Professional Documents

Culture Documents

Iso Manual

Uploaded by

Sanjay MalhotraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Iso Manual

Uploaded by

Sanjay MalhotraCopyright:

Available Formats

This publication may contain both public domain & copyrighted material.

New material copyright M E Turner

Other titles available online

www.govmedia.com

MIL-HDBK-1004/1 30 MAY 1988 SUPERSEDING DM-4.1 MARCH 1983

MILITARY HANDBOOK ELECTRICAL ENGINEERING PRELIMINARY DESIGN CONSIDERATIONS

AMSC N/A DISTRIBUTION STATEMENT A. UNLIMITED APPROVED FOR PUBLIC RELEASE: DISTRIBUTION IS AREA FACR

ABSTRACT This handbook provides basic design guidance in the proper selection of electric power sources and distribution systems. It was developed from extensive reevaluation of facilities and is presented for use by experienced architects and engineers. The contents cover electric power preliminary design considerations such as preliminary data, estimation of loads, selection of electric power source, uninterruptible power supply (UPS) system design, installation of distribution systems, levels of distribution voltage, grounding of distribution systems, and selection of distribution systems.

iii

PAGE iv INTENTIONALLY BLANK

FOREWORD This handbook has been developed from an evaluation of facilities in the shore establishment, from surveys of the availability of new materials and construction methods, and from selection of the best design practices of the Naval Facilities Engineering Command (NAVFACENGCOM), other Government agencies, and the private sector. This handbook was prepared using, to the maximum extent feasible, national professional society, association, and institute standards. Deviations from this criteria, in the planning, engineering, design, and construction of naval shore facilities, cannot be made without prior approval of NAVFACENGCOMHQ Code 04. Design cannot remain static any more than can the functions it serves or the technologies it uses. Accordingly, recommendations for improvement are encouraged and should be furnished to Commanding Officer, Chesapeake Division, Naval Facilities Engineering Command, Code 406, Washington Naval Yard, Washington, DC 20374-2121, telephone (202) 433-3314. THIS HANDBOOK SHALL NOT BE USED AS A REFERENCE DOCUMENT FOR PROCUREMENT OF FACILITIES CONSTRUCTION. IT IS TO BE USED IN THE PURCHASE OF FACILITIES ENGINEERING STUDIES AND DESIGN (FINAL PLANS, SPECIFICATIONS, AND COST ESTIMATES). DO NOT REFERENCE IT IN MILITARY OR FEDERAL SPECIFICATIONS OR OTHER PROCUREMENT DOCUMENTS.

ELECTRICAL ENGINEERING DESIGN CRITERIA MANUALS

Criteria Manual MIL-HDBK-1004/1 MIL-HDBK-1004/2 MIL-HDBK-1004/3 MIL-HDBK-1004/4 4.05 MIL-HDBK-1004/6 4.07 4.09 NOTE:

Title Preliminary Design Considerations Power Distribution Systems Switchgear and Relaying Electrical Utilization Systems 400-Hertz Medium-Voltage Conversion and Low-Voltage Systems Lightning Protection Wire Communication and Signal Systems Energy Monitoring and Control Systems (Army)

PA CHESDIV PACDIV CHESDIV CHESDIV CHESDIV CHESDIV CHESDIV HDQTRS

Design manuals, when revised, will be converted to military handbooks. This handbook is issued to provide immediate guidance to the user. However, it may or may not conform to format requirements of MIL-HDBK-1006/3 and will be corrected on the next update.

vi

PRELIMINARY ELECTRICAL DESIGN CONSIDERATIONS CONTENTS Page Section 1 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.8.1 1.8.2 1.8.3 1.8.4 1.8.5 Section 2 2.1 2.2 2.2.1 2.2.1.1 2.2.1.2 2.2.1.3 2.2.2 2.2.2.1 2.2.2.2 2.2.3 2.2.4 2.3 2.3.1 2.3.2 2.3.2.1 2.3.2.2 2.3.2.3 2.3.2.4 2.3.2.5 2.3.2.6 2.3.3 2.3.4 2.3.5 2.3.6 2.4 2.4.1 2.4.2 2.4.3 2.4.4 PRELIMINARY DATA Scope ..................................................1 Cancellation ...........................................1 Related Criteria .......................................1 Other Government Criteria Sources ......................1 Other Sources of Criteria ..............................1 Load Data ..............................................2 Load Analysis ..........................................2 Terminology ............................................2 Demand Factor ..........................................2 Coincidence Factor .....................................2 Diversity Factor .......................................2 Load Factor ............................................2 Maximum Demand .........................................2 ESTIMATION OF LOADS Preparation of Load Data ...............................3 Individual Loads .......................................3 Lighting ...............................................3 Small Appliance Loads ..................................3 Electric Power Loads ...................................3 System Loss ............................................3 Demand and Load Factors ...............................10 Guides for Demand Factors .............................10 Guides for Load Factors ...............................10 Load Growth ...........................................10 Emergency Loads .......................................17 Area Loads ............................................17 General Loads .........................................17 Coincidence Factor ....................................17 Relationships .........................................17 Selection .............................................17 Electric Power Consumption ............................17 Influencing Factors ...................................23 Individual Loads ......................................23 Groups of Loads or Areas ..............................23 Load Growth ...........................................23 System Losses .........................................23 Emergency Loads .......................................24 Expansion .............................................24 Activity Loads ........................................24 General Loads .........................................24 Coincidence Factor ....................................24 Load Growth ...........................................24 Expansion .............................................24

vii

Page Section 3 3.1 3.2 3.3 3.3.1 3.3.2 3.3.3 3.3.4 3.4 3.4.1 3.4.2 3.4.3 3.4.4 3.5 3.5.1 3.5.2 3.5.3 3.5.4 3.5.5 3.5.5.1 3.5.5.2 Section 4 4.1 4.2 4.3 4.4 4.5 4.5.1 4.5.2 4.6 4.6.1 4.6.2 4.7 4.7.1 4.7.2 4.8 4.8.1 4.8.2 4.8.3 4.8.4 4.8.5 4.9 4.10 4.11 4.12 4.12.1 4.12.1 4.12.3 4.12.4 4.13 SELECTION OF ELECTRIC POWER SOURCE Policy ................................................25 Economic Factors ......................................25 Electric Power Sources ................................25 Primary ...............................................25 Standby ...............................................25 Emergency .............................................25 Uninterruptible (No-Break) Electric Power .............26 Acceptable Electric Power Sources .....................26 Primary ...............................................26 Standby ...............................................26 Emergency .............................................26 Uninterruptible (No-Break) Electric Power .............26 Purchased Electric Power Requirements .................26 Adequacy ..............................................27 Reliability ...........................................27 Rates .................................................27 Primary Service Right-of-Way ..........................27 Primary Substations ...................................28 Voltage ...............................................28 Economics ............................................. UNINTERRUPTIBLE POWER SYSTEMS Requirements ..........................................29 Criteria ..............................................29 Power Load Categories .................................29 Definitions ...........................................30 Redundancy ............................................34 "Cold" Standby Redundant UPS System ...................34 Parallel Redundant UPS System .........................34 Electric Service and Bypass Connectors ................34 Electric Service Size .................................34 Maintenance Bypass Provisions .........................34 UPS Distribution System ...............................36 Critical Load Protection ..............................36 Critical Motor Loads ..................................36 Emergency Electric Power Source Requirements ..........36 Automatic Operation ...................................36 Paralleling ...........................................36 Starting and Maintenance Considerations ...............37 Service Configuration for Small Loads .................37 Battery Charging Restrictions .........................37 Electromagnetic Interference (EMI) Suppression ........37 UPS Battery ...........................................37 Remote Alarms .........................................37 UPS and Battery Room Requirements .....................37 Installation Considerations ...........................38 NEC, OSHA, and ANSI Requirements ......................38 Emergency Lighting Requirements .......................38 Telephone Requirements ................................38 Environmental Control .................................38

viii

Page Section 5 5.1 5.1.1 5.1.2 5.2 5.2.1 5.2.2 Section 6 6.1 6.2 6.2.1 6.2.2 6.2.2.1 6.2.2.2 6.2.2.3 6.2.2.4 6.2.2.5 Section 7 7.1 7.2 7.2.1 7.2.2 7.2.3 Section 8 8.1 8.2 8.2.1 8.2.2 8.2.3 8.2.4 8.2.5 8.2.6 8.2.7 8.2.8 8.2.8.1 8.2.8.2 8.2.8.3 8.2.9 8.2.10 8.2.11 INSTALLATION OF DISTRIBUTION SYSTEM Overhead Method .......................................39 General ...............................................39 Limitations ...........................................39 Underground Method ....................................39 Applications ..........................................39 Expansibility .........................................39 LEVELS OF DISTRIBUTION VOLTAGE Criteria Coverage .....................................40 System Voltages .......................................40 Power Generated at Site ...............................40 Purchased Energy ......................................40 2,400 V System ........................................40 4,160 V System ........................................40 6,900 V System ........................................40 12,000 V to 13,800 V Systems ..........................40 15,000 V to 34,500 V Systems ..........................40 GROUNDING OF DISTRIBUTION SYSTEMS General Requirements ..................................41 Methods ...............................................41 Solid Grounding .......................................41 Resistance Grounding ..................................41 Reactance Grounding ...................................41 SELECTION OF DISTRIBUTION SYSTEMS Selection Factors .....................................42 Systems Available .....................................42 Conventional Simple-Radial Distribution System ........42 Modern Simple-Radial Distribution System ..............42 Modified Modern Simple-Radial Distribution System .....42 Loop Primary-Radial Distribution Type .................42 Banked Secondary-Radial Distribution System ...........42 Primary Selective-Radial Distribution System ..........42 Secondary Selective-Radial Distribution System ........49 Simple Network Distribution System ....................49 Network Protector .....................................49 Limitation ............................................49 Secondary Loops .......................................49 Simple Spot-Network Distribution System ...............52 Primary Selective Network Distribution System .........52 Primary Selective Spot-Network Distribution System ....52

ix

Page FIGURES 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Theoretical Relationship Between Load Factor and Coincidence Factor at U.S. Naval Shore Establishments .......... 20 Typical Nonredundant Configuration (UPS) ........................32 Typical "Cold" Standby Redundant Configuration (UPS) ............33 Typical Parallel Redundant Configuration (UPS) ..................35 Conventional Simple-Radial Distribution System ..................43 Modern Simple-Radial Distribution System ........................44 Modified Modern Simple-Radial Distribution System ...............45 Loop Primary-Radial Distribution System .........................46 Banked Secondary-Radial Distribution System .....................47 Primary Selective-Radial Distribution System ....................48 Secondary Selective-Radial Distribution System ..................50 Simple Network Distribution System ..............................51 Simple Spot-Network Distribution System .........................53 Primary Selective Network Distribution System ...................54 Primary Selective Spot-Network Distribution System ..............55 TABLES 1 2 3 4 5 6 7 8 Factors for Individual Facilities by Navy Category Code ..........4 Demand Factors for Specific Loads ...............................11 Annual Hours Use of Demand for Specific Loads ...................11 Academic Building (Code 171-10) Demand and Load Factor Calculations ........................................12 Guides for Selection of Demand Factors ..........................13 Guides for Selection of Load Factors ............................15 Method of Calculating Coincident Peak Demand ....................18 Relationship Between Load Factor and Coincidence Factor .........21

BIBLIOGRAPHY ............................................................56 REFERENCES ..............................................................57

Section 1:

PRELIMINARY DATA

1.1 Scope. This handbook provides the criteria necessary for the proper selection of electric power sources and distribution systems. It covers preliminary load estimating factors, electrical power sources, and distribution systems. 1.2 Cancellation. This handbook cancels and supersedes DM-4.1, Electrical Engineering Preliminary Design Considerations, of December l979, and change dated 1 March 1983. 1.3 Load Data. Before specific electric power sources and distribution systems can be considered, realistic preliminary load data must be compiled. The expected electric power demand on intermediate substations, and on the main electric power supply, shall be calculated from the connected load layout by applying appropriate factors. Determine these factors by load analysis and by combining loads progressively. To combine the loads, start at the ends of the smallest feeders and work back to the electric power source. Because all loads must be on a common kilowatt (kW) or kilovoltampere (kVA) basis, it is necessary to convert motor horsepower ratings to input kilowatts or kilovolt-amperes before combining them with other loads already expressed in those terms. Preliminary electric power load estimates can be made by using the approximate value of one kilovolt-ampere of input per horsepower (hp) at full load. Preliminary estimates of lighting loads may be made by assuming watts per ft2 (m2) of building area. 1.4 Load Analysis. To determine appropriate load estimating factors, using the tables and factors in this manual as guides analyze the characteristics of each load. Consider items such as environmental conditions of weather, geographical location, and working hours, as the situation dictates. Notice that when the load densities in w/ft2 (m2) are used only in preliminary estimates, the demand and load factors will be used in the final designs. 1.5 Terminology. Five terms are essential to the analysis of load characteristics: demand factor, coincidence factor, diversity factor, and maximum demand. These terms are defined in paras. 1.5.1 through 1.5.4. 1.5.1 Demand Factor. The demand factor is the ratio of the maximum demand on a system to the total connected load of the system or EQUATION: Demand factor = Maximum demand load Total load connected (1)

1.5.2 Coincidence Factor. The coincidence factor is the ratio of the maximum demand of a system, or part under consideration, to the sum of the individual maximum demands of the subdivisions or EQUATION: Coincidence factor = Maximum system demand Sum of individual maximum demands (2)

1.5.3 Diversity Factor. coincidence factor or EQUATION:

The diversity factor is the reciprocal of the = Sum of individual maximum demands Maximum system demand (3)

Diversity factor

1.5.4 Load Factor. The load factor is the ratio of the average load over a designated period of time, usually 1 year, to the maximum load occurring in that period or EQUATION: Load factor = Average load Maximum load (4)

1.5.5 Maximum Demand. The maximum demand is the integrated demand for a specified time interval, i.e., 5 minutes, 15 minutes, 30 minutes, or other appropriate time intervals, rather than the instantaneous or peak demand.

Section 2: 2.1 Preparation of Load Data. steps such as: a) b) c) individual loads, area loads, and activity loads.

ESTIMATION OF LOADS Load data are generally computed in

A particular design problem may be limited to step a), to steps a) and b), or may encompass steps a), b), and c). This section outlines each step as a separate entity, dependent only on previous steps for data. Paragraphs 2.2 through 2.4.4 describe the three loads. 2.2 Individual Loads. Individual loads are those with one incoming service supplying utilization voltage to the premises. In general, these loads would comprise single structures. Large structures could contain more than one function; for example, aircraft operations, aircraft fire and rescue stations, and photographic buildings. Under this condition, factors that have been developed and keyed to Navy category codes (refer to Table 1) would be used. In this case, the factors listed under Navy Category Code 141-40, 141-20, and 141-60, respectively, would be combined to obtain the total load. 2.2.1 Lighting. To eliminate lighting loads, divide a facility area into its significant components by function (for example, office, storage, mechanical, and corridor). Determine the average lighting level and type of light source for each area. Consider requirements for supplementary lighting (for example, floodlighting, security lighting, and special task lighting). Preliminary load estimates may be made based on the following load allowances: a) 1 W/ft2 (10.76W/m2) for each 6 to 8 fc (60 to 80 dekalux) of incandescent illumination. b) 1 W/ft2 for each 15 to 20 fc (150 to 200 dekalux) of fluorescent illumination. c) 1 W/ft2 for each 12 to l8 fc (120 to l80 dekalux) of mercury vapor illumination. d) 1 W/ft2 for each 26 to 36 fc (260 to 360 dekalux) of metal halide illumination. e) 1 W/ft2 for each 33 to 54 fc (330 to 540 dekalux) of high pressure sodium illumination. 2.2.1.1 Small Appliance Loads. Small appliance loads shall include those served by general purpose receptacles. In general, the dividing of areas by function for estimating lighting loads will serve for estimating small appliance loads. The determination of loads requires not only a knowledge of the function of an area, but to what extent its occupants use small appliances. For example, an office area demand may average about 1 W/ft2 3

Table 1 Factors for Individual Facilities by Navy Category Code (See Note 1) DEMAND LOAD NAVY FACTOR FACTOR CODE DESCRIPTION (%) (%) 100 Operational and Training Facilities: 121 Aircraft fueling/dispensing facility . . . . . . . .40-60 16-20 122 Marine fuel dispensing . . . . . . . . . . . . . . .40-60 16-20 123 10 Filling station . . . . . . . . . . . . . . . . . . .40-60 13-17 125 16 Miscellaneous POL pipeline facilities . . . . . . . .100 13-17 126 Liquid fueling and dispensing-other . . . . . . . . .40-60 3- 7 131 Communications - buildings . . . . . . . . . . . . .60-65 70-75 131 40 Telephone exchange building . . . . . . . . . . . . .55-70 20-25 133 75 Air surveillance radar building . . . . . . . . . . .55-70 70-75 137 40 Port control office . . . . . . . . . . . . . . . . .55-70 20-25 141 11 Air passenger terminal building . . . . . . . . . . .65-80 28-32 141 20 Aircraft fire and rescue station . . . . . . . . . .25-35 13-17 141 30 Aircraft line operations building . . . . . . . . . .65-80 24-28 141 40 Aircraft operations building *EXC 141-70* . . . . .65-80 28-32 141 60 Photographic building . . . . . . . . . . . . . . . .65-80 16-20 171 10 Academic instruction building . . . . . . . . . . . .40-60 22-26 171 20 Applied instruction building . . . . . . . . . . . .35-65 24-28 171 40 Drill Hall . . . . . . . . . . . . . . . . . . . . .75-85 3- 7 200 Maintenance and Production Facilities: 211 05 Maintenance Hangar O/H space (high bay) . . . . . . .45-50 28-30 211 06 Maintenance Hangar - 01 space (crew equipment). . . .45-50 28-30 211 07 Maintenance Hangar - 02 space (administrative) . . .45-50 28-30 211 10 Aircraft overhaul and repair shop (NARF) . . . . . .32-38 25-30 211 12 Paint/finishing hangar . . . . . . . . . . . . . . .65-75 25-27 211 20 Engine overhaul shop (NARF) . . . . . . . . . . . . .32-38 20-25 211 30 Aircraft/engine accessories overhaul shop (NAR) . . .32-38 25-30 211 75 Parachute/survival equipment . . . . . . . . . . . .60-65 23-28 211 81 Engine test cell (Non-NARF) . . . . . . . . . . . . .42-48 25-30 211 96 Maintenance, aircraft spares storage (MISC) . . . . .58-63 23-28 212 20 Missile equipment maintenance ship . . . . . . . . .35-40 15-20 213 10 Drydock . . . . . . . . . . . . . . . . . . . . . . .5-10 0.5-1 214-10 Combat vehicle maintenance shop . . . . . . . . . . .55-65 20-25 214-20 Automobile vehicle maintenance - noncombat . . . . .55-65 20-25 215 Maintenance - weapons / spares . . . . . . . . . . .70-80 20-25 216 10 Ammunition rework and overhaul shop . . . . . . . . .35-40 18-22 216 20 Rocket rework and overhaul shop . . . . . . . . . . .35-40 18-22 216 30 Mines and depth charge rework shop . . . . . . . . .35-40 15-20 216 40 Torpedo shop . . . . . . . . . . . . . . . . . . . .45-55 18-22 216 50 Special weapons shop . . . . . . . . . . . . . . . .35-40 18-22 216 60 Quality evaluation laboratory . . . . . . . . . . . .55-65 22-27 Note 1: Demand factors include allowance for system loss.

Table 1 (Continued) Factors for Individual Facilities by Navy Category Code[1] DEMAND LOAD NAVY FACTOR FACTOR CODE DESCRIPTION (%) (%) 217 218 218 218 219 221 222 222 223 225 225 225 225 226 226 226 226 226 226 226 227 227 228 229 229 229 229 300 310 310 310 316 317 400 421 423 431 441 441 441 441 441 10 20 40 50 10 10 10 20 10 10 20 30 50 10 15 20 35 40 55 65 10 10 10 10 20 30 40 13 15 19 10 20 Electronics/communications maintenance shop . . . . Construction/weight handling equipment shop . . . . Railroad equipment shop . . . . . . . . . . . . . . Battery shop . . . . . . . . . . . . . . . . . . . Public works shop . . . . . . . . . . . . . . . . . Aircraft engine assembly plant . . . . . . . . . . Missile assembly buildings . . . . . . . . . . . . Missile handling launch equipment . . . . . . . . . Fabrication/assembly building . . . . . . . . . . . Small arms plant . . . . . . . . . . . . . . . . . Light gun (20mm/51n) plant . . . . . . . . . . . . Heavy gun (6/161n) plant . . . . . . . . . . . . . Launcher/projector plant . . . . . . . . . . . . . Bag charge filling plant . . . . . . . . . . . . . Case filling plant . . . . . . . . . . . . . . . . Case overhaul tank repair facility . . . . . . . . Major-caliber projectile loading plant . . . . . . Medium-caliber projectile loading plant . . . . . . Cast high explosives filling plant . . . . . . . . Propellant and related chemical facility . . . . . Radio and radar equipment plant . . . . . . . . . . Sonar equipment plant . . . . . . . . . . . . . . . Parachute/survival equipment plant . . . . . . . . Asphalt plant . . . . . . . . . . . . . . . . . . . Concrete batching plant . . . . . . . . . . . . . . Rock crusher plant . . . . . . . . . . . . . . . . Sawmill . . . . . . . . . . . . . . . . . . . . . . Research, Development, Test & Evaluation Facilities: Chemistry and Toxicology Laboratory . . . . . . . . Materials Laboratory . . . . . . . . . . . . . . . Physics Laboratory . . . . . . . . . . . . . . . . Ammunition, explosives, and toxics laboratory . . . Electrical and electronics systems laboratory . . . Supply Facilities: Ammunition storage installation . . . . . . . . . . Ammunition storage-liquid propellant . . . . . . . Cold storage warehouse . . . . . . . . . . . . . . General warehouse Navy . . . . . . . . . . . . . . Controlled humidity warehouse . . . . . . . . . . . Hazardous/flammable storehouse . . . . . . . . . . Underground storage . . . . . . . . . . . . . . . . Disposal, salvage, scrap building . . . . . . . . . .35-40 .35-45 .35-45 .55-65 .32-38 .32-38 .35-40 .35-40 .22-27 .15-20 .15-20 .16-21 .15-20 .62-67 .35-40 .35-40 .35-40 .35-40 .35-40 .30-40 .50-55 .50-55 .35-40 .75-80 .75-80 .75-80 .45-55 .70-80 .30-35 .70-80 .28-32 .20-30 .75-80 .75-80 .70-75 .75-80 .60-65 .75-80 .65-70 .35-40 20-25 20-25 15-20 20-25 18-22 20-25 15-20 15-20 24-29 22-27 22-27 21-26 22-27 23-28 23-28 18-22 18-22 18-22 18-22 32-38 23-28 23-28 20-25 7-12 15-20 15-20 15-20 22-28 27-32 22-28 20-25 3-7 ..... 20-25 20-25 23-28 33-38 20-25 23-28 25-20

10 10 20 30 40 70

1Demand factors include allowance for system loss.

Table 1 (Continued) Factors for Individual Facilities by Navy Category Code[1] DEMAND LOAD NAVY FACTOR FACTOR CODE DESCRIPTION (%) (%) 500 510 530 540 550 600 610 620 700 711 712 714 721 721 721 721 721 722 723 723 723 724 724 724 724 730 730 730 730 730 730 730 730 730 730 730 730 730 10 20 10 10 10 10 Hospital-Medical Facilities: Hospital . . . . . . . . . . . . . . . . . . . . Laboratory . . . . . . . . . . . . . . . . . . . Dental Clinic . . . . . . . . . . . . . . . . . . Medical Clinic . . . . . . . . . . . . . . . . . Administrative Facilities: Administrative Office . . . . . . . . . . . . . . Administrative facility, underground . . . . . . Housing and Community Facilities: Family housing-dwellings . . . . . . . . . . . . Substandard: Trailers-family housing . . . . . . Detached garages . . . . . . . . . . . . . . . . Bachelor enlisted quarters . . . . . . . . . . . Bachelor enlisted quarters E5/E6 . . . . . . . . Bachelor enlisted quarters E7/E9 . . . . . . . . Civilian barracks GS 01/6 . . . . . . . . . . . Disciplinary barracks . . . . . . . . . . . . . . Detached dining facilities, enlisted men . . . . Latrine, detached . . . . . . . . . . . . . . . . Laundry, detached . . . . . . . . . . . . . . . . Garage, detached . . . . . . . . . . . . . . . . UOPH, W-1/O-2 . . . . . . . . . . . . . . . . . UOPH, O-3 and above . . . . . . . . . . . . . . Civilian quarters, GS-7/PLS . . . . . . . . . . . Dining facility (attached) commissioned personnel Fire station . . . . . . . . . . . . . . . . . . Confinement facility . . . . . . . . . . . . . . Police station . . . . . . . . . . . . . . . . . Gate/sentry house . . . . . . . . . . . . . . . . Bakery . . . . . . . . . . . . . . . . . . . . . Enlisted personnel locker room . . . . . . . . . Laundry/dry cleaning plant . . . . . . . . . . . Dependent school - nursery school . . . . . . . . Dependent school - kindergarten . . . . . . . . . Dependent school - grade school . . . . . . . . . Dependent school - high school . . . . . . . . . Fallout shelter . . . . . . . . . . . . . . . . . Bus station . . . . . . . . . . . . . . . . . . . . . . . .38-42 .32-37 .35-40 .45-50 45-50 20-25 18-23 20-23 20-35 35-40 10-15 10-15 2-4 38-42 38-42 38-42 38-42 38-42 45-60 20-25 20-25 2-4 20-25 20-25 20-25 30-40 13-17 33-38 20-25 28-33 45-60 18-23 20-25 10-15 10-15 10-15 12-17 30-35 30-35

. .50-65 . .50-65 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60-70 .70-75 .40-50 .35-40 .35-40 .35-40 .35-40 .35-40 .30-35 .75-80 .30-35 .40-50 .40-50 .40-50 .40-50 .35-40 .25-35 .60-65 .48-53 .70-75 .30-35 .75-80 .30-35 .75-80 .75-80 .75-80 .65-70 .80-85 .80-85

10 11 12 13 30 40 10 20 30 40 11 12 22 30 10 15 20 25 30 35 40 45 50 55 60 65 67

1Demand factors include allowance for system loss.

Table 1 (Continued) Factors for Individual Facilities by Navy Category Code[1] DEMAND LOAD NAVY FACTOR FACTOR CODE DESCRIPTION (%) (%) 730 730 730 740 740 740 740 740 740 740 740 740 740 740 740 740 740 740 740 740 740 740 740 760 800 811 811 811 811 812 812 813 821 821 821 826 827 70 83 85 01 18 23 26 30 36 40 43 46 50 53 56 60 63 66 70 76 80 86 88 10 10 25 45 60 20 40 20 12 22 50 20 20 Decontamination facility . . . . . . . . . . . . . .75-80 Chapel . . . . . . . . . . . . . . . . . . . . . . .65-70 Post Office . . . . . . . . . . . . . . . . . . . . .75-80 Exchange retail store . . . . . . . . . . . . . . . .65-70 Bank . . . . . . . . . . . . . . . . . . . . . . . .75-80 Commissary including backup storage . . . . . . . . .55-60 Installation restaurant . . . . . . . . . . . . . . .45-75 Exchange auto repair station . . . . . . . . . . . .40-60 Hobby shop, art/crafts . . . . . . . . . . . . . . .30-40 Bowling Alley . . . . . . . . . . . . . . . . . . . .70-75 Gymnasium . . . . . . . . . . . . . . . . . . . . . .70-75 Skating rink . . . . . . . . . . . . . . . . . . . .70-75 Field house . . . . . . . . . . . . . . . . . . . . .75-80 Indoor swimming pool . . . . . . . . . . . . . . . .55-60 Theater . . . . . . . . . . . . . . . . . . . . . . .45-55 Commissioned officers' mess, open . . . . . . . . . .55-60 Enlisted personnel club . . . . . . . . . . . . . . .55-60 Petty officers' mess, open . . . . . . . . . . . . .55-60 Mess open, E-7 through E-9 . . . . . . . . . . . . .55-60 Library . . . . . . . . . . . . . . . . . . . . . . .75-80 Golf club house . . . . . . . . . . . . . . . . . . .75-80 Exchange installation warehouse . . . . . . . . . . .58-63 Educational services office . . . . . . . . . . . . .70-75 Museum/memorial building . . . . . . . . . . . . . .75-80 Utilities and Ground Improvements: Electric power plant-diesel . . . . . . . . . . . . .60-65 Electric power plant-steam . . . . . . . . . . . . .60-65 Electric power plant-gas turbine . . . . . . . . . .60-65 Standby generator plant . . . . . . . . . . . . . . .75-80 Street lighting . . . . . . . . . . . . . . . . . . .95-.. Perimeter/security lighting . . . . . . . . . . . . .80-85 Substation, more than 499 KV . . . . . . . . . . . .25-30 Fossil fuel heating plant - medium . . . . . . . . .55-60 Fossil fuel heating plant - large . . . . . . . . . .55-60 Non-nuclear steam plant . . . . . . . . . . . . . . .50-55 Chilled water plant 25/100 tons . . . . . . . . . . .60-70 Air conditioning-chilled water transmission/ distribution system - medium (25/100 tons) . . . . 60-70 Combination sewage and industrial waste treatment plant . . . . . . . . . . . . . . . . . 60-70 Sewage-industrial waste pumping station . . . . . . .55-60 Incinerator building and incinerator . . . . . . . .55-60 Water treatment facilities . . . . . . . . . . . . .60-80 Wells-potable water . . . . . . . . . . . . . . . . .60-80 15-2 5-25 20-25 25-32 20-25 25-30 15-25 15-20 25-30 10-15 20-45 10-15 7-12 25-50 8-13 15-20 18-23 18-23 15-20 30-35 15-20 23-28 30-35 30-35 58-63 58-63 58-63 5-10 46-.. 22-27 20-25 30-60 30-60 30-40 25-30 25-30 15-20 30-35 15-20 15-25 15-25

831 10 832 833 841 841 30 22 10 50

1Demand factors include allowance for system loss. 7

Table 1 (Continued) Factors for individual Facilities By Navy Category Code[1] DEMAND LOAD NAVY FACTOR FACTOR CODE DESCRIPTION (%) (%) 843 20 890 20 890 42 125 10 132 10 Fire protection pumping station . . . . . . . . . . Do not include -operate for test off peak. Compressed air plant . . . . . . . . . . . . . . . .45-50 25-30 Air-conditioning plant, . . . . . . . . . . . . . . .60-70 25-30 Miscellaneous Operational and Training Facilities: POL pipeline . . . . . . . . . . . . . . . . . . . . Antenna - communications . . . . . . . . . . . . . .95-.. 46-.. Miscellaneous Facilities for Ship Repair and Shipbuilding . . . . . . . . . . . . . . . . . . . . Ship repair shops: Central tool shop - (06) (E). . . . . . . . . . . .32-37 23-28 Shipfitting shop - (11) (A) . . . . . . . . . . . .22-27 24-29 Sheet metal shop - (17) (B) . . . . . . . . . . . .10-15 15-20 Forge and heat treatment space (23) (F) . . . . . .25-30 13-18 Inside machine shop - (31) (G). . . . . . . . . . .16-21 21-26 Boiler making shop - (41) (D) . . . . . . . . . . .12-17 14-19 Electrical shop - (51) (M). . . . . . . . . . . . .33-38 20-25 Pipefitting shop - (56) (J) . . . . . . . . . . . .22-27 17-22 Woodworking shop - (64) (R) . . . . . . . . . . . .25-30 21-26 Abrasive blast facility . . . . . . . . . . . . . .30-35 10-15 Paint and blasting shop - (71) (S). . . . . . . . .50-55 23-28 Riggers shop - (72) (T) . . . . . . . . . . . . . .50-55 20-25 Sail loft . . . . . . . . . . . . . . . . . . . . .35-40 20-25 Foundry - (81) (K) . . . . . . . . . . . . . . . .35-40 22-27 Patternmaking shop - (94) (X) . . . . . . . . . . .28-33 12-17 Pumphouse, drydocks . . . . . . . . . . . . . . . . 75-80 0.1-0.2 Miscellaneous Facilities for Naval Ordnance Manufacture: Ammunition components building . . . . . . . . . . .15-20 20-25 Manufacturing . . . . . . . . . . . . . . . . . . . .30-45 17-32 Explosive loading . . . . . . . . . . . . . . . . . .65-70 25-30 Miscellaneous explosives storage and handling . . . .65-70 5-10 Assembly building . . . . . . . . . . . . . . . . . .40-50 20-25 Detonator building . . . . . . . . . . . . . . . . .65-70 20-25 Pelleting . . . . . . . . . . . . . . . . . . . . . .40-50 20-25 Plastic beading . . . . . . . . . . . . . . . . . . .55-60 18-23 Sewing room . . . . . . . . . . . . . . . . . . . . .35-40 25-30 Projective assembly breakdown . . . . . . . . . . . .55-60 18-23 Machine shop . . . . . . . . . . . . . . . . . . . .16-21 21-26 Phosphorous plant . . . . . . . . . . . . . . . . . .35-40 25-30 TNT detonator (military) . . . . . . . . . . . . . .35-40 15-20 Ammunition tank box assembly . . . . . . . . . . . .35-40 15-20 Box emptying . . . . . . . . . . . . . . . . . . . .35-40 15-20

213 213 213 213 213 213 213 213 213 213 213 213 213 213 213 213 226 226 226 226 226 226 226 226 226 226 226 226 226 226 226

41 42 43 44 49 53 54 55 56 59 60 61 62 63 64 67

1Demand factors include allowance for system loss. 8

Table 1 (Continued) Factors for Individual Facilities by Navy Category Code1 DEMAND LOAD NAVY FACTOR FACTOR CODE Description (%) (%) 226 226 226 226 Plating maintenance . . . . . . . . . . Mixing . . . . . . . . . . . . . . . . Segregation fleet return . . . . . . . Plaster load . . . . . . . . . . . . . Fluoroscope building . . . . . . . . . Tank building rocket . . . . . . . . . Hydrostatic test . . . . . . . . . . . Phosphorous loading . . . . . . . . . . 226 Vacuum and hydraulic pump building . . 226 Cable drive . . . . . . . . . . . . . . 226 Dryer building . . . . . . . . . . . . Miscellaneous Production Facilities: 229 50 Printing plant . . . . . . . . . . . . Miscellaneous Storage Facilities: 750 Community Facilities - morale, welfare, recreation - exterior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35-40 .40-45 .35-40 .35-40 .45-50 .40-45 .35-40 .35-40 .35-40 .35-40 .75-80 18-23 18-23 15-20 15-20 18-23 15-20 15-20 15-20 12-17 12-17 3- 8 25-30

. . . . . . .45-55

and . . . . . . .Determine by load count and time. 750 30 Outdoor swimming pool installation . . . . . . . . .80-85 20-25 750 54 Band stand . . . . . . . . . . . . . . . . . . . . .75-80 15-25 Miscellaneous Facilities for Utilities and Ground Improvements: 821 09 Heating plant building (condensate) . . . . . . . . .55-60 25-40 821 09 Heating plant building (heating) . . . . . . . . . .55-60 30-35 833 40 Garbage house . . . . . . . . . . . . . . . . . . . .75-80 20-25 841 Potable water - supply/treatment/storage . . . . . .Determine by load count and time. 845 20 Pipeline nonpotable water . . . . . . . . . . . . . .55-60 3- 8 852 30 Pedestrian bridge . . . . . . . . . . . . . . . . . .80-85 20-25 872 20 Guard and watch towers . . . . . . . . . . . . . . .80-.. 46-.. 890 20 Compressed air plant . . . . . . . . . . . . . . . .60-65 20-25 1Demand factors include allowance for system loss.

(10.76 W/m2), but could vary from a low of 0.5 W/ft2 (5.38 W/m2) to a high of 1.5 W/ft2 (16 W/m2) depending on the specific tasks to be performed. A minimum of 0.1 W/ft2 (1 W/m2) for auditoriums to a maximum of 2.5 W/ft2 (27 W/m2) for machine shops is possible, although the upper limit would occur very rarely. Mechanical spaces in building storage areas and similar spaces in which outlets are provided but infrequently used are usually neglected in computing loads, except for special cases. 2.2.1.2 Electric Power Loads. Electric power loads shall include all loads other than lighting loads and those served by general purpose receptacles and comprise the environmental system electric power requirements and the facility occupancy equipment electric power requirements. 2.2.1.3 System Loss. A system loss of approximately 6 percent, based on calculated maximum demand, should be added to the building load. 2.2.2 Demand and Load Factors. The demand and load factors for a specific facility will vary with the division of load and hours of usage. Refer to Tables 2 and 3 for values that can be applied to determine demand and load factors. Table 4 is included as a guide and an aid in illustrating the method of determining loads, which are calculated for a particular type of building, such as an academic and general instruction building (Navy Code 171-10). The values given are empirical and will vary from activity to activity, and may vary from one facility to another within an activity. Annual hours use of demand must be determined for each case in accordance with methods of operation and characteristics of the installation. Demand factors and load factors for individual facilities by the Navy category code given in Table 1 are based on a survey of existing Navy facilities and past experience. Such factors should be used for quick estimating purposes and as a check when a more precise calculation is undertaken (refer to Table 4). 2.2.2.1 Guides for Demand Factors. factors, refer to Table 5. For guides on the selection of demand

2.2.2.2 Guides for Load Factors. Guides for the selection of load factors indicate the need for special considerations (refer to Table 6). Factors in the middle of the range are for the average facility at the peacetime shore establishment and should be used unless the guides in Table 6 indicate otherwise. 2.2.3 Load Growth. Determine the requirements for load growth for anticipated usage and life expectancy with particular attention to the possibility of adding heavy loads in the form of air conditioning, electric heating, electric data processing, and electronic communication equipment. Before determining the size of service and method of distribution to a facility, an economic analysis shall be made to determine the most feasible way of serving this future load. This analysis shall include the effect on the existing installation if future loads require reinforcing or rehabilitation of the service system.

10

Table 2 Demand Factors for Specific Loads (See Note 1) ESTIMATED QUICK TYPES OF LOADS RANGE OF ESTIMATING DEMAND FACTOR DEMAND FACTOR (%) (%) MOTORS: General purpose, machine tool, cranes, elevators, ventilation, compressors, pumps, etc. .............................. 20 - 100 30 MOTORS: Miscellaneous, fractional, and small appliances ......................... 10 - 50 25 Resistance ovens, heaters, and furnaces .... 80 - 100 80 Induction furnaces ......................... 80 - 100 80 Lighting ................................... 65 - 100 75 Arc welders ................................ 25 - 50 30 Resistance welders ......................... 5 - 40 20 Air-conditioning equipment ................. 60 - 100 70 Refrigeration compressors .................. 40 - 100 60 Note 1: Demand factors include allowance for system loss. Table 3 Annual Hours of Demand Usage for Specific Loads QUICK ESIMATING HOURS USE TYPES OF LOADS 1-SHIFT 2-SHIFT 3-SHIFT OPERATION OPERATION OPERATION MOTORS: General purpose ....................... 1,200 1,600 2,000 MOTORS: Miscellaneous, fractional, and small appliances ...................... 1,500 1,800 2,100 Resistance ovens, heaters, and furnaces . 1,000 1,300 1,600 Induction furnaces ...................... 900 1,200 1,500 Lighting ................................ 2,200 2,800 3,500 Arc welders ............................. 500 700 900 Resistance welders ...................... 500 700 900 Air-conditioning equipment Less than 1,500 cooling degree days ... 1,200 1,400 1,600 1,500 to 1,500 cooling degree days .... 1,600 1,800 2,000 More than 2,500 cooling degree days ... 2,200 2,500 2,800

11

Table 4 Academic Building (Code 171-10) Demand and Load Factor Calculations (See Note 1) MOTORS GENERAL MISCELLANEOUS FRACAIR TIONAL LIGHTING CONDITOTAL & SMALL TIONING APPLIANCES 1. Watts/square foot 1.0 1.0 2.7 4.5 9.2 (Watts/square meter) 10 10 26.5 45 91.5 2. Connected load 100 kw 100 kw 265 kw 450 kw 915 kw 3. Specific load demand factor 30% 10% 75% 70% 4. Maximum demand load (line 2 X line 3) 30 kw 10 kw 200 kw 315 kw 555 kw 5. Annual operating (1-shift) usage 1,200 hrs 1,500 hrs 2,200 hrs 1600 hrs 6. Annual usage in megawatt hours (line 4 X line 5) 36 15 440 504 995 7. Demand factor line 4 Formula = 60% (1) line 2 8. Load factor line 6 Formula = (4) line 4 X 8760 hrs

20%

Note 1: Calculated for a 100,000 square-foot (10,000 square meter) building. See tables 2 and 3 for data used for lines 3 and 5 respectively. Load growth is included in connected load. Maximum demand load includes allowance for system loss. For this illustration, the coincidence factor occurring when individual demand loads are added is considered to be 1.00 and has not been shown.

12

Table 5 Guides for Selection of Demand Factors Selection of factors in upper half of Selection of factors in lower half of range for conditions described below range for conditions described below GENERAL GUIDES Facilities in active use and Facilities of intermittent use or approaching maximum capacity. not being fully utilized. Loads predominantly lighting. Motor loads made up of a number of Loads predominantly heating. independently operated small motors. Loads dominated by one or two Motor loads controlled automatically large motors. unless control depends upon weather conditions. OPERATIONAL AND TRAINING FACILITIES Instruction buildings with little or Large instruction buildings with no electric equipment. electrical demonstration and Communications buildings with training equipment. telephonic equipment only. MAINTENANCE AND PRODUCTION FACILITIES Shops and facilities when engaged in No special guides. mass production of similar parts. RESEARCH, DEVELOPMENT, AND TEST FACILITIES Facilities used for repetitive No special guides. testing of material or equipment. SUPPLY FACILITIES Refrigerated warehouses in South. Warehouses with many items of Dehumidified warehouses in Mississippi electric materials handling Valley and along seacoasts. equipment, including cranes and Warehouses for active storage. elevators. HOSPITAL AND MEDICAL FACILITIES No special guides. No special guides.

13

Table 5 (Continued) Guides for Selection of Demand Factors ADMINISTRATIVE FACILITIES Large administrative buildings with Casual offices, offices used mechanical ventilation and air infrequently by foremen and conditioning. supervisors, or offices in which Note: Group large administrative there is little prolonged desk buildings separately only when work. administration is a significant part of total activity load. HOUSING AND COMMUNITY FACILITIES Enlisted barracks at training centers. Food service facilities where load Public quarters where less than 25 is primarily cooking and baking. family units are involved. Restaurants, exchanges, cafeterias, and other food service facilities when gas or steam is primary fuel. UTILITIES AND GROUND IMPROVEMENTS Central heating plants serving No special guides. extended areas and buildings. Water pumping stations serving extended areas or carrying most of load of water systems. Central station compressed air plants.

14

Table 6 Guides for Selection of Loads Factors Select factors in upper half of range Select factors in lower half of conditions described below range for conditions described below GENERAL GUIDES Facilities operated on two or more Facilities used intermittently. shifts. Inactive facilities. Loads that are primarily fluorescent Large motor loads when the load or high intensity discharge lighting. consists of relatively small Many small independently operated numbers of motors. motors. Wholesale-type service facilities. Electronic equipment continuously operated for immediate use. Cooling and dehumidification loads for year-round climate control in southern climates. Retail-type service loads and loads that are in active use. OPERATIONAL AND TRAINING FACILITIES Large, permanent instruction Special-purpose instruction and buildings in active use. training facilities not regularly used. MAINTENANCE AND PRODUCTION FACILITIES Shops with battery charging Welding loads or loads made up equipment operated after hours. primarily of welding equipment. Active shops at full employment. Job-order workshops. Mass production shops. Shops with large, heavy special function machines. Large induction or dielectric heating loads. RESEARCH, DEVELOPMENT, AND TEST FACILITIES No special guides. No special guides.

15

Table 6 (Continued) Guides for Selection of Loads Factors SUPPLY FACILITIES Refrigerated and dehumidified Refrigerated warehouses in North. warehouses in South or in humid Warehouses with large materials climates. handling equipment loads. Warehouses for active storage and in continuous use. HOSPITAL AND MEDICAL FACILITIES Clinics and wards with daily No special guides. operating hours and in active use. ADMINISTRATIVE FACILITIES Large, active, well-lighted No special guides. offices with ventilation and air-conditioning equipment. HOUSING AND COMMUNITY FACILITIES Navy exchanges with food service Restaurants and exchanges serving facilities. only one meal a day. Gymnasiums used in connection Restaurants and exchanges with gas or with physical therapy. steam food preparation equipment. Barracks at schools and training Chapels used primarily on Sundays. centers. Subsistence buildings serving less than four meals a day. Laundries with dry cleaning plants. Exchanges operated less than 8 hrs/day. Gatehouses operated less than 24 hrs/day. UTILITIES AND GROUND IMPROVEMENTS Heating plants that supply both Heating plants in South. heating and process steam. Water plants with little power load. Air-conditioning plants for year-round control of environment in South. Compressed air plants consisting of many banked compressors operating automatically.

16

2.2.4 Emergency Loads. The determination of emergency electric power requirements is based on three types of loads (refer to Section 3 for types of loads to be included in each category): a) b) c) minimum essential load, emergency load for vital operations, and uninterruptible (no-break) load.

When the three categories of emergency electric power requirements have been ascertained, determine where local emergency facilities are required, where loads may be grouped for centralized emergency facilities, and what loads are satisfied by the reliability of the general system. Base the aforementioned determinations on safety, reliability, and economy, in that order. 2.3 Area Loads. Area loads consist of groups of individual facility loads served by a subdivision of the electric distribution system. The term "area" applies to the next larger subdivision of an overall distribution system. Demand loads for an area must be known for sizing the distribution wiring and switching, and in a large installation will be required for the design of substations serving the area. Table 7 gives an example of how the coincident peak demand is calculated. 2.3.1 General Loads. To obtain the general load, add roadway lighting, area lighting, obstruction lighting, and other loads not included in individual facility loads. 2.3.2 Coincidence Factor. Determine the maximum expected demands, taking into consideration whether loads within the area peak at the same or at different times. 2.3.2.1 Relationships. Figure 1 indicates the relationship that exists between the load factor of individual facility loads and the coincidence of their peak demands with the peak demand of the group. This relationship was developed by a study of the loads of selected naval shore activities and by the application of factors developed to the formulas published by the Institute of Electrical and Electronic Engineers (IEEE). For collateral reading on this subject, refer to IEEE Technical Paper 45-116 Coincidence-Factor Relationship of Electric Service Load Characteristics. Table 8 is Figure 1 in tabular form with values shown to the nearest whole dollar, except for low load factors. 2.3.2.2 Selection. Areas with relatively insignificant residential type loads, where the load curve indicates that most of the electric power consumed in the area is used during the 40 normal working hours of a week, have coincidence factors at the higher end of the range. 2.3.2.3 Electric Power Consumption. In general, areas where large amounts of electric power are consumed outside the usual 40 working hours a week have a coincidence factor at the lower end of the range (examples are hospitals, areas operated on two or more shifts, or large barracks type activities). The upper limit of the range is for a 40 hour per week operation; the lower limit is for a 60 hour per week operation. 17

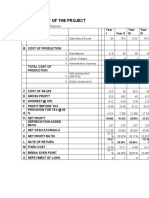

Table 7 Method of Calculating Coincident Peak Demand Parenthesized () numbers refer to Notes TOTAL DEMND MAXIMUM LOAD COIN- COINCONNECT- FACTDEMAND FAC- CIDCIDNAVY ED LOAD OR TOR ENCE ENCE CODE DESCRIPTION FACPEAK TOR (kW) (%) (%) (%) (%) (kW) 125 16 Fuel oil pump house.................................................. 125 16 Fuel oil pump house.................................................. 125 16 Total 0.3 100 0.3 52 52(1) 0.2 125 125 131 131 131 131 20 20 35 50 50 50 Filling station ...... 3.0 60 1.8 18 57(1) 1.0 Filling station bldg . 0.3 80 0.2 20 61(1) 0.1 Receiver building 2.1 65 1.4 72 79 1.1 Transmitter building................................................. Transmitter building................................................. Total .............. 37.2 65 24.2 72 79 19.1 Tacan building ....... 0.7 65 0.5 72 79 0.4 Radar building ....... 1.2 70 0.8 72 79 0.6 Aircraft fire and rescue station ..... 8.0 30 2.4 15 52(1) 1.2 Aircraft operations building ........... 80.2 80 64.2 28 68(1) 43.6 Photographic building 10.5 70 7.4 18 57(1) 4.2 Academic instruc. bldg.............................................. Academic instruc. bldg.............................................. Academic instruc. bldg.............................................. Academic instruc. bldg.............................................. Total 47 60 28.2 22 62(1) 17.5 Operational Trainer facility ........... 0.1 80 0.1 15 52(1) .... Aircraft overhaul and repair shop .... 7,600 38 2,890 25 95(2) 2,745 Paint/finishing hangar 127 70 89.0 26 66(1) 58.3 Engine preparation and storage shop.................................................... Engine maint. shop.................................................. Engine maint. shop.................................................. Total .............. 405 40 162 15 52(1) 84.2 Engine test cell ..... 360 45 162 28 68(1) 110 Missile equipment maint. shop ........ 3.0 40 1.2 22 62(1) 0.7 Auto veh. maint. facs............................................... Auto veh. maint. facs............................................... Auto veh. maint. facs............................................... Auto veh. maint. facs............................................... Total 370 60 222 25 65(1) 145 18

133 25 133 75 141 20 141 40 141 171 171 171 171 171 60 10 10 10 10 10

171 35 211 10 211 12 211 22 211 21 211 21 211 21 211 83 212 20 214 214 214 214 214 20 20 20 20 20

Table 7 (Continued) Method of Calculating Coincident Peak Demand 730 10 Fire station ......... 14.6 30 4.4 15 521 2.3 Total 3,325 System loss (6%) 194 Grand total 3,429 (1) The coincidence factor has been increased to allow for low load factor and number of facilities in the area. Refer to para. 2.3.2.4, Influencing Factors, of this handbook. (2) The coincidence factor has been increased because of the relative magnitude of the load. Refer to para. 2.3.2.5, Individual Loads, of this handbook.

19

20

Table 8 Relationship Between Load Factor and Coincidence Factor COINCIDENCE FACTOR COINCIDENCE FACTOR (%) (%) LOAD Loads (hr/wk) LOAD LOADS (hr/wk) FACTOR FACTOR (%) 40 60 (%) 40 60 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 2.5 7.5 12 17 21 25 28 32 35 38 41 44 46 49 51 53 54 56 57 59 60 61 62 63 64 65 66 67 68 69 69 69 70 70 71 71 71 71 72 72 72 72 72 1.5 4.5 8 11 14 17 20 22 24 26 29 32 34 36 38 40 42 44 46 48 50 51 53 54 55 56 56 57 58 59 60 61 62 63 64 64 65 65 65 66 66 66 67 21 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 73 73 73 73 73 73 73 74 74 74 74 75 75 76 76 77 77 78 78 78 78 79 79 80 81 81 82 82 82 82 82 82 83 84 85 86 87 88 89 90 91 92 93 69 70 70 70 71 71 71 71 72 72 72 73 73 74 74 75 75 76 76 77 77 78 78 79 80 80 81 81 81 82 82 82 83 84 85 86 87 88 89 90 91 92 93

Table 8 (Continued) Relationship Between Load Factor and Coincidence Factor COINCIDENCE FACTOR COINCIDENCE FACTOR (%) (%) LOAD Loads (hr/wk) LOAD LOADS (hr/wk) FACTOR FACTOR (%) 40 60 (%) 40 60 44 45 46 47 48 49 50 73 73 73 73 73 73 73 67 67 67 68 68 69 69 94 95 96 97 98 99 100 94 95 96 97 98 99 100 94 95 96 97 98 99 100

22

2.3.2.4 Influencing Factors. The number of individual loads in a group and their load factors influence the individual load coincidence factor. The coincidence factors in Table 8 apply for groups of l00 or more individual loads. These coincidence factors can also be used for groups of as few as 30 to 50 individual loads if their load factor is 0.30 or greater. For areas of fewer individual loads, the mathematical relationship from IEEE Technical Paper 45-116 provides a basis for estimating the connected coincidence factor as shown by the following equation:

2.3.2.5 Individual Loads. The coincidence factors in Table 8 are based on the individual loads in a group being substantially the same size. If a single load or small group of loads in an area represents a substantial percentage of overall load, the coincidence factors as given in Table 8 will no longer apply. With an individual load, increase the coincidence factor to a value commensurate with its effect on the overall area load. This is not in addition to, but in place of, the normal coincidence factor. Determine this value by considering intergroup coincidence factors given in paragraph 2.3.2.6. (An example of facility Navy code 211-70 is presented in Table 7.) For a small group, determine the coincidence peak load, and to this apply the appropriate intergroup coincidence factor to obtain the coincidence peak load for the area. 2.3.2.6 Groups of Loads or Areas. Where groups of loads within an area, or areas within a facility are combined, an additional intergroup coincidence factor will exist. For loads of a similar nature, the intergroup coincidence factor should be in the range 0.93 to 1.00. If loads of a varying nature (evening loads and daytime loads) are combined, the intergroup coincidence factor should be in the range of 0.70 to 1.00. The lower values will occur when the magnitudes of the loads are nearly balanced, and the higher ones when the combined load is predominantly one type. 2.3.3 Load growth. In addition to planned expansion, increased application of electric equipment will generate an increase in load. When sizing components, such as transformers or feeders for the area system, consider possible load growth in addition to that included in the determination of individual loads. 2.3.4 demands. demand. System Losses. Add distribution system losses to estimated area For a good approximation, use 6 percent of the calculated maximum

23

2.3.5 Emergency Loads. Review the overall emergency requirements for the area, based on criteria for the facility or as furnished by the using agency, to determine the following: a) The emergency loads that may be combined in groups to take advantage of the coincidence factor. b) The type of distribution system needed for reliability and to economically satisfy at least the less critical emergency load requirements. This reliability can be provided only if the source of electric power is not the determining factor. c) Area loads that must be added to individual emergency loads; for example, security lighting and minimum roadway lighting. 2.3.6 Expansion. The planned development of the area, as shown on the activity general development map, shall be considered for requirements of future expansion. 2.4 Activity Loads. Activity loads are loads that consist of two or more area loads served from a single electric power source and an integrated distribution system. 2.4.1 General Loads. Follow the approach used in para. 2.3 for area loads. Area loads used for determining activity coincidence demand should be the area coincident demand exclusive of allowance for load growth. 2.4.2 Coincidence Factor. Refer to para. 2.3.2 for the necessary approach. Where dissimilar areas, whether residential, administrative, or industrial, are part of an activity, make a careful analysis of the coincidence factor used. 2.4.3 Load Growth. As for an area, components should be sized after due consideration has been given to load growth. Apply this increase to the coincident demand of the activity. 2.4.4 Expansion. The planned development of the activity, as shown on its general development map, shall be considered for requirements of future expansion.

24

Section 3:

SELECTION OF ELECTRIC POWER SOURCE

3.1 Policy. In electric power source selection, use the same criteria employed for selection of electric power plants in NAVFAC DM-3, Mechanical Engineering Series. 3.2 Economic Factors. Use the same criteria presented for economic studies of electric generating plants in the NAVFAC DM-3 Series. 3.3 Electric Power Sources. The electric power supply for a major shore activity usually will consist of three sources: primary, standby, and emergency (alternate). In addition, some operations cannot tolerate any electric power interruption, thus requiring uninterruptible power supply (UPS) systems. MIL-HDBK-1190 Facility Planning and Design Guide, Chapter 7 under "Alternate Power Sources," indicates systems and functions authorized to have alternate power sources and provides design criteria for such alternate sources. 3.3.1 Primary. The primary or preferred source should have sufficient capacity to provide for peak electric power demand during normal peacetime operations. 3.3.2 Standby. The standby source should have enough capacity so that the standby system can supply all of the minimum essential operating electric load of the activity and, when added to the capacity of the primary source, will provide a combined capacity sufficient to serve the estimated peak demand under mobilization conditions. This "minimum essential operating electric load" is the minimum electric power necessary to support the absolutely essential operations of the activity, with illumination reduced to a bare minimum and with all convenience loads and other loads (such as hospital elevators, except the minimum required for patient and food transportation) suspended. Where major intermittent loads, such as drydock pumping, electric furnaces, electric welders, and wind tunnels, are involved, it is necessary to determine whether concurrent operation of such equipment can be avoided. 3.3.3 Emergency. The emergency sources, usually one or more engine-driven, manual, or automatic-starting emergency generators, should have sufficient total capacity to provide the electric power demand for vital operations. Vital operations are those that can tolerate electric power interruption only for relatively short durations. For certain operations, the permissible electric power interruption is as long as 4 hours, for others it is only l0 seconds. The latter condition will require automatic start but the former condition may be manual start. The emergency source should be of sufficient capacity to provide a continuous and adequate supply for vital operations, but should be planned to bear a sound relation to the standby service provided. Vital operations will normally be in two categories: a) b) Operations recognized by local, state, or national codes, and Operations determined as vital by the major claimant or user.

To qualify as a vital operation, the electric power outages must cause loss of 25

primary missions, thus resulting in disastrous situations or extreme safety hazards as compared to minor disruption and inconvenience. Such vital operations may include, but are not necessarily limited to, communications, ventilation, and lighting of combat operations centers, personnel bomb shelters, anti-aircraft, harbor defenses, industrial processes that might cause explosion if interrupted, hospital surgeries, blood banks, bone banks, iron lungs, and similar operations. 3.3.4 Uninterruptible (No-Break) Electric Power. An Uninterruptible Power Supply (UPS) system is necessary for certain electronic or other equipment that perform a critical functions and require continuous, disturbance-free electric power to operate properly. This electric power system must, under all conditions, provide regulated electric power to the critical load. 3.4 Acceptable Electric Power Sources. Electric power sources acceptable for supplying shore facilities are given in paras. 3.4.1 through 3.4.4. 3.4.1 Primary. The primary source of electric power may be navy-owned generating equipment or one or more feeders from an outside electric power system. 3.4.2 Standby. Where the primary source of electric power is Navy-owned generation, the standby source may be other Navy-owned generation or service supplied over a feeder, or feeders, from an outside electric power supplier. Where the primary source of electric power is from an outside electric power supplier, the standby source may be Navy-owned generation or service supplied over a feeder, or feeders, from a different outside electric power supplier or supply from an alternate feeder from the same outside electric power supplier. The alternate feeder must be located at some distance from the normal feeder, and supplied independently of the substation and generating source of the normal feeder. Where this is not feasible, a supply from transmission lines or substations of the outside electric power supplier, which themselves have dual supplies, is an acceptable alternative. 3.4.3 Emergency. Permanently installed, mobile or semimobile, manual or automatic starting generating equipment should be provided to supply emergency electric power. Emergency generating capacity should not exceed the minimum required to supply electric power for vital operations, and should be located as close to those loads as practicable. Provisions for normal load growth (15 to 20 percent spare capacity) shall be provided. As a minimum, the provisions of NFPA 110 Emergency and Standby Power Systems, shall apply. 3.4.4 Uninterruptible (No-Break) Electric Power. Permanently installed, automatically operated equipment should be provided to supply uninterruptible electric power. Equipment capacity should not exceed the minimum required to supply electric power for critical loads, and equipment should be located as close to these loads as practicable. Provision for normal load growth (15 to 20 percent spare capacity) shall be provided. 3.5 Purchased Electric Power Requirements. In the selection of private utility electric power supplies consider the factors in paras. 3.5.1 through 3.5.5. 26

3.5.1 Adequacy. Determine the capability of the electric utility company to furnish electric power, of the required characteristics, to meet the immediate estimated demand. The capability of the utility to meet the demand under mobilization conditions should be determined on the best basis available. Ascertain whether or not the utility has enough construction in its program to meet the loads anticipated for the next 5 years. 3.5.2 Reliability. Investigate the history of outages of the contemplated utility company to determine if it can provide the degree of reliability required by the particular installation. The investigation shall include the following items: a) A 5-year history of service outages in the area, including: (1) The time and date of each occurrence (2) Duration, time, and date of each restoration (3) Cause (4) Steps taken to restore service and (5) A probability analysis showing the expected number of outages of 1 minute, 5 minutes, 10 minutes, 30 minutes, and 60 minutes. b) A one-line diagram of the supplier's system, showing the location of all switching equipment, circuit breakers, relaying, and similar components. c) A short circuit study of the system, including interrupting capacities of all switching equipment, time constants, and short circuit currents for both existing and expanded facilities in the area. d) Voltage regulation, nominal voltage, and normal operating voltage of supplier's facilities. e) Climatic and other physical conditions prevailing in the area and on the system that may affect the reliability of service. Some utilities will only supply a minimum of data for items a) to c), and evaluation may be necessary using data available from other military installations in the area. 3.5.3 Rates. To take advantage of the lowest available cost of electric energy, compare electric energy rates with estimated maximum demand and consumption. Compare the estimated demand block with prices per kilowatthour of other customers served by the same utility company. Choice of either primary or secondary connection shall be based on selection of connection charges and rental of company equipment that provide the maximum advantage to the Government. An analysis of rates shall be based on the company's complete tariff covering all types of services. This review will entail comparison of several tariffs that are available on an alternative basis, as well as the Contractor's general rules and regulations that modify the tariffs. 3.5.4 Primary Service Right-of-Way. The supply company should provide the right-of-way for all of its electric lines up to the Government property (refer to MIL-HDBK-1004/2, Power Distribution Systems). 27

3.5.5

Primary Substations

3.5.5.1 Voltage. A substation may not be required where the utility company serves energy at 13.8 kV or less; distribution may be at this voltage. In some cases, if the loads are large enough, distribution may be done at higher voltage up to a maximum of 35 kV. Refer to Section 6 for information on levels of distribution voltage, and MIL-HDBK-1004/2 for data on substations. 3.5.5.2 Economics. Usually, ownership of main substations serving an activity is determined by engineering and economic factors. Distribution system voltages, as well as amortization costs of substations, should be the controlling factors.

28

Section 4:

UNINTERRUPTIBLE POWER SYSTEMS

4.1 Requirements. Uninterruptible power system (UPS) will use centrally-procured Government-Furnished Equipment (GFE). GFE includes the UPS module and the UPS battery. The emergency generator is not normally included as part of the GFE. Procurement of this equipment is beyond the scope of this handbook. However, the installation of such equipment in conjunction with auxiliary systems must be properly designed, which requires an understanding of the specialized equipment and concepts involved. This section covers the equipment installation criteria which, when integrated with the individual project requirements, shall produce a safe, reliable, and cost efficient design. 4.2 Criteria. The latest issues of the following documents shall be used to ensure correct installation of the GFE equipment: SUBJECT SOURCE UPS Module...................Manufacturer's installation instructions Battery......................Manufacturer's installation instructions Emergency Power..............IEEE 446, Recommended Practice for Emergency Standby Power Systems and DM-12.1, Electronic Facilities Engineering Environmental considerations (mechanical design)..........DM-3 and DM-12.1 4.3 Power Load Categories. Power load categories are illustrated in Figure 4 of DM-12.1. The pertinent categories, listed below, are defined in DM-12.1: a) b) c) d) e) f) g) Station load Nonoperational load Operational load Utility load ("nontechnical load") Electronic load ("technical load") Noncritical electronic load ("noncritical technical load") Critical electronic load ("critical technical load")

29

4.4

Definitions.

The following definitions of terms shall apply:

a) Uninterruptible Power Supply System - An uninterruptible power supply system consists of UPS equipment, backup power source(s), environmental equipment, switchgear, and controls which together provide a reliable, continuous quality electric power system. b) Critical Electronic Load - The critical electronic load is that part of the load that requires continuous quality electric power for its successful operation. c) Uninterruptible Power Supply (UPS) - An uninterruptible power supply (UPS) consists of one or more UPS modules, an energy storage battery, and accessories as required to provide a reliable and high quality power supply. The UPS isolates the load from the primary and emergency power sources and, in the event of a power interruption, provides regulated power to the critical load for a specified period depending on the battery capacity. The battery normally has a 15-minute capacity when operating at full load. d) UPS Module - A UPS module is the static power conversion portion of the UPS system and consists of a rectifier, an inverter, and associated controls along with synchronizing, protective, and auxiliary devices. UPS modules may be designed to operate either individually or in parallel. e) Nonredundant UPS Configuration. The nonredundant UPS configuration consists of one UPS module with a static bypass circuit and a battery, and a maintenance bypass cabinet. Upon failure of the UPS module, the static bypass circuit automatically transfers the critical electronic load to the primary or emergency source without an interruption to the load (see Figure 2). f) "Cold" Standby Redundant UPS Configuration. The "cold" standby redundant UPS configuration consists of two independent nonredundant UPS modules with a common battery. One UPS module operates on the line, and the other UPS module is turned off. Should the operating UPS module fail, its static bypass circuit will automatically transfer the critical electronic load to the primary or emergency source without an interruption to the critical load. The second UPS module is then manually energized and placed in the bypass mode of operation. To transfer the critical load, external make-before-break nonautomatic circuit breakers (or contactors) are operated to place the load on the second UPS bypass circuit. Finally, the critical electronic load is returned from the bypass to the second UPS module via the static switch. The two UPS modules cannot operate in parallel; therefore, an interlock circuit must be provided to prevent this condition (see Figure 3). UPS modules are to be transferred to and from "cold" standby every three months. The mode of operation is as follows: (1) Transfer Circuit Interlock, External Bypass - The two circuit breakers (or contactors) shall be nonautomatic and motor operated. Transfer to and from one UPS to the other shall be a closed circuit (make-before-break) transition and shall be possible only when both UPS's are in the bypass mode of operation. 30

(2) Transfer Circuit Operation - To transfer critical load from UPS module No. 1 to UPS module No. 2, both modules are placed in the bypass mode. The make-before-break nonautomatic circuit breakers are operated to transfer the critical load to the bypass circuit of UPS module No. 2, after

31

which the critical load is transferred to supply the inverter output. UPS module No. 1 can then be completely isolated for maintenance or repair. g) Parallel Redundant UPS Configuration. A parallel redundant UPS configuration consists of two or more UPS modules with a system control cabinet and a common battery. UPS modules operate in parallel, and the system is capable of supplying the rated critical load upon failure of any one UPS module. The failed UPS module will be disconnected from other UPS modules without an interruption to the critical load (see Figure 4). 4.5 Redundancy. For facilities requiring UPS systems, a nonredundant UPS system is satisfactory for most operations. The justification for the added expense of either redundant system is given in paras 4.5.1 and 4.5.2. 4.5.1 "Cold" Standby Redundant UPS System. Provide a "cold" standby redundant UPS system when the installation site is isolated and logistic support is poor or when the primary electric power supply exhibits poor reliability by experiencing more than four power interruptions per month or when the primary electric power supply provides voltage or frequency fluctuations which are beyond the limits permitted in MIL-HDBK-411, Long Haul Communications (DCA) Power and Environmental Control for Physical Plant. 4.5.2 Parallel Redundant UPS System. Provide a parallel redundant UPS system when the frequency of the primary electric power supply must be converted to serve the critical load (that is, 50 Hz to 60 Hz, or 60 Hz to 400 Hz). 4.6 Electric Service and Bypass Connectors. Two separate electric services, one to the UPS rectifier circuit and the other to the UPS bypass circuit shall be provided. Where possible, they shall emanate from two separate buses with the UPS bypass connected to the electronic (noncyclic) bus and the rectifier connected to the utility (cyclic) bus. This connection provides isolation of sensitive electronic loads from the effects of UPS rectifier harmonic distortion and motor startup current inrush. 4.6.1 Electric Service Size. A UPS system is considered to be a continuous type load, and service to both the rectifier and bypass circuits should be sized in accordance with article 220 of the National Electric Code. The required current for the rectifier circuit is calculated based on the UPS output rating divided by the UPS efficiency and multiplied by a load factor of 125 percent to take into account battery charging. The UPS bypass circuit may be rated for less current since both UPS losses and battery charging requirements need not be supplied. 4.6.2 Maintenance Bypass Provisions. To provide for maintenance of equipment, bypass provisions are provided as follows: a) For the non-redundant UPS unit, install an external bypass switch in order to completely isolate the UPS unit (see Figure 2). This is to enable testing of the UPS unit, including the static switch, with dummy load without interruption to the critical bus. b) Each module of the "cold" standby redundant UPS has the same built-in bypass circuit provisions as the nonredundant UPS. Complete 34

35

isolation of one UPS module (including its bypass) from the other module is inherent in the "cold" standby redundant configuration (see Figure 3). c) The parallel redundant UPS contains a built-in manual bypass circuit in the control cabinet which will serve to isolate the UPS modules during emergency conditions or maintenance. This manual bypass circuit provides make-before-break switching and contains synchronizing provisions. Where frequency conversion is provided by the UPS, a solid state frequency conversion system or a motor-generator set will be required to bypass the UPS module. 4.7 UPS Distribution System. The UPS system serves critical loads only. Noncritical loads are served by separate distribution systems supplied from either the electronic or utility bus as appropriate. 4.7.1 Critical Load Protection. Provide critical load panels with current-limiting circuit breakers or fast acting fuses to shorten the transient effects of undervoltages caused by load faults. 4.7.2 Critical Motor Loads. Due to the energy losses and the starting current problem inherent in motor-generator sets, their connection to a UPS bus should be limited to frequency-conversion applications only. Generally, motor-generator sets shall be started on the UPS bypass circuit. However, motor-generator sets may be started on the rectifier mode of operation under the following conditions: a) When rating of the motor-generator set is less than 5 percent of the UPS rating. b) When reduced voltage starters are utilized for each motor load.

c) When more than one motor-generator set is connected to the critical bus, each set must be energized sequentially rather than simultaneously. Solid state frequency conversion systems may be considered in lieu of motor-generator sets. 4.8 Emergency Electric Power Source Requirements. The UPS system can serve the critical electronic load continously during periods of normal source electric power outage only if one or more emergency engine generators are provided and sized to supply not only UPS equipment, but all necessary auxiliary equipment such as lighting, ventilation, and air conditioning. The emergency electric power source shall meet the criteria given in paras. 4.8.1 through 4.8.5. 4.8.1 Automatic Operation. The emergency generator(s) shall be automatic start, automatic transfer-to-load upon normal electric power failure and shall include provisions for automatic load shedding and load restoration where required. 4.8.2 Paralleling. At a minimum, manual synchronizing of the emergency generator(s) with the normal electric power source shall be provided. As an alternative, automatic synchronizing of the emergency generator with the 36