Professional Documents

Culture Documents

Codeline, 150 PSI, Drawing - 80S15

Uploaded by

RamanNegiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Codeline, 150 PSI, Drawing - 80S15

Uploaded by

RamanNegiCopyright:

Available Formats

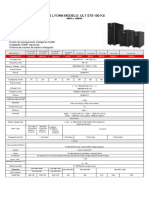

DWG PART QTY REF NUMBER

DESCRIPTION SHELL

MATERIAL

Dash Length -1 -2 -3

L P S IN(MM) IN(MM) IN(MM) 59.15 (1502) 99.15 (2518) 139.15 (3534) 179.15 (4550) 219.15 (5566) 259.15 (6582) 299.15 (7598) 339.15 (8614) 47 (1194) 87 (2210) 127 (3226) 167 (4242) 207 (5258) 247 (6274) 287 (7290) 327 (8306) 23X1 (588) 56X1 (1422) 80X1 (2032) 64X2 (1626) 78X2 (1981) 92X2 (2337) 106X2 (2692) 120X2 (3048)

1 2 3

1 ORDER A/R SECTION A/R

SHELL F/C Port F/C Port Seal HEAD

Filament Wound Epoxy/Glass composite - Head locking grooves integrally wound in place. CF3M* Ethylene Propylene. 6061-T6 Aluminium alloy - Hard anodized Engineering Thermoplastic. Engineering Thermoplastic. Engineering Thermoplastic. Ethylene Propylene - O - Ring Ethylene Propylene - O - Ring

Approx Weight LB(KG) 55 (25) 64 (29) 73 (33) 82 (37) 90 (41) 99 (45) 108 (49) 117 (53)

4 5 6 7 8 9

2 2 2 2 2 2

96156 96160 96162 45066 96000 45312

Bearing Plate Sealing Plate Permeate Port Port Nut Head Seal Perm Port Seal

-4 -5 -6 -7 -8

HEAD INTERLOCK 10 2 47336 Quick Release Spiral Ring 316 Stainless Steel. VESSEL SUPPORT 11 12 13 *2 *2 4 52169 45042 46265 Saddle Strap Assy. Strap screw. Engineering Thermoplastic. 304 Stainless Steel-PVC Cushion. 5/16-18 UNC, 18-8 Stainless Steel.

ELEMENT INTERFACE 14 15 16 17 2 2 4 1 A/R 52245 A/R 96163 Adapter Adapter seal PWT Seal Thrust Cone Engineering Thermoplastic. Ethylene Propylene - O - Ring Ethylene Propylene - O - Ring Engineering Thermoplastic.

* 3 each furnished with length code 4,5,6,7 & 8.

RATING: DESIGN PRESSURE..150 PSIG at 190F (1.0 MPa at 88C) MIN. OPERATING TEMP...20F (-7C) FACTORY TEST PRESSURE. CE / ASME 225 PSIG / 165 PSIG (1.6 MPa) (1.13 MPa) QUALIFICATION PRESSURE ......900 PSI (6.2 MPa) INTENDED USE: The CodeLine 80S15 Fiberglass RO Pressure Vessel is designed for continuous, long term use as housing for reverse osmosis membrane elements to desalt typical brackish waters at pressures up to 150 psi. Any make of eight-inch nominal diameter spiral-wound element is easily accommodated; the appropriate interfacing hardware for the element specified is furnished with the vessel. The CodeLine 80S15 is designed in accordance with the engineering standards of the Boiler and Pressure Vessel Code of the American Society of Mechanical Engineers (ASME) Code. At small additional cost vessels can be inspected during construction by an ASME Authorized Inspector and ASME Code stamped.

PRECAUTIONS: DOread, understand and follow all instructions; failure to take every precaution will void warranty and may result in vessel failure DOmount the shell on horizontal members at span S using compliant vessel supports furnished; Shim saddles if required. Tighten hold down straps just snug DOalign and center side ports with the manifold header. Correct, causes of misalignment in a row of vessels connected to the same header DOuse flexible type IPS grooved-end pipe couplings, at side ports; allow full, 0.125 inch gap between port and piping, and position piping to maximize flexibility of connection. DOprovide flexibility in, and support for piping manifolds so that vessel can grow in length under pressure without undue restraint; provide additional flexible joints in large pipes leading to manifold header. DOprovide overpressure protection for vessel set at not more than 105% of design pressure DOinspect end closures regularly; replace components that have deteriorated and correct causes of corrosion DO Lubricate seals sparingly, using nonpetroleum Based lubricants, i.e. Parker Super O-lube, Glycerin or suitable silicone based lubricants. DO NOTwork on any component until first verifying that pressure is relieved from vessel DO NOTmake rigid piping connections to ports or clamp vessel in any way that resists growth of fiberglass shell under pressure; ***DIA = 0.015 in. (0.4mm) and ***L = 0.2 in. (6mm) for a length code 8 vessel DO NOT hang piping manifolds from ports or use vessel in any way to support other components DO NOTtighten Permeate Port connection more than one turn past hand tight DO NOT operate vessel without connecting both Permeate Ports internally to complete set of elements or otherwise plug ports internally so that external piping connection is not subjected to feed pressure DO NOTinstall Spacer on downstream end of vessel DO NOToperate vessel without Thrust Cone installed downstream DO NOTpressurize vessel until double-checking to verify that the Locking Ring is in place and fully seated. DO NOToperate vessel at pressure and temperature in excess of its rating. DO NOToperate vessel with permeate pressure in excess of 125 psi at 190F (0.86 Mpa at 88 0 C). DO NOTtolerate leaks or allow end closures to be routinely wetted in any way DO NOToperate outside the pH range 3-10.

PP PP

ORDERING: Using the chart below, please check the features you require VESSEL LENGTH CODE please check one MODEL 80S15 -1 -2 -3 -4 -5 -6 -7 -8

MEMBRANE BRAND AND MODEL Please supply adapters for the following membrane brand and specific model Brand_________________________ Model_______________________ CERTIFICATION REQUIRED ASME Stamped and National Board Registered. CE Marked Standard. Certified by Pentair water. In compliance with the ASME Sec X but not Code Stamped. Hydro testing at 1.1 times the design pressure Hydro testing at 1.5 times the design pressure PERMEATE PORT SELECTION Serial Number End Size of the Permeate Port Type of Connection FNPT 1 MNPT Noryl 1.25 BSPTM SS316L 1.5 BSPTF IPS GROOVED Zeron 100 SANITARY

ADAPTER KITS

UP STREAM DOWN STREAM

Material of Construction Non Serial Number End Size of the Permeate Port Type of Connection FNPT

1 MNPT Noryl

1.25 BSPTM

1.5 BSPTF IPS GROOVED Zeron 100 SANITARY

The CodeLine 80S15 must be installed, operated and maintained in accordance with the listed precautions and good industrial practice to assure safe operation over a long service life. The high performance Filament wound FRP shell must be allowed to expand under pressure; undue restraint at support points or piping connections can cause leaks to develop in the shell. This side-ported vessel requires special precautions in mounting and connection to piping so that the vessel will not be subjected to excessive stress due to bending moments acting at the side openings in the fiberglass shell. The end closure, incorporating close fitting, interlocking metal components, must be kept dry and free of corrosion; deterioration can lead to catastrophic mechanical failure of the head. Pentair Water will assist the purchaser in determining the suitability of this standard vessel for their specific operating conditions. The final determination however, including evaluation of the standard material of construction for compatibility with the specific corrosive environment, shall be the responsibility of the purchaser. Alternate materials with enhanced corrosion resistance are available on special order. Specifications are subject to change without notice.

Material of Construction Note:

SS316L

Standard offering is 1.0 FNPT in PET/Noryl. 1.25& 1.5 BSPTF, 1.25 & 1.5 FNPT and 1.25 SANITARY connections cannot be offered Sanitary permeate port cannot be offered in PET/Noryl

STRAP ASSEMBLY Standard SS304 FEED/CONCENTRATE PORT SELECTION Material of Construction SA 351, Gr-CF3M Optional SA995, Gr-Duplex SS (CD3MN) Optional SA 995, Gr-Super Duplex SS (CD3MWCuN) Standard - CF3M 1D5D Optional Multi ports :( Refer SPEC.SHEET/PM/1.5-3for Multi port selection) Serial number end Opposite end BEARING PLATE MATERIAL Standard SB221, Gr-6061,T6 Aluminium Optional SA479, Gr-SS 316L D E F PORT SIZE CODE 1 GROOVED END 2 GROOVED END 2 GROOVED END Optional SS316 Optional SS316L

Configuration

DWG. NO. 99159-L.

Pentair Water

PAGE 2 OF 3.

Note: Please refer to 99321 for sanitary details and refer page-3 for optional Part numbers.

BEARING PLATE PART NUMBERS PERMEATE PORT SIZE ALUMINIUM SS316L 1.0"/1.25" 97346 96156 1.5" 96879 97350

SEALING PLATE PART NUMBERS Standard used for Aluminium BP 96160 Optional used for SS316L BP 96477

PERM PORT RETAINER RING & PORT NUT PART NUMBERS 1.0" / 1.25" Standard Port nut 45066 1.5" Port Retainer Ring 45247

STRAP ASSEMBLY PART NUMBERS SS304 SS316 SS316L 46926 94371 45042

F/C PORT & SEAL PART NUMBER SIZE 1.5" 2.0" 2.5" *CF3M 98024 98025 98026 **CD3MN 97353 97357 97364 ***CD3MWCuN 96507 96643 96556 SEAL 96077 96078 96079

SIZE

MATERIAL

NORYL 1.0" SS316L # ZERON 100 NORYL 1.25" SS316L # ZERON 100 NORYL 1.5" SS316L # ZERON 100

PERMEATE PORT PART NUMBERS & PERMPORT TO F/C PORT OFFSET DISTANCE FNPT MNPT BSPTF BSPTM PART PART PART PART NUMBER DIM "A" NUMBER DIM "A" NUMBER DIM "A" NUMBER DIM "A" 96162 5.508 97659 6.508 96301 5.508 97660 6.508 96752 5.508 97347 6.508 97351 5.508 97355 6.508 97349 5.508 97348 6.508 97352 5.508 97356 6.508 NA NA 97655 6.508 NA NA 97360 6.508 NA NA 96487 6.508 NA NA 97362 6.508 NA NA 97359 6.508 NA NA 97363 6.508 NA NA 97663 6.108 NA NA 97369 6.108 NA NA 97368 6.108 NA NA 97371 6.108 NA NA 97292 6.108 NA NA 97372 6.108

IPS GROOVED PART NUMBER DIM "A" 97661 6.808 97322 6.808 97293 6.808 97662 6.808 97311 6.808 97365 6.808 97656 6.738 97449 6.738 97374 6.738

You might also like

- DWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)Document3 pagesDWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)RamanNegiNo ratings yet

- Drawing 80H30Document3 pagesDrawing 80H30kpranjal15No ratings yet

- (2012) Complete IELTS Bands 5-6.5 Student's BookDocument3 pages(2012) Complete IELTS Bands 5-6.5 Student's BookAhmed Hamdy0% (1)

- Codeline Drawing 80S30 Non CodedDocument2 pagesCodeline Drawing 80S30 Non CodedDarren PonichaiNo ratings yet

- DWG REF QTY Number Description Material Shell: Order SectionDocument2 pagesDWG REF QTY Number Description Material Shell: Order SectionRamanNegiNo ratings yet

- Codeline Drawing 80S45 Non CodedDocument2 pagesCodeline Drawing 80S45 Non CodedoctavioNo ratings yet

- Codeline 80S45Document3 pagesCodeline 80S45Julian Bocanegra ReyesNo ratings yet

- Codeline Drawing 80H60Document3 pagesCodeline Drawing 80H60octavioNo ratings yet

- Datasheet Codeline OCTA 80S SeriesDocument4 pagesDatasheet Codeline OCTA 80S SeriesJulian Bocanegra ReyesNo ratings yet

- DWG REF QTY Number Description Material ShellDocument2 pagesDWG REF QTY Number Description Material ShellimtiyazNo ratings yet

- Diapham Valve PDFDocument8 pagesDiapham Valve PDFthouche007No ratings yet

- Klamflexproduct BrochureDocument24 pagesKlamflexproduct BrochureblindjaxxNo ratings yet

- Steam TrapDocument2 pagesSteam TrapAmpornchai PhupolNo ratings yet

- Baum GMBH Assembly instructions-DIN April 2012 PDFDocument2 pagesBaum GMBH Assembly instructions-DIN April 2012 PDFRensvanLoon1No ratings yet

- FMC Weco Wing Union CatalogDocument16 pagesFMC Weco Wing Union CatalogSargunam Sankaravadivel100% (2)

- 2010 KMT Waterjet PSC Catalog - LDocument39 pages2010 KMT Waterjet PSC Catalog - LaeradriNo ratings yet

- Ib 10Document2 pagesIb 10dchz_62No ratings yet

- Camlock CatalogoDocument12 pagesCamlock CatalogoPascualSalvador100% (1)

- KVC 01Document35 pagesKVC 01hamidreza_m85No ratings yet

- Spirax Sarco BTM-7Document3 pagesSpirax Sarco BTM-7Bambang Agung LaxmonoNo ratings yet

- Crane - Series.rs Center LineDocument23 pagesCrane - Series.rs Center LinenedwestNo ratings yet

- 15 Metal Seated Butterfly ValvesDocument8 pages15 Metal Seated Butterfly ValvesrajfmcNo ratings yet

- Split SleeveDocument3 pagesSplit Sleeveast654No ratings yet

- Eaton HansenKingDocument80 pagesEaton HansenKingKING COMERCIAL LTDANo ratings yet

- SPO Webversion HighDocument6 pagesSPO Webversion HighchadNo ratings yet

- Burmad 400 Series-Globe Type Deluge ValveDocument8 pagesBurmad 400 Series-Globe Type Deluge Valvenastyn-1No ratings yet

- 01 Rubber HoseDocument26 pages01 Rubber Hosewenny_tpdNo ratings yet

- Compact solenoid valves for commercial applicationsDocument16 pagesCompact solenoid valves for commercial applicationsJorge Jarpa VNo ratings yet

- Plug Valves enDocument24 pagesPlug Valves enAtty AttyNo ratings yet

- Formed-Cylinders 2007-04 LoDocument14 pagesFormed-Cylinders 2007-04 LomartinvandoornNo ratings yet

- Neojv 0040 enDocument0 pagesNeojv 0040 enLuis GuevaraNo ratings yet

- A1-Cam Groove CouplingsDocument40 pagesA1-Cam Groove CouplingsedwinramonNo ratings yet

- 3 Piece Tube Bore Ball Valves, / "-4": High Purity ApplicationsDocument4 pages3 Piece Tube Bore Ball Valves, / "-4": High Purity ApplicationsrodrurenNo ratings yet

- Bombas Dosificadoras Milton Roy Lmi CDocument2 pagesBombas Dosificadoras Milton Roy Lmi CErikLjNo ratings yet

- Series 826YD Specification SheetDocument2 pagesSeries 826YD Specification SheetFEBCONo ratings yet

- High Pressure Forged Gate Valves Pressure Temperature RatingsDocument16 pagesHigh Pressure Forged Gate Valves Pressure Temperature Ratingsg9g9No ratings yet

- Model 2100bDocument4 pagesModel 2100bkeyur1109No ratings yet

- CraneDocument32 pagesCranesabes26100% (1)

- Mangas PDFDocument14 pagesMangas PDFluisfer811No ratings yet

- Series 510 Specification SheetDocument2 pagesSeries 510 Specification SheetFEBCONo ratings yet

- Sree TB 0002Document12 pagesSree TB 0002Tanmoy DuttaNo ratings yet

- Trampa Socket WeldDocument2 pagesTrampa Socket WeldOscar Nieves ZamoraNo ratings yet

- Centrifugal Pump BrochuresDocument16 pagesCentrifugal Pump BrochuresAbsar Mamun100% (3)

- Atomac BrochureDocument28 pagesAtomac BrochureManish TulaskarNo ratings yet

- TD62LM and TD62M Thermodynamic Steam Traps With Replaceable Seats (Screwed /socket Weld)Document2 pagesTD62LM and TD62M Thermodynamic Steam Traps With Replaceable Seats (Screwed /socket Weld)Rupesh DesaiNo ratings yet

- Spirax Sarco PDFDocument4 pagesSpirax Sarco PDFandresaroNo ratings yet

- Plumbing and Propane CatalogDocument40 pagesPlumbing and Propane Catalogdannyboy738No ratings yet

- Series LF860 Specification SheetDocument2 pagesSeries LF860 Specification SheetFEBCONo ratings yet

- Style 997 Transition Coupling HDPE Plastic To Steel: Product DescriptionDocument2 pagesStyle 997 Transition Coupling HDPE Plastic To Steel: Product DescriptionJason MillerNo ratings yet

- Interruptor de Presion - AscoDocument9 pagesInterruptor de Presion - AscoJosephGutierrezNo ratings yet

- SpecDocument2 pagesSpecneversigNo ratings yet

- Enquiry Data in MailDocument20 pagesEnquiry Data in MailNITINNo ratings yet

- Ficha Tecnica PikotekDocument2 pagesFicha Tecnica Pikoteking_arriagaNo ratings yet

- 2 Specification For GRP PipingDocument4 pages2 Specification For GRP Pipinggc_panchaNo ratings yet

- Model"Dc": Dual Chamber Orifice FittingDocument13 pagesModel"Dc": Dual Chamber Orifice FittingFrankNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Codeline, 300 PSI, Drawing - 80H30Document3 pagesCodeline, 300 PSI, Drawing - 80H30RamanNegiNo ratings yet

- Codeline, 150 PSI, Drawing - 80H15Document3 pagesCodeline, 150 PSI, Drawing - 80H15RamanNegiNo ratings yet

- Codeline, 150 PSI, Drawing - 80S15Document3 pagesCodeline, 150 PSI, Drawing - 80S15RamanNegiNo ratings yet

- Codeline, 150 PSI, Drawing - 80H15Document3 pagesCodeline, 150 PSI, Drawing - 80H15RamanNegiNo ratings yet

- Codeline, 300 PSI, Drawing - 80H30Document3 pagesCodeline, 300 PSI, Drawing - 80H30RamanNegiNo ratings yet

- The Human BrainDocument9 pagesThe Human BrainRamanNegiNo ratings yet

- Pump Design PDFDocument8 pagesPump Design PDFkuselanmlNo ratings yet

- Piping Engineer Interview QuestionsDocument2 pagesPiping Engineer Interview QuestionsRamanNegi100% (1)

- Wa0000.Document7 pagesWa0000.Kumkum KumbarahalliNo ratings yet

- VDVDVXVCFDBCVCDocument390 pagesVDVDVXVCFDBCVCHafiz Rahmat UllahNo ratings yet

- Hassāniyya Arabic DialectDocument15 pagesHassāniyya Arabic DialectTiddukla Tadelsant Imedyazen100% (1)

- Esolutions Manual - Powered by CogneroDocument31 pagesEsolutions Manual - Powered by CogneroAll About MusicNo ratings yet

- Hydraulic Filter ReportDocument6 pagesHydraulic Filter ReportSandrock_01sr2No ratings yet

- DNV Os C104 2014Document40 pagesDNV Os C104 2014Moe LattNo ratings yet

- Libro de FLOTACIÓN-101-150 PDFDocument50 pagesLibro de FLOTACIÓN-101-150 PDFIsaias Viscarra HuizaNo ratings yet

- Refrigerador Haier Service Manual Mother ModelDocument32 pagesRefrigerador Haier Service Manual Mother Modelnibble1974100% (1)

- Bio PharmaceuticsDocument48 pagesBio PharmaceuticsRajan Kashyap100% (2)

- Narayana Iit Academy India: Paper - IDocument39 pagesNarayana Iit Academy India: Paper - Iaatt aattNo ratings yet

- SK EngineeringDocument16 pagesSK EngineeringOmkar waghuleNo ratings yet

- Ups Lyonn Modelo: Ult St5-100 KS: 10KVA A 120KVADocument1 pageUps Lyonn Modelo: Ult St5-100 KS: 10KVA A 120KVASebastian Matias CruzNo ratings yet

- Bearden On Maxwell's EquationsDocument10 pagesBearden On Maxwell's Equationspaulsub63No ratings yet

- OOPS using C++ Question BankDocument32 pagesOOPS using C++ Question BankPushpa Bg100% (1)

- Zebralette User GuideDocument24 pagesZebralette User GuideGiacomo TimbrelloNo ratings yet

- Blockchain Unconfirmed Transaction Hack Script Docx PDF FreeDocument2 pagesBlockchain Unconfirmed Transaction Hack Script Docx PDF FreeHealing Relaxing Sleep Music100% (1)

- Design of RC Building - ExerciseDocument6 pagesDesign of RC Building - Exercisesajeerala100% (1)

- E16 8 2Document4 pagesE16 8 2Branko FerenčakNo ratings yet

- Java Programming 3-4: Sorting and Searching Practice ActivitiesDocument2 pagesJava Programming 3-4: Sorting and Searching Practice ActivitiesДжон КрасулинNo ratings yet

- Canon I Sensys LBP5300 5360Document192 pagesCanon I Sensys LBP5300 5360GonzaloNo ratings yet

- Power Electronics - MITDocument210 pagesPower Electronics - MITVasco RodriguesNo ratings yet

- Materials Refractive Index and Extinction CoefficientDocument276 pagesMaterials Refractive Index and Extinction CoefficientDr-Mandeep SinghNo ratings yet

- UntitledDocument135 pagesUntitledtaraji dawlaNo ratings yet

- Beyond SVGFDocument66 pagesBeyond SVGFLiliana QueiroloNo ratings yet

- Review For Mastery: VocabularyDocument3 pagesReview For Mastery: VocabularyHala EidNo ratings yet

- F-500 Encapsulator TechnologyDocument6 pagesF-500 Encapsulator TechnologyBdSulianoNo ratings yet

- Matrix Assisted Laser Desorption Ionization Mass Spectrometry Maldi-Tof MsDocument4 pagesMatrix Assisted Laser Desorption Ionization Mass Spectrometry Maldi-Tof MsElizabeth Katherine Aigaje EspinosaNo ratings yet

- ContiTech Rubber Hose Handling InstructionsDocument9 pagesContiTech Rubber Hose Handling InstructionssmithworkNo ratings yet

- Session5 Automotive PackagingDocument72 pagesSession5 Automotive PackagingShivprasad Savadatti100% (1)

- Steel and Timber Report Compiled (Aaa) PDFDocument42 pagesSteel and Timber Report Compiled (Aaa) PDFLee Chen ChoonNo ratings yet