Professional Documents

Culture Documents

Part 2 R410A Three Pipe Heat Recovery V4+ Selection Procedure 380 415V, 50Hz, 3N (Combinable)

Uploaded by

wolfzemunOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Part 2 R410A Three Pipe Heat Recovery V4+ Selection Procedure 380 415V, 50Hz, 3N (Combinable)

Uploaded by

wolfzemunCopyright:

Available Formats

Selection Procedure

MCAC-VTSM-2011-02

Part 2

Selection Procedure

1 Introduction ....................................................................... 17 2 Unit selection (Based on cooling load) ........................... 20

16

Selection Procedure

MCAC-VTSM-2011-02

Selection Procedure

1 Introduction

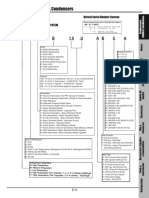

1.1 Model Selection Procedure

Select the model and calculate the capacity for each refrigerant system according to the procedure shown below. Calculation of the indoor air-conditioning load, Calculate the maximum air-conditioning load for each room

or zone.

Selection of an air conditioning system

Select

the ideal air conditioning system for air conditioning of each room or zone a suitable control system for the selected air conditioning system

Design of the control system

Design

Preliminary selection of indoor and outdoor units

Make

preliminary selections that are within the allowable range for the system

Check of the tubing length and elevation difference

Check that the length of refrigerant tubing and the elevation difference are within the allowable ranges correction coefficient for model, outdoor temperature conditions, tubing length and elevation

Calculation of the corrected outdoor unit capacity

Capacity

difference

Calculation of the actual capacity for each indoor unit

Calculate

the corrected indoor/outdoor capacity ratio, based on the corrected outdoor unit capacity and the total corrected capacity of all indoor units in the same system

Recheck of the actual capacity for each indoor unit

If

the capacity is inadequate, reexamine the unit combinations.

1.2 Indoor Unit Selection

Enter INDOOR UNIT CAPACITY TABLES at given indoor and outdoor temperature. Select the unit that the capacity is the nearest to and greater than given load.

Note: Individual indoor unit capacity is subject to change by the combination. Actual capacity has to be calculated according to the combination by using outdoor unit capacity table.

1.2.1 Calculation of Actual Capacity of Indoor Unit

Because the capacity of a multi air-conditioner changes according to the temperature conditions, tubing length, elevation difference and other factors, select the correct model after taking into account the various correction values. When selecting The model, calculate the corrected capacities of the outdoor unit and each indoor unit. Use the corrected outdoor unit capacity and the total corrected capacity of all the indoor units to calculate the actual final capacity of each indoor unit.

Find the indoor unit capacity correction coefficient for the following items Capacity correction for the indoor unit temperature conditions

From the graph of capacity characteristics, use the indoor temperature to find the capacity correction coefficient.

Capacity distribution ratio based on the indoor unit tubing length and elevation difference. First, in the same way as for the outdoor unit, use the tubing length and elevation difference for each indoor unit to find the correction coefficient from the graph of capacity change characteristics

Capacity distribution ratio for each indoor unit = Correction coefficient for that indoor unit / Correction coefficient for the outdoor unit

1.3 Outdoor Unit Selection

Allowable combinations are indicated in INDOOR UNIT COMBINATION TOTAL CAPACITY INDEX TABLE. In general, outdoor unit can be selected as follows though the location of the unit, zoning and usage of the rooms may be considered. The indoor and outdoor unit combination is determined that the sum of indoor unit capacity index is nearest to Selection Procedure 17

Selection Procedure

MCAC-VTSM-2011-02

and smaller than the capacity index at 100% combination ratio of each outdoor unit. Up to 8~16 indoor units can be connected to one outdoor unit. It is recommended to choose a larger outdoor unit if the installation space is large enough. If the combination ratio is greater than 100%, the indoor unit selection shall be reviewed by using actual capacity of each indoor unit. INDOOR UNIT COMBINATION TOTAL CAPACITY INDEX TABLE

Outdoor Unit 8HP 10HP 16HP 18HP 20HP 24HP 26HP 28HP 30HP Indoor Unit Combination Ratio (kW) 130% 32.76 36.4 59.02 69.16 72.8 98.28 95.42 105.56 109.2 120% 30.24 33.6 54.48 63.84 67.2 90.72 88.08 97.44 100.8 110% 27.72 30.8 49.94 58.52 61.6 83.16 80.74 89.32 92.4 100% 25.2 28.0 45.4 53.2 56.0 75.6 73.4 81.2 84.0 90% 22.68 25.2 40.86 47.88 50.4 68.04 66.06 73.08 75.6 80% 20.16 22.4 36.32 42.56 44.8 60.48 58.72 64.96 67.2 70% 17.64 19.6 31.78 37.24 39.2 52.92 51.38 56.84 58.8 60% 15.12 16.8 27.24 31.92 33.6 45.36 44.04 48.72 50.4 50% 12.6 14.0 22.7 26.6 28.0 37.8 36.7 40.6 42.0

INDOOR UNIT CAPACITY INDEX

Unit Size Capacity Index (kW) Unit Size Capacity Index (kW) Model 22 2.2 Model 160 16 Model 28 2.8 Model 200 20 Model 36 3.6 Model 250 25 Model 45 4.5 Model 280 28 Model 56 5.6 Model 71 7.1 Model 80 8.0 Model 90 9.0 Model 112 11.2 Model 140 14.0

1.3 Actual Performance Date

Use OUTDOOR UNIT CAPACITY TABLES. Determine correct table according to the outdoor unit model and combination ratio. Enter the table at given indoor and outdoor temperature and find the outdoor unit capacity and power input. The individual indoor unit capacity (power input) can by calculated as follows. IUC=OUC INX/TNX Where, IUC: Each indoor unit capacity OUC: Outdoors unit capacity INX: Each indoor unit capacity index TNX: Total capacity index Then, correct the indoor unit capacity according to the piping length. If the corrected capacity is smaller than the load, the size of indoor unit has to be increased and repeat the same selection procedure.

1.4 Variation in capacity in accordance with the length of refrigerant pipe

1.4.1 Cooling capacity modification Modification coefficient of the length and high difference of refrigerant pipe:

18

Selection Procedure

MCAC-VTSM-2011-02

Selection Procedure

H (m)

50 40 30 20

% 100 99 97 94 92 89 87 87

10 0 - 10 - 20 - 30 - 40

83

10

20

30

40

50

60

70

80

90

100 110 120 130 140 150 160 170 175

L (m)

L: Refrigerant pipe equivalent length H: Height difference between outdoor and indoor

1.4.2 Heating capacity modification Modification coefficient of the length and high difference of refrigerant pipe: H (m)

50 40 30 20 10

99

98

97

- 10 - 20 - 30 - 40 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 175

96

100 %

L(m)

L: Refrigerant pipe equivalent length H: Height difference between outdoor and indoor

Selection Procedure

19

Selection Procedure

MCAC-VTSM-2011-02

2 Unit selection (Based on cooling load)

2.1 Given condition

2.1.1 Design condition (Cooling: Indoor 20 C (WB), Outdoor 35 C (DB)) 2.1.2 Cooling load Location

Load (kW) Room A 2.1 Room B 2.8 Room C 3.5 Room D 4.6

Room E

5.8

Room F 7.2

2.1.3 Power supply unit: Outdoor 380~415V-3Ph-50Hz, Indoor 220~240V-1Ph-50Hz. 2.1.4 Pipe length: 50m 2.1.5 Height difference: 30m

2.2 Indoor unit selection

Select the suitable capacity for condition of Indoor 20 C (WB), Outdoor 35 C (DB) using indoor unit capacity table. The selected result is as follows. (Assuming the indoor unit type is duct)

Location Load (kW) Unit size Capacity (kW) Room A 2.1 22 2.3 Room B 2.8 28 2.9 Room C 3.5 36 3.7 Room D 4.6 45 4.8 Room E 5.8 56 6.0 Room F 7.2 71 7.5

2.3 Outdoor unit selection

2.3.1 Assume the indoor unit and outdoor unit combination as follows 2.3.1.1 Calculate the total nominal capacity of indoor units in the combination according to the above table: 2.2 1 +2.8 1+ 3.6 1 +4.5 1+ 5.6 1 + 7.1 1 = 25.8kW 2.3.1.2 Select outdoor unit: MDV-280(10)W/D1RN1T(B) which has nominal cooling capacity: 28kW. Calculate the proportion between and : 258/280= 92% 2.3.2 Result : Because the proportion is within 50130%, it is a Right selection. 2.3.3 Real function data with indoor unit combination For the 92% combination, calculate the cooling capacity of outdoor unit (MDV-280(10)W/DRN1(B)). 26.65KW 90% (Indoor temperature : WB 20 C, Outdoor temperature: DB 35 C) 29.61KW 100%(Indoor temperature : WB 20 C, Outdoor temperature: DB 35 C) Then calculated the outdoor capacity in 92% combination index: Therefore: 26.65+ {(29.61-26.65)/ 10} 2= 27.24; Outdoor unit (MDV-280(10)W/D1RN1T(B)) , design cooling temperature: DB 35 C Capacity modification coefficient with pipe length (50m) and height difference (30m): 0.958 Each indoor unit cooling capacity

MDV-D22T2: 27.24 22/258 0.958 = 2.22(kW) MDV-D28T2: 27.24 28/258 0.958 = 2.83 (kW) MDV-D36T2: 27.24 36/258 0.958 = 3.64 (kW) MDV-D45T2: 27.24 45/258 0.958 = 4.55 (kW) MDV-D56T2: 27.24 56/258 0.958 = 5.66 (kW) MDV-D71T2: 27.24 71/258 0.958 = 7.18 (kW)

Location Load (kW) Unit size Capacity (kW) Room A 2.1 22 2.22 Room B 2.8 28 2.83 Room C 3.5 36 3.64 Room D 4.6 45 4.55 Room E 5.8 56 5.66 Room F 7.2 71 7.18

20

Selection Procedure

MCAC-VTSM-2011-02

Selection Procedure

2.4 Conclusion

Generally, we think this result is acceptable, so we can think we have accomplished the calculation. But if you think this result is not acceptable, you can repeat the above process.

Remark: In this sample, we dont consider the other capacity modification index and assume them are 1.0.

For more details about the effect factor such as outside ambient/inside ambient DB/WD , please refer to the performance table of indoor and outdoor units.

Selection Procedure

21

You might also like

- SPLIT Gasni GeneratorDocument2 pagesSPLIT Gasni GeneratorwolfzemunNo ratings yet

- Data Sheet Three Point Controlled Actuator AMV 100: DescriptionDocument4 pagesData Sheet Three Point Controlled Actuator AMV 100: DescriptionwolfzemunNo ratings yet

- Trade Authorization 2010Document1 pageTrade Authorization 2010wolfzemunNo ratings yet

- New Product News - MDV Low Static Pressure Duct Indoor UnitDocument3 pagesNew Product News - MDV Low Static Pressure Duct Indoor UnitwolfzemunNo ratings yet

- AHU ManualDocument17 pagesAHU ManualwolfzemunNo ratings yet

- Product News-MDV Unified On & Off Central ControllerDocument3 pagesProduct News-MDV Unified On & Off Central ControllerwolfzemunNo ratings yet

- Modular AHU ManualDocument17 pagesModular AHU ManualwolfzemunNo ratings yet

- News Letter - New 4 Way Compact Cassette FCUDocument2 pagesNews Letter - New 4 Way Compact Cassette FCUwolfzemunNo ratings yet

- Part 3 R410A Three Pipe Heat Recovery V4+ Outdoor Unit Specification & Performance 50Hz (CombinablDocument33 pagesPart 3 R410A Three Pipe Heat Recovery V4+ Outdoor Unit Specification & Performance 50Hz (CombinablwolfzemunNo ratings yet

- Part 1 R410A Three Pipe Heat Recovery V4+ Genaral Information 380 415V, 50Hz, 3N (Combinable)Document15 pagesPart 1 R410A Three Pipe Heat Recovery V4+ Genaral Information 380 415V, 50Hz, 3N (Combinable)wolfzemunNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Catalogo Unidad Condensadora Bomba de Calor PC090-180 y PD180-240 Americana AHRI PDFDocument126 pagesCatalogo Unidad Condensadora Bomba de Calor PC090-180 y PD180-240 Americana AHRI PDFBladimir Patino - TRS BUCARAMANGANo ratings yet

- Kin Xin Engineering Catalogue SubmissionsDocument16 pagesKin Xin Engineering Catalogue SubmissionsDlone ZhuangNo ratings yet

- Mitsubishi Lossnay Energy Recovery Ventilator (ERV) BrochureDocument20 pagesMitsubishi Lossnay Energy Recovery Ventilator (ERV) Brochuree-ComfortUSA100% (1)

- 38-character AC unit title for growth, transfer & media roomsDocument6 pages38-character AC unit title for growth, transfer & media roomssolquihaNo ratings yet

- Homemade HRV, PDF, Jan 2004Document39 pagesHomemade HRV, PDF, Jan 2004JohnNo ratings yet

- ASHRAE HVAC Design Manual For Hospitals & Clinics - 2003 PDFDocument298 pagesASHRAE HVAC Design Manual For Hospitals & Clinics - 2003 PDFSameeh Kaddoura100% (5)

- Amc Hvac VtuDocument2 pagesAmc Hvac VtuDolphin Engineering Services100% (1)

- Mitsubishi System CatalogDocument76 pagesMitsubishi System Cataloge-ComfortUSANo ratings yet

- ThermostatDocument22 pagesThermostatManish100% (1)

- Panasonic CS-SA12CKP User ManualDocument11 pagesPanasonic CS-SA12CKP User ManualIvanGrozniNo ratings yet

- Resume (Salim Ahmed) MEPDocument3 pagesResume (Salim Ahmed) MEPSalim AhmedNo ratings yet

- AHU Operational Control Spreadsheet TrainingDocument17 pagesAHU Operational Control Spreadsheet Trainingniti860No ratings yet

- Air System Sizing Summary For FCU-01Document4 pagesAir System Sizing Summary For FCU-01imtz2013No ratings yet

- Seminar On Magnetic Refrigeration: A Promising Substitute For Vapour Compression SystemDocument16 pagesSeminar On Magnetic Refrigeration: A Promising Substitute For Vapour Compression SystemJayahari .M.VNo ratings yet

- DC Inverter: Domestic Air ConditionerDocument79 pagesDC Inverter: Domestic Air ConditionerBvm BvmmNo ratings yet

- Compressors, Chillers & Condensers Catalog SectionDocument3 pagesCompressors, Chillers & Condensers Catalog SectionLionder GarciaNo ratings yet

- J. A. Marino Product CatalogDocument112 pagesJ. A. Marino Product CatalogJMIKEMARINONo ratings yet

- Visio LPG PlantDocument2 pagesVisio LPG PlantOpen Knowledge and Education Book ProgramsNo ratings yet

- FUJITSU Tehnicki-Prirucnik-Dizalice-Topline-Zrak-Voda PDFDocument60 pagesFUJITSU Tehnicki-Prirucnik-Dizalice-Topline-Zrak-Voda PDFNIkica BukaricaNo ratings yet

- Cooling Tower - Question and AnswersDocument6 pagesCooling Tower - Question and AnswersFawaaz Khurwolah67% (3)

- Termal Master 2500Document5 pagesTermal Master 2500khaled amiri100% (1)

- Ag Ser8300 Fcu A4 PDFDocument32 pagesAg Ser8300 Fcu A4 PDFMarin MariusNo ratings yet

- GHANZ Auckland 13sep2012 GHPs A Technology OverviewDocument31 pagesGHANZ Auckland 13sep2012 GHPs A Technology OverviewElman WacoNo ratings yet

- Oxford Cryo PDFDocument6 pagesOxford Cryo PDFkeineahnungNo ratings yet

- Process of Cryogenic CoolingDocument2 pagesProcess of Cryogenic CoolingJesse LeeNo ratings yet

- Split Type Air Conditioners: DC Inverter Control 60 HZDocument21 pagesSplit Type Air Conditioners: DC Inverter Control 60 HZteguh prasetyoNo ratings yet

- Ventiloconvector PDFDocument2 pagesVentiloconvector PDFMihai STANNo ratings yet

- 11wiring Diagram of Auxiliary Heater (ACH)Document6 pages11wiring Diagram of Auxiliary Heater (ACH)Алексей ЄвтушокNo ratings yet

- Refrigeration and Air ConditioningDocument7 pagesRefrigeration and Air ConditioningManjunatha EikilaNo ratings yet

- Basic Technical Training: Takasago Thermal Engineering Co., LTDDocument68 pagesBasic Technical Training: Takasago Thermal Engineering Co., LTDpubudunishantha50% (2)