Professional Documents

Culture Documents

3.2 Scada General

Uploaded by

Anjaneyulu BodhanapuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3.2 Scada General

Uploaded by

Anjaneyulu BodhanapuCopyright:

Available Formats

Electronics Division

SCADA

SYSTEM CONCEPTS & PROJECTS

Electronics Division

SCADA

SUPERVISORY CONTROL AND DATA ACQUISITION SYSTEM

A SCADA system is an automation system which is used to collect data, monitor performance and control a plant or equipment in a wide range of applications like: Electrical power distribution and generation plants Water management systems Manufacturing systems

Electronics Division

SCADA

A typical Water SCADA application would be to monitor water levels at various water sources like reservoirs and tanks and when the water level exceeds a preset threshold, activate the system of pumps to move water to tanks with low water levels.

Electronics Division

SCADA

In BHEL-EDN, we provide SCADA systems for the electrical substations and switchyards to monitor and control the station equipment. SCADA virtually the brain of a Substation Automation System

Electronics Division

SCADA

The main components of a SCADA system are: Remote Terminal Units (RTUs) Control Room Computer (HMI) Communication equipment

Electronics Division

SCADA Configuration

To RCC on IEC 870-5-101

Printers

HMI view node Station HMI Station HMI Disturbance Viewer Gateway

GPS system Ethernet network Switch

FO Connection

Redundant Ethernet Bus Switch

FO Connection

Switch

FO Connection

Numerical Protection Relay

Bay Control

Numerical Protection Relay

Bay Control

Numerical Protection Relay

Bay Control

Field Signals

Field Signals

Field Signals

Electronics Division

Sub systems

Control and monitoring system for individual Bays Human Machine Interface Ethernet LAN Peripherals Printers Display units Keyboard Mouse Interface system to Numerical relays Gateway for remote communication with Remote Control Centre (RCC)

Electronics Division

SCADA Configuration

REMOTE maxVUE

maxSTATIONS

ENGINEERS STATION / maxSTORIAN

Redundant 100 Mbps maxNET

maxLINK

REMOTE TERMINAL UNITS (RTUs) External Systems Server less Configuration Scalableas large as required

Electronics Division

HMI ...

Operator Stations maxVUE Workbench

maxSTATIONS Generic name for .

Engineering Station

maxSTORIAN Remote maxVUE

maxLINKS

maxNET

100 Mbps (full duplex)

maxDNA GT Controls

PLCs Numerical Relays External systems

Electronics Division

REMOTE TERMINAL UNIT

The Remote Terminal Units may consist of a programmable logic converter (PLC) or dedicated hardware unit with its CPU, Analog Input modules, Digital Input/ Output Modules. The RTUs and PLCs are responsible for data collection such as meter readings, equipment status etc and communicate back to the HMI Computer system.

Electronics Division

REMOTE TERMINAL UNIT

The RTU operations include Scanning of inputs at a fast rate Processing such as change of state Time stamping of changes Storage of data awaiting polling from the SCADA master Some RTUs can initiate reporting to the SCADA master The RTU may do some alarm processing RTU respond to the simple request to read complete data Complex control function to be executed

Electronics Division

REMOTE TERMINAL UNIT

SCADA systems monitor and make slight changes to function optimally. SCADA systems are considered closed loop systems and run with relatively little human intervention The RTUs are usually set to specific requirements, however, most RTU allow human intervention, for instance, in a factory setting, the RTU might control the setting of a conveyer belt, and the speed can be changed or overridden at any time by human intervention for optimum performance In addition, any changes or errors are usually automatically logged for and/or displayed.

Electronics Division

REMOTE TERMINAL UNIT

SCADA systems implement a distributed database - tag database, which contains data elements called tags or points. A point represents a single input or output value monitored or controlled by the system. Points can be either "hard" or "soft". A hard point is representative of an actual input or output connected to the system, while a soft point represents the result of logic and math operations applied to other hard and soft points. Point values are normally stored as value-timestamp combinations; the value and the timestamp when the value was recorded or calculated. A series of value-timestamp combinations is the history of that point. It's also common to store additional information tags such as: path to field device and alarming information.

Electronics Division

REMOTE TERMINAL UNIT

Data acquisition and display of switchyard equipment for Status Alarms Values voltage frequency real power reactive power current Independent bay control unit for each bay Detection and reporting of alarms Sequence of events with 1 ms resolution Control of circuit breakers, isolators, tap changer

Electronics Division

REMOTE TERMINAL UNIT

Software interlocking to ensure safe operation of equipments Select before execute Bypass interlocks whenever required Command supervision

Electronics Division

System introduction

Distributed Processing Unit (DPU)

I/O Bus 8 pack rack Connector (DPU and I/O) Field 48V Field 24V System 24V

I/O Bus

Connectors

Eight-pack rack

I/O Modules

Remote Terminal Unit (RTU) Panels

D P U D P U I O

I O I O I O

I O I O I O

I O I O I O

I/O signals

Electronics Division

RTU Overview

Controller, Input/Output, Power Supply, Network Interfaces, Field Terminations RTU Components : Distributed Processing Unit ( maxDPU) I/O Modules (maxPAC) Network Switches Power Supply Rack

Electronics Division

RTU Overview

maxPAC Racks: contains I/O back planes and Edge connectors for modules connectors for 24 V logic and 24/48 V field power supply ribbon cable connectors to interconnect I/O bus of different chassis

Electronics Division

REMOTE TERMINAL UNIT

CPU unit Digital Input Module Digital output module Analog input module

Electronics Division

Distributed Processing Unit

32 Bit Intel Processor Redundant / Stand-alone modes Windows CE.net Operating System Dual ethernet ports, to maxNET

Dual 100 Mbps highway connections for high speed NO intermediate servers / communication modules Network hardened to withstand problems Optional IRIG input for satellite time synchronization High temperature tolerance and low power - No fans, no batteries for low maintenance, high reliability

Electronics Division

Distributed Processing Unit

128 MByte RAM 64 MByte Removable Compact Flash Non-volatile FLASH memory maintains the control strategy configuration even if power is lost 8,500 function blocks for high capacity complex control Event Reporting to 1 msec Resolution User configurable program execution time between 10 msec - 500 msec 10,000 event queue Directly accessible from all maxSTATIONS Supports off-line simulation and testing

Electronics Division

ANALOG INPUT MODULE

Salient Points of Analog Input Modules:

AI (IOP301, IOP302, IOP305) 16 Channels V/I 4 - 20 mA or 0 - 2.4 V 15 bit + sign Bit, 0.1% Accuracy of full scale Scan time: 100 ms (isolated) Variants - 3 wire RTD( IOP303), TC(IOP304)

Electronics Division

DIGITAL INPUT MODULE

Salient Points of Digital Input Modules: DI (IOP330, IOP331, IOP332, IOP333, IOP334) 16 isolated or non isolated channels per module 24/48 V DC, 120/240 V AC/DC

Electronics Division

DIGITAL OUTPUT MODULE

Salient Points of Digital Output Modules: DO (IOP350, IOP351) 16 Channels per module Individual Red LEDs provide output indication for each channel Green LED for system power and healthy communication

Electronics Division

DPU Redundancy

maxNET

Parallel I/O Bus

Primary and secondary are selected through configuration Fatal diagnostic error causes transfer in <3 msec Secondary DPU configuration can be modified and transfer initiated for testing purposes

Electronics Division

I/O Redundancy

I/O Can be Redundant ...

I/O

I/O I/O I/O

I/O

Redundant DPU Bus

I/O

... And Shared

Electronics Division

A SCADA system reports to human operators over a specialized computer that is variously called a master station - HMI (HumanMachine Interface) The HMI displays this information in an easily understood graphics form, archives the data received, transmits alarms and permits operator control as required. The HMI is a PC system running powerful graphic and alarm software programs. The collected data is usually viewed on one or more SCADA Host computers located at the central or master site. SCADA applications can monitor and control hundreds to hundreds of thousands of I/O points.

HMI Functions

Electronics Division

Software

System software: Application software Engineering & configuration Operating system software: Windows 2000/ Windows XP

Electronics Division

HMI Features

All operation from maxSTATIONS Alarms, SOE part of maxVUE display All maxSTATIONS, desk-top placed No hardwired back-up Large Video Screen (LVS) for display Typical Typical Modern ModernControl Controlroom room

Electronics Division

HMI

Single Line diagram Displays Control dialogues Interlocking logic station wide System status Annunciation (audio ,visual) Alarm list Event List Trending Reports Gateway communication with RCC using IEC 870 -5-101 protocol

Electronics Division

Electronics Division

Alarm Display

Abnormal conditions generate alarm Associate occurrence of alarm to preassigned picture Assignment of priorities for each point Segregation of alarm summary pages Alarm summary

Electronics Division

Electronics Division

Reports

Trend reports : Daily, monthly, semi-annually, yearly for mean and peak values Historical Reports : Automatic (daily at 15 min intervals, weekly, monthly, yearly) On demand By occurrence of pre-defined events

Electronics Division

Reports

Printing of Reports : Daily voltage and frequency curves for 24 hours Weekly trend curves for real and derived analog values Max and min values ,frequency of occurrence and duration of max and min values for each analog parameter in a 24 hour period Number of operations of breaker, date time indications Equipment operation details shift wise during 24 hours Details of MW, MVAR, current, etc for specified time period on demand Printout of system frequency and average frequency

Electronics Division

Reports

Fill-in-the-box type report configuration with different templates and formats Easy-to-use dialogs for report scheduling

Clear reports to printers and Monitors

Electronics Division

Trends

Real time Trends : Continuous updating of parameters Curve diagrams or tabular form Adjustable update intervals Historical Trends: Data retrieval by specifying the time /date

Electronics Division

Real Time and History Trending

Flexible trends embedded into schematics or as stand-alone pages See the current situation and explore history - seamless integration maxSTORIAN Process History

Up to eight points in one trend Change trended points during run-time Easy-to-use time handling for browsing the history

Electronics Division

maxLINK

maxNET

External Systems

Interface to external systems: PLC networks, Numerical relays LDC Interface Supports multiple simultaneous communication protocols Supports data transfer from other systems and networks Provision in DPUs also All data available to maxSTATIONS Windows-XP based

Electronics Division

Communication Networks

WITH REDUNDANCY Between the RTU in the field and the HMI system in the Control Room SCADA communications can employ a diverse range of both wired (lease line, dialup line, fiber, cable) and wireless media (licensed radio, cellular, WLANor satellite) Communication within a plant will be by data cable, wire or fiberoptic, while regional systems most commonly utilize radio Failure of one highway does not affect operation of other. Fibre optic communication

Electronics Division

maxNET Communications Network

Proven Industry Standard, Switched Fast Ethernet Ultra high speed (100 Mbps) redundant network Multiple simultaneous communication Utilizes intelligent switching No collisions occur. Traffic is never stopped

Electronics Division

Full Duplex Communications

maxSTATIONS

Effectively doubles the communications bandwidth

Switched Hub Switched Hub

One DPU can send alarm information while.. another DPU is receiving operator commands

DPUs

Electronics Division

maxNET

100 Mbps Switched Ethernet

Host Computer and Remote Workstations

100 Mbps Full Duplex switch to switch 100 Mbps Full Duplex drops

D P U

D P U

A I

D I

Full duplex, high speed communications between maxSTATIONS Modem hubs. All interfaces, links and Optical Repeater switches are redundant All stations are directly HMI Region connected Control Region Flexible topology Uses industry standard Parallel I/O Bus hardware Serial Interface Capacity greatly exceeds (MODBUS ) system maximum loading

Plant Management Network

FDX D P U A O D O

Remote MAXStation

Process I/O Signals

Electronics Division

Wireless SCADA

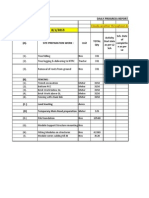

Wireless SCADA is required in those applications when wired communications to the remote site is prohibitively expensive or it is too time consuming to construct wired communications. In particular types of industry like Oil & Gas or Water & Wastewater, wireless SCADA is often the only solution due to the remoteness of the sites. Wireless SCADA systems can be built on private radio (licensed or unlicensed), cellular or satellite communications; each of these has its unique set of characteristics as given in the Table.

Electronics Division

Wireless SCADA

Private Licensed Typical Range 30 -60 Private Mobile License-free 30 cell coverage No Fast 9600 Yes Yes No Fast 1200 to 1.2M Yes Yes Satellite

Government Approval Yes No Setup Time Moderate Fast 9600 Data Rate (kbps) 9600 19,200 Monthly Rates? No No Not RTU/RF integration ? Yes usually

Electronics Division

System Diagnosis

DIAGNOSTICS Provided for Controller I/O cards Communication system

Electronics Division

SCADA System

ADVANTAGES:

On line help Ease of operation Sharing of information Safety of equipment Interlocking conditions Prevent unsafe operating conditions

Electronics Division

SCADA System

Other benefits SCADA Systems provide: Reduces operational costs Provides immediate knowledge of system performance Improves system efficiency and performance Increases equipment life Reduces costly repairs Reduces number of man-hours (labor costs) required for troubleshooting or service Frees up personnel for other important tasks Facilitates compliance with regulatory agencies through automated report generating

Electronics Division

BHEL Experience

Power plant switchyard , transmission sub stations at 110, 132, 220 , 400KV level are controlled and monitored from the switchyard / central control room

Electronics Division

BHEL EXPERIENCE

SCADA FOR POWER PLANT SWITCHYARD /SUBSTATION SUPPLIED: Kovilkalappal CCPP 110KV switchyard Perungulam CCPP 110KV switchyard Baiji , Iraq GTPP 400KV switchyard Dhuvaran CCPP 132 KV switchyard Kuttalam CCPP 110KV switchyard

Electronics Division

BHEL EXPERIENCE

SCADA FOR POWER PLANT SWITCHYARD /SUBSTATION SUPPLIED: Vindyachal STPP 400KV switchyard Alamathy 400KV/230KV/110KV substation Korba East TPS 220KV switchyard Bellary TPS 220 /400 KV switchyard Mejia TPS 220KV switchyard Chandrapura 220 KV switchyard Kutch Lignite TPS 220KV switchyard

Electronics Division

Substation SCADA System for 2X250MW VSTPP Stage 3

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Computer Network Lab ManualDocument51 pagesComputer Network Lab ManualR -BrotHERsNo ratings yet

- Daily Progress ReportDocument63 pagesDaily Progress ReportAnjaneyulu BodhanapuNo ratings yet

- Daily Progress ReportDocument63 pagesDaily Progress ReportAnjaneyulu BodhanapuNo ratings yet

- Daily Progress ReportDocument63 pagesDaily Progress ReportAnjaneyulu BodhanapuNo ratings yet

- Esquematico YEZZ 5EDocument32 pagesEsquematico YEZZ 5EJose LunarNo ratings yet

- L2VPN ArchitecturesDocument651 pagesL2VPN Architecturestudocris100% (3)

- Mobile Telephone Number Codes For IndiaDocument17 pagesMobile Telephone Number Codes For IndiaPalaniNo ratings yet

- NTPC Unchahar Schedule Bhel Format-1Document3 pagesNTPC Unchahar Schedule Bhel Format-1Anjaneyulu Bodhanapu100% (1)

- Powerwave Product CatalogDocument531 pagesPowerwave Product CatalogPedro SpenoulisNo ratings yet

- Ece Gate Paper 20 AnswersDocument13 pagesEce Gate Paper 20 AnswersAnjaneyulu BodhanapuNo ratings yet

- Gate Forum Ece Paper 24Document16 pagesGate Forum Ece Paper 24Anjaneyulu BodhanapuNo ratings yet

- HappyDocument1 pageHappyAnjaneyulu BodhanapuNo ratings yet

- Ece Gate Paper 19 AnswersDocument13 pagesEce Gate Paper 19 AnswersAnjaneyulu BodhanapuNo ratings yet

- Gateforum Ece Question Paper-25Document16 pagesGateforum Ece Question Paper-25Anjaneyulu Bodhanapu100% (1)

- Gate Ece Paper 19Document14 pagesGate Ece Paper 19Anjaneyulu BodhanapuNo ratings yet

- Targate'16: Test Id: 161273Document20 pagesTargate'16: Test Id: 161273TC ChandrakalaNo ratings yet

- Ece Gate Paper 21 AnswersDocument14 pagesEce Gate Paper 21 AnswersAnjaneyulu BodhanapuNo ratings yet

- Ece Gate Paper 22 AnswersDocument13 pagesEce Gate Paper 22 AnswersAnjaneyulu BodhanapuNo ratings yet

- Ece Gate Paper 20Document14 pagesEce Gate Paper 20Anjaneyulu BodhanapuNo ratings yet

- Ece Gate Paper 25 AnswersDocument19 pagesEce Gate Paper 25 AnswersAnjaneyulu BodhanapuNo ratings yet

- Gateforum Ece Question PaperDocument17 pagesGateforum Ece Question PaperAnjaneyulu BodhanapuNo ratings yet

- Ece Gate Paper 24 AnswersDocument22 pagesEce Gate Paper 24 AnswersAnjaneyulu BodhanapuNo ratings yet

- Ece Gate Paper 26 AnswersDocument17 pagesEce Gate Paper 26 AnswersAnjaneyulu BodhanapuNo ratings yet

- Gate Ece Paper 21Document15 pagesGate Ece Paper 21Anjaneyulu BodhanapuNo ratings yet

- Ece Gate 22Document12 pagesEce Gate 22Anjaneyulu BodhanapuNo ratings yet

- Isro ScheduleDocument4 pagesIsro ScheduleAnjaneyulu BodhanapuNo ratings yet

- Gate Ece Paper 23Document17 pagesGate Ece Paper 23Anjaneyulu BodhanapuNo ratings yet

- Comments Complaince - Cmcs - 19 08 13-Bhel ReplyDocument1 pageComments Complaince - Cmcs - 19 08 13-Bhel ReplyAnjaneyulu BodhanapuNo ratings yet

- Technical Specifications - Part 9 ExhibitDocument2 pagesTechnical Specifications - Part 9 ExhibitAnjaneyulu BodhanapuNo ratings yet

- IIyr IVsem Linear Integrated Circuits and Applications PDFDocument12 pagesIIyr IVsem Linear Integrated Circuits and Applications PDFShubhamSharmaNo ratings yet

- Icrb - Recruitment of Scientist/Engineer 'SC'Document1 pageIcrb - Recruitment of Scientist/Engineer 'SC'Anjaneyulu BodhanapuNo ratings yet

- Semiconductor NotesDocument6 pagesSemiconductor Notesksb9790No ratings yet

- Road Permit Covering LetterDocument1 pageRoad Permit Covering LetterAnjaneyulu BodhanapuNo ratings yet

- Procedure in SiteDocument1 pageProcedure in SiteAnjaneyulu BodhanapuNo ratings yet

- 330 755 753.1 6.68 15.29 15.25 As Per Iit-K Report (For 1cum) For Trial Mix (0.02cum)Document2 pages330 755 753.1 6.68 15.29 15.25 As Per Iit-K Report (For 1cum) For Trial Mix (0.02cum)Anjaneyulu BodhanapuNo ratings yet

- Current Approches of Wifi Positioning: Robin Henniges, TU-Berlin, 2012Document8 pagesCurrent Approches of Wifi Positioning: Robin Henniges, TU-Berlin, 2012aug2010No ratings yet

- Koforidua Technical University (Ktu) : Waps Networks Training Academy 4 5 November 2022Document71 pagesKoforidua Technical University (Ktu) : Waps Networks Training Academy 4 5 November 2022Rexford AmponsahNo ratings yet

- Mototrbo Dgp8000 Ex Series Atex Radio: Keeping You Safer in The Toughest EnvironmentsDocument4 pagesMototrbo Dgp8000 Ex Series Atex Radio: Keeping You Safer in The Toughest Environmentscrispix2000No ratings yet

- Sharp LC 60le651e LC 60le652e Mk2 PDFDocument124 pagesSharp LC 60le651e LC 60le652e Mk2 PDFKadour CondorNo ratings yet

- RFC 2327 - SDP - Session Description ProtocolDocument84 pagesRFC 2327 - SDP - Session Description ProtocolKyuhyun Mal0% (1)

- IkusiDocument50 pagesIkusigiezthaNo ratings yet

- Coil winding chart for amateur radio antenna constructionDocument2 pagesCoil winding chart for amateur radio antenna constructionDefaultAnomolyNo ratings yet

- ES524CPX00074 - VxRail Installation and Implementation - Classroom - Participant Guide PDFDocument507 pagesES524CPX00074 - VxRail Installation and Implementation - Classroom - Participant Guide PDFSalome MarimbaNo ratings yet

- Ac Lab Manual-srs Ec-491Document92 pagesAc Lab Manual-srs Ec-491ajclutchgodNo ratings yet

- HUNQ2 Working Principle and Signal FlowDocument3 pagesHUNQ2 Working Principle and Signal Flowfrancisco moralesNo ratings yet

- Overview of Cisco 1100 Series Integrated Services RoutersDocument12 pagesOverview of Cisco 1100 Series Integrated Services Routersyesid marroquinNo ratings yet

- Emf Measurements in The Bts Cellular Stations of Vodafone AlbaniaDocument6 pagesEmf Measurements in The Bts Cellular Stations of Vodafone AlbaniawormingNo ratings yet

- OpenScape Personal EditionDocument4 pagesOpenScape Personal EditionKossay Ben AchourNo ratings yet

- BTP-2002NP Feed Button Program Guide V2.0Document3 pagesBTP-2002NP Feed Button Program Guide V2.0Hugo Martínez MooreNo ratings yet

- EQT Router Manual 1v5Document64 pagesEQT Router Manual 1v5Dan CoolNo ratings yet

- Frehiwot Mola PDFDocument76 pagesFrehiwot Mola PDFborisyilNo ratings yet

- Monolithic Amplifier: 50, BroadbandDocument1 pageMonolithic Amplifier: 50, BroadbandElektroninis PastasNo ratings yet

- 215-06268 A0Document186 pages215-06268 A0vamsi6764No ratings yet

- Minikit Plus Quick Start Guide Uk FR SP de It NL PTDocument88 pagesMinikit Plus Quick Start Guide Uk FR SP de It NL PTAdorjani IstvanNo ratings yet

- HV-72QIC HVCAM WIFI Camera Insturctions - For Web BrowserDocument18 pagesHV-72QIC HVCAM WIFI Camera Insturctions - For Web BrowserlowlesNo ratings yet

- Comparison GPS GLONASS Galileo PLNRaju2Document38 pagesComparison GPS GLONASS Galileo PLNRaju2Saurabh SumanNo ratings yet

- 5G AreaysDocument3 pages5G AreaysdrphraoNo ratings yet

- Sure Signal Premium - UK High Level Design v3.0Document80 pagesSure Signal Premium - UK High Level Design v3.0Hector SolarteNo ratings yet

- Technology Overview: Introduction To Digital CertificateDocument10 pagesTechnology Overview: Introduction To Digital CertificateG.m. RajaNo ratings yet

- En DMR Hytera-Dispatch-System 201402111Document6 pagesEn DMR Hytera-Dispatch-System 201402111nonlungomalargoNo ratings yet