Professional Documents

Culture Documents

On The Networking Mechanisms of Additives-Accelerated Phenol-Formaldehyde Polycondensates

Uploaded by

A MahmoodOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

On The Networking Mechanisms of Additives-Accelerated Phenol-Formaldehyde Polycondensates

Uploaded by

A MahmoodCopyright:

Available Formats

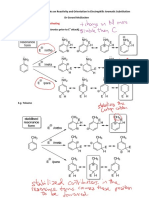

On the Networking Mechanisms of Additives-Accelerated PhenolFormaldehyde Polycondensates

A. PIZZI, R. GARCIA, S. WANG ENSTIB, University of Nancy 1, Epinal, France

Received 30 December 1996; accepted 28 March 1997

ABSTRACT: Determination by thermomechanical analysis (TMA) of the average num-

ber of degrees of freedom of polymer segments between crosslinking nodes of phenolformaldehyde (PF) resin-hardened networks indicate that additive-accelerated PF resin polycondensations and hardening presented several different acceleration mechanisms. Some additives such as sodium carbonate appear to present purely an acceleration effect on the polycondensation reaction. Other additives such as propylene carbonate appear to present an acceleration effect by also inducing an increase in the average functionality of the system, due to alternate crosslinking reactions to which the accelerator itself does participate, leading to a tighter nal network. These alternate crosslinking reactions can be of a different nature. In the propylene carbonate case, the reaction is related to a KolbeSchmitt reaction. In formamide, instead, it is related to its hydrolysis to formic acid and ammonia with the subsequent rapid reaction of the latter with two or more hydroxybenzyl alcohol groups of PF resols. The rapid reaction of the {NH2 group of formamide with two hydroxybenzyl alcohol groups of PF resols, a reaction which is also characteristic of urea and methylamine, also appears likely to occur. Both liquid- and solid-phase 13C-NMR supporting evidence of the mechanisms proposed is also presented. 1997 John Wiley & Sons, Inc. J Appl Polym Sci 66: 255266, 1997

INTRODUCTION

Alkaline phenolformaldehyde (PF) resins have been used successfully for many decades as exterior wood adhesives for bonded wood products.1 While the inuence of many additives on their hardening has been studied for a long time, the mechanisms of hardening acceleration induced by these additives, especially in the presence of the wood substrate, has only started to be studied in recent years.2 5 Thus, mechanisms of PF hardening acceleration by catalytic surface activation by lignocellulosic materials have been reported, 6 as well as a variety of mechanisms based on PF hardening acceleration induced by carboxylic acid

Correspondence to: A. Pizzi.

Journal of Applied Polymer Science, Vol. 66, 255 266 ( 1997 ) 1997 John Wiley & Sons, Inc. CCC 0021-8995/97 / 020255-12

esters, 2 5 anhydrides, 7 amides, 4,8,9 and others. Some of the mechanisms which have been proposed are based on circumstantial, indirect evidence rather than on direct evidence, mainly because the chemistry of phenolic resins which is characterized by the presence of an almost innite variety of oligomeric positional isomerides produced with the progressing of the reaction is particularly difcult and tedious to unravel.10 Some of these mechanisms are not supported by any direct evidence 5 and are often only assumptions based on unacceptable interpretations of the organic chemistry involved. Recently, 1113 a method was presented which allows one to determine the average number of degrees of freedom of the polymer segments between crosslinking nodes both during hardening of and of hardened polycondensation networks as a function of the relative deection of thermomechanical analysis (TMA) measurements in bending. The

255

8EAA

/ 8eaa$$4501

08-05-97 17:17:14

polaas

W: Poly Applied

4501

256

PIZZI, GARCIA, AND WANG

method has proved applicable with good results to melamineformaldehyde, 12 melamineureaformaldehyde, 14 phenolformaldehyde, 12 resorcinol formaldehyde, 12 and tanninformaldehyde 12,15 polycondensates and also to radical crosslinking polymers such as unsaturated polyesters and complex vinyls.1113 In this article, the mechanisms of accelerated hardening and networking induced by several of these additives such as esters, carboxylic acid anhydrides, amides, amines, sodium carbonate, and propylene carbonate are examined by this technique on the basis of the type of hardened network and its density of crosslinking that they yield as well as on the basis of 13C-NMR results as supporting evidence.

h at 60C. The liquid sample was analyzed by 13C-NMR. 3. Fifty grams of the liquid PF resin prepared above was reacted and gelled with 4.5 g formamide at 90C for 15 min. The airdried gelled resin was analyzed by solidphase CP-MAS 13C-NMR. 4. Fifty grams of the commercial liquid PRF resin of pH 8.3 was cured at ambient temperature (i) by addition of 5 g paraformaldehyde (the resin gelled in about 5 h) and (ii) by addition of 5 g paraformaldehyde followed by 5 g of 30% ammonia solution (the resin gelled in a few seconds).

13

C-NMR Spectra

EXPERIMENTAL

PhenolFormaldehyde (PF) Resin Preparation Ninety-four parts by mass of phenol were mixed with 40 parts (20/80) of a methanol/water solution and 55 parts by mass of a 96% paraformaldehyde powder. After stirring for 30 min at 40C, the temperature was increased over a period of 30 min to reux (94C). A total of 20 parts by mass of a 33% sodium hydroxide solution was added in four equal parts at 15 min intervals over the previous total of 60 min. The mixture was kept at reux for 30 min and was then cooled. The resin solids content was 58%; viscosity, 300 centipoises at 25C; and nal pH, 10.8. In the case of the variation which to the above resin formamide, 60 g, was added, the reaction was continued at reux for 15 min after addition of the formamide, while the rest of the procedure was left the same.

Liquid 13C-NMR spectra were obtained on a Bru ker MSL 300 FT-NMR spectrometer. Chemical shifts were calculated relative to (CH3 )3Si(CH2 )3SO3Na dissolved in D2O for NMR shifts control.16 The spectra were done at 62.90 MHz for a number of transients of approximately 1000. All spectra were run with a relaxation delay of 5 s and chemical shifts were accurate to 1 ppm. Solid-state CP-MAS (cross-polarization magic angle spinning) 13C-NMR spectra of each sample were obtained on a Bru ker MSL300 FT-NMR spectrometer at a frequency of 75.47 MHz. Chemical shifts were calculated relative to TMS for NMR control. Acquisition time was 0.026 s with the number of transients about 1200. All spectra were run with a relaxation delay of 5 s and were accurate to 1 ppm with a CP time of 1 ms and spectral width of 20,000 Hz. Spinning rates were 3.5 kHz. Thermomechanical Analysis (TMA) Determination of Average Number of Degrees Freedom of Accelerated PF Resin-cured Networks Recently work on the formation of polymer networks by photopolymerizable and polyester surface nishes on wood and of polycondensation resins used as wood adhesives has yielded a mathematical relationship 11 13 among the energy of interaction ( E ) at the synthetic polymer/wood interface calculated by molecular mechanics (work of adhesion), the number of degrees of freedom ( m ) of the segment of the synthetic polymer between two crosslinking nodes, the coefcient of branching a, hence, the functionality of the starting monomer, and the relative deection ( f ) obtained by thermomechanical analysis (TMA) of

Reactions of Different Phenols and of Phenolic Resins with Propylene Carbonate and Formamide in Absence or Presence of Formaldehyde 1. Four grams resorcinol in 4 g water at pH 12 was reacted with 3.7 g propylene carbonate for 2 h at 60C. After separation by centrifugation of the sodium hydrogen carbonate solids formed, the liquid sample was analyzed by 13C-NMR. 2. Four grams resorcinol in 6 g water at pH 12 was reacted with 1.7 g formamide for 2

8EAA

/ 8eaa$$4501

08-05-97 17:17:14

polaas

W: Poly Applied

4501

PHENOLFORMALDEHYDE POLYCONDENSATES

257

Table I Thermomechanical Analysis (TMA) Results for the Determination of the Density of Crosslinking of Different PF Resin / Accelerator-Hardened Networks Deection (mm) PF alone /5% Na2CO3 /4.8% propylene carbonate /7.1% glycerol triacetate /5% acetic anhydride /2.2% formamide /1.5% methylamine 16.1 14.2 9.9 12.4 11.4 11.0 11.5 tgel (C) 142 132 143 138 140 136 133 tvitrif. (C) 158 154 161 160 169 157 153

a

0.5 0.5 0.5 0.5 0.5 0.5 0.5

m 6.8 5.9 4.0 5.1 4.7 4.5 4.7

a

0.5 0.33 0.33 0.33 0.5

m 6.8 2.4 3.2 2.8 4.7

The amounts of accelerators added are expressed in percentages by weight on PF resin to achieve equal molar percentages of active component.

wood specimens coated or bonded with the adhesive through the expression f km / aE , where k is a constant.11 13 Regression equations 12 correlating directly m with E and m with f have been derived for hardened phenolformaldehyde (PF), resorcinolformaldehyde (RF), melamineformaldehyde (MF), and tanninformaldehyde (TF) resins. These relationships will then be used to correlate the number-average degree of polymerization (DPn ) and pgel with m for the same PF resin hardened alone and in the presence of the different hardening accelerators used. To this purpose, the PF resin above was tested dynamically by thermomechanical analysis (TMA) on a Mettler apparatus. Samples of beechwood alone and of two beechwood plies bonded with each system of liquid polycondensate resins / accelerator (comparable molar amount as indicated in Table I) in a layer of 350 mm, for a total sample dimensions of 21 1 6 1 1.1 mm, were tested in a nonisothermal mode between 40 and 220C at a heating rate of 10C/min with a Mettler 40 TMA apparatus in three-point bending on a span of 18 mm, exercizing a force cycle of 0.1/0.5N on the specimens with each force cycle of 12 s (6 s/6 s). The classical mechanics relation between force and deection E [ L 3 /(4bh 3 )][ DF /( D fwood 0 D fadhesive )] allows the calculation of the Youngs modulus E for each of the cases tested. As the deections D f obtained were proven to be constant and reproducible 12,13 and as they are proportional to the exibility of the assembly, the relative exibility as expressed by the Youngs modulus of the two primers can be calculated for the

two nishes through the relationship E1 / E2 D f2 / D f1 . The values of m , E , and a for the resins presented in Table I were then calculated according to already reported methods according to the phenomenological equation f km / aE and connected regression equations which have already been reported.11 13 In Table I are reported the values of m obtained from this analysis for systems in which further reactions on the phenolic ring other than the formaldehyde and methylol group attack have been demonstrated, or are suspected. They present a value of Florys a both of 0.5 (phenol trifunctional) and of 0.33 (phenol nuclei tetrafunctional), while systems, such the control PF resin alone, for which further attack on the ring does not appear to occur, are reported for only values of a 0.5.

DISCUSSION

The results in Table I indicate that equimolar amounts of different additives added to the same phenolic resin give a different average number of degrees of freedom m of the hardened network of the PF resin. This means that the average densities of crosslinking of the nal networks produced are different for different accelerating additives, indicating that different mechanisms of hardening acceleration of the PF resin appear to be at work. The rst important difference is the difference between the value of m of the PF resin to which additives have not been added in relation to the values of m of all the additive added resins.

8EAA

/ 8eaa$$4501

08-05-97 17:17:14

polaas

W: Poly Applied

4501

258

PIZZI, GARCIA, AND WANG

Figure 1 Comparative increase of relative moduli as a function of temperature of TMA joints bonded with the same PF resin alone and accelerated with equivalent molar percentages of sodium carbonate and propylene carbonate.

It is not the advancement of the resin or the rate of its curing in nonisothermal experiments which determines its density of crosslinking: Whatever variation of the pH was introduced in the control resin, better crosslinking and a lower variation of m than what is presented in Table I could not be achieved; the value presented in Table I is the lowest achieved. This is an indication that most of the additives do not just accelerate the hardening of the resin but participate in some way in the crosslinking of it. The second difference of interest is that sodium carbonate and propylene carbonate present a very different behavior. While sodium carbonate behaves mostly as a pure accelerator, this is not the case for propylene carbonate. Thus, in Figure 1, the trend in the elastic modulus curves of the PF resin alone and of the PF resin added of equivalent carbonic acid amounts by the addition of sodium and propylene carbonate is shown. Sodium carbonate imparts to the PF elastic modulus curve exactly the same trend as does the PF control case (the two curves are parallel) but with the acceler-

ator-added curve shifted to lower temperatures hence, earlier reaction times and a lower gel time temperature. Thus, sodium carbonate behaves as a true accelerator of PF hardening. The trend in the propylene carbonate elastic modulus curve obtained by thermomechanical analysis (TMA) instead shows (i) at rst a faster increase followed by a slower increase than that the sodium carbonate case (Fig. 1), while still presenting a value of the gel temperature more similar to that of the PF resin alone than what was obtained with sodium carbonate, a gel point which might then be obtained in a different manner. (ii) Second, after the initial part of the curve, a second stage of the modulus increase curve appears to lead to a much tighter crosslinked network than in the case of sodium carbonate. This indicates that some important difference between the type of action of the two accelerators exists: Sodium carbonate, in the main, does not appear to increase the crosslinking of the resin but just accelerates it, while propylene carbonate might well present both a similar accelerating mechanism, although clearly to a different extent, as well as being an active part of the process of crosslinking. If this was really due only to the accelerating in0 uence of the HCO 3 ion as has been advocated 4,5 (a mechanism for which no evidence has been presented), then the curves of the two materials would be coincident, and they are not. In this regard, it is interesting to note that even when it 0 was tried to demonstrate that exclusively HCO3 induced acceleration exists, it was found otherwise, and as a consequence, 5 the experimental data had to be overcorrected based on unrealistic pH effects (see Fig. 2). What was observed for the modulus curves is conrmed by macroscopic gel time tests at 100C shown in Table II, from which it is clear that sodium carbonate is a better accelerator at lower proportions of addition, but that at a higher proportion of additions where a structural rather than a catalysis effect is likely to be predominant, propylene carbonate becomes by far the better accelerator. Further proof of complex reactions between propylene carbonate and phenolic nuclei leading to compounds in which the carbonic acid has attacked the phenolic is shown in Figure 3(a) and (b). In Figure 3(a) is shown the 13C-NMR spectrum of the product of the reaction of resorcinol (a stronger nucleophile than phenol for which such a reaction would be more easily observed) with propylene carbonate, in the absence of formalde-

8EAA

/ 8eaa$$4501

08-05-97 17:17:14

polaas

W: Poly Applied

4501

PHENOLFORMALDEHYDE POLYCONDENSATES

259

Figure 2 Variation of pH as a function of time at 50C of a PF resin to which were added different percentages of sodium carbonate.

hyde. The NMR spectrum of resorcinol alone before the reaction is shown in Figure 3(b). In Figure 3(a), the major peaks of the pattern shown are those of resorcinol unreacted, namely, its C1 and C3 at 160.70 ppm, C5 at 133 ppm, C4 and C6 at 109.91 ppm, and C2 at 106 ppm and of the propylene glycol, namely, {CH2{OH at 70.54 u ppm, of of CH{OH at 69.22 ppm, and of {CH3 U at 20.60 ppm. On this major, expected pattern, the very clear second pattern of peaks of the reaction product is clearly visible: Hence, peaks at 178.61, 169.54, 164.55, 134.49, 112.40, and 110.36 ppm. In Table III are given the assignments expected and found for the two best-tting and, hence, most probable compounds formed and represented by this pattern of peaks. From Table III, it is clear that the reaction products are the following:

Table II Gel Times in Minutes of PF Resin Alone and Accelerated by Na2CO3 and by Propylene Carbonate Additive on PF Resin Solids 0% PF alone PF / Na2CO3 PF / propylene carbonate 40.33 40.33 40.33 5% 13.55 24.22 10% 12.35 22.70 20% 12.63 6.63

More interesting still is that while CO | 3 might exist superimposed on the 169.54 ppm peak of the {COOH, although the relative intensities of the signals at 169.54 ppm and at 178.61 ppm ({ COO 0 ) in relation to the two signals at 110.36 and 112.48 ppm indicate that even CO | 3 might be completely absent, there is no trace of either 0 HCO 3 (which has obviously precipitated out of solution as NaHCO3 [Ref. 5]) or of any other carbonic acid and carbon dioxide (which should appear at {128 ppm [Ref. 17]) species. The possibility of the product peaks pattern belonging to a dicarboxylic acid species, thus a resorcinol nuclei carrying two vicinal carboxilic acid groups, namely, on C5 and C6, was also considered. However, only two of the six expected shifts of the six carbon atoms of the resorcinol ring match the shifts which could be expected with this species, and, thus, this species is clearly not present. The idea that a dicarboxylic species might be present was derived by the fact that the carboxyl carbons of an aromatic anhydride would give a signal between 163 and 165 ppm (Ref. 17) (i.e., phthalic anhydride carboxyls appear at 163.1 ppm) and

8EAA

/ 8eaa$$4501

08-05-97 17:17:14

polaas

W: Poly Applied

4501

260

PIZZI, GARCIA, AND WANG

Figure 3 Liquid-phase 13C-NMR of (a) the reaction mix of resorcinol and propylene carbonate in the absence of formaldehyde and (b) of resorcinol alone.

8EAA

/ 8eaa$$4501

08-05-97 17:17:14

polaas

W: Poly Applied

4501

PHENOLFORMALDEHYDE POLYCONDENSATES

261

Table III Expected and Experimentally Found Deviations Deviations from Resorcinol Carbon Shifts in ppm for the Compound Obtained by Reaction of Resorcinol with Propylene Carbonate [Fig. 3(a)]

Compound I Expected (ppm) C1 C2 C3 C4 C5 C6 C|O ({COOH) C|O ({COO0) C|O (anhydride) 00.3 /5.2 00.3 /1.6 /2.1 /1.6 172.6 177.6 Found (ppm) 0.0 /4.9 0.0 /2.5 /1.9 /2.5 169.5 178.6

Compound II Expected (ppm) /1.6 0.0 /5.2 0.0 /1.6 /2.1 172.6 177.6 Found (ppm) /4.6 0.0 /4.9 0.0 /1.7 /2.2 169.5 178.6

Anhydride Expected (ppm) 00.3 /5.2 00.3 /1.6 /2.1 /1.6 163165 Found (ppm) 0.0 /4.9 0.0 /2.5 /1.9 /2.5 164.6

that a clear signal at 164.55 ppm exists, this signal having been interpreted above as the only clear nonmixed peak indicating the existence of compound II. An aromatic anhydride, however, does not need to be a cyclic anhydride. A perfect match of the shifts reported is attained for a compound of the type

thus, an aromatic noncyclic anhydride. Hence, what appears to be present in the supernatant solution, and not in the mostly sodium hydrogen carbonate precipitate, 5 is a mixture of compounds I and II as already indicated above or a mixture of compound I of its carboxylate ion and of the above anhydride. The second possibility appears to be the most likely due to the better t between expected and found peak shifts and patterns as shown in Table III. This also means that a link between phenolic nuclei, other than a methylene bridge, can be formed. Just a few of these addi-

tional crosslinks in a polymeric resin, even for a short, transient period of time if they are unstable, and even in lower proportion than for resorcinol (as is likely to be the case for phenol which is less reactive), are enough to increase the average functionality 18,19 of a polymeric PF resin system. Formaldehyde should not be in such an excess, so that a considerable amount of ortho and para sites is still available (for steric reasons, the more crowded a resin is on these sites, the more hindrance would exist to limit reaction on a meta site, too). The characteristic and very unusual aspect of an attack on the meta site has been remarked on and reported before.2 It is also clear that if the anhydride exists it might decompose at a higher temperature curing, with what type of further reactions it is not possible to say with the data available. The same accelerating mechanism based on the hydrogen-bonding-based intermediate activated complexes ascribed to hydrogen carbonate ions was also ascribed to formamide.4 Weaker acid carboxylic amides do not show any accelerating effect.4 However, at least one amide which does not really present the structure advocated for the same intermediate to be formed, namely, urea, the diamide of carbonic acid, is well known to ac-

8EAA

/ 8eaa$$4501

08-05-97 17:17:14

polaas

W: Poly Applied

4501

262

PIZZI, GARCIA, AND WANG

celerate PF hardening under an alkaline environment 8,9 and well known to accelerate it by a completely different mechanism8,9 than the one proposed.4 The amidic groups of urea react readily under an alkaline environment with two and three methylol groups of PF resins 8,9 to form ureato-phenol methylene bridges. In Table I are then presented the values of m for a formamide-accelerated PF resin and for a PF resin to which methylamine has been added. Methylamine has a completely different structure than that of formamide and cannot form the intermediate activated complexes advocated for the proposed acceleration mechanism by formamide. It has, however, a reactive {NH2 group which could accelerate the hardening of a PF resin by simultaneously reacting with two methylol groups of the PF resin, a mechanism similar to that of urea. It was chosen instead of urea to avoid any controversy which could arise in the case of the latter due to the presence of two reactive amidic groups. If the hydrogen-bond-induced intermediate activated complex mechanism4 is valid, the value of

m for formamide should be, at most, identical to that of the PF resin alone and not in anyway lower. If the mechanism by {NH2 group reaction with the PF resin hydroxybenzyl alcohol groups is instead valid, 8,9 then formamide should give a much lower value of m hence, a much tighter hardened network than that of the phenolic resin alone, and methylamine which can only present this latter mechanism should give a result of m comparable to that obtained with formamide. The results in Table I for the PF resin alone, formamide, and methyl urea show clearly that it is the latter mechanism which causes the hardening acceleration. Conrmation of the difference in the mechanism can be gathered by the liquid 13CNMR of the reaction of a solution of resorcinol with formamide at 60C for 2 h (Fig. 4) and the solid-phase CP-MAS 13C-NMR of the reaction product of a PF resol with formamide (Fig. 5). In the rst one, superimposed on the formamide (169.44 ppm) and resorcinol (164.22, 164.16, 133.23, 133.12, 109.89, and 108.20 ppm) patterns is also a peak at 173.95 ppm that appears to repre-

Figure 4 Liquid-phase 13C-NMR of the reaction mix of resorcinol and formamide in the absence of formaldehyde.

8EAA

/ 8eaa$$4501

08-05-97 17:17:14

polaas

W: Poly Applied

4501

PHENOLFORMALDEHYDE POLYCONDENSATES

263

Figure 5 Solid-state CP-MAS 13C-NMR of the hardened PF resin accelerated with formamide (* spinning side bands).

sent the carboxylate ion of formic acid HCOO 0 , the latter being approximately three times the size of the C|O peak of undissociated formamide and indicating that formamide undergoes considerable dissociation into formic acid and ammonia under the conditions characteristic of a wood adhesive. The hydrolysis of amides in both acid and alkaline environments is a well-known reaction and it is more marked the greater is the acidity of the carboxylic acid constituting the amide.20 The mechanism of acceleration suggested by formamide hydrolysis is then that of a rapid hydrolysis of the amide to formic acid and ammonia followed by the rapid and simultaneous reaction of two or even three phenolic methylol groups with the ammonia itselfhence:

This mechanism indicates that the slightly tighter hardened PF network obtained with formamide in relation to what was obtained with methylamine is possibly only due to the presence of some tribenzylamine bridges of which methylamine is not capable. The rapid reaction of the {NH2 of formamide with methylol groups before its partial hydrolysis cannot, however, be excluded and is also quite likely. The solid-phase CP-MAS 13C-NMR spectrum in Figure 5 appears to conrm the above. In this are clearly visible the small peaks pertaining to the carbonyl group of undissociated formamide ( 167 ppm) 17 and of the carboxylic group of undissociated formic acid ( 166 ppm) 17 as well as the clear peaks at 63 and 71 ppm ( these last two belonging one to o,o- and p,p -methylenes and one to {CH2{NH{CH2{) and at 117.5 ppm (ArC{CH2{NH{) on top of the normal pattern of a hardened resorcinol formaldehyde resin, namely, peaks at 154 ppm (ArC{OH), at 131 ppm (ArC{H and ArC{CH2{), and 36 ppm ({ CH2{) bands. Solid-phase CP-MAS 13C-NMR spectra of a phenolresorcinolformaldehyde

8EAA

/ 8eaa$$4501

08-05-97 17:17:14

polaas

W: Poly Applied

4501

264

PIZZI, GARCIA, AND WANG

Figure 6 Solid-state CP-MAS 13C-NMR of a PRF resin hardened at ambient temperature by addition of 10% paraformaldehyde and accelerated by addition of 10% by weight 30% ammonia solution in water (* spinning side bands).

(PRF) resin hardened by addition of formaldehyde only and by addition of formaldehyde / a high amount of ammonia (Figs. 6 and 7) show the appearance in Figure 6 of the strong band at 105 ppm (characteristic of aromatic carbons linked to benzylamine bridges, but in Figure 5 obscured by a spinning side band due to the small amount of formamide used) and also the presence

of the 71 ppm band ({ CH2{NH{CH2{) which does not appear in the resin hardened without ammonia, conrming the above mechanism of acceleration pertaining to formamide. Gel times of PF and RF resins accelerated with formamide and with ammonia also show that ammonia gives faster gel times but of the same order of magnitude as formamide.21

Figure 7 Solid-state CP-MAS 13C-NMR of a PRF resin hardened at ambient temperature by addition of 10% paraformaldehyde (* spinning side bands).

8EAA

/ 8eaa$$4501

08-05-97 17:17:14

polaas

W: Poly Applied

4501

PHENOLFORMALDEHYDE POLYCONDENSATES

265

Compounds based on a reasonably strong carboxylic acid like formic acid, such as methyl formate and formamide, are very likely to give this type of reaction and additional crosslinking, too. Methyl formate is known to be the faster accelerator after propylene carbonate, 2,3,22 while the results for formamide in Table I clearly indicate that for formamide additional crosslinking is present. Thus, formamide participates in the reaction by both crosslinking with the methylol groups of the PF resin through its {NH2 groups. All the above is nothing that could not have been foreseen by classical organic chemistry knowledge: Nucleophilic acyl substitution reactions of carboxylic acid esters, amides, anhydrides, and chlorides are one of the most fundamental and well-known reactions of these compounds.23,24 Once the nature of the accelerating mechanism induced by increased crosslinking and its existence through the determination of the number of degrees of freedom m of the PF networks formed is dened, it would be necessary to address the nature of the rst accelerating mechanism which appears to be common to both sodium carbonate and propylene carbonate. Only speculation is possible: The mechanism involved could be one of the two proposed up to now, namely, the hydrogen carbonate ion intermediate activated complex mechanism, 4 proposed without any evidence and for which direct evidence would be rather difcult to gather, and the mechanism25,26 based on rapid transesterication reactions of the hydroxybenzyl alcohol group of a PF resol. This latter mechanism is based on the easily occurring transesterication of propylene carbonate with methanol through which dimethyl carbonate is rapidly obtained 25,26 and suggests that dibenzyl carbonate bridges are initially formed between phenolic nuclei which are eventually transformed to dimethylene ether bridges by the loss of CO2 . In this regard, other reactive materials which will readily undergo transesterication analogous to that of propylene carbonate with methanol are trialkyl borates, tetraalkyl titanates, and trialkyl phosphites in an alkaline environment: Gas injection of methyl borate (and carbon dioxide) has been found to enhance as well the results of wood composites bonded with formaldehyde-based resins, 27 just as the addition of propylene carbonate and glycerol triacetate have been shown to do in wood composites bonded with phenolic resins.3 With the data presented in this article, it is not possible to distinguish which one of the two mechanisms is the

one which is valid or even if other mechanisms could be possible. In conclusion, additive accelerated PF resin polycondensations appear to present several different acceleration mechanisms. Some additives such as sodium carbonate appear to present purely an accelerating effect on the polycondensation reaction. Other additives such as propylene carbonate present both an acceleration effect as well as inducing an increase in the average functionality of the system, due to alternate crosslinking reactions to which the accelerator itself does participate, leading to a tighter nal network. These alternate crosslinking reactions can be of a different nature, such as in the propylene carbonate case, in which the reaction is related to a KolbeSchmitt reaction, and the rapid reaction of {NH2 groups of formamide and of the ammonia obtained by its alkaline hydrolysis with two, or more (for ammonia) hydroxybenzyl alcohol groups of PF resols, which is also characteristic of urea and methylamine.

REFERENCES

1. A. Pizzi, Wood Adhesives Chemistry and Technology, Marcel Dekker, New York, 1983, Vol. 1. 2. A. Pizzi and A. Stephanou, J. Appl. Polym. Sci., 49, 2157 (1993). 3. A. Pizzi and A. Stephanou, Holzforschung, 48 (2), 150 (1994). 4. M. Higuchi, S. Tohmura, and I. Sakata, Mokuzai Gakkaishi, 40 (6), 604 ( 1994). 5. S. Tohmura and M. Higuchi, Mokuzai Gakkaishi, 41 (12), 1109 (1995). 6. A. Pizzi, B. Mtsweni, and W. Parsons, J. Appl. Polym. Sci., 52, 1847 (1994). 7. A. Pizzi and A. Stephanou, J. Appl. Polym. Sci., 51, 1351 (1994). 8. A. Pizzi, A. Stephanou, I. Antunes, and G. De Beer, J. Appl. Polym. Sci., 50, 2201 (1993). 9. M. Ohyama, B. Tomita, and C.-Y. Hse, Holzforschung, 49, 87 (1995). 10. N. J. L. Megson, Phenolic Resin Chemistry, Butterworth, London, 1958. 11. F. Probst, M.-P. Laborie, A. Pizzi, A. Merlin, and X. Deglise, Holzforschung, to appear. 12. A. Pizzi, J. Appl. Polym. Sci., 63, 603 (1997). 13. A. Pizzi, F. Probst, and X. Deglise, J. Adhes. Sci. Technol., 11, 573 (1997). 14. C. Cremonini and A. Pizzi, Holzforsch. Holzverwert., 49, 11 (1997). 15. R. Garcia, PhD Thesis, University of Nancy 1, Nancy, France, 1997.

8EAA

/ 8eaa$$4501

08-05-97 17:17:14

polaas

W: Poly Applied

4501

266

PIZZI, GARCIA, AND WANG

16. E. Breitmaier and W. Voelter, Carbon-13 NMR Spectroscopy, 3rd ed., VCH, Weinheim, 1987. 17. E. Pretsch, T. Clerc, J. Seibl, and W. Simon, Tables of Spectral Data for Structure Determination of Organic Compounds, 2nd ed., Springer-Verlag, Berlin, 1989. 18. W. H. Carrothers, Collected Papers, Wiley-Interscience, New York, 1940. 19. F. Rodriguez, Principles of Polymer Systems, 3rd ed., Hemisphere, New York, 1989. 20. J. McMurry, Organic Chemistry, 3rd ed., Brooks/ Cole, Pacic Grove, CA, 1992, p. 822. 21. S. Wang, unpublished results, 1996.

22. P. H. R. B. Lemon, Int. J. Mater. Prod. Technol., 5 (1), 25 ( 1990). 23. J. McMurry, Organic Chemistry, 3rd ed., Brooks/ Cole, Pacic Grove, CA, 1992, pp. 701702. 24. P. Sykes, A Guidebook to Mechanism in Organic Chemistry, Longmans, London, 1963, pp. 203204. 25. A. Knop and L. A. Pilato, Phenolic Resins, Springer-Verlag, Berlin, 1985. 26. L. A. Pilato, private communication, 1994. 27. R. L. Geimer, A. Leao, D. Ambruster, and A. Pablo, in Proceedings of the 28th International Particleboard Symposium, Washington State University, Pullman, 1994, pp. 243259.

8EAA

/ 8eaa$$4501

08-05-97 17:17:14

polaas

W: Poly Applied

4501

You might also like

- Effect of Methacrylate Co-Agents On Peroxide Cured PP Epdm Thermoplastic VulcanizatesDocument17 pagesEffect of Methacrylate Co-Agents On Peroxide Cured PP Epdm Thermoplastic VulcanizatesFairmont Ind Quality DivisionNo ratings yet

- SPEEK membrane dimensional swelling reduction via blending fully aromatic polyamideDocument8 pagesSPEEK membrane dimensional swelling reduction via blending fully aromatic polyamideMuhamad Adnan RinaldiNo ratings yet

- Effect of F P and OH P Molar Ratios and Condensation Viscosity On The Structure of Phenol Formaldehyde Resol Resins For Overlays A Statistical StudyDocument7 pagesEffect of F P and OH P Molar Ratios and Condensation Viscosity On The Structure of Phenol Formaldehyde Resol Resins For Overlays A Statistical StudyRobert RicardoNo ratings yet

- Polymers 11 01855Document15 pagesPolymers 11 01855Abdalrzag EmhemmedNo ratings yet

- Ribeiro Et Al-2013-Journal of Applied Polymer ScienceDocument13 pagesRibeiro Et Al-2013-Journal of Applied Polymer ScienceDiana BejaranoNo ratings yet

- Melamine Formaldehyde: Curing Studies and Reaction MechanismDocument7 pagesMelamine Formaldehyde: Curing Studies and Reaction MechanismHanna MalikNo ratings yet

- Ultrasonic and S Pectroscopic Study of Polychloroprene and Pmma BlendsDocument40 pagesUltrasonic and S Pectroscopic Study of Polychloroprene and Pmma Blendsswapnil kaleNo ratings yet

- Adv 20203Document9 pagesAdv 20203Aju ChirakkalNo ratings yet

- Siimer2003 Article ThermalBehaviourOfUrea-formaldDocument11 pagesSiimer2003 Article ThermalBehaviourOfUrea-formaldMarcus WongNo ratings yet

- Peroxide Crosslinking of PVC Foam FormulationsDocument7 pagesPeroxide Crosslinking of PVC Foam FormulationsSantiago RodriguesNo ratings yet

- Temperature Dependent Interaction Parameters of Poly (Methyl Methacrylate) Poly (2 Vinyl Pyridine) and Poly (Methyl Methacrylate) Poly (4 Vinyl Pyridine) Pairs 2009 Reactive and Functional PolymersDocument5 pagesTemperature Dependent Interaction Parameters of Poly (Methyl Methacrylate) Poly (2 Vinyl Pyridine) and Poly (Methyl Methacrylate) Poly (4 Vinyl Pyridine) Pairs 2009 Reactive and Functional PolymersAtul ChaudhariNo ratings yet

- Poly (Vinyl Methyl Ether) Poly (Methyl Methacrylate) Blends Using Diblock CopolymerDocument5 pagesPoly (Vinyl Methyl Ether) Poly (Methyl Methacrylate) Blends Using Diblock Copolymerfadhillah ivanNo ratings yet

- Melamine Formaldehyde: Curing Studies and Reaction MechanismDocument8 pagesMelamine Formaldehyde: Curing Studies and Reaction Mechanismfazil putraNo ratings yet

- Structure and Curing Mechanism of Resol Phenol-Formaldehyde Prepolymer ResinsDocument8 pagesStructure and Curing Mechanism of Resol Phenol-Formaldehyde Prepolymer Resinsmahdavian76No ratings yet

- He Et Al-2003-Macromolecular Rapid CommunicationsDocument4 pagesHe Et Al-2003-Macromolecular Rapid CommunicationsFelipe Vázquez DávilaNo ratings yet

- Progress in The Understanding of Tyramine Electropolymerisation MechanismDocument11 pagesProgress in The Understanding of Tyramine Electropolymerisation MechanismSarim DastgirNo ratings yet

- 10.1002@app.48267Document7 pages10.1002@app.48267Suvee VashuNo ratings yet

- Effects of Chain Conformation on Miscibility and Mechanical Properties in Polymer BlendsDocument10 pagesEffects of Chain Conformation on Miscibility and Mechanical Properties in Polymer BlendsNorafiqah Ismail100% (1)

- Pani Pmma NanoDocument4 pagesPani Pmma NanoRanjana SinghNo ratings yet

- NIH Public Access: Author ManuscriptDocument9 pagesNIH Public Access: Author ManuscriptSyedFaridAliNo ratings yet

- Phase behavior and mechanical properties of heterophasic polypropylene–ethylene/propylene copolymers systemsDocument7 pagesPhase behavior and mechanical properties of heterophasic polypropylene–ethylene/propylene copolymers systemsJade Dhalle EncarnacionNo ratings yet

- Melamine Formaldehyde Curing Studies andDocument7 pagesMelamine Formaldehyde Curing Studies andtahera aqeelNo ratings yet

- Maleic Anhydride Grafting of Polypropylene: Peroxide and Solvent EffectsDocument8 pagesMaleic Anhydride Grafting of Polypropylene: Peroxide and Solvent EffectsShella Putri RahayuNo ratings yet

- 10 1023@a@1011895000500 PDFDocument5 pages10 1023@a@1011895000500 PDFShraddha WNo ratings yet

- Materials Science and Engineering ADocument10 pagesMaterials Science and Engineering ARushyanth KRNo ratings yet

- PSSA519Document13 pagesPSSA519nadjet polyNo ratings yet

- The S T U D Y of The Copolymerization of Styrene A N D Acrylonitrile To High Conversion. Application of Low Conversion Reactivity RatiosDocument8 pagesThe S T U D Y of The Copolymerization of Styrene A N D Acrylonitrile To High Conversion. Application of Low Conversion Reactivity RatiosPhilip ShihNo ratings yet

- Catalysis Communications: Guangyong Xie, Gongyi Liu, Long Li, Tingcheng Li, Aiqing Zhang, Jiwen FengDocument4 pagesCatalysis Communications: Guangyong Xie, Gongyi Liu, Long Li, Tingcheng Li, Aiqing Zhang, Jiwen FengyukathejiNo ratings yet

- Polypropylene/Clay Nanocomposites: Combined Effects of Clay Treatment and Compatibilizer Polymers On The Structure and PropertiesDocument11 pagesPolypropylene/Clay Nanocomposites: Combined Effects of Clay Treatment and Compatibilizer Polymers On The Structure and PropertiesDini Hariyati AdamNo ratings yet

- 10.3933_applrheol-26-33503Document7 pages10.3933_applrheol-26-33503kls.thorodinsonNo ratings yet

- UV Radiation Filter Using Phenyl Salicylate-Sepiolite SystemsDocument8 pagesUV Radiation Filter Using Phenyl Salicylate-Sepiolite SystemsHERNANDEZ1010No ratings yet

- Degradation and Thermal Properties of in Situ Compatibilized PS-POE Blends - FAZER AQUIDocument7 pagesDegradation and Thermal Properties of in Situ Compatibilized PS-POE Blends - FAZER AQUIInorfTIVE Reciclagem TecnológicaNo ratings yet

- PMMA Nanofibres Using Different SolventsDocument7 pagesPMMA Nanofibres Using Different SolventsvetrixNo ratings yet

- Effects of The Composition of Hot-Melt Adhesives On Their Bulk and Interfacial PropertiesDocument7 pagesEffects of The Composition of Hot-Melt Adhesives On Their Bulk and Interfacial PropertieskübraNo ratings yet

- PETPP Blending by Using PP-g-MA Synthesized by SolDocument9 pagesPETPP Blending by Using PP-g-MA Synthesized by SolAman EmaanNo ratings yet

- 2008 Synthesis, Characterization, and Photovoltaic Properties of Novel Semiconducting Polymers WithDocument8 pages2008 Synthesis, Characterization, and Photovoltaic Properties of Novel Semiconducting Polymers WithDoktor transmisionesNo ratings yet

- Wang Et Al-2007-Polymer InternationalDocument8 pagesWang Et Al-2007-Polymer InternationalLong LeNo ratings yet

- Synthesis and Solubilities of 3 9 Dipyrolidino 2 4 8 10 Tetraoxa 3 9 Diphosphaspiro 5 5 Undecane 3 9 Dioxide in Selected SolventsDocument7 pagesSynthesis and Solubilities of 3 9 Dipyrolidino 2 4 8 10 Tetraoxa 3 9 Diphosphaspiro 5 5 Undecane 3 9 Dioxide in Selected SolventsoksanaNo ratings yet

- Characterization of Phenol-Formaldehyde Prepolymer Resins by in Line FT-IR SpectrosDocument7 pagesCharacterization of Phenol-Formaldehyde Prepolymer Resins by in Line FT-IR SpectroskkkkNo ratings yet

- Informacio ArticleDocument17 pagesInformacio ArticleAdrian Villa GabarronNo ratings yet

- Effect of EPDM As A Compatibilizer On Mechanical Properties and Morphology of PP/LDPE BlendsDocument13 pagesEffect of EPDM As A Compatibilizer On Mechanical Properties and Morphology of PP/LDPE BlendsOumaima BenNo ratings yet

- Effects of Argon and Oxygen Plasmas on Polysulfone Membrane SurfaceDocument5 pagesEffects of Argon and Oxygen Plasmas on Polysulfone Membrane SurfaceSupaporn YuenyaoNo ratings yet

- Sattar 2015Document12 pagesSattar 2015Amina AshrafNo ratings yet

- The energy storage and reuse have attracted considerable attention in recent years because of the energy crisisDocument6 pagesThe energy storage and reuse have attracted considerable attention in recent years because of the energy crisisawchemicals19No ratings yet

- Tpu PC PDFDocument15 pagesTpu PC PDFmohammad norooziNo ratings yet

- Changes in Thermodynamic Interactions at Highly Immiscible Polymer/Polymer Interfaces Due To Deuterium LabelingDocument4 pagesChanges in Thermodynamic Interactions at Highly Immiscible Polymer/Polymer Interfaces Due To Deuterium LabelingAtul ChaudhariNo ratings yet

- Study On Preparation and Properties of Silane-Crosslinked Polyethylene/ Magnesium Hydroxide/ Montmorillonite NanocompositesDocument15 pagesStudy On Preparation and Properties of Silane-Crosslinked Polyethylene/ Magnesium Hydroxide/ Montmorillonite NanocompositesAmirhosein FazilatiNo ratings yet

- ELSEVIER 1998 PPy CompositeDocument13 pagesELSEVIER 1998 PPy CompositeWilliam VianaNo ratings yet

- Thermo-Mechanical Chain Branching of Commercial High Density Polyethylene During ExtrusionDocument9 pagesThermo-Mechanical Chain Branching of Commercial High Density Polyethylene During ExtrusionRimaz RameezNo ratings yet

- Synthesis of Amphiphilic Graphene NanoplateletsDocument4 pagesSynthesis of Amphiphilic Graphene NanoplateletsovyttNo ratings yet

- Phosphazene PublicationDocument6 pagesPhosphazene Publicationanon_963545076No ratings yet

- Kinetics of Polyesterification: Modelling and Simulation of Unsaturated Polyester Synthesis Involving 2-Methyl-1,3-PropanediolDocument7 pagesKinetics of Polyesterification: Modelling and Simulation of Unsaturated Polyester Synthesis Involving 2-Methyl-1,3-PropanediolMamoon ShahidNo ratings yet

- Blends of Poly (Ethylene Terephthalate) /polycarbonate by The Use of Lanthanum Acetyl Acetonate CatalystDocument7 pagesBlends of Poly (Ethylene Terephthalate) /polycarbonate by The Use of Lanthanum Acetyl Acetonate CatalystWellington C. de AraujoNo ratings yet

- Grafting of Maleic Anhydride On Polypropylene by Reactive Extrusion - Effect of Maleic Anhydride and Peroxide Concentrations On Reaction Yield and Product CharacteristicsDocument10 pagesGrafting of Maleic Anhydride On Polypropylene by Reactive Extrusion - Effect of Maleic Anhydride and Peroxide Concentrations On Reaction Yield and Product CharacteristicsShella Putri RahayuNo ratings yet

- Blends of Polyethylene TerephthalatepolycarbonateDocument7 pagesBlends of Polyethylene TerephthalatepolycarbonateArt Jun NaolNo ratings yet

- Jps 03 41 1677 AcarDocument4 pagesJps 03 41 1677 AcarMerry PaembonanNo ratings yet

- Clivaje FmocDocument12 pagesClivaje FmocAna Maria Barrera DiazNo ratings yet

- Experimental Methods and Results from Self-Assembled DNA TilesDocument10 pagesExperimental Methods and Results from Self-Assembled DNA TilesMahirami PadronNo ratings yet

- Modified Polymers, Their Preparation and Properties: Main Lectures Presented at the Fourth Bratislava Conference on Polymers, Bratislava, Czechoslovakia, 1-4 July 1975From EverandModified Polymers, Their Preparation and Properties: Main Lectures Presented at the Fourth Bratislava Conference on Polymers, Bratislava, Czechoslovakia, 1-4 July 1975A. RomanovRating: 5 out of 5 stars5/5 (1)

- Chemesthesis: Chemical Touch in Food and EatingFrom EverandChemesthesis: Chemical Touch in Food and EatingShane T. McDonaldNo ratings yet

- A 269 - 00 - Qti2os0wma - PDFDocument5 pagesA 269 - 00 - Qti2os0wma - PDFJose Oliveros ArdilaNo ratings yet

- A 249 - A 249M - 03 Qti0os9bmjq5ts1sruq - PDFDocument11 pagesA 249 - A 249M - 03 Qti0os9bmjq5ts1sruq - PDFMan98No ratings yet

- A 270 - 03 - Qti3mc0wmwDocument5 pagesA 270 - 03 - Qti3mc0wmwehsanNo ratings yet

- A 269 - 04 Qti2oqDocument6 pagesA 269 - 04 Qti2oqfekihassan100% (1)

- A 250 - A 250M - 95 R01 Qti1mc9bmjuwts1sruq - PDFDocument7 pagesA 250 - A 250M - 95 R01 Qti1mc9bmjuwts1sruq - PDFMan98No ratings yet

- Astm A0213 - 1 (En) PDFDocument13 pagesAstm A0213 - 1 (En) PDFRahul SamalaNo ratings yet

- A 254 - 97 R02 Qti1na - PDFDocument4 pagesA 254 - 97 R02 Qti1na - PDFMan98No ratings yet

- A 270 - 01 Qti3mc0wmq - PDFDocument5 pagesA 270 - 01 Qti3mc0wmq - PDFsingaravelan narayanasamyNo ratings yet

- A 268 - A 268M - 03 Qti2oc0wmw - PDFDocument6 pagesA 268 - A 268M - 03 Qti2oc0wmw - PDFMan98No ratings yet

- A 234 - A 234M - 04 Qtiznc9bmjm0tq - PDFDocument8 pagesA 234 - A 234M - 04 Qtiznc9bmjm0tq - PDFLuis Daniel ContrerasNo ratings yet

- A 254 - 97Document4 pagesA 254 - 97Maicol K. Huamán TitoNo ratings yet

- A 249 - A 249M - 01 Qti0os0wmq - PDFDocument8 pagesA 249 - A 249M - 01 Qti0os0wmq - PDFMan98No ratings yet

- A 53 - A 53m - 00 QtuzltawDocument7 pagesA 53 - A 53m - 00 QtuzltawPablo CzNo ratings yet

- A 268 - A 268M - 01 Qti2oc0wmq - PDFDocument6 pagesA 268 - A 268M - 01 Qti2oc0wmq - PDFMan98No ratings yet

- A 234 - A 234M - 01 Qtiznc0wmq - PDFDocument8 pagesA 234 - A 234M - 01 Qtiznc0wmq - PDFLuis Daniel ContrerasNo ratings yet

- A 249 - A 249M - 04 Qti0os9bmjq5tq - PDFDocument10 pagesA 249 - A 249M - 04 Qti0os9bmjq5tq - PDFMan98No ratings yet

- A 234 - A 234M - 03 Qtiznc9bmjm0ts1sruq - PDFDocument10 pagesA 234 - A 234M - 03 Qtiznc9bmjm0ts1sruq - PDFLuis Daniel ContrerasNo ratings yet

- A 250 - A 250M - 95 Qti1mc05nq - PDFDocument4 pagesA 250 - A 250M - 95 Qti1mc05nq - PDFMan98No ratings yet

- A 214 - A 214M - 96 Qtixnc05ng - PDFDocument2 pagesA 214 - A 214M - 96 Qtixnc05ng - PDFMan98No ratings yet

- A 249 - A 249M - 98 Qti0os05oeux PDFDocument7 pagesA 249 - A 249M - 98 Qti0os05oeux PDFMan98No ratings yet

- A 250 - A 250M - 04 Qti1mc9bmjuwtq - PDFDocument4 pagesA 250 - A 250M - 04 Qti1mc9bmjuwtq - PDFMan98No ratings yet

- A 250 - A 250M - 95 R01 Qti1mc05nviwmq - PDFDocument4 pagesA 250 - A 250M - 95 R01 Qti1mc05nviwmq - PDFMan98No ratings yet

- A 213 - A 213M - 03 Qtixmy0wmw - PDFDocument10 pagesA 213 - A 213M - 03 Qtixmy0wmw - PDFMan98No ratings yet

- A 249 - A 249M - 03 Qti0os0wmw - PDFDocument9 pagesA 249 - A 249M - 03 Qti0os0wmw - PDFMan98No ratings yet

- A 234 - A 234M - 00 Qtiznc0wma - PDFDocument8 pagesA 234 - A 234M - 00 Qtiznc0wma - PDFCherie JohnsonNo ratings yet

- A 234 - A 234M - 00 Qtiznc0wmee - PDFDocument8 pagesA 234 - A 234M - 00 Qtiznc0wmee - PDFLuis Daniel ContrerasNo ratings yet

- A 213 - A 213M - 03 Qtixmy0wm0i - PDFDocument12 pagesA 213 - A 213M - 03 Qtixmy0wm0i - PDFMan98No ratings yet

- A 213 - A 213M - 01 Qtixmy0wmue - PDFDocument9 pagesA 213 - A 213M - 01 Qtixmy0wmue - PDFErolNo ratings yet

- A 213 - A 213M - 01 Qtixmy0wmqDocument8 pagesA 213 - A 213M - 01 Qtixmy0wmqfadjarNo ratings yet

- A 213 Â " A 213M Â " 03 - QTIXMY0WM0MDocument13 pagesA 213 Â " A 213M Â " 03 - QTIXMY0WM0MhNo ratings yet

- Unit 4 Chemistry NotesDocument72 pagesUnit 4 Chemistry NotesRabiatNo ratings yet

- Halides (Q.B) AdvancedDocument26 pagesHalides (Q.B) AdvancedRaj ModiNo ratings yet

- Hydrophilic Finish For TextilesDocument14 pagesHydrophilic Finish For TextilesRavichakaravarthi BulletNo ratings yet

- CLS Aipmt-18-19 XII Che Study-Package-7 SET-1 Chapter-14Document6 pagesCLS Aipmt-18-19 XII Che Study-Package-7 SET-1 Chapter-14Sanchit PREDATORNo ratings yet

- Introduction To Biopolymer PhysicsDocument261 pagesIntroduction To Biopolymer Physicsunknown159No ratings yet

- Organic Name Reaction TrickDocument43 pagesOrganic Name Reaction TrickHunter DracolusNo ratings yet

- Repulping Wet Strength PapersDocument7 pagesRepulping Wet Strength PapersHarbeer SinghNo ratings yet

- Glandz Product ListDocument24 pagesGlandz Product ListRahul PambharNo ratings yet

- CHAPTER 7 - HaloalkanesDocument42 pagesCHAPTER 7 - HaloalkanesPaolo NaguitNo ratings yet

- 1,4 ButanediolDocument7 pages1,4 ButanediolElham Drs100% (1)

- Polar, Protic, and Aprotic Solvents: A GuideDocument11 pagesPolar, Protic, and Aprotic Solvents: A GuideSiddarth PalletiNo ratings yet

- Hydrogenation PDFDocument18 pagesHydrogenation PDFAle SanzNo ratings yet

- 1 Pre-Board Examination - 2020-21: Dav Public Schools, Odisha, Zone-IiDocument9 pages1 Pre-Board Examination - 2020-21: Dav Public Schools, Odisha, Zone-IiAshutosh sahooNo ratings yet

- Organometallic Offline Test SeriesDocument21 pagesOrganometallic Offline Test SeriesLuCaNo ratings yet

- Class 10 Science Chapter NotesDocument192 pagesClass 10 Science Chapter NotesTarunNo ratings yet

- Ethylene Oxide: Jump ToDocument31 pagesEthylene Oxide: Jump ToMusa Eltayeb100% (1)

- TDS Ac-Eagle (Oh138-30m60) 60%Document2 pagesTDS Ac-Eagle (Oh138-30m60) 60%Joseph FayekNo ratings yet

- VISIOMER® Amino Methacrylates - Technical InformationDocument5 pagesVISIOMER® Amino Methacrylates - Technical InformationFabio MastantuonoNo ratings yet

- Nicolet Spectral LibrariesDocument1,209 pagesNicolet Spectral LibrariesRahma Rahayu DinarlitaNo ratings yet

- Anticorrosion Additive For Metalworking FluidsDocument10 pagesAnticorrosion Additive For Metalworking FluidsFra FraNo ratings yet

- A-Level Paper 2 pp2Document16 pagesA-Level Paper 2 pp2Charlie MarstonNo ratings yet

- Syllabus Guide for Bachelor of Pharmacy ProgramDocument9 pagesSyllabus Guide for Bachelor of Pharmacy ProgramSakthi Krishnan100% (3)

- Aromatics HandoutDocument8 pagesAromatics HandoutJan ChretienNo ratings yet

- Tetrabutylammonium IodideDocument5 pagesTetrabutylammonium IodideVân Tú NguyễnNo ratings yet

- Difference Between Acetic Acid and Glacial Acetic AcidDocument4 pagesDifference Between Acetic Acid and Glacial Acetic AcidAnonymous S3wsIptcONo ratings yet

- Lec 1 - MCDocument15 pagesLec 1 - MCDivyam JainNo ratings yet

- The Effect of Substituents on Reactivity and Orientation in EASDocument5 pagesThe Effect of Substituents on Reactivity and Orientation in EASMatthew Ng100% (1)

- UNIT 2 Organic, Energetics, Kinetics and Equilibrium Part 1Document7 pagesUNIT 2 Organic, Energetics, Kinetics and Equilibrium Part 1Rameez Mazhar SiddiqiNo ratings yet

- Favorskii Rearrangement Synthetic ApplicationsDocument18 pagesFavorskii Rearrangement Synthetic ApplicationsMUhammad AsifNo ratings yet

- Lab 25Document5 pagesLab 25Nor Ashikin IsmailNo ratings yet