Professional Documents

Culture Documents

Led Display

Uploaded by

Jayesh JainOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Led Display

Uploaded by

Jayesh JainCopyright:

Available Formats

Chapter 1 Project Overview

CHAPTER 1 PROJECT OVERVIEW

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 1

Chapter 1 Project Overview

CHAPTER 1 PROJECT OVERVIEW

1.1 INTRODUCTION

Visual impact is the most effective mode of influencing human minds which is the main aim of Advertisements etc. A display device serves this purpose. A display device is a device for presentation of information for visual or tactile reception, acquired, stored, or transmitted in various forms. The display devices used to display information on machines, clocks, railway departure indicators and many other devices require a simple display of limited resolution. The display consists of a matrix of lights or mechanical indicators arranged in a rectangular configuration (other shapes are also possible, although not common) such that by switching on or off selected lights, text or graphics can be displayed. Various modifications has been made in the display board. Now LED display panels are widely used throughout the world in all situations to create images for visual displays in a variety of applications including communication and visual display devices. LED array display board is a popular instrument for commercial usage. Many banks, shops and cinemas are willing to install one piece of it because of its versatility. LED array display board can be very bright and eye-catching. Display signs used for advertising or for displaying direction or other information to motorists have an important feature in common. They should be eye-catching and their information should be easy to absorb. In advertising, a signboard made of an LED display generally standing at a conspicuous location, such as a bustling road, is widely used. The LED display comprises a plurality of LEDs controlled by special hardware and software to perform moving images on a screen thereof to attract the attention of passersby. The LED array display board is used in a bank to show the current stock market value, currency exchange rate and interests rate. It can also be used in a shop to tell people the prices and other commercial information. LED display board serves the above purposes with advantages rendered by LEDs.

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 2

Chapter 1 Project Overview

LEDs produce more light per watt than incandescent bulbs; this is useful in battery powered or energy-saving devices. LEDs can emit light of an intended color without the use of color filters that traditional lighting methods require. This is more efficient and can lower initial costs.

The solid package of the LED can be designed to focus its light. Incandescent and fluorescent sources often require an external reflector to collect light and direct it in a usable manner. LEDs are ideal for use in applications that are subject to frequent onoff cycling, unlike fluorescent lamps that burn out more quickly when cycled frequently, or HID lamps that require a long time before restarting.

Organic light emitting diodes (OLED) are a promising technology for flat panel displays. Owing to high brightness, fast response speed, light weight, thin and small features, full color, no viewing angle differences, no need for an LCD back-light board and low electrical consumption, an organic light emitting diode display takes the lead to substitute a twist nomadic (TN), a super twist nomadic (STN) liquid crystal display, or a small-sized thin-film transistor (TFT) LCD display. Light emitting diodes are useful in a wide range of high and low resolution display devices.

1.2 OBJECTIVE

Display technology pervades all aspects of present day life, from televisions to automobile dashboards to laptop computers to digital cameras. Single colored LED display boards are very common nowadays. The same yellow or red colored board is not attractive .The introduction of multicolored LEDs into the display boards make them attractive. This project is oriented towards the development of a prototype of a multicolored LED display board which is being controlled by an LED driver. The use of multicolor LED opens door to many applications. The display board is made on readily available components. The important requirement is that the display board

Dept. Of Electrical & Electronics, SDITS Khandwa Page 3

Chapter 1 Project Overview

should have long life expectancy, high tolerance to humidity, low power consumption and minimal heat generation. The fundamental part is a 64X16 LED module which could be repeated column wise or row wise to enlarge the display without any change in circuitry. Both single line and double line display could be affected. Motivation towards the project was to make available a readily expandable multicolor display board which can be used for multiple purposes.

1.3 PRINCIPLE

This project can be made by using following two principles they are as follow:1. Co-ordinate drives. 2. Shift register. In this project we use shift register. According To this concept in a LED matrix if the pattern of data is given to first column and the same data is cut and paste to left or right but in any one direction, to the next adjacent column. Then the data is seems to be moving

1.4 SPECIFICATIONS

64 x 16 multicolored LED modules. Keyboard interface. High speed response. Power supply requirement: 5V, 3A

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 4

Chapter 2 System Overview

CHAPTER 2 SYSTEM OVERVIEW

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 5

Chapter 2 System Overview

CHAPTER 2 SYSTEM OVERVIEW

2.1 BLOCK DIAGRAM

A simplified block diagram is given below

Fig 1. Block diagram of LED board display.

2.1.1 LED Matrix A 64X16 LED module is the fundamental part of the display. LED display panels use matrix addressing techniques to organize the light emitting elements or pixels into a number of rows and columns with each pixel at an intersection of a particular row and a particular column. A light emitting device (LED) display is typically supplied with data addressed from graphical memory location in accordance with a column-major display. The LED display illuminates pixels on a column basis by providing sourcing and sinking currents to diodes in the display. An LED display is typically made up of various dots arranged in a matrix pattern having rows and columns. The dots are usually called pixels where the pixels are made up of several LEDs. Illuminating the pixel requires activating an intersecting row and column thereby providing a closed current path that includes the pixel to be illuminated. The individual LEDs emit light of three basic colors: red, green and blue. Typically, each pixel is composed of at least one LED of each color. In LED

Dept. Of Electrical & Electronics, SDITS Khandwa Page 6

Chapter 2 System Overview

displays, one dot is formed by utilizing a plurality of cannon ball-shaped LED lamps each having different luminescent colors. The intensity of the LEDs is usually controlled by controlling the current to the individual LEDs. This is done by means of a led driver. A pixel can produce a specific perceived color by varying the drive to the three colors of LEDs that comprise the pixel. By controlling the current drive to each of the LEDs that makes up a pixel and in turn controlling each of the pixels that make up a matrix of pixels, an LED display device is capable of displaying a plurality of colors and light intensities so as to realize, for example, a multi-color display. As the resolution of displays increases, the number of pixels in each row and column also increases and the amount of time available to illuminate each pixel decreases. As the illumination time decreases, each pixel must be driven with a larger current to provide a pixel intensity that maintains acceptable image intensity and viewing characteristics. Light Emitting Diode: Multicolor LEDs are used to provide colorful display. They primarily provide three colors: red, green, and blue. By the combination of these colors in correct proportion many varieties of color are possible. The three colors could be individually controlled as controlling two single LEDs. 2.1.2 LED Driver The control of the LED display module is done by means of LED driver. It is programmable using microcontroller. An LED Driver has a shift register embedded that will take data in serial format and transfer it to parallel. It performs following functions: It controls the intensity and brightness of the display. It controls the color of the display. It decides which led is to be lighted to display specific character. It receives the input signal specifying the character to be displayed from the microcontroller which is controlled by host computer using USB interface.

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 7

Chapter 2 System Overview

2.1.3 Microcontroller The character to be displayed is inputted from the host computer using Keyboard interface. RS232 is used to provide the Keyboard interface to the LED driver which controls the display. The PIC is programmed such that it provides Keyboard interface. A self programmable PIC is used. 2.1.4 Keyboard interfacing It provides the communication between the User and display board. It also can provide interfacing the microcontroller.

2.2 ADVANTAGES & APPLICATIONS

Advantages: No More Monotonous Same Advertisement again and again for days/months. (message to be displayed can be changed instantaneously) Instant, Current and Hot Topics reach the Public immediately. Common Display system which displays instant messages like Flash News, in Places like exhibitions, Road side Hoardings. Instant Message Delivery. Easy to change messages. Attractive multicolor display. A high density display board could be used for video display. Eye catching display serving the purpose of advertisements. Media for indoor & outdoor advertising and are clearly visible from very long distance.

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 8

Chapter 2 System Overview

Applications: Advertisement Hoardings with dynamic update of Flash News. Instant update of Petrol Prices to all petrol Bunks from a Central office. Stock Tickers, which displays dynamically current value of the Stocks and the trend. Current Prices of Commodities at different parts of the country. Shopping malls & retail stores. Railway information. Amusement Parks & Zoo's. Traffic Information. Pedestrian countdown system for maximum pedestrian safety.

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 9

Chapter 3 Project Design

CHAPTER 3 PROJECT DESIGN

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 10

Chapter 3 Project Design

CHAPTER 3 PROJECT DESIGN

3.1 LED MODULE

Hardware requirements: 64x16 LED array. LED driver MAX 232. Microcontroller AT89S52. Shift register. Resistors 22 K, 15K. Capacitor 0.01F.

3.1.1 LED Array It consists of 2 multicolored LEDs arranged in 64x16 matrix format. The LED used is LED 339-1VRKGBBW1 from ever bright. It is a multicolored common cathode led with LEDs; Red & Green LED Multicolor LED provides primarily Red, green, colors by giving bias to appropriate pins. Specifications: If (typical forward current): 20mA. Cut in Voltage Red: 1.6V. Green: 1.8V.

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 11

Chapter 3 Project Design

3.1.2 LED Driver MAX232 LED driver used is MAX232. It can drive 64 single LEDs. The 232 can source up to 40mA and control an 8x8 single LED matrix. (Here 2 MAX232 is used to control a 4X4 matrix). Individual LEDs can be turned on or off with 3 wire serial interface (CLK, DATA, LOAD). 16 Brightness steps are also provided, which can control the brightness of all the 64 LEDs. Thus it provides both software and hardware control of brightness. It drives common cathode LED display. It provides 100MHz serial interface. The LED driver has a 16 bit shift register. Input signals are CLK, DIN, and LOAD. Serial data at DIN, sent in 16-bit packets, is shifted into the internal 16-bit shift register with each rising edge of CLK regardless of the state of LOAD. The data is then latched into either the digit or control registers on the rising edge of LOAD/CS. LOAD/CS must go high concurrently with or after the 16th rising clock edge, but before the next rising clock edge or data will be lost. Data at DIN is propagated through the shift register and appears at DOUT 16. 5 clock cycles later. Data is clocked out on the falling edge of CLK. Specifications: Operating Supply Voltage: 5V Shutdown Supply Current: 150A Operating Supply Current: 330 mA ISEG: -40mA

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 12

Chapter 3 Project Design

Fig 2. MAX 232 Pinout.

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 13

Chapter 3 Project Design

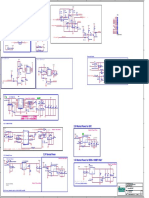

3.2 DESIGN

MAX232 can drive 64 single LEDs. A multicolor led is equal to 3 single LEDs. Thus two MAX232 is used to drive a 4 x 4 LED module. Each MAX7219 has 8 segment lines (SEG Dp through SEG G) to control the anode (horizontal) lines of the display and 8 digit lines (DIG0 through DIG7) to control the cathode (vertical) lines. Here one MAX7219 is used to control the red and green LEDs which have a common cathode. Another MAX7219 is used to control the two blue LEDs. Only 4 digit lines of an LED driver are used. The current value is to be set at 20mA which is the safe value for the LED. This is provided by selecting a resistance equal to 22K. For the expansion of the display, cascading of the MAX232s is done. This is done by connecting LOAD and CLK inputs of all the devices together and connecting DOUT to DIN on adjacent devices. DOUT is a CMOS logiclevel output that easily drives DIN of successively cascaded parts.

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 14

Chapter 3 Project Design

Fig 3. LED driver circuit.

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 15

Chapter 3 Project Design

Fig 4. Schematic diagram of 4x4 LED modules.

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 16

Chapter 3 Project Design

3.2.1 AT89S52 The AT89S52 is a low-power, high-performance CMOS 8-bit microcontroller with 8K bytes of in-system programmable Flash memory. The device is manufactured using Atmels high-density nonvolatile memory technology and is compatible with the industry-standard 80C51 instruction set and pinout. The on-chip Flash allows the program memory to be reprogrammed in-system or by a conventional nonvolatile memory programmar. By combining a versatile 8-bit CPU with in-system programmable Flash on a monolithic chip, the Atmel AT89S52 is a powerful microcontroller which provides a highly-flexible and cost-effective solution to many embedded control applications. The AT89S52 provides the following standard features: 8K bytes of Flash, 256 bytes of RAM, 32 I/O lines, Watchdog timer, two data pointers, three 16-bit timer/counters, a sixvector two-level interrupt architecture, a full duplex serial port, on-chip oscillator, and clock circuitry. In addition, the AT89S52 is designed with static logic for operation down to zero frequency and supports two software selectable power saving modes. The Idle Mode stops the CPU while allowing the RAM, timer/counters, serial port, and interrupt system to continue functioning. The Power-down mode saves the RAM con-tents but freezes the oscillator, disabling all other chip functions until the next interrupt or hardware reset. FEATURES: Compatible with MCS-51 Products. 8K Bytes of In-System Programmable (ISP) Flash Memory Endurance: 1000 Write/Erase Cycles. 4.0V to 5.5V is Operating Range. Fully Static Operation: 0 Hz to 33 MHz. Three-level Program Memory Lock. 256 x 8-bit Internal RAM. 32 Programmable I/O Lines. Three 16-bit Timer/Counters. Eight Interrupt Sources. Full Duplex UART Serial Channel. Low-power Idle and Power-down Modes.

Dept. Of Electrical & Electronics, SDITS Khandwa Page 17

Chapter 3 Project Design

Interrupt Recovery from Power-down Mode. Watchdog Timer. Dual Data Pointer. Power-off Flag. Fast Programming Time. Flexible ISP Programming. (Byte and Page Mode) Green (Pb/Halide-free) Packaging Option.

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 18

Chapter 3 Project Design

3.2.2 Block diagram

Fig 5. Block diagram of 89S52.

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 19

Chapter 3 Project Design

3.2.3 PIN diagram

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 20

Chapter 3 Project Design Fig 6. Pin diagram of 89S52.

3.2.4 Pin Description VCC Supply voltage. GND Ground. Port 0-Port 0 is an 8-bit open drain bidirectional I/O port. As an output port, each pin can sink eight TTL inputs. When 1s are written to port 0 pins, the pins can be used as high-impedance inputs. Port 0 can also be configured to be the multiplexed low-order address/data bus during accesses to external program and data memory. In this mode, P0 has internal pull-ups. Port 0 also receives the code bytes during Flash programming and outputs the code bytes during program verification. External pull-ups are required during program verification. Port 1- Port 1 is an 8-bit bidirectional I/O port with internal pull-ups. The Port 1 output buffers can sink/source four TTL inputs. When 1s are written to Port 1 pins, they are pulled high by the internal pull-ups and can be used as inputs. As inputs, Port 1 pins that are externally being pulled low will source current (IIL) because of the internal pull-ups. In addition, P1.0 and P1.1 can be configured to be the timer/counter 2 external count input (P1.0/T2) and the timer/counter 2 trigger input (P1.1/T2EX), respectively, as shown in the following table. Port 1 also receives the low-order address bytes during Flash programming and verification.

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 21

Chapter 3 Project Design Table 1. Description of Port Pin P1.0-P1.7.

Port 2 - Port 2 is an 8-bit bidirectional I/O port with internal pullups. The Port 2 output buffers can sink/source four TTL inputs. When 1s are written to Port 2 pins, they are pulled high by the internal pull-ups and can be used as inputs. As inputs, Port 2 pins that are externally being pulled low will source current (IIL) because of the internal pull-ups. Port 2 emits the high-order address byte during fetches from external program memory and during accesses to external data memory that uses 16-bit addresses (MOVX @ DPTR). In this application, Port 2 uses strong internal pull-ups when emitting 1s. During accesses to external data memory that uses 8-bit addresses (MOVX @ RI), Port 2 emits the contents of the P2 Special Function Register. Port 2 also receives the high-order address bits and some control signals during Flash programming and verification. Port 3 - Port 3 is an 8-bit bidirectional I/O port with internal pullups. The Port 3 output buffers can sink/source four TTL inputs. When 1s are written to Port 3 pins, they are pulled high by the internal pull-ups and can be used as inputs. As inputs, Port 3 pins that are externally being pulled low will source current (IIL) because of the pull-ups. Port 3 receives some control signals for Flash programming and verification. Port 3 also serves the functions of various special features of the AT89S52, as shown in the following table.

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 22

Chapter 3 Project Design

Table 2. Description of Port Pin P3.0-P3.7.

RST - Reset input. A high on this pin for two machine cycles while the oscillator is running resets the device. This pin drives high for 98 oscillator periods after the Watchdog times out. The DISRTO bit in SFR AUXR (address 8EH) can be used to disable this feature. In the default state of bit DISRTO, the RESET HIGH out feature is enabled. ALE/PROG - Address Latch Enable (ALE) is an output pulse for latching the low byte of the address during accesses to external memory. This pin is also the program pulse input (PROG) during Flash programming. In normal operation, ALE is emitted at a constant rate of 1/6 the oscillator frequency and may be used for external timing or clocking purposes. Note, however, that one ALE pulse is skipped during each access to external data memory. If desired, ALE operation can be disabled by setting bit 0 of SFR location 8EH. With the bit set, ALE is active only during a MOVX or MOVC instruction. Otherwise, the pin is weakly pulled high. Setting the ALE-disable bit has no effect if the microcontroller is in external execution mode. PSEN - Program Store Enable (PSEN) is the read strobe to external program memory. When the AT89S52 is executing code from external program memory, PSEN is activated twice each machine cycle, except that two PSEN activations are skipped during each access to external data memory. EA/VPP - External Access Enable. EA must be strapped to GND in order to enable the device to fetch code from external program

Dept. Of Electrical & Electronics, SDITS Khandwa Page 23

Chapter 3 Project Design

memory locations starting at 0000H up to FFFFH. Note, however, that if lock bit 1 is programmed, EA will be internally latched on reset. EA should be strapped to VCC for internal program executions. This pin also receives the 12-volt programming enable voltage (VPP) during Flash programming. 4.11 XTAL1 Input to the inverting oscillator amplifier and input to the internal clock operating circuit. 4.12 XTAL2 Output from the inverting oscillator amplifier.

Special Function Registers A map of the on-chip memory area called the Special Function Register (SFR). Note that not all of the addresses are occupied, and unoccupied addresses may not be implemented on the chip. Read accesses to these addresses will in general return random data, and write accesses will have an indeterminate effect. User software should not write 1s to these unlisted locations, since they may be used in future products to invoke new features. In that case, the reset or inactive values of the new bits will always be 0. Timer 2 Registers: Control and status bits are contained in registers T2CON and T2MOD for Timer 2. The register pair (RCAP2H, RCAP2L) is the Capture/Reload registers for Timer 2 in 16-bit capture mode or 16-bit auto-reload mode. Interrupt Registers: The individual interrupt enable bits are in the IE register. Two priorities can be set for each of the six interrupt sources in the IP register.

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 24

Chapter 3 Project Design

Table 3. Description of symbols and their functions.

3.2.5 Shift Register In digital circuits, a shift register is a cascade of flip flops, sharing the same clock, in which the output of each flip-flop is connected to the "data" input of the next flip-flop in the chain, resulting in a circuit that shifts by one position the "bit array" stored in it, shifting in the data present at its input and shifting out the last bit in the array, at each transition of the clock input. More generally, a shift register may be multidimensional, such that its "data in" and stage outputs are themselves bit arrays: this is implemented simply by running several shift registers of the same bit-length in parallel. 3.2.5 20MHz Crystal oscillator The crystal oscillator is used to provide the clock for the PIC. A crystal oscillator has a very stable Q. It is equivalent to an LCR circuit. It oscillates at its resonating frequency. Here the crystal provides 20 MHz clock to the PIC. It requires resistors and capacitors to oscillate properly.

Dept. Of Electrical & Electronics, SDITS Khandwa Page 25

Chapter 3 Project Design

Fig 7. Crystal Oscillator.

3.2.6 Key Board Pin Pin 1 Data. Pin 2 Not Connected. Pin 3 GND. Pin 4 Vcc (+5V). Pin 5 Clock. Pin 6 Not Connected. The PS/2 protocol can actually do two-way communication -- that is to say you can actually send information to the keyboard. This can be used to set the LED lights on the keyboard. PS/2 Keyboard Protocol

Dept. Of Electrical & Electronics, SDITS Khandwa Page 26

Chapter 3 Project Design

As stated in the video, the PS/2 Interface is quite easy to implement. To send a key stroke, the keyboard begins driving the clock line. On the falling edge of the clock line, the data line represents the current bit. Each keystroke is sent as 11 bits: first a start bit of 0, then the 8 bits of the scan code (least significant bit first), then a parity bit (odd parity, which we did not implement for simplicity's sake), and finally a stop bit (always 1). All data is transmitted one byte at a time and each byte is sent in a frame consisting of 11-12 bits. These bits are: 1 start bit. This is always 0. 8 data bits, least significant bit first. 1 parity bit (odd parity). 1 stop bit. This is always 1. 1 acknowledge bit (host-to-device communication only)

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 27

Chapter 3 Project Design Fig 8. Pin Description of keyboard socket.

3.2.7 Status LEDs They show the state of USB. The various conditions are shown below.

Table 4.USB device state LED status.

3.2.8 Design For providing the clock using crystal oscillator 22pF capacitors and 1Mohm resistors are required. They make the crystal oscillate properly. A capacitor 0.47 F is connected across the pin 18. It is required for the proper functioning of internal voltage regulator. A decoupling capacitor of value 0.1 F is connected across the power pins of USB socket. Status LEDs are connected at pins 19 and 20.

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 28

Chapter 3 Project Design

Fig 9.Example of 4X4 matrix keyboard interfacing with IC.

3.3 POWER SUPPLY

Fig 10. Block diagram of power supply. Dept. Of Electrical & Electronics, SDITS Khandwa Page 29

Chapter 3 Project Design

Fig 11. Circuit diagram of power supply.

Hardware requirements: A Transformer (230-9V, 1A). Bridge Rectifier (Power Diode BY127). Voltage Regulator IC 7805. Power Transistor 2n2955. Capacitor (4.7F 35V). Resistor (10 K ohm)

3.3.1 Transformer A transformer is a static electrical device that transfers energy by inductive coupling between its winding circuits. A varying current in the primary winding creates a varying magnetic flux in the transformer's core and thus a varying magnetic flux through the secondary winding. This varying magnetic flux induces a varying electromotive force (emf) or voltage in the secondary winding.

Dept. Of Electrical & Electronics, SDITS Khandwa Page 30

Chapter 3 Project Design

Transformers range in size from thumbnail-sized used in microphones to units weighing hundreds of tons interconnecting the power grid. A wide range of transformer designs are used in electronic and electric power applications. Transformers are essential for the transmission, distribution, and utilization of electrical energy. We use step down transformer which step down the voltage from 230V to 9V.

Fig 12. Step-down transformer (230V- 9V).

3.3.2 Bridge rectifier The bridge rectifier provides full wave rectification from a two wire AC input. It is formed of power diode BY127. The ac input voltage is applied to the diagonally opposite ends of the bridge. . The load resistance is connected between the other two ends of the bridge. For the positive half cycle of the input ac voltage, diodes D1 and D3 conduct, whereas diodes D2 and D4 remain in the OFF state. The conducting diodes will be in series with the

Dept. Of Electrical & Electronics, SDITS Khandwa Page 31

Chapter 3 Project Design

load resistance RL and hence the load current flows through RL. For the negative half cycle of the input ac voltage, diodes D2 and D4 conduct whereas, D1 and D3 remain OFF. The conducting diodes D2 and D4 will be in series with the load resistance RL and hence the current flows through RL in the same direction as in the previous half cycle. Thus a bi-directional wave is converted into a unidirectional wave.

Fig 13. Bridge rectifier.

3.3.3 Regulator IC 7805 The 78xx (sometimes L78xx, LM78xx, MC78xx...) is a family of selfcontained fixed linear voltage regulator integrated circuits. The 78xx family is commonly used in electronic circuits requiring a regulated power supply due to their ease-of-use and low cost. For ICs within the family, the xx is

Dept. Of Electrical & Electronics, SDITS Khandwa Page 32

Chapter 3 Project Design

replaced with two digits, indicating the output voltage (for example, the 7805 has a 5 volt output, while the 7812 produces 12 volts). The 78xx line are positive voltage regulators: they produce a voltage that is positive relative to a common ground. There is a related line of 79xx devices which are complementary negative voltage regulators. 78xx and 79xx ICs can be used in combination to provide positive and negative supply voltages in the same circuit.

Fig 14.Voltage regulator (IC7805).

Specifications Output Voltage =5V. Ripple rejection ratio =78dB. Input regulation 3mV.

Dept. Of Electrical & Electronics, SDITS Khandwa Page 33

Chapter 3 Project Design

Load regulation 15mV.

3.3.4 Capacitor A capacitor (originally known as condenser) is a passive two-terminal electrical component used to store energy in an electric field. The forms of practical capacitors vary widely, but all contain at least two electrical conductors separated by a dielectric (insulator); for example, one common construction consists of metal foils separated by a thin layer of insulating film. Capacitors are widely used as parts of electrical circuits in many common electrical devices.

Fig 15. Capacitor.

3.3.5 Resistor A resistor is a passive two-terminal electrical component that implements electrical resistance as a circuit element.

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 34

Chapter 3 Project Design

The current through a resistor is in direct proportion to the voltage across the resistor's terminals. This relationship is represented by Ohm's law: I = V/R where I is the current through the conductor in units of amperes, V is the potential difference measured across the conductor in units of volts, and R is the resistance of the conductor in units of ohms.

Fig 16. Resistor.

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 35

Chapter 4 PCB Design

CHAPTER 4 PCB DESIGN

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 36

Chapter 4 PCB Design

CHAPTER 4 PCB DESIGN

4.1 PCB DESIGINING PROCESS

A printed circuit board, or PCB, is used to mechanically support and electrically connect electronic components using conductive pathways, tracks or signal traces etched from copper sheets laminated onto a nonconductive substrate. When the board has only copper tracks and features, and no circuit elements such as capacitors, resistors or active devices have been manufactured into the actual substrate of the board, it is more correctly referred to as printed wiring board (PWB) or etched wiring board. Use of the term PWB or printed wiring board although more accurate and distinct from what would be known as a true printed circuit board, has generally fallen by the wayside for many people as the distinction between circuit and wiring has become blurred. Today printed wiring (circuit) boards are used in virtually all but the simplest commercially produced electronic devices, and allow fully automated assembly processes that were not possible or practical in earlier era tag type circuit assembly processes. A PCB populated with electronic components is called a printed circuit assembly (PCA), printed circuit board assembly or PCB Assembly (PCBA). In informal use the term "PCB" is used both for bare and assembled boards, the context clarifying the meaning.

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 37

Chapter 4 PCB Design

Fig 17. Printed circuit board.

4.2 MANUFACTURING

Excluding exotic products using special materials or processes, all printed circuit boards manufactured today can be built using the following four items which are usually purchased from manufacturers: Laminates. Copper-clad laminates. Resin impregnated B-stage cloth (Pre-preg). Copper foil.

4.3 PROCESS There are ten steps for preparing PCB they are: 1. Patterning (etching) The majority of printed circuit boards today are made from purchased laminate material with copper already applied to both sides. The unwanted copper is removed by various methods leaving only the desired copper traces, this is called subtractive. In an additive method, traces are electroplated onto a bare substrate using a complex process with many steps. The advantage of the additive method is less pollution of the environment. The method chosen for PCB manufacture depends on the desired number of boards to be produced. Double-sided boards or multi-layer boards use plated-through holes, called vias, to connect traces on different layers of the PWB. 2. Chemical etching Chemical etching is usually done with ammonium per sulfate or ferric chloride. For PTH (plated-through holes), additional steps of electro less deposition are done after the holes are drilled, then copper is electroplated to build up the thickness, the boards are screened, and plated with tin/lead. The tin/lead becomes the resist leaving the bare copper to be etched away.

Dept. Of Electrical & Electronics, SDITS Khandwa Page 38

Chapter 4 PCB Design

The simplest method, used for small-scale production and often by hobbyists, is immersion etching, in which the board is submerged in etching solution such as ferric chloride. Compared with methods used for mass production, the etching time is long. Heat and agitation can be applied to the bath to speed the etching rate. In bubble etching, air is passed through the etchant bath to agitate the solution and speed up etching. Splash etching uses a motor-driven paddle to splash boards with etchant; the process has become commercially obsolete since it is not as fast as spray etching. In spray etching, the etchant solution is distributed over the boards by nozzles, and re circulated by pumps. Adjustment of the nozzle pattern, flow rate, temperature, and etchant composition gives predictable control of etching rates and high production rates. As more copper is consumed from the boards, the etchant becomes saturated and less effective; different etchants have different capacities for copper, with some as high as 150 grams of copper per liters of solution. In commercial use, etchants can be regenerated to restore their activity, and the dissolved copper recovered and sold. Small-scale etching requires attention to disposal of used etchant, which is corrosive and toxic due to its metal content. The etchant removes copper on all surfaces exposed by the resist. "Undercut" occurs when etchant attacks the thin edge of copper under the resist; this can reduce conductor widths and cause open-circuits. Careful control of etch time is required to prevent undercut. Where metallic plating is used as a resist, it can "overhang" which can cause short-circuits between adjacent traces when closely spaced. Overhang can be removed by wirebrushing the board after etching. 3. Lamination "Multi layer" printed circuit boards have trace layers inside the board. One way to make a 4-layer PCB is to use a two-sided copper-clad laminate, etch the circuitry on both sides, then laminate to the top and bottom prepreg and copper foil. Lamination is done by placing the stack of materials in a press and applying pressure and heat for a period of time. This results in an inseparable one piece product. It is then drilled, plated, and etched again to

Dept. Of Electrical & Electronics, SDITS Khandwa Page 39

Chapter 4 PCB Design

get traces on top and bottom layers. Finally the PCB is covered with solder mask, marking legend, and a surface finish may be applied. Multi-layer PCB does allow for much higher component density. 4. Drilling Holes through a PCB are typically drilled with small-diameter drill bits made of solid coated tungsten carbide. Coated tungsten carbide is recommended since many board materials are very abrasive and drilling must be high RPM and high feed to be cost effective. Drill bits must also remain sharp so as not to mar or tear the traces. Drilling with high-speedsteel is simply not feasible since the drill bits will dull quickly and thus tear the copper and ruin the boards. The drilling is performed by automated drilling machines with placement controlled by a drill tape or drill file. These computer-generated files are also called numerically controlled drill (NCD) files or "Excellent files". The drill file describes the location and size of each drilled hole. These holes are often filled with annular rings (hollow rivets) to create vias. Vias allow the electrical and thermal connection of conductors on opposite sides of the PCB. When very small vias are required, drilling with mechanical bits is costly because of high rates of wear and breakage. In this case, the vias may be evaporated by lasers. Laser-drilled vias typically have an inferior surface finish inside the hole. These holes are called micro vias. It is also possible with controlled-depth drilling, laser drilling, or by predrilling the individual sheets of the PCB before lamination, to produce holes that connect only some of the copper layers, rather than passing through the entire board. These holes are called blind vias when they connect an internal copper layer to an outer layer, or buried vias when they connect two or more internal copper layers and no outer layers. The hole walls for boards with 2 or more layers can be made conductive and then electroplated with copper to form plated-through holes. These holes electrically connect the conducting layers of the PCB. For multilayer boards, those with 3 layers or more, drilling typically produces a smear of the high temperature decomposition products of bonding agent in the laminate system. Before the holes can be plated through, this smear must be removed by a chemical de-smear process, or by plasma-etch. The de-smear process

Dept. Of Electrical & Electronics, SDITS Khandwa Page 40

Chapter 4 PCB Design

ensures that a good connection is made to the copper layers when the hole is plated through. On high reliability boards a process called etch-back is performed chemically with a potassium permanganate based etchant or plasma. The etch-back removes resin and the glass fibers so that the copper layers extend into the hole and as the hole is plated become integral with the deposited copper. 5. Exposed conductor plating and coating PCBs are plated with solder, tin, or gold over nickel as a resist for etching away the unneeded underlying copper. After PCBs are etched and then rinsed with water, the solder mask is applied, and then any exposed copper is coated with solder, nickel/gold, or some other anti-corrosion coating. Matte solder is usually fused to provide a better bonding surface or stripped to bare copper. Treatments, such as benzimidazolethiol, prevent surface oxidation of bare copper. The places to which components will be mounted are typically plated, because untreated bare copper oxidizes quickly, and therefore is not readily solder able. Traditionally, any exposed copper was coated with solder by hot air solder leveling (HASL). The HASL finish prevents oxidation from the underlying copper, thereby guaranteeing a solder able surface. This solder was a tin-lead alloy, however new solder compounds are now used to achieve compliance with the RoHS directive in the EU and US, which restricts the use of lead. One of these lead-free compounds is SN100CL, made up of 99.3% tin, 0.7% copper, 0.05% nickel, and a nominal of 60ppm germanium. It is important to use solder compatible with both the PCB and the parts used. An example is Ball Grid Array (BGA) using tin-lead solder balls for connections losing their balls on bare copper traces or using lead-free solder paste. Other plating used are OSP (organic surface protectant), immersion silver (IAg), immersion tin, electro less nickel with immersion gold coating (ENIG), and direct gold plating (over nickel). Edge connectors, placed along one edge of some boards, are often nickel plated then gold plated. Another coating consideration is rapid diffusion of coating metal into Tin solder. Tin

Dept. Of Electrical & Electronics, SDITS Khandwa Page 41

Chapter 4 PCB Design

forms intermetallics such as Cu5Sn6 and Ag3Cu that dissolve into the Tin liquidus or solidus (@50C), stripping surface coating or leaving voids. Electrochemical migration (ECM) is the growth of conductive metal filaments on or in a printed circuit board (PCB) under the influence of a DC voltage bias. Silver, zinc, and aluminum are known to grow whiskers under the influence of an electric field. Silver also grows conducting surface paths in the presence of halide and other ions, making it a poor choice for electronics use. Tin will grow "whiskers" due to tension in the plated surface. Tin-Lead or Solder plating also grows whiskers, only reduced by the percentage Tin replaced. Reflow to melt solder or tin plate to relieve surface stress lowers whisker incidence. Another coating issue is tin pest, the transformation of tin to a powdery allotrope at low temperature. 6. Solder resist Areas that should not be soldered may be covered with "solder resist" (solder mask). One of the most common solder resists used today is called LPI (liquid photoimageable). A photo sensitive coating is applied to the surface of the PWB, then exposed to light through the solder mask image film, and finally developed where the unexposed areas are washed away. Dry film solder mask is similar to the dry film used to image the PWB for plating or etching. After being laminated to the PWB surface it is imaged and develops as LPI. Once common but no longer commonly used because of its low accuracy and resolution is to screen print epoxy ink. Solder resist also provides protection from the environment. 7. Silkscreen Line art and text may be printed onto the outer surfaces of a PCB usually by screen printing epoxy ink in a contrasting color, but can also be done with LPI or dry film like the solder resist. When space permits, the legend can indicate component designators, switch setting requirements, test points, and other features helpful in assembling, testing, and servicing the circuit board. Some digital printing solutions are used instead of screen printing. This technology allows printing variable data onto the PCB, including individual serial numbers as text and bar code.

Dept. Of Electrical & Electronics, SDITS Khandwa Page 42

Chapter 4 PCB Design

8. Test Unpopulated boards may be subjected to a bare-board test where each circuit connection (as defined in a netlist) is verified as correct on the finished board. For high-volume production, a bed of nails tester, a fixture or a rigid needle adapter is used to make contact with copper lands or holes on one or both sides of the board to facilitate testing. A computer will instruct the electrical test unit to apply a small voltage to each contact point on the bedof-nails as required, and verify that such voltage appears at other appropriate contact points. A "short" on a board would be a connection where there should not be one; an "open" is between two points that should be connected but are not. For small- or medium-volume boards, flying probe and flyinggrid testers use moving test heads to make contact with the copper/silver/gold/solder lands or holes to verify the electrical connectivity of the board under test. Another method for testing is industrial CT scanning, which can generate a 3D rendering of the board along with 2D image slices and can show details such a soldered paths and connections. 9. Printed circuit assembly After the printed circuit board (PCB) is completed, electronic components must be attached to form a functional printed circuit assembly, or PCA (sometimes called a "printed circuit board assembly" PCBA). In throughhole construction, component leads are inserted in holes. In surface-mount construction, the components are placed on pads or lands on the outer surfaces of the PCB. In both kinds of construction, component leads are electrically and mechanically fixed to the board with a molten metal solder. There are a variety of soldering techniques used to attach components to a PCB. High volume production is usually done with SMT placement machine and bulk wave soldering or reflow ovens, but skilled technicians are able to solder very tiny parts (for instance 0201 packages which are 0.02 in. by 0.01 in.) by hand under a microscope, using tweezers and a fine tip soldering iron for small volume prototypes. Some parts may be extremely difficult to solder by hand, such as BGA packages. Often, through-hole and surface-mount construction must be combined in a single assembly because some required components are available only in surface-mount packages, while others are available only in through-hole

Dept. Of Electrical & Electronics, SDITS Khandwa Page 43

Chapter 4 PCB Design

packages. Another reason to use both methods is that through-hole mounting can provide needed strength for components likely to endure physical stress, while components that are expected to go untouched will take up less space using surface-mount techniques.

10. Protection and packaging PCBs intended for extreme environments often have a conformal coating, which is applied by dipping or spraying after the components have been soldered. The coat prevents corrosion and leakage currents or shorting due to condensation. The earliest conformal coats were wax; modern conformal coats are usually dips of dilute solutions of silicone rubber, polyurethane, acrylic, or epoxy. Another technique for applying a conformal coating is for plastic to be sputtered onto the PCB in a vacuum chamber. The chief disadvantage of conformal coatings is that servicing of the board is rendered extremely difficult. Many assembled PCBs are static sensitive, and therefore must be placed in antistatic bags during transport. When handling these boards, the user must be grounded (earthed). Improper handling techniques might transmit an accumulated static charge through the board, damaging or destroying components. Even bare boards are sometimes static sensitive. Traces have become so fine that it's quite possible to blow an etch off the board (or change its characteristics) with a static charge. This is especially true on non-traditional PCBs such as MCMs and microwave PCBs.

4.4 DESINING

The software used for circuit design is EAGLE. The program consists of three main modules: Layout Editor, Schematic Editor, Auto router which is embedded in a single user interface. Therefore there is no need for converting net lists between schematics and layouts. Its General features are: Online Forward- and Back-Annotation.

Dept. Of Electrical & Electronics, SDITS Khandwa Page 44

Chapter 4 PCB Design

Context sensitive help function. No hardware copy protection. Multiple windows for board, schematic and library. Powerful User Language. Integrated text editor. Available for Windows und Linux.

Layout Editor has following features Maximum drawing area 1.6 x 1.6m (64 x 64 inch). Resolution 1/10,000mm (0.1 micron). Up to 16 signal layers. Conventional and SMT parts. Comes with a full set of part libraries. Easily create your own parts with the fully integrated library editor. Undo/redo function for ANY editing command, to any depth. Script files for batch command execution. Copper pouring. Cut and paste function for copying entire sections of a drawing. Design rule check.

Schematic Editor provides the following features Up to 99 sheets in one schematic. Electrical rule check. Gate- and pin swap. Create a board from a schematic with a single command.

The PCB design comprises of three sections: 4.4.1 LED array

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 45

Chapter 4 PCB Design

It is a double sided PCB with the upper side of PCB comprising of the anode lines of the LEDs .the cathode lines are laid on the bottom side of the PCB. The anode lines are horizontal lines. The cathode lines are vertical lines. The track width is 10 mils. ((for 1A current). a circular pad has been laid with Diameter of pad 0.5 mm greater than hole diameter. Pads are laid for nodes on the top side and holes for cathodes and vice versa. Tracks have angles of 45 degree or so (never 90 degree).

Fig 18. PCB of LEDs.

4.4.2 LED driver circuit This is designed as two layers PCB. The tracks never end at 90 degrees the VCC tracks (20 mils) are having greater width than normal tracks. The ground tracks are of width 40mils.

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 46

Chapter 4 PCB Design

Fig 19. PCB of MAX 232.

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 47

Chapter 5 Software

CHAPTER 5 SOFTWARE

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 48

Chapter 5 Software

CHAPTER 5 SOFTWARE

5.1 INTRODUCTION

Simplicity and ease which higher programming languages bring in, as well as broad application of microcontrollers today, were reasons to incite some companies to adjust and upgrade BASIC programming language to better suit needs of microcontroller programming. What did we thereby get? First of all, developing applications is faster and easier with all the predefined routines which BASIC brings in, whose programming in assembly would take the largest amount of time. This allows programmer to concentrate on solving the important tasks without wasting his time on, say, code for printing on LCD display. To avoid any confusion in the further text, we need to clarify several terms we will be using frequently throughout the book: Programming language is a set of commands and rules according to which we write the program. There are various programming languages such as BASIC, C, Pascal, etc. There is plenty of resources on BASIC programming language out there, so we will focus our attention particularly to programming of microcontrollers. Program consists of a sequence of commands written in programming language that microcontroller executes one after another. Chapter 2 deals with the structure of BASIC program in details.

Compiler is a program run on computer and its task is to translate the original BASIC code into language of zeros and ones that can be fed to microcontroller. The process of translation of BASIC program into executive HEX code is shown in the figure below. The program written in BASIC and saved as file program. Pbas is converted by compiler into assembly code (program.asm). The generated assembly code is further translated into executive HEX code which can be written to microcontroller memory.

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 49

Chapter 5 Software

Programmer is a device which we use to transfer our HEX files from computer to microcontroller memory.

Fig 20. Software implementation process. Dept. Of Electrical & Electronics, SDITS Khandwa Page 50

Chapter 5 Software

5.2 LOADING PROGRAM TO MICRO CONTROLLER

As a result of successful compiling of our previous code, mikroBasic will generate HEX file. HEX file is created for each module you have included in the project. In the process of compiling, .mcl files will be linked together to output asm, lst and hex files. If you want to distribute your module without disclosing the source code, you can send your compiled library (file extension .mcl). User will be able to use your library as if he had the source code. Although the compiler is able to determine which routines are implemented in the library, it is a common practice to provide routine prototypes in a separate text file. HEX file is the one you need to program the microcontroller. Commonly, generated HEX will be standard 8-bit Merged Intel HEX format, accepted by the vast majority of the programming software. The programming device (programmer) with accessory software installed on PC is in charge of writing the physical contents of HEX file into the internal memory of a microcontroller. The content of a file blink.hex is given below:

: 100000000428FF3FFF3FFF3F031383168601FF30A5 : 10001000831286000630F000FF30F100FF30F2005E : 10002000F00B13281A28F10B16281928F20B1628A2 : 10003000132810281A30F000FF30F100F00B2128AF : 100040002428F10B21281E284230F000F00B26282E : 1000500086010630F000FF30F100FF30F200F00BB7 :1000600032283928F10B35283828F20B3528322868 : 100070002F281A30F000FF30F100F00B4028432801 : 10008000F10B40283D284230F000F00B45280428B1 : 100090004828FF3FFF3FFF3FFF3FFF3FFF3FFF3F3E : 02400E007A3FF7 : 00000001FF

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 51

Chapter 5 Software

Besides loading a program code into programming memory, programmer also configures the target microcontroller, including the type of oscillator, protection of memory against reading, watchdog timer, etc. The following figure shows the connection between PC, programming device and the MCU.

Fig 21. Connection between computer & microcontroller.

Note that the programming software should be used only for the communication with the programming device it is not suitable for code writing.

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 52

Chapter 5 Software

5.3 WRITING HEX FILE

Proload is a software which accepts only hex files. Once the machine code is converted into hex code, that hex code has to be dumped into the microcontroller placed in the programmer kit and this is done by the Proload. Programmer kit contains a microcontroller on it other than the one which is to be programmed. This microcontroller has a program in it written in such a way that it accepts the hex file from the keil compiler and dumps this hex file into the microcontroller which is to be programmed. As this programmer kit requires power supply to be operated, this power supply is given from the power supply circuit designed above. It to switch on that power supply, a source is required. Thus this is accomplished from the power supply board with an output of 12volts or from an adapter connected to 230 V AC. Install the Proload Software in the PC. Now connect the Programmer kit to the PC (CPU) through serial cable. Power up the programmer kit from the ac supply through adapter. Now place the microcontroller in the GIF socket provided in the programmer kit. Click on the proload icon in the PC. A window appears providing the information like Hardware model, com port, device type, Flash size etc. Click on browse option to select the hex file to be dumped into the microcontroller and then click on Auto program to program the microcontroller with that particular hex file. The status of the microcontroller can be seen in the small status window in the bottom of the page. After this process is completed, remove the microcontroller from the programmer kit and place it in your system board. Now the system board behaves according to the program written in the microcontroller.

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 53

Chapter 6 Applications

Advantages &

CHAPTER 6 ADVANTAGES & APPLICATIONS

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 54

Chapter 6 Applications

Advantages &

CHAPTER 6 ADVANTAGES & DISADVANTAGES

6.1 ADVANTAGES

Easy to implement. More reliable. Secured data transfer. Can be used in places where human beings cannot work. Robust system. High accuracy because of sensors and microcontroller. Can store the message in the memory. It is user friendly. Bright display in even day light. High life span of LEDs. Low power consumption.

6.2 DISADVANTAGES

Special types of command are used to edit the notice. Skilled person is required to operate.

6.3 APPLICATIONS

LED Moving Message Signs are used in any appropriate locations.LED Moving Message Signs are used in any appropriate

Dept. Of Electrical & Electronics, SDITS Khandwa Page 55

Chapter 6 Applications

Advantages &

locations to communicate different kind of messages, from time to time, to many number of people who pass by such area.PowerOn Automations Private Limited is a group company of M/s Manilec Controls and Devices Private Limited company incorporated in early 90s for manufacturing of Electronic and Electrical products. To display real time and temperature: Large size digital clocks indoor or outdoor for shop floors, towers, petrol pumps, educational institutes, etc. The moving display functions grab attention of the people to whatever you want to say. Moving message has a batten backed memory of 10000 character letters and is available in various sizes to suit your requirement. Bringing forth a wide range of attractive and effective advertising solutions through LED display systems, animation sign boards, lead token boards, lighting & display signs, electronic signs, etc. The patrons can avail from us a world class array of LED Display Systems, which is available in various color combinations and designs. These products can be used for both outdoor and indoor displaying applications. Moreover, these can also be customized as per customers' specifications. The following are the features: The keyboard is used to type message that is to be displayed Display is kept in a metallic box to provide complete protection from environmental damage. Primarily used for industrial, official as well as commercial purposes. We are identified as one of the leading service providers of Moving LED Display. These products are made from high quality raw material which is skillfully crafted by our expert designers. Due to their stability and superb finish, these are broadly appreciated in the market. The products are known for better screen resolution and highbrightness performance.

Rolling Message displays are also popularly known as Alphanumeric Displays, Moving message Displays, Scrolling displays. MIPLs Scrolling Display Systems are a unique opportunity to enhance the power of your communication manifold. With unmatched features

Dept. Of Electrical & Electronics, SDITS Khandwa Page 56

Chapter 6 Applications

Advantages &

such as variety in sizes, unbelievable flexibility, various inputs, and highly competitive prices, these display systems stand way apart from the conventional displays. The highlighting feature of these display systems is the availability of the latest technology comparable to others, at a very low price as well as the enormous flexibility, versatility and cost effectiveness.

6.4 CURRENTLY USE USES: FOREX RATE BOARD.

Fig 22. FOREX service rate board.

SIZE OF CHARACTER HIGHT AVILABLE 0.5, 0.8 & 1

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 57

Chapter 6 Applications

Advantages &

EACH COLUMN WITH 88.88,888.88,888888 WITH DECIMAL SHIFT COLUMN AVAILABLE: 1,2,3,4. PROGRAMMABLE WITH: IR REMOTE CONTROL, PC AT KEYPAD OR PC TOKEN DISPLAY. NOTICE BOARD. MOVING DISPLAY (MONO & MULTI COLOR MULTILANGUAGE.). AIRPORT SIGN. GAS STATION SIGN RAILWAYS. TRAFFIC SIGN. MULTIPLEX SIGN. LED VIDEO WALL. CALENDAR CLOCK.

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 58

Chapter 7

Conclusion & Future Enhancement

CHAPTER 7 CONCLUSION & FUTURE ENHANCEMENT

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 59

Chapter 7

Conclusion & Future Enhancement

CHAPTER 7 CONCLUSION & FUTURE ENHANCEMENT

7.1 FUTURE ENHANCEMENT

Can be controlled by using computer with serial cable. Can be made Wireless using Transmitter & receiver. The wireless LED board could be developed. GSM and GPRS based Designs are Public utility products for mass communication. This is a Scrolling (Moving) Message Electronic Display Board which displays the messages received as SMS or GPRS Packets.

7.2 CONCLUSION

By implementation of this project we can display or scroll the messages, notices at notice board on colleges, railway stations, bus display system and other place where it is required. In order to save the papers. The major drawback of this project is its keyboard interfacing by which it is not easy to change the notices. So, in future this project can be made wireless by receiver and transmitter and serial port could also be enable by which the messages, notices can be changed through computer.

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 60

Chapter 7

Conclusion & Future Enhancement

REFERENCES

http://mebss.blogspot.in/2012/09/step-down-transformers.html http://www.electroschematics.com/5362/mobile-charger-usingbike-battery/ http://www.talonix.com/shop/category.aspx? catid=128#.UXLlTaI9HzE http://www.westfloridacomponents.com/BridgeRectifiers.html http://ram-e-shop.com/oscmax/catalog/index.php?cPath=32 http://ecbuddy.blogspot.in/2011/02/at89s52-pin-diagram.html http://homepage.ntlworld.com/alanet.marshall1/WSpage/X1CNC/X1CNCpage2.htm https://www.physics.iitm.ac.in/courses_files/courses/eleclab03_od d/regulated_power_supply.htm

Dept. Of Electrical & Electronics, SDITS Khandwa

Page 61

You might also like

- Types of Digital Display DevicesDocument4 pagesTypes of Digital Display DeviceschouguleNo ratings yet

- Solar InverterDocument20 pagesSolar InverterHacker 123No ratings yet

- GSM Based Led Scrolling Display Board PDFDocument14 pagesGSM Based Led Scrolling Display Board PDFsabNo ratings yet

- Embedded Systems Projects ListDocument38 pagesEmbedded Systems Projects ListMayank ChauhanNo ratings yet

- Led Based Wireless Notice Board Using GSMDocument23 pagesLed Based Wireless Notice Board Using GSMaaa111yyyNo ratings yet

- Android Controlled Scrollling LED Message DisplayDocument0 pagesAndroid Controlled Scrollling LED Message Displaymiss_mkccNo ratings yet

- Arduino Based Home Energy MonitorDocument29 pagesArduino Based Home Energy Monitorsurya tejaNo ratings yet

- Schematic Diagrams-7: Display PC BoardDocument1 pageSchematic Diagrams-7: Display PC BoardBinh NguyenNo ratings yet

- Bionic Eyes Restore Vision Loss with Implant TechnologyDocument19 pagesBionic Eyes Restore Vision Loss with Implant TechnologyRakshitNo ratings yet

- Solar Panel Inverter Schematic V2.3Document6 pagesSolar Panel Inverter Schematic V2.3Amanda PalmgrenNo ratings yet

- SSK Guide PDFDocument50 pagesSSK Guide PDFbhaskarjalanNo ratings yet

- Smart Energy Meter Using Arduino and GSMDocument6 pagesSmart Energy Meter Using Arduino and GSMRoman PuriNo ratings yet

- Electronic Paper: An Introduction to E-Paper DisplaysDocument27 pagesElectronic Paper: An Introduction to E-Paper DisplaysPendem naveenNo ratings yet

- Instruction Manual For ControllerDocument47 pagesInstruction Manual For ControllerJo Lingatong100% (1)

- Protection of Distribution Transformer by Using SCADADocument45 pagesProtection of Distribution Transformer by Using SCADAbharathdaruru204100% (1)

- Heart Rate and Pulse Waveform MonitorDocument33 pagesHeart Rate and Pulse Waveform MonitorPraveen dewalNo ratings yet

- LED DisplayDocument25 pagesLED DisplayCreative StudioNo ratings yet

- Solar Battery Charger With MPPT Using MicrocontrollerDocument28 pagesSolar Battery Charger With MPPT Using MicrocontrollerTrương Văn TrọngNo ratings yet

- Mini ProjectsDocument55 pagesMini ProjectsSampath KumarNo ratings yet

- PDP42V5 Service ManualDocument59 pagesPDP42V5 Service ManualEduardo Cordova100% (1)

- CP1L-CP1E Getting Started GuideDocument182 pagesCP1L-CP1E Getting Started GuideSuzaini SupingatNo ratings yet

- 8 Bit USB Debug AdapterDocument7 pages8 Bit USB Debug AdapterhoangdaiNo ratings yet

- DCAC Pure Sine WaveDocument69 pagesDCAC Pure Sine WaveTrie NouNo ratings yet

- Components For Grid Connected Solar Inverters in Residential ApplicationsDocument6 pagesComponents For Grid Connected Solar Inverters in Residential ApplicationsAvi JeetNo ratings yet

- Voice Controlled Home Automation SystemDocument29 pagesVoice Controlled Home Automation SystemAbhijit PattnaikNo ratings yet

- IOT Paralysis Patient Health Care SystemDocument3 pagesIOT Paralysis Patient Health Care Systemstar100% (2)

- PIC Power SupplyDocument0 pagesPIC Power Supplyaqdus100% (1)

- Controlling DC Motors With The L298N Dual HDocument27 pagesControlling DC Motors With The L298N Dual Hchafic WEISSNo ratings yet

- 6V Solar Charge Controller CircuitDocument11 pages6V Solar Charge Controller Circuitbazoka fransiskusNo ratings yet

- Home Automation Using Wi-FiDocument44 pagesHome Automation Using Wi-FiMerawi WubishetNo ratings yet

- Sony Chassis Eg1hDocument133 pagesSony Chassis Eg1hcsibaludekNo ratings yet

- LCD Panel Basic ConceptsDocument16 pagesLCD Panel Basic ConceptsshafiuddinkagziNo ratings yet

- Arduino MPPT V3Document16 pagesArduino MPPT V3Isabella Sanchez0% (1)

- Service Manual (Common) : History Information For The Following ManualDocument153 pagesService Manual (Common) : History Information For The Following ManualSagar KaushikNo ratings yet

- Smart Street Light For Energy ConservationDocument5 pagesSmart Street Light For Energy ConservationkhalidNo ratings yet

- Sony Smart LEDDocument153 pagesSony Smart LEDCadwill100% (2)

- Sony Kdl-40r474a Chassis Rb1fkDocument76 pagesSony Kdl-40r474a Chassis Rb1fkManuelDaríoCadavidValderramaNo ratings yet

- Ultrasonic sensor spectacles guide blind peopleDocument19 pagesUltrasonic sensor spectacles guide blind peopleparitosh kushwahaNo ratings yet

- UFS3Document3 pagesUFS3Abd Rasyad HermawanNo ratings yet

- Recycling Old Bad Power SuppliesDocument10 pagesRecycling Old Bad Power SuppliesMoln LeslieNo ratings yet

- Repairing The TV Source HAIER LCD LB32B1120Document7 pagesRepairing The TV Source HAIER LCD LB32B1120sachinNo ratings yet

- Power circuit board layoutDocument11 pagesPower circuit board layoutaldoNo ratings yet

- Battery Management System Prop R1 092611Document26 pagesBattery Management System Prop R1 092611jashwanthmekalaNo ratings yet

- Emerson Commander SK Getting Started Guide Size A-DDocument52 pagesEmerson Commander SK Getting Started Guide Size A-DGorbaniRanderesNo ratings yet

- Advanced Electronic Protection System To Prevent Exam Paper LeakagesDocument135 pagesAdvanced Electronic Protection System To Prevent Exam Paper LeakagesSyed Viquar AhmedNo ratings yet

- 9MA10272.00.02.2017 EWCM9000 PRO UserGuide ENDocument266 pages9MA10272.00.02.2017 EWCM9000 PRO UserGuide ENPrestoneKNo ratings yet

- Electronic Project 3Document50 pagesElectronic Project 3AdilNo ratings yet

- Prepaid Energy Meter Using Aurdino and GSMDocument3 pagesPrepaid Energy Meter Using Aurdino and GSMNarendra PatelNo ratings yet

- On "GSM BASED E-NOTICE BOARD"Document28 pagesOn "GSM BASED E-NOTICE BOARD"Rahul Garg75% (4)

- Schematic MPU 6050Document1 pageSchematic MPU 6050Nguyen HoaNo ratings yet

- TCONDocument5 pagesTCONLotteDomineNo ratings yet

- Interfacing Servo Motor With PIC Microcontroller - MikroCDocument7 pagesInterfacing Servo Motor With PIC Microcontroller - MikroCMahendiran CrNo ratings yet

- Solar Tracking System For Efficient Power Generation Using Image ProcessingDocument9 pagesSolar Tracking System For Efficient Power Generation Using Image ProcessingIJRASETPublicationsNo ratings yet

- Frequency Divider Circuit Using 555 and 4017 Using 555 Timer IC and 4017 Counter ICDocument6 pagesFrequency Divider Circuit Using 555 and 4017 Using 555 Timer IC and 4017 Counter ICNamith NamithNo ratings yet

- Z3 Compact Component Replacement 009Document13 pagesZ3 Compact Component Replacement 009Rostã Farias100% (1)

- Sony KDL-60W610B - RB2G 9-888-602-01 PDFDocument27 pagesSony KDL-60W610B - RB2G 9-888-602-01 PDFIDGG2011No ratings yet

- Panasonic L32C22 2010 LCD Training GuideDocument97 pagesPanasonic L32C22 2010 LCD Training Guidedeskjet5150100% (1)

- Multicol Ur Display BoardDocument2 pagesMulticol Ur Display Boardishan varshneyNo ratings yet

- LED Moving Message Displays SeminarDocument13 pagesLED Moving Message Displays Seminarpushpa100% (3)

- Project PresentationDocument16 pagesProject PresentationKavyapriya VNo ratings yet

- 634380182152028750Document20 pages634380182152028750Jayesh JainNo ratings yet

- Seminar on Cloud Computing Services, Advantages, and ChallengesDocument23 pagesSeminar on Cloud Computing Services, Advantages, and ChallengesJayesh JainNo ratings yet

- Summer Training in BhelDocument25 pagesSummer Training in BhelKunal NaganiNo ratings yet

- Led Based Notice BoardDocument26 pagesLed Based Notice BoardJayesh JainNo ratings yet

- Supercapacitors 130206061102 Phpapp02Document22 pagesSupercapacitors 130206061102 Phpapp02Jayesh JainNo ratings yet

- Protec Cio Introd 1Document74 pagesProtec Cio Introd 1Jayesh JainNo ratings yet

- Present 2Document35 pagesPresent 2Jayesh JainNo ratings yet

- Presentation ON Global Positioning System: Guided ByDocument21 pagesPresentation ON Global Positioning System: Guided ByJayesh JainNo ratings yet

- Title Page No. Chapter - 1 Project Overview 01-04Document5 pagesTitle Page No. Chapter - 1 Project Overview 01-04Jayesh JainNo ratings yet

- Shri Dadaji Institute of Technology & Science: Seminar OnDocument18 pagesShri Dadaji Institute of Technology & Science: Seminar OnJayesh JainNo ratings yet

- Nuclear Power PlantDocument13 pagesNuclear Power PlantJayesh JainNo ratings yet

- Lesson 14 - HydraulicsDocument24 pagesLesson 14 - HydraulicsNarablues IndonesiaNo ratings yet

- 1Document3 pages1Jayesh JainNo ratings yet

- Metal Detector-Project ReportDocument26 pagesMetal Detector-Project ReportTimK77% (52)

- Solar Power Generation Using MCDocument76 pagesSolar Power Generation Using MCAnurag S GowdaNo ratings yet

- Cloud Computing 2Document49 pagesCloud Computing 2Jayesh JainNo ratings yet

- Presentation ON Global Positioning System: Guided ByDocument21 pagesPresentation ON Global Positioning System: Guided ByJayesh JainNo ratings yet

- R. Rakesh Kashyap (0925924) 2 Semester MCADocument57 pagesR. Rakesh Kashyap (0925924) 2 Semester MCArakesh1988100% (1)

- An Introduction To Saas and Cloud Computing: Ross CooneyDocument39 pagesAn Introduction To Saas and Cloud Computing: Ross CooneyReetu KellurNo ratings yet

- Dcmotor 090522042653 Phpapp02Document46 pagesDcmotor 090522042653 Phpapp02hellzguardianNo ratings yet

- Practical Training Seminar on Transformer ManufacturingDocument17 pagesPractical Training Seminar on Transformer ManufacturingJayesh JainNo ratings yet

- DIN EN 10213 - 2008 - Fundidos em AçoDocument29 pagesDIN EN 10213 - 2008 - Fundidos em AçoLeonardo MartinsNo ratings yet

- Software MetricsDocument253 pagesSoftware MetricsAditya ChourasiyaNo ratings yet

- CS20 Instruction Manual: Inverted Vertical Turning CellDocument83 pagesCS20 Instruction Manual: Inverted Vertical Turning CellHenryNo ratings yet

- Klasifikasi Material: Myrna Ariati Wahyuaji Narottama PutraDocument49 pagesKlasifikasi Material: Myrna Ariati Wahyuaji Narottama Putrachink07No ratings yet

- Cube Law by Inverter Drive Systems LTD - ABB AVP - InvertersDocument1 pageCube Law by Inverter Drive Systems LTD - ABB AVP - InvertersbicodanaNo ratings yet

- Contact Centre CapabilityDocument2 pagesContact Centre CapabilityshyamchepurNo ratings yet

- VP R&D/VP QualityDocument3 pagesVP R&D/VP Qualityapi-79326007No ratings yet

- Fsls 11.10 Adminguide EngDocument67 pagesFsls 11.10 Adminguide Engsurender78No ratings yet

- Engineering Data Sheet: 49187073 E 1145842 1 of 1 October 21, 2016 60HzDocument1 pageEngineering Data Sheet: 49187073 E 1145842 1 of 1 October 21, 2016 60HzGustavo VillarrealNo ratings yet

- Catalogo-Wellhead-Marvic (Valvulas WKM EXPANDING)Document41 pagesCatalogo-Wellhead-Marvic (Valvulas WKM EXPANDING)mantilla7No ratings yet

- Calcium Sulfate Crystallization in Phosphoric Acid PDFDocument133 pagesCalcium Sulfate Crystallization in Phosphoric Acid PDFabderrahimnNo ratings yet

- CV Software Engineer Sarika DhingraDocument2 pagesCV Software Engineer Sarika DhingravirenderbishnoiNo ratings yet

- Coiled Tubing For Downhole ProcessDocument10 pagesCoiled Tubing For Downhole ProcessCristian BarbuceanuNo ratings yet

- Thermodynamic Revision DocumentsDocument7 pagesThermodynamic Revision DocumentshakimiNo ratings yet

- Quality Criterion of Road Lighting Measurement and ExploringDocument96 pagesQuality Criterion of Road Lighting Measurement and ExploringNitin UpadhyayNo ratings yet

- Ficha Tecnica Komatsu 400 - 7Document52 pagesFicha Tecnica Komatsu 400 - 7bariciado1No ratings yet

- Arduino Uno Schematic Annotated1Document1 pageArduino Uno Schematic Annotated1matthewwu2003100% (1)

- Queen Sala Celinda Del Rosario LECCION2 Actividad de Produccion 2.4Document4 pagesQueen Sala Celinda Del Rosario LECCION2 Actividad de Produccion 2.4Salustino AbreuNo ratings yet

- Acoustic ManualDocument88 pagesAcoustic ManualAlex Feria100% (1)

- Regional Contest Package in EIM NC IIDocument3 pagesRegional Contest Package in EIM NC IIAlNo ratings yet

- Colorado Passenger Tramway Safety Board Adam Lee Accident ReportDocument28 pagesColorado Passenger Tramway Safety Board Adam Lee Accident ReportMichael_Lee_RobertsNo ratings yet

- Hdpe Alathon H5520 EquistarDocument2 pagesHdpe Alathon H5520 EquistarEric Mahonri PereidaNo ratings yet

- 4 General Types of Polymers Molecular StructureDocument3 pages4 General Types of Polymers Molecular StructureArgel Linard Francisco MabagaNo ratings yet

- Ganz Hydro-Power: Over 150 Years of ExperienceDocument1 pageGanz Hydro-Power: Over 150 Years of ExperiencepalanaruvaNo ratings yet

- Life 365 V 2 Users ManualDocument67 pagesLife 365 V 2 Users ManualAmanda VegaNo ratings yet

- Operating Manual Parts List: 1000Vmc (Siemens)Document226 pagesOperating Manual Parts List: 1000Vmc (Siemens)apodshNo ratings yet

- DirectX 11 Practical ProjectsDocument64 pagesDirectX 11 Practical Projectszubair ansariNo ratings yet

- COMEC Modular Storage SolutionsDocument8 pagesCOMEC Modular Storage SolutionsPedro ChapadoNo ratings yet

- Manual E-Claw EngDocument18 pagesManual E-Claw Engshyampillai2007No ratings yet

- IPTC 12029 Selection Criteria For Artificial Lift Technique in Bokor FieldDocument13 pagesIPTC 12029 Selection Criteria For Artificial Lift Technique in Bokor FieldJean Carlos100% (1)