Professional Documents

Culture Documents

Bollhoff Quicksert Expansion Inserts

Uploaded by

Ace Industrial SuppliesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bollhoff Quicksert Expansion Inserts

Uploaded by

Ace Industrial SuppliesCopyright:

Available Formats

0221/01.

02

Expansion inserts and studs

QUICKSERT

Precision threaded inserts and threaded studs with installation tools, for plastic and light metal part for after moulding insertion

Bllhoff GmbH Fastening and assembly systems P.O. Box 14 02 29 33622 Bielefeld Archimedesstr. 1 4 33649 Bielefeld Germany Telephone (*49) 5 21 / 44 82 - 03 (2 32) Telefax (*49) 5 21 / 44 82-3 71 www.bollhoff.com E-Mail: hoernli@boellhoff.de

sa l

es Fo @ r lo ac w ei es nd t p su ric pp es lie : s. co m

QUICKSERT expansion insert type 1230 The cost-efficient solution for threaded connections in light metals and plastics

After installation

Before installation

sa l

Advantages

No need to tap threads Rapid, cost-efficient insertion Chipless insertion in smooth locating holes Loadable screw thread in light metals Loadable screw thread in thermoplastic and thermoset materials** after demoulding the parts Suitable for insertion positions which are only accessible from one side Screw connections can be undone and retightened any number of times Can be fitted to fully finished surfaces

es Fo @ r lo ac w ei es nd t p su ric pp es lie : s. co m

Basic principle

The QUICKSERT expansion insert is threaded onto the rotating threaded mandrel of the P 2001 insertion tool and introduced into the locating hole. The hole may be preformed or produced as a pocket hole or through-hole using conventional drills. The axial pulling movement of the mandrel causes the QUICKSERT to shear off at the predetermined breaking point between the anchoring sleeve and the threaded bush. The latter is drawn into the anchoring sleeve and enlarges it. The axial and circumferential knurl of the anchoring sleeve is forced into the sides of the hole at the same time. The threaded insert is now anchored so that it can neither twist nor be pulled out.

** The suitability of this type of insert in plastics which are susceptible to stress cracking (e. g. PC, PPO) must be determined separately.

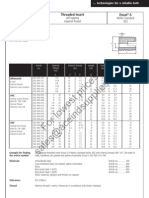

Technical data of QUICKSERT expansion insert type 1230

D

Anchoring sleeve D1 a D1 a

Threaded bush

Materials:

es Fo @ r lo ac w ei es nd t p su ric pp es lie : s. co m

Thread:

Overall fitted l1 length Overall length l Knurl d2 Product code steel Product code brass d D

+0,1

Steel 1.0718 Zn 8 bk cC Brass Cu Zn 38 Pb 2 Aluminium (on request) ISO as per DIN 13 6 H

L1 min

Terms of delivery: DIN 267

Locating hole

Lmin 8,8

E1min 4,8 6,3 8,2 9,8 11,5

a* 2 2 2,5 3 4

M3 M4 M5 M6 M8

1230 003 0048

1230103 0048

8,0

4,8

5,5

5,5

1230 004 0063 1230 005 0082 1230 006 0098 1230 008 0115

1230104 0063 1230105 0082 1230106 0098 1230108 0115

10,5

6,3

6,5 7,5 9

6,5 7,5 9

11,8

13,5

8,2

15,2 18,8 21,0

16,0

9,8

19,0

11,5

12

12

Dimensions in mm

Brass threaded inserts are recommended for use in plastic material. Special lengths, special thread diameters and other materials or surface finishes on request. * The values are merely for guidance. They may have to be increased after insertion tests, e. g. in brittle materials.

Processing

Manual insertion tool B 73000

d M5 M6 M8

Product code

2353 010 5000 2353 010 6000 2353 010 8000

sa l

Volume insertion tool B 73000

Basic tool without threaded mandrel and nosepiece Product code Nominal Tool with threaded mandrel and nosepiece Product code Replacement unit Product code Threaded mandrel Product code Nosepiece Product code

M3 M4 2361530 0000 M5 M6 M8

2361530 3000 2361530 4000 2361530 5000 2361530 6000 2361530 8000

2361130 3010 2361130 4010 2361130 5010 2361130 6010 2361130 8010

2361130 3020 2361130 4020 2361130 5020 2361130 6020 2361130 8020

2361130 3030 2361130 4030 2361130 5030 2361130 6030 2361130 8030

Example for ordering: Threaded mandrel M 4 2361130 4020

E1 min

QUICKSERT expansion studs

QUICKSERT type 1240

Advantages

W E N

The high-strength stud is a cold-headed part available up to strength class 10.9 through heat treatment High resistance to torsion and extraction in thermoplastic and thermoset materials Straightforward, rapid processing using spin/pull/spin tools, e. g. P 2001 and P 803 Prototypes (specimens, pilot series) can be produced as turned parts

Special features

Tried-and-tested basic principle of the QUICKSERT threaded insert type 1230 Two-part element

sa l

es Fo @ r lo ac w ei es nd t p su ric pp es lie : s. co m

Sizes from M 5 to M 8

Galvanized steel bolt as a cold-headed part or turned part

Sleeve as turned part of brass or galvanized steel with the required surface finish

Basic principle

The QUICKSERT expansion stud is threaded into the insertion tool and introduced into the locating hole. The hole may be preformed or produced as a pocket hole or throught-hole using conventional drills. The axial pulling movement of the tool causes the QUICKSERT to shear off between anchoring sleeve and the threaded stud. The latter is pulled into the anchoring sleeve and enlarges it. The axial and circumferential knurl on the anchoring sleeve is pressed into the sides of the hole at the same time. The threaded stud is now anchored so that it can neither twist nor be pulled out.

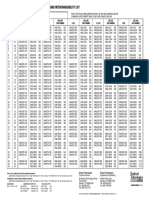

Type 1240

d

Locating hole

d2

L2 min

l2

Lmin

l1

Fitted Anchorage Product code d M4 M5 M6 M8 steel 1240 004 0010 1240 005 0015 1240 006 0020 1240 008 0020 lenght l 10,5 13,5 16,0 19,0 anchorage length l1 6,3 8,2 9,8 11,5 Thread length l2 10,0 15,0 20,0 20,0 Knurl d2 6,5 7,5 9,8 12,8 D+0,1 6,5 7,5 9,8 12,8

Locating hole

Lmin 11,8 15,2 18,8 21,0

L2min 6,3 8,2 9,8 11,5

a* 2,8 2,5 3,8 4,8

Article numbers 1240 . . . . . . . with optional stud length on request. Special length, special thread diameters and other materials or surface finishes on request. * The values are for guidance only. They may have to be increased after insertion tests, e. g. in brittle materials. * * The suitability of this type of insert in plastics which are susceptible to stress cracking (e. g. PC, PPO) must be determined separately. German and international property rights pending or granted.

You might also like

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Bollhoff Quicksert Expansion InsertsDocument4 pagesBollhoff Quicksert Expansion InsertsAce Industrial SuppliesNo ratings yet

- Hollo Bolt Technical Information File029418Document8 pagesHollo Bolt Technical Information File029418Chris FindlayNo ratings yet

- 07 Katalog E-I Lemp Intercable EngDocument257 pages07 Katalog E-I Lemp Intercable EngCristian Anghel100% (1)

- Fischer Anchor BoltDocument10 pagesFischer Anchor Bolticehorizon88No ratings yet

- Miller 09Document149 pagesMiller 09Emílio BeckerNo ratings yet

- Bti in Products Systra Safety at Work Workshop RequirementsDocument70 pagesBti in Products Systra Safety at Work Workshop Requirementsmarkl411No ratings yet

- Anchor SupportsDocument7 pagesAnchor Supportstejasp8388No ratings yet

- Dywidag DSI Baranchor enDocument8 pagesDywidag DSI Baranchor enwalitedisonNo ratings yet

- Hollo BoltDocument5 pagesHollo Boltikirby77No ratings yet

- FS Prospekt Englisch 1 0Document4 pagesFS Prospekt Englisch 1 0Denis AugustoNo ratings yet

- Bollhoff Snaplock MiniDocument3 pagesBollhoff Snaplock MiniAce Industrial SuppliesNo ratings yet

- Hettich CAM FixturesDocument23 pagesHettich CAM Fixturesgoingforward77No ratings yet

- Anclaje Quimico HILTIDocument84 pagesAnclaje Quimico HILTIWuceirNo ratings yet

- 1 Input Data: Profis Anchor 2.6.6Document6 pages1 Input Data: Profis Anchor 2.6.6Collin NguNo ratings yet

- DSI-DYWIDAG Tie RoTie Rodsds 02 PDFDocument6 pagesDSI-DYWIDAG Tie RoTie Rodsds 02 PDFAnonymous 4ghB3BQNo ratings yet

- Ds and S Cutting Ring Opticam Assembly enDocument3 pagesDs and S Cutting Ring Opticam Assembly enAlex PeñaNo ratings yet

- Flupec Catalog Etansari Translatie PDFDocument446 pagesFlupec Catalog Etansari Translatie PDFRadu VasileNo ratings yet

- Hettich Fittings BroucherDocument23 pagesHettich Fittings BrouchergitamamNo ratings yet

- HeliCoil Tangless InsertsDocument6 pagesHeliCoil Tangless InsertsAce Industrial SuppliesNo ratings yet

- FRE D Slot CuttersDocument18 pagesFRE D Slot CuttershorakftNo ratings yet

- Hitsert Screwlock en 0205Document6 pagesHitsert Screwlock en 0205WANKEL25No ratings yet

- Clamping ToolsDocument190 pagesClamping ToolsИван РадивојевићNo ratings yet

- Understanding - Unbrako Fasteners (Technical Brochure)Document48 pagesUnderstanding - Unbrako Fasteners (Technical Brochure)pavan_jssatebNo ratings yet

- Fluro CatalogueDocument56 pagesFluro CatalogueachinvanshNo ratings yet

- Nety ComandaDocument82 pagesNety ComandaVASILIINo ratings yet

- 738546Document3 pages738546DmitriiSpiridonovNo ratings yet

- Hilti AnchorDocument6 pagesHilti AnchorantonioNo ratings yet

- HF-Katalog 2 EN - Technische Informationen PDFDocument27 pagesHF-Katalog 2 EN - Technische Informationen PDFMaheshNo ratings yet

- Dywidag DSI Strandanchors enDocument8 pagesDywidag DSI Strandanchors enjack21abNo ratings yet

- X BT Brochure en W3987Document68 pagesX BT Brochure en W3987Paul RobbinsNo ratings yet

- Main Steel ConnectionsDocument40 pagesMain Steel ConnectionsIndrayadi AbdillahNo ratings yet

- Conec DSub HoodsDocument54 pagesConec DSub HoodsAmílcar DuarteNo ratings yet

- H Rod DatasheetDocument2 pagesH Rod DatasheetJohnnie StrydomNo ratings yet

- KVT FP FILKO EN 26-02-2013 WebDocument32 pagesKVT FP FILKO EN 26-02-2013 WebCornel CarabusNo ratings yet

- Marechal Plugs Sockets Decontactors PNDocument8 pagesMarechal Plugs Sockets Decontactors PNrocketvtNo ratings yet

- SN398 2008-04 eDocument4 pagesSN398 2008-04 ewasim_akp9885No ratings yet

- BTi Ausschnitt Katalog BT-Spannschloss R en WebDocument10 pagesBTi Ausschnitt Katalog BT-Spannschloss R en WebvishalgoreNo ratings yet

- English - Catalog For GasketDocument29 pagesEnglish - Catalog For GasketAhmed GamalNo ratings yet

- A4-P 1.0 enDocument4 pagesA4-P 1.0 enshani5573No ratings yet

- Shield Anchor Hex Bolt: Steel Yellow Zinc PlatedDocument1 pageShield Anchor Hex Bolt: Steel Yellow Zinc PlatedMarko KavaricNo ratings yet

- Deep Hole Drlling On Maching Centres BOTEKDocument2 pagesDeep Hole Drlling On Maching Centres BOTEKmapalptsNo ratings yet

- MB 219-229 PDFDocument11 pagesMB 219-229 PDFAmitava DattaNo ratings yet

- Hilti Hit Hy 200 With Hit VDocument18 pagesHilti Hit Hy 200 With Hit VRobinReyndersNo ratings yet

- Fastening SystemsDocument74 pagesFastening SystemsskyvaneNo ratings yet

- Intercable Cat enDocument0 pagesIntercable Cat enAnand SankalechaNo ratings yet

- (Corus) SHS Jointing - Flowdrill and Hollo-BoltDocument13 pages(Corus) SHS Jointing - Flowdrill and Hollo-Bolt_at_to_No ratings yet

- 1 Input Data: WWW - Hilti.co - UkDocument6 pages1 Input Data: WWW - Hilti.co - UkihpeterNo ratings yet

- Hydroformed Metal Bellows - Design HandbookDocument128 pagesHydroformed Metal Bellows - Design Handbookchipulino100% (1)

- Craig & Derricott Isolators & Switch Disconnectors CatalogueDocument40 pagesCraig & Derricott Isolators & Switch Disconnectors CataloguerocketvtNo ratings yet

- CuñaDocument20 pagesCuñaJulian Granados RicoNo ratings yet

- Kistler LVDTDocument2 pagesKistler LVDTKarmen CevilleNo ratings yet

- Hettich Drawer FitingsDocument23 pagesHettich Drawer FitingsgitamamNo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- HeliCoil Tangless ApplicationsDocument2 pagesHeliCoil Tangless ApplicationsAce Industrial SuppliesNo ratings yet

- HeliCoil Product RangeDocument40 pagesHeliCoil Product RangeAce Industrial SuppliesNo ratings yet

- PowerCoil Screw Thread InsertsDocument103 pagesPowerCoil Screw Thread InsertsAce Industrial SuppliesNo ratings yet

- HeliCoil Stud-Lock InsertsDocument2 pagesHeliCoil Stud-Lock InsertsAce Industrial SuppliesNo ratings yet

- HeliCoil Self Tapping InsertsDocument4 pagesHeliCoil Self Tapping InsertsAce Industrial SuppliesNo ratings yet

- HeliCoil Insert Specs ImperialDocument1 pageHeliCoil Insert Specs ImperialAce Industrial SuppliesNo ratings yet

- HeliCoil Insert Specs MetricDocument1 pageHeliCoil Insert Specs MetricAce Industrial SuppliesNo ratings yet

- HeliCoil Aftermarket Kits Oxygen SensorDocument1 pageHeliCoil Aftermarket Kits Oxygen SensorAce Industrial SuppliesNo ratings yet

- HeliCoil Aftermarket Catalogue 2Document24 pagesHeliCoil Aftermarket Catalogue 2Ace Industrial SuppliesNo ratings yet

- HeliCoil Screw Thread InsertsDocument36 pagesHeliCoil Screw Thread InsertsAce Industrial Supplies0% (1)

- HeliCoil Tangless Gall Resistant InsertsDocument2 pagesHeliCoil Tangless Gall Resistant InsertsAce Industrial SuppliesNo ratings yet

- HeliCoil Pipe Thread Inserts NPT ANPT NPSCDocument8 pagesHeliCoil Pipe Thread Inserts NPT ANPT NPSCAce Industrial SuppliesNo ratings yet

- HeliCoil Stud-Lock ApplicationsDocument2 pagesHeliCoil Stud-Lock ApplicationsAce Industrial SuppliesNo ratings yet

- HeliCoil Gall Resistant InsertsDocument2 pagesHeliCoil Gall Resistant InsertsAce Industrial SuppliesNo ratings yet

- HeliCoil Serrated Spark Plug InsertsDocument4 pagesHeliCoil Serrated Spark Plug InsertsAce Industrial Supplies100% (1)

- Bollhoff Rivkle RivnutsDocument52 pagesBollhoff Rivkle RivnutsAce Industrial SuppliesNo ratings yet

- HeliCoil NPT Inserts 8UNDocument4 pagesHeliCoil NPT Inserts 8UNAce Industrial SuppliesNo ratings yet

- HeliCoil Primer Free II ApplicationsDocument2 pagesHeliCoil Primer Free II ApplicationsAce Industrial SuppliesNo ratings yet

- HeliCoil Aftermarket KIts Sav-A-Thread HTDocument1 pageHeliCoil Aftermarket KIts Sav-A-Thread HTAce Industrial SuppliesNo ratings yet

- HeliCoil Aftermarket CatalogueDocument24 pagesHeliCoil Aftermarket CatalogueAce Industrial SuppliesNo ratings yet

- HeliCoil Primer Free II InsertsDocument2 pagesHeliCoil Primer Free II InsertsAce Industrial SuppliesNo ratings yet

- HeliCoil NPT Inserts 8UN 2Document2 pagesHeliCoil NPT Inserts 8UN 2Ace Industrial SuppliesNo ratings yet

- Ensat Self Tapping Inserts 307 308 SeriesDocument1 pageEnsat Self Tapping Inserts 307 308 SeriesAce Industrial SuppliesNo ratings yet

- Ensat Self Tapping Inserts 303 SeriesDocument1 pageEnsat Self Tapping Inserts 303 SeriesAce Industrial SuppliesNo ratings yet

- HeliCoil Aftermarket Kits Head Bolt Thread RepairDocument1 pageHeliCoil Aftermarket Kits Head Bolt Thread RepairAce Industrial SuppliesNo ratings yet

- Ensat Self Tapping Inserts 302 Series ImperialDocument1 pageEnsat Self Tapping Inserts 302 Series ImperialAce Industrial SuppliesNo ratings yet

- Ripp Lock WashersDocument8 pagesRipp Lock WashersAce Industrial SuppliesNo ratings yet

- Ensat Self Tapping Inserts 302 Series MetricDocument1 pageEnsat Self Tapping Inserts 302 Series MetricAce Industrial SuppliesNo ratings yet

- RivclinchDocument28 pagesRivclinchAce Industrial SuppliesNo ratings yet

- WTI Screw Thread InsertsDocument16 pagesWTI Screw Thread InsertsAce Industrial SuppliesNo ratings yet

- 8 Card Guides & Pullers PDFDocument12 pages8 Card Guides & Pullers PDFfuaunNo ratings yet

- Heli-Coil Metric Inserts Aerospace Standard Interchangeability ListDocument2 pagesHeli-Coil Metric Inserts Aerospace Standard Interchangeability ListshadiNo ratings yet

- Using Lock-N-Stitch Procedures For Casting Repair InsertosDocument32 pagesUsing Lock-N-Stitch Procedures For Casting Repair InsertosAlan GonzalezNo ratings yet

- Avdel Brief HistoryDocument20 pagesAvdel Brief Historyjuli fitriyantoNo ratings yet

- Helicoil Catalog - hc2000 Rev.5Document36 pagesHelicoil Catalog - hc2000 Rev.5Hugo CastroNo ratings yet

- B20D Parts Manual Section 2 EngineDocument76 pagesB20D Parts Manual Section 2 EngineerickbothaNo ratings yet

- Spiralock Catalog - 2019 PDFDocument40 pagesSpiralock Catalog - 2019 PDFjuli fitriyantoNo ratings yet

- Design of Joints General LectureDocument126 pagesDesign of Joints General LectureZarkovic011100% (2)

- HILTI Chemical Injection AnchoringDocument6 pagesHILTI Chemical Injection AnchoringBaden Lim-bonautNo ratings yet

- Nasarap RDC v101 CompressedDocument298 pagesNasarap RDC v101 CompressedMatthew Kevin Kumar CNo ratings yet

- Aftermarket CatalogAM802 HelicoilDocument24 pagesAftermarket CatalogAM802 HelicoilDavid OrtízNo ratings yet

- Threaded Insert Systems: Edition 05 2013Document48 pagesThreaded Insert Systems: Edition 05 2013Shanil BussooaNo ratings yet

- FastenersDocument46 pagesFastenerschirags_99100% (1)

- Threaded Inserts: Types of InsertDocument2 pagesThreaded Inserts: Types of InsertwanpudinNo ratings yet

- HC 150RP (Ep) MontabertDocument17 pagesHC 150RP (Ep) MontabertFacundo100% (1)

- Jergens Inc Key-Locking InsertsDocument16 pagesJergens Inc Key-Locking InsertsThor InternationalNo ratings yet

- Service Letter: Pilatus Aircraft Ltd. Ch-6371 Stans, SwitzerlandDocument54 pagesService Letter: Pilatus Aircraft Ltd. Ch-6371 Stans, SwitzerlandDiego CabreraNo ratings yet

- Cop 1132Document11 pagesCop 1132ESRANo ratings yet

- Neral Notes On Engineering Hardware - FastenersDocument45 pagesNeral Notes On Engineering Hardware - Fastenersbrotaccristian100% (1)

- HeliCoil Tangless InsertsDocument2 pagesHeliCoil Tangless InsertsAce Industrial SuppliesNo ratings yet

- HeliCoil Aftermarket Catalogue 2Document24 pagesHeliCoil Aftermarket Catalogue 2Ace Industrial SuppliesNo ratings yet

- Chrysler Dodge CALIBER Service Manual (2007) # - IntroducciónDocument17 pagesChrysler Dodge CALIBER Service Manual (2007) # - IntroducciónKart MichelNo ratings yet

- Heli-Coil Catalog HC2000 Rev12Document40 pagesHeli-Coil Catalog HC2000 Rev12anon_512891835No ratings yet

- HeliCoil Aftermarket CatalogueDocument24 pagesHeliCoil Aftermarket CatalogueAce Industrial SuppliesNo ratings yet

- KVT KEENSERTS Thread Inserts EN 12-2015 Web-CatalogDocument12 pagesKVT KEENSERTS Thread Inserts EN 12-2015 Web-CatalogvenothNo ratings yet

- Helicoil Plus en 0100Document56 pagesHelicoil Plus en 0100Khổng MạnhNo ratings yet

- Cat 3176c Montagem Da Cabeça.Document7 pagesCat 3176c Montagem Da Cabeça.César PérezNo ratings yet

- TM 10-5411-247-13PDocument408 pagesTM 10-5411-247-13PAdvocate100% (1)

- SONEX Fuel TankDocument3 pagesSONEX Fuel Tankviorelu99No ratings yet