Professional Documents

Culture Documents

900 Spe 5001 Met&syst

Uploaded by

yoi_123Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

900 Spe 5001 Met&syst

Uploaded by

yoi_123Copyright:

Available Formats

MULTI PURPOSE REACTOR PLANT

Discipline Code: EL Contract Job No.: 002/SP/EP7020/08-S0 Project spec. Title : Doc. No.: 900-SPE-5001 Rev.A

ELECTRICAL METHODES AND SYSTEM

ELECTRICAL METHODES AND SYSTEM

CLIENTS : PROJECT TITLE : CONTRACT TITLE : LOCATION :

ECOGREEN OLEOCHEMICALS MULTI PURPOSE RECTOR PLANT PROJECT

BATAM, INDONESIA CONTRACTOR DATE BY CHKD APVD OWNER DATE APVD

Rev. 1 IFRA

3-Nov-10

CONFIDENTIAL

MULTI PURPOSE REACTOR PLANT PROJECT Discipline Code: EL Contract Job No.: 002/SP/EP7020/08-S0 Project spec. Title : Doc. No.: 900-SPE-5001 Page: Rev.A 2 of 30

ELECTRICAL METHODES AND SYSTEM

Table of Contents Sec Title Page

1. SCOPE...........................................................................................................................................3 2. REFERENCES..............................................................................................................................3 3. UNITS OF MEASURE AND LANGUAGE...............................................................................3 4. BASIC CONSIDERATIONS.......................................................................................................4 5. SITE CONDITIONS.....................................................................................................................4 6. HAZARDOUS AREA CLASSIFICATION...............................................................................4 7. POWER GENERATION AND DISTRIBUTION.....................................................................5 8. UTILIZATION VOLTAGE........................................................................................................6 9. DEVIATION IN SUPPLY VOLTAGE AND FREQUENCY................................................11 10. EMERGENCY POWER GENERATION AND DISTRIBUTION.....................................12 11. LOAD SHEDDING AND MOTOR RESTART SYSTEM...................................................13 12. ELECTRICAL LOAD DATA CALCULATION ...............................................................13 13. SYSTEM STUDIES..................................................................................................................13 14. LV SWITCHGEAR AND MCC..............................................................................................14 15. SYSTEM PROTECTION AND METERING.......................................................................14 16. UPS SYSTEM..........................................................................................................................15 17. LOCAL CONTROL STATION (LCS) FOR MOTOR CONTROL...................................15 18. SUBSTATIONS........................................................................................................................16 19. PAINTING................................................................................................................................17 20. PROTECTION GRADE OF ELECTRICAL EQUIPMENT..............................................17 21. NAMEPLATES.........................................................................................................................17 22. CABLING SYSTEM................................................................................................................17 23. UNDERGROUND CABLING SYSTEMS.............................................................................18 24. ABOVE GROUND CABLING SYSTEM..............................................................................21 25. CABLE AND CORE MARKER.............................................................................................25 26. TERMINATION.......................................................................................................................25 27. ELECTRICAL WIRE AND CABLES...................................................................................26 28. LIGHTING................................................................................................................................28 29. CATHODIC PROTECTION ................................................................................................30

CONFIDENTIAL

MULTI PURPOSE REACTOR PLANT PROJECT Discipline Code: EL Contract Job No.: 002/SP/EP7020/08-S0 Project spec. Title : Doc. No.: 900-SPE-5001 Page: Rev.A 3 of 30

ELECTRICAL METHODES AND SYSTEM

1.

SCOPE This specification covers the minimum design requirements for electrical power supply and distribution systems, motor control and cabling systems for Multi Purpose Reactor Plant Project.

2.

REFERENCES The latest revision of applicable sections of the codes, standards, and specifications listed below (including addenda, and documents incorporated by reference) shall be considered an integral part of this specification. IEC NFPA NEMA API IP : : : : : International Electro-technical Commission National Fire Protection Associations National Electrical Manufacturers Associations American Petroleum Institute Institute of Petroleum

BSI : British Standards Institution Other codes and standards such as ANSI, IEEE, Indonesian code, JIS/JEM/JEC may be also applied with approval by Owner. The codes and standards of the countries of origin may be applied to raw materials and massproduced components, subject to the Vendor clearly indicating the scope of application in his technical and commercial quotations.

3.

UNITS OF MEASURE AND LANGUAGE SI units of measure shall be used for electric system designs unless otherwise specified. The English language shall be used for all documents.

CONFIDENTIAL

MULTI PURPOSE REACTOR PLANT PROJECT Discipline Code: EL Contract Job No.: 002/SP/EP7020/08-S0 Project spec. Title : Doc. No.: 900-SPE-5001 Page: Rev.A 4 of 30

ELECTRICAL METHODES AND SYSTEM

4.

BASIC CONSIDERATIONS Consistent with reasonable economy and considering investment and operation expenditures, the design of electrical facilities shall be based on the features and requirements of the plant where electrical facilities are to be installed. Primary considerations are: Safety of personnel during operation and maintenance, and adequate protection to equipment. Easy maintenance Interchangeability of equipment

5.

SITE CONDITIONS Altitude Ambient Temperature : Less than 1000 m : 680F 910F

For design of outdoor Elec. Equipment : 1040F For design of indoor Elec. Equipment with Air Conditioning systems: 1040F Average Relative Humidity Soil Temperature at 0.8m deep Soil thermal resistivity : 90 % : 860F : 2120F cm / w

Soil thermal resistivity & soil electrical resistivity shall be verified with further tests during design stage. 6. HAZARDOUS AREA CLASSIFICATION Plant areas shall be classified according to the API RP505. The selection of electrical equipment and material to be installed in hazardous areas shall be in accordance with IEC 60079. Electrical equipment shall be selected according to the following Zone Classification criteria: Zone 1 Area Electrical apparatus should be excluded from Zone 1 areas. Where this is not practical, the equipment shall comply with one (1) of the following types;

CONFIDENTIAL

MULTI PURPOSE REACTOR PLANT PROJECT Discipline Code: EL Contract Job No.: 002/SP/EP7020/08-S0 Project spec. Title : Doc. No.: 900-SPE-5001 Page: Rev.A 5 of 30

ELECTRICAL METHODES AND SYSTEM

- Ex(e) (Increased safety) - Ex(p) (Pressurized enclosure) - Ex(d)( Flame proof enclosure) Zone 2 Area - Ex(n) (Type N protection) - Ex(e) (Increased safety) - Ex(d) (Flame proof enclosure for internal sparking equipment)

Non-hazardous Area - Standard Industrial equipment suitable for the installation Explosion proof electrical equipment / materials suitable for Division 1 or 2 may be also used in hazardous area. Division 1 is considered equal to Zone 1 and Division 2 is considered equal to Zone 2. Electrical equipment and materials for hazardous areas shall be selected according to the applicable codes and standards of the country where the equipment/materials are manufactured. Approved equipment must be listed or certified for use in the particular hazardous location by an internationally recognized testing organization.

7.

POWER GENERATION AND DISTRIBUTION The power Supply shall have 0.38 kV voltage rating, 3 phases, 50 Hz and connected to 0.38 kV busbar (main substation) . The electric power to be required for the plant operation shall be supplied from Power distribution of 400V shall be secondary selective system with each bus tie breaker normally open (N.O.). Power loss at one side bus shall cause an automatic transfer to another side bus with permissive from bus fault condition. The two incoming breakers and one tie-breaker are interlocked so that only two of the three breakers can be closed. The returning to normal operation and manual transfer without any power interruption shall be

CONFIDENTIAL

MULTI PURPOSE REACTOR PLANT PROJECT Discipline Code: EL Contract Job No.: 002/SP/EP7020/08-S0 Project spec. Title : Doc. No.: 900-SPE-5001 Page: Rev.A 6 of 30

ELECTRICAL METHODES AND SYSTEM

performed by operators. The each incoming side of secondary selective system shall be rated for the total busbar load to cover all loads under its switchgear without incoming power supply from another side. Cable sizing to each motor shall be sized based on the motor full load current considering derating factor from installation method. The power to building loads (HVAC, Lighting) shall be controlled and distributed from Distribution Panels properly located in each building.

8.

UTILIZATION VOLTAGE Motors above 150 kW Motors above 0.37 kW up to 150 kW Motors rated 0.37 kW and below Welding Outlet Space Heater/auxiliary power supply : 6.6 kV, 3 phases, 50Hz : 400 V, 3 phases, 50Hz : 230 V, 1 phase, 50Hz : 380 V, 3 phases, 3 poles + earth : 220 V, 1 phase, 2 wires, 50Hz

Control Supply for Switchgear, Relays, Elec. Controllers : 220 VAC Control Supply for motors connected to LV & MV MCC : 220 VAC (from self control transformer at each MCC unit)

SYSTEM EARTHING AND LIGHTNING PROTECTION

8.1

General Earthing, Bonding and lightning protection facilities shall be provided to: Protect electrical equipment from damage and to insure operation of electrical overcurrent devices (System neutral earthing) Protect personnel against shock from electrical enclosures or equipment (Enclosure and equipment earthing) Protect structures and equipment against damage from lightning (Lightning protection) Insure against ignition of flammable mixtures by static electricity or stray current (Static electricity protection)

CONFIDENTIAL

MULTI PURPOSE REACTOR PLANT PROJECT Discipline Code: EL Contract Job No.: 002/SP/EP7020/08-S0 Project spec. Title : Doc. No.: 900-SPE-5001 Page: Rev.A 7 of 30

ELECTRICAL METHODES AND SYSTEM

8.2

Earthing System Earthing systems shall consist of networks installed around major process units, buildings, structures, distribution centers, substations, etc. Networks shall consist of earthing buses (main loops), earthing electrodes, and earthing conductors for equipment. Where different earthing systems, except systems for process control and computer system, are installed close together, they shall be interconnected at convenient points to bring all earthing to a common potential. Earthing for lightning protection for structures/buildings which are equipped with lightning rods shall be physically isolated from the main earthing system. Earthing rods shall be located at the base of each protected structures/buildings. Equipment that is located remotely from the main earthing network may be earthed by means of individual earthing conductors and earthing electrodes. All earthing electrodes at substations and generating stations shall be interconnected in a loop by earthing conductors. Earthing resistances shall not be exceed the following values: -Total earthing resistance of loop network - An earthing electrode - An earthing electrode for lightning protection - System neutral earthing - Instrument earthing (maximum) : : : : : 5 ohms 25 ohms 5 ohms 5 ohms 5 ohms

A separate earthing system shall be provided for electronic instrument boards. It shall be physically isolated from other earthing systems. For further details, refer to Instrument Specification.

8.3

Methods and Materials Earthing, Bonding and Lightning Protection Conductors All earthing, bonding and earth return conductors shall be PVC insulated (green or green with yellow stripe) soft-drawn stranded copper wire. Earthing buses for earthing networks shall have 70 mm2 conductors. All lightning protection conductors, such as down conductors and electrode conductors shall be bare hardCONFIDENTIAL

MULTI PURPOSE REACTOR PLANT PROJECT Discipline Code: EL Contract Job No.: 002/SP/EP7020/08-S0 Project spec. Title : Doc. No.: 900-SPE-5001 Page: Rev.A 8 of 30

ELECTRICAL METHODES AND SYSTEM

drawn copper or stranded aluminum wire or bar. All earthing conductor shall be sized as follows: LV Switchgear and MCCs Other electrical panels Lighting panel board frames Welding outlet frame Motor frames Neutral earthing for solid earthing Neutral earthing for low resistance earthing Static electricity Bonding wire Fences Other equipment Lightning protection : : : : : : : : : : : : 120 mm2 25-35 mm2 35 mm2 16 mm2 16-70 mm2 150 mm2 70 mm2 35 mm2 4-16 mm2 16 mm2 4-16 mm2 70 mm2

Note : The equipment earthing conductor shall need not be larger than the circuit conductors supplying electrical power to the equipment. Underground earthing conductors shall be directly buried at least 300 mm below finished grade. Underground earthing conductors shall be laid in cable trenches as far as routing permits. Basically, aboveground earthing conductors shall be laid on cable tray. Earthing conductors extending aboveground shall be protected by hard PVC conduit at least 150 mm above and below the finished grade or concrete surface.

Earthing and Bonding Connection All earthing or bonding conductor connections to structures and equipment shall be made aboveground. Lug bolted connectors shall be used to allow periodical maintenance.

CONFIDENTIAL

MULTI PURPOSE REACTOR PLANT PROJECT Discipline Code: EL Contract Job No.: 002/SP/EP7020/08-S0 Project spec. Title : Doc. No.: 900-SPE-5001 Page: Rev.A 9 of 30

ELECTRICAL METHODES AND SYSTEM

Earthing lugs shall be fabricated from hot dipped galvanized steel. All aboveground connections of earthing wires shall be made with compression type connectors and wrapped with PVC tape. All underground connections of earthing wires shall be made by Cadweld, Teikaweld or C-clamp and wrapped with PVC tape. Earthing Electrodes Earthing electrodes shall be made by long zinc clad steel or copper clad steel rods driven below grade. Each earthing rod shall be installed in an earthing well which shall function as an inspection pit for verifying earthing resistance. The loop conductor shall be connected to the top of the earthing rod. The earthing rod shall be connected to the loop conductor by a bolted connector. If more than one electrode is connected to an earthing system, the electrodes shall be spaced at least 3 m apart. Equipment located remotely shall be furnished with a dedicated earthing rod connected directly to the equipment. No earthing well for inspection purposes is required. Electrical System Earthing Neutral earthing for each system voltage level shall be as follow: 400 V system : Solidly earthed

Enclosure and Equipment Earthing Earthing Point of Wiring System o The metal enclosures for wire and cable, such as conduits, cable trays, and raceways shall be considered electrically continuous by metallic connection, and earthed at each end by direct connection to earthing network, bonding or metalic connection to other earthed enclosures. Connections shall be made to the switchgear or control center earth buses

CONFIDENTIAL

MULTI PURPOSE REACTOR PLANT PROJECT Discipline Code: EL Contract Job No.: 002/SP/EP7020/08-S0 Project spec. Title : Doc. No.: 900-SPE-5001 Page: Rev.A 10 of 30

ELECTRICAL METHODES AND SYSTEM when such equipment is used.

The metal armor of cables shall be bonded together across each splice, and to the metal enclosures of equipment at each end of the cable utilizing cable glands.

The metallic shields in shielded cables shall be earthed at the supply side only.

Earthing Point of Equipment o The metal enclosures of all electrical equipment shall be earthed by connecting to the earthing network using a dedicated earthing conductor or by a earthing conductor in the multi conductor cables. o o o o o Fences, handrails and stairways at substations shall be earthed to an earthing network. Metal enclosure which may be source of static electricity shall be earthed to an earthing network. Electrical equipment, even though bolted directly to an earthed metallic structure, shall be earthed separately. Machinery skid base containing electrical equipment. (Two points in diagonally opposite ) Local control stations shall be connected to an additional earthing conductor branched from the main earthing loop.

Lightning Protection Lightning protection systems shall be installed basically in accordance with BS6651. Non-steel structures higher than 20 m shall, in general, be provided with a lightning protection system. Tall steel structures, columns, towers, vessels etc. which require lightning protection shall be earthed with 70 mm2 earthing wires at two points of their base and shall be connected into the main earthing loop. The steel structures, columns, towers, vessels, tanks etc, provided they are electrically continuous, shall be considered protected against lightning by those

CONFIDENTIAL

MULTI PURPOSE REACTOR PLANT PROJECT Discipline Code: EL Contract Job No.: 002/SP/EP7020/08-S0 Project spec. Title : Doc. No.: 900-SPE-5001 Page: Rev.A 11 of 30

ELECTRICAL METHODES AND SYSTEM

connection to the earthing network. Static Electricity Protection All storage tanks, columns, towers, vessels, heat exchangers and other process equipment not mounted on an earthed steel structure shall be separately earthed. Process equipment mounted on an earthed steel structure fixed with carbon steel bolting shall not require additional earthing. Buildings or structures having metallic frames or siding shall be earthed at a minimum of two locations. These locations shall be at opposite extremities of the structure. Above ground pipelines shall be connected to the earthing network only at the boundary of plant area. Flanged joints without insulated linings in metallic pipelines shall be considered electrically continuous.

9.

DEVIATION IN SUPPLY VOLTAGE AND FREQUENCY Voltage and Frequency variation (during normal operation and steady state conditions) Voltage variation not more than +/- 10% from the rated voltage at generator and consumer terminals Frequency Deviation not more than +/- 10% from the rated

Maximum allowable voltage drop during normal operation and steady state conditions Main Feeders : 10% Motor and plant static load cables from MCC at full loads : 20% Lighting Circ. (from LV distribution boards to furthest lighting fixtures): 15%

Maximum allowable voltage drop during starting or reacceleration of motors: At motor terminals: not more than 15 % (except very large motor to be connected to the captive transformers and to be considered individually based on studies, if applicable.)

CONFIDENTIAL

MULTI PURPOSE REACTOR PLANT PROJECT Discipline Code: EL Contract Job No.: 002/SP/EP7020/08-S0 Project spec. Title : Doc. No.: 900-SPE-5001 Page: Rev.A 12 of 30

ELECTRICAL METHODES AND SYSTEM

10.

EMERGENCY POWER GENERATION AND DISTRIBUTION Emergency power for the plant shall be provided by standby diesel driven generator to facilitate the start up and safe and orderly shutdown of the plant in the event of loss of main power generation. The size and number of standby generator shall be finalized during engineering design. The diesel generator shall supply power to essential loads such as emergency lighting including those for control room, substation and generator shelter, UPS including plant control system and emergency shut down system, DC power supply units, Hazard Monitoring System, Communication systems, HVAC loads for Control Room and Generator Operation, auxiliary loads of one main generator Diesel Engine Generator, critical motor operated valves and essential auxiliaries of major machinery if any, air compressor to provide instrument air to emergency services. The emergency generator shall be sized for the required running loads plus its 25% spare. The emergency generator shall be started and supply the power to the emergency power distribution system automatically in the event of total power disturbance of main generators (Black Start Capability). Electrical synchronizing facilities shall be provided for emergency generator. The load running test during commissioning test and periodical maintenance after plant operation for Diesel Engine Generator shall be performed using plant actual loads. The emergency power shall be generated at the 380V low voltage level and distributed to downstream substations as required. The control panel of generator set shall be located inside main control building or substation adjacent to the generator set. Only engine running status, breaker status, neutral earthing switch status, common alarm & trip status and analogue signals of V, A, KW, PF, Hz shall be communicated to Main Control Room by hard-wiring or softlink / RS 485,etc and no control action can be achieved from remote location.

CONFIDENTIAL

MULTI PURPOSE REACTOR PLANT PROJECT Discipline Code: EL Contract Job No.: 002/SP/EP7020/08-S0 Project spec. Title : Doc. No.: 900-SPE-5001 Page: Rev.A 13 of 30

ELECTRICAL METHODES AND SYSTEM

11.

LOAD SHEDDING AND MOTOR RESTART SYSTEM 11.1 Load Shedding System The electrical loads to be shed under emergency conditions shall be studied and finalized during engineering stage. 11.2 Motor Re-acceleration Automatic reacceleration and re-start scheme shall be provided for necessary motors based on process requirement.

12.

ELECTRICAL LOAD DATA CALCULATION Maximum normal running plant load = x (%) C + y (%) I Peak load = x (%) C + y (%) I + z (%) S C : Continuous I : Intermittent S : Stand-by x, y, z : Diversity Factors Default values for initial load assessment or if the diversity factors not finalized; x = 100 % (all driven equipment should be operating at its duty point. But some diversity may need to be applied to non-process loads, e.g. Office and workshop power and lighting - typically 80 %) y = 30 % z = 10 % Instead of z (%)S, only one of the largest electrical stand-by units per switchgear line-up may have to be considered when establishing the peak load.

13.

SYSTEM STUDIES The following calculations shall be performed for the design and study of electrical system and sizing of electrical equipment;

CONFIDENTIAL

MULTI PURPOSE REACTOR PLANT PROJECT Discipline Code: EL Contract Job No.: 002/SP/EP7020/08-S0 Project spec. Title : Doc. No.: 900-SPE-5001 Page: Rev.A 14 of 30

ELECTRICAL METHODES AND SYSTEM

Load Data Calculation Short Circuit Calculation Load Flow Calculation Motor Starting Calculation

14.

LV SWITCHGEAR AND MCC LV switchgear 400V shall be metal clad, IP31, single bus, draw-out type, Air Circuit Breakers. LV MCC shall be metal enclosed, IP31, with drawable motor control or feeder unit. Approximately 10 % of total MCC units as spare and approximately 10 % future space shall be provided per each MCC line-up subject to manufacturers standard practice. transformers shall be provided.

15.

SYSTEM PROTECTION AND METERING 15.1 Switchgears Incoming of 380V switchgear Over current relay with instantaneous unit Earth fault relay Feeders of 380 V Switchgear Over current relay with instantaneous unit Earth fault relay Ammeter with selector switch Multifunction relay which cover all above protections and meters requirement is preferable (Solid State Relay).

CONFIDENTIAL

MULTI PURPOSE REACTOR PLANT PROJECT Discipline Code: EL Contract Job No.: 002/SP/EP7020/08-S0 Project spec. Title : Doc. No.: 900-SPE-5001 Page: Rev.A 15 of 30

ELECTRICAL METHODES AND SYSTEM

15.2

LV MCC unit Magnetic Trip Molded Case Circuit Breaker (sized to be tripped at approximately 10 times of motor full load current) with contactor and thermal relay for motor units Thermal Magnetic Molded Case Circuit Breaker for feeder units. Earth Fault Relay for motor units of at least 5.5 kW and above, and for feeder supply units of breaker over 100 A trip rating Single phase Ammeter for motor units of 30 kW and above Running (red) / Stopped (green) / Fault (Amber) Lamp for MCC units No start / stop control switch for motor units The intelligent type solid state motor protection and control system can be also applied for LV MCC unit with manufactures standard central unit and maintenance facilities.

16.

UPS SYSTEM UPS systems will provide power to the DCS or PLC, Safety Instrumented System and other critical loads. The UPS system will receive power from the emergency supply with a bypass circuit from the emergency motor control center. UPS power supply unit shall be provided in substation. The UPS shall be capable of operating on small diesel engine driven generators for emergency power that may have larger frequency variations than the larger primary power generators. UPS systems shall be double configuration with voltage stabilizer at bypass line. Battery back-up time for both UPS power supply unit shall be 60 minutes.

17.

LOCAL CONTROL STATION (LCS) FOR MOTOR CONTROL LCS shall be provided with start/stop control function suitable for area classification with locking feature which is padlock able in off position. LCS shall be hard-wired directly to the motor starter in the MCC.

CONFIDENTIAL

MULTI PURPOSE REACTOR PLANT PROJECT Discipline Code: EL Contract Job No.: 002/SP/EP7020/08-S0 Project spec. Title : Doc. No.: 900-SPE-5001 Page: Rev.A 16 of 30

ELECTRICAL METHODES AND SYSTEM

Motors automatically controlled by DCS or PLC shall have Hand-off-Auto selector switch on LCS. For all air fin-fan motors, LCS shall be located close to air fin-fan unit.

18.

SUBSTATIONS In general, substations shall be elevated with the height from grade to the under side of the lowest beam by min. 1500 mm for bottom entry of underground cables with cable glands. Substations shall be located in non-hazardous, safe areas and furnished by air conditioning. Personnel access doors with panic bar and equipment access double doors of adequate size shall be provided for all substations. The under floor space sides of each substation, not covered with firewall, shall be fenced with proper chain link. Substation floor shall be concrete surface and steel channel shall be installed, level and flush with finished floor grade for mounting the electrical panels. Electrical panels shall be tag welded or bolted to the floor steel. In general, cables shall enter the substation from bottom side. Suitable cable support frames made of channel, angle and unistrut below the substation shall be provided to support cables. All LV and control cables shall be fixed by coated stainless steel all purpose band 'Band it' or equivalent. For cable glanding below the substation, suitable gland box below SWGR/MCC. The box shall have removable covers of galvanized sheet on front and rear complete with neoprene gaskets. The box shall be hot dip galvanized. Substations shall have a separate battery room with access from outside the substation. Provisions shall be made for sufficient diffusion and ventilation of the gases from the battery to prevent the accumulation of an explosive mixture. Package type substations may be provided wherever practical including small

CONFIDENTIAL

MULTI PURPOSE REACTOR PLANT PROJECT Discipline Code: EL Contract Job No.: 002/SP/EP7020/08-S0 Project spec. Title : Doc. No.: 900-SPE-5001 Page: Rev.A 17 of 30

ELECTRICAL METHODES AND SYSTEM

power distribution such as tank farm, buildings, offsite users etc.

19.

PAINTING Color of Electrical Equipment (Switchgear / MCC panel, Distribution & Lighting Panels etc.) shall be RAL7032 or equivalent.

20.

PROTECTION GRADE OF ELECTRICAL EQUIPMENT Protection grade of enclosures of outdoor Electrical Equipment ( Outdoor Distribution & Lighting Panels etc.) shall be IP55. Protection grade of enclosures of indoor Electrical Equipment (Substation Switchger / MCC, UPS, Panel etc.) shall be IP31.

21.

NAMEPLATES All electrical equipment such as Switchgear/MCC, control stations, transformers, panels, junction box etc. shall have an engraved non-corrosive nameplate. The nameplates will be attached to the equipment with stainless steel machine screws wherever possible, or on stainless steel mounting brackets, as required, adjacent to the equipment.

22.

CABLING SYSTEM Electrical power and control cables for outdoor installation shall be armored cables and shall be installed underground as direct buried cables or aboveground in cable trays. In aboveground cabling system, the cable tray system shall be mainly used. Non armored cables can be utilized for building loads and interconnecting cables inside substations and control rooms. The bolts, nuts, washers and U-bolts to be used for electrical installation shall be made of stainless steel. The support materials for electrical installation such as angles and channels shall be hot dipped galvanized steel.

CONFIDENTIAL

MULTI PURPOSE REACTOR PLANT PROJECT Discipline Code: EL Contract Job No.: 002/SP/EP7020/08-S0 Project spec. Title : Doc. No.: 900-SPE-5001 Page: Rev.A 18 of 30

ELECTRICAL METHODES AND SYSTEM

23.

UNDERGROUND CABLING SYSTEMS There are two types of underground cabling system as follows: Direct-buried cable system Underground conduit system 23.1 Direct-Buried Cable Systems Direct-buried cable systems shall be either of the following two types: Cable buried directly in a trench with exposed earth sidewalls and bottom, and covered with red concrete slabs or tiles for protection. Cable buried directly in a trench with reinforced concrete or brick sidewalls / covers and an earth bottom. 23.2 Underground Conduit Systems Underground conduit systems shall be either of the following two types: 23.3 Conduits laid underground. These are called direct-buried conduits. Conduits laid underground and encased in concrete. These are called duct banks. Types of Cable The types of cable to be used shall be as specified in section 31. 23.4 Routing of Underground Cabling Systems The route of the underground cable shall be determined by considering the following: The route of the cable shall avoid aboveground and underground obstructions so that reasonable access to the cable is assured. Wherever practical, trenches shall run in unpaved areas and shall be routed adjacent and parallel to roadways. A clearance of not less than 300 mm shall be maintained between the cables and underground piping. Cables crossing under main roads, paved heavy traffic roads, shall be run in duct

CONFIDENTIAL

MULTI PURPOSE REACTOR PLANT PROJECT Discipline Code: EL Contract Job No.: 002/SP/EP7020/08-S0 Project spec. Title : Doc. No.: 900-SPE-5001 Page: Rev.A 19 of 30

ELECTRICAL METHODES AND SYSTEM

banks, or reinforced concrete culverts. Earth wall cable trench shall be used in unpaved area. Concrete or brick wall trench shall be used in paved area. 23.5 Design of Direct-Buried Cable Systems Types of Underground Cable Trench Earth Wall Trench : The sides and bottom of earth wall cable trenches shall be exposed earth. Red concrete slabs or tiles with a minimum thickness of 50 mm shall be laid on the top layer of the sand fill. These slabs shall extend approximately 150 mm beyond the cable on both sides of the trench. Concrete or Brick Wall Trench : Concrete or brick wall cable trenches shall consist of reinforced concrete or brick sidewalls and covers, and a bottom of exposed earth. The trenches and covers shall be designed to withstand the maximum loading for the area in which they are to be installed. Trench covers shall be painted red. The covers shall be flush with the adjacent pavement or finish grade. Cable Depth and Separation The minimum cover for cables installed in earth wall trenches between surface of cables at top layer and the finished grade. The bottom layer of cables in trenches shall be installed on a cushion of screened sand. Other voltage cables may be installed in the same trench up to a maximum of four layers with 100mm vertical separation between layers. The top layer of cables and all future cables shall be below the bottom of the trench cover for concrete or brick wall trenches, and below the bottom of the protective covering for earth wall trenches. The space between the top layer of cables and the trench cover or protective covering shall be completely filled with screened sand. No other cables shall be installed in the same trench with the high-voltage main

CONFIDENTIAL

MULTI PURPOSE REACTOR PLANT PROJECT Discipline Code: EL Contract Job No.: 002/SP/EP7020/08-S0 Project spec. Title : Doc. No.: 900-SPE-5001 Page: Rev.A 20 of 30

ELECTRICAL METHODES AND SYSTEM

distribution cables except for low-voltage interlock, relaying, and control cables for the switchgear associated with the distribution cables. These low-voltage cables shall be separated horizontally from the distribution cables by a masonry barrier or screened sand. Turns in trenches shall be constructed so that the cables can be installed with the required bending radius. Space for Future Cables Trenches for direct-buried cables shall be designed with space for future cables as listed below. The future cables include additional cables required (means design allowance) during the detailed engineering stage of the Project. A minimum of 10 % (with minimum 2 cables line space) of future cables shall be estimated based on the number of cables originally installed. The space for future cables shall be in the upper part of the trench. 23.6 Design of Underground Conduit Systems Types of Conduit Underground conduit to be used for duct bank shall be rigid polyvinyl chloride (PVC) or high-density polyethylene. Direct-Buried Conduits The Direct-Buried Conduits consist of: In unpaved areas In concrete paved areas Duct Banks In duct banks, underground conduit runs shall be encased in concrete. The minimum depth to the top of the concrete encasement shall be 450 mm from finish grade. Conduit Separation The minimum separation between the outside surfaces of conduits shall be 25 mm for nominal conduit sizes of 42 mm (1-1/2 inch) and smaller, and 50 mm for sizes larger than 42 mm (1-1/2 inch).

CONFIDENTIAL

MULTI PURPOSE REACTOR PLANT PROJECT Discipline Code: EL Contract Job No.: 002/SP/EP7020/08-S0 Project spec. Title : Doc. No.: 900-SPE-5001 Page: Rev.A 21 of 30

ELECTRICAL METHODES AND SYSTEM

Conduits Extended to Aboveground Nonmetallic conduits shall not be extended aboveground except for stub-ups within switchgear, control center and similar equipment enclosures in non hazardous locations and except for grounding wires. Where aboveground extensions are required, a transition to rigid metal conduit shall be made underground. Stub-up rigid metal conduit shall be properly sealed using soft seal or equivalent after cable installation. Non metallic conduit shall not be used in the process area and buildings located in the process area, example: substation.

23.7

Cable Splices and Terminations Cables shall be laid in one length wherever possible. All splices and terminations for high voltage cables shall be made according to the cable manufacturer's recommendations.

23.8

Cable Route Marking A system of aboveground cable route markers shall be provided to identify underground cables in unpaved areas as follows: Markers shall be located at every point where the direct-buried cable or conduit changes direction. Markers shall be provided on both sides of the trench which are 2.0 m wide or more. For cable trenches less than 2.0 m wide, markers shall be provided at their center. Where cable trenches are identified by painting or equivalent, the markers are not required. Cable marker shall be provided

24.

ABOVE GROUND CABLING SYSTEM 24.1 General Aboveground cabling and wiring systems are the following: Cable trays Rigid metal conduit systems Thin-wall metallic conduit systems

CONFIDENTIAL

MULTI PURPOSE REACTOR PLANT PROJECT Discipline Code: EL Contract Job No.: 002/SP/EP7020/08-S0 Project spec. Title : Doc. No.: 900-SPE-5001 Page: Rev.A 22 of 30

ELECTRICAL METHODES AND SYSTEM

Floor raceway systems 24.2 Types of Cable The types of cables using aboveground vary depending on the services and conditions as shown in Subsection 31.

24.3

Cable Trays Cable tray systems shall be heavy duty, ladder type. Punched type trays and other similar supports may be utilized if required. Cable tray systems shall be used in hazardous or non-hazardous, indoor or outdoor locations. They shall be located so that they will not be damaged, such as by traffic or during maintenance. Trays and other fittings shall be made of hot-dipped galvanized steel. Cable trays shall have removable covers in locations where cables are subject to damage from falling objects, corrosive liquids or direct sunlight. In other locations, trays shall be open-topped. When removable covers are applied on cable trays in more than one (1) layer installation, they shall be provided on top layer only. Cable trays and ladders shall be supported properly at intervals recommended by the manufacturer. The arrangement of cable in or on supports shall be as follows: Control cables shall be laid between power cables wherever possible. MV and LV cables may be laid in the same cable trays Trays carrying only control or instrument cables may have cables arranged in more than two layers. Cables shall be arranged to minimize the number of crossovers. Tray supports shall be of heavy duty construction and galvanized or if practical, painted. Where there are up to three cables runs, they can be supported directly from / along the structure by using clip or galvanized steel angle.

CONFIDENTIAL

MULTI PURPOSE REACTOR PLANT PROJECT Discipline Code: EL Contract Job No.: 002/SP/EP7020/08-S0 Project spec. Title : Doc. No.: 900-SPE-5001 Page: Rev.A 23 of 30

ELECTRICAL METHODES AND SYSTEM

24.4

Rigid Metal Conduit Systems Conduits, elbows, couplings and other associated fittings shall be hot dipped galvanized steel. Conduit feeding equipment that is subject to vibration shall terminate in flexible conduits suitable for the area classification. All conduits shall be threaded with an absolute minimum of five full threads. Threads shall taper 3/4 inch per foot. Breathers and drains shall be provided at high and low points of the conduit system to prevent the accumulation of condensed water. Breathers and drains shall also be provided in junction boxes, explosion proof panel boards and generally in equipment enclosures subject to accumulating condensed water by its shape and position in the conduit system A run of conduit between outlet and outlet, fitting and fitting, or outlet and fitting shall not contain more than the equivalent of four quarter bends (360 degrees, total). Minimum conduit used will be 3/4 inch except for those situations of instrumentation equipment which call for 1/2 inch conduit. When conduit runs exceed the equivalent of a 61 m (200 feet) straight run or contain more than the equivalent of three 90 degree bends, pull fittings must be installed. One 90 degree bend is to be considered to be equivalent to 15.25 m (50 feet) of straight run. No single bend shall exceed 90 degrees. Conduit and conduit fittings shall not be welded to any structure. Conduit shall be installed a minimum of 300 mm (1 foot) from un-insulated hot piping or hot surfaces. Conduit connections to end devices shall be from below to prevent moisture ingress. Side entries are acceptable, but top entries should be avoided.

24.5

Thin-Wall Metallic Conduit Systems Thin-wall metallic conduit systems shall not be used for outdoor areas and classified locations. (EMT shall be used for only indoor wiring system.)

CONFIDENTIAL

MULTI PURPOSE REACTOR PLANT PROJECT Discipline Code: EL Contract Job No.: 002/SP/EP7020/08-S0 Project spec. Title : Doc. No.: 900-SPE-5001 Page: Rev.A 24 of 30

ELECTRICAL METHODES AND SYSTEM

24.6

Floor Raceway Systems Acceptable floor raceway systems shall be restricted to under floor raceways and cellular concrete floor raceways. Floor raceway systems shall not be used for outdoor areas and classified locations. The total cross-sectional area of all contained conductors at any cross section of a floor raceway shall not exceed 40 % of the interior cross-sectional area of the floor raceway. Metal junction boxes shall be used with floor raceways and shall be electrically continuous with the raceway. The junction boxes shall be located at floor grade and sealed to exclude water or concrete. Splices and taps shall be made only in header access units or junction boxes. Routing of Aboveground Wiring Systems Cable shall be installed according to the manufacturer's recommendation. In no case shall manufacturer's maximum allowable pulling tension, armor compression, etc., be exceeded during cable installation. Wiring systems shall not be installed closer than 150 mm from surfaces with temperatures of 1130F to 1490F and not closer than 300 mm from surfaces with temperatures above 1490F. Where it is necessary to route a wiring system close to a high-temperature surface, a high-reflectance thermal barrier shall be installed between the system and the surface. All cables shall run in one length wherever possible. Splices and Terminations Splices and terminations for cables operating above 600 volts shall be made according to the cable manufacturer's recommendations by one of the following methods: Straight (in-line) splices Heat shrink sleeve or similarly terminating device.

24.7

24.8

CONFIDENTIAL

MULTI PURPOSE REACTOR PLANT PROJECT Discipline Code: EL Contract Job No.: 002/SP/EP7020/08-S0 Project spec. Title : Doc. No.: 900-SPE-5001 Page: Rev.A 25 of 30

ELECTRICAL METHODES AND SYSTEM

25.

CABLE AND CORE MARKER

All cables except for lighting systems shall be marked with a Type 316 stainless steel tag with embossed lettering secured with Type 316 stainless steel ties or nylon markers enclosed in a clear heat shrink sleeve. A cable marker shall be installed on both ends of each cable. Where cables pass through duct banks, a marker shall be installed on both sides of each penetration in addition to being marked on both ends of the cable. All cores of control cables shall have wires clearly identified with permanently embossed type or equal heat-shrinkable wire markers at every termination point. Where it is determined that heat-shrinkable wire markers are not practical, slip-on permanently embossed sleeves shall be used. For internal wiring of electrical equipment and panels, equivalent vendor standard core identification system is acceptable. These wire numbers must correspond to the wire numbers shown on electrical drawings. An individual wire shall have the same assigned number at each end and at each location where it is terminated. Cable marker shall be provided on both ends of each cable and in every 5 meter long distance between both ends.

26.

TERMINATION Control and instrument wires shall be terminated on terminal blocks in junction box for external cables with suitable insulated compression terminals installed with a ratchet type crimping tool with proper dies. Ring tongue or locking fork type terminals shall be used when terminating to screw-type terminals. Straight pin type ferrules shall be used when terminating to screw-clamp type terminals. A removable bottom plate or threaded hub(s) for cable gland installation of external cables shall be provided at local panel and / or junction box for package unit.

Where control and instrument wires terminate in a device where terminal points are not provided (such as instruments or solenoids with pigtails), terminal blocks are to be installed if the number of terminal points exceed four within a junction box. If four or less, terminations are to be made utilizing self-insulated crimp type butt splice connectors.

CONFIDENTIAL

MULTI PURPOSE REACTOR PLANT PROJECT Discipline Code: EL Contract Job No.: 002/SP/EP7020/08-S0 Project spec. Title : Doc. No.: 900-SPE-5001 Page: Rev.A 26 of 30

ELECTRICAL METHODES AND SYSTEM

No more than two wires shall be terminated on any one terminal point. Jumper links or combs shall be used to connect together extra terminals to allow termination of more than two wires to the same terminal point. Splices at lighting fixtures and receptacles not located indoors shall be made with self insulated crimp type butt splice connectors. These connections shall be water proofed with rubber tape and vinyl plastic electrical tape to prevent the entrance of moisture into the connector. Where a lug or terminal is not provided with equipment, power wire shall be terminated with compression ring tongue terminals. Terminals shall be installed with a ratchet type or hydraulic crimping tool with the proper dies. Motor terminations shall be made with ring tongue compression terminals installed on the power wire and the motor lead. Stainless steel bolts, nuts, and lock washers shall be used to connect the ring tongue compression terminals. The threaded hub shall be provided at terminal box of motors for cable gland installation of external cables. The type of thread shall be per ISO metric and size of thread shall be designated on data sheet during design stage.

27.

ELECTRICAL WIRE AND CABLES 27.1 Cable Specifications All power and control cables (wires) shall conform to the following types: XLPE/SWA/PVC : Cross-linked polyethylene insulated, PVC bedded, galvanized steel wire or non-magnetic metal wire (only for single core cable) armored and PVC outer sheathed able. XLPE/PVC PVC/SWA/PVC : Cross-linked polyethylene insulated and PVC outer sheathed cable. : Polyvinyl chloride insulated, PVC bedded, galvanized steel wire or non-magnetic metal wire (only for single core cable) armored and PVC outer sheathed cable. PVC/PVC : Polyvinyl chloride insulated and PVC sheathed outer cable.

CONFIDENTIAL

MULTI PURPOSE REACTOR PLANT PROJECT Discipline Code: EL Contract Job No.: 002/SP/EP7020/08-S0 Project spec. Title : Doc. No.: 900-SPE-5001 Page: Rev.A 27 of 30

ELECTRICAL METHODES AND SYSTEM : Polyvinyl chloride insulated cable (wire).

PVC

All cables shall conform to IEC 60502 except for PVC insulated single core cables (wires) which shall conform to IEC 60227. 27.2 Cable Sizing For the sizing of power cables, the following aspects shall be considered: Thermal short circuit capacity ( for over 3 kV cables ) Voltage drop Current rating Minimum conductor sizes shall be as listed below: LV control cables : 1.5 mm2 LV power cables : 2.5 mm2 27.3 Cable Construction The conductor shall be either compact round stranded uncoated copper wires or solid soft annealed uncoated copper wires, as specified in IEC 60228. Suitable fillers (as specified in IEC) shall be used in the interstices of the cable to give the completed cable a substantially circular cross section. The outer sheath shall be flame retardant (not applied for cable installations outside the plant). 27.4 Color Identification of cable core and outer sheath HV / MV cable Three cores One core Outer Sheath LV Power & Control cable One core Two cores Three cores Three core + Grounding

CONFIDENTIAL

: Red, Yellow, Blue : Vendor Standard : Red : Black : Red, Black : Red, Yellow, Blue : Red, Yellow, Blue + Green

MULTI PURPOSE REACTOR PLANT PROJECT Discipline Code: EL Contract Job No.: 002/SP/EP7020/08-S0 Project spec. Title : Doc. No.: 900-SPE-5001 Page: Rev.A 28 of 30

ELECTRICAL METHODES AND SYSTEM

Four cores Four core + Grounding Five cores and above Outer Sheath 28. LIGHTING 28.1 General

: Red, Yellow, Blue, Black : Red, Yellow, Blue, Black + Green : Black with white numbers : Black

Lighting shall be provided for the following areas: Process operating areas Utility areas Offsite Pump areas Storage tank areas Loading and unloading areas Parking areas Plant main roads Buildings (Indoor & Outdoor)

Lighting shall not be provided for the following outdoor areas, unless otherwise specified: Waste disposal ponds Plant perimeter and/or security fences Access road outside battery limit Future area

Street lighting systems shall High Pressure Sodium fixtures mounted on poles. Outdoor general plant lighting and street lighting shall be controlled by a photo-cell located at each substation and manual by operator. Tank farm shall be provided with flood lighting. No lighting fixture is required on the tank stairs and tank roof.

CONFIDENTIAL

MULTI PURPOSE REACTOR PLANT PROJECT Discipline Code: EL Contract Job No.: 002/SP/EP7020/08-S0 Project spec. Title : Doc. No.: 900-SPE-5001 Page: Rev.A 29 of 30

ELECTRICAL METHODES AND SYSTEM

28.2

Types of Lighting Fixture and Receptacle The number of different types of lighting fixture used in an area shall be restricted as follows to simplify maintenance work: For outdoor area lighting Mercury vapor lamp Fluorescent lamp For street lighting Mercury vapor lamp For emergency lighting Fluorescent lamp Incandescent lamp : : 20 W, 40 W (20 W x 2) 100 W : 400 W, 250 W : : 70 W, 100 W, 150 W, 250 W, 400 W 20 W, 40 W (20 W x 2)

For convenience receptacle (outdoor use): 15 A, 2 poles + 1 ground Lighting fixtures in outdoor locations shall be equipped with a gasketed glove, reflector and guard. Mercury vapor lamps shall be a high power factor type. Fluorescent lamps shall have a high power factor and rapid start type ballast. All incandescent fixtures shall be a screw-in type. Lighting fixtures in hazardous area shall be suitable type as per applicable codes and standards for each classified area. 28.3 Emergency Lighting Emergency lighting shall be fluorescent type fixtures, shall be provided in outdoor areas to permit safe movement of personnel in normal operating areas during power outages. Approximately 10 % of the total number of lighting fixtures in the process and important utility areas such as around stage of towers, generator and air compressor shall be provided as emergency lighting. Emergency lighting shall not be required at operation vessels and tanks. Emergency lighting for buildings shall be provided in the plant control rooms, substations, generator shelter, HVAC panel and mechanical rooms, workshops, laboratories, and escape exit light at all manned buildings.

CONFIDENTIAL

MULTI PURPOSE REACTOR PLANT PROJECT Discipline Code: EL Contract Job No.: 002/SP/EP7020/08-S0 Project spec. Title : Doc. No.: 900-SPE-5001 Page: Rev.A 30 of 30

ELECTRICAL METHODES AND SYSTEM

Power for emergency lighting shall be supplied from distribution line backed up by an emergency diesel generator. There shall be separate distribution panels fed from the emergency generator. The emergency lighting fixtures inside plant control rooms, substations and generator shelter shall be provided with self battery pack for 30 minutes operation.

28.4

Receptacles, Welding Outlet Convenience receptacles 15A, 230 V, two poles (phase and neutral) + Earth shall be located so that any point in the plant areas where repairs, adjustment, or inspections may be made can reach nearest receptacle with a 30m extension cord. The plug for convenience receptacles shall be supplied at the rate of 1 piece per 10 receptacles. Convenience receptacles shall be installed at 1 meter above grade or floor. All convenience receptacles and plugs shall be suitable for the area classification. Welding Outlets, 380V, 3 phases, 63A, 3 poles + Earth shall be provided in process and utility areas where welding is performed on the basis of 50m extension cord. Power supply to welding outlets shall be distributed from LV MCC in substations.

28.5

Illumination Levels The lighting system shall be designed to provide minimum average maintained (in service) horizontal lighting illuminance requirement as per API 540. Lighting intensities are measured at 1 m above floor level. A maintenance factor of 0.8 is used to calculate these intensities.

29.

CATHODIC PROTECTION Design, material, installation, testing of cathodic protection system, in general shall be as per the recommendation of National Association of Corrosion Engineers (NACE) RP-01-69, and National Electrical Code (NEC) NFPA-70. The detailed design of cathodic protection is covered in Specification Doc. No. 900-SPE5010.

CONFIDENTIAL

You might also like

- BAFOKENG RASIMONE PLATINUM MINE STYLDRIFT MERENSKY PH1 ELECTRICAL DESIGNDocument20 pagesBAFOKENG RASIMONE PLATINUM MINE STYLDRIFT MERENSKY PH1 ELECTRICAL DESIGNNghia Huynh NgocNo ratings yet

- 8942V 00 CN 16 12 007 1 SDocument23 pages8942V 00 CN 16 12 007 1 SAshwin SevariaNo ratings yet

- Sizing Calculation of Generator Step up TransformerDocument3 pagesSizing Calculation of Generator Step up TransformerMadhabNo ratings yet

- S-05-25 Generator Step-Up Transformer DataShts R0 NDA1Document20 pagesS-05-25 Generator Step-Up Transformer DataShts R0 NDA1selapNo ratings yet

- Work-Report: Guideline For Dimensioning of LV-CablesDocument13 pagesWork-Report: Guideline For Dimensioning of LV-CablesahmedNo ratings yet

- Calculating transformer loss cost ratesDocument3 pagesCalculating transformer loss cost ratesRatana KemNo ratings yet

- 11 KV MV Board.Document10 pages11 KV MV Board.costea0028No ratings yet

- Persian Gulf Bid Boland Gas Treating Project Earth Resistance CalculationDocument24 pagesPersian Gulf Bid Boland Gas Treating Project Earth Resistance Calculationsivasan10006098No ratings yet

- NGR Technical InformationDocument6 pagesNGR Technical InformationPrabakar PNo ratings yet

- LightingDocument13 pagesLightingDanang Tri PermadiNo ratings yet

- DG Set - Rev 0Document30 pagesDG Set - Rev 0jhakg_169712275No ratings yet

- S Gen Lightning 00Document15 pagesS Gen Lightning 00raviaggrawalla8727No ratings yet

- 1.0 Power System StudiesDocument7 pages1.0 Power System StudiesL Rahman AliffiantoNo ratings yet

- Calculate Voltage Dip of DG During Motor StartingDocument1 pageCalculate Voltage Dip of DG During Motor StartingshivaramNo ratings yet

- Techint Trainee Manual Hazardous Area ClassificationDocument7 pagesTechint Trainee Manual Hazardous Area ClassificationYogesh MittalNo ratings yet

- Pear Exe Kqks Ele Cal 0002 - Ac Ups and Battery Sizing - RevdDocument47 pagesPear Exe Kqks Ele Cal 0002 - Ac Ups and Battery Sizing - Revdazhar azharNo ratings yet

- WP03-MV Switchgear For Mining Applications-V2Document20 pagesWP03-MV Switchgear For Mining Applications-V2Juan TobiasNo ratings yet

- DBNPP MDM1 ASYYY 07 342001 0001 - Rev03Document31 pagesDBNPP MDM1 ASYYY 07 342001 0001 - Rev03Krishnan KrishNo ratings yet

- Overcurrent Protective Device Coordination StudyDocument3 pagesOvercurrent Protective Device Coordination StudySankalp TiwariNo ratings yet

- Etap - Spel InterfaceDocument9 pagesEtap - Spel Interfacemiguelgg78No ratings yet

- S LV SWG Vip - 00Document35 pagesS LV SWG Vip - 00afsar.erNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument10 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Busducts: Low and Medium VoltageDocument14 pagesBusducts: Low and Medium VoltagesaturasatuNo ratings yet

- Ocl Ele Main SLD 1-11-2017 Main SLDDocument1 pageOcl Ele Main SLD 1-11-2017 Main SLDSanjay SahulNo ratings yet

- Lightning Protection Calculations New BuildingsDocument22 pagesLightning Protection Calculations New Buildingsimri ssNo ratings yet

- Item 06a p1916 0657 4004 Calculation Note Short Circuit Currents - C IfaDocument42 pagesItem 06a p1916 0657 4004 Calculation Note Short Circuit Currents - C Ifaapi-3704641100% (2)

- Saudi Electricity Company DC Short Circuit Calculations Al Dhahiyah 380/115kV BSPDocument4 pagesSaudi Electricity Company DC Short Circuit Calculations Al Dhahiyah 380/115kV BSPSomnath DasNo ratings yet

- Earthing Transformer Sizing Rev 00Document4 pagesEarthing Transformer Sizing Rev 00Ahmed Saber0% (1)

- Power Systems Study Specifications XXXDocument8 pagesPower Systems Study Specifications XXXharmlesdragonNo ratings yet

- Lightning Protection System Calculation - Section-1: Owner ContractorDocument12 pagesLightning Protection System Calculation - Section-1: Owner ContractorabdelhalimNo ratings yet

- Calculation of Non Linear Resistor (Al Hassa Housing 115Kv/13.8Kv S/S)Document7 pagesCalculation of Non Linear Resistor (Al Hassa Housing 115Kv/13.8Kv S/S)vthiyagainNo ratings yet

- Abb GisDocument17 pagesAbb GisluangkokNo ratings yet

- Transformer SizingDocument15 pagesTransformer SizingRaj100% (1)

- NGR - Ohm Calc Trafo 5MVA-20kVDocument6 pagesNGR - Ohm Calc Trafo 5MVA-20kVbarukomkssNo ratings yet

- Study Report - GLS FoilDocument64 pagesStudy Report - GLS FoilNeeraj SinghNo ratings yet

- Relay Coordination Preliminary Report Draft-BDocument4 pagesRelay Coordination Preliminary Report Draft-Bramesh1950No ratings yet

- Optimal Load Scheduling (NEC)Document26 pagesOptimal Load Scheduling (NEC)Rudanek100% (1)

- Saudi Aramco 2616 document analysisDocument290 pagesSaudi Aramco 2616 document analysisbillNo ratings yet

- Data Sheet For Power TransformerDocument3 pagesData Sheet For Power TransformerNakkolopNo ratings yet

- Battery Sizing 3 Trafo (Latest)Document20 pagesBattery Sizing 3 Trafo (Latest)jm.mankavil6230No ratings yet

- CP652 AL DHAKHIRA TREATMENT WORKS ELECTRICAL DESIGNDocument30 pagesCP652 AL DHAKHIRA TREATMENT WORKS ELECTRICAL DESIGNedwin fernandez100% (1)

- 1.1 kV XLPE Power Cable Technical Data SheetDocument1 page1.1 kV XLPE Power Cable Technical Data SheetgallantprakashNo ratings yet

- Maximum Power Point Tracking Powered Solar PV Grid Integrated System Using DSTATCOMDocument8 pagesMaximum Power Point Tracking Powered Solar PV Grid Integrated System Using DSTATCOMIJRASETPublicationsNo ratings yet

- Resume Sabir MoiduDocument9 pagesResume Sabir MoiduSABIRNo ratings yet

- Cable HV Report PDFDocument8 pagesCable HV Report PDFJayson PatrickNo ratings yet

- Solar Power Station Design and CalculationsDocument4 pagesSolar Power Station Design and CalculationsAhmed waleedNo ratings yet

- VP-THI-QG59-130 Data Sheet For Main Motor (QG3&4) Rev.C2Document12 pagesVP-THI-QG59-130 Data Sheet For Main Motor (QG3&4) Rev.C2umeshNo ratings yet

- D000-EL-701 Rev 4Document19 pagesD000-EL-701 Rev 4Sardar PerdawoodNo ratings yet

- 44ac2700-00-E.05-0005-A4 - DC Ups SizingDocument14 pages44ac2700-00-E.05-0005-A4 - DC Ups SizingSatrajit BanerjeeNo ratings yet

- MV Cables Sizing Verification Rev 07Document19 pagesMV Cables Sizing Verification Rev 07Ahmed SaberNo ratings yet

- 10.SEC - Standards For The Connection of Small Scale Solar PV - v3 - CleanDocument44 pages10.SEC - Standards For The Connection of Small Scale Solar PV - v3 - CleanThabet Al-AlamiNo ratings yet

- DP16004 YT10 90ZEN 140115 Elec - Power - Cable Sizing Calculation - Rev P1Document26 pagesDP16004 YT10 90ZEN 140115 Elec - Power - Cable Sizing Calculation - Rev P1rahul.srivastavaNo ratings yet

- Motor StartingDocument16 pagesMotor StartingBabar SaleemNo ratings yet

- Variable Shunt ReactorsDocument8 pagesVariable Shunt ReactorsAdeniji OlusegunNo ratings yet

- Etap ExampleDocument2 pagesEtap Examplerobertovm2002No ratings yet

- Power transmission network 220kV and above in IndiaDocument1 pagePower transmission network 220kV and above in IndiaBarnidhar Singh0% (1)

- 12 Electrical Design Basis PDFDocument32 pages12 Electrical Design Basis PDFKatamaneni Koteswararao78% (37)

- PTT BVW#7 Compressor Station Electrical Design ManualDocument20 pagesPTT BVW#7 Compressor Station Electrical Design Manualgamron100% (2)

- 3technical Specifications - Part-II - Volume IDocument53 pages3technical Specifications - Part-II - Volume IBright IndiaNo ratings yet

- KLM PROJECT STANDARDS and SPECIFICATIONS Offshore Elecrical Design Well Platform Rev01Document6 pagesKLM PROJECT STANDARDS and SPECIFICATIONS Offshore Elecrical Design Well Platform Rev01manicheNo ratings yet

- Basic Plumbing PDFDocument8 pagesBasic Plumbing PDFSamuel YudelzonNo ratings yet

- Basic Plumbing PDFDocument8 pagesBasic Plumbing PDFSamuel YudelzonNo ratings yet

- 1 - FYFE Company ProfileDocument18 pages1 - FYFE Company Profileyoi_123No ratings yet

- PlumbingDocument256 pagesPlumbingyoi_123No ratings yet

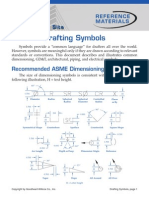

- Autocad SymbolsDocument8 pagesAutocad SymbolsSenchaa100% (1)

- G NielmenDocument1 pageG Nielmenyoi_123No ratings yet

- Pig LaunchingDocument2 pagesPig LaunchingChinonso OnuoraNo ratings yet

- Company Profile 2009Document16 pagesCompany Profile 2009yoi_123No ratings yet

- Ertas & JonesDocument1 pageErtas & Jonesyoi_123No ratings yet

- 2 - Tyfo Fyfe Fibrwrap Indonesia Project List - Okt.2013Document8 pages2 - Tyfo Fyfe Fibrwrap Indonesia Project List - Okt.2013yoi_123No ratings yet

- Concurrent Design & ICT 1990 - 2000: Perangkat Lunak Drawing Modeling Messing Calculation Simulation - Data BaseDocument1 pageConcurrent Design & ICT 1990 - 2000: Perangkat Lunak Drawing Modeling Messing Calculation Simulation - Data Baseyoi_123No ratings yet

- Offshore Structures - Analysis and Design by Dr.S.nallayarasuDocument115 pagesOffshore Structures - Analysis and Design by Dr.S.nallayarasumariusz19781103100% (9)

- A. Perkemb Engineering Design - 1Document1 pageA. Perkemb Engineering Design - 1yoi_123No ratings yet

- Process Engineering Activity SequenceDocument1 pageProcess Engineering Activity Sequenceyoi_123100% (1)

- Typical Activities Sequence OutlineDocument1 pageTypical Activities Sequence Outlineyoi_123No ratings yet

- Log Book Presentasi RevisiDocument72 pagesLog Book Presentasi Revisiyoi_123No ratings yet

- Pressure Drop Calculation Sheet: A4 K D 2.8257 7.149 ReDocument1 pagePressure Drop Calculation Sheet: A4 K D 2.8257 7.149 Reyoi_123No ratings yet

- Typical Engineering NetworkDocument1 pageTypical Engineering Networkyoi_123No ratings yet

- Field+Inspection+Report HydrotestDocument36 pagesField+Inspection+Report Hydrotestyoi_123No ratings yet

- JF VerticalFirePumps E00636 (1) Brosur From Vendor BCUDocument6 pagesJF VerticalFirePumps E00636 (1) Brosur From Vendor BCUyoi_123No ratings yet

- Engineering Work Brekdown For Typical Process Plant ProjectDocument2 pagesEngineering Work Brekdown For Typical Process Plant Projectyoi_123No ratings yet

- Jadwal Optimalisasi Depo Plumpang PertaminaDocument1 pageJadwal Optimalisasi Depo Plumpang Pertaminayoi_123No ratings yet

- Proses Umum AmoniakDocument22 pagesProses Umum Amoniakyoi_123No ratings yet

- Inergen Fire Extinghusing Concentration 40 %Document7 pagesInergen Fire Extinghusing Concentration 40 %yoi_123No ratings yet

- Air Compressor SpecDocument11 pagesAir Compressor Specyoi_123No ratings yet

- JF VerticalFirePumps E00636 (1) Brosur From Vendor BCUDocument6 pagesJF VerticalFirePumps E00636 (1) Brosur From Vendor BCUyoi_123No ratings yet

- Blasting and Painting Procedure - 1Document6 pagesBlasting and Painting Procedure - 1Azrul Rais64% (11)

- Manual Autodesk Plant 3D English PDFDocument592 pagesManual Autodesk Plant 3D English PDFjlvega18100% (7)

- Intro To Plant Design 2012 Review AnswersDocument42 pagesIntro To Plant Design 2012 Review Answersyoi_123No ratings yet

- CH340G USB To UART Interface DatasheetDocument3 pagesCH340G USB To UART Interface DatasheetDavid MoodyNo ratings yet

- Service Manual: Hcd-Bx6Av/Dx6AvDocument54 pagesService Manual: Hcd-Bx6Av/Dx6AvchuftaNo ratings yet

- Module 8 Three Phase Systems v3Document43 pagesModule 8 Three Phase Systems v3Pao CastillonNo ratings yet

- Ost ReportDocument23 pagesOst ReportPratik Chourasia100% (2)

- Head TripDocument15 pagesHead TripAnonymous gQHmr3tUmNo ratings yet

- Man3000 InstallationDocument47 pagesMan3000 InstallationRicardo Garrancho50% (2)

- QSC RMX1450 PDFDocument7 pagesQSC RMX1450 PDFJohnny Tenezaca DuarteNo ratings yet

- 9702 m16 QP 42 PDFDocument24 pages9702 m16 QP 42 PDFSeong Hun LeeNo ratings yet

- Operations ResearchDocument37 pagesOperations ResearchShashank BadkulNo ratings yet

- APG-83 Vs APG-80Document8 pagesAPG-83 Vs APG-80David Vương100% (2)

- 1985 D11 Hitachi Power MOSFET Data BookDocument362 pages1985 D11 Hitachi Power MOSFET Data BookTodorosss Jj100% (1)

- Constant Voltage Power Supply & Constant CurrentDocument2 pagesConstant Voltage Power Supply & Constant CurrentJake BrooksNo ratings yet

- Users Manual Mcs-51Document28 pagesUsers Manual Mcs-51Subkhan KholiqiNo ratings yet

- Hafizhul Ayyasi Khairullah English Journal on Voltage Flicker DetectionDocument4 pagesHafizhul Ayyasi Khairullah English Journal on Voltage Flicker DetectionYoshiro KitetsuNo ratings yet

- Types of Electric CircuitDocument14 pagesTypes of Electric CircuitKing LeonidasNo ratings yet

- DS3231Document6 pagesDS3231Doğu KayaNo ratings yet

- Model 5000 User ManualDocument12 pagesModel 5000 User Manualdonilvai limaNo ratings yet

- Geoeel Manual Export Rev GDocument318 pagesGeoeel Manual Export Rev GJoshuaOrieroNo ratings yet

- Waltenhofen PendulumDocument3 pagesWaltenhofen PendulumhayiyNo ratings yet

- Transfero T EN Low PDFDocument12 pagesTransfero T EN Low PDFLucas Penalva Costa SerraNo ratings yet

- Catalogue ContentDocument16 pagesCatalogue ContentAnumita DixitNo ratings yet

- LabVIEW 8.5 Basics IDocument498 pagesLabVIEW 8.5 Basics ICarlos Andres Mendoza ChacónNo ratings yet

- PGH FC-FB-S7CP 76Document264 pagesPGH FC-FB-S7CP 76Ismael GraciaNo ratings yet

- Sightline Product OverviewDocument18 pagesSightline Product OverviewStanley Ochieng' OumaNo ratings yet

- Quad Active BridgeDocument7 pagesQuad Active BridgeVishal MjNo ratings yet

- 385C Waw1-Up PDFDocument4 pages385C Waw1-Up PDFJUNA RUSANDI SNo ratings yet

- IP44, IP55, and IP65 junction boxes guideDocument5 pagesIP44, IP55, and IP65 junction boxes guideRUPESH KUMARNo ratings yet

- Realistic ConstraintsDocument4 pagesRealistic ConstraintscommunicationridersNo ratings yet

- Thermal Methods of AnalysisDocument76 pagesThermal Methods of AnalysisAzuriak1100% (2)

- Turn Over LetterDocument3 pagesTurn Over LetterJake MonteroNo ratings yet