Professional Documents

Culture Documents

Series 641 Recoil Brochure

Uploaded by

Mrityunjay MallikCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Series 641 Recoil Brochure

Uploaded by

Mrityunjay MallikCopyright:

Available Formats

Glenfield.49602.

c:Layout 1 20/04/2010 13:52 Page 1

Glenfield Valves Limited

SERIES 641 R E C O I L C H E C K V A LV E S

www.glenfield.co.uk

Glenfield.49602.c:Layout 1 20/04/2010 13:52 Page 2

Glenfield Valves' manufacturing facilities are located at an 8 acre riverside location in Kilmarnock, Scotland. Since Glenfield Valves Ltd became part of The AVK Group in 2001 considerable investments have taken place in infrastructure improvements, product re-design to reflect improvements in operation, and the latest technology in machine tools and management information systems. Glenfield Valves has always been a valve manufacturer with a global outlook and today is part of a leading valve manufacturer, complying to various international valve standards such as BS, EN, DIN, AWWA, AS, ISO etc. Since Glenfield designed its first Fixed Cone Free Discharge Valve in 1950, we have been a highly rated supplier for Dams, Reservoirs and Hydro Power projects. Some of our many references are mentioned on page 15. Our Aim is to become : Your Reliable Long Term Partner with Focus on Providing a Comprehensive Range of High Quality Valves for Flow Control Applications We will achieve this through our focused product management strategy, our innovative approach to design and manufacturing and long term reliance to our customers.

Glenfield.49602.c:Layout 1 20/04/2010 13:52 Page 3

GLENFIELD SERIES 641 RECOIL CHECK VALVES AN ENGINEERED HIGH PERFORMANCE SOLUTION

Many check valves of conventional design behave perfectly satisfactorily in pumping or gravity systems, in which sluggish to moderately brisk flow reversal can occur. These are generally described as systems with low deceleration gradient and often comprise of single pump installation having low to moderate branch velocities. There are, however, a growing proportion of systems with the potential for rapid flow reversal occurring. This introduces onerous reflux conditions which an ordinary check valve cannot operate effectively within. Typical of the many active systems are pumping installations which adopt high branch velocities, and in addition, provide automatic stopping and starting delivery into a vertically rising main, have multi pump sets delivering in to a common main, or incorporate a pneumatic accumulator either for water storage or for surge suppression purposes. All of these lively systems demand the use of a check valve which provides the highly perfected closing characteristic of the finely engineered Glenfield Recoil Check Valve. The valve possesses an extremely low reverse velocity potential and has the flexibility to adapt to varying system deceleration modes. It is vitally important that a Check Valve which is intended to work in extreme conditions has incorporated within it every mechanical and hydraulic feature that can be directed towards accelerating the closing of the door. Through extensive laboratory testing, the Glenfield Valves Recoil Valve has been designed to achieve this characteristic.

Glenfield.49602.c:Layout 1 20/04/2010 13:52 Page 4

GLENFIELD SERIES 641 RECOIL CHECK VALVES 4

Glenfield Valves Ltd Series 641 Recoil Check Valves are designed to ensure that rapid valve closure and resistance to door slam are achieved. It is through a combination of all of the following design features that results in the Glenfield Valves Series 641 Recoil Valve superior to conventional swing check valves. All of these design features ensure that the Glenfield Series 641 Recoil Valve is superior to conventional swing check valve designs. Slope of the body face, and the door opening arc length. Weight of the door, and the manner in which the weight is distributed. Location of the hinge pin in relation to the plane of the faces. Large volume area around the door to reduce turbulence at the closure point.

Features

High Density Door Integral Body/Door Unit Frictionless Bearings Voluminous Body Selected Angular Travel Minimum Reverse Velocity Flexible Closure Time

Benefits

Maximum Closing Force Accurate Alignment Fast Operation Minimum Hydraulic Resistance Optimum Arc Length Faster closing time Perfect System Match

Glenfield.49602.c:Layout 1 20/04/2010 13:52 Page 5

CROSS-SECTIONAL DETAIL OF DN350 DN500 SINGLE DOOR DESIGN

DN600 DN1200 RANGE MULTIPLE DOOR DESIGN

In order to minimize valve door travel, valves of DN600 and above incorporate a multidoor design.

Glenfield.49602.c:Layout 1 20/04/2010 13:52 Page 6

CROSS-SECTIONAL DETAIL OF DN600 DN1200 MULTIPLE DOOR DESIGN

VALVE DN SIZE DN600 - DN800 DN900 - DN1200

NUMBER OF DOORS 2 3

Glenfield.49602.c:Layout 1 20/04/2010 13:52 Page 7

RECOIL VALVE SPECIFICATIONS 7

APPLICATIONS For Water and neutral liquids up to 70 Degrees C NOTE: The Valves are not suitable for sewerage applications unless the sewerage is finely comminuted. The Valves are designed to operate in the horizontal position only.

PRESSURE TESTS Hydrostatic Test : Body at 1.5 x PN Rating Seat at 1.1 x PN Rating

FLANGE STANDARDS Cast and drilled to BS EN 1092-2 : PN16 PN10 drilling available on request

OPTIONAL EXTRAS Limit / Proximity Switch By Pass Valves PN25 Valves

SERIES NUMBERS Series 641/11 : DN100 DN500 PN 16 with Single Door Series 641/21 : DN600 DN1200 PN 16 with Multiple Doors Series 641/13 : DN100 DN500 PN 25 with Single Door Series 641/23 : DN600 DN1200 PN25 with Multiple Doors

Glenfield.49602.c:Layout 1 20/04/2010 13:52 Page 8

SPECIFICATIONS

The Recoil Valves are available to the different specifications detailed below :-

BRITISH SPECIFICATION MATERIAL OF CONSTRUCTION Body / Cover : Doors / Stoppers : Body Seat : Door Face : Hinge Pin : Fasteners : Seals : Coating : Ductile Iron BS EN 1563 EN-GJS-500/7 Ductile Iron BS EN 1563 EN-GJS-500/7 Gun Metal BS EN 1982 CC491K Gun Metal BS EN 1982 CC491K Stainless Steel BS EN 10088 Grade 1.4305 Zinc Plated Carbon Steel EPDM WBS listed Internal and External Blue 2-Pack Epoxy to 250 microns dry film thickness

GULF SPECIFICATION MATERIAL OF CONSTRUCTION Body / Cover : Doors / Stoppers : Body Seat : Door Face : Hinge Pin : Fasteners : Seals : Coating : Ductile Iron BS EN 1563 EN-GJS-500/7 Ductile Iron BS EN 1563 EN-GJS-500/7 Gun Metal BS EN 1982 CC491K Gun Metal BS EN 1982 CC491K Stainless Steel BS EN 10088 Grade 1.4401 Stainless Steel Grade A4 EPDM WBS listed Internal and External Blue 2-Pack Epoxy to 300 microns dry film thickness

Glenfield.49602.c:Layout 1 20/04/2010 13:52 Page 9

DIMENSIONS 9

COMPONENT LIST ITEM 1 2 3 4 5 6 7 8 9 DESCRIPTION BODY DISC COVER BODY SEAT DISC FACE HINGE PIN FASTENERS SEALS AIR PLUG

DIMENSIONS & WEIGHTS DN100 DN500 RANGE APPROX WEIGHT (kg) 81 154 290 447 612 1038 1100 1564 2240

DN

LNS NUMBER

A (mm) 495 610 762 965 1067 1219 1219 1295 1473

B (mm) 210 260 343 387 426 464 464 546 635

C (mm) 311 412 533 620 683 819 819 978 1149

D (mm) 159 210 273 315 347 457 457 572 660

E (mm) 202 245 296 354 390 470 470 508 546

F (mm) 100 130 150 230 230 305 305 406 457

100 150 200 250 300 350 400 450 500

641-100-11100000 641-150-11100000 641-200-11100000 641-250-11100000 641-300-11100000 641-350-11100000 641-400-11100000 641-450-11100000 641-500-11100000

Glenfield.49602.c:Layout 1 20/04/2010 13:52 Page 10

DIMENSIONS 10

COMPONENT LIST ITEM 1 2 3 4 5 6 7 8 9 DESCRIPTION BODY DISC COVER BODY SEAT DISC FACE HINGE PIN FASTENERS SEALS AIR PLUG

DIMENSIONS & WEIGHTS DN600 DN1200 RANGE G LNS A B C D E F DN (mm) NUMBER (mm) (mm) (mm) (mm) (mm) (mm) No APPROX K of WEIGHT (mm) (option) (option) Door (kg) H (mm) 890 80 1230 2 1950

600 21100000

641-700-

641-600-

940 1270 670

345

250

300

700 21100000 1016 1387 735 800 21100000 1040 1490 780 900 21100000 1300 1800 930

641-300641-900641-800-

378

260

300

1008

80

1342

2500

360

320

320

1018

80

1455

2700

470

360

360

1225

80

1795

3600

1000 11100000 1400 1924 1000 520 1200 11100000 1500 2218 1160 553

641-350-

360

360

1285

80

1915

4500

400

400

1550

100

2195

6800

Glenfield.49602.c:Layout 1 20/04/2010 13:52 Page 11

GLENFIELD RECOIL CHECK VALVES VALVE CHARACTERSTICS HEAD LOSS CURVE

11

Glenfield.49602.c:Layout 1 20/04/2010 13:52 Page 12

Glenfield Valves Limited

Continental Europe, Russia, South Eastern Europe: AVK International A/S - Denmark - www.avkvalves.com Tel +45 8754 2100 Fax+45 8754 2120 AVK Sales Companies Europe: AVK Norge - Norway - www.avk.no AVK Mittelmann - Germany - www.avkmittelmann.com AVK Nederland - Netherlands - wwwavknederland.nl AVK Belgium - Belgium - dj@avkvalves.be AVK Armadan - Poland - www.avk.com.pl AVK France - France - avk@avk.fr AVK Valvulas - Spain - avk@avkvalvulas.com UK and Ireland: AVK UK - England - www.avkuk.co.uk Tel +44 1604 601188 Fax +44 1604 604818 M.&G. Ltd - Ireland - gerry@mandg.ie www.mandg.ie Tel +353 1451 1144 Fax +353 1451 1376 North America: American AVK Co. - 2155 Meridian Blvd., Minden, NV 89423, U.S.A. Tel +1 559 452 4310 Fax +1 559 452 4349 Email: sales@americanavk.com Web: www.americanavk.com Latin America and Caribbean: AVK Overseas - Latin America administration@avkoverseas.com Tel +1 559 451 0435 Fax +1 559 451 0437 Brazil: AVK Valvulas do Brasil Ltda. andre.alves@avkvalves.com.br Tel +55 15 3411 5145 South Africa: AVK Valves Southern Africa (Pty) Ltd. South Africa - avkvalves@mweb.co.za Tel +27 44 4951 626 Fax +27 44 4951 310/459 Australia: AVK Australia Pty Ltd - 559A Grand Junction Road, AUS-Wingfield, S.A. 5013, Australia Tel +61 8 8368 0900 Fax +61 8 8368 0970 Email: info@avkvalves.com.au Web: www.avkvalves.com.au

The Middle East: AVK Middle East - www.avk.ae P .O. Box 293870, Dubai, U.A.E. Tel +971 4299 8110 Fax +971 4299 8113 Saudi Valves Manufacturing Co. Ltd. Saudi Arabia - www.avk.com.sa Tel +971 2637 1570 Fax +971 2637 9380 Dutco Tennant United Arab Emirates - www.dutcotennant.com Dubai: Tel +971 4222 0186 Fax +971 4223 6193 Abu Dhabi: Tel +971 2634 8495 Fax +971 2551 5904 Al Ain: Tel +971 3721 9774 Fax +971 3721 9776 Arabi Company W.L.L. - Kuwait - opd@arabigroup.com Tel +965 472 4058 Fax +965 472 4059 Al Obeidly & Gulf Eternit Trading Co. Doha - Qatar obeidly@qatar.net.qa Tel +974 469 4111 Fax +974 469 4449 Asia: AVK Malaysia Sdn. Bhd Tel +603 329 16 004 Fax +603 329 17 067 Web: www.avkvalves.com.my AVK Vietnam 6th Floor, 14 Nguyen Van Hgoc, Ba Dinh District, Hanoi, Vietnam Tel: +84 4 766 6929 Fax: +84 4 766 6928 Email: avk_av@hn.vnn.vn Web: www.avkvalves.com.my AVK Phillipines Email: sales@avk.ph Web: www.avkvalves.com.my China and Hong Kong: AVK Valves - China - info@avkchina.com Tel +86 21 5308 7733 Fax +86 21 5308 9989 China/Hong Kong Tel +852 2773 0846 Fax +86 2773 1164 Mr. Cao Yuzhu - Unit 1601, Tower No.5, Wanda Plaza, 93 Jiangou Road, Chaoyang District, Beijing, 100022, P .R.China Email:cao.cyz@avkchina.com Tel: +86 10 5820 5669 Web: www.avkchina.com Fax: +86 10 5960 3072 Advance Trading & Eng Ltd. Tel +852 2429 9808 Fax +852 2429 2921

You might also like

- High-Performance GM LS-Series Cylinder Head GuideFrom EverandHigh-Performance GM LS-Series Cylinder Head GuideRating: 4.5 out of 5 stars4.5/5 (2)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Fentek CatalogDocument48 pagesFentek Catalogjoseherreramogollon100% (1)

- A 18-Page Statistics & Data Science Cheat SheetsDocument18 pagesA 18-Page Statistics & Data Science Cheat SheetsAniket AggarwalNo ratings yet

- Condenser Bushings GuideDocument8 pagesCondenser Bushings Guidesarkar1981No ratings yet

- Pounder's Marine Diesel Engines and Gas TurbinesFrom EverandPounder's Marine Diesel Engines and Gas TurbinesRating: 4 out of 5 stars4/5 (15)

- mf8240 160824142620 PDFDocument698 pagesmf8240 160824142620 PDFArgopartsNo ratings yet

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryFrom EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryRating: 5 out of 5 stars5/5 (3)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Ace Valves Brochure PDFDocument48 pagesAce Valves Brochure PDFMaria Gabriela Bustelo50% (2)

- Control Choke Valve 9000Document8 pagesControl Choke Valve 9000sabi_shi100% (2)

- Subdivision Development GuidelinesDocument240 pagesSubdivision Development Guidelines1004.No ratings yet

- AVK Butterfly BrochureDocument44 pagesAVK Butterfly Brochurevinurules20No ratings yet

- False CeilingDocument70 pagesFalse CeilingBharti Sikri93% (15)

- Hydraulic Grade LineDocument0 pagesHydraulic Grade LinemuazeemKNo ratings yet

- Hydraulic Grade LineDocument0 pagesHydraulic Grade LinemuazeemKNo ratings yet

- Users Guide To SWMM5 Edn 13Document947 pagesUsers Guide To SWMM5 Edn 13TamarajoulyNo ratings yet

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- Crane - Series.rs Center LineDocument23 pagesCrane - Series.rs Center LinenedwestNo ratings yet

- MIR VALVE API 6D Ball Valve Catalogue Rev2 Feb. 2014Document16 pagesMIR VALVE API 6D Ball Valve Catalogue Rev2 Feb. 2014zhengshuiNo ratings yet

- Choke E Series MasterFloDocument14 pagesChoke E Series MasterFloianherzogNo ratings yet

- AVK Resilient Seated Gate ValvesDocument36 pagesAVK Resilient Seated Gate ValvesCarel De JagerNo ratings yet

- Problem set 1 covers energy, heat, gases, and thermodynamicsDocument15 pagesProblem set 1 covers energy, heat, gases, and thermodynamicsFikret BazNo ratings yet

- Piston ValveDocument28 pagesPiston ValveDamien BouticourtNo ratings yet

- CatalogDocument236 pagesCatalogRochdi SahliNo ratings yet

- Velan Forged Steel CatalogueDocument26 pagesVelan Forged Steel CatalogueJuan Carlos Ojeda RamirezNo ratings yet

- Bellow Seal ValvesDocument36 pagesBellow Seal ValvesJake SparrowNo ratings yet

- Rainwater Systems: Design and Installation GuideDocument22 pagesRainwater Systems: Design and Installation GuideGELIGNITENo ratings yet

- The Range of Valves-DataDocument70 pagesThe Range of Valves-DataAshraf SalehNo ratings yet

- API 6A and 6D Ball ValvesDocument27 pagesAPI 6A and 6D Ball ValveszayerirezaNo ratings yet

- Wavin Sewer SytemDocument44 pagesWavin Sewer SytemterinthomasNo ratings yet

- Spare Parts Manual (HB2200-2000DP)Document20 pagesSpare Parts Manual (HB2200-2000DP)drmasster100% (1)

- Vel PQCV Web Catalogo Velan Duo CheckDocument21 pagesVel PQCV Web Catalogo Velan Duo Checkel_apache10No ratings yet

- MANUAL DezumidificatorDocument98 pagesMANUAL DezumidificatorcivodulNo ratings yet

- Velan Bellows SealDocument19 pagesVelan Bellows SealdscribddevoreNo ratings yet

- CAT DewranceDocument93 pagesCAT DewranceHorvatAladar100% (1)

- Valvula para CoqueDocument12 pagesValvula para CoqueKerry DillonNo ratings yet

- 855 (1400)Document6 pages855 (1400)Harman Singh NagpalNo ratings yet

- Velan's Global Leadership in Industrial Valve ManufacturingDocument8 pagesVelan's Global Leadership in Industrial Valve ManufacturingmujeebtalibNo ratings yet

- Axial FlowDocument72 pagesAxial FlowZulhilmi ZalizanNo ratings yet

- Geovent CatalogDocument108 pagesGeovent CatalogadnanNo ratings yet

- Nyborg Marine ApplicationsDocument382 pagesNyborg Marine ApplicationsrobertpasNo ratings yet

- VAG Absperrklappen02-05Document27 pagesVAG Absperrklappen02-05Muhamad FajriNo ratings yet

- Deu BlinDocument58 pagesDeu Blinraghunath.psNo ratings yet

- Industrial Penstocks GuideDocument19 pagesIndustrial Penstocks Guidedundee2012No ratings yet

- Double Block and Bleed Valves - Instrumentation - Oliver ValvesDocument4 pagesDouble Block and Bleed Valves - Instrumentation - Oliver ValvesKehinde AdebayoNo ratings yet

- Marley Aquatower: SteelcrossflowcoolingtowerDocument12 pagesMarley Aquatower: SteelcrossflowcoolingtowerBrian CaseNo ratings yet

- CP Range: Redefining Flow ControlDocument8 pagesCP Range: Redefining Flow ControlSmootherNo ratings yet

- ValvesDocument28 pagesValveslolaNo ratings yet

- 9100 Flanged BrochureDocument16 pages9100 Flanged Brochureanugrah_dimas5441No ratings yet

- Catalog (1) API 600 GATE VALVES PDFDocument140 pagesCatalog (1) API 600 GATE VALVES PDFMohsen HalweniNo ratings yet

- Europa Valve Non Slam Check ValvesDocument16 pagesEuropa Valve Non Slam Check ValvesBryan KellyNo ratings yet

- Calobri 12.10Document140 pagesCalobri 12.10miroslav11No ratings yet

- Valvetop D-Series With AS-interface: Installation, Operation & Maintenance ManualDocument16 pagesValvetop D-Series With AS-interface: Installation, Operation & Maintenance ManualAdeel RazaNo ratings yet

- Ventilation CowlsDocument12 pagesVentilation CowlsShahadatuliskandar RosliNo ratings yet

- 03 Ovalni I Pljosnati ZatvaraciDocument4 pages03 Ovalni I Pljosnati ZatvaracisalicurriNo ratings yet

- Es LF919 PDFDocument4 pagesEs LF919 PDFWattsNo ratings yet

- Hauraton PDFDocument84 pagesHauraton PDFPavl BoeNo ratings yet

- 12 Caldwell VL-8Document1 page12 Caldwell VL-8Thomas StempienNo ratings yet

- Hms Griswold Efgbro506Document8 pagesHms Griswold Efgbro506Alex Jhony GeorgeNo ratings yet

- KL Vacuum Product Catalogue 2011 05Document104 pagesKL Vacuum Product Catalogue 2011 05aconibet9040No ratings yet

- Danfoss Price List For 2012Document40 pagesDanfoss Price List For 2012Arbee AquinoNo ratings yet

- Virgo Welded Valve BrochureDocument8 pagesVirgo Welded Valve BrochureHerrera Jorge AgustínNo ratings yet

- D2000 Clamp Ring ClosuresDocument8 pagesD2000 Clamp Ring Closuresgennaro_basileNo ratings yet

- Api Bottom Load ValveDocument2 pagesApi Bottom Load ValveMạnh Ngô ĐứcNo ratings yet

- Eko4000-4100 WebDocument4 pagesEko4000-4100 WebSubramanian SaravananNo ratings yet

- Modelo D6 - 10-6 Series Model 100Document24 pagesModelo D6 - 10-6 Series Model 100Vitort SpadNo ratings yet

- 75th Conference on Glass Problems: A Collection of Papers Presented at the 75th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, Ohio, November 3-6, 2014From Everand75th Conference on Glass Problems: A Collection of Papers Presented at the 75th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, Ohio, November 3-6, 2014S. K. SundaramNo ratings yet

- Water 06 00976 PDFDocument17 pagesWater 06 00976 PDFShashank YadavNo ratings yet

- SWM RelatedDocument42 pagesSWM RelatedMrityunjay MallikNo ratings yet

- PPE Seminar MaterialDocument34 pagesPPE Seminar MaterialMrityunjay MallikNo ratings yet

- Water 06 00976 PDFDocument17 pagesWater 06 00976 PDFShashank YadavNo ratings yet

- SWM RelatedDocument42 pagesSWM RelatedMrityunjay MallikNo ratings yet

- Level SpreaderDocument18 pagesLevel SpreaderMrityunjay MallikNo ratings yet

- Portland Stormwater Manual 2016 RequirementsDocument502 pagesPortland Stormwater Manual 2016 RequirementsMrityunjay MallikNo ratings yet

- PEO PaperDocument4 pagesPEO PaperMrityunjay MallikNo ratings yet

- Bentley Civil Guide: V8I Selectseries 3Document44 pagesBentley Civil Guide: V8I Selectseries 3Mrityunjay MallikNo ratings yet

- ECA ApplicationDocument21 pagesECA ApplicationMrityunjay MallikNo ratings yet

- SWM Criteria 2012Document126 pagesSWM Criteria 2012kamranNo ratings yet

- Report On Heritage City Stree and Consulting: The Financial Claims DenouncedDocument2 pagesReport On Heritage City Stree and Consulting: The Financial Claims DenouncedMrityunjay MallikNo ratings yet

- Technical ManualDocument12 pagesTechnical ManualMrityunjay MallikNo ratings yet

- Bupa Global Claim Form: 1 Patient'S DetailsDocument4 pagesBupa Global Claim Form: 1 Patient'S Details123owenNo ratings yet

- KM Regulations for Works near Electricity Transmission LinesDocument25 pagesKM Regulations for Works near Electricity Transmission LinesTommy YapNo ratings yet

- Dr15-Dr07 Catchment With New Pump StationDocument1 pageDr15-Dr07 Catchment With New Pump StationMrityunjay MallikNo ratings yet

- Gtc107 SpecDocument5 pagesGtc107 SpecAslam AhamedNo ratings yet

- Your Results - Citizenship and Immigration CanadaDocument2 pagesYour Results - Citizenship and Immigration CanadaMrityunjay MallikNo ratings yet

- Management of Construction Dewatering Guideline Manual - ASHGHAL - Final - March 2014Document117 pagesManagement of Construction Dewatering Guideline Manual - ASHGHAL - Final - March 2014RaoofNo ratings yet

- DIP OPT1 20161011 WestDocument1 pageDIP OPT1 20161011 WestMrityunjay MallikNo ratings yet

- 2016 CSF Info Pack - Al ThayyalDocument23 pages2016 CSF Info Pack - Al ThayyalMrityunjay MallikNo ratings yet

- Amenities Booking FormDocument1 pageAmenities Booking FormMrityunjay MallikNo ratings yet

- User Guide For Short StoryDocument5 pagesUser Guide For Short StoryMrityunjay MallikNo ratings yet

- Rami Azzam CV Dec 2013Document4 pagesRami Azzam CV Dec 2013Mrityunjay MallikNo ratings yet

- Consultant-Pqd Iiwwtw Part 2-RevDocument21 pagesConsultant-Pqd Iiwwtw Part 2-RevMrityunjay MallikNo ratings yet

- How many times do clock hands overlap in a dayDocument6 pagesHow many times do clock hands overlap in a dayabhijit2009No ratings yet

- "Smart Attendance Using F Ttendance Management Using Face Recognition" Anagement SystemDocument13 pages"Smart Attendance Using F Ttendance Management Using Face Recognition" Anagement Systemamer HNo ratings yet

- Sae Technical Paper Series 2015-36-0353: Static and Dynamic Analysis of A Chassis of A Prototype CarDocument12 pagesSae Technical Paper Series 2015-36-0353: Static and Dynamic Analysis of A Chassis of A Prototype CarGanesh KCNo ratings yet

- Map Book 4Document58 pagesMap Book 4executive engineerNo ratings yet

- Sap - HR Standard Operating Procedure: Facility To Reset Password of ESSDocument6 pagesSap - HR Standard Operating Procedure: Facility To Reset Password of ESSPriyadharshanNo ratings yet

- Safety and Arming Device Timer 6-7-1976Document5 pagesSafety and Arming Device Timer 6-7-1976nguyenhNo ratings yet

- Reflection 4Document7 pagesReflection 4danilo miguelNo ratings yet

- Qc-Sop-0 - Drilling of PoleDocument7 pagesQc-Sop-0 - Drilling of PoleAmeerHamzaWarraichNo ratings yet

- Duplichecker Plagiarism Report 3Document3 pagesDuplichecker Plagiarism Report 3Mushfiqur RahmanNo ratings yet

- Positive Leadership and Adding Value - A Lifelong Journey: June 2017Document7 pagesPositive Leadership and Adding Value - A Lifelong Journey: June 2017CescSalinasNo ratings yet

- Water Is EnergyDocument96 pagesWater Is EnergyRadu BabauNo ratings yet

- Features Description: LT3598 6-String 30ma LED Driver With 1.5% Current MatchingDocument24 pagesFeatures Description: LT3598 6-String 30ma LED Driver With 1.5% Current MatchingMick Thomson RcNo ratings yet

- KTO12 Curriculum ExplainedDocument24 pagesKTO12 Curriculum ExplainedErnesto ViilavertNo ratings yet

- Wheel Radial Fatigue Test MachineDocument1 pageWheel Radial Fatigue Test MachineAlex NuñezNo ratings yet

- Perfect Secrecy: Chester Rebeiro IIT MadrasDocument50 pagesPerfect Secrecy: Chester Rebeiro IIT MadrasDr. Jayanthi V.S.No ratings yet

- English 10 - WHLP - Q1 - Module 3Document3 pagesEnglish 10 - WHLP - Q1 - Module 3Mar Florence SebastianNo ratings yet

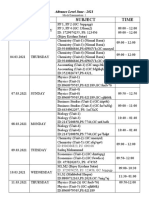

- Mock Examination Routine A 2021 NewDocument2 pagesMock Examination Routine A 2021 Newmufrad muhtasibNo ratings yet

- Building Resilience Philippines Urban PoorDocument16 pagesBuilding Resilience Philippines Urban PoorYasmin Pheebie BeltranNo ratings yet

- Starting and Configuring Crontab in CygwinDocument2 pagesStarting and Configuring Crontab in CygwinSamir BenakliNo ratings yet

- International Financial Management 7th Edition Eun Test BankDocument25 pagesInternational Financial Management 7th Edition Eun Test BankMatthewRosarioksdf100% (58)

- Tutorial Quartus II Simulation VHDLDocument27 pagesTutorial Quartus II Simulation VHDLHeitor B. S. BezerraNo ratings yet

- SANY HDForklift Brochure-112018Document14 pagesSANY HDForklift Brochure-112018Rossman Mejicanos100% (1)

- FMVSS 139 2022-10-01Document7 pagesFMVSS 139 2022-10-01skr_757No ratings yet

- 5054 s09 QP 1Document20 pages5054 s09 QP 1Hany ElGezawyNo ratings yet

- Chapter 10 TestDocument7 pagesChapter 10 Testapi-348969276No ratings yet