Professional Documents

Culture Documents

Vessel Design

Uploaded by

Dinda Naiya AzhariCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vessel Design

Uploaded by

Dinda Naiya AzhariCopyright:

Available Formats

Chapter

Vessels

10

Horizontal Tanks (HT) ....................................................................... 10-3 Vertical Tanks (VT) ............................................................................ 10-8

G3 ICARUS Corporation, 1998.

10-2 ICARUS Reference

ICARUS Corporation, 1998. G3

Chapter 10: Vessels

10-3

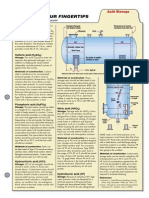

Horizontal Tanks (HT)

Horizontal vessels are commonly used as settling drums, surge tanks, reactors and distillate drums. A settling drum is used for phase separation between two immiscible liquids. The L/D ratio of a settling drum is normally four. A surge tank or surge drum is used to maintain a constant flowrate of liquid to a downstream piece of equipment when the flowrate of liquid from the upstream piece of equipment is fluctuating. The fluctuations in flow rate are absorbed by the surge drum by allowing the liquid level in this drum to rise and fall. Horizontal drums are frequently filled with catalyst and used as reactors. Placing catalyst in horizontal vessels allows shallow bed depths and large cross-sectional areas. A typical example of horizontal vessels being used as reactors is the Claus reactor. A distillate or reflux drum provides space for overhead condensables from a distillation column to separate from vapors. Surge drums and distillate drums are normally vertical. If there is settleable water in the feed to these vessels, however, the vessel is erected with a water pot. The horizontal vessel is a pressure vessel fabricated according to the rules of the specified code (i.e., Section VIII Division 1 of the ASME Code) and erected in the horizontal position. Although the horizontal vessel may be supported by lugs in an open steel structure, the more usual arrangement is for the vessel to be erected at grade and supported by a pair of saddles. Cylindrical, pressure/vacuum, code design and construction, includes heads, single wall (base material, clad/lined), saddles/ lugs, nozzles and manholes.

Description

Type

Multi-wall design for high pressure service with total wall thickness of individual, thin, heat-shrunk cylinders (maximum 2 INCHES [50 MM] thick) heat shrunk, pressure vacuum design and construction according to user-designated design code standard. This item is a horizontal process vessel, the total wall thickness of which is made up of individual cylinders. Each individual cylinder is no more than two inches thick. The composite is made as follows. A cylinder is fabricated with a diameter slightly larger than the innermost cylinder. This cylinder is expanded thermally, slipped over the inner cylinder and as it cools, a tight shrink fit is obtained. This procedure is repeated until the total wall thickness is built up.

Application Symbol: Defines vessel function and related

MULTI WALL

piping/instrumentation model. Default: *blank* blank - Standard continuous process vessel BATCH - Batch process vessel STORAGE - Storage vessel RECVR - Receiver KO - Knock-out drum Shell Material: For clad plate, specify the backing plate material. (Cladding is defined below.) See Chapter 28 for materials. Default: *A 515*. Capacity: Enter either capacity or diameter and length. Diameter: Enter either capacity or diameter and length. Vessel T-T Length: Enter either capacity or diameter and length. Design Press. - Gauge: If pressure and vacuum entered, design is for worst case. Default: *15* PSIG [*100* KPA]. Design Vacuum - Gauge: If pressure and vacuum entered, design is for worst case. Default: pressure. Design Temperature: Default: 650 DEG F [340 DEG C] ferrous material; 250 DEG F [120 DEG C] other material. Operating Temp.: Default: design temperature. Cladding Material: See Chapter 28; for cladding materials.

Continued on next page

G3 ICARUS Corporation, 1998.

10-4 ICARUS Reference

Horizontal Tanks (HT) - continued

Description

Type

MULTI WALL - continued

Manhole Diameter: Max: 48 INCHES [1,200 MM];

Default: *18* INCHES [*450* MM]

Number of Manholes: Default: *1*. % All. for Internals: Specify an allowance for internals as a

percent of basic vessel weight. Default: *0.0*.

Diameter of Drip Leg: Drip leg (boot) diameter and length must

be specified if required.

Length of Drip Leg: Drip leg (boot) diameter and length must be

specified if required.

Base Matl Thickness: Base material thickness including

corrosion allowance.

Corrosion Allowance: Default: 0.125 INCHES [3 MM] for CS,

0.0 for other materials.

Weld Efficiency %: 50 - 100; ASME/JIS codes only, where

allowed for thin wall vessels; Default: Area Basis.

Stress Relief: Default: See Area Design Basis.

CODE - Provide stress relief if code requires YES - Provide stress relief NO - No stress relief required Cladding Thickness: Default: 1.125 INCHES [3 MM] if cladding material is specified; otherwise 0.0. Stiffg Ring Spacing: Default stiffeners designed for vacuum only, enter 0.0 if not required.

Head Type Symbol:

ELLIP - 2:1 ellipsoidal HEMI - Hemispherical TORI - Torispherical (ASME) No. Body Flange Sets: Number of sets (pairs) of body flanges of same diameter as vessel. Diameter Option: Defines desired diameter as ID or OD; Default - see Area Design Basis. OD - Outside diameter ID - Inside diameter

ICARUS Corporation, 1998. G3

Chapter 10: Vessels

Horizontal Tanks (HT) - continued

10-5

Description

Type

Horizontal pressure/vacuum drum. Use minus pressure for vacuum design. The capacity excludes the volume of the heads. If both the vessel dimensions and capacity are specified, the system-calculated capacity must agree with the specified capacity to within plus or minus 10% to avoid an error condition. To secure desired vessel size, specify the diameter and height directly. A value must be specified if vessel diameter and/or vessel height (or length) are not specified. If vessel diameter and height (or length) are specified, the vessel volume is calculated from these dimensions. If only vessel capacity is specified, a straight side length-to-diameter ratio is chosen by the system, considering cost and practicability. (Default ratio is 2:1.)

Application Symbol: Defines vessel function and related

HORIZ-DRUM

piping/instrumentation model. Default: *blank* blank - Standard continuous process vessel BATCH - Batch process vessel STORAGE - Storage vessel RECVR - Receiver KO - Knock-out drum Shell Material: For clad plate, specify the backing plate material. (Cladding is defined below.) See Chapter 28 for materials. Default: *A 515*. Capacity: Enter either capacity or diameter and length. The capacity excludes the volume of the heads. If both the vessel dimensions and capacity are specified, the system-calculated capacity must agree with the specified capacity to within plus or minus 10% to avoid an error condition. To secure desired vessel size, specify the diameter and height directly. A value must be specified if vessel diameter and/or vessel height (or length) are not specified. If vessel diameter and height (or length) are specified, the vessel volume is calculated from these dimensions. If only vessel capacity is specified, a straight side length-to-diameter ratio is chosen by the system, considering cost and practicability. Diameter: Enter either capacity or diameter and length. A value must be specified if vessel capacity is not specified. If both capacity and height (or length) are specified, the diameter is calculated from these values. Vessel T-T Length: Enter either capacity or diameter and length. A value must be specified if vessel capacity is not specified. If both vessel capacity and diameter are specified, the height (or length) is calculated from these values. Design Press. - Gauge: If pressure and vacuum entered, design is for worst case; Default: *15* PSIG [*100* KPA] pressure. Design Vacuum - Gauge: If pressure and vacuum entered, design is for worst case. Default: pressure. Design Temperature: Default: 650 DEG F [340 DEG C] ferrous material; 250 DEG F [120 DEG C] other material.

Continued on next page

G3 ICARUS Corporation, 1998.

10-6 ICARUS Reference

Horizontal Tanks (HT) - continued

Description

Type

HORIZ-DRUM - continued

Operating Temp.: Default: design temperature. The operating

temperature is used in the calculation of piping and insulation thickness. Cladding Material: See Chapter 28 for cladding materials. Manhole Diameter: Max: 48 INCHES [1,200 MM]; Default: *18* INCHES [*450* MM]. Number of Manholes: Default: *1*. % All. for Internals: Specify an allowance for internals as a percent of basic vessel weight. Default: *0.0*. This value adjusts vessel weight and cost accordingly. Diameter of Drip Leg: Drip leg (boot) diameter and length must be specified if required. Length of Drip Leg: Drip leg (boot) diameter and length must be specified if required. Base Material Thickness: Base material thickness including corrosion allowance. Corrosion Allowance: Default: 0.125 INCHES [3 MM] for CS, 0.0 for other materials. Weld Efficiency %: ASME/JIS codes only, where allowed for thin wall vessel; Default: Area Basis. Range: 50 - 100. Stress Relief: Default: See Area Design Basis. CODE - Provide stress relief if code requires YES - Provide stress relief NO - No stress relief required Cladding Thickness: Default: 0.125 INCHES [3 MM] if cladding material is specified, otherwise: 0.0. Stiffg Ring Spacing: Default stiffeners designed for vacuum only, enter 0.0 if not required. Head Type Symbol: If no value is specified, the system selects the torispherical type and calculates its thickness. If the head is thicker than the vessel shell, the system selects the 2:1 ellipsoidal type head thickness. If the head is still thicker than the shell, the system selects the hemispherical type head. ELLIP - 2:1 elliposidal HEMI - Hemispherical TORI - Torispherical (ASME) No. Body Flange Sets: Number of sets (pairs) of body flanges of same diameter as vessel. Diameter Option: Defines desired diameter as ID or OD; Default - see Area Design Basis. OD - Outside diameter ID - Inside diameter

ICARUS Corporation, 1998. G3

Chapter 10: Vessels

Horizontal Tanks (HT) - continued

10-7

Description

Type

Jacketed horizontal pressure/vacuum drum.

Application Symbol: Defines vessel function and related

JACKETED

piping/instrumentation model. Default: *blank* blank - Standard continuous process vessel BATCH - Batch process vessel STORAGE - Storage vessel RECVR - Receiver KO - Knock-out drum Shell Material: For clad plate, specify the backing plate material. See Chapter 28 for materials. Default: *A 515*. Capacity: Enter either capacity or diameter and length. Diameter: Enter either capacity or diameter and length. Vessel T-T Length: Enter either capacity or diameter and length. Design Press. - Gauge: If pressure and vacuum entered, design is for worst case; Default: *15* PSIG [*100* KPA]. Design Vacuum - Gauge: If pressure and vacuum entered, design is for worst case; Default: pressure. Design Temperature: Default: 650 DEG F [340 DEG C] ferrous material; 250 DEG F [120 DEG C] other materials. Operating Temp: Default: design temperature. Cladding Material: See Chapter 28 for materials. Jacket Press. - Gauge: Default: *90* PSIG [*620* KPA]. Jacket Type: Default: *FULL* FULL - Full jacket PIPE - Half-pipe jacket Jacket Material: See Chapter 28 for materials. Default: *CS*. Manhole Diameter: Max: 48 INCHES [1,200]; Default: 18 INCHES [450 MM]. Number of Manholes: Default: *1*. % All. for Internals: Specify an allowance for internals as a percent of basic vessel weight. Default: *0.0*. Diameter of Drip Leg: Drip leg (boot) diameter and length must be specified if required. Length of Drip Leg: Drip leg (boot) diameter and length must be specified if required. Base Matl Thickness: Base material thickness including corrosion allowance. Corrosion Allowance: Default: 0.125 INCHES [3 MM] for CS, 0.0 for other material, double if jacketed. Weld Efficiency %: ASME/JIS codes only, where allowed for thin wall vessels; Default: Area Basis. Range: 50 - 100. Stress Relief: Default: See Area Design Basis. CODE - Provide stress relief if code requires YES - Provide stress relief NO - No stress relief required Cladding Thickness: Default: 0.125 INCHES [3 MM] if cladding material is specified; otherwise: 0.0. Stiffg Ring Spacing: Default stiffeners designed for vacuum only, enter 0.0 if not required.

Head Type Symbol:

ELLIP - 2:1 elliposidal HEMI - Hemispherical TORI - Torispherical (ASME) No. Body Flange Sets: Number of sets (pairs) of body flanges of same diameter as vessel. Diameter Option: Defines desired diameter as ID or OD; Default: See Area Design Basis. OD - Outside diameter ID - Inside diameter

G3 ICARUS Corporation, 1998.

10-8 ICARUS Reference

Vertical Tanks (VT)

Vertical process vessels are typically used as either surge drums or knock out drums. When used as surge drums, they act like shock absorbers, maintaining a constant flowrate of liquid out of the vessel regardless of the flowrate into it. If liquid flows in faster than the constant rate it flows out, the vessel fills with liquid. If liquid flows in slower than the constant rate it is removed, then the liquid level drops. The liquid level is constantly fluctuating in order to absorb these variations in flow and maintain a constant flowrate out. When a vertical process vessel is used as a knock out drum, a mixture of gas and liquid flows into the vessel and this mixture is separated into its gas and liquid components within the vessel. The gas then flows out the top of the vessel and the liquid flows out the bottom. Vertical process vessels, as their name indicates, are erected in the vertical position. They are cylindrical in shape with each end capped by a domed cover called a head. The length to diameter ratio of a vertical vessel is typically 3:1. Typically, vertical process vessels hold less than 5000 GALLONS. Vertical tanks include: process, storage applications liquid, gas, solid processing and storage; pressure/vacuum code design for process and certain storage vessel types; includes heads, single wall, saddles, lugs, nozzles, manholes, legs or skirt, base ring, davits where applicable.

Description

Type

Pressure/Vacuum Service Cylindrical vertical pressure/vacuum vessel. Use minus pressure for vacuum design.

Application Symbol: Defines vessel function and related

CYLINDER

piping/instrumentation model. Default: *blank* blank - Standard continuous process vessel BATCH - Batch process vessel STORAGE - Storage vessel RECVR - Receiver KO - Knock-out drum Shell Material: For clad plate, specify the backing plate material. See Chapter 28 for materials. Default: *A 515*. Capacity: Enter either capacity or diameter and height. The capacity excludes the volume of the heads. If both the vessel dimensions and capacity are specified, the system calculated capacity must agree with the specified capacity to within plus or minus 10% to avoid an error condition. To secure desired vessel size, specify the diameter and height directly. A value must be specified if vessel diameter and/or vessel height (or length) are not specified. If vessel diameter and height (or length) are specified, the vessel volume is calculated from these dimensions. (Default is 2:1.) If only vessel capacity is specified, a straight side length-to-diameter ratio is chosen by the system, considering cost and practicability. Diameter: Enter either capacity or diameter and height. A value must be specified if vessel capacity is not specified. If both vessel capacity and height (or length) are specified, the diameter is calculated from these values. If both vessel capacity and diameter are specified, the height (or length) is calculated from these values. Vessel T-T Height: Enter either capacity or diameter and height. See Diameter.

Continued on next page

ICARUS Corporation, 1998. G3

Chapter 10: Vessels

Vertical Tanks (VT) continued

10-9

Description

Type

CYLINDER - continued

Design Press. - Gauge: If pressure and vacuum entered, design is

for worst case; Default: *15* PSIG [*100* KPA].

Design Vacuum - Gauge: If pressure and vacuum entered, design

is for worst case; Default: pressure.

Design Temperature: Default: 650 DEG F [340 DEG C] ferrous

material, 250 DEG F [120 DEG C] other material.

Operating Temp.: Default: design temperature. Skirt Height: Skip if legs required, enter 0.0 if hung in OPEN

structure; Default: 1.5 x diameter. If the capacity is 10,000 GALLONS [37 M3] or less, the vessel is designed with 4-feet [1.25 M] pipe legs. For a capacity greater than 10,000 GALLONS [37 M3], the vessel is designed with a skirt. The skirt height is calculated as 1.5 x vessel diameter, with minimum and maximum calculated heights of 4 - 32 FEET [1.25 - 9.5 M]. Leg Height: Skip if skirt required, enter 0.0 if hung in OPEN structure; Default: *4* FEET [1.25 M]. See Skirt Height. Wind/Seismic Design: Default: Vessel designed for wind and seismic loads defined in Project Basis. W+S - Wind and seismic design required WIND - Wind design only SEIS - Seismic design only NONE - Delete wind and seismic design Fluid Volume %: For seismic design, fluid volume as a % of vessel volume (water assumed). Max: 100; Default: *20*. Manhole Diameter: Max: 48 INCHES [1,200 MM]; Default: 18 INCHES [450 MM]. Number of Manholes: Default: *1*. % All. for Internals: Default: *0.0*; Specify an allowance for internals as a percent of basic vessel weight. Base Matl Thickness: Base material thickness including corrosion allowance. Corrosion Allowance: Default: 0.125 INCHES [3 MM for CS, 0.0 for other materials. No. Body Flange Sets: Number of sets (pairs) of body flanges of same diameter as vessel. Weld Efficiency %: ASME/JIS codes only, where allowed for thin wall vessels; Defaults: Area Basis. Range: 50 - 100. Stress Relief: Default: See Area Design Basis. CODE - Provide stress relief if code requires YES - Provide stress relief NO - No stress relief required Cladding Material: If no cladding material is specified, the system assumes that the vessel is not clad regardless of any input for cladding thickness. See Chapter 28 for materials. Cladding Thickness: Default: 0.125 INCHES [3 MM] if cladding material is specified, otherwise 0.0. See Cladding Material. Stiffg Ring Spacing: Default stiffeners designed for vacuum only, enter 0.0 if not required.

Continued on next page

G3 ICARUS Corporation, 1998.

10-10 ICARUS Reference

Vertical Tanks (VT) continued

Description

Type

CYLINDER - continued

Head Type Symbol: If no value is specified, the system selects

the torispherical type head and calculates the thickness. If the head is thicker than the vessel shell, the system selects the 2:1 ellipsoidal type head and recalculates the head thickness. If the head is still thicker than the shell, the system selects the hemispherical type head. ELLIP - 2:1 elliposidal HEMI - Hemispherical TORI - Torispherical (ASME) Bottom Head Thick: Base material thickness including corrosion allowance. Top Head Thickness: Base material thickness including corrosion allowance. Diameter Option: Defines desired diameter as ID or OD; Default: See Area Design Basis. OD - Outside diameter ID - Inside diameter ASME Design Basis: Applicable only for ASME code design. See following entries for fatigue data. Default: *D1NF*. D1NF - ASME Division 1 - no fatigue analysis D1F - ASME Division 1 - with fatigue analysis D2NF - ASME Division 2 - no fatigue analysis D2F - ASME Division 2 - with fatigue analysis Start-up Cycles x 1000: ASME fatigue only. Thousands of start-up cycles during the full equipment life. Range: 5.00 - 0.02. Pressure Cycles x 1000: ASME fatigue only. Thousands of deviations from design pressure during equipment life. Default: *0*. Pressure Amplitude %: ASME fatigue only. Amplitude of process deviation as percent of design pressure. Default: *0*. No. Hydrostatic Test: ASME fatigue only. Number of hydrostatic tests during the full equipment life. Default: *0*. Temp. Cycles x 1000: ASME fatigue only. Thousands of deviations from design temperature in equipment life. Default: *0*. Temp. Amplitude %: ASME fatigue only. Amplitude of temperature as a percent of design temperature. Default: *0*.

ICARUS Corporation, 1998. G3

Chapter 10: Vessels 10-11

Vertical Tanks (VT) continued

Description

Type

Multi-wall design for high pressure service. Total wall thickness of individual thin heat shrunk cylinders (maximum 2 INCH [50 MM] thick each).

Application Symbol: Defines vessel function and related

MULTI WALL

piping/instrumentation model. Default: *blank* blank - Standard continuous process vessel BATCH - Batch process vessel STORAGE - Storage vessel RECVR - Receiver KO - Knock-out drum Shell Material: For clad plate, specify the backing plate material. See Chapter 28 for materials. Default: *A 515*. Capacity: Enter either capacity or diameter and height. Diameter: Enter either capacity or diameter and height. Vessel T-T Height: Enter either capacity or diameter and height. Design Press. - Gauge: If pressure and vacuum entered, design is for worst case. Default: *15* PSIG [*100* KPA]. Design Vacuum - Gauge: If pressure and vacuum entered, design is for worst case. Design Temperature: Default: 650 DEG F [340 DEG C] ferrous material, 250 DEG F [120 DEG C] other material. Operating Temp.: Default: design temperature. Skirt Height: Skip if legs required, enter 0.0 if hung in OPEN structure; Default: 1.5 x diameter. Leg Height: Skip if skirt required, enter 0.0 if hung in OPEN structure; Default: *4* FEET [*1.25* M]. Wind/Seismic Design: Default: Vessel designed for wind and seismic loads defined in Project Basis. W+S - Wind and seismic design required WIND - Wind design only SEIS - Seismic design only NONE - Delete wind and seismic design Fluid Volume %: Max: 100; Default: *20*; For seismic design; fluid volume as a % of volume (water assumed). Manhole diameter: Max: 48 INCHES [1,200 MM]; Default: *18* INCHES [*450* MM]. Number of Manholes: Default: *1*. % All. for Internals: Specify an allowance for internals as a percent of basic vessel weight. Default: *0.0*. Base Matl Thickness: Base material thickness including corrosion allowance. Corrosion Allowance: Default: 0.125 INCHES [3 MM] for CS, 0.0 for other materials. No. Body Flange Sets: Number of sets (pairs) of body flanges of same diameter as vessel. Weld Efficiency %: ASME/JIS codes only, where allowed for thin wall vessels; Range: 50 - 100; Default: Area Basis. Stress Relief: Default: see Area Design Basis. CODE - Provide stress relief if code requires YES - Provide stress relief NO - No stress relief required

Continued on next page

G3 ICARUS Corporation, 1998.

10-12 ICARUS Reference

Vertical Tanks (VT) continued

Description

Type

MULTI WALL - continued

Cladding Material: See Chapter 28 for cladding materials. Cladding Thickness: Default: 0.125 INCHES [3 MM] if cladding

material is specified, otherwise - 0.0.

Stiffg Ring Spacing: Default stiffeners designed for vacuum

only, enter 0.0 if not required.

Head Type Symbol:

ELLIP - 2:1 elliposidal HEMI - Hemispherical TORI - Torispherical (ASME) Bottom Head Thick: Base material thickness including corrosion allowance. Top Head Thickness: Base material thickness including corrosion allowance. Diameter Option: Defines desired diameter as ID or OD; Default: see Area Design Basis. OD - Outside diameter ID - Inside diameter ASME Design Basis: Applicable only for ASME code design. See following entries for fatigue data. Default: *D1NF*. D1NF - ASME Division 1 - no fatigue analysis D1F - ASME Division 1 - with fatigue analysis D2NF - ASME Division 2 - no fatigue analysis D2F - ASME Division 2 - with fatigue analysis Start-up Cycles x 1000: ASME fatigue only. Thousands of start-up cycles during the full equipment life. Range: 5.00 - 0.02. Pressure Cycles x 1000: ASME fatigue only. Thousands of deviations from design pressure during equipment life. Default: *0*. Pressure Amplitude %: ASME fatigue only. Amplitude of process deviation as percent of design pressure. Default: *0*. No. Hydrostatic Test: ASME fatigue only. Number of hydrostatic tests during the full equipment life. Default: *0*. Temp. Cycles x 1000: ASME fatigue only. Thousands of deviations from design temperature in equipment life. Default: *0*. Temp. Amplitude %: ASME fatigue only. Amplitude of temperature as a percent of design temperature. Default: *0*.

ICARUS Corporation, 1998. G3

Chapter 10: Vessels 10-13

Vertical Tanks (VT) continued

Description

Type

Jacketed, cylindrical, vertical pressure/vacuum vessel.

Application Symbol: Defines vessel function and related

JACKETED

piping/instrumentation model. Default: *blank* blank - Standard continuous process vessel BATCH - Batch process vessel STORAGE - Storage vessel RECVR - Receiver KO - Knock-out drum Shell Material: For clad plate, specify the backing plate material. (Cladding is specified below.) Default: *A 515*. Capacity: Enter either capacity or diameter and height. Diameter: Enter either capacity or diameter and height. Vessel T-T Height: Enter either capacity or diameter and height. Design Press. - Gauge: If pressure and vacuum entered, design is for worst case. Default: *15* PSIG [*100* KPA]. Design Vacuum - Gauge: If pressure and vacuum entered, design is for worst case. Default: pressure. Design Temperature: Default: 650 DEG F [340 DEG C] ferrous material, 250 DEG F [120 DEG C] other material. Operating Temp.: Default: design temperature. Jacket Press. - Gauge: Default: *90* PSIG [*620* KPA]. Jacket Type: Default: *FULL* FULL - Full jacket PIPE - Half-pipe jacket Jacket Material: See Chapter 28 for materials. Default: *CS*. Skirt Height: Skip if legs required, enter 0.0 if hung in OPEN structure; Default: *1.5 x diameter*. Leg Height: Skip if skirt required. Enter 0.0 if hung in OPEN structure; Default: *4* FEET [*1.25* M]. Wind/Seismic Design: Default: Vessel designed for wind and seismic loads defined in Project Basis. W+S - Wind and seismic design required WIND - Wind design only SEIS - Seismic design only NONE - Delete wind and seismic design Fluid Volume %: Max: 100; Default: *20*; For seismic design; fluid volume as a % of vessel volume (water assumed). Manhole Diameter: Max: 48 INCHES [1,200 MM]; Default: *18* INCHES [*450* MM]. Number of Manholes: Default: *1*. % All. for Internals: Specify an allowance for internals as a percent of basic vessel weight. Default: *0.0*. Base Matl Thickness: Base material thickness including corrosion allowance. Corrosion Allowance: Default: 0.125 INCHES [3 MM] for CS, 0.0 for other material, double if jacketed. No. Body Flange Sets: Number of sets (pairs) of body flanges of same diameter as vessel. Weld Efficiency %: ASME/JIS codes only, where allowed for thin wall vessels; Range: 50 - 100; Default: Area Basis.

Continued on next page

G3 ICARUS Corporation, 1998.

10-14 ICARUS Reference

Vertical Tanks (VT) continued

Description

Type

JACKETED - continued

Stress Relief: Default: See Area Design Basis.

CODE - Provide stress relief if code requires YES - Provide stress relief NO - No stress relief required Cladding Material: See Chapter 28 for cladding materials. Cladding Thickness: Default: 0.125 INCHES [3 MM] if cladding material is specified, otherwise - 0.0. Stiffg Ring Spacing: Default stiffeners designed for vacuum only, enter 0.0 if not required.

Head Type Symbol:

ELLIP - 2:1 elliposidal HEMI - Hemispherical TORI - Torispherical (ASME) Bottom Head Thick: Base material thickness including corrosion allowance. Top Head Thickness: Base material thickness including corrosion allowance. Diameter Option: Defines desired diameter as ID or OD; Default: see Area Design Basis. OD - Outside diameter ID - Inside diameter ASME Design Basis: Applicable only for ASME code design. See following entries for fatigue data. Default: *D1NF*. D1NF - ASME Division 1 - no fatigue analysis D1F - ASME Division 1 - with fatigue analysis D2NF - ASME Division 2 - no fatigue analysis D2F - ASME Division 2 - with fatigue analysis Start-up Cycles x 1000: ASME fatigue only. Thousands of start-up cycles during the full equipment life. Range: 5.00 - 0.02. Pressure Cycles x 1000: ASME fatigue only. Thousands of deviations from design pressure during equipment life. Default: *0*. Pressure Amplitude %: ASME fatigue only. Amplitude of process deviation as percent of design pressure. Default: *0*. No. Hydrostatic Test: ASME fatigue only. Number of hydrostatic tests during the full equipment life. Default: *0*. Temp. Cycles x 1000: ASME fatigue only. Thousands of deviations from design temperature in equipment life. Default: *0*. Temp. Amplitude %: ASME fatigue only. Amplitude of temperature as a percent of design temperature. Default: *0*.

ICARUS Corporation, 1998. G3

Chapter 10: Vessels 10-15

Vertical Tanks (VT) continued

Description

Type

High Pressure Gas/Liquid Storage Sphere pressure/vacuum design to 3000 PSIG [20500 KPA]. Use minus pressure for vacuum design. This item is used by chemical, rubber, petroleum and paper industries for storing large volumes of anhydrous ammonia, butadiene, butane and other gases at high temperature. A spherical tank is elevated and supported by legs fabricated from structural steel columns or pipe. Sphere sizes range as high as 90 FEET in diameter and are typically constructed of high strength steel. These tanks are commonly used for high pressure storage of gases and volatile liquids, typically in the range of 5 - 250 PSIG. Storing volatile liquids at high pressures raises the boiling point of the liquid and therefore minimizes or eliminates that need for costly refrigeration equipment to liquify the material being stored.

Shell Material: For clad plate, specify the backing plate material.

SPHERE

See Chapter 28 for materials. Default: *A 515*.

Capacity: Enter either capacity or diameter. Diameter: Enter either capacity or diameter. Design Press. - Gauge: -15 - 3,000 PSIG [-100 - 20,5000];

Default: 15 PSIG [100 KPA].

Design Temperature: Max: 1,500 DEG F [815 DEG C];

Default: *68* DEG F [*20* DEG C].

Operating Temp.: Default: design temperature. Manhole Diameter: Max: 48 INCHES [1,200 MM];

Default: *18* INCHES [*450* MM].

Number of Manholes: Default: *1*. % All. for Internals: Specify an allowance for internals as a

percent of basic vessel weight. Default: *0.0*.

Base Matl Thickness: Base material thickness including

corrosion allowance.

Corrosion Allowance: Default: 0.125 INCHES [3 MM] for CS,

0.0 for other materials.

Cladding Material: See Chapter 28 for cladding materials. Cladding Thickness: Default: 0.125 INCHES [3 MM]

if cladding material is specified, otherwise - 0.0.

Diameter Option: Defines desired diameter as ID or OD;

Default: see Area Design Basis. OD - Outside diameter ID - Inside diameter ASME Design Basis: Applicable only for ASME code design. See following entries for fatigue data. Default: *D1NF*. D1NF - ASME Division 1 - no fatigue analysis D1F - ASME Division 1 - with fatigue analysis D2NF - ASME Division 2 - no fatigue analysis D2F - ASME Division 2 - with fatigue analysis Start-up Cycles x 1000: ASME fatigue only. Thousands of start-up cycles during the full equipment life. Range: 5.00 - 0.02.

Continued on next page

G3 ICARUS Corporation, 1998.

10-16 ICARUS Reference

Vertical Tanks (VT) continued

Description

Type

SPHERE - continued

Pressure Cycles x 1000: ASME fatigue only. Thousands of

deviations from design pressure during equipment life. Default: *0*. Pressure Amplitude %: ASME fatigue only. Amplitude of process deviation as percent of design pressure. Default: *0*. No. Hydrostatic Test: ASME fatigue only. Number of hydrostatic tests during the full equipment life. Default: *0*. Temp. Cycles x 1000: ASME fatigue only. Thousands of deviations from design temperature in equipment life. Default: *0*. Temp. Amplitude %: ASME fatigue only. Amplitude of temperature as a percent of design temperature. Default: *0*.

ICARUS Corporation, 1998. G3

Chapter 10: Vessels 10-17

Vertical Tanks (VT) continued

Description

Type

Spheroid to 750000 GALLONS [2840 M3]. Field erected. This item is commonly used for storage of gasolines and other volatile liquids. Spheroids vary in shape and size, but generally fall into one of the following categories: Hemispheriod: Spherical segments comprising the roof and bottom of the tank are joined to a cylindrical middle section. Hemispheriods are used for pressures up to 5 PSI and capacities to 25,000 barrels. For capacities to 50,000 barrels the roof and bottom are noded. Hortonspheriod: Spherical segments are joined together in a somewhat elliptical shape. Hortonspheroids are capable of handling storage at pressure from 5 to 30 PSIG. Hortonspheroids and hemispheroids are designed to rest on a prepared grade conforming to the shape of the bottom (usually sand). Spheroidal shaped tanks are often more economical than cylindrical pressure vessels for storage at pressures greater than 0.5 PSI.

Shell Material: For clad plate, specify the backing plate material.

SPHEROID

See Chapter 28 for materials. Default: *A 515*.

Capacity: Enter either capacity or diameter and height.

Range: 60,000 - 750,000 GALLONS [230 - 2,840 M3];

Diameter: Enter either capacity or diameter and height. Height: Enter either capacity or diameter and height. Design Press. - Gauge: Range: 0.0 - 15 PSIG [0.0 - 100 KPA];

Default: *15* PSIG [*100* KPA].

Design Temperature: Default: *68* DEG F [*20* DEG C]. Operating Temp.: Default: design temperature. Manhole Diameter: Max: 48 INCHES [1,200 MM];

Default: *18* INCHES [*450* MM].

Number of Manholes: Default: *1*. % All. for Internals: Default: Specify an allowance for internals

as a percent of basic vessel weight. Default: *0.0*.

Base Matl Thickness: Base material thickness including

corrosion allowance.

Corrosion Allowance: Default: 0.125 INCHES [3 MM] for CS,

0.0 for other materials.

Cladding Material: See Chapter 28 for cladding materials. Cladding Thickness: Default: 0.125 INCHES [3 MM] if cladding

material is specified, otherwise - 0.0.

Diameter Option: Defines desired diameter as ID or OD;

Default - see Area Design Basis. OD - Outside diameter ID - Inside diameter

G3 ICARUS Corporation, 1998.

10-18 ICARUS Reference

Vertical Tanks (VT) continued

Description

Type

Near-Atmospheric Liquid Storage The available roof types are FLAT, FLOAT, CONE, LIFT, OPEN, INFLT, and INCN. Use minus pressure for vacuum design. Field erected. STORAGE Flat roof tank

Floating roof tanks are frequently used in the storage of kerosene and jet fuels. Floating roofs may be installed inside a tank with a fixed roof or used as a tanks only cover. Typically constructed from polyurethane foam blocks or nylon cloth impregnated with rubber or plastic, floating roofs are designed to completely contact the surface of the storage products and thereby eliminate the vapor space between the product level and the fixed roof. This feature makes floating roofs desirable for the following reasons: 1. Reduction of evaporation and breathing losses. 2. Reduction of tank corrosion. 3. Increased safety from fire or explosion. Floating root tanks are suitable for storage of products having vapor pressures from 2 to 15 PSIA. Products that boil at temperatures under the normal range of atmospheric conditions should not be stored in floating roof tanks.

Floating roof tank

Cone roof tanks are used for storage of low pressure products (e.g., oil, diesel and asphalt.) Cone roof tanks are usually field fabricated out of carbon steel. Roofs are sloped upward to the center at a slight angle. Typically, ranging from 50,000 - 1,000,000 GALLONS capacities, they are used for storage of low vapor pressure products (less than 2 PSIA) when evaporation looses and breathing losses are not considered important.

Cone roof tank

Lifter roof tanks are generally field fabricated. They have a minimum capacity of 40,000 GALLONS [152 M2]. Lifter roof tanks can be specified with pressure from 0 - 0.05 PSIG [0 - 0.3 KPA] and a maximum temperature of 250 DEG F [120 DEC C]. The default temperature is *68* DEG F [*20* DEG C].

Lifter roof tank

Open top tanks are designed and constructed according to user-generated design code standards. Open top tanks have a maximum temperature of 250 DEG F [120 DEC C]. The default temperature is *68* DEG F [*20* DEG C].

Open top tank

Continued on next page

ICARUS Corporation, 1998. G3

Chapter 10: Vessels 10-19

Vertical Tanks (VT) continued

Description

Type

STORAGE - continued

Shell Material: For clad plate, specify the backing plate

material (cladding is defined below). See Chapter 28 for materials. Default: *A285C*. Capacity Units: Unit of measure for the capacity entry. Enter capacity unit symbol as entered in project specifications. If units are not changed, enter GALLONS [M3] or BARRELS [M3]. Capacity: Enter either capacity (see capacity unit entry for units) or diameter and height. Diameter: Enter either capacity or diameter and height. Height: Enter either capacity or diameter and height. Roof Type: Default: *FLAT* FLAT - Flat roof tank CONE - Cone roof tank FLOAT - Floating roof tank LIFT - Lifter OPEN - Open roof tank INFLT - Internal floater with flat roof INCN - Internal floater with cone roof Bottom Type: Default: *FLAT* FLAT - Single flat bottom DBL - Double bottom Design Press. - Gauge: 0.0 - 2.5 PSIG [0.0 - 17 KPA]; Default: *0.05* PSIG [*0.35* KPA]. Design Temperature: Default: *68* DEG F [*20* DEG C]. Operating Temperature: Default: design temperature. Manhole Diameter: Max: 48 INCHES [1,200 MM]; Default: *18* INCHES [*450* MM]. Number of Manholes: Default: *1*. % All. for Internals: Specify an allowance for internals as a percent of basic vessel weight. Default: *0.0*. Base Matl Thickness: Base material thickness including corrosion allowance. Corrosion Allowance: Default: *0.125* INCHES [*3* MM] for CS, *0.0* for other materials. Cladding Materials: See Chapter 28 for cladding materials. Cladding Thickness: Default: *0.125* INCHES [*3* MM] if cladding material is specified; otherwise: *0.0*. Specific Gravity: Range: 0.2 - 5.0; Default: *1.0*. Diameter Option: Defines desired diameter as ID or OD; Default: See Area Design Basis. OD - Outside diameter ID - Inside diameter Diam. Flame Arrestor: Range: 1.0 - 8.0 IN DIAM [25.0 - 200.0 MM DIAM]. Diam. Conserv. Vent: Range: 1.0- 8.0 IN DIAM [25.0 - 200.0 MM DIAM].

G3 ICARUS Corporation, 1998.

10-20 ICARUS Reference

Vertical Tanks (VT) continued

Description

Type

Cryogenic storage tank - double wall, superinsulated.

Shell Material: See Chapter 28 for materials. Default: *SS304*. Capacity: Enter either capacity or diameter and height.

CRYOGENIC

Range: 300.0 - 60,000.0 GALLONS [1.20 - 227.00 M3].

Diameter: Enter either capacity or diameter and height. Vessel t-t Height: Enter either capacity or diameter and height. Design Press. - Gauge: If both pressure and vacuum are entered,

design is for worst case. Default: 250.0 PSIG [1,720 KPA].

Design Vacuum - Gauge: If both pressure and vacuum are

entered, design is for worst case. Default: pressure.

Design Temperature: Default: -320.0 DEG F [-195 DEG C]. Operating Temp.: Default: design temperature. Jacket Press. - Gauge: Min: -14.70 PSIG [-100.0 KPA];

Default: -14.70 PSIG [-100.0 KPA]

Jacket Material: See Chapter 28 for materials. Default: *CS*. Skirt Height: Skip if legs are required. Enter 0.0 if hung in

OPEN structure. Default: 1.5 x diameter.

Leg Height: Skip if legs are required. Enter 0.0 if hung in

OPEN structure. Default: 1.5 x diameter.

Wind/Seismic Design: Default: Vessel designed for wind and

seismic loads defined in Project Basis. W+S - Wind and seismic design required WIND - Wind design only SEIS - Seismic design only NONE - Delete wind and seismic design Fluid Volume %: For seismic design, fluid volume as a % of vessel volume (water assumed). Manhole Diameter: Max: 48.0 INCHES [1,200.0 MM]; Default: 18.0 INCHES [450.0 MM] Number of Manholes: Default: *0*. % All. for Internals: Specify an allowance for internals as a percent of basic vessel height. Base Matl Thickness: Base material thickness including corrosion allowance. Corrosion Allowance: Default: 0.125 INCHES [3 MM] for CS, 0.0 for other materials. Weld Efficiency %: ASME/JIS codes only, where allowed for thin wall vessels. Range: 50 - 100; Default: Area Basis. Stress Relief: Default: See Area Design Basis. CODE - Provide stress relief if code requires YES - Provide stress relief NO - No stress relief Stiffg Ring Spacing: Default stiffeners designed for vacuum only, enter 0.0 if not required.

Head Type Symbol:

- 2:1 ellipsoidal - Hemispherical - Torispherical (ASME) Diameter Option: Defines desired diameter as ID or OD. Default: See Area Design Basis. OD - Outside diameter ID - Inside diameter

ELLIP HEMI TORI

ICARUS Corporation, 1998. G3

Chapter 10: Vessels 10-21

Vertical Tanks (VT) continued

Description

Type

Flat bottom dome top. FRP to 30000 GALLONS [113 M3], HAVAG to 7000 GALLONS [26 M3]. Fiberglass Reinforced Plastic Storage Tank: Filament-wound with a bisphenol - a polyester resin (e.g., Atlac 282). Flat bottom and dome top under 2.5 PSIG [16.7 KPA], otherwise dished heads. Haveg Storage Tank.

Material Selection: Default: *FRP*

PLAST TANK

FRP - FRP HAVEG - Haveg Volume: Volume or diameter + height required input Range: 1,000 - 30,000 GALLONS [3.8 - 113 M3] Diameter: Volume or diameter + height input. Max: 12.0 FEET [93.6 M]. Height: Volume or diameter + height required input. Gauge Pressure: Range: 0.00 - 15.00 PSIG [0 - 100 KPA]; Default: *0.05* PSIG [*0.3* KPA]. Temperature: Max: 300 DEG F [120 DEG C]; Default: *68* DEG F [*20* DEG C].

Wooden storage tanks to 50000 GALLONS [1890 M3].

Material Selection: Default: *CYPRS*

WOOD TANK

CYPRS - Cypress REDWD - Redwood PINE - Pine FIR - Fir Volume: Volume or diameter + height required input. Range: 800 - 50,000 GALLONS [3.1 - 189 M3]. Diameter: Volume or diameter + height required input. Gauge Pressure: Range: 0.0 - 0.05 PSIG [0.0 - 0.3 KPA]. Default: *0.05* PSIG [*0.3* KPA]. Temperature: Max: 250 DEG F [120 DEG C]; Default: *68* DEG F [*20* DEG C].

G3 ICARUS Corporation, 1998.

10-22 ICARUS Reference

Vertical Tanks (VT) continued

Description

Type

Near-Atmospheric Gas Storage Telescoping gas holder. Low pressure gas vessel.

Shell Material: For clad plate, specify the backing plate material.

GAS HOLDER

See Chapter 28 for materials. Default: *A285C*.

Capacity: Enter either capacity or diameter and height. Diameter: Enter either capacity or diameter and height. Height: Enter either capacity or diameter and height. Design Press. - Gauge: Range: 0.0 - 2.5 PSIG [0.0 - 17 KPA];

Default: *0.05* PSIG [*0.35* KPA].

Design Temperature: Default: *68* DEG F [*20* DEG C]. Operating Temp.: Default: Design temperature. Manhole Diameter: Max: 48 INCHES [1,200 MM];

Default: *18* INCHES [*450* MM]

Number of Manholes: Default: *1*. % All. for Internals: Specify an allowance for internals as a

percent of basic vessel weight. Default: *0.0*.

Base Matl Thickness: Base material thickness including

corrosion allowance.

Corrosion Allowance: Default: 0.125 INCHES [3 MM] if

cladding material is specified; otherwise 0.0.

Cladding Material: See Chapter 28 for materials. Cladding Thickness: Default: 0.125 INCHES [3 MM] if

cladding material is specified, otherwise 0.0.

Diameter Option: Defines desired diameter as ID or OD.

Default: - See Area Design Basis. OD - Outside diameter ID - Inside diameter

Atmospheric Solid/Liquid Storage Cone bottom, flat top storage bin.

Shell Material: For clad plate, specify the backing plate material.

CONE BTM

See Chapter 28 for materials. Default: *A285C*.

Capacity: Enter either capacity or diameter and height. Diameter: Enter either capacity or diameter and height. Height: Enter either capacity or diameter and height. Design Press. - Gauge: Min: 0.0 PSIG [0.0 KPA];

Default: 0.05 PSIG [0.35 KPA].

Design Temperature: Default: 68 DEG F [20 DEG C] to

0.05 PSI [0.35 KPA]; else 650 DEG F [340 DEG C] ferrous, 250 DEG F [120 DEG C] other. Operating Temp.: Default: Design temperature. Leg Height: Enter 0.0 if bin hung in OPEN structure; Default: *4* FEET [*1.25* M].

Continued on next page

ICARUS Corporation, 1998. G3

Chapter 10: Vessels 10-23

Vertical Tanks (VT) continued

Description

Type

CONE BTM - continued

Manhole Diameter: Max: 48 INCHES [1,200 MM];

Default: *18* INCHES [*450* MM].

Number of Manholes: Default: *1*. % All. for Internals: Specify an allowance for internals as a

percent of basic vessel weight. Default: *0.0*.

Base Matl Thickness: Base material thickness including

corrosion allowance.

Corrosion Allowance: Default: *0.125* INCHES [*3* MM] for

CS, *0.0* for other materials.

No. Body Flange Sets: Number of sets (pairs) of body flanges of

same diameter as vessel.

Stress Relief: Default: See Area Design Basis

CODE - Provide stress relief if code requires YES - Provide stress relief NO - No stress relief Cladding Material: See Chapter 28 for materials. Cladding Thickness: Default *0.125* INCHES [*3* MM] if cladding material is specified; otherwise: *0.0*. Bottom Head Tank: Base material thickness including corrosion allowance. Top Head Thickness: Base material thickness including corrosion allowance. Diameter Option: Defines desired diameter as ID or OD; Default - see Area Design Basis. OD - Outside diameter ID - Inside diameter ASME Design Basis: Applicable only for ASME code design. See following entries for fatigue data. Default: *D1NF*. D1NF - ASME Division 1 - no fatigue analysis D1F - ASME Division 1 - with fatigue analysis D2NF - ASME Division 2 - no fatigue analysis D2F - ASME Division 2 - with fatigue analysis Start-up Cycles x 1000: ASME fatigue only. Thousands of start-up cycles during the full equipment life. Range: 5.00 - 0.02. Pressure Cycles x 1000: ASME fatigue only. Thousands of deviations from design pressure during equipment life. Default: *0*. Pressure Amplitude %: ASME fatigue only. Amplitude of process deviation as percent of design pressure. Default: *0*. No. Hydrostatic Test: ASME fatigue only. Number of hydrostatic tests during the full equipment life. Default: *0*. Temp. Cycles x 1000: ASME fatigue only. Thousands of deviations from design temperature in equipment life. Default: *0*. Temp. Amplitude %: ASME fatigue only. Amplitude of temperature as a percent of design temperature. Default: *0*.

G3 ICARUS Corporation, 1998.

10-24 ICARUS Reference

Vertical Tanks (VT) continued

Description

Type

Live bottom storage bin.

Shell Material: For clad plate, specify the backing plate material.

LIVE BTM

See Chapter 28 for materials. Default: *A285C*.

Capacity: Enter either capacity or diameter and height. Diameter: Enter either capacity or diameter and height. Height: Enter either capacity or diameter and height. Design Temperature: Default: *68* DEG F [*20* DEG C] Operating Temp.: Default: Design temperature. Leg Height: Enter 0.0 if bin hung in OPEN structure;

Default: *4* FEET [*1.25* M].

Manhole Diameter: Max: 48 INCHES [1,200 MM];

Default: *18* INCHES [*450* MM].

Number of Manholes: Default: *1*. % All. for Internals: Specify an allowance for internals as a

percent of basic vessel weight. Default: *0.0*.

Base Matl Thickness: Base material thickness including

corrosion allowance.

Corrosion Allowance: Default: *0.125* INCHES [*3* MM] for

CS, *0.0* for other materials.

No. Body Flange Sets: Number of sets (pairs) of body flanges of

same diameter as vessel.

Stress Relief: Default: See Area Design Basis.

CODE - Provide stress relief if code requires YES - Provide stress relief NO - No stress relief Cladding Material: See Chapter 28 for materials. Cladding Thickness: Default *0.125* INCHES [*3* MM] if cladding material is specified; otherwise: *0.0*. Diameter Option: Defines desired diameter as ID or OD; Default - see Area Design Basis. OD - Outside diameter ID - Inside diameter

ICARUS Corporation, 1998. G3

Chapter 10: Vessels 10-25

Vertical Tanks (VT) continued

Description

Type

Tile Chests Tile chests provide tile lined tanks for storage of liquids, suspensions or slurries. Although tile chests are used in the chemical industry, they are predominantly used in pulp and paper mills for storing fiber suspensions at various stages of processing. Chests can be rectangular or cylindrical and may be concrete or metallic. Various designs are available depending on the nature of the fluid high density, low density. Tile Chests, rectangular concrete include the follow options. Single tile chest Group of tile chests One chest in a group of chests.

Grouping Option: PARTGRP is used for one chest in

CHEST-REC

assemblage, WHLGRP to define an entire assemblage. Default: *PARTGRP*. SINGLE - Tile chest is a single stand-alone item PARTGRP - One chest of a multi-group assemblage WHLGRP - Entire multi-group assemblage Length: Enter either chest dimensions or capacity. Height: Enter either chest dimensions or capacity. Width: Enter either chest dimensions or capacity. Chest Capacity: Enter either chest dimensions or capacity. For WHLGRP only - capacity of entire group, otherwise - capacity this chest. Tile/Lining Type: Default: *25RSB* 25RSB - 2.5 INCHES [62 MM] red shale brick 45RSB - 4.5 INCHES [112 MM] red shale brick 80RSB - 8.0 INCHES [200 MM] red shale brick Tile/Lining %: Percent of chest surface to be lined, 100% = one side; 200% = inside + outside. Max: 200; Default: 100. Configuration: Default: *OPEN* OPEN - Open top chest CLOSED - Chest has a roof Installation Option: Default: *GRADE* GRADE - Tile chest is constructed on grade STRUCT - Tile chest is within a structure Capacity of Group: For PARTGRP chest only, capacity of entire group; Default: 4x chest capacity. No. Chests in Group: For WHLGRP chest only, enter number of chests in entire assemblage. Default: *4*. Partition Lengthwise: Number of full length partitions parallel to length dimension (may be fraction). Partition Widthwise: Number of width wide partitions parallel to width dimension (may be fraction).

Continued on next page

G3 ICARUS Corporation, 1998.

10-26 ICARUS Reference

Vertical Tanks (VT) continued

Description

Type

CHEST-REC - continued

Soil Type Symbol:

- Bearing: 2000 PSF [100 KN/M2] - Bearing: 4000 PSF [200 KN/M2] - Bearing: 4000 PSF [200 KN/M2] - Bearing: 4000 PSF [200 KN/M2] - Bearing: 600 PSF [300 KN/M2] - Bearing: 8000 PSF [400 KN/M2] - Bearing: 12000 PSF [600 KN/M2] - Bearing: 16000 PSF [800 KN/M2] - Bearing: 20000 PSF [1000 KN/M2] - Bearing: 30000 PSF [1400 KN/M2] - Bearing: 80000 PSF [3800 KN/M2] Product Density: Default: *62.4* PCF. Exclude Excavation %: Exclude portion of calculated quantity if not required or common with other items. Max: 100; Default: *0.0*. Exclude Footings %: Exclude portion of calculated quantity if not required or common with other items. Max: 100; Default: *0.0*. Exclude Floor %: Exclude portion of calculated quantity if not required or common with other items. Max: 100; Default: *0.0*. Exclude Wall-Length %: Exclude portion of calculated quantity if not required or common with other items. Max: 100; Default: *0.0*. Exclude Wall-Width %: Exclude portion of calculated quantity if not required or common with other items. Max: 100; Default: *0.0*.

SOFT CLAY FIRM CLAY WET SAND SAND+CLAY DRY SAND SAND GRAVEL SOFT ROCK HARDPAN MED-ROCK HARD ROCK.

ICARUS Corporation, 1998. G3

Chapter 10: Vessels 10-27

Vertical Tanks (VT) continued

Description

Type

Tile Chests, Cylindrical Low density tile chest with a capacity range of 3000 to 300000 GALLONS [12 to 1135 M3]. Chest is available in concrete or metallic materials of construction. High density tile chest with a capacity range of 30000 to 1300000 GALLONS [114 to 4921 M3]. Chest is available in concrete or metallic materials of construction.

Shape Symbol: Default: *CYLLD*

CHEST-CYL

- Cylindrical chest, low density stock - Cylindrical chest, high density stock Diameter: Chest dimensions or capacity required. Height: Chest dimensions or capacity required. Chest Capacity: Chest dimensions or capacity required. Tile/Lining Type: Default: *25RSB* 25RBS - 2.5 INCH [62 MM] red shale brick 45RSB - 4.5 INCH [112 MM] red shale brick 80RSB - 8.0 INCH [200 MM] red shale brick Tile/Lining %: Percent of chest to be lined. 100% = one side; 200% = inside + outside. Max: 200; Default: *100*. Configuration: Default: *OPEN* OPEN - Open top chest CLOSED - Chest has a roof Installation Option: Default: *GRADE* GRADE - Tile chest is constructed on grade STRUCT - Tile chest is within a structure

Soil Type Symbol:

CYLLD CYLHD

(CYLLD)

(CYLHD)

- Bearing: 2000 PSF [100 KN/M2] - Bearing: 4000 PSF [200 KN/M2] - Bearing: 4000 PSF [200 KN/M2] - Bearing: 4000 PSF [200 KN/M2] - Bearing: 600 PSF [300 KN/M2] - Bearing: 8000 PSF [400 KN/M2] - Bearing: 12000 PSF [600 KN/M2] - Bearing: 16000 PSF [800 KN/M2] - Bearing: 20000 PSF [1000 KN/M2] - Bearing: 30000 PSF [1400 KN/M2] - Bearing: 80000 PSF [3800 KN/M2] Product Density: Default: *62.4* PCF [1,000 KG/M3]. Exclude Excavation %: Exclude portion of calculated quantity if not required or common with other items. Max: 100; Default: *0.0*. Exclude Footings %: Exclude portion of calculated quantity if not required or common with other items. Max: 100; Default: *0.0*. Exclude Floor %: Exclude portion of calculated quantity if not required or common with other items. Max: 100; Default: *0.0*.

SOFT CLAY FIRM CLAY WET SAND SAND+CLAY DRY SAND SAND GRAVEL SOFT ROCK HARDPAN MED-ROCK HARD ROCK.

G3 ICARUS Corporation, 1998.

10-28 ICARUS Reference

Vertical Tanks (VT) continued

Description

Type

Shell Material: For clad plate, specify the backing plate material.

CHEST-MTL

(Cladding is defined below.) Default: *A285C*. Capacity: Enter either capacity or diameter and height. Diameter: Enter either capacity or diameter and height. Height: Enter either capacity or diameter and height. Tile/Lining Type: Default: *25RSB* 25RSB - 2.4 INCH [62 MM] red shale brick 45RSB - 4.5 INCH [112 MM] red shale brick 80RSB - 8.0 INCH [200 MM] red shale brick Tile/Lining %: Percent of chest surface to be lined. 100% = one side; 200% = inside + outside. Max: 200; Default: *100*. Roof Type: Default: *FLAT* FLAT - Flat roof tank CONE - Cone roof tank FLOAT - Floating roof tank LIFT - Lifter OPEN - Open top tank INFLT - Internal floater with flat roof INCN - Internal floater with cone roof Design Press. - Gauge: Range: 0 - 2.5 PSIG [0 - 17.0 KPA]; Default: *0.05* PSIG [*0.35* KPA]. Ignore this field for open top tanks. Design Temperature: Default: *68* DEG F [*20* DEG C]. Operating Temp.: Default: Design temperature. Manhole Diameter: Max: 48 INCHES [1,200 MM]; Default: *18* INCHES [450.0 MM]. Number of Manholes: Default: *1*. % All. for Internals: Specify an allowance for internals as a percent of basic vessel weight. Default: *0.0*. Base Matl Thickness: Base material thickness including corrosion allowance. Corrosion Allowance: Default: *0.125* INCHES [*3* MM] for CS, *0.0* for other materials. Cladding Material: See Chapter 28 for cladding materials. Cladding Thickness: Default: *0.125* INCHES [*3* MM] for cladding material, otherwise *0.0*. Specific Gravity: Range: 0.2 - 5.0; Default: *1.0*. Diameter Option: Defines desired diameter as ID or OD. Default: See Area Design Basis. Bottom Type: Default: *FLAT* FLAT - Single flat bottom DBL - Double bottom

ICARUS Corporation, 1998. G3

You might also like

- Design Pressure VesselDocument136 pagesDesign Pressure VesselHarshal JadhavNo ratings yet

- Mechanical Design and Material Selection for Process EquipmentDocument26 pagesMechanical Design and Material Selection for Process EquipmentibicengNo ratings yet

- Presser Vessel DesignDocument30 pagesPresser Vessel DesignAsila Ahmed100% (1)

- 30% of Damage Caused by Vessel Design FailuresDocument32 pages30% of Damage Caused by Vessel Design FailuresJay Lawson100% (1)

- Main parts and nozzles used in equipment manufacturingDocument17 pagesMain parts and nozzles used in equipment manufacturingDeepikaNo ratings yet

- Thick Walled Pressure VesselDocument56 pagesThick Walled Pressure VesselErick PalladaNo ratings yet

- ColumnsDocument12 pagesColumnsEnas Al-khawaldehNo ratings yet

- Pressure VesselDocument7 pagesPressure VesselClarence AG YueNo ratings yet

- Engineering Thermodynamics ProblemsDocument3 pagesEngineering Thermodynamics Problemsdhruv0010% (1)

- Distillation SequencingDocument4 pagesDistillation SequencingIsabel TriestyNo ratings yet

- InputCOIL PDFDocument9 pagesInputCOIL PDFneelNo ratings yet

- Equipment Design and CostsDocument36 pagesEquipment Design and CostsDivyesh Patel100% (2)

- Tks 324 Mechanical Design of Process Equipment-01Document62 pagesTks 324 Mechanical Design of Process Equipment-01Rahani Hyuga100% (1)

- 2-Aa Storage Tank - Basic Training Rev 2Document52 pages2-Aa Storage Tank - Basic Training Rev 2mohamedbadawyNo ratings yet

- Training Manual For PVelite Basic LevelDocument41 pagesTraining Manual For PVelite Basic LevelsudokuNo ratings yet

- Flash CalculationDocument24 pagesFlash Calculationproabbey100% (1)

- Pneumatic Actuator Air ConsumptionDocument1 pagePneumatic Actuator Air ConsumptionHomer SilvaNo ratings yet

- Design of Compact Plate Fin Heat ExchangerDocument61 pagesDesign of Compact Plate Fin Heat ExchangerIndra Uchiha100% (3)

- Jet Mixing CalculationDocument3 pagesJet Mixing CalculationRachel FloresNo ratings yet

- Plate Heat ExchangersDocument7 pagesPlate Heat ExchangersBaneMarkovicNo ratings yet

- Tech Guidance Storage TankDocument17 pagesTech Guidance Storage TankMichael SandersNo ratings yet

- Chimney & Venting Sizing HandbookDocument50 pagesChimney & Venting Sizing HandbookCallGRNo ratings yet

- Databook Pressure VesselsDocument79 pagesDatabook Pressure VesselssofraNo ratings yet

- Pressure Vessel Design Code FormulasDocument14 pagesPressure Vessel Design Code FormulasSoner SalarNo ratings yet

- 9.1 Overview: 9 Wiped Film EvaporatorDocument12 pages9.1 Overview: 9 Wiped Film EvaporatorNoman AslamNo ratings yet

- Design of Pressure VesselsDocument23 pagesDesign of Pressure VesselsSuryaprakashNo ratings yet

- Dowtherm BookDocument30 pagesDowtherm BookMeghnad M GavitNo ratings yet

- CBE 417 FlashDrumSizing Wankat PDFDocument7 pagesCBE 417 FlashDrumSizing Wankat PDFAbdul RehmanNo ratings yet

- Acid StorageDocument1 pageAcid StorageChelsea SkinnerNo ratings yet

- Air CoolersDocument18 pagesAir CoolersPRATIK P. BHOIRNo ratings yet

- Mandatory Appendix 9Document2 pagesMandatory Appendix 9Asep DarojatNo ratings yet

- Experiment - 7: Aim: Sizing of Pressure VesselDocument5 pagesExperiment - 7: Aim: Sizing of Pressure VesselHomesick TutorsNo ratings yet

- Vacuum Distillation ColumnsDocument2 pagesVacuum Distillation Columnsmehfuzansari1100% (1)

- 2a - Packed ColumnsDocument55 pages2a - Packed ColumnsDoaa Badarneh100% (1)

- The Physical Properties of The Hot Fluid Have Been Extrapolated Beyond The Valid Temperature RangeDocument3 pagesThe Physical Properties of The Hot Fluid Have Been Extrapolated Beyond The Valid Temperature RangeSrihari KodimelaNo ratings yet

- Reaction VesselsDocument6 pagesReaction VesselsKim Christian Galaez100% (1)

- Basco IBC Catalog 2013Document16 pagesBasco IBC Catalog 2013Mario BarbarićNo ratings yet

- Calculation of Overall Heat Transfer CoefficientDocument2 pagesCalculation of Overall Heat Transfer CoefficientSrihari KodimelaNo ratings yet

- Tank Venting API 2000Document3 pagesTank Venting API 2000Gusfi CarsurinNo ratings yet

- MDMT of Ammonia ReservoirDocument5 pagesMDMT of Ammonia ReservoiryogacruiseNo ratings yet

- P & I Design ERS Sizing MethodsDocument34 pagesP & I Design ERS Sizing MethodsYunping Huang100% (1)

- Vessel DesignDocument43 pagesVessel Designhomiez99No ratings yet

- Membrane Separation Process-Week 10Document52 pagesMembrane Separation Process-Week 10baymaxxxxxNo ratings yet

- Report On Desiging CompanyDocument53 pagesReport On Desiging CompanyArpit ThumarNo ratings yet

- Pressure Vessel Design: Chapter 13: Mechanical Design of Process Equipment by Towler & SinnotDocument40 pagesPressure Vessel Design: Chapter 13: Mechanical Design of Process Equipment by Towler & SinnotEzekielNo ratings yet

- 7.2.24 - Breather ValvesDocument28 pages7.2.24 - Breather Valvessav33No ratings yet

- All Models Are Wrong PreiewDocument12 pagesAll Models Are Wrong PreiewJoão VictorNo ratings yet

- Equivalent Length Calculator - RevADocument10 pagesEquivalent Length Calculator - RevArkrajan1502No ratings yet

- Heat Exchangers: The Effectiveness - NTU Method: Sections 11.4 Through 11.7Document15 pagesHeat Exchangers: The Effectiveness - NTU Method: Sections 11.4 Through 11.7Joli SmithNo ratings yet

- Vessels: G3 © ICARUS Corporation, 1998Document28 pagesVessels: G3 © ICARUS Corporation, 1998Aob AprilNo ratings yet

- Pressure Vessel Training ModuleDocument40 pagesPressure Vessel Training ModuleIdil Fitri100% (1)

- DP2 Process Design Guidelines With Example Storage Tank DesignDocument4 pagesDP2 Process Design Guidelines With Example Storage Tank DesignNicholasBeresfordNo ratings yet

- Storage TanksDocument62 pagesStorage Tankstoychom2013No ratings yet

- Mechanical Design Standards for Shell and Tube Heat ExchangersDocument46 pagesMechanical Design Standards for Shell and Tube Heat ExchangersDawitNo ratings yet

- AST - Tank Shell DesignDocument17 pagesAST - Tank Shell DesignAntony Bruno GenewinNo ratings yet

- Pressure Vessel Design ManualDocument6 pagesPressure Vessel Design ManualJasmine Eliza EspejoNo ratings yet

- Mechanical Design of Shell and TubeDocument21 pagesMechanical Design of Shell and TubeMahesh ewRRpuqQrcNo ratings yet

- Mechanical Design and Design CriteriaDocument32 pagesMechanical Design and Design CriteriaGhost RileyNo ratings yet

- Vessel VolumesDocument72 pagesVessel VolumesPaula RiveraNo ratings yet

- ChE 192 Handout 6a (Storage Tank)Document4 pagesChE 192 Handout 6a (Storage Tank)Aiza CabolesNo ratings yet

- An Automatic Mains Voltage SwitchDocument6 pagesAn Automatic Mains Voltage SwitchKelechi H. HenryNo ratings yet

- Assessment For Learning ToolDocument5 pagesAssessment For Learning ToolDinda Naiya AzhariNo ratings yet

- Continuing Education and Training of AcademicDocument14 pagesContinuing Education and Training of AcademicDinda Naiya AzhariNo ratings yet

- 1 N 4001Document5 pages1 N 4001roozbehxoxNo ratings yet

- Working Hypotheses in ScienceDocument4 pagesWorking Hypotheses in ScienceDinda Naiya AzhariNo ratings yet

- Design, Development and Testing of a Small-Scale Screw Press ExpellerDocument9 pagesDesign, Development and Testing of a Small-Scale Screw Press ExpellerAlex Adams100% (2)

- Science, Technology, Engineering, and Mathematics (STEM) Education What Form? What Function?Document11 pagesScience, Technology, Engineering, and Mathematics (STEM) Education What Form? What Function?Dinda Naiya Azhari100% (1)

- Chemical Operations Safety AuditDocument4 pagesChemical Operations Safety AuditDinda Naiya AzhariNo ratings yet

- Chemical Composition of The MesocarpDocument6 pagesChemical Composition of The MesocarpDinda Naiya AzhariNo ratings yet

- A Cognitive Theory of Inquiry TeachingDocument2 pagesA Cognitive Theory of Inquiry TeachingDinda Naiya AzhariNo ratings yet

- Instrumentation HandbookDocument315 pagesInstrumentation Handbookarvindron67% (6)

- DIGITAL SPEEDOMETER - Measures Speed in Kmph Using Infrared LED & PhototransistorDocument2 pagesDIGITAL SPEEDOMETER - Measures Speed in Kmph Using Infrared LED & PhototransistorSrikanth ReddyNo ratings yet

- A Cognitive Theory of Inquiry TeachingDocument2 pagesA Cognitive Theory of Inquiry TeachingDinda Naiya AzhariNo ratings yet

- 001 enDocument2 pages001 enDinda Naiya AzhariNo ratings yet

- Microwave Plasma Gasification of Coal in Water VapourDocument3 pagesMicrowave Plasma Gasification of Coal in Water VapourDinda Naiya AzhariNo ratings yet

- Design of Steel StructuresDocument50 pagesDesign of Steel StructuresAkhil VNNo ratings yet

- CV1013 - SteelDocument103 pagesCV1013 - SteelAsh KongNo ratings yet

- Ulfe.r9607 02 2 PDFDocument4 pagesUlfe.r9607 02 2 PDFsabari ramasamyNo ratings yet

- Estimate of 1000 M CulvertDocument113 pagesEstimate of 1000 M CulvertManish PatelNo ratings yet

- Above Ground Storage Tank InspectionDocument9 pagesAbove Ground Storage Tank InspectionbeqsNo ratings yet

- A480A480M-14b Standard Specification For General Requirements For Flat-Rolled Stainless and Heat-Resisting Steel Plate, Sheet, and StripDocument27 pagesA480A480M-14b Standard Specification For General Requirements For Flat-Rolled Stainless and Heat-Resisting Steel Plate, Sheet, and Striptjt4779100% (1)

- Making Angle Iron FramesDocument3 pagesMaking Angle Iron FramesStephen WoodNo ratings yet

- PIP STE05121 Anchor Bolt Design GuideDocument56 pagesPIP STE05121 Anchor Bolt Design Guidepklin8866100% (4)

- F1852Document8 pagesF1852mrezaiNo ratings yet

- PIP STE05121 Anchor Bolt Design Guide PDFDocument56 pagesPIP STE05121 Anchor Bolt Design Guide PDFjamilNo ratings yet

- SAEJ403v001 - 1020-1045Document11 pagesSAEJ403v001 - 1020-1045Pablo CastroNo ratings yet

- Adaptable Multi Nut Fastner With Manual Height Adjustment SystemDocument48 pagesAdaptable Multi Nut Fastner With Manual Height Adjustment SystemANAND KRISHNANNo ratings yet

- Παρουσίαση EC3 Connections Και ΙNSTANT Steel 2012Document28 pagesΠαρουσίαση EC3 Connections Και ΙNSTANT Steel 2012danemsalNo ratings yet

- Properties of Stainless SteelsDocument22 pagesProperties of Stainless Steelsngoclinh87No ratings yet

- RR and RD Piles: Design and Installation ManualDocument56 pagesRR and RD Piles: Design and Installation ManualJulián Camilo MateusNo ratings yet

- Data Rates-Canal Works Part 1Document20 pagesData Rates-Canal Works Part 1vpmohammedNo ratings yet

- Bridge Technical Note 2018 - 001 Bridge Traffic Barriers June 2018Document2 pagesBridge Technical Note 2018 - 001 Bridge Traffic Barriers June 2018JunnoKaiserNo ratings yet

- Indian structural steel standards comparison chartDocument6 pagesIndian structural steel standards comparison chartRatnakar PatilNo ratings yet

- Section 520-Piling: 520.1 General DescriptionDocument24 pagesSection 520-Piling: 520.1 General Descriptionmkpasha55mpNo ratings yet

- Mil DTL 12560KDocument52 pagesMil DTL 12560KGökhan ÇiçekNo ratings yet

- Introduction of Aluminum FormworkDocument19 pagesIntroduction of Aluminum FormworkJanice YuanNo ratings yet

- Bavaria Flux BF 5.1Document3 pagesBavaria Flux BF 5.1Filipe CordeiroNo ratings yet

- Sans 719 PipeDocument19 pagesSans 719 PipeFabio Miguel100% (1)

- Steel Fabrication and Installation: SINCE 1935Document8 pagesSteel Fabrication and Installation: SINCE 1935Engineering ComillaNo ratings yet

- USS PlateDocument78 pagesUSS Platepipedown456No ratings yet

- 0000 45eg 0004 - R00 - SignoffDocument28 pages0000 45eg 0004 - R00 - Signoffleroy2007100% (1)

- SGT Grant C Practical Lev 2Document2 pagesSGT Grant C Practical Lev 2Adrian MendezNo ratings yet

- Updated steel design guides Blue Red and Green BooksDocument1 pageUpdated steel design guides Blue Red and Green BooksRufus ChengNo ratings yet

- Moment Connections Seismic ApplicationsDocument46 pagesMoment Connections Seismic Applicationsshak543100% (14)

- Seismic Design of Eccentrically Braced FramesDocument32 pagesSeismic Design of Eccentrically Braced FramesMauricio RiquelmeNo ratings yet