Professional Documents

Culture Documents

TD06 093 PDF

Uploaded by

ARCC2030Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TD06 093 PDF

Uploaded by

ARCC2030Copyright:

Available Formats

1

2006 IEEE PES Transmission and Distribution Conference and Exposition Latin America, Venezuela

Methods for Live Line OPGW Cables Stringing at Voltage Levels of 400 kV and 765kV

Jos A. Pardias G., Jos . Balbs S., Mara J. Villamizar del R., Manuel R. Briceo S., and Robert Boquete V.

levels of 765 kV, 400 kV and 230 kV. The operating transmission lines selected for the above mentioned replacement includes 547 km at tension levels of 765 kV, 736 km to 400 kV and 82 km to 230 kV (interconnection with Colombia). It is important to mention that these transmission lines are supervised by the Interconnected Systems Planning Office (OPSIS by its spanish acronym), entity that regulates the deenergization of the National Electric System in accordance with the daily demand of energy and other aspects related to the maintenance of substations, generation plants and even of the transmission lines at national level. Due to these facts, it was necessary to adopt a strategy for the installation of the OPGW cables that must take into account three (3) operative conditions of the lines [1]: Deenergization every day for ten (10) hours. Deenergization for ten (10) hours, only weekends and holidays. Permanent operation (live line). On the other hand, since the time of project was devised to be executed in a period of one (1) year, three (3) separated work programs were established, meaning that three (3) different contractors would work simultaneously on lines with different operative restrictions and work schemes. This situation offered a good opportunity for CVG EDELCAs engineers to know about diverse methods for OPGW-type cable installation under the operative conditions already mentioned. Also, because of time constraints, it was decided to have three (3) different manufacturers of OPGW cables in order to have them delivered in less than three (3) months. II. PREVIOUS ENGINEERING First, CVG EDELCA by means of the implementation of multimedia technology (georeferenced videos), made previous studies to know the topography and existing access ways to towers, in order to locate better payout sites. This would allow the optimization of the OPGW cables lengths to be installed and also their prompt fabrication from the signing of the contract. After this, it began the reinforcement assessment for the ground wires supports at the top of the towers. It is important to mention that, in average, the transmission lines involved in this project have more than twenty-two (22) years in service and some of them reach ages up to thirty seven (37) years, and

Index TermsGrounding systems, live line work, OPGW cables, stringing methods, transmission lines.

I. INTRODUCTION

VG EDELCA is a venezuelan state-owned public utility that operates a transmission system that comprises 2100 km of overhead lines at 765 kV, 3200 km at 400 kV and about 625 km at 230 kV and 115 kV, covering a big part of the venezuelan territory and also having interconnections with neighbours countries such as Colombia and Brazil. More than 70% of the electric energy generated in the country is transmitted through this system providing electrical power to the most populated areas. At present, more than 1200 km of CVG EDELCAs aerial lines have OPGW cables (ground wires with optical fibers inside). In 2005 the company proposed to extend the network of OPGW cables to cover the major cities and also to interconnect it with another operators involved in the telecommunications business by using the existing infrastructure. Then, it was decided to carry out a replacement project of conventional Alumoweld ground wires installed in its lines, by OPGW-type cables with 24 optical fibers inside, along 1366 km from transmission lines operating at voltage

J. A. Pardias, J. . Balbs, M. J. Villamizar, M. R. Briceo and R. Boquete are with the Transmission Lines Division in CVG Electrificacin del Caron C. A. (CVG EDELCA), Caracas Venezuela (e-mail: jpardinas@edelca.com.ve; jbalbas@edelca.com.ve; mvillamizar@edelca.com.ve; mabriceno@edelca.com.ve; rboquete@edelca.com.ve).

1-4244-0288-3/06/$20.00 2006 IEEE

in these time periods, these lines had been interconnected to other transmission systems resulting in an increase of the short circuit levels for which they were designed. This implied an increased diameter for the new cables to be installed, which, added to the fact that OPGW cables have larger diameters because of containing optical fibers inside, led to the supposition that about 60% of the structures must be reinforced in order to support for the new OPGW cables. The contractual specifications allowed to use the conventional groundwire as pilot line to pull the new OPGW cable. However, in case of transmission lines in highly corrosive areas, it is necessary to do a detailed verification to ensure that it could be used as pilot line or as a pre-pilot to pull a nylonmade pilot rope which in turn would pull the new OPGW cable. In specified requirements, it is necessary to have new, or with very little use, stringing equipment, reversible or dual type (capable to operate as puller or tensioner), use of sheaves with neoprene lined grooves and minimal diameters of 500 mm as well as double travelers in towers with angles greater than 30, identification of critical zones such as crossings of the lines with highways, another transmission lines, etc., which by the way must be protected [1], [2]. A fundamental aspect to be taken into account in live line tension stringing with regard to those conventional methods, are the safety distances that must be maintained at all moments between the ground wires and the energized phase conductors in order to guarantee the safety of the personnel involved in the work, and avoiding also the unexpected outage of the energized lines. It is therefore the sag control of the ground wires with regard to the energized conductors a priority aspect of control, as well as the strict application of a series of safety rules that can be classified as preparation rules and execution rules. Previous to the stringing maneuvers, preparation rules imply a series of considerations that must be taken into account in order to guarantee the safe execution of all procedures; among these are included: Verification of the minimum approach distances and ergonomic distances [3]. Routine safety briefings to the personnel involved in the execution of the works. Definition of safety zones to work within the tension sites. Verification of clear communication links along the stringing section. Exhaustive check of the condition of the existing groundwire for its use as pilot line to pull the new OPGW cable. Evaluation of the status of the towers grounding systems. On the other hand, the basic safety execution rules are related to suitable grounding, before, during and after the stringing process, so much of the machinery (ground grids, Fig. 1), as well as the cables used during the pulling stage (rolling grounds, Fig. 2); and also with proper handling of the hardware during the maneuvers in voltage proximity [3], [4].

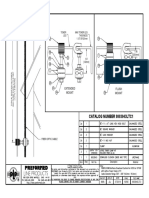

Fig. 1. Detail of the ground grid for the stringing equipment.

Fig. 2. Detail of the rolling ground installed on the OPGW cable.

Another fundamental and mandatory rule to consider for the execution of the works is the disconnection, in this case by CVG EDELCA, of the automatic reclosers. This is with the purpose of avoiding risks to the personnel in the event that an unprogrammed outage took place in the line being worked on. III. LIVE LINE STRINGING METHODS Considering the operative conditions: deenergization or continuous operation (live line), previously mentioned, there were implemented three (3) stringing methods to install OPGW cables: A. Conventional Method [5] Having the lines deenergized for ten (10) hours, the controlled tension stringing method consisted in locating the stringing machines, preferably with capacity of dual operation, on stringing sections with an average length of 5.5 km; the pulling tensions in the order of 500 kgf at an average speed around 40 m/min which suposes that the whole stringing process was carried out between three (3) and four (4) hours. With this conventional stringing method there were installed approximately 1.054 km of OPGW cables.

B. Provisional Ground Wire Support Method This stringing method is similar to the conventional one with the peculiarities inherent to the fact that the line is energized, which implies that at all times there must be guaranteed the minimal distances allowed between the cables to install and the energized conductors below them. This is achieved fundamentally controlling the cables sag during its pulling and the adequate separation with the phase conductors in the ascents and descents of the first one to the pulling machines. Regarding the sag control, this is achieved by using special stringing machines capable of pulling the cables in any direction; which allows that the same machine could be used to pull or to brake the cable coiled in its drums (reversible machine). If both machines are placed in counterposition at the same mechanical tension, that is to say, applying each of them the same value of mechanical tension in opposite directions, the cable will be in mechanical balance; then the stringing direction will be determined by the unbalance in the mechanical tensions applied by each one of the machines, resulting in a completely controlled movement, because the machines have the capacity to fix so much the value of the pulling tension as that of balance (braking). On the other hand, to control the ascents and descents of the cable within the so called stringing corridor (Fig. 3), it is necessary the installation on the top of the tower of specially designed devices to displace the ground wire from its original position to a safe one located exactly between the energized conductors (Fig. 4).

Fig. 4. Detail of the provisional ground wire support structure installed on the top of the tower to displace the cable to the stringing corridor [6].

Fig. 3. Stringing corridor.

In case of the ascents and descents of the cable to install from the pulleys down to the stringing equipment in payout sites of difficult access, it is advisable, to forward the cable along the towers body by means of the use of pulleys that guarantee the correct bending radius for the OPGW cable [1]. As mentioned before, to achieve the necessary control of the stringing tension of the ground wire, reversible machines are needed with capability to act as puller or tensioner, and that also have the characteristic to fix and limit the mechanical tension and speed, according to the specifications [1], [2]. In the case of CVG EDELCAs transmission lines operating at voltage levels of 765 kV, the machines used for the stringing of the OPGW cables present the following features: Maximum mechanical tension as puller/tensioner: 4000 kgf. Continuous mechanical tension as puller/tensioner: 3500 kgf. Minimal mechanical tension as puller/tensioner: 2500 kgf. Tension control system by means of dynamometer, with automatic stop at a previously fixed value of tension. With this particular methodology there were installed 123 km of OPGW cable on the 765 kV line La ArenosaYaracuy. It is important to mention that, additionally to the special safety considerations necessary for the application of any live line installation methodology, based on the acquired experience in the execution of these kinds of projects, two (2) important peculiarities associated with its implementation could be identified: Need of qualified personnel to operate the stringing machinery. Existance of critical stages during the execution of the works; these would be: the ascents and descents of the cables to install on the towers in the tensions sites and the sag control of the OPGW cables sag to avoid risks of flashovers. C. SelfPropelled Traction Machine Method This method is one of the most innovative developed for safe live line stringing. For the first time applied in Venezuela, it possesses the peculiarity that uses a series of equipment and specific accessories (Fig. 5 and Fig. 6), for its

implementation, among which we can mention: Reversible single wheel. Supporting rope, made with dielectric material in different lengths. Tightening rope, of approximately 20 m long.. Wire grip. Self-propelled traction machine. Recoverer.

in intervals of approximately 15 m long, the reversible single wheels (that previously were raised to the top of the tower). This procedure must be carried out in all the spans corresponding to the stringing section to execute. When the traction machine completely covers the respective span, the supporting rope is anchored to the top of the tower and attached to the wire grip to begin slackening the existing groundwire and later tightening the supporting rope, following the graphic sequence showed in Fig. 7.

Fig. 5. Special accesories and equipment used for the implementation of the SelfPropelled Traction Machine Method [7].

Fig. 7. Relative exchange of positions between the OPGW cable and the supporting rope [8].

Fig. 6. SelfPropelled Traction Machine installed onto the ground wire.

This particular stringing method is executed following the sequence of maneuvers described next: Once placed the stringing equipment it begins to prepare the supporting rope, which must include the whole length of the correspondent span. The supporting rope has different lengths indicated with a color code. In the end of the supporting rope must be attached the special tightening rope, this special rope has several resin stoppers (in intervals of 2,5 m) that works as a wedge when tightening the supporting rope with the wire grip. After preparing the necessary length of the supporting rope, it has to be extended along the span using the selfpropelled traction machine, previously placed on the existing overhead groundwire. During the trip of the machine over the cable, it is necessary to attach manually,

Fig. 7 shows the system composed by the reversible single wheels and the supporting rope once the traction machine completes its trip. When the mechanical tension is increased progressively on the supporting rope, it will reach a superior value of mechanical tension with regard to the existing ground wire; which brings as consequence, the relative exchange of positions between the ground wire and the supporting rope. Once the ground wire remains suspended on the reversible single wheels installed on the supporting rope, only the pulling of the OPGW cable is pending. Then, after tightening the supporting rope, it is necessary to put the existing ground wire onto the pulleys that were previously installed on the top of the structures. Later, the pulling of the new OPGW cable will begin, using the existing ground wire as a pilot line. It is important to emphasize that during the whole pulling process it must be guaranteed that the set composed by the cables, the supporting rope and the reversible single wheels is all the time keeping the correct safety clearances, according to the voltage level of the line. Finally, once installed completely the OPGW cable only remains pending the sagging and clippingin, for which it

is necessary to withdraw the supporting rope and all other accesories attached to it. Then, it is necessary to reduce the mechanical tension applied on the supporting rope so that this one returns to its original position suspended on the reversible single wheels, supported now by the new OPGW cable installed; once done this, proceed to place the recoverer attached to the supporting rope in the opposite side of the span to finally pull it manually. The whole process described above is showed in the following graphic scheme:

maneuvers due to the huge quantity of details and meticulous procedures involved in each stage of the process; on the other hand, it is important to highlight the high level of safety that implies the application of this methodology because at all times the cables to be installed are maintained away from the energized conductors. For stringing a reel with an average cable length of 5.5 km, four (4) traction machines were used and the whole installation process took about three (3) days, beginning with the installation of the supporting ropes and finishing with the sagging and clippingin of the new OPGW cable. IV. CONCLUSIONS Both live line stringing methods were suitable, presenting similar performances. The flexibility and efficiency of the SelfPropelled Traction Machine Method was verified in lines with more than twenty (20) years in service, with successful results due to the low mechanical tensions applied on the old cables. On the other hand, it was verified the simple and safe application of the Provisional Ground Wire Support Method on UHV lines (765 kV), that need considerable safety distances. Although the execution of this replacement project of conventional Alumoweld ground wires by OPGW cables had, as a fundamental scope, to have a communications platform along the country that will be interconnected by other similar networks of users, from the point of view of the transmission lines involved, there were generated a series of aggregated values to the project, such as: New OPGW cables were installed with improved short circuit capacities, which supposes a more reliable operation of the transmission lines, and of course, of the entire transmission system. Reconditioning of the existing access ways to the towers. Replacement of old ground wires, renewal of suspension and deadend clamps and dampers, that in some lines have had more than thirty five (35) years of having been installed, so that it can be said that a major maintenance project has been carried out. Additionally, the replaced materials will be object of studies in laboratories of CVG EDELCA, in order to determine its current mechanical conditions as well as also they have been affected by corrosive environments. These studies are the basis for better planning in preventive maintenance. It was established the criterion for reinforcing both ground wires supports, so that in the future will be possible to install another OPGW cable without any trouble concerning to the structural capacity of the tower. A technical audit of the physical state of the structures, insulators and earthing systems of the structures was done. This will allow, if necessary, to correct the possible shortcomings on these technical aspects in order to improve the status of the transmission lines.

Fig. 8. Execution scheme of the SelfPropelled Traction Machine Method [7].

This methodology was applied in approximately 189 km corresponding to the lines GuriLa Canoa N 3 and La CanoaEl Tigre N 3, operating both at a voltage level of 400 kV. Among the peculiarities that characterize this methodology we must emphasize the need of previous preparation for the personnel that executes the stringing

V. REFERENCES

[1] CVG EDELCA, Suministro de materiales y montaje de cables de guarda del tipo OPGW en lneas de transmisin en operacin Especificaciones particulares y planos de licitacin, vol. II, Sep. 2004. CVG EDELCA, Suministro de materiales y montaje de cables de guarda del tipo OPGW en lneas de transmisin en operacin Especificaciones generales, vol. IV, Sep. 2004. Live working Minimum approach distances for a. c. Systems in the voltage range 72,5 kV to 800 kV A method of calculation, IEC International Standard 61472, Second edition, 2004. Live working Guidelines for the installation of transmission line conductors and earthwires Stringing equipment and accesory items, IEC Technical Report 61328, Second edition, 2003. IEEE Guide to the Installation of Overhead Transmission Line Conductors, IEEE 524-1992. L. J. Fernndez Gonzlez, R. Garca Fernndez, M. . Fernndez Fernndez and C. Ramiro Visser, Mtodo de tendido de fibra ptica con la lnea en tensin, CIER, Madrid, Oct. 2002. MEC TSURIKIN METHOD. Available: http://www.meitodenki.co.jp/eng/home.html; http://www.meitodenki.co.jp/eng/mec2.html; http://www.meitodenki.co.jp/eng/mec3.html. Siemens, LIVELINE Optical Ground Wire Installation, S46999l4187-P431, First edition, Nov. 2004.

[2]

[3]

Manuel R. Briceo S. was born in Caracas, Venezuela. He received the B.Sc. degree in Civil Engineering from Universidad Jos Mara Vargas, CaracasVenezuela. Since 1996 he has been with C.V.G. Electrificacin del Caron (CVG EDELCA) in the Transmission Lines Construction Department. His research interests are new overhead lines construction methods and technologies, and transmission lines towers foundations design.

[4]

[5] [6]

[7]

Jos . Balbs S. was born in Anaco, Venezuela. He received the B.Sc. degree in Electrical Engineering from Universidad de Oriente, AnzoteguiVenezuela; and the M.Sc. degree in Power Systems Analysis from University of Manchester Institute of Science and Technology (UMIST). Since April 2003 he has been Transmission Lines Construction Department Chief of CVG EDELCA. His research interest are new overhead lines construction methods and technologies. Mara J. Villamizar del R. was born in Caracas, Venezuela. She received the B.Sc. degree in Mechanical Engineering from Universidad de Los Andes, MridaVenezuela. She also is an Especialist on Public Management from IESA, Caracas Venezuela, and is currently working with C.V.G. Electrificacin del Caron (CVG EDELCA) at the Transmission Lines Construction Department. Her research interests are live line stringing methods and maintenance. Robert Boquete V. was born in Caracas, Venezuela. He received the B.Sc. degree in Electrical Engineering from Universidad Simn Bolvar, CaracasVenezuela. He is currently working with C.V.G. Electrificacin del Caron (CVG EDELCA) at the Transmission Lines Construction Department. His research interest are OPGW cables, new conductor technologies and innovative methods for constructing overhead transmission lines.

[8]

Jos A. Pardias G. was born in Valencia, Venezuela. He received the B.Sc. degree in Electrical Engineering from Universidad de Carabobo, VelenciaVenezuela. Since 1980 he has been with C.V.G. Electrificacin del Caroni, C.A. (CVG EDELCA) in the Transmission Line Division. He is involved in Technical Specification, Latticed Tower Design, Tower Testing, Route Selection, Transmission Line Design by (PLS CADD and BELT) software, Project Control, Environmental Impact Study, etc. From 1985 he was the on-site Project Engineer of The Transmission Lines in 115 kV, 230 kV, 400 kV and 765 kV. Since 2002 he has been Transmission Lines Division Manager of CVG EDELCA. Mr. Pardias Gonzalez is associate member of the Group B2 of Conseil International Des Grands Reseaux Electriques (CIGRE).

You might also like

- Installation Procedure Coyote6.5x17dome - sp2980Document20 pagesInstallation Procedure Coyote6.5x17dome - sp2980ARCC2030No ratings yet

- Installation Procedure SP2130 - SpiralVibDamperDocument2 pagesInstallation Procedure SP2130 - SpiralVibDamperARCC2030No ratings yet

- Data Sheet FIBERLIGN - Downlead - CushionDocument4 pagesData Sheet FIBERLIGN - Downlead - CushionARCC2030No ratings yet

- Fiberlign Dielectric Damper Adss .462 - .563Document1 pageFiberlign Dielectric Damper Adss .462 - .563ARCC2030No ratings yet

- Pipe Line Leak DetectionDocument28 pagesPipe Line Leak DetectionARCC2030No ratings yet

- Data Sheet FIBERLIGN - Dielectric - Dead-EndDocument8 pagesData Sheet FIBERLIGN - Dielectric - Dead-EndARCC2030No ratings yet

- Installation Procedure Sp2732-2fiberlign - de - 1Document4 pagesInstallation Procedure Sp2732-2fiberlign - de - 1ARCC2030No ratings yet

- 24 Count Splice TrayDocument1 page24 Count Splice TrayARCC2030No ratings yet

- Installation Procedure Sp2709-3Document2 pagesInstallation Procedure Sp2709-3ARCC2030No ratings yet

- Catalog Number 8004072EDocument1 pageCatalog Number 8004072EARCC2030No ratings yet

- 8003043LTC1 FIBERLIGN Urethane Downlead Cushion .563-.656Document1 page8003043LTC1 FIBERLIGN Urethane Downlead Cushion .563-.656ARCC2030No ratings yet

- 5060xxx Fiberlign Adss Corona CoilDocument1 page5060xxx Fiberlign Adss Corona CoilARCC2030No ratings yet

- OPGW EvaluationDocument4 pagesOPGW EvaluationARCC2030No ratings yet

- Over Head Line SpecificationsDocument208 pagesOver Head Line SpecificationsARCC2030No ratings yet

- ACCC Midal Data (European Sizes)Document23 pagesACCC Midal Data (European Sizes)Kapil MishraNo ratings yet

- Descriptive Geometry Book 1Document28 pagesDescriptive Geometry Book 1ARCC2030No ratings yet

- Process Mapping and Process-Based Internal AuditsDocument59 pagesProcess Mapping and Process-Based Internal AuditsTiagoHillerman100% (1)

- Accc InstallationDocument4 pagesAccc InstallationARCC2030No ratings yet

- Kerite Underground Cable Engineering HandbookDocument24 pagesKerite Underground Cable Engineering HandbookARCC2030No ratings yet

- FTTH Handbook - 2017 - V8 - FINAL PDFDocument204 pagesFTTH Handbook - 2017 - V8 - FINAL PDFNavid Mir Motahhary100% (1)

- Fiber Optic CablesDocument24 pagesFiber Optic CablesARCC2030No ratings yet

- Cat07 Design GuideV10Document20 pagesCat07 Design GuideV10Mce RegNo ratings yet

- ACCC Midal Data (European Sizes)Document23 pagesACCC Midal Data (European Sizes)Kapil MishraNo ratings yet

- Cat07 Design GuideV10Document20 pagesCat07 Design GuideV10Mce RegNo ratings yet

- Etisalat telecom design guide for buildingsDocument12 pagesEtisalat telecom design guide for buildingsLaith ShakirNo ratings yet

- A Tutorial On Optical Ground Wire Ratings Analysis For Protection EngineersDocument9 pagesA Tutorial On Optical Ground Wire Ratings Analysis For Protection EngineersARCC2030No ratings yet

- ADVA Fiber RequirementsDocument8 pagesADVA Fiber RequirementsARCC2030No ratings yet

- OSP FO WorkDocument50 pagesOSP FO WorkARCC2030No ratings yet

- Eia Tia - 568BDocument8 pagesEia Tia - 568BSlavisa MileticNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Xi Subiect Olimpiada Sectiunea A Var1Document2 pagesXi Subiect Olimpiada Sectiunea A Var1theodor2radu0% (1)

- Proposal of FreelanceDocument3 pagesProposal of FreelanceSantuNo ratings yet

- STS Activity 1Document3 pagesSTS Activity 1SHARAINE PRINCESS CASTILLONo ratings yet

- Introduction To Quantum ComputingDocument131 pagesIntroduction To Quantum ComputingImpala RemziNo ratings yet

- Global PEB System and Solutions Company ProfileDocument10 pagesGlobal PEB System and Solutions Company ProfileswapnilNo ratings yet

- LO Extraction Part 3 Extractor LogicDocument15 pagesLO Extraction Part 3 Extractor LogicVijay ChandraNo ratings yet

- Windrock 6320 Brochure 2013Document4 pagesWindrock 6320 Brochure 2013Amaury André100% (1)

- Volkswagen Car PartsDocument2 pagesVolkswagen Car PartsMcDowellMcDowell50No ratings yet

- Installation Instructions: Sirius Retrofit Kit - P/N 65 11 0 406 351Document8 pagesInstallation Instructions: Sirius Retrofit Kit - P/N 65 11 0 406 351Sébastien MahutNo ratings yet

- Top 50 Android Interview QuestionsDocument9 pagesTop 50 Android Interview QuestionsluongbetaNo ratings yet

- Project Report On Brand Preference of Mobile Phone Among College Students1Document61 pagesProject Report On Brand Preference of Mobile Phone Among College Students1Faraz Haq100% (1)

- Circuit breaker testing with micro-logic trip unitDocument16 pagesCircuit breaker testing with micro-logic trip unitgeo_biNo ratings yet

- Computer Science PracticalDocument41 pagesComputer Science Practicalsikander.a.khanixd26No ratings yet

- Influencer Marketing to Hit $8 Billion by 2020Document1 pageInfluencer Marketing to Hit $8 Billion by 2020shahfirozNo ratings yet

- DAS Event210a-01 MANULDocument2 pagesDAS Event210a-01 MANULCiho SebastianNo ratings yet

- Deep Dive On Amazon Guardduty: Needle - Needle.Needle Wait These Are All NeedlesDocument36 pagesDeep Dive On Amazon Guardduty: Needle - Needle.Needle Wait These Are All Needlesmasterlinh2008No ratings yet

- Generalised Job Description - Chief Information Officer V1.0Document3 pagesGeneralised Job Description - Chief Information Officer V1.0SplatttttttNo ratings yet

- Types of Comments in JavaDocument4 pagesTypes of Comments in JavaAltamashNo ratings yet

- KING LONG Operation Manual XMQ6900JDocument132 pagesKING LONG Operation Manual XMQ6900JWence Clement AgustinNo ratings yet

- EHV AC & DC TRANSMISSION MCQ questionsDocument4 pagesEHV AC & DC TRANSMISSION MCQ questionsRitNo ratings yet

- 20533C ENU TrainerHandbookDocument588 pages20533C ENU TrainerHandbookovidiuviper100% (1)

- Dse4420 Installation InstDocument2 pagesDse4420 Installation InstMuhammad Denny67% (3)

- Newrock Configuration Auto ProvisionDocument38 pagesNewrock Configuration Auto ProvisionMinh NguyenNo ratings yet

- IF10VF PANEL Version 5Document47 pagesIF10VF PANEL Version 5ScribdTranslations100% (3)

- Error MSGDocument360 pagesError MSGAlexandre LepesqueurNo ratings yet

- TimingBeltInterval D3 VOLVODocument8 pagesTimingBeltInterval D3 VOLVOdjclaudiuNo ratings yet

- Unit 1Document59 pagesUnit 1ayush charde 786No ratings yet

- Canteen Credit System Automates Manual ProcessDocument24 pagesCanteen Credit System Automates Manual ProcessCRYPTO GAMINGNo ratings yet

- Introduction to Maintenance ManagementDocument13 pagesIntroduction to Maintenance Managementn.tNo ratings yet

- HR Policies and PracticesDocument25 pagesHR Policies and PracticesIndu ManakkatNo ratings yet