressure 0.5 - 10 kPa [OC4]. Covers percentage substance in the product up to 100 % (unless stated differently) [G13]. No Limit Covers daily exposures up to 8 hours (unless stated differently) [G2]. Assumes a good basic standard of occupational hygiene is implemented [G1]. Risk Management Measures 12 Handle substance within a closed system [E47]. Handle substance within a closed system [E47].

Handle substance within a closed system [E47]. Ensure material transfers are under containment or extract ventilation [E66]. Use a sampling system designed to control exposure [E89]. No specific measures identified [EI18]. Transfer via enclosed lines [E52].No other specific measures identified [EI20]. Ensure material transfers are under containment or extract ventilation [E66].

19 / 42

MATERIAL SAFETY DATA SHEET

according to Regulation (EC) No. 1907/2006

STYRENE MONOMER

Version 1.0 PROC 8b Material transfers [CS3]. Unloading storage tanks for road, rail or boat transport PROC 8b Equipment maintenance [CS5]. Manufacturing equipment maintenance: opening and cleaning manufacturing equipment for maintenance purposes PROC 8b Material transfers [CS3]. Waste management : recovery using condensation or adsorption/ desorption processes PROC 2 Material transfers [CS3]. Waste management : transfer of process wastes to storage containers: off-line in workplace PROC 8b Section 3 3.1. Health Section 4 4.1. Health Revision Date 11/29/2010

Gen. Variant: SDS_NL Print Date 11/29/2010 MSDS No.: BE645

Clear transfer lines prior to de-coupling [E39].Ensure operation is undertaken outdoors [E69]. Avoid carrying out activities involving exposure for more than 1 hour [OC27] Avoid carrying out activities involving exposure for more than 1 hour [OC27]

Handle substance within a closed system [E47].

Avoid carrying out activities involving exposure for more than 1 hour [OC27]

Exposure Estimation Used of ECETOC TRA Version 2 with modifications. Guidance to check compliance with the Exposure Scenario Predicted exposures are not expected to exceed the DN(M)EL when the Risk Management Measures/Operational Conditions outlined in Section 2 are implemented [G22]. Where other Risk Management Measures/Operational Conditions are adopted, then users should ensure that risks are managed to at least equivalent levels [G23]. Exposure Scenario Title Continuous mass polymerisation of Polystyrene (HIPS and GPPS) CAS: 100-42-5 Sector of Use: SU3, SU12 Process Categories: PROC2, PROC8a, PROC8b, PROC9, PROC14, PROC15 Environmental Release Categories: ERC6c Manufacture of polymers from monomers in continuous and batch processes, include sparging, discharging, and reactor maintenance and immediate polymer product formation. Operational conditions and risk management measures Control of worker exposure Liquid, vapour pressure 0.5 - 10 kPa [OC4]. Covers percentage substance in the product up to 100 % (unless stated differently) [G13]. No Limit Covers daily exposures up to 8 hours (unless stated differently) [G2]. 20 / 42

Section 1 Title Use Descriptor

Processes, tasks, activities covered Section 2 Section 2.1 Product characteristics Physical form of product Concentration of substance in product Amounts used Frequency and duration of use

MATERIAL SAFETY DATA SHEET

according to Regulation (EC) No. 1907/2006

STYRENE MONOMER

Version 1.0 Revision Date 11/29/2010

Gen. Variant: SDS_NL Print Date 11/29/2010 MSDS No.: BE645

Other Operational Conditions affecting worker exposure Contributing Scenarios Number of contributing Scenario Material transfers [CS3]. Loading tank storage from road, rail or boat transport PROC 8b Continuous process [CS54]. Styrene Storage in tanks PROC 2 Continuous process [CS54]. Charging reactor via pipeline PROC 2 Material transfers [CS3]. Heat exchange and agitator in reactor PROC 2 Continuous process [CS54]. Devolatilisation tower PROC 2 Continuous process [CS54]. Recycling styrene from tower to rector via pipeline PROC 2 Process sampling [CS2]. Sampling from reactors/devolatilisation tower PROC 8a Laboratory activities [CS36]. Laboratory - Quality Control PROC 15 Extrusion and masterbatching [CS88]. Extruder - Pelletizing PROC 14 Small package filling [CS7]. Small package filling - Packaging of product PROC 9 Equipment maintenance [CS5]. Manufacturing equipment maintenance: opening and cleaning manufacturing equipment for maintenance purposes PROC 8b Bulk transfers [CS14]. Finished product Loading of road tanker, railcar, container PROC Material transfers [CS3]. Waste management : recovery using condensation or adsorption/ desorption processes PROC 2 Material transfers [CS3]. Waste management : transfer of process wastes to storage containers: off-line in workplace PROC 8b Section 3

Assumes a good basic standard of occupational hygiene is implemented [G1]. Risk Management Measures 14 Clear transfer lines prior to de-coupling [E39].Avoid carrying out activities involving exposure for more than 1 hour [OC27] Handle substance within a closed system [E47]. Handle substance within a closed system [E47]. Handle substance within a closed system [E47]. Handle substance within a closed system [E47]. Handle substance within a closed system [E47]. Use a sampling system designed to control exposure [E89]. No specific measures identified [EI18]. Limit the substance content in the product to 5% [OC17]. Limit the substance content in the product to 5% [OC17]. Avoid carrying out activities involving exposure for more than 1 hour [OC27]

Limit the substance content in the product to 5% [OC17].

Handle substance within a closed system [E47].

Avoid carrying out activities involving exposure for more than 1 hour [OC27]

Exposure Estimation 21 / 42

MATERIAL SAFETY DATA SHEET

according to Regulation (EC) No. 1907/2006

STYRENE MONOMER

Version 1.0 3.1. Health Section 4 4.1. Health Revision Date 11/29/2010

Gen. Variant: SDS_NL Print Date 11/29/2010 MSDS No.: BE645

Used of ECETOC TRA Version 2 with modifications. Guidance to check compliance with the Exposure Scenario Predicted exposures are not expected to exceed the DN(M)EL when the Risk Management Measures/Operational Conditions outlined in Section 2 are implemented [G22]. Where other Risk Management Measures/Operational Conditions are adopted, then users should ensure that risks are managed to at least equivalent levels [G23]. Exposure Scenario Title Batch suspension polymerisation of Polystyrene (HIPS and GPPS) CAS: 100-42-5 Sector of Use: SU3, SU12 Process Categories: PROC2, PROC3, PROC8a, PROC8b, PROC9, PROC14, PROC15 Environmental Release Categories: ERC6c Manufacture of polymers from monomers in continuous and batch processes, include sparging, discharging, and reactor maintenance and immediate polymer product formation. Operational conditions and risk management measures Control of worker exposure Liquid, vapour pressure 0.5 - 10 kPa [OC4]. Covers percentage substance in the product up to 100 % (unless stated differently) [G13]. No Limit Covers daily exposures up to 8 hours (unless stated differently) [G2]. Assumes a good basic standard of occupational hygiene is implemented [G1]. Risk Management Measures 13 Clear transfer lines prior to de-coupling [E39].Avoid carrying out activities involving exposure for more than 1 hour [OC27] Handle substance within a closed system [E47]. Provide a good standard of general ventilation (not less than 3 to 5 air changes per hour) [E11] Provide a good standard of general ventilation (not less than 3 to 5 air changes per hour) [E11] Provide a good standard of general ventilation (not less than 3 to 5 air changes per hour) [E11] Use a sampling system designed to control exposure [E89].

Section 1 Title Use Descriptor

Processes, tasks, activities covered Section 2 Section 2.1 Product characteristics Physical form of product Concentration of substance in product Amounts used Frequency and duration of use Other Operational Conditions affecting worker exposure Contributing Scenarios Number of contributing Scenario Material transfers [CS3]. Loading tank storage from road, rail or boat transport PROC 8b Material transfers [CS3]. Styrene Storage in tanks PROC 2 Material transfers [CS3]. Charging reactors via pipeline PROC 3 Batch process [CS55]. Dispersing and heat in reactor PROC 3 Batch process [CS55]. Washed and dried tanks PROC 3 Process sampling [CS2]. Sampling from reactors/tanks PROC 8a

22 / 42

MATERIAL SAFETY DATA SHEET

according to Regulation (EC) No. 1907/2006

STYRENE MONOMER

Version 1.0 Revision Date 11/29/2010

Gen. Variant: SDS_NL Print Date 11/29/2010 MSDS No.: BE645

Laboratory activities [CS36]. Laboratory - Quality Control PROC 15 Operation of solids filtering equipment [CS117]. Pelletizing PROC 14 Small package filling [CS7]. Small package filling - Packaging of product PROC 9 Equipment maintenance [CS5]. Manufacturing equipment maintenance: opening and cleaning manufacturing equipment for maintenance purposes PROC 8b Bulk transfers [CS14]. Finished product Loading of road tanker, railcar, container PROC Material transfers [CS3]. Waste management : recovery using condensation or adsorption/ desorption processes PROC 2 Material transfers [CS3]. Waste management : transfer of process wastes to storage containers: off-line in workplace PROC 8b Section 3 3.1. Health Section 4 4.1. Health

No specific measures identified [EI18]. Limit the substance content in the product to 5% [OC17]. Limit the substance content in the product to 5% [OC17]. Avoid carrying out activities involving exposure for more than 1 hour [OC27]

Limit the substance content in the product to 5% [OC17].

Handle substance within a closed system [E47].

Avoid carrying out activities involving exposure for more than 1 hour [OC27]

Exposure Estimation Used of ECETOC TRA Version 2 with modifications. Guidance to check compliance with the Exposure Scenario Predicted exposures are not expected to exceed the DN(M)EL when the Risk Management Measures/Operational Conditions outlined in Section 2 are implemented [G22]. Where other Risk Management Measures/Operational Conditions are adopted, then users should ensure that risks are managed to at least equivalent levels [G23]. Exposure Scenario Title Production of Expandable Polystyrene CAS: 100-42-5 Sector of Use: SU3, SU12 Process Categories: PROC2, PROC3, PROC8a, PROC8b, PROC9, PROC14, PROC15 Environmental Release Categories: ERC6c Manufacture of polymers from monomers in continuous and batch processes, include sparging, discharging, and reactor maintenance and immediate polymer product formation. Operational conditions and risk management measures Control of worker exposure Liquid, vapour pressure 0.5 - 10 kPa [OC4].

Section 1 Title Use Descriptor

Processes, tasks, activities covered Section 2 Section 2.1 Product characteristics Physical form of product

23 / 42

MATERIAL SAFETY DATA SHEET

according to Regulation (EC) No. 1907/2006

STYRENE MONOMER

Version 1.0 Revision Date 11/29/2010

Gen. Variant: SDS_NL Print Date 11/29/2010 MSDS No.: BE645

Concentration of substance in product Amounts used Frequency and duration of use Other Operational Conditions affecting worker exposure Contributing Scenarios Number of contributing Scenario Material transfers [CS3]. Loading tank storage from road, rail or boat transport PROC 8b Material transfers [CS3]. Styrene Storage in tanks PROC 2 Material transfers [CS3]. Charging reactors via pipeline PROC 3 Batch process [CS55]. Dispersing and heat in reactor PROC 3 Batch process [CS55]. Washed and dried tanks PROC 3 Process sampling [CS2]. Sampling from reactors/tanks PROC 8a Laboratory activities [CS36]. Laboratory - Quality Control PROC 15 Operation of solids filtering equipment [CS117]. Pelletizing PROC 14 Small package filling [CS7]. Small package filling - Packaging of product PROC 9 Equipment maintenance [CS5]. Manufacturing equipment maintenance: opening and cleaning manufacturing equipment for maintenance purposes PROC 8b Bulk transfers [CS14]. Finished product Loading of road tanker, railcar, container PROC Material transfers [CS3]. Waste management : recovery using condensation or adsorption/ desorption processes PROC 2 Material transfers [CS3]. Waste management : transfer of process wastes to storage containers: off-line in workplace

Covers percentage substance in the product up to 100 % (unless stated differently) [G13]. No Limit Covers daily exposures up to 8 hours (unless stated differently) [G2]. Assumes a good basic standard of occupational hygiene is implemented [G1]. Risk Management Measures 13 Clear transfer lines prior to de-coupling [E39].Avoid carrying out activities involving exposure for more than 1 hour [OC27] Handle substance within a closed system [E47]. 0 Provide a good standard of general ventilation (not less than 3 to 5 air changes per hour) [E11] Provide a good standard of general ventilation (not less than 3 to 5 air changes per hour) [E11] Provide a good standard of general ventilation (not less than 3 to 5 air changes per hour) [E11] Use a sampling system designed to control exposure [E89]. No specific measures identified [EI18]. Limit the substance content in the product to 5% [OC17]. Limit the substance content in the product to 5% [OC17]. Avoid carrying out activities involving exposure for more than 1 hour [OC27]

Limit the substance content in the product to 5% [OC17].

Handle substance within a closed system [E47].

Avoid carrying out activities involving exposure for more than 1 hour [OC27]

24 / 42

MATERIAL SAFETY DATA SHEET

according to Regulation (EC) No. 1907/2006

STYRENE MONOMER

Version 1.0 PROC 8b Revision Date 11/29/2010

Gen. Variant: SDS_NL Print Date 11/29/2010 MSDS No.: BE645

Section 3 3.1. Health Section 4 4.1. Health

Exposure Estimation Used of ECETOC TRA Version 2 with modifications. Guidance to check compliance with the Exposure Scenario Predicted exposures are not expected to exceed the DN(M)EL when the Risk Management Measures/Operational Conditions outlined in Section 2 are implemented [G22]. Where other Risk Management Measures/Operational Conditions are adopted, then users should ensure that risks are managed to at least equivalent levels [G23]. Exposure Scenario Title Production of Styrenic Copolymers CAS: 100-42-5 Sector of Use: SU3, SU12 Process Categories: PROC2, PROC3, PROC8a, PROC8b, PROC9, PROC15 Environmental Release Categories: ERC6c Manufacture of polymers from monomers in continuous and batch processes, include sparging, discharging, and reactor maintenance and immediate polymer product formation. Operational conditions and risk management measures Control of worker exposure Liquid, vapour pressure 0.5 - 10 kPa [OC4]. Covers percentage substance in the product up to 100 % (unless stated differently) [G13]. No Limit Covers daily exposures up to 8 hours (unless stated differently) [G2]. Assumes a good basic standard of occupational hygiene is implemented [G1]. Risk Management Measures 13 Clear transfer lines prior to de-coupling [E39].Avoid carrying out activities involving exposure for more than 1 hour [OC27] Handle substance within a closed system [E47]. Provide a good standard of general ventilation (not less than 3 to 5 air changes per hour) [E11] Provide a good standard of general ventilation (not less than 3 to 5 air changes per hour) [E11] Provide a good standard of general ventilation (not less than 3 to 5 air changes per hour) [E11]

Section 1 Title Use Descriptor

Processes, tasks, activities covered Section 2 Section 2.1 Product characteristics Physical form of product Concentration of substance in product Amounts used Frequency and duration of use Other Operational Conditions affecting worker exposure Contributing Scenarios Number of contributing Scenario Material transfers [CS3]. Loading tank storage from road, rail or boat transport PROC 8b Material transfers [CS3]. Styrene Storage in tanks PROC 2 Material transfers [CS3]. Charging reactors via pipeline PROC 3 Batch process [CS55]. Dissolving and polymerisation reactor PROC 3 Batch process [CS55]. Suspension reactor PROC 3

25 / 42

MATERIAL SAFETY DATA SHEET

according to Regulation (EC) No. 1907/2006

STYRENE MONOMER

Version 1.0 Revision Date 11/29/2010

Gen. Variant: SDS_NL Print Date 11/29/2010 MSDS No.: BE645

Batch process [CS55]. Washed and dried tanks PROC 3 Process sampling [CS2]. Sampling from reactors/tanks PROC 8a Laboratory activities [CS36]. Laboratory - Quality Control PROC 15 Small package filling [CS7]. Small package filling - Packaging of product PROC 9 Equipment maintenance [CS5]. Manufacturing equipment maintenance: opening and cleaning manufacturing equipment for maintenance purposes PROC 8b Bulk transfers [CS14]. Finished product Loading of road tanker, railcar, container PROC Material transfers [CS3]. Waste management : recovery using condensation or adsorption/ desorption processes PROC 2 Material transfers [CS3]. Waste management : transfer of process wastes to storage containers: off-line in workplace PROC 8b Section 3 3.1. Health Section 4 4.1. Health

Provide a good standard of general ventilation (not less than 3 to 5 air changes per hour) [E11] Use a sampling system designed to control exposure [E89]. No specific measures identified [EI18]. Limit the substance content in the product to 5% [OC17]. Avoid carrying out activities involving exposure for more than 1 hour [OC27]

Limit the substance content in the product to 5% [OC17].

Handle substance within a closed system [E47].

Avoid carrying out activities involving exposure for more than 1 hour [OC27]

Exposure Estimation Used of ECETOC TRA Version 2 with modifications. Guidance to check compliance with the Exposure Scenario Predicted exposures are not expected to exceed the DN(M)EL when the Risk Management Measures/Operational Conditions outlined in Section 2 are implemented [G22]. Where other Risk Management Measures/Operational Conditions are adopted, then users should ensure that risks are managed to at least equivalent levels [G23]. Exposure Scenario Title Manufacturing of UP/VE resins and formulated resins (Gelcoat, Colour Paste, Putty, Bonding paste / Adhesive, etc.) CAS: 100-42-5 Sector of Use: SU3, SU12 Process Categories: PROC1, PROC3, PROC4, PROC5, PROC8a, PROC8b, PROC9, PROC15 Environmental Release Categories: ERC2 Processing of formulated polymers including material transfers, additives handling, moulding, curing and forming activities, material re-works, storage and associated maintenance. 26 / 42

Section 1 Title Use Descriptor

Processes, tasks, activities covered

MATERIAL SAFETY DATA SHEET

according to Regulation (EC) No. 1907/2006

STYRENE MONOMER

Version 1.0 Revision Date 11/29/2010

Gen. Variant: SDS_NL Print Date 11/29/2010 MSDS No.: BE645

Section 2 Section 2.1 Product characteristics Physical form of product Concentration of substance in product Amounts used Frequency and duration of use Other Operational Conditions affecting worker exposure Contributing Scenarios Number of contributing Scenario General exposures [CS1]. Use in contained batch processes [CS37]. PROC 1

Operational conditions and risk management measures Control of worker exposure Liquid, vapour pressure 0.5 - 10 kPa [OC4]. Covers percentage substance in the product up to 100 % (unless stated differently) [G13]. No Limit Covers daily exposures up to 8 hours (unless stated differently) [G2]. Assumes a good basic standard of occupational hygiene is implemented [G1]. , Operation is carried out at elevated temperature (> 20C above ambient temperature) [OC7]. Risk Management Measures 12 Use in semi-automated and predominantly enclosed filling lines [E41]. Provide a good standard of general ventilation. Natural ventilation is from windows and doors etc. Controlled ventilation means air is supplied or removed by a powered fan. [E1]. Ensure operatives are trained to minimise exposures [EI119]. Wear suitable gloves tested to EN374 [PPE15]. Use in semi-automated and predominantly enclosed filling lines [E41]. Use bulk or semi-bulk handling systems [E43]. Provide extract ventilation to points where emissions occur [E54]. Ensure operatives are trained to minimise exposures [EI119]. Wear suitable gloves tested to EN374 [PPE15]. Use in semi-automated and predominantly enclosed filling lines [E41]. Provide a good standard of general ventilation (not less than 3 to 5 air changes per hour) [E11]. Wear suitable gloves tested to EN374 [PPE15]. Provide a good standard of general ventilation (not less than 3 to 5 air changes per hour) [E11]. Provide extract ventilation to points where emissions occur [E54]. Wear suitable gloves tested to EN374 [PPE15].

Bulk transfers [CS14]. Receipt and storage of raw materials in bulk or as packed goods, indoor and outdoor; Raw material assembly and charging; dispensing of liquids and solids via pipeline; PROC 3 General exposures (closed systems) [CS15]. Dissolving linear UP/VE polymer into styrene in blending vessel (or dissolver) PROC 3 Material transfers [CS3]. All internal transport Raw material assembly and charging / raw material dispensing of liquids and solids manually from bulk storage or packed goods into blending tank PROC 4 Drum/batch transfers [CS8]; Pouring from small containers [CS9]; Transfer from/pouring from containers [CS22]; Mixing operations (open systems) [CS30]. Mixing liquid and solid components / into final formulated resin in blending vessel; Examples are gelcoat blending and compounding PROC 5 Process sampling [CS2]. Sampling from blender PROC 4

Provide extract ventilation to points where emissions occur [E54]. Keep lids of containers closed during blendingWear suitable gloves tested to EN374 [PPE15].

Provide a good standard of general ventilation (not less than 3 to 5 air changes per hour) [E11]. Avoid dip sampling. [E42]. Wear suitable gloves tested to EN374 [PPE15]. 27 / 42

MATERIAL SAFETY DATA SHEET

according to Regulation (EC) No. 1907/2006

STYRENE MONOMER

Version 1.0 Revision Date 11/29/2010

Gen. Variant: SDS_NL Print Date 11/29/2010 MSDS No.: BE645

Laboratory activities [CS36]. All laboratory activities Quality control work of samples from reactor and blending vessel; R&D work including handling of samples from 1 kg to 1 drum PROC 15 Bulk transfers [CS14]. All activities related to transport finished product to customer Dispensing final UP/VE resin (linear UP/VE polymer + styrene + additives) / into storage tank, IBC, drum or pail PROC 9 Bulk transfers [CS14]. All activities related to transport finished product to customer Dispensing final UP/VE resin (linear UP/VE polymer + styrene + additives) into roadtanker . Tier2 assessment has been done to prove safe use of styrene PROC 8b Equipment cleaning and maintenance [CS39]. Cleaning and maintenance of blending vessel, roadtankers etc. PROC 3 Equipment cleaning and maintenance [CS39]. Cleaning and maintenance of pipes, pumps, filters, etc. PROC 8a Disposal of wastes [CS28]. Waste management / handling and storage of waste for removal for off-site treatment or for on-site treatment like incineration and/or biological waste water treatment PROC 8a

Carry out in a vented booth or extracted enclosure [E57]. Wear suitable gloves tested to EN374 [PPE15].

Fill containers/cans at dedicated fill points supplied with local extract ventilation [E51]. Wear suitable gloves tested to EN374 [PPE15].

Use bulk or semi-bulk handling systems [E43]. Wear suitable gloves tested to EN374 [PPE15].

Section 3 3.1. Health Section 4 4.1. Health

Drain down and flush system prior to equipment break-in or maintenance [E55]. Apply vessel entry procedures including use of forced supplied air [AP15]. Wear suitable gloves tested to EN374 [PPE15]. Drain down system prior to equipment break-in or maintenance [E65]. Drain or remove substance from equipment prior to break-in or maintenance [E81]. Wear suitable gloves tested to EN374 [PPE15]. Provide a good standard of general ventilation. Natural ventilation is from windows and doors etc. Controlled ventilation means air is supplied or removed by a powered fan. [E1]. Dispose of empty containers and wastes safely [C&H8]. Dispose of waste in accordance with environmental legislation [C&H11]. Avoid carrying out activities involving exposure for more than 1 hour [OC27]. Wear suitable gloves tested to EN374 [PPE15]. Wear a respirator conforming to EN140 with Type A filter or better [PPE22]. Exposure Estimation Use of ECETOC TRA Version 2 with modificatations. Guidance to check compliance with the Exposure Scenario Predicted exposures are not expected to exceed the DN(M)EL when the Risk Management Measures/Operational Conditions outlined in Section 2 are implemented [G22]. Where other Risk Management Measures/Operational Conditions are adopted, then users should ensure that risks are managed to at least equivalent levels [G23]. Exposure Scenario Title FRP manufacturing in an industrial setting, using UP/VE resins and/or formulated resins (gelcoat, bonding paste, putty etc.) CAS: 100-42-5 Sector of Use: SU3, SU12 28 / 42

Section 1 Title Use Descriptor

MATERIAL SAFETY DATA SHEET

according to Regulation (EC) No. 1907/2006

STYRENE MONOMER

Version 1.0 Revision Date 11/29/2010

Gen. Variant: SDS_NL Print Date 11/29/2010 MSDS No.: BE645

Processes, tasks, activities covered Section 2 Section 2.1 Product characteristics Physical form of product Concentration of substance in product Amounts used Frequency and duration of use Other Operational Conditions affecting worker exposure Contributing Scenarios Number of contributing Scenario Rolling, Brushing [CS51]; Roller, spreader, flow application [CS98] All open mould applications where resins is applied by brushing, rolling and other low energy spreading operations; Examples are handlamination, gelcoatbrushing, filament winding PROC 10 Spraying [CS10]; Spraying (automatic/robotic) [CS97] All open mould applications where resins is applied by spraying, either manually or automated or by robot. Examples are spray lamination, gelcoat spraying and "chop-hoop" filament winding PROC 7 Spraying [CS10]; Spraying (automatic/robotic) [CS97] All open mould applications where resins is applied by spraying, either manually or automated or by robot. Examples are spray lamination, gelcoat spraying and "chop-hoop" filament winding PROC 7 Dipping, immersion and pouring [CS4]; Rolling, Brushing [CS51]; Roller, spreader, flow application [CS98] Application of repair putties; Application of bonding pastes / adhesives. PROC 10

Process Categories: Proc : 3, 5, 7, 8a, 10, 13, 14, 15 Environmental Release Categories: ERC6d Processing of formulated polymers including material transfers, moulding and forming activities, material re-works and associated maintenance. Operational conditions and risk management measures Control of worker exposure Liquid, vapour pressure 0.5 - 10 kPa [OC4]. Covers percentage substance in the product up to 100 % (unless stated differently) [G13]. No Limit Covers daily exposures up to 8 hours (unless stated differently) [G2]. Assumes a good basic standard of occupational hygiene is implemented [G1]. , Assumes activities are at ambient temperature (unless stated differently) [G17]. Risk Management Measures 14 Provide a good standard of general ventilation (10 to 15 air changes per hour) [E40]. Use long handled brushes and rollers where possible [E58]. Ensure the ventilation system is regularly maintained and tested [E74]. Dispose of empty containers and wastes safely [C&H8]. Wear suitable gloves tested to EN374 [PPE15]. Wear suitable coveralls to prevent exposure to the skin [PPE27]. Carry out in a vented booth or extracted enclosure [E57]. Ensure the ventilation system is regularly maintained and tested [E74]. Dispose of empty containers and wastes safely [C&H8]. Wear suitable gloves tested to EN374 [PPE15]. Wear suitable coveralls to prevent exposure to the skin [PPE27].

Provide a good standard of general ventilation (not less than 3 to 5 air changes per hour) [E11]. Use long handled tools where possible [E50]. Carefully pour from containers [E62]. Wear suitable gloves tested to EN374 [PPE15]. Wear suitable coveralls to prevent exposure to the skin [PPE27]. Wear a respirator conforming to EN140 with Type A filter or better [PPE22]. Limit the substance content in the product to 25% [OC18]. Provide a good standard of general ventilation (10 to 15 air changes per hour) [E40]. Wear suitable gloves (tested to EN374) and eye protection [RPE19].

29 / 42

MATERIAL SAFETY DATA SHEET

according to Regulation (EC) No. 1907/2006

STYRENE MONOMER

Version 1.0 Revision Date 11/29/2010

Gen. Variant: SDS_NL Print Date 11/29/2010 MSDS No.: BE645

Dipping, immersion and pouring [CS4]; Continuous process [CS54]. Continuous processes with open impregnation steps, such as pultrusion with open impregnation baths and (semi-) continuous production of flat laminates PROC 13 Casting operations [CS32]; Mixing operations (open systems) [CS30]. Casting and mixing operations in (semi) open containers. Examples are centrifugal casting, casting of polymer concrete and artificial marble and the manufacturing of SMC / BMC/ TMC, etc PROC 5 General exposures (closed systems) [CS15]. Mixing liquid and solid components / into final formulated resin in blending vessel; Examples are gelcoat blending and compounding, formulation of repair putties, bonding pastes, chemical anchoring, etc PROC 5 Material transfers [CS3]; Automated process with (semi) closed systems [CS93]; Use in contained batch processes [CS37]. Resin injection and transfer processes, such as vacum infusion, RTM, impregnation of sewer relining sleeves PROC 3 Material transfers [CS3]; Production or preparation or articles by tabletting, compression, extrusion or pelletisation [CS100]; Treatment by heating [CS129]; Batch processes at elevated temperatures [CS136]. Processes where curing of UP / VE resins takes place at high temperature. Examples are pultrusion with injection dies and processing of SMC / BMC / TMC, etc PROC 14 Material transfers [CS3]. Product delivery/storage - delivery of bulk and packaged products - outdoor / indoor PROC 3 Drum/batch transfers [CS8]; Pouring from small containers [CS9]; Transfer from/pouring from containers [CS22]; Mixing operations (open systems) [CS30]. Loading of mixing equipment; Preparation of material for application; (liquid products) - batch, indoor PROC

Provide extract ventilation to points where emissions occur [E54].

Limit the substance content in the product to 25% [OC18]. Provide extract ventilation to points where emissions occur [E54]. Wear suitable gloves tested to EN374 [PPE15].

Handle substance within a predominantly closed system provided with extract ventilation [E49]. Provide a good standard of general ventilation (10 to 15 air changes per hour) [E40]. Put lids on containers immediately after use [E9]. Wear suitable gloves tested to EN374 [PPE15].

Provide a good standard of general ventilation (not less than 3 to 5 air changes per hour) [E11]. Put lids on containers immediately after use [E9]. Wear suitable gloves tested to EN374 [PPE15].

Limit the substance content in the product to 25% [OC18]. Provide a good standard of general or controlled ventilation (3 to 5 air changes per hour) [E40] or:[G9] Provide the operation with a properly sited receiving hood [E71]. Wear suitable gloves tested to EN374 [PPE15].

Transfer via enclosed lines [E52]. Provide a good standard of general ventilation (not less than 3 to 5 air changes per hour) [E11]. Provide extract ventilation to points where emissions occur [E54]. Put lids on containers immediately after use [E9]. Wear suitable gloves tested to EN374 [PPE15].

30 / 42

MATERIAL SAFETY DATA SHEET

according to Regulation (EC) No. 1907/2006

STYRENE MONOMER

Version 1.0 5 Revision Date 11/29/2010

Gen. Variant: SDS_NL Print Date 11/29/2010 MSDS No.: BE645

Equipment maintenance [CS5]; Maintenance of small items [CS18]. Equipment cleaning and maintenance, open indoor PROC 8a Laboratory activities [CS36]. Quality control work of samples from blending vessel; R&D work including handling of samples from 1 kg to 1 drum PROC 15 Disposal of wastes [CS28]. Handling of non cured waste; Waste management / handling and storage of waste for removal for off-site treatment or for onsite treatment like incineration and/or biological waste water treatment PROC 8a Section 3 3.1. Health Section 4 4.1. Health

Provide extract ventilation to points where emissions occur [E54]. Wear suitable gloves tested to EN374 [PPE15].

No specific measures identified [EI18].

Provide extract ventilation to points where emissions occur [E54]. Contain and dispose of waste according to local regulations [C&H14]. Put lids on containers immediately after use [E9]. Wear suitable gloves tested to EN374 [PPE15].

Exposure Estimation Use of ECETOC TRA Version 2 with modificatations. Guidance to check compliance with the Exposure Scenario Predicted exposures are not expected to exceed the DN(M)EL when the Risk Management Measures/Operational Conditions outlined in Section 2 are implemented [G22]. Where other Risk Management Measures/Operational Conditions are adopted, then users should ensure that risks are managed to at least equivalent levels [G23]. Exposure Scenario Title FRP manufacturing in a professional setting, using UP/VE resins and/or formulated resins (gelcoat, bonding paste, putty etc.) CAS: 100-42-5 Sector of Use:SU22, SU12 Process Categories: Proc : 3, 4, 5, 8a, 10, 11 Environmental Release Categories: ERC6c Processing of formulated polymers including material transfers, moulding and forming activities, material re-works and associated maintenance. Operational conditions and risk management measures Control of worker exposure Liquid, vapour pressure 0.5 - 10 kPa [OC4]. Covers percentage substance in the product up to 100 % (unless stated differently) [G13]. No Limit Covers daily exposures up to 8 hours (unless stated differently) [G2]. 31 / 42

Section 1 Title Use Descriptor

Processes, tasks, activities covered Section 2 Section 2.1 Product characteristics Physical form of product Concentration of substance in product Amounts used Frequency and duration of use

MATERIAL SAFETY DATA SHEET

according to Regulation (EC) No. 1907/2006

STYRENE MONOMER

Version 1.0 Revision Date 11/29/2010

Gen. Variant: SDS_NL Print Date 11/29/2010 MSDS No.: BE645

Other Operational Conditions affecting worker exposure Contributing Scenarios Number of contributing Scenario Rolling, Brushing [CS51]; Roller, spreader, flow application [CS98] All open mould applications where resins is applied by brushing, rolling and other low energy spreading operations; Examples are handlamination, gelcoatbrushing, semi- continuous production of flat panels and laminates PROC 10 Spraying [CS10]. All open mould applications where resins is applied by spraying. Examples are spray lamination and gelcoat spraying PROC 11 Dipping, immersion and pouring [CS4]; Rolling, Brushing [CS51]; Roller, spreader, flow application [CS98] Application of repair putties; Application of bonding pastes / adhesives. PROC 10 Dipping, immersion and pouring [CS4]; Rolling, Brushing [CS51]; Roller, spreader, flow application [CS98] Application of floorings, mastics, coatings, castings PROC 10 Material transfers [CS3]; Pouring from small containers [CS9]. Preparation of material for application (liquids) transfer of material from one container to another; Formulating / blending resins, gelcoats, bonding pastes, putties etc. in blending vessels PROC 5 Use in contained batch processes [CS37]. Sewer relining operation PROC 4 Use in contained batch processes [CS37]. Application of chemical anchoring PROC 3 Equipment maintenance [CS5]; Maintenance of small items [CS18]. Equipment cleaning and maintenance, open indoor PROC 8a

Assumes a good basic standard of occupational hygiene is implemented [G1]. , Assumes activities are at ambient temperature (unless stated differently) [G17]. Risk Management Measures 9 Provide a good standard of general ventilation (not less than 3 to 5 air changes per hour) [E11]. Use long handled brushes and rollers where possible. [E58]. Wear suitable gloves tested to EN374 [PPE15]. Wear a respirator conforming to EN140 with Type A filter or better [PPE22].

Provide a good standard of general ventilation (not less than 3 to 5 air changes per hour) [E11]. Keep people not involved in the activity, away from the operation. Avoid carrying out activities involving exposure for more than 4 hours [OC28]. Wear suitable gloves tested to EN374 [PPE15]. Wear a full face respirator conforming to EN140 with Type A filter or better [PPE24]. Limit the substance content in the product to 25% [OC18]. Provide a good standard of general ventilation (not less than 3 to 5 air changes per hour) [E11]. Wear suitable gloves tested to EN374 [PPE15]. Wear a respirator conforming to EN140 with Type A filter or better [PPE22]. Provide a good standard of general ventilation (not less than 3 to 5 air changes per hour) [E11]. Wear suitable gloves tested to EN374 [PPE15]. Wear a respirator conforming to EN140 with Type A filter or better [PPE22]. Use drum pumps or carefully pour from container [E64]. Provide a good standard of general ventilation (not less than 3 to 5 air changes per hour) [E11]. Put lids on containers immediately after use [E9]. Wear suitable gloves tested to EN374 [PPE15]. Wear a respirator conforming to EN140 with Type A filter or better [PPE22]. Wear suitable gloves tested to EN374 [PPE15]. Wear a respirator conforming to EN140 with Type A filter or better [PPE22]. Wear suitable gloves tested to EN374 [PPE15].

Provide a good standard of general ventilation (not less than 3 to 5 air changes per hour) [E11]. Avoid carrying out activities involving exposure for more than 1 hour [OC27].Wear suitable gloves tested to EN374 [PPE15].

32 / 42

MATERIAL SAFETY DATA SHEET

according to Regulation (EC) No. 1907/2006

STYRENE MONOMER

Version 1.0 Revision Date 11/29/2010

Gen. Variant: SDS_NL Print Date 11/29/2010 MSDS No.: BE645

Disposal of wastes [CS28]. Handling of non cured waste; Waste management / handling and storage of waste for removal for off-site treatment or for onsite treatment like incineration and/or biological waste water treatment PROC 8a Section 3 3.1. Health Section 4 4.1. Health

Provide a good standard of general ventilation (not less than 3 to 5 air changes per hour) [E11]. Dispose of empty containers and wastes safely [C&H8]. Avoid carrying out activities involving exposure for more than 1 hour [OC27]. Wear suitable gloves tested to EN374 [PPE15]. Exposure Estimation Use of ECETOC TRA Version 2 with modificatations. Guidance to check compliance with the Exposure Scenario Predicted exposures are not expected to exceed the DN(M)EL when the Risk Management Measures/Operational Conditions outlined in Section 2 are implemented [G22]. Where other Risk Management Measures/Operational Conditions are adopted, then users should ensure that risks are managed to at least equivalent levels [G23]. Exposure Scenario Title Production of Styrene Butadiene Rubber (SBR) CAS: 100-425 Sector of Use: SU3, SU11 Process Categories: PROC2, PROC3, PROC8a, PROC8b, PROC9, PROC15 Environmental Release Categories: ERC6c Manufacture of polymers from monomers in continuous and batch processes, include sparging, discharging, and reactor maintenance and immediate polymer product formation. Operational conditions and risk management measures Control of worker exposure Liquid, vapour pressure 0.5 - 10 kPa [OC4]. Covers percentage substance in the product up to 100 % (unless stated differently) [G13]. No Limit Covers daily exposures up to 8 hours (unless stated differently) [G2]. Assumes a good basic standard of occupational hygiene is implemented [G1]. Risk Management Measures 15 Clear transfer lines prior to de-coupling [E39].Avoid carrying out activities involving exposure for more than 1 hour [OC27] Handle substance within a closed system [E47]. Provide a good standard of general ventilation (not less than 3 to 5 air changes per hour) [E11] Provide a good standard of general ventilation (not less than 3 to 5 air changes per hour) [E11] 33 / 42

Section 1 Title Use Descriptor

Processes, tasks, activities covered Section 2 Section 2.1 Product characteristics Physical form of product Concentration of substance in product Amounts used Frequency and duration of use Other Operational Conditions affecting worker exposure Contributing Scenarios Number of contributing Scenario Material transfers [CS3]. Loading tank storage from road, rail or boat transport PROC 8b Material transfers [CS3]. Styrene Storage in tanks PROC 2 Material transfers [CS3]. Charging reactors via pipeline PROC 3 Batch process [CS55]. Polymerisation reactor PROC 3

MATERIAL SAFETY DATA SHEET

according to Regulation (EC) No. 1907/2006

STYRENE MONOMER

Version 1.0 Revision Date 11/29/2010

Gen. Variant: SDS_NL Print Date 11/29/2010 MSDS No.: BE645

Batch process [CS55]. Vacuum steam distillation PROC 3 Batch process [CS55]. Coagulation reactor PROC 3 Batch process [CS55]. Drying tank PROC 3 Material transfers [CS3]. Recycling styrene from distillator to reactor via pipeline PROC 3 Process sampling [CS2]. Sampling from reactors PROC 8a Laboratory activities [CS36]. Laboratory - Quality Control PROC 15 Small package filling [CS7]. Small package filling - Packaging of product PROC 9 Equipment maintenance [CS5]. Manufacturing equipment maintenance: opening and cleaning manufacturing equipment for maintenance purposes PROC 8b Bulk transfers [CS14]. Finished product Loading of road tanker, railcar, container PROC Material transfers [CS3]. Waste management : recovery using condensation or adsorption/ desorption processes PROC 2 Material transfers [CS3]. Waste management : transfer of process wastes to storage containers: off-line in workplace PROC 8b Section 3 3.1. Health Section 4 4.1. Health

Provide a good standard of general ventilation (not less than 3 to 5 air changes per hour) [E11] Provide a good standard of general ventilation (not less than 3 to 5 air changes per hour) [E11] Provide a good standard of general ventilation (not less than 3 to 5 air changes per hour) [E11] Provide a good standard of general ventilation (not less than 3 to 5 air changes per hour) [E11] Use a sampling system designed to control exposure [E89].0 No specific measures identified [EI18]. Limit the substance content in the product to 5% [OC17].0 Avoid carrying out activities involving exposure for more than 1 hour [OC27]

Limit the substance content in the product to 5% [OC17].

Handle substance within a closed system [E47].

Avoid carrying out activities involving exposure for more than 1 hour [OC27]

Exposure Estimation Use of ECETOC TRA Version 2 with modificatations. Guidance to check compliance with the Exposure Scenario Predicted exposures are not expected to exceed the DN(M)EL when the Risk Management Measures/Operational Conditions outlined in Section 2 are implemented [G22]. Where other Risk Management Measures/Operational Conditions are adopted, then users should ensure that risks are managed to at least equivalent levels [G23]. Exposure Scenario Title Production of Styrene Butadiene Latex (SBL) CAS: 100-42-5 Sector of Use: SU3, SU11 Process Categories: PROC2, PROC3, PROC8a, PROC8b, 34 / 42

Section 1 Title Use Descriptor

MATERIAL SAFETY DATA SHEET