Professional Documents

Culture Documents

Guide instrument air utility estimates

Uploaded by

yogacruiseOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Guide instrument air utility estimates

Uploaded by

yogacruiseCopyright:

Available Formats

As part of preparing a process discipline manual for one of my previous organizations, one section that I had prepared was

"Guidelines for Preparation of Utility Summary". This document besides containing an excel template for utility summary also had some guidelines for determining the consumption of utilities such as instrument air, cooling water make-up, potable water and water requirements for a safety shower. I am reproducing some information: 1 Instrument Air Requirement The following guidelines may be adopted for estimating instrument air consumption for different types of pneumatic instruments: - Control Valves with diaphragm actuator and positioner and I/P converter-2.0Nm /h - Control (generally on-off type) valves with piston actuator and positioner 5 Nm /h 10% of this consumption will be considered in calculations. The estimated total instrument air quantity should be multiplied by 1.3 to account for uncertainties in the data used for the estimate and to allow the installation of additional instruments during the early years of plant operation. 2 Cooling Tower Make-up -Evaporation Loss: Approximately equal to 1% of circulation rate for each 5.5C (10F) of cooling tower temperature range. - Drift Loss: 0.1 % of circulation rate as a preliminary estimate. - Blowdown: This quantity is dependent on circulation rate, range, and cycles of concentration Total Make-up water = Evaporation Loss + Drift Loss + Blowdown 3 Potable Water Requirement As a conservative estimate a figure of 150 litres per day per person should be considered for preliminary calculations for potable water. This includes water for drinking and sanitation. 4 Safety Shower Water quantity requirement for safety showers to be considered based on each safety shower operating for 15 minutes per day. A minimum flow rate of 4.5 m /h for each safety shower is recommended as per ANSI Z538.1. As an example if there are 10 safety showers required to be installed for the project, then the water requirement may be calculated as follows: Quantity required per day per safety shower = 4.5 x (15/60) = 1.125 m /day No. of showers = 10 Total water quantity for safety showers for the project = 10 x 1.125 = 11.25 m /day Other utilities such as Fuel Gas, Nitrogen, Steam etc. are not considered because they cannot be generalized and require specific consumption calculations depending on the project / plant requirement. Let me hear comments from the knowledgable members and readers of "Cheresources". Regards, Ankur.

3 3 3 3 3

Point No. 1, 2 & 3 are almost tallying with my figures. I do not have idea on Safety Shower.

icingrock Feb 21 2012 06:36 PM

Control (generally on-off type) valves with piston actuator and positioner 5 Nm3/h 10% of this consumption will be considered in calculations I don't have experiences with design of utilities so my question could be not heavy.What do you mean by 10% of 5 Nm3/h should be considered in calculations.If 0.5 Nm3/h should be considered for calculation, what about the other 4.5 Nm3/h.

sameerjb Feb 21 2012 09:56 PM very nicely compiled Ankur...thks a lot

debasisq8 Feb 21 2012 11:18 PM Thanx Ankur

ankur2061 Feb 21 2012 11:21 PM 'icingrock', on 22 Feb 2012 - 06:46 AM, said: Control (generally on-off type) valves with piston actuator and positioner 5 Nm3/h 10% of this consumption will be considered in calculations I don't have experiences with design of utilities so my question could be not heavy.What do you mean by 10% of 5 Nm3/h should be considered in calculations.If 0.5 Nm3/h should be considered for calculation, what about the other 4.5 Nm3/h. On-off valves are either in open or closed position as required by the process. In any of these static positions, on-off valve will not consume any instrument air except for leakage losses from the cyclinder which is negligible. Thus of the total on-off valves in the plant, operation of 10% of them simulataneously can be considered conservative enough to include in instrument air calculations. This is the logic behind the statement that "10% of this consumption will be considered in calculations"

Hope this helps.

Regards, Ankur

Qalander (Chem) Feb 21 2012 11:57 PM Dear Congratulations! Good info;seems reliable to fairly estimate in practical way. Thanks.

Robert Montoya Feb 22 2012 03:22 PM Dear Ankur; is important take into account in the instrument air 30% due the consumption during the regeneration of air dryer tower.

Zack Adam Apr 16 2012 11:10 AM Dear Ankur; For the item 1 Some considered (10%-15% Margin for Control Valve + Continuous IA users) x 1.3 (30% uncertainties) + Max Intermittent User

For the Intermittent users, some call for 3 biggest SDVs

May I know what are the continuous air consumers that normally considered in IA Receiver calculation?

any comments

ankur2061 Apr 16 2012 11:53 AM

Zack,

IA receiver is sized on a hold-up time of 10-15 minutes from maximum pressure to min. pressure (say 8.5 barg to 4.5 barg) considering the maximum consumption and no air supply from the compressor

Continuous IA users in a plant are diaphragm type modulating control valves.

Regards, Ankur

RAJIV JAIN May 11 2012 12:03 PM dear ankur can u pls tell what is the compree sed air 4kg/cm2g for a ods pump for acidic slurry 10m3/hr 10m head

You might also like

- Air Consumption - On Off ValveDocument11 pagesAir Consumption - On Off Valvepradip_rana3375100% (3)

- Relief and Blowdown System FlaringDocument5 pagesRelief and Blowdown System FlaringRicardo NapitupuluNo ratings yet

- Safety Interlocks in Crude Heaters Using PLC: Cochin University of Science and Technology KOCHI - 682 022Document75 pagesSafety Interlocks in Crude Heaters Using PLC: Cochin University of Science and Technology KOCHI - 682 022Niju ShamilNo ratings yet

- Case Study 1. Developing HYSYS Material Stream: 1.1. Component and Fluid List SelectionDocument7 pagesCase Study 1. Developing HYSYS Material Stream: 1.1. Component and Fluid List SelectionChakravarthy BharathNo ratings yet

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- Guidelines For The Safe and Optimum Design ofDocument9 pagesGuidelines For The Safe and Optimum Design ofMoca PhoenixNo ratings yet

- PSV Load Calculation For Gas Expantion Fire CaseDocument2 pagesPSV Load Calculation For Gas Expantion Fire Caseeinsten777No ratings yet

- Relief Valve Sizing - FireDocument2 pagesRelief Valve Sizing - Firevlcmstne04No ratings yet

- Flare Radiation Modelling: Ask The Experts Webinar SeriesDocument32 pagesFlare Radiation Modelling: Ask The Experts Webinar SeriesAiman LatifNo ratings yet

- Fire Tube ReboilerDocument2 pagesFire Tube ReboilerAnonymous 7vljJzHNo ratings yet

- 1007 DISQ 0 P PH 48071 Shutdown PhilosophyDocument12 pages1007 DISQ 0 P PH 48071 Shutdown PhilosophyAnonymous XbmoAFtINo ratings yet

- Pipenet Vision Spray/Sprinkler Module User and Reference ManualDocument280 pagesPipenet Vision Spray/Sprinkler Module User and Reference ManualabsahkahNo ratings yet

- Tank Venting Requirements (API 2000) 2Document3 pagesTank Venting Requirements (API 2000) 2RubensBoerngenNo ratings yet

- IVPL Control Valve Sizing ManualDocument20 pagesIVPL Control Valve Sizing ManualGanesh YadavNo ratings yet

- Nioec SP 47 27Document29 pagesNioec SP 47 27sgh1355No ratings yet

- Kg-Tower ManualDocument5 pagesKg-Tower ManualJohnny50% (2)

- HP Fuel Gas SystemDocument8 pagesHP Fuel Gas SystemAnonymous QSfDsVxjZNo ratings yet

- PSV D-103Document24 pagesPSV D-103DIANTORONo ratings yet

- Emergency Shutdown (ESD) System PhilosophyDocument1 pageEmergency Shutdown (ESD) System PhilosophyTimothy Leonard100% (1)

- Calculation of maximum inbreathing and outbreathing flow ratesDocument2 pagesCalculation of maximum inbreathing and outbreathing flow ratesFendy ShirahNo ratings yet

- Flare SystemDocument68 pagesFlare SystemDjayustinus Heri HermawanNo ratings yet

- Safeguarding Memorandum ExplainedDocument2 pagesSafeguarding Memorandum ExplainedSarfraz AliNo ratings yet

- Chapter 3 - Compressed Air Treatment (Dryers and Filters)Document34 pagesChapter 3 - Compressed Air Treatment (Dryers and Filters)ppluis90No ratings yet

- Hydrocarbon RecoveryDocument29 pagesHydrocarbon RecoveryAlekhya BandaruNo ratings yet

- Fire Relief Rate Calculation-Part 2Document4 pagesFire Relief Rate Calculation-Part 2zubair195No ratings yet

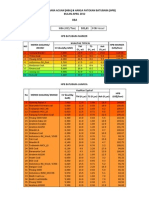

- PSV Sizing Report (Fire Case)Document7 pagesPSV Sizing Report (Fire Case)Elias EliasNo ratings yet

- PSV Sizing - Blocked Outlet GasDocument1 pagePSV Sizing - Blocked Outlet GasSilas Onyekwe100% (1)

- Comments Response SheetDocument8 pagesComments Response Sheetcherif yahyaoui67% (3)

- Spreadsheet - Gas Blanketed Tanks - Inbreathing Process Calculations & Control Valve Sizing - Rev2Document26 pagesSpreadsheet - Gas Blanketed Tanks - Inbreathing Process Calculations & Control Valve Sizing - Rev2venkatesh801No ratings yet

- Depressuirng Calculation ResultsDocument6 pagesDepressuirng Calculation ResultsIoana PopescuNo ratings yet

- Basic Temperature Control SystemDocument26 pagesBasic Temperature Control SystemRajeev ValunjkarNo ratings yet

- JERES-J-901 Instrument Air Supply SystemsDocument13 pagesJERES-J-901 Instrument Air Supply SystemsMahi IndraNo ratings yet

- E-I-04-Instrument List PDFDocument4 pagesE-I-04-Instrument List PDFManu BadilloNo ratings yet

- Hazardous Area ClassificationDocument2 pagesHazardous Area ClassificationMahdiNo ratings yet

- PSV Sizing Psv-402 Update PsetDocument7 pagesPSV Sizing Psv-402 Update PsetBui Khoi NguyenNo ratings yet

- Dec 07Document44 pagesDec 07c_nghiaNo ratings yet

- 2016-S-RPT-000-0001 Rev 1 Fire and Explosion Report 06-12-2012Document21 pages2016-S-RPT-000-0001 Rev 1 Fire and Explosion Report 06-12-2012Basil OguakaNo ratings yet

- Calculating Average Gas Release RatesDocument5 pagesCalculating Average Gas Release RatesakashawalkerNo ratings yet

- Simulation, System and Analytical: Lainnya Blog Berikut Buat Blog MasukDocument8 pagesSimulation, System and Analytical: Lainnya Blog Berikut Buat Blog MasukIkhsanudin AbdullahNo ratings yet

- Instrument Air Consumption CalculationDocument3 pagesInstrument Air Consumption CalculationVenkatesan N0% (1)

- Aspen Fired Heater Models Embedded in HYSYSDocument11 pagesAspen Fired Heater Models Embedded in HYSYSВалентин СелищевNo ratings yet

- Controlled and Non-Controlled Type DepressuringDocument12 pagesControlled and Non-Controlled Type Depressuringgrimdorlf100% (1)

- Emergency Shutdown System or ESD SystemDocument3 pagesEmergency Shutdown System or ESD Systemkamala 123No ratings yet

- Distributed Process Control ReportFrom EverandDistributed Process Control ReportNo ratings yet

- Aspen Flare System AnalyzerDocument10 pagesAspen Flare System Analyzerharyonodaniel50% (2)

- PSV Scenario and CalculationDocument35 pagesPSV Scenario and CalculationBaba Johneh0% (1)

- Guide For Vessel Sizing PDFDocument24 pagesGuide For Vessel Sizing PDFManish542No ratings yet

- Depressuring Flow - Quick Manual MethodDocument3 pagesDepressuring Flow - Quick Manual MethodElton Situmeang100% (1)

- FlareTot - Total Flare AnalysisDocument8 pagesFlareTot - Total Flare AnalysisArjun KapoorNo ratings yet

- On The Design of Thermal BreathingDocument6 pagesOn The Design of Thermal BreathingLizbeth Fiallos AvilaNo ratings yet

- IA Compressor & SystemDocument51 pagesIA Compressor & SystemKazi Irfan100% (1)

- PIPENET VISION User Interface ChapterDocument47 pagesPIPENET VISION User Interface Chapterelvithaf67% (3)

- Chemical Process Design and Simulation: Aspen Plus and Aspen Hysys ApplicationsFrom EverandChemical Process Design and Simulation: Aspen Plus and Aspen Hysys ApplicationsRating: 2 out of 5 stars2/5 (1)

- Guidelines for Determining the Probability of Ignition of a Released Flammable MassFrom EverandGuidelines for Determining the Probability of Ignition of a Released Flammable MassNo ratings yet

- Handbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4From EverandHandbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4Rating: 5 out of 5 stars5/5 (1)

- Protection Relay of Generator TestDocument6 pagesProtection Relay of Generator Testyogacruise100% (2)

- Tan Delta-FDocument1 pageTan Delta-FyogacruiseNo ratings yet

- Steam BlowingDocument6 pagesSteam BlowingS V NAGESHNo ratings yet

- Hipot Testing Dielectric Strength Test EepDocument14 pagesHipot Testing Dielectric Strength Test EepyogacruiseNo ratings yet

- Vibration Guidelines C132530Document1 pageVibration Guidelines C132530yogacruiseNo ratings yet

- Calculation Sheet of Bus Protection Unit 3 FinalDocument17 pagesCalculation Sheet of Bus Protection Unit 3 Finalyogacruise100% (1)

- EDG TestDocument6 pagesEDG Testyogacruise100% (1)

- Honeywell Chart Recorder QuestionDocument1 pageHoneywell Chart Recorder QuestionyogacruiseNo ratings yet

- Boiler Feed Pump KSBDocument9 pagesBoiler Feed Pump KSByogacruiseNo ratings yet

- Zirconium IdentificationDocument2 pagesZirconium IdentificationyogacruiseNo ratings yet

- XA Manual-V1.2Document72 pagesXA Manual-V1.2Mohamed Elsayed100% (1)

- Tan Delta-FDocument1 pageTan Delta-FyogacruiseNo ratings yet

- Harga Batubara Acuan April 2012Document6 pagesHarga Batubara Acuan April 2012satuiku100% (1)

- Ge DGCM Field Rtu CatalogDocument12 pagesGe DGCM Field Rtu CatalogyogacruiseNo ratings yet

- Stiffness Coefficients For Nozzles in API 650 Tanks - 2Document8 pagesStiffness Coefficients For Nozzles in API 650 Tanks - 2yogacruise100% (2)

- Magnetrol Level Flow Tech HandbookDocument44 pagesMagnetrol Level Flow Tech HandbookDelfinshNo ratings yet

- Budget For FEED of An Onshore Oil FieldDocument1 pageBudget For FEED of An Onshore Oil FieldyogacruiseNo ratings yet

- SS 310 Temperature Limit AlternativesDocument3 pagesSS 310 Temperature Limit AlternativesyogacruiseNo ratings yet

- Non Metallic Expansion JointDocument2 pagesNon Metallic Expansion JointyogacruiseNo ratings yet

- Manhole On Weld SeamDocument1 pageManhole On Weld SeamyogacruiseNo ratings yet

- Pure Argon For Non Carbon SteelDocument3 pagesPure Argon For Non Carbon SteelyogacruiseNo ratings yet

- Refractory Repair Procedure GuideDocument3 pagesRefractory Repair Procedure Guideyogacruise50% (2)

- What Code To Design Chlorine TankDocument3 pagesWhat Code To Design Chlorine TankyogacruiseNo ratings yet

- If The Misalignment Between The Head and Shell in A Pressure Vessel Exceeds The ASME Requirement1Document8 pagesIf The Misalignment Between The Head and Shell in A Pressure Vessel Exceeds The ASME Requirement1yogacruiseNo ratings yet

- WUXI HUAGUANG BOILER CO., LTD. (无锡华光锅炉股份有限公司) : Wang Fu Jun Zhao Xiao Li Zhang Wei Min Wang Fu Jun Tang Xing LiangDocument4 pagesWUXI HUAGUANG BOILER CO., LTD. (无锡华光锅炉股份有限公司) : Wang Fu Jun Zhao Xiao Li Zhang Wei Min Wang Fu Jun Tang Xing LiangyogacruiseNo ratings yet

- Instrument Cable LayoutDocument2 pagesInstrument Cable LayoutyogacruiseNo ratings yet

- Chimney RateDocument6 pagesChimney RateyogacruiseNo ratings yet

- 3 Heating Load Calculation: 3.1 Heat Transmission LossDocument14 pages3 Heating Load Calculation: 3.1 Heat Transmission LossyogacruiseNo ratings yet

- Surge Gas Pilene Cross CountryDocument2 pagesSurge Gas Pilene Cross CountryyogacruiseNo ratings yet

- Expansion Bellows Leak RepairDocument1 pageExpansion Bellows Leak RepairyogacruiseNo ratings yet

- E12817 GT AC5300 Manual EnglishDocument152 pagesE12817 GT AC5300 Manual Englishlegato1984No ratings yet

- Control and On-Off Valves GuideDocument87 pagesControl and On-Off Valves Guidebaishakhi_b90100% (3)

- Ite 001aDocument6 pagesIte 001ajoshuaNo ratings yet

- Saint Louis University Baguio City Principal'S Recommendation FormDocument1 pageSaint Louis University Baguio City Principal'S Recommendation FormnidzNo ratings yet

- 12 Fa02Document4 pages12 Fa02corsovaNo ratings yet

- Guide: Royal Lepage Estate Realty BrandDocument17 pagesGuide: Royal Lepage Estate Realty BrandNazek Al-SaighNo ratings yet

- 3095MV Calibration Procedure W QuickCal Merian 4010Document8 pages3095MV Calibration Procedure W QuickCal Merian 4010luisalbertopumaNo ratings yet

- Ranking 4Document34 pagesRanking 4Deepti BhatiaNo ratings yet

- Strength of A440 Steel Joints Connected With A325 Bolts PublicatDocument52 pagesStrength of A440 Steel Joints Connected With A325 Bolts Publicathal9000_mark1No ratings yet

- 6303A HP Flare Drain DrumDocument16 pages6303A HP Flare Drain DrumMohammad MohseniNo ratings yet

- Wa0001Document8 pagesWa0001varshasharma05No ratings yet

- Strategic Information Systems Planning: Course OverviewDocument18 pagesStrategic Information Systems Planning: Course OverviewEmmy W. RosyidiNo ratings yet

- Plumbing Practical Problems QuizDocument5 pagesPlumbing Practical Problems QuizLoren ViejayNo ratings yet

- Method of MomentsDocument114 pagesMethod of MomentsankladhaNo ratings yet

- System Engineering Management Plan (SEMPDocument2 pagesSystem Engineering Management Plan (SEMPKatie WestNo ratings yet

- Excel Dashboard WidgetsDocument47 pagesExcel Dashboard WidgetskhincowNo ratings yet

- D72140GC10 46777 UsDocument3 pagesD72140GC10 46777 UsWilliam LeeNo ratings yet

- January 2021 price list for Petro motor oils and diesel engine oilsDocument2 pagesJanuary 2021 price list for Petro motor oils and diesel engine oilsSAFIR ULLAHNo ratings yet

- Jotafloor SL UniversalDocument6 pagesJotafloor SL UniversalrogandatambunanNo ratings yet

- CV Summary for IT Position Seeking Recent GraduateDocument5 pagesCV Summary for IT Position Seeking Recent Graduateeang barangNo ratings yet

- Letter To Local Residents From Sutton Council Re. Lidl Development To Replace Matalan Ref DM2019-02113 10 January 2020Document5 pagesLetter To Local Residents From Sutton Council Re. Lidl Development To Replace Matalan Ref DM2019-02113 10 January 2020etajohnNo ratings yet

- Android Car Navigation User ManualDocument74 pagesAndroid Car Navigation User ManualРисте ПановNo ratings yet

- Product Portfolio ManagementDocument10 pagesProduct Portfolio ManagementSandeep Singh RajawatNo ratings yet

- Cisco As5300 Voice GatewayDocument12 pagesCisco As5300 Voice GatewayAbderrahmane AbdmezianeNo ratings yet

- Sheet #6Document2 pagesSheet #6AHMED BAKRNo ratings yet

- Advanced Excel FormulasDocument25 pagesAdvanced Excel Formulasskmohit singhalNo ratings yet

- RCE Unpacking Ebook (Translated by LithiumLi) - UnprotectedDocument2,342 pagesRCE Unpacking Ebook (Translated by LithiumLi) - Unprotecteddryten7507No ratings yet

- Breaking Shackles of Time: Print vs Digital ReadingDocument2 pagesBreaking Shackles of Time: Print vs Digital ReadingMargarette RoseNo ratings yet

- Protection Systems TransformerDocument14 pagesProtection Systems Transformerrajabharath12No ratings yet

- Brake Pedals and ValveDocument4 pagesBrake Pedals and Valveala17No ratings yet