Professional Documents

Culture Documents

Chapter 3, CFD Theory

Uploaded by

Anil Frivolous AbstemiousCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 3, CFD Theory

Uploaded by

Anil Frivolous AbstemiousCopyright:

Available Formats

Chapter 3 INTRODUCTION TO CFD 3.

1 INTRODUCTION TO COMPUTATIONAL FLUID DYNAMICS

What is Computational Fluid Dynamics? Computational Fluid Dynamics (CFD) is a computer-based tool for simulating the behavior of systems involving fluid flow, heat transfer, and other related physical processes. It works by solving the equations of fluid flow (in a special form) over a region of interest, with specified (known) conditions on the boundary of that region. Essentially there are three methods for determine the solution to flow problems viz. Experimental, Analytical and Numerical. The Analytical methods aim at getting a closed form solution in the entire domain assuming the process to follow continuum hypothesis. These are generally restricted to simple geometry, simple physics and generally linear problems. Once the problem becomes complex, the various assumptions that are needed to be made to obtain a closed form solution, entails loss of accuracy of the critical parameter of interest. This leads them to be used as a check on the accuracy of a numerical procedure but makes them mainly unsuitable for the analysis of real engineering problems but makes them mainly unsuitable for engineering analysis. However, they give the direction and general nature of the solution. Hence over the years, scientists and engineers have resorted to experimental techniques concentrating in the regions of interest. These experimental techniques have their inherent problems viz. that they are equipment oriented, and they need large resources of hardware, time and operating costs. Their applications are also limited due to scaling considerations. Further theses involve certain measurement difficulties and handling of large quantity of data. Numerical methods have emerged as a third method and have overcome the restrictions in both experimental and analytical methods. They involve the discretization of the governing mathematical equations in a way such that the numerical solutions can be obtained. This approach forms the core of Computational Fluid Dynamics, commonly known as CFD. The

popularity of CFD has been possible due to great developments in computing algorithms that have enabled fast Graphic User Interface that makes the interpretation and Visualization of the results easier. CFD methods have their own disadvantage in terms of specifications of proper boundary conditions, truncation errors, convergence problems, right choice of turbulence models and parameters, right choice of discretization method etc. This applications of CFD to practice problems need understanding of basic theory to overcome the above mentioned problems.

3.2

COMPARISON OF APPROACHES

The below table 3.1 shows the advantages & disadvantages between different approaches Table 3.1 Comparison of Approaches Approach Advantages 1. Capable of being most Experimental Realistic Disadvantages 1.Equipment required 2. Scaling problems 3.Tunnel corrections 4.Measurement difficulties 5. Operating costs 1. Restricted to simple geometry and physics. 2. Restricted to linear Problems 1. No restriction to linearity 2. Complicated physics can Computational be treated 3. Time evolution of flow can be obtained 1. Truncation errors. 2. Boundary condition problems 3. Computer costs

1.Clean, general information, which is Theoretical usually in formula form.

3.3 COMPARISION OF COMPUTATIONAL AND EXPERIMENTAL METHODS Comparison between computational and experimental methods is shown in Table 3.2 Table 3.2 Comparison between Computational & Experimental Methods Area Computational methods 1. Software used for all flow types. 2. Turbulence rarely resolved except through use of simpler models. 3. Enable physical situations to be modeled where experiments would be unsafe. 4. Allows geometry variation to be achieved quickly. Experimental methods

Capability

1. Exact simulation if fullscale situation can be used. 2. Experimental situation also being a model of desired flow situation.

Accuracy

1. Depends on algorithms used. 2. Depends on mesh density.

Detail

1. All variables are calculated at every mesh point or cell. 2. Variables can be integrated to find overall properties. 1. Solutions can take long time to iterate. This depends on the problems being solved and the speed of computer being used. 1. Requires relatively cheap hardware but expensive software. 2. Time and care is needed to get good results. 3. Specialists are required to achieve good results.

1. Should be correct within the limits of experimental errors, if geometry and scale effects are realistic and equipment is appropriately designed and calibrated. 1. Easy to find overall properties such as pressure drop, forces and moments 2. Difficulty and expensive to instrument so that anything more than a crude sample of the data is produced. 1. Time needed for setup and calibration. Results are usually quick to gather once this is done. 1. Instrumentation is expensive in many cases. 2. Raw experiment is cheap to carry out but data achieved is limited.

Time

Cost

3.4

THE HISTORY OF CFD

Computers have been used to solve fluid flow problems for many years. Numerous programs have been written to solve either specific problems, or specific classes of problem. From the mid-1970s the complex mathematics required to generalize the algorithms began to be understood, and general-purpose CFD solvers were developed. These began to appear in the early 1980s and required what were then very powerful computers, as well as an in-depth knowledge of fluid dynamics, and large amounts of time to set up simulations. Consequently CFD was a tool used almost exclusively in research. Recent advances in computing power, together with powerful graphics and interactive 3-D manipulation of models mean that the process of creating a CFD model and analyzing the results is much less labour-intensive, reducing the time and therefore the cost. Advanced solvers contain algorithms, which enable robust solution of the flow field in a reasonable time. As a result of these factors, Computational Fluid Dynamics is now an established industrial design tool, helping to reduce design timescales and improve processes throughout the engineering world. CFD provides a cost-effective and accurate alternative to scale model testing, with variations on the simulation being performed quickly, offering obvious advantages.

3.5

THE MATHEMATICS OF CFD

The set of equations which describe the processes of momentum, heat and mass transfer are known as the Navier-Stokes equations. These are partial differential equations which were derived in the early nineteenth century. They have no known general analytical solution but can be discretised and solved numerically. Equations describing other processes, such as combustion, can also be solved in conjunction with the Navier-Stokes equations. Often, an approximating model is used to derive these additional equations, turbulence models being a particularly important example. There are a number of different solution methods which are used in CFD codes. The most common, and the one on which CFX is based, is known as the finite volume technique. In this technique, the region of interest is divided into small sub-regions, called control volumes. The

equations are discretised and solved iteratively for each control volume. As a result, an approximation of the value of each variable at specific points throughout the domain can be obtained. In this way, one derives a full picture of the behavior of the flow

3.6

CFD METHODOLOGY

CFD may be used to determine the performance of a component at the design stage or it can be used to analyse difficulties with an existing component and lead to its improved design. For example, the pressure drop through a component may be considered excessive.

3.7

THE DESIGN OPTIMIZATION PROBLEM

Objective

Design CFD Solver Parameter s Constraint s

Response Parameter s Constraint s

Figure 3.1. The design optimization flowchart. At present, in order to shorten product development time, there is a strong tendency to perform design using computational fluid dynamics (CFD) tools instead of experiments. CFD is a method that is becoming more and more popular in the modeling of flow systems in many fields, including reaction Engineering. The block diagram in Fig no: 3.1 explains the optimization problemit is recognized that experiments remain essential during the final design stages. CFD based modeling however has many advantages during preliminary design, because it is less timeconsuming than experiments and because it allows greater flexibility. Early experience with CFD based modeling has shown that these computational tools should be used carefully. Any kind of CFD computation requires the specification of inlet and boundary

conditions. Obviously these conditions determine the flow and temperature field resulting from the CFD computation. The specification of inlet and boundary conditions requires appropriate measurements or available data onsite.

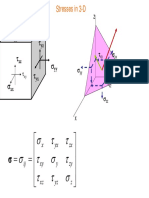

3.8 GOVERNING EQUATIONS OF CFD

CFD is playing a strong role as a design tool as well as a research tool. In CFD the physical aspects of any fluid flow is governed by three principles. The fundamental equations of fluid mechanics are based on the following Universal laws of conservation: 1. Conservation of mass 2. Conservation of momentum 3. Conservation of energy These fundamental physical principles can be expressed in terms of basic mathematical equations. These equations are generally in integral or partial differential form. These equations and their derivatives are replaced in CFD by discretised algebraic forms, which are in turn solved to get flow field values at discrete points in space and/or time. The end product is a collection of numbers, in contrast to closed-form analytical solution. In CFD approach, the equations that govern a process of interest are solved numerically. Numerical methods have evolved especially FDM, FVM algorithms for solving ordinary and partial differential equations. The equation that results from applying the conservation of mass to a fluid is called the continuity equation. Conservation of momentum is based on application of Newton's Second Law to a fluid element, which yields a vector equation, which is also called Navier-Stokes Equation. The conservation of Energy is based on the application of First Law of Thermodynamics to a fluid element. In addition to the equations developed from these universal laws, it is necessary to establish relationships between fluid properties in order to close the system of equations. An example of

such a relationship is the equation of state, which relates the thermodynamic variables pressure p, density , and Temperature T. Historically there have been two different approaches taken to derive the equations of fluid mechanics viz., phenomenological approach and kinetic theory approach. In the phenomenological approach certain relationship between stress and rate of strain, heat flux and temperature gradient are postulated, and the fluid dynamic equations are then developed from the conservation laws. The required constants of proportionality between stress and rate of strain and heat flux and Temperature gradient (which are called Transport Coefficients) must be determined experimentally. In the kinetic theory approach also known as the mathematical theory of non-uniform gases, the fluid dynamic equations are obtained with the transport coefficients defined in terms of certain integral relations, which involves dynamics of colliding particles. A viscous flow is one where transport phenomenon of friction, thermal conduction and/ or mass diffusion is included. These transport phenomena are dissipative. So they always increase the entropy of the flow. For this type of viscous flow modeling the Navier-stokes equations are applied. If these phenomena are neglected, the flow is called inviscid flow and for this Euler equations are applied.

These are mathematical statements of three fundamental physical principles upon which fluid dynamics is based shown as flow chart in fig 3.2.

Fundamental physical principles Mass is conserved

Newtons second law Energy is conserved

Models of flow

Fixed finite control

Moving finite Fixed infinitesimall y small volume Moving infinitesimally

Governing equations of fluid flow Continuit y equation Moment um equation Energy equation

Forms of these equations particularly suited forCFD Figure 3.2 Block diagram of physical and mathematical basis

3.9

CONTINUITY EQUATION

The basic continuity equation of fluid flow is as follows:

Net flow out of control volume = time rate of decrease of mass inside control volume The continuity equation in partial differential equation form is given by, /t +. (V)=0 .3.1

= Fluid density

/t = the rate of increase of density in the control volume. . (V)=the rate of mass flux passing out of control volume. The first term in this equation represents the rate of increase of density in the control volume and the second term represents the rate of mass flux passing out of the control surface, which surrounds the control volume. This equation is based on Eulerian approach. In this approach, a fixed control volume is defined and the changes in the fluid are recorded as the fluid passes through the control volume. In the alternative Lagrangian approach, an observer moving with the fluid element records the changes in the properties of the fluid element. Eulerian approach is more commonly used in fluid mechanics. For a Cartesian coordinate system, where u, v, w represent the x, y, z components of the velocity vector, the continuity equation becomes

( u ) + ( v ) + ( w) = 0 + t x y z

.3.2

A flow in which the density of fluid assumed to remain constant is called Incompressible flow. For Incompressible flow, =Constant. The continuity equation reduces to

u v w + + =0 x y z

.3.3

3. 10 MOMENTUM EQUATION Newton's Second Law applied to a fluid passing through an infinitesimal, fixed control volume yields the following momentum equation:

( v ) + . VV = f + . ij t

.3.4 Where,

/t() V

represents rate of increase of momentum per unit volume. represents the rate of momentum lost by convection through the control volume surface.

f

. ij

ij

represents the body force per unit volume.

represents the surface force per unit volume and

stress tensor.

While solving the equation, the fluid is considered as Newtonian fluid, i.e., stress is directly proportional to the rate of strain. If the flow is considered as incompressible and the coefficient of viscosity is assumed constant the equation becomes,

DV = f p + 2V Dt

.3.5

This equation is good approximation for incompressible flow of a gas.

3.11

ENERGY EQUATION

The first law of Thermodynamics applied to a fluid passing through an infinitesimal fixed control volume yields the energy equation i.e. increase in energy in the system is equal to the heat added to the system plus the work done on the system. Rate of change of energy inside the fluid element = Rate of work done on element due to body and surface forces

Net flux of heat in to element +

Et Q = .EtV = .q + f .V + .(ij .V ) t t Where,

.3.6

Represents the rate of increase of Et in the control volume Represents the rate of the total energy lost by convection (per unit volume) through the control surface

Represents the rate of heat produced by external agencies Represents the rate of heat lost by conduction per unit volume through the control surface.

Represents the work done on the control volume by the body forces

Represents the work done on the control volume by the surface forces. In terms of enthalpy, the final form of Energy equation is

Dh DP Q = + .q + Dt Dt t

.3.7

Where,

is known as dissipation function and represents the rate at which mechanical energy is

expended in the process of deformation of the fluid due to viscosity.

3.12THEORY Solutions in CFD are obtained by numerically solving a number of balances over a large number of control volumes or elements. The numerical solution is obtained by supplying boundary conditions to the model boundaries and iteration of an initially guessed solution. The balances, dealing with fluid flow, are based on the Navier Stokes Equations for conservation of mass (continuity) and momentum. These equations are modified per case to solve a specific problem. The control volumes (or) elements, the mesh are designed to fill a large scale geometry, described in a CAD file. The density of these elements in the overall geometry is determined by the user and affects the final solution. Too coarse a mesh will result in an over simplified flow profile, possibly obscuring essential flow characteristics. Too fine meshes will unnecessarily increasing iteration time. After boundary conditions are set on the large scale geometry the CFD code will iterate the entire mesh using the balances and the boundary conditions to find a converging numerical solution for the specific case. 3.12.1 FLUID FLOW FUNDAMENTALS The Physical aspects of any fluid flow are governed by three fundamental principles: Mass is conserved; momentum and Energy is conserved. These fundamental principles can be expressed in terms of mathematical equations, which in their most general form are usually non-linear partial differential equations. Computational Fluid Dynamics (CFD) is the science of determining a numerical solution to the governing equations of fluid flow whilst advancing the solution through space or time to obtain a numerical description of the complete flow field of interest.

The governing equations for Newtonian fluid dynamics, the unsteady Navier-Stokes equations, have been known for over a century. However, the analytical investigation of reduced forms of these equations is still an active area of research as is the problem of turbulent closure for the

Reynolds averaged form of the equations. For non-Newtonian fluid dynamics, chemically reacting flows and multiphase flows theoretical developments are at a less advanced stage. Experimental fluid dynamics has played an important role in validating and delineating the limits of the various approximations to the governing equations. The wind tunnel, for example, as a piece of experimental equipment, provides an effective means of simulating real flows. Traditionally this has provided a cost effective alternative to full scale measurement. However, in the design of equipment that depends critically on the flow behavior, for example the aerodynamic design of an aircraft, full scale measurement as part of the design process is economically impractical. This situation has led to an increasing interest in the development of a numerical wind tunnel. 3.13 THE STRATEGY OF CFD

The strategy of CFD is to replace the continuous domain with a discrete domain using a grid. In the continuous domain, each flow variable is defined at every point in the domain. In the discrete domain, each flow variable is defined only at grid points. So in the discrete domain, the variable would be defined only at N grid points. Continuous Domain 0x1 Discrete Domain x = x1, x2Xn

x=0

x=1

x1

xi

xN Grid point

Coupled PDEs + boundary Conditions in continuous variables.

Coupled algebraic equations in Discrete variables

In a CFD solution, one would directly solve for the relevant flow variables only at grid points. The values at other locations are determined by interpolating the values at the grid points. In the governing equations define the variables in the discrete form. The discrete system is a large set

of coupling algebraic equations in the discrete variables. Setting up the discrete system and solving it involves a very large number of repetitive calculations. This idea can be applied to any general problem. 3.14 TURBULENT FLOW Turbulent fluid motion is an irregular condition of flow in which the various quantities show a random variation with time and space coordinates so statistically distinct average values can be discerned. The differences between laminar and turbulence flow: higher values of friction drag and pressure drop are associated with turbulent flow. The diffusion rate of a scalar quantity is usually greater in a turbulent flow rather than laminar flow, and turbulent flows are usually noiser. A turbulent boundary layer can normally negotiate a more extensive region of unfavourable pressure gradient prior to separation than can a boundary layer. The unsteady Navier-Stokes equations are generally considered to govern turbulent flows in the continuum regime. 3.15 MODELLING TURBULENT FLOWS The method to solve turbulent flows by direct numerical simulation (DNS) requires that all relevant length scales be resolved from the smallest eddies to scales on the order of the physical domain of the problem domain. The computation needs to be 3-D even if the time-mean aspects of the flow are 2-D, and the time steps must be small enough that the small-scale motion can be resolved in a time accurate manner even if the flow is steady in a time-mean sense. Another approach is large-eddy simulation (LES), in which large-scale structure of the turbulent flow is computed directly and only the effects of smallest and more nearly isotropic eddies are modeled. The grid models required for LES is an order of magnitude less than DNS and for practical engineering problems, even LES is beyond present day computing power. The computational effort required for LES is less than DNS. Now these are replaced by approximated modeling methods used as the primary design procedure for engineering applications.

The main thrust of present day CFD for turbulent flow is through the Time/mass (Favre) averaged Navier-Stokes equations In computational fluid mechanics and heat transfer in turbulent flow is through the time averaged Navier-stokes equations. These equations are also referred as Reynolds-averaged Navier-Stokes equations (RANS). The Reynolds equations are derived by decomposing the dependent variables in the conservation equations into time-mean and fluctuating components and then time averaging the entire equation. Two types of averaging is presently used, the classical Reynolds averaging and the mass-weighted averaging suggested by Favre. Time averaging the equations of motion gives rise to new terms, which can be interpreted as "apparent" stress gradients and heat flux quantities associated with the turbulent motion. These new quantities must be related to the mean flow variables through turbulence models. This process introduces further assumptions and approximations. Thus this method on the turbulent flow problem through solving the Reynolds equations of motion does not follow entirely from first principles, since additional assumptions must be made to close the system of equations. For flows in which density fluctuations can be neglected, the two formulations become identical.

3.16

THE GENERAL DIFFERENTIAL EQUATION

A generalized conservation principle is obeyed by all the independent variables of interest, so the basic balance or conservation equation is (Outflow from cell) (inflow into the cell) = (net source within the cell.) The quantities being balanced are the dependent variables like mass of a phase, mass of a chemical species, energy, momentum, turbulence quantities, electric charge etc.

The terms appearing in the balance equation are convection, diffusion, time variation and source terms. If the dependent variable is denoted by , the general differential equation or the general purpose CFD equation is given as

.3.8 Where, p, u, v, w, h, k, =Dependent variable, () t, x, y, z =independent variable =Exchange coefficient =Scalars S =source terms = Boundary conditions sources Div =divergence (V. J) Grad =gradient (V) 3.17 REYNOLDS AVERAGED NAVIER-STOKES EOUATION

In the conventional averaging procedure, following Reynolds, we define a time averaged quantity f as

.3.9 We require that t be large compared to the period of the random fluctuations associated with the turbulence, but small with respect to the time constant for any slow variations in the flow field associated ordinary unsteady flows.

In the conventional Reynolds decomposition, the randomly changing flow variables are replaced by time averages plus fluctuations about the average. For Cartesian coordinate system, we may write

Fluctuations in other fluid properties such as viscosity, thermal conductivity, and specific heat are usually small and will be neglected here. By definition, the average of a fluctuating quantity is zero

.3.10 It should be clear from these definitions that for symbolic flow variable f and g, the following relations hold:

.3.11 It should also be clear that, where f' = 0, the time average of the product of two fluctuating quantities is, in general, not equal to zero, i.e., f, f' 0 .In fact, the root mean square of the

velocity fluctuations is known as the turbulence intensity.

For treatment of compressible flows and mixtures of gases in particular, mass-weighed averaging is convenient. In this approach we define mass-averaged variables according to f.

.3.12 We note that only the velocity components and thermal variables are mass averaged. Fluid properties such as density and pressure are treated as before. To substitute into conservation equations, we define new fluctuating quantities by

.3.13 It is very important to note that the time averages of the doubly primed fluctuating quantities (u, v, etc.) are not equal to zero, in general, unless p'=0. In fact, it can be shown that,

.3.14 Instead, the time average of the doubly primed fluctuation multiplied by the density is equal to zero.

3.18

REYNOLDS FORM OF CONTINUITY EQUATION

Reynolds form of the average equations of continuity for incompressible flow is as follows.

.3.15 For compressible flow the continuity equation becomes

.3.16 Reynolds form of the momentum equation for incompressible flow is

.3.17 For compressible flows the momentum equation becomes

.3.18 If we compare the original N-S equations with dependent variables based on instantaneous velocities with Reynolds average N-S (RANS) equations with dependent variable based on time averaged/mass averaged velocities we find an additional term namely,

These apparent stress gradients due to transport of momentum by turbulent fluctuations are called Reynolds stresses. Similar correlation functions for turbulent heat flux will correspond to the averaged energy equation. These Reynolds stresses and other correlation functions need to be modeled for closure of the RANS. Modeling these is the subject of turbulence.

3.19

K-EPSILON MODEL

Boussinesq suggested that the apparent turbulent shearing stresses might be related to the rate of mean strain through an apparent scalar turbulent or "eddy" viscosity. For the general Reynolds stress tensor the Boussinesq assumption gives

.3.19 Where the turbulent viscosity, k is is the kinetic energy of turbulence given by,

.3.20 By analogy with kinetic theory, by which molecular (laminar) viscosity for gases be evaluated with reasonable accuracy, we might expect that the turbulent viscosity can be modeled as

.3.21 Where V and l are characteristic velocity and length scale of turbulence respectively. The problem is to find suitable means of evaluating them.

Algebraic turbulence models invariably utilize Boussinesq assumption. One of the most successful of this type of model was suggested by Prandtl and is known as "mixing length hypothesis".

.3.22 Where a mixing length can be thought of as a transverse distance over which particles maintain their original momentum, somewhat on the order of a mean free path for the collision or mixing

of globules of fluid. The product

can be interpreted as the characteristic

velocity of turbulence, V. In the above equation, u is the component of velocity in the primary flow direction, and y is the coordinate transverse to the primary flow direction. There are other models, which use one partial differential equation for the transport of turbulent kinetic energy (TKE) from which velocity scales are obtained. The length scale is prescribed by an algebraic formulation. The most common turbulence model generally used is the two-equation turbulence model or k- model. There are so many variants of this model. In these models the length scale is also obtained from solving a partial differential equation. The most commonly used variable for obtaining the length scale is dissipation rate of turbulent kinetic energy denoted by E. Generally the turbulent kinetic energy is expressed as turbulent intensity as defined below.

3.23 K= (Actual K.E in Flow) (mean K.E in Flow)

3.24, 3.25 The transport PDE used in standard k- model is as follows

.3.26 Thus for any turbulent flow problem, we have to solve in addition to continuity, momentum and energy equations, two equations for transport of TKE and its dissipation rate.

.3.27

3.20

TURBULENCE MODELING

Special attention needs to be paid to accurate modeling of turbulence. The presence of turbulent fluctuations, which are functions of time and position, contribute a mean momentum flux or Reynolds stress for which analytical solutions are nonexistent. These Reynolds stresses govern the transport of momentum due to turbulence and are described by additional terms in the Reynolds-averaged Navier-Stokes equations. The purpose of a turbulence model is to provide numerical values for the Reynolds stresses at each point in the flow. The objective is to represent the Reynolds stresses as realistically as possible, while maintaining a low level of complexity. The turbulence model chosen should be best suited to the particular flow problem. A wide range of models is available, and type of model that is chosen must be done so with care. It is understood that these models are not used when modeling laminar flows. The final result of the flow, turbulence, reaction, heat transfer, and multiphase calculations will be a detailed map of the local liquid velocities, temperatures, chemical reactant concentrations, reaction rates, and volume fractions of the various phases. These outcomes can be analyzed in detail using graphical visualization, calculation of overall parameters and integral volume or surface averages, and comparison with experimental or plant data. This analysis phase is referred

to as post processing. Because of improvements in computer power and enhanced graphics software, it is now much easier for CFD analysts to create animations of their data. These often help in understanding complex flow phenomena that are sometimes difficult to see from static plots. 3.21 DISCRETIZATION OF GOVERNING EOUATIONS

The above governing partial differential equations are continuous functions of x, y, z. In the finite difference approach, the continuous problem domain "discretised", so that the dependent variables are considered to exist only at discrete points. Derivatives are approximated by differences, resulting in algebraic representation of the PDE. Thus a problem involving differential calculus has been transformed into algebraic problem. The nature of the resulting algebraic system depends upon the character of the problem posed the original PDE. Equilibrium problems usually result in a system of algebraic equations that must be solved simultaneously throughout the domain in conjunction with specified boundary values. These are mathematically known as elliptic problems. Marchingproblems result in algebraic equations that usually solved one at a time. These are known as parabolic or hyperbolic problems. Three methods are generally used for discretization, 1. Finite difference method. 2. Finite control volume method. 3. Finite element method. The discretization (numerical simulation) techniques used in CFD are shown in Fig 3.3

Discretization techniques

Finite differenc

Finite volume

Finite element

Basic derivations of finite differences:

Basic derivations of finite-volume equations

Finite-difference equations: truncation errors

Types of solutions: explicit and

Stability analysis Figure 3.3. Block Diagram of Numerical Solution Techniques in CFD

3.21.1DISCRETIZATION To solve the non-linear partial differential equations from the previous section, it is necessary to impose a grid on the flow domain of interest, see Fig. 3.4. Discrete values of fluid velocities, properties, pressure and temperature, are stored at each grid point (the intersection of two grid lines). To obtain a matrix of algebraic equations, a control volume is constructed (shaded area in the figure) whose boundaries (shown by dashed lines) lie midway between grid points P and its neighbors N, S, E, W. A complex process of formal integration of the differential equations over the control volume, followed by interpolation schemes to determine flow quantities at the control volume boundaries (n, s, e, w) in Fig. 3.4, finally yield a set of algebraic equations for each grid point P: (AP B) p - AC c = C 3.28 where the subscript c on , A and refers to a summation over neighbor nodes N, S, E and W, is a general symbol for the quantity being solved for (u, v or t), AP, etc. are the combined convection-diffusion coefficients (obtained from integration and interpolation), and B and C are, respectively, the implicit and explicit source terms (and generally represent the force(s) which drive the flow, e.g. a pressure difference).

N

n

e P

S x y

Fig 3.4 Control Volume on Grid Point 3.21.2 DISCRETIZATION USING FINITE-VOLUME METHOD In the finite-volume method, quadrilateral/triangle is commonly referred to as a cell and a grid point as a node. In 2D, one could also have triangular cells. In 3D, cells are usually hexahedral, tetrahedral, or prisms. In the finite-volume approach, the integral form of the conservation equations are applied to the control volume defined by a cell to get the discrete equations for the cell. For example, the integral form of the continuity equation for steady, incompressible flow is

V . n

dS = 0

3.29

The integration is over the surface S of the control volume and n is the outward normal at the surface. Physically, this equation means that the net volume flow into the control volume is zero. Consider the rectangular cell shown below in fig 3.5

face 4 (u4,v4) face 1 y (u1, v1) face 3 (u3, v3)

Cell center

face 2 (u2,v2)

Y x X Fig 3.5 Rectangular Cell

The velocity at face i is taken to be V i = ui i + vi

. Applying the mass conservation equation

(3.29) to the control volume defined by the cell gives

y - v2 y +v4 x + u3 x =0 -u1

3.30

This is the discrete form of the continuity equation for the cell. It is equivalent to summing up the net mass flow into the control volume and setting it to zero. So it ensures that the net mass flow into the cell is zero i.e. that mass is conserved for the cell. Usually the values at the cell centers are stored. The face values u1, v2, etc. are obtained by suitably interpolating the cellcenter values for adjacent cells. Similarly, one can obtain discrete equations for the conservation of momentum and energy for the cell. One can readily extend these ideas to any general cell shape in 2D or 3D and any conservation equation. 3.21.3 SALIENT FEATURES OF FINITE VOLUME METHOD

1. 2. 3. 4. 5. 6.

Integral forms of governing equations are discretised in space. Can be used on arbitrary mesh. Definition of control volume arbitrary. Basic qualities such as mass, momentum etc. are conserved at discrete level. Flexible and fundamentally conservative for complicated geometry. Conservative discretization. 3.31

Ud + F .d S = Qd t S

- Control volume S- Surface enveloping U- Conserved scalar F- Diffusive and convective flux Q- Volumetric source of U

3.22

BENEFITS OF CARRYING OUT CFD ANALYSIS

Low cost: The most important advantage of computational prediction is its low cost. In most applications, the cost of a computer run is many orders of magnitude lower than the cost of a corresponding experimentation investigation. This can reduce or even eliminate the need for expensive or large-scale physical test facilities. This factor assumes increasing importance as the physical situation to be studied becomes larger and more complicated. Further whereas the prices of most items are increasing, computing cost is likely to be even lower in the future. 0 Speed: A computational investigation can be performed with remarkable speed. A

designer can study the implication of hundreds of different configurations in less than a day and choose the optimum design. With the ability to reuse information generated in other stages of the design, rapid evaluation of design alternatives can be made. On the other hand, a corresponding experimental investigation would take a long time. Complete information: A computer solution of problem gives detailed and complete information .It can provide the values of all relevant variables (such as velocity, pressure, temperature, concentration, turbulence intensity) throughout the domain of interest. This provides a better understanding of the flow phenomenon and the product performance because knowledge of such values is not restricted to those areas that can be instruments during testing. For this reason, even when an experiment is performed, there is great value in obtaining a companion computer solution to supplement the experimental information. Ability to simulate realistic conditions: In a theoretical calculation, realistic conditions can be easily simulated. There is no need to resort to small scale or cold models. Through a computer program, there is little difficulty in having very large or very small dimensions, in treating very low or very high temperature, in handling toxic or flammable substances, or in following very fast or very slow processes. Ability to simulate ideal conditions: A prediction method is sometimes used to study a basic phenomenon, rather than a complex engineering application. In the study of phenomenon, one wants to focus attention on a few essential parameters and eliminates all irrelevant features. Thus

many idealizations are desirable for example, two dimensionality, constant density, an adiabatic surface, or infinite reaction rate. In a computation, such conditions can be easily and exactly setup, whereas even careful experimental can barely approximate the idealization. Reduction of failure risks: CFD can also be used to investigate configurations that may be too large to test or which pose a significant safety risk, including pollutant spread nuclear accident scenarios. This can often provide confidence in operation, reduce or eliminate the cost of problem solving during installations, reduce product liability risks. 3.23 APPLICATIONS OF CFD The major applications of CFD are in the following fields of engineering to simulate Various parameters. CFD has become a powerful influence on the way fluid dynamicists and aero dynamicists. Fluid flow pattern and conditions in common engineering equipment like, Heat

Aerodynamic design of transportation vehicles likes cars, aircraft, etc. Exchangers, Stirred reactors, Ducts, Pulverizes, Boilers, Turbo machinery viz. Steam, Gas and Hydro turbines. Fluid flow in electric equipment like computers, control panels etc. Heat transfer equipment including reactions and radiative modeling like burners, NOx Metropolitan authorities can determine where pollutant-emitting industrial plant may be

estimation. Cooling of Generators, motors, Transformers etc. safely located, and under what conditions motor vehicle access must be restricted so as to preserve air quality. Meteorologists and oceanographers to foretell wind and water currents. Hydrologists and others concerned with ground water to forecast the effects of changes to ground-surface cover, of the creation of dams and aqueducts on the quantity and quality of water supplies. Petroleum engineers to design optimum oil-recovery strategies and the equipment for Automobile and engine applications: To improve performance means environmental putting them into practice. quality, fuel economy of modern trucks and cars. It is study of the external flow over the body of a vehicle, or the internal flow through the internal combustion engines.

Industrial manufacturing applications: A mold being filled with liquid modular cast iron.

The liquid flow field is calculated as a function of time. Another example is the manufacture of ceramic materials. Civil engineering applications: Problems involving the theology of rivers, lakes etc are also subject of investigations using CFD. Example is filling of mud from an underwater mud capture reservoir. Environmental engineering applications: The discipline of heating, air conditioning and general air circulation through buildings. Another example is fluid burning in furnaces. Bio-medical Engineering applications: Used to analyze the blood flow through grafted blood vessels

3.24 OVERVIEW

OF

FLUENT

There are many CFD packages in the market now, FLUENT is most widely used and this package has been used in this project for the simulation. FLUENT, Inc. is the world's largest computational fluid dynamics (CFD) software provider, enabling solutions for a broad array of fluid flow and heat transfer phenomenon. It uses the finite-volume method to solve the governing equations for a fluid. It provides the capability to use different physical models such as incompressible or compressible, inviscid or viscous, laminar or turbulent, etc. Geometry and grid generation is done using GAMBIT which is the preprocessor bundled with FLUENT. GAMBIT is a software package designed to help analysts and designers build and mesh models for computational fluid dynamics (CFD) and other scientific applications. GAMBIT receives user input by means of its graphical user interface (GUI). The GAMBIT GUI makes the basic steps of building, meshing, and assigning zone types to a model simple and intuitive, yet it is versatile enough to accommodate a wide range of modeling applications. It also provides tools for checking the quality of the mesh.

FLUENT is written in the C language and makes full use of the flexibility and power offered by the language. Consequently, true dynamics memory allocation, efficient data structures and flexible solver control are all made possible in addition, FLUENT uses client/server architecture. FLUENTs CFD solvers provide a wide range of physical models and numerical techniques. From combustion to plastic extrusion, from supersonic airfoils to fluidized beds, FLUENT provides the physics and numeric needed to get accurate answers and stable calculations. The benefits of using FLUENT and CFD are better designs, lower risk and faster time to the market place for your product or process. Each simulation using CFD, including FLUENT, consists of five basic, but important steps. These steps are described below. In each of the following steps, the user has to specify the input parameters, which control the execution of the code and post processing of the results. Step 1 Preliminary Inputs During this step the user allocates memory for the CFD simulation and prepare them to be entered into the CFD software. Step 2 Grid Generation: This step is used to specify the geometry of the system, such as radius of a pipe that is to be modeled. It is also during this step that the user sets the boundary conditions. Step 3 Flow Parameters The fluid characteristics, such as density and viscosity are very important to the CFD simulation. It is during this step that these two parameters, as well at the mass flow rate, will be set. Step 4 Solve This step many times proves to be the easiest for the user. The user simply tells the program how many calculations to perform and activates the solver. Step 5 Post Processing The final step consists of the analysis of the results as well as interpretation. FLUENT provides output in both visual and numerical form. Both are key in understanding the flow results. In that is going to be

performed. At this point it is also helpful to gather the inputs needed for the rest of the simulation

every CFD simulation whether simple or complex, these five basic steps are followed. It is of the utmost importance that care be taken while entering the input in each ofthese steps to ensure quality results. CFD, if used correctly, is as very useful and powerful tool.

You might also like

- Multiple Rotating Frame TutorialDocument20 pagesMultiple Rotating Frame TutorialBadhriNarayananNo ratings yet

- Adams View HelpDocument260 pagesAdams View HelpVolkan UzerNo ratings yet

- Formability Simulation DFE (Die Face Engineering) Process GuidanceDocument0 pagesFormability Simulation DFE (Die Face Engineering) Process Guidancejagas123455123No ratings yet

- Using Adams/View - MD Adams 2010Document1,556 pagesUsing Adams/View - MD Adams 2010pkokatam100% (1)

- Section 18 Design of Plastic Gears PDFDocument15 pagesSection 18 Design of Plastic Gears PDFSergio CandiottiNo ratings yet

- AdamsCar PoliMilanoDocument140 pagesAdamsCar PoliMilanoAnonymous WDTFw8EK100% (2)

- CNC and MastercamDocument18 pagesCNC and MastercambellaNo ratings yet

- Designing the Stapler ComponentsDocument41 pagesDesigning the Stapler ComponentsEmmanuel Morales ChilacaNo ratings yet

- 10 - Plasticadvisor PDFDocument5 pages10 - Plasticadvisor PDFDaniel SayaoNo ratings yet

- DF5.8.1 Formability Training ManualDocument107 pagesDF5.8.1 Formability Training ManualkillimakilliNo ratings yet

- Simulation and Control of Fluid Flows Around Objects Using Computational Fluid DynamicsDocument54 pagesSimulation and Control of Fluid Flows Around Objects Using Computational Fluid DynamicsSagar KamatNo ratings yet

- Instruction Design With Studio ShapeDocument124 pagesInstruction Design With Studio ShapenghiaNo ratings yet

- Rack and Pinion Steering DesigningDocument19 pagesRack and Pinion Steering DesigningAudrian Louven Realubit Sabado0% (2)

- Mat mt11050 GDocument362 pagesMat mt11050 Gandreeaoana45No ratings yet

- C16 NX11 PDFDocument82 pagesC16 NX11 PDFVignesh WaranNo ratings yet

- Static and Dynamic Analysis of HCR Spur Gear Drive UsingDocument54 pagesStatic and Dynamic Analysis of HCR Spur Gear Drive Usingjr-parshanthNo ratings yet

- Abstract-Design of Vertical Axis Wind TurbineDocument2 pagesAbstract-Design of Vertical Axis Wind TurbinePratik Sinha50% (2)

- Numerical Analysis and Optimal Design For New Automotive Door Sealing With Variable Cross-SectionDocument12 pagesNumerical Analysis and Optimal Design For New Automotive Door Sealing With Variable Cross-SectionkarolNo ratings yet

- Name Plate Directions Mastercam XDocument30 pagesName Plate Directions Mastercam Xchicho6404100% (2)

- An overview of gear manufacturing processes and materialsDocument89 pagesAn overview of gear manufacturing processes and materialsRamalingam AlagarajaNo ratings yet

- Fused Deposition Modeling (FDM)Document10 pagesFused Deposition Modeling (FDM)siddharthsainiNo ratings yet

- Auto Noise Vibration Harshness Analysis Full VehicleDocument5 pagesAuto Noise Vibration Harshness Analysis Full VehicleManeesh M KaimalNo ratings yet

- Hyper MeshDocument363 pagesHyper MeshsuhaschNo ratings yet

- Intro Cad Cam Cae ImpDocument64 pagesIntro Cad Cam Cae ImpManmit SalunkeNo ratings yet

- c01 nx8.5 EvalDocument20 pagesc01 nx8.5 EvalSeshi ReddyNo ratings yet

- MotionManager Animation SolidworksDocument38 pagesMotionManager Animation SolidworksSudeep Rkp0% (1)

- Getting Started Using ADAMS/VibrationDocument63 pagesGetting Started Using ADAMS/VibrationvibrosticsNo ratings yet

- CATIA V5 Tutorials: Mechanism Design & AnimationDocument36 pagesCATIA V5 Tutorials: Mechanism Design & AnimationValentinNo ratings yet

- PowerMill 2019 Feature Comparison MatrixDocument2 pagesPowerMill 2019 Feature Comparison MatrixBojan RadovanovicNo ratings yet

- Controlling The Geometry of SlotsDocument35 pagesControlling The Geometry of SlotsAnonymous 7ZTcBnNo ratings yet

- 3DQuickPress V5.2.1 Training ManualDocument247 pages3DQuickPress V5.2.1 Training Manualabas50% (2)

- One CAM System, No Limits: Standardizing On NX CAM Saves Time, Lowers Costs and Improves QualityDocument2 pagesOne CAM System, No Limits: Standardizing On NX CAM Saves Time, Lowers Costs and Improves QualityrasgeetsinghNo ratings yet

- DMU Fitting Simulation for CATIA AssemblyDocument9 pagesDMU Fitting Simulation for CATIA Assemblytest1No ratings yet

- Book - Adams Tutorial Ex17 W PDFDocument121 pagesBook - Adams Tutorial Ex17 W PDFKamran ShahidNo ratings yet

- DMU Fitting CatiaDocument439 pagesDMU Fitting Catiabui_trongNo ratings yet

- NX NF TipsUndTricksDocument12 pagesNX NF TipsUndTricksThilo Breitsprecher100% (1)

- NX CAD Design Engineer CourseDocument2 pagesNX CAD Design Engineer CourseSK ARIF MAHAMMADNo ratings yet

- Ravi Resume PDFDocument2 pagesRavi Resume PDFRavi Prakash M PNo ratings yet

- Economic Solution For Data Acquisition in A Formula SAE Race CarDocument6 pagesEconomic Solution For Data Acquisition in A Formula SAE Race CarmclarenrulzNo ratings yet

- Tebis 4.0 R3 A4 2016Document8 pagesTebis 4.0 R3 A4 2016Paul VeramendiNo ratings yet

- Experience Meets SimulationDocument8 pagesExperience Meets SimulationMrLanternNo ratings yet

- DESIGN - AND - FABRICATION - OF - AUTOMATIC - SPRAY - PAINTING - MACHINE - Ijariie7676 PDFDocument7 pagesDESIGN - AND - FABRICATION - OF - AUTOMATIC - SPRAY - PAINTING - MACHINE - Ijariie7676 PDFHussain MuslimNo ratings yet

- Guide to Load Analysis for Durability in Vehicle EngineeringFrom EverandGuide to Load Analysis for Durability in Vehicle EngineeringP. JohannessonRating: 4 out of 5 stars4/5 (1)

- Fluid AssignmentDocument23 pagesFluid AssignmentYush KumarNo ratings yet

- Computational Fluid Mechanics Simulation and Computation With Gambit and FluentDocument69 pagesComputational Fluid Mechanics Simulation and Computation With Gambit and FluentYush KumarNo ratings yet

- CFD Report (Introduction To CFD)Document10 pagesCFD Report (Introduction To CFD)Israel Torres100% (1)

- Experiment 3: Title: Introduction To CFDDocument2 pagesExperiment 3: Title: Introduction To CFDPurnank NagraleNo ratings yet

- Introduction to CFD simulationsDocument3 pagesIntroduction to CFD simulationsJonyzhitop TenorioNo ratings yet

- Chapter 5 CFDDocument12 pagesChapter 5 CFDvadiyalaNo ratings yet

- Fluent Workshop Lecture NotesDocument206 pagesFluent Workshop Lecture NoteszubbbuNo ratings yet

- Introduction To CFX-5Document8 pagesIntroduction To CFX-5sangsharmaNo ratings yet

- What Is CFDDocument2 pagesWhat Is CFDJerry MateoNo ratings yet

- Fluid CFD ReportDocument5 pagesFluid CFD Reportjawad khalidNo ratings yet

- Computational Fluid DynamicsDocument4 pagesComputational Fluid DynamicsAravind ManneNo ratings yet

- An Introduction To Computational Fluids Dynamics Professor AndersonDocument12 pagesAn Introduction To Computational Fluids Dynamics Professor AndersonAshik GRNo ratings yet

- Review Rehva Guidebook ColourDocument4 pagesReview Rehva Guidebook ColourigormininNo ratings yet

- CFD PDFDocument45 pagesCFD PDFKuba RaNo ratings yet

- What Is CFD 2Document16 pagesWhat Is CFD 2216 ShravaniDumbreNo ratings yet

- RR310803 HeattransferDocument8 pagesRR310803 HeattransferAnil Frivolous AbstemiousNo ratings yet

- HEAT TRANSFER 2011 JNTUH Question PaperDocument8 pagesHEAT TRANSFER 2011 JNTUH Question PaperAnil Frivolous AbstemiousNo ratings yet

- RR320306 HeattransferDocument8 pagesRR320306 HeattransferAnil Frivolous AbstemiousNo ratings yet

- 3185 Handout NusseltDocument2 pages3185 Handout NusseltRajatacharyaNo ratings yet

- Greetings - InformalDocument5 pagesGreetings - InformalWilson Barbosa GreenleaphNo ratings yet

- Heat Transfer KeysDocument1 pageHeat Transfer KeysAnil Frivolous AbstemiousNo ratings yet

- Heat Transfer ObjectivesDocument8 pagesHeat Transfer ObjectivesAnil Frivolous AbstemiousNo ratings yet

- Hypermesh Basics Tutorials-1Document40 pagesHypermesh Basics Tutorials-1api-3717939100% (8)

- Mind MappingDocument27 pagesMind Mappingsiva_mmNo ratings yet

- Making Green TeaDocument1 pageMaking Green TeaAnil Frivolous AbstemiousNo ratings yet

- Notes - Measurement of Air ConsumptionDocument7 pagesNotes - Measurement of Air ConsumptionAnil Frivolous Abstemious100% (2)

- PDF GATE 2010 ME SolutionsDocument11 pagesPDF GATE 2010 ME SolutionsAnil Frivolous AbstemiousNo ratings yet

- Types of Boilers PDFDocument5 pagesTypes of Boilers PDFJosé RubioNo ratings yet

- PDF GATE 2010 ME SolutionsDocument11 pagesPDF GATE 2010 ME SolutionsAnil Frivolous AbstemiousNo ratings yet

- Steam Generators 2Document33 pagesSteam Generators 2gbharathreddysNo ratings yet

- ANSYS FLUENT Conjugate Heat Transfer TutorialDocument30 pagesANSYS FLUENT Conjugate Heat Transfer Tutorialteguh hady aNo ratings yet

- STEAM BOILERS: FIRE TUBE AND WATER TUBE CLASSIFICATIONDocument19 pagesSTEAM BOILERS: FIRE TUBE AND WATER TUBE CLASSIFICATIONAnil Frivolous AbstemiousNo ratings yet

- # Compact & Stylish Category Cameras:: Sony Digital Still CamerasDocument2 pages# Compact & Stylish Category Cameras:: Sony Digital Still CamerasAnil Frivolous AbstemiousNo ratings yet

- Testing of I C EnginesDocument31 pagesTesting of I C EnginesAnil Frivolous AbstemiousNo ratings yet

- ANSYS 10.0 Workbench Tutorial - Exercise 1, Workbench BasicsDocument36 pagesANSYS 10.0 Workbench Tutorial - Exercise 1, Workbench BasicssangeethsreeniNo ratings yet

- Design Modeler BasicsDocument22 pagesDesign Modeler BasicsAnil Frivolous AbstemiousNo ratings yet

- Hints On Writing Technical PapersDocument4 pagesHints On Writing Technical PapersBoda KishanNo ratings yet

- Entropy and The UniverseDocument31 pagesEntropy and The UniverseAnil Frivolous AbstemiousNo ratings yet

- Psu Syllabus MechanicalDocument2 pagesPsu Syllabus Mechanicalammu0312No ratings yet

- Heat Exchanger 03Document14 pagesHeat Exchanger 03Sukumar SaxenaNo ratings yet

- HeadLamp Fluent DODocument27 pagesHeadLamp Fluent DOİsmet YazganNo ratings yet

- Principles of Ic EnginesDocument15 pagesPrinciples of Ic EnginesIvan KopićNo ratings yet

- Heat TransferDocument16 pagesHeat TransferAnil Frivolous AbstemiousNo ratings yet

- Solid Mechanics Topic 2: Superposition Method for Statically Indeterminate BeamsDocument50 pagesSolid Mechanics Topic 2: Superposition Method for Statically Indeterminate BeamsDiShanNo ratings yet

- STS3001 Slno 30 File 1Document4 pagesSTS3001 Slno 30 File 1shubhamNo ratings yet

- FsdfsDocument6 pagesFsdfsoafwfwurNo ratings yet

- The Chi-Squared Test With TI-Nspire IB10Document5 pagesThe Chi-Squared Test With TI-Nspire IB10p_gyftopoulosNo ratings yet

- UR Script ManualDocument102 pagesUR Script ManualAlexandru BourNo ratings yet

- Matrix Inversion Method and ApplicationsDocument5 pagesMatrix Inversion Method and ApplicationsAjeeth KumarNo ratings yet

- SURA'S 7th STD 5 in 1 Term 3 EM Sample Study MaterialsDocument112 pagesSURA'S 7th STD 5 in 1 Term 3 EM Sample Study Materialssanjay0% (1)

- SpiraxSarco-B2-Steam Engineering Principles and Heat TransferDocument186 pagesSpiraxSarco-B2-Steam Engineering Principles and Heat Transferdanenic100% (4)

- Grade 6 MTAP Division FinalsDocument3 pagesGrade 6 MTAP Division FinalsHershey JimenezNo ratings yet

- Brics Brics: Optimization Theory - A Modern Face of Applied MathematicsDocument6 pagesBrics Brics: Optimization Theory - A Modern Face of Applied MathematicsHossam AhmedNo ratings yet

- SPC For Non-Normal DataDocument4 pagesSPC For Non-Normal DataEdNo ratings yet

- Tiny ES6 Notebook Curated JavaScript ExamplesDocument100 pagesTiny ES6 Notebook Curated JavaScript ExamplesJesus Leon Cordero100% (1)

- Lashkari and Sarvaiya - Matlab Based Simulink Model of Phasor Measurement Unit and OptimalDocument4 pagesLashkari and Sarvaiya - Matlab Based Simulink Model of Phasor Measurement Unit and OptimalJulio MendozaNo ratings yet

- SPY Trading Sheet - Monday, August 2, 2010Document2 pagesSPY Trading Sheet - Monday, August 2, 2010swinganddaytradingNo ratings yet

- Question Bank Unit-I Mechatronics, Sensor and Transducers (2 Mark Questions)Document11 pagesQuestion Bank Unit-I Mechatronics, Sensor and Transducers (2 Mark Questions)ChippyVijayanNo ratings yet

- Sample Paper 10: Class - X Exam 2021-22 (TERM - II) Mathematics BasicDocument3 pagesSample Paper 10: Class - X Exam 2021-22 (TERM - II) Mathematics BasicTanushi GulatiNo ratings yet

- Solar Still Research PaperDocument8 pagesSolar Still Research PaperGopakumar NairNo ratings yet

- CAPE Applied Mathematics Past Papers 2005P2B PDFDocument5 pagesCAPE Applied Mathematics Past Papers 2005P2B PDFEquitable BrownNo ratings yet

- SPH Bearing Draft 09.06.11Document39 pagesSPH Bearing Draft 09.06.11pandeydbNo ratings yet

- Met 2aDocument70 pagesMet 2aharshaNo ratings yet

- FdsafdasDocument5 pagesFdsafdasdonthackmexzNo ratings yet

- Common Monomial FactorDocument31 pagesCommon Monomial FactorErika Lloren Luyun-Galia100% (1)

- Aluminium 2014 t6 2014 t651 PDFDocument3 pagesAluminium 2014 t6 2014 t651 PDFAbhishek AnandNo ratings yet

- Architecture's DesireDocument203 pagesArchitecture's DesireRaluca GîlcăNo ratings yet

- Geological Model SimulationDocument10 pagesGeological Model SimulationYadirita Sanchez VillarrealNo ratings yet

- Stats Workbook For College StudentsDocument337 pagesStats Workbook For College StudentsClifford CurtisNo ratings yet

- Project Risks Analysis: Sensitivity Analysis and CorrelationsDocument11 pagesProject Risks Analysis: Sensitivity Analysis and CorrelationsMohammed AlmusawiNo ratings yet

- Resume Cit PDFDocument1 pageResume Cit PDFJUNE CARLO ENCABONo ratings yet

- Poisson Distribution & ProblemsDocument2 pagesPoisson Distribution & ProblemsEunnicePanaliganNo ratings yet

- pm9sb 133Document0 pagespm9sb 133api-237494396No ratings yet