Professional Documents

Culture Documents

Inspection Test Plan For Fabrication

Uploaded by

Ashwani DograOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inspection Test Plan For Fabrication

Uploaded by

Ashwani DograCopyright:

Available Formats

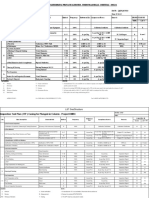

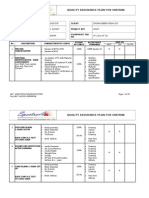

INSPECTION AND TEST PLAN

Job No. : Client : References Client Projects Number: A B Applicable Codes: C H W M R RI NSF Procedures: RT UT Project : Legend ITP For :

Date ITP No.: Rev. Page

: : :

5/10/2012 GC-ITP-000 0 of

Fabrication

: RKM Inspector : Client inspector : Third Party Inspector : Hold Point : Witness Point : Monitoring : Review Document : Report Issuance : Radiographic Test : Ultrasonic Test : Magnetic Particle Test : Liquid Penetrant Test : Hardness Test : Visual Test : Dimensional Check : Hydrostatic Test : Dry Film Thickness check : Postweld Heat Treatment : Welding Procedure Specification : Procedure Qualification Record : Welder Performance Qualification : Tightening Check : Authorized Inspector

Owner Approval

AWS D1.1

NSF- MAT- 001 NSF-PRO- 001 NSF-QCD-008 NSF -QCD-005 NSF-TEC-001 NSF-QCD-007 NSF-PRO-003 NSF-GEN-001 NSF-QCD-004

Store control Weld control N.D.T control Ultra sonic Examination Handling and Packing Magnetic particle Examination Painting Control Fabrication Radiographic Examination

MT PT HV VT DT HT DFT PWHT WPS PQR WPQ TG AI

Prepared By

Approved By

Customer Approval

Name Signature Date

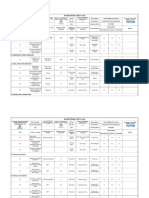

INSPECTION AND TEST PLAN

Date : ITP No. : Rev. : Page :

ITP For :

Fabrication

5/10/2012 GC-ITP-000 0 of

Job No. : Dwg No. : Ser. #

Client :

Project : Rev. :

Item No. : Inspection

Activity Description

APPROVAL

Acceptance Criteria

Verifying Document

Type

Sign Date

Sign Date

Sign Date

Remarks & Reports No.

I 1 2 3 II 1 2 III 1 2 3 4 5 IV 1 2 3

Drawing approval 100% Material certificate check WPS's,WPQ's,PQR AND NDT

MATERIAL PREPARATION

100% 100% 100%

Drawing specs EN 10025

client approval client approval client approval

H H H

AWS D1.1

100% Material check for confirmity and visual

100%

EN 10025 WPS&Approved Drawings

Material Certificate ITP

VT&DT DT

H M

Marking,Cutting,Rolling and Edge preparation

100%

FABRICATION ASSEMBLY Correct Joint design

100% 100% 100% 100% 50%

WPS&Approved Drawings,AWS D1.1 Work order , Drawings Welder List WPS&Approved Drawings,AWS D1.1 Approved Drawing

ITP ITP

Welder List

VT&DT VT

H H R

Check identification Qualified welder check Check Fitup&Tack welds Drilling check

NDT

ITP ITP

VT&DT VT&DT

H H

Visual check for Complete welds(Dynamic or static ) 100%

AWS D1.1(table 6.1)

visual Report UT Report MT Report

VT&DT UT MT

H H&RI H&RI

UT FOR BUTT WELD FULL PENETRATION SPLICE JOINTS FOR THICKNESS 8 MM (Dynamic or static ) MT FOR SINGLE WALL CJP < 8MM FROM BOTH

SIDES(Dynamic or static )

100%

AWS D1.1(table 6.2,table 6.3)

100%

AWS D1.1

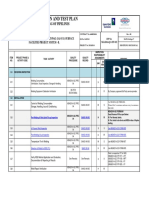

INSPECTION AND TEST PLAN

Date : ITP No. : Rev. : Page :

ITP For :

5/10/2012 GC-ITP-000 0 3 of

Job No. : Dwg No. : Ser. #

Client :

Project : Rev. :

Fabrication

Item No. : Inspection

Activity Description

Acceptance Criteria

Verifying Document

Type

Sign Date

Sign Date

Sign Date

Remarks & Reports No.

FOR DOUBLE WALL CJP < 8MM AT TWO STAGES : 1st step 100% MT AFTER ROOT PASS DIRECTLY MAX 3 MM -2nd step 100% MT( AFTER FILLING + CAP )(Dynamic or static ) 10% OF THE LENGTH UT FOR BUTT WELDS FULL PENTRATION FOR THICKNESS 8 MM OF ALL WELDS 1000 MM , 5% OF THE LENGTH UT FOR BUTT WELDS FULL PENTRATION FOR THICKNESS 8 MM FOR ALL WELDS < 1000 MM (For static loads)

100%

AWS D1.1

MT Report

MT

H&RI

AWS D1.1 table 6.2

UT Report

UT

H&RI

50% OF THE LENGTH UT FOR BUTT WELDS FULL PENTRATION FOR THICKNESS 8 MM OF ALL WELDS (For Dynamic Loads) 10% OF THE LENGTH MT FOR FILLET& P.P WELDS FOR ALL WELDS 1000 MM , 5% OF THE LENGTH MT FOR FILLET& P.P WELDS FOR ALL WELDS < 1000 MM (For static loads) 100% OF THE LENGTH MT FOR FILLET& P.P WELDS FOR ALL WELDS (For Dynamic Loads)

50%

AWS D1.1 table 6.3

UT Report

UT

H&RI

AWS D1.1

MT Report MT Report MT Report

UT Report

MT MT MT

UT

H&RI H&RI H&RI H&RI

100%

AWS D1.1

MT for the root pass for all welds greater than 100% 38 mm UT lamination test for all plates or sections TH 23 mm restrained at a tee junction by a butt 100% weld

AWS D1.1

AWS D1.1

V 1 2 3 4 5 6 7

FINAL INSPECTION

Final dimension check Surface preperation for painting Painting check Galvanizing check Documentation check packing check Final release for shipment

100% 100% 100% 100% 100% 100% 100%

Approved Drawing & En 5950-2 Client Specs

ITP painting report painting report Galvanizing Report ITP Packing Report Final Release

VT&DT VT VT& D.F.T check VT& D.F.T check

H H&RI H&RI H&RI H

Client Specs

Client Specs Client Specs Client Specs Client Specs

VT

H&RI H&RI

You might also like

- Procedure For WQTDocument13 pagesProcedure For WQTdevikar8umNo ratings yet

- 038-Pro Welding Consumable Control Procedure PDFDocument20 pages038-Pro Welding Consumable Control Procedure PDFKöksal Patan100% (7)

- 03 Welding Control Procedure - Asf QC WCP 001Document7 pages03 Welding Control Procedure - Asf QC WCP 001el_sharkawy2011100% (1)

- B2020-TDC-VF-009 Vessel Fabrication R0Document5 pagesB2020-TDC-VF-009 Vessel Fabrication R0Ramalingam PrabhakaranNo ratings yet

- Approved Welding Procedures List RegioDocument2 pagesApproved Welding Procedures List Regiogabriel__regio100% (1)

- Fabrication Method StatmentDocument11 pagesFabrication Method StatmentAkhilesh KumarNo ratings yet

- Field Itp For Piping Work Samur Project Rev-5 (23 April 2013)Document28 pagesField Itp For Piping Work Samur Project Rev-5 (23 April 2013)Echik KiciNo ratings yet

- Itp For Fabrication Steel Structure of Warehouse and WorkshopDocument6 pagesItp For Fabrication Steel Structure of Warehouse and WorkshopPhong Do100% (1)

- Chqlist For Fabrication & InspectionDocument12 pagesChqlist For Fabrication & InspectionSuresh ShuklaNo ratings yet

- Fabrication Inspection ProcedureDocument11 pagesFabrication Inspection Procedurewill_herry100% (6)

- ITP - Fabrication of Structural SteelDocument2 pagesITP - Fabrication of Structural Steelsahad100% (6)

- Welding Procedures and Welding Qualiy Control For PipingDocument18 pagesWelding Procedures and Welding Qualiy Control For PipingImam BuchairiNo ratings yet

- Procedure - Fit-Up & AssemblyDocument8 pagesProcedure - Fit-Up & AssemblyRakesh RanjanNo ratings yet

- SOP - 06 - Visual and Dimensional ProcedureDocument22 pagesSOP - 06 - Visual and Dimensional ProcedureSuci YatiningtiyasNo ratings yet

- Daily Progres 22 AprilDocument2 pagesDaily Progres 22 AprilIqbal Nurrasa Bakti100% (3)

- Dimensional Inspection ReportDocument2 pagesDimensional Inspection Reportshabbir626No ratings yet

- QAP StructureDocument2 pagesQAP Structureayoki100% (1)

- WI Dimensional Control Sign1Document6 pagesWI Dimensional Control Sign1gusyahri001No ratings yet

- Api 650 RTDocument3 pagesApi 650 RTAdi QCNo ratings yet

- ITP For Steel Structure1Document3 pagesITP For Steel Structure1吴兴泊No ratings yet

- Electrode Handling Procedure - Simple - SMAWDocument7 pagesElectrode Handling Procedure - Simple - SMAWGalih Suksmono Adi0% (1)

- Sequence of InspectionDocument7 pagesSequence of InspectionRomi Abdul RahmanNo ratings yet

- ITP - Steel ErectionDocument10 pagesITP - Steel ErectionGhayas RanjhaNo ratings yet

- ITP Structural SteelDocument14 pagesITP Structural SteelNavneet SinghNo ratings yet

- Fit Up ReportDocument41 pagesFit Up ReportFendik NewbieNo ratings yet

- INSPECTION AND TEST PLAN (ITP) FOR TEST TANK PDM T-1001 A Rev B PDFDocument7 pagesINSPECTION AND TEST PLAN (ITP) FOR TEST TANK PDM T-1001 A Rev B PDFgst ajah100% (4)

- Inspection & Test Plan: Sub-Contractor Con - Tractor Saudi AramcoDocument1 pageInspection & Test Plan: Sub-Contractor Con - Tractor Saudi AramcoDelta akathehusky100% (1)

- ITP For Fabrication & Erection of TanksDocument20 pagesITP For Fabrication & Erection of TanksosersNo ratings yet

- Fabrication Division QMDDocument11 pagesFabrication Division QMDRakesh RanjanNo ratings yet

- Fit-Up Preparation and Acceptance Criteria As Per Project RequirementsDocument6 pagesFit-Up Preparation and Acceptance Criteria As Per Project RequirementsAbdülHak ÖZkaraNo ratings yet

- Fabrication ProcedurDocument7 pagesFabrication ProcedurHarry PangestuNo ratings yet

- Fabrication ProcedureDocument17 pagesFabrication ProcedureThi Pham100% (9)

- General Format For Girder Fabrication Check ListDocument4 pagesGeneral Format For Girder Fabrication Check ListBhanu Pratap ChoudhuryNo ratings yet

- Method Statement No: 04 Fabrication and Installation of Steel Structure SUPPORT (SPS-B065-099) FOR 52-K0624Document9 pagesMethod Statement No: 04 Fabrication and Installation of Steel Structure SUPPORT (SPS-B065-099) FOR 52-K0624Azel Bumagat94% (18)

- Vishwabalaa Engineering Private Limited, Thirumazhisai, Chennai - 600124Document2 pagesVishwabalaa Engineering Private Limited, Thirumazhisai, Chennai - 600124sanil50% (2)

- Request For Inspection of MaterialDocument3 pagesRequest For Inspection of MaterialSopi Labu100% (1)

- Inspection Test Plan - Piping FabricationDocument5 pagesInspection Test Plan - Piping Fabricationhassan_ndt80% (5)

- Qa Inspection and Test PlanDocument1 pageQa Inspection and Test Planit4scribdNo ratings yet

- Erection and Painting of Steel StructureDocument11 pagesErection and Painting of Steel StructureomarcadNo ratings yet

- Welding TerminologyDocument18 pagesWelding Terminologymahi1437100% (1)

- Inspection and Test PlanDocument28 pagesInspection and Test Planmfvallega88% (17)

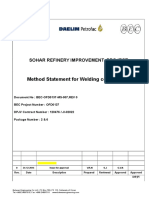

- Method Statement For Welding Control System: Sohar Refinery Improvement ProjectDocument14 pagesMethod Statement For Welding Control System: Sohar Refinery Improvement Projectmansih457100% (1)

- QA-000-AA-5013 ITP For Structure Steel Erection Works Rev1 (APPROVED)Document10 pagesQA-000-AA-5013 ITP For Structure Steel Erection Works Rev1 (APPROVED)miaicarba100% (2)

- QIR-105-Material Receiving Inspection ReportDocument2 pagesQIR-105-Material Receiving Inspection ReportSamer Bayati50% (2)

- QCF108 Grouting Inspection ReportDocument1 pageQCF108 Grouting Inspection Reportminhnn100% (3)

- 2037-PL-PL-0058-IR-T-014 Dated 10.12.19Document16 pages2037-PL-PL-0058-IR-T-014 Dated 10.12.19Dadaso Baburao Jamdar100% (1)

- Marine Facilities Work Egyptian LNG Project-Idku Work Instruction FOR Handling of Consuamable MaterialsDocument6 pagesMarine Facilities Work Egyptian LNG Project-Idku Work Instruction FOR Handling of Consuamable Materialszaki fadlNo ratings yet

- How To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3) Welding & NDTDocument5 pagesHow To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3) Welding & NDTVKT TiwariNo ratings yet

- Inspection Test Plan For Fabrication & Erection 2016Document14 pagesInspection Test Plan For Fabrication & Erection 2016Boj Mingi0% (1)

- Procedure For Receipt, Storage and Handling of Welding Consumable (Rev 1)Document8 pagesProcedure For Receipt, Storage and Handling of Welding Consumable (Rev 1)dee1985100% (2)

- ITP For Steel StructureDocument3 pagesITP For Steel Structuretrey100% (4)

- Daily Weld Fit-Up and Production Report (Field Weld) - Pipeline-Satr-W-2007Document5 pagesDaily Weld Fit-Up and Production Report (Field Weld) - Pipeline-Satr-W-2007smdriyazbasha100% (2)

- Bus Duct-SPBDDocument5 pagesBus Duct-SPBDSimbu ArasanNo ratings yet

- Bay Marshalling BoxesDocument4 pagesBay Marshalling BoxesSimbu ArasanNo ratings yet

- WPS - Smaw - 2Document6 pagesWPS - Smaw - 2Harkesh RajputNo ratings yet

- Quality Assurance Plan For Unitank:: QAP/AAV/MFG/00107/UT Crown Beers India LTD: AAVI-GA-003, R0, 210507 00107Document10 pagesQuality Assurance Plan For Unitank:: QAP/AAV/MFG/00107/UT Crown Beers India LTD: AAVI-GA-003, R0, 210507 00107Narayana Mugalur100% (1)

- Inspection and Test Plan: Rev Created by Checked by Approved by Date Issue StatusDocument18 pagesInspection and Test Plan: Rev Created by Checked by Approved by Date Issue StatusoberaiNo ratings yet

- Sample QAPDocument3 pagesSample QAPsniperiNo ratings yet

- PQMP-ITP-001 Rev 0Document27 pagesPQMP-ITP-001 Rev 0asexyguyNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- Casting and Forging DiscontinuitiesDocument25 pagesCasting and Forging DiscontinuitiesAshwani Dogra100% (1)

- Principle of Substation DesignDocument9 pagesPrinciple of Substation DesignAshwani Dogra100% (1)

- Electrode SheetDocument6 pagesElectrode SheetAshwani Dogra100% (2)

- Generator AuxiliariesDocument37 pagesGenerator AuxiliariesAshwani Dogra100% (1)

- Busbar, Connectors and ClampsDocument12 pagesBusbar, Connectors and ClampsAshwani Dogra100% (1)

- Circuit BreakerDocument64 pagesCircuit BreakerAshwani Dogra100% (1)

- Feed Water Deaeration in Thermal Power PlantDocument46 pagesFeed Water Deaeration in Thermal Power PlantAshwani Dogra100% (2)

- Control & Instrumentation Commissioning - An OverviewDocument36 pagesControl & Instrumentation Commissioning - An OverviewAshwani Dogra100% (1)

- Air Preheater in Thermal Power Plant Problem N SolDocument25 pagesAir Preheater in Thermal Power Plant Problem N SolAshwani Dogra100% (2)

- Design of Earthing System For HVDocument22 pagesDesign of Earthing System For HVAshwani Dogra100% (1)

- Generator Hydrogen CoolingDocument31 pagesGenerator Hydrogen CoolingAshwani Dogra67% (3)

- Badarpur Thermal Power SatationDocument132 pagesBadarpur Thermal Power Satationdiwakar_npti100% (2)

- Earthing SytemDocument33 pagesEarthing SytemAshwani Dogra100% (1)

- Introduction To Industrial Safety and Accident PreventionDocument42 pagesIntroduction To Industrial Safety and Accident PreventionAshwani DograNo ratings yet

- Power Plant Commissioning PDFDocument274 pagesPower Plant Commissioning PDFLaholDelveca89% (27)

- Control & Instrumentation Commissioning - An OverviewDocument36 pagesControl & Instrumentation Commissioning - An OverviewAshwani Dogra100% (1)

- Set of Questions Risk ManagementDocument2 pagesSet of Questions Risk ManagementAshwani Dogra100% (1)

- Safety Work PermitDocument36 pagesSafety Work PermitAshwani Dogra100% (1)

- Presentation On NTPC Inspection ServicesDocument34 pagesPresentation On NTPC Inspection ServicesAshwani Dogra100% (3)

- Safe Practices in Material HandlingDocument65 pagesSafe Practices in Material HandlingAshwani DograNo ratings yet

- Fire Fighting Systems in Power StationsDocument68 pagesFire Fighting Systems in Power StationsAshwani Dogra100% (1)

- Fire Fighting Systems in Power StationsDocument68 pagesFire Fighting Systems in Power StationsAshwani Dogra100% (1)

- Different Cycles in Gas Turbine & Steam TurbineDocument18 pagesDifferent Cycles in Gas Turbine & Steam TurbineAshwani DograNo ratings yet

- Auxiliary Steam System in Thermal Power PlantDocument15 pagesAuxiliary Steam System in Thermal Power PlantAshwani Dogra100% (3)

- Transmission Line PresentationDocument55 pagesTransmission Line PresentationAshwani Dogra89% (9)

- Turbine Condensate System in Thermal Power PlantDocument35 pagesTurbine Condensate System in Thermal Power PlantAshwani Dogra100% (1)

- Transformer Protections in Thermal Power PlantDocument45 pagesTransformer Protections in Thermal Power PlantAshwani Dogra100% (3)

- Compressed Air System in Thermal Power PlantDocument12 pagesCompressed Air System in Thermal Power PlantAshwani Dogra100% (4)

- Turbine Vacuum System in Thermal Power PlantDocument28 pagesTurbine Vacuum System in Thermal Power PlantAshwani Dogra100% (1)

- Turbine Condensate System in Thermal Power PlantDocument35 pagesTurbine Condensate System in Thermal Power PlantAshwani Dogra100% (1)

- Larsen & Toubro Limited-Kansbahal-Foundry PDFDocument16 pagesLarsen & Toubro Limited-Kansbahal-Foundry PDFChristy Austin100% (1)

- 34 CR Ni Mo 6Document4 pages34 CR Ni Mo 6Krzysztof WrzeszczNo ratings yet

- Book SteelDocument69 pagesBook SteelĐình Sỹ TTPNo ratings yet

- Asme Ix QuizDocument5 pagesAsme Ix Quizamalhaj2013No ratings yet

- Rusting and Corrosion: Conditions For Iron To RustDocument3 pagesRusting and Corrosion: Conditions For Iron To Rusthussein hajiNo ratings yet

- Secondary Steel Making PDFDocument22 pagesSecondary Steel Making PDF80,795,086 likesNo ratings yet

- Api 651Document2 pagesApi 651muhammadazhanudin100% (2)

- ANS Materials Handbook PDFDocument368 pagesANS Materials Handbook PDFIsaac Loco SilvaNo ratings yet

- Workshop Technology: Subject Code: ENEG 101 Semester: I by K.K.SahooDocument14 pagesWorkshop Technology: Subject Code: ENEG 101 Semester: I by K.K.SahooKamalakanta Sahoo50% (2)

- Aluminum - Min Bend Radius PDFDocument5 pagesAluminum - Min Bend Radius PDFmimi_chan_17No ratings yet

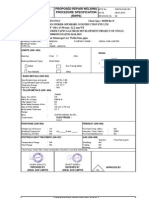

- Rev 2 - Proposed Repair WPSDocument2 pagesRev 2 - Proposed Repair WPSRakesh Patel75% (4)

- DENR Administrative Order No-2017-10Document2 pagesDENR Administrative Order No-2017-10Manila Today100% (1)

- Specification For Carbon Structural Steel: SA-36 /SA-36MDocument7 pagesSpecification For Carbon Structural Steel: SA-36 /SA-36MTony VazquezNo ratings yet

- Assab 618HH enDocument8 pagesAssab 618HH enSamanthaPereraNo ratings yet

- Att#11 - A - Painting ProcedureDocument14 pagesAtt#11 - A - Painting ProcedureClémentNo ratings yet

- Alcoa Innovation Welding Workshop: Kyle Williams - Alcoa Technical CenterDocument53 pagesAlcoa Innovation Welding Workshop: Kyle Williams - Alcoa Technical CenterspiritveluNo ratings yet

- Vendor Document Cover SheetDocument11 pagesVendor Document Cover SheetSagar SawantNo ratings yet

- High Strength Sheet Steel, 180 Mpa Through 700 Mpa Yield StrengthsDocument18 pagesHigh Strength Sheet Steel, 180 Mpa Through 700 Mpa Yield StrengthsRicardo UriasNo ratings yet

- Corrosion Control of Reinforcement BarsDocument6 pagesCorrosion Control of Reinforcement BarsBhaskar ReddyNo ratings yet

- Chain CatalogDocument2 pagesChain CatalogJosh CasementNo ratings yet

- Literature Review On Metal FabricationDocument4 pagesLiterature Review On Metal Fabricationc5t0jsyn100% (1)

- Astm A691Document6 pagesAstm A691jithinjose86100% (2)

- European Standards For Destructive Test MethodsDocument6 pagesEuropean Standards For Destructive Test MethodsAdil HasanovNo ratings yet

- Astm 182Document15 pagesAstm 182ISABELNo ratings yet

- HW9 PracticexDocument7 pagesHW9 PracticexJod JDNo ratings yet

- Wollo University Kiot: Designinig of Bushed Pin CouplingDocument16 pagesWollo University Kiot: Designinig of Bushed Pin CouplingBirhanu AsfawNo ratings yet

- Guidelines On The Specification and Use of HVOF CoatingsDocument46 pagesGuidelines On The Specification and Use of HVOF CoatingsDaniel VillaflorNo ratings yet

- GATEMSM CompressedDocument13 pagesGATEMSM CompressedChaitanya Kishore ChitikenaNo ratings yet

- Copper Alloy C95500Document12 pagesCopper Alloy C95500keuboNo ratings yet

- Lucrari ISIDocument13 pagesLucrari ISIAndra DenisaNo ratings yet