Professional Documents

Culture Documents

AK About

Uploaded by

SasiKumar PetchiappanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AK About

Uploaded by

SasiKumar PetchiappanCopyright:

Available Formats

Ask about Parametric and Feature-Based Modeling

Another feature of modern CAD systems is the ability to create parametric models. In a parametric model, each entity, such as a boolean primitive, a line or arc in a wireframe, or a filleting operation, has parameters associated with it. These parameters control the various geometric properties of the entity, such as the length, width and height of a rectangular prism, or the radius of a fillet. They also control the locations of these entities within the model. These parameters can be changed by the operator as necessary to create the desired part. Parametric modelers that use a history-based method keep a record of how the model was built. When the operator changes parameters in the model and regenerates the part, the program repeats the operations from the history, using the new parameters, to create the new solid. There are many uses for this type of modeling. Designers can test various sizes of parts to determine which is the ``best'' part for their use by simply adjusting the model parameters and regenerating the part. Some parametric modelers also allow constraint equations to be added to the models. These can be used to construct relationships between parameters. If several parameters always require the same value, or a certain parameter depends on the values of several others, this is the best way to ensure that these relationships are always correct. These modelers allow other methods of relating entities as well. Entities can be located, for example, at the origin of curves, at the end of lines or arcs, at vertices, or at the midpoints of lines and faces. They can also be located at a distance or at the end of a vector from these points. When the model is regenerated, these relationships are maintained. Some systems will also allow geometric constraints between entities. These can require that entities be, for example, parallel, tangent, or perpendicular. Feature-based modelers allow operations such as creating holes, fillets, chamfers, bosses, and pockets to be associated with specific edges and faces. When the edges or faces move because of a regeneration, the feature operation moves along with it, keeping the original relationships. The choices made developing these models are very important. If the features aren't referenced correctly, they may not end up in the correct place if the model is regenerated. A feature that is located at an X and Y offset from a corner of the face instead of at the center of the face will not remain at the center of the face when the model is regenerated unless constraints are added to the model that will change the X and Y offsets to keep the feature at the center of the face. [Shah]

Parametric Modelling Basics

Nowadays, parametric 3D CAD solid and surface models are the principal means of communicating design ideas and developing new products and systems. 3D parametric modelling facilitates visual thinking and the design process, and represents a welcome addition to the traditional three R's of reading,writing and arithmetic. It stimulates students to use their imagination and problem solving skills and helps them to become more technologically literate. Worldwide, parametric modelling systems are part of a technology education reform movement that seeks to improve critical thinking and multidimensional problem-solving skills, while also inspiring and preparing a growing number of students to become the engineers, designers and technologists of tomorrow.

Parametric modelling enables learners to think and create in three dimensions with sophisticated design software typically used by manufacturers. Integrating it into technological subjects will inspire more students to become the innovators of tomorrow by choosing careers in product design, engineering and technology. The integration of parametric modelling into the technological subjects will give these subjects a great future and make them even more relevant to the needs of society. It will modernise these subjects and bring excitement, interest, and vibrancy to them and facilitate the realisation of their potential.

What is Parametric Modelling?

Parametric modellers are often referred to as Mechanical CAD (MCAD) modellers and can be described as parametric, feature-based, solid and surface modelling design tools. Let us look briefly at these terms.

Parametric

The term parametric essentially means that MCAD software uses parameters. The most significant of these parameters are dimensions, and in MCAD software, dimensions drive the geometry, as opposed to the geometry driving the dimensions, which is the case in 2D and traditional 3D solid modellers. Therefore when you change a dimension value, this causes the model size to change. In addition, the relations or constraints used to create the features of a part are also captured in the model.

Features

A feature is the basic unit of a parametric solid model. Just as an assembly is made up of individual parts, a part file is made up of individual elements called features. Each feature has intelligent properties that define it. When a feature is created, the geometric constraints and

dimensions that apply to it are specified. The modeller stores these properties and uses them to generate the feature. Examples of these basic building blocks called features are bosses, holes, ribs, cuts, fillets, and chamfers. New features are dependent on existing features in such a manner that design changes are captured automatically. In essence, feature-based modelling captures the designer's intent. If an element of the feature, or a related part of the model, changes, the modelling software re-generates that feature in accordance with the defining properties assigned to it. For example, an edge that is defined to be tangent to an arc will move to preserve the tangency constraint if the size of the arc is changed. Features can be classified into two main types, namely sketched features and applied or placed features.

Sketched Features

A sketched feature requires a 2-D sketch that is then transformed into a feature in one of four main ways. These part modelling methods are extrude, revolve, sweep and loft.

Applied features

Applied features are applied directly to the model and do not require a sketch. Fillets, chamfers, draft and shell are examples of these features.

Solid Modelling

A solid model completely and unambiguously represents the geometry and topology of a part. In addition to the information contained in surface models, solid models contain volume information. This means that a solid model can provide such information as the mass properties of a part and interference checking between parts in an assembly.

Associativity

3D modelling software can automatically update related parts of the model when design changes are made and there is full bi-directional associativity between parts, assemblies and drawings. This means that your drawings are always correct as they are based on the parts and assembly models and changes to a drawing transfer back to parts and assemblies.

Advantages of Parametric Modelling.

3D parametric solid modelling offers the following advantages over traditional 2D drawings:

In addition to standard orthographic views, 3D solid models also offer an unlimited range of ways to view the model, including rendered and animated views. 3D modelling software can automatically update related parts of the model when design changes are made and there is full bi-directional associativity between parts, assemblies and drawings. 3D systems provide easier design revisions. Changes can be made at the level of each individual sketch and feature. If a sketch is not the required size, it can be easily edited by selecting the

relevant dimensions. Similarly, the definition of individual features can be edited by changing their properties. 3D systems are more motivational, interesting and appealing for today's students who have never used a typewriter, owned a vinyl record or a black and white television. Parametric modellers have a rollback feature that shows the sequence in which the model was created. This is an invaluable tool for learning modelling strategies from existing models and is also very useful for assessing student work Not alone is the modelling sequence captured in a parametric system but modelling errors are highlighted for the user. With 2D systems there is no error checking. 3D conveys a superior sense of what an artefact will look like. Form and shape and overall model proportions are more easily understood and defined in 3D. In essence, 3D systems provide better design visualization. 3D systems better capture design intent. This essentially relates to how the model should behave when design changes are made. 3D systems provide automated drawing production. Within industry, 3D systems provide better integration with downstream applications and reduced engineering cycle time. The accuracy and completeness of the design definition in the CAD database make the models suitable for use in analysis and for transfer to rapid prototyping and manufacturing machinery.

The Parametric Solid Modelling Process

The starting point for a parametric solid model is a sketch that need only be the approximate size and shape of the part or feature being created, as dimensions can be added later to change the size and shape of the geometry. While a parametric solid model is an intelligent representation of a part, it is important to analyse and plan every part before modelling to determine the most efficient sequence for creating the features. Poor modelling strategies will result in parts that take longer to create and that are difficult to edit. Features should be created to allow for maximum part flexibility and variation. Rather than perceiving the finished solid model as a large solid mass, it needs to be viewed as a composition of features that are likely to be modified.

Before starting to sketch, the model should be studied to identify the best profile to use for creating the base feature. The best profile is that which best describes the overall shape of the part, and will minimise the number of remaining features needed to complete the model. Each new part contains three infinite reference planes, which represent the front, top and right planes in space, each of which passes through the origin, which is the zero point in space.

The general procedure for parametric modelling is to decide on the best or most descriptive profile for the first sketch for the base (first) feature of the model. You then select the most appropriate sketch plane on which to create this first sketch so that the final model will have the correct orientation when viewed pictorially. The sketch geometry should be created by capturing constraints as you sketch, and then dimensioned to fully define the geometry.

Although sketches do not have to be fully defined to create features, normally it is better to do so to avoid possible later model distortion. A fully defined sketch is black and is the desired state, whereas an underdefined sketch is blue. An overdefined sketch is red.

The 2D sketch is then turned into a 3D solid usually by an extrusion or a revolve process. As noted previously, sketches can also be turned into solid features through a sweep or loft process. Extrusions pull the sketch normal to the sketch plane, while a revolved feature rotates the sketch around an axis. Sweeping moves the sketch along a path made up of straight or curved geometry, while lofting uses multiple sketches to transition from one shape to another. Each sketch is linked to its resulting feature. If you go back and change the sketch, the feature will update to reflect the change. Normally each sketched feature will require its own sketch. Fillets and rounds can be added to the model to round sharp corners that would be inappropriate to do in a sketch. From the finished solid model you can create a drawing file with standard dimensioned orthographic and isometric views.

You might also like

- Steps For PF Amount Transfer (New) ..............Document5 pagesSteps For PF Amount Transfer (New) ..............SasiKumar PetchiappanNo ratings yet

- Work Permit (Ra Puram) - 28-Nov - 2013Document1 pageWork Permit (Ra Puram) - 28-Nov - 2013SasiKumar PetchiappanNo ratings yet

- Grade 3 MathsDocument3 pagesGrade 3 MathsSasiKumar PetchiappanNo ratings yet

- Slot Information Report - 07!15!2015!19!28-07Document2 pagesSlot Information Report - 07!15!2015!19!28-07SasiKumar PetchiappanNo ratings yet

- Slot Information Report - 07!15!2015!19!28-07Document2 pagesSlot Information Report - 07!15!2015!19!28-07SasiKumar PetchiappanNo ratings yet

- User Manual 5 PDFDocument518 pagesUser Manual 5 PDFSasiKumar PetchiappanNo ratings yet

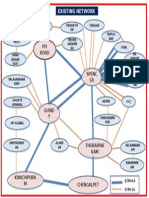

- Existing Network Connecting Key Areas in ChennaiDocument1 pageExisting Network Connecting Key Areas in ChennaiSasiKumar PetchiappanNo ratings yet

- Chapter-4: 4.1 Matrix MaterialsDocument17 pagesChapter-4: 4.1 Matrix MaterialsSasiKumar PetchiappanNo ratings yet

- Question Bank: Ee 1403 - Design of Electrical ApparatusDocument11 pagesQuestion Bank: Ee 1403 - Design of Electrical ApparatussuriyasureshNo ratings yet

- Institution Paper Presentation Contests: S.No Name of The Program Duration of The Program Resource Person(s)Document34 pagesInstitution Paper Presentation Contests: S.No Name of The Program Duration of The Program Resource Person(s)SasiKumar PetchiappanNo ratings yet

- Chapter-5: 5.1 Fabrication Techniques of Composite MaterialsDocument6 pagesChapter-5: 5.1 Fabrication Techniques of Composite MaterialsSasiKumar PetchiappanNo ratings yet

- Theory of Machines12Document1 pageTheory of Machines12SasiKumar PetchiappanNo ratings yet

- Content Materials1Document40 pagesContent Materials1SasiKumar PetchiappanNo ratings yet

- Front Pagels and BonofideDocument2 pagesFront Pagels and BonofideSasiKumar PetchiappanNo ratings yet

- A R Collage of Engineering and TechnologyDocument1 pageA R Collage of Engineering and TechnologySasiKumar PetchiappanNo ratings yet

- Ieee Electronics 2013 - 2014Document49 pagesIeee Electronics 2013 - 2014SasiKumar PetchiappanNo ratings yet

- SalmanDocument2 pagesSalmanSasiKumar PetchiappanNo ratings yet

- Quality ConceptDocument2 pagesQuality ConceptSasiKumar PetchiappanNo ratings yet

- Muhammad NijasDocument2 pagesMuhammad NijasSasiKumar PetchiappanNo ratings yet

- Design Fundamentals and Methods for Materials SelectionDocument1 pageDesign Fundamentals and Methods for Materials SelectionSasiKumar PetchiappanNo ratings yet

- Electrical Based Titles 2009-2010Document2 pagesElectrical Based Titles 2009-2010Siva SankarNo ratings yet

- Write The Procedure To Compile and Install Linux Kernel From SourceDocument1 pageWrite The Procedure To Compile and Install Linux Kernel From SourceSasiKumar PetchiappanNo ratings yet

- Centre For Research Anna University:: Chennai 600025 Enrolment Form/ Registration Renewal FormDocument1 pageCentre For Research Anna University:: Chennai 600025 Enrolment Form/ Registration Renewal FormruthshaNo ratings yet

- 2K Factor PDFDocument6 pages2K Factor PDFvmgobinathNo ratings yet

- 405 M.E. Computer Science and EngineeringDocument68 pages405 M.E. Computer Science and EngineeringThanuambikaNo ratings yet

- Food and OilDocument11 pagesFood and OilSasiKumar PetchiappanNo ratings yet

- Iat-2 EgDocument1 pageIat-2 EgSasiKumar PetchiappanNo ratings yet

- Line Chart 3Document2 pagesLine Chart 3SasiKumar PetchiappanNo ratings yet

- Time Table For EngDocument1 pageTime Table For EngSasiKumar PetchiappanNo ratings yet

- Rainwater Harvesting Basic ComponentsDocument3 pagesRainwater Harvesting Basic ComponentsSasiKumar PetchiappanNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Geometric Boundaries SI SellDocument9 pagesGeometric Boundaries SI SellErman KILICNo ratings yet

- 94CDocument6 pages94CAjay MalikNo ratings yet

- Geometry formulas for areas, perimeters, volumes and surface areasDocument2 pagesGeometry formulas for areas, perimeters, volumes and surface areasPoppy HowellNo ratings yet

- (Sheldon Axler) Linear Algebra Done Right Ch01 EspaciosVectorialesDocument20 pages(Sheldon Axler) Linear Algebra Done Right Ch01 EspaciosVectorialesCarlos Orlando Solórzano VillalbaNo ratings yet

- EG Question - Final - PrintDocument9 pagesEG Question - Final - PrintgandhiramNo ratings yet

- Two Angles and Plate Section Moments of InertiaDocument14 pagesTwo Angles and Plate Section Moments of InertiaIsrael MogrovejoNo ratings yet

- MathPath Breakout Catalog 2016Document17 pagesMathPath Breakout Catalog 2016Bharat ShresthNo ratings yet

- Trigonometry For IIT JEEDocument3 pagesTrigonometry For IIT JEEblue_l1No ratings yet

- Test Paper For Iit JeeDocument4 pagesTest Paper For Iit JeeGaurav YadavNo ratings yet

- Isometric Layout Drawing Isometric Offsets Calculating Isometric Offsets Isometric Dimensioning & LabelingDocument18 pagesIsometric Layout Drawing Isometric Offsets Calculating Isometric Offsets Isometric Dimensioning & LabelingA K NairNo ratings yet

- Mechanism vector solutionsDocument6 pagesMechanism vector solutionsmajahzcoNo ratings yet

- Aidann Gia Bacolodan Lab FiveDocument9 pagesAidann Gia Bacolodan Lab FiveaidanngiaNo ratings yet

- Department of Education: Time Technical Instruction SpielDocument16 pagesDepartment of Education: Time Technical Instruction SpielMarvin Yebes ArceNo ratings yet

- Math1 2Document41 pagesMath1 2mivel82872No ratings yet

- LC45B 45 10 18Document9 pagesLC45B 45 10 18Joan B. BascoNo ratings yet

- Math Modelization HMU HANDOUTDocument93 pagesMath Modelization HMU HANDOUTNguyễn ThủyNo ratings yet

- DLL - Mathematics 6 - Q4 - W3Document8 pagesDLL - Mathematics 6 - Q4 - W3Rosebuds NvjsNo ratings yet

- Grade 7 Triangle Inequality HWDocument7 pagesGrade 7 Triangle Inequality HWPooja SharmaNo ratings yet

- Nepal road network and Gulmi district locationDocument1 pageNepal road network and Gulmi district locationGopi Raj PunNo ratings yet

- First Summative Test in Math 5 - 4th QuarterDocument3 pagesFirst Summative Test in Math 5 - 4th QuarterKatherine P-PastoralNo ratings yet

- Alpha-Beta TransformationDocument3 pagesAlpha-Beta TransformationM_Rocha0% (1)

- Solutions to CSEC Maths P2 January 2021Document44 pagesSolutions to CSEC Maths P2 January 2021cgxxfxr100% (1)

- G H$ (BV Narjm: Series RLHDocument11 pagesG H$ (BV Narjm: Series RLHcharanNo ratings yet

- Angles FundamentalsDocument7 pagesAngles FundamentalsLovely Amor CatipayNo ratings yet

- LOM-03 - Subjective SolvedDocument13 pagesLOM-03 - Subjective SolvedRaju SinghNo ratings yet

- NMTC Stage 2 2016 Solutions Sub Junior Group 7 8Document3 pagesNMTC Stage 2 2016 Solutions Sub Junior Group 7 8TanayNo ratings yet

- Tsra#1 Adv XiDocument12 pagesTsra#1 Adv XiAnonymous User0% (1)

- S4 11-12 Half Yearly Core Maths I 2Document17 pagesS4 11-12 Half Yearly Core Maths I 2Frankie LauNo ratings yet

- Constructing Polygons and Solving ProblemsDocument2 pagesConstructing Polygons and Solving ProblemsAngelo Rey NavaNo ratings yet

- The Schillinger System of Musical Composition and Contemporary Co PDFDocument10 pagesThe Schillinger System of Musical Composition and Contemporary Co PDFdavidNo ratings yet