Professional Documents

Culture Documents

Heat Transfer Water Tube Boiler

Uploaded by

ilyaskureshiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Heat Transfer Water Tube Boiler

Uploaded by

ilyaskureshiCopyright:

Available Formats

EXAMPLE OF THERMODYNAMIC CALCULATION OF D-TYPE WATER TUBE BOILER WITH SUPERHEATER AND ECONOMIZER USING BOILER DESIGN SOFTWARE

EXAMPLE OF THERMODYNAMIC CALCULATION OF D-TYPE WATER TUBE BOILER WITH SUPERHEATER AND ECONOMIZER USING BOILER DESIGN SOFTWARE

EXAMPLE OF THERMODYNAMIC CALCULATION OF D-TYPE WATER TUBE BOILER WITH SUPERHEATER AND ECONOMIZER USING BOILER DESIGN SOFTWARE

EXAMPLE OF THERMODYNAMIC CALCULATION OF D-TYPE WATER TUBE BOILER WITH SUPERHEATER AND ECONOMIZER USING BOILER DESIGN SOFTWARE

EXAMPLE OF THERMODYNAMIC CALCULATION OF D-TYPE WATER TUBE BOILER WITH SUPERHEATER AND ECONOMIZER USING BOILER DESIGN SOFTWARE

HEAT TRANSFER IN BOILER *********************** DATE :MARK :D-TYPE WATER TUBE MAKE :REMARK:DEMO FUEL TYPE: GASEOUS LIQUID : WATER BOILER TYPE: STEAM MAX. ABSOLUTE WORKING PRESSURE: 25 bar BOILER FAMILY: WATER TUBE GAS DATA -------CH4-CONTENT = 100 vol%

LOWER HEATING VALUE = 35883 kJ/m3 HIGHER HEATING VALUE = 39819 kJ/m3 GAS DENSITY = .716 kg/m3 GAS OVERPRESSURE = 0 mbar ATMOSPHERIC PRESSURE = 1013 mbar GAS TEMPERATURE = 0 dC GAS RATE = 1150 m3/h COMBUSTION AIR TEMP. = 20 dC

BOILER GEOMETRY DATA -------------------FURNACE DATA ............ FURNACE IS HORIZONTAL THERE IS TUBE ARRAY SUPERHEATER IN FURNACE TUBE ROWS HAVE PLAIN ARRANGEMENT TUBE SECTION LENGTH TOTAL TUBE LENGTH NUMBER OF TUBE ROWS DISTANCE BETWEEN TUBE ROWS = = = = 1.7 m 129.2 m 4 .1 m

EXAMPLE OF THERMODYNAMIC CALCULATION OF D-TYPE WATER TUBE BOILER WITH SUPERHEATER AND ECONOMIZER USING BOILER DESIGN SOFTWARE

NUMBER OF TUBES IN ROW = DISTANCE BETWEEN TUBES IN ROW= NUMBER OF TUBES LIQUID ENTERS= TUBE OUTER DIAMETER = TUBE WALL THICKNESS =

19 .1 m 19 .0381 m .0032 m = = = = = = 2 m 5.1 m .0032 m 6.5 m .385 m2 92.3 m2

FURNACE WIDTH PERP. TO GAS FLOW FURNACE HEIGHT PERP. TO GAS FLOW WALL THICKNESS LENGTH IN GAS FLOW DIRECTION CROSS SECTION AREA AFTER FURNACE FURNACE COOLED AREA

GEOMETRY DATA OF TUBE ARRAY ECONOMIZER ...................................... MATERIAL: CARBON STEEL TUBE ROWS HAVE INDENTED ARRANGEMENT LIQUID TEMPERATURE ENTERING ECO = CROSS SECTION IN GAS FLOW DIRECTION= ECO STACK CONNECTOR CROSS SECTION = TUBE SECTION LENGTH = NUMBER OF TUBE ROWS = DISTANCE BETWEEN TUBE ROWS = NUMBER OF TUBES IN ROW = DISTANCE BETWEEN TUBES IN ROW = NUMBER OF TUBES LIQUID ENTERS = TUBE OUTER DIAMETER = TUBE WALL THICKNESS = OTHER DATA ---------FEED LIQUID TEMPERATURE EXCESS AIR/LAMBDA VALUE STACK CONNECTOR CROSS SECTION AREA TOTAL COOLED AREA CALCULATION RESULTS ------------------ADIABATIC COMBUSTION TEMPERATURE RELEASED HEAT BY COMBUSTION CONDENSATE HEAT IN FLUE GAS TEMPERATURE OF LIQUID/STEAM IN BOILER GAS VELOCITY IN BOILER FLUE APERTURE = = = = = 1895.5 dC 11549.7 kW 1290.6 kW 224 dC 18.8 m/s = 102 dC = 1.1 = .385 m2 = 92.3 m2 102 dC 2.3 m2 .4 m2 2.1 m 19 .1 m 19 .1 m 19 .0381 m .0032 m

EXAMPLE OF THERMODYNAMIC CALCULATION OF D-TYPE WATER TUBE BOILER WITH SUPERHEATER AND ECONOMIZER USING BOILER DESIGN SOFTWARE

GAS SIDE PRESSURE DROP IN BOILER GAS SIDE PRESSURE DROP WITH ECONOMIZER FLUE GAS RATE THROUGH BOILER BOILER THERMAL OUTPUT STEAM RATE FEED LIQUID RATE AVERAGE AREA THERMAL LOAD PERCENTAGE OF HEAT TAKEN UP IN FURNACE GAS EXIT TEMPERATURE FROM BOILER ECONOMIZER THERMAL OUTPUT GAS EXIT TEMPERATURE FROM ECONOMIZER LIQUID TEMPERATURE FROM ECONOMIZER GAS SIDE PRESSURE DROP IN ECONOMIZER

= = = = = = = = = = = = =

.01 mbar 2.89 mbar 13338.2 m3/h 9746.2 kW 14173.3 kg/h 14816.3 l/h 105.6 kW/m2 100 % 260.2 dC 360.4 kW 191.5 dC 123.7 dC 2.89 mbar

EFFICIENCY (BASED ON LOWER FUEL HEATING VALUE - DIN METHOD) BOILER EFFICIENCY BOILER EFFICIENCY WITH ECONOMIZER EFFICIENCY INCREASE BY ECONOMIZER COMBUSTION (STACK) EFFICIENCY FLUE GAS LOSSES FLUE GAS LOSSES = = = = = = 84.4 % 87.5 % 3.1 % 92.4 % 7.6 % 882.9 kW

EFFICIENCY (BASED ON HIGHER FUEL HEATING VALUE - ASME METHOD) BOILER EFFICIENCY BOILER EFFICIENCY WITH ECONOMIZER EFFICIENCY INCREASE BY ECONOMIZER COMBUSTION (STACK) EFFICIENCY FLUE GAS LOSSES (LATENT HEAT INCLUDED) FLUE GAS LOSSES (LATENT HEAT INCLUDED) BOILER JACKET LOSSES (AS SET BY DIN 4702 T3) BOILER JACKET LOSSES (AS SET BY DIN 4702 T3) HEAT TRANSFER IN FURNACE ........................ STEAM GENERATED GAS EXIT TEMP. MEAN GAS TEMP. AREA THERMAL LOAD VOLUME THERMAL LOAD GAS VELOCITY RADIATION CONVECTION HEAT TRANSFERRED GAS SIDE PRESSURE DROP = = = = = = = = = = 14782.4 kg/h 260.2 dC 650.8 dC 105.6 kW/m2 174.2 kW/m3 1 m/s 9624 kW 122.1 kW 9746.2 kW .005 mbar = = = = = = = = 75.9 % 78.7 2.8 % 83.9 % 16.1 % 2173.5 kW .4 % 57.7 kW

EXAMPLE OF THERMODYNAMIC CALCULATION OF D-TYPE WATER TUBE BOILER WITH SUPERHEATER AND ECONOMIZER USING BOILER DESIGN SOFTWARE

HEAT TRANSFER ON SUPERHEATER (ENERGY CONSUMING PART) SUPERHEATED STEAM TEMPERATURE CONVECTION RADIATION HEAT TRANSFERRED GAS VELOCITY AROUND TUBES STEAM VELOCITY IN TUBES WALL TEMPERATURE ON GAS SIDE WALL TEMPERATURE ON STEAM SIDE GAS SIDE PRESSURE DROP = = = = = = = = = 262 dC 60.8 kW 340.8 kW 401.6 kW 1.4 m/s 1.258 m/s 534 dC 531.7 dC .003 mbar

HEAT TRANSFER IN TUBE ARRAY ECONOMIZER ...................................... HEAT CONTENT OF ENTERING GASES = HEAT TRANSFERRED = MEAN TEMP. IN ECONOMIZER = LIQUID EXIT TEMP. FROM ECONOMIZER= GAS EXIT TEMPERATURE = GAS VELOCITY AROUND TUBES = LIQUID VELOCITY IN TUBES = WALL TEMPERATURE ON GAS SIDE = WALL TEMPERATURE ON LIQUID SIDE = GAS SIDE PRESSURE DROP = 1344.3 kW 360.4 kW 219.5 dC 123.7 dC 191.5 dC 8.6 m/s .015 m/s 149.4 dC 149.1 dC 2.89 mbar

You might also like

- PTC 4.1 Boiler Test EficiencyDocument11 pagesPTC 4.1 Boiler Test EficiencyPra Tiwi100% (2)

- Fluid FlowDocument88 pagesFluid FlowFren R.100% (2)

- FLUE GAS ANALYSIS AND HEAT EXCHANGER SIZINGDocument3 pagesFLUE GAS ANALYSIS AND HEAT EXCHANGER SIZINGRajendraNo ratings yet

- ASME - PTC4.1 .Boiler Efficiency TestDocument29 pagesASME - PTC4.1 .Boiler Efficiency TestBC Harish92% (13)

- Calculation of Steam BlowingDocument46 pagesCalculation of Steam BlowingRamachandran Venkatesh50% (2)

- Heat Transfer in Fire Tube Boiler Software SumulationDocument7 pagesHeat Transfer in Fire Tube Boiler Software SumulationLiam Moylan50% (2)

- Rigid Pipeline DesignDocument123 pagesRigid Pipeline DesignAditya Prasad100% (1)

- Lab ManualDocument10 pagesLab ManualKen MakNo ratings yet

- Sample Computation For Superheater Size and QuantityDocument7 pagesSample Computation For Superheater Size and QuantityAu Tagolimot100% (1)

- CONDENSATE DE-SUPERHEATING CALCULATIONSDocument8 pagesCONDENSATE DE-SUPERHEATING CALCULATIONSMechanicalVee18No ratings yet

- Chimney Calculations 14-7-2003Document4 pagesChimney Calculations 14-7-2003surinder yadavNo ratings yet

- Thermal Design of Heat ExchangersDocument24 pagesThermal Design of Heat ExchangersWira NugrohoNo ratings yet

- Shellmax Boiler Design CalculationDocument2 pagesShellmax Boiler Design Calculationrahult19No ratings yet

- Boiler Drum Thickness CalculationDocument3 pagesBoiler Drum Thickness Calculationsumang254567% (3)

- Boiler CalcDocument92 pagesBoiler CalcPrasanta Kumar BeheraNo ratings yet

- DraughtDocument33 pagesDraughtNipun SabharwalNo ratings yet

- Htri 105 PDFDocument1 pageHtri 105 PDFhirenpatel_62No ratings yet

- Film Temp Calculation For Thermic Fluid ApplicationDocument2 pagesFilm Temp Calculation For Thermic Fluid ApplicationmayurjannuNo ratings yet

- Boiler ReferenceDocument29 pagesBoiler ReferencetagolimotNo ratings yet

- Deaerator Venting Capacity CalculationsDocument2 pagesDeaerator Venting Capacity CalculationsEng Alf100% (1)

- IBRDocument5 pagesIBRcirius_coolNo ratings yet

- Verification of Capacity of Secondary Air Fan For Bagasse Fired BoilerDocument2 pagesVerification of Capacity of Secondary Air Fan For Bagasse Fired BoilerAu TagolimotNo ratings yet

- U-Tube Heat Exchanger Design: Tubes SpecDocument8 pagesU-Tube Heat Exchanger Design: Tubes SpecVipul SharmaNo ratings yet

- Pressure Testing Request FormDocument1 pagePressure Testing Request FormSyed Mahmud Habibur RahmanNo ratings yet

- Radiation and Convection Heat TransferDocument5 pagesRadiation and Convection Heat TransfergsdaundhNo ratings yet

- Project No. 16279S Project Name Bapco - JVTST: Calculation of Emissivity of Process GasDocument11 pagesProject No. 16279S Project Name Bapco - JVTST: Calculation of Emissivity of Process GasrajachemNo ratings yet

- Progen: Pipe Thickness Calculation As Per IBR 350 Eqn.Document4 pagesProgen: Pipe Thickness Calculation As Per IBR 350 Eqn.P s JagatheesanNo ratings yet

- Boiler Efficiency Calculation MethodDocument2 pagesBoiler Efficiency Calculation MethodSomplak KudaNo ratings yet

- Highlight of IBRDocument15 pagesHighlight of IBRAnonymous XBq5J84No ratings yet

- Boiler and Boiler CalculationsDocument7 pagesBoiler and Boiler CalculationsChaya Stia ClaluiNo ratings yet

- h (V) (m) M (T) /η 45 (0.7734) (20) 1800 (298) /0.8Document9 pagesh (V) (m) M (T) /η 45 (0.7734) (20) 1800 (298) /0.8RajashekarBheemaNo ratings yet

- Ibr Stand PipeDocument11 pagesIbr Stand PipeP s JagatheesanNo ratings yet

- Shell Side Fluid Heat Load and Tube Side Fluid Heat Transfer CalculationsDocument6 pagesShell Side Fluid Heat Load and Tube Side Fluid Heat Transfer CalculationsrajachemNo ratings yet

- PF Furnace DesignDocument21 pagesPF Furnace DesignDSGNo ratings yet

- Air Cooled Heat Exchanger CourseDocument2 pagesAir Cooled Heat Exchanger Courserodrigoperezsimone100% (1)

- Ibr Calculation Boiler Integral PipingDocument25 pagesIbr Calculation Boiler Integral PipingP s Jagatheesan100% (1)

- Chapter 2 FiretubeDocument18 pagesChapter 2 FiretubeWael Abdel-MageedNo ratings yet

- COMBUSTIÓN CALCULATIONS USING THE MILLION BTU (1.055 MJ) METHODDocument9 pagesCOMBUSTIÓN CALCULATIONS USING THE MILLION BTU (1.055 MJ) METHODLuciana RequejoNo ratings yet

- Boiler Design Step 2Document2 pagesBoiler Design Step 2Amad TaupiqNo ratings yet

- Traveling Grate Boiler 50 TPH 95 KGCM 450CDocument52 pagesTraveling Grate Boiler 50 TPH 95 KGCM 450CMajid KhanNo ratings yet

- Heat Exchanger DesignDocument48 pagesHeat Exchanger DesignJose SotoNo ratings yet

- TubesheetDocument14 pagesTubesheethassnain iqbalNo ratings yet

- Boilers Chimney Draft and Breeching CalculationDocument15 pagesBoilers Chimney Draft and Breeching Calculationjoabjim8392No ratings yet

- Index: L&T, E & C Engineering DECDocument22 pagesIndex: L&T, E & C Engineering DECinderNo ratings yet

- Exhaust Gas Pressure Drop in DuctDocument6 pagesExhaust Gas Pressure Drop in DuctMyungkwan HaNo ratings yet

- Proceedings of The South African Sugar Technologists' Association boiler selectionDocument35 pagesProceedings of The South African Sugar Technologists' Association boiler selectionAlsmoual AbdallaNo ratings yet

- Vessel Volume CalculationDocument2 pagesVessel Volume CalculationDhia Slama100% (1)

- Ibr CalcDocument4 pagesIbr CalcUmesh Kondkar100% (7)

- Boiler Furnace Design and DutyDocument6 pagesBoiler Furnace Design and Dutyأمير حارث100% (1)

- Example of Thermodynamic Calculation of Fire Tube Boiler With Boiler ...Document6 pagesExample of Thermodynamic Calculation of Fire Tube Boiler With Boiler ...Kazem QarebeiglooNo ratings yet

- Boiler Design Comparison (Metric) WARGA Design Versus Optimized 3-Pass Scotch MarineDocument18 pagesBoiler Design Comparison (Metric) WARGA Design Versus Optimized 3-Pass Scotch MarineAli hegaigNo ratings yet

- Hybrid Boiler Thermodynamic Calculation: InstructionsDocument48 pagesHybrid Boiler Thermodynamic Calculation: InstructionsNITINNo ratings yet

- Locomotive Boiler Thermodynamic CalculationDocument37 pagesLocomotive Boiler Thermodynamic CalculationNITINNo ratings yet

- D-type water tube boiler calculation guideDocument40 pagesD-type water tube boiler calculation guideNITINNo ratings yet

- Super Critical Boiler Cycle GuideDocument32 pagesSuper Critical Boiler Cycle GuideJayaraman Kamaraj100% (1)

- MINIMIZING ATMOSPHERIC EMISSIONS IN HYDROCARBON PROCESSING WITH HIGH-EFFICIENCY HEAT EXCHANGERSDocument17 pagesMINIMIZING ATMOSPHERIC EMISSIONS IN HYDROCARBON PROCESSING WITH HIGH-EFFICIENCY HEAT EXCHANGERSJaishree ChauhanNo ratings yet

- Optimization and Analysis of Tube-In-tube Heat Exchanger With Fins-LibreDocument145 pagesOptimization and Analysis of Tube-In-tube Heat Exchanger With Fins-Libre윤병택No ratings yet

- Energy Saving Opportunities in Ammonia and Urea Plant: Kribhco'S ExperienceDocument38 pagesEnergy Saving Opportunities in Ammonia and Urea Plant: Kribhco'S Experienceigunhakam55100% (1)

- Ate 2016 12959R1Document15 pagesAte 2016 12959R1jeremytoh89No ratings yet

- Development of The "Micro Combustor"Document6 pagesDevelopment of The "Micro Combustor"Haris AbdullaNo ratings yet

- Condenser Performance Analysis and Its ImprovementDocument23 pagesCondenser Performance Analysis and Its Improvementanup_nair100% (1)

- ME 4226 Heat Exchanger Compiled WconclusionDocument26 pagesME 4226 Heat Exchanger Compiled Wconclusionhamish888No ratings yet

- Encyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"From EverandEncyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"No ratings yet

- Scribd 85Document1 pageScribd 85ilyaskureshiNo ratings yet

- Scrib 99Document1 pageScrib 99ilyaskureshiNo ratings yet

- MTK Platform Layout and Partition SettingsDocument6 pagesMTK Platform Layout and Partition SettingsAbhishek SaxenaNo ratings yet

- Article SearchDocument75 pagesArticle SearchilyaskureshiNo ratings yet

- Scribd 12Document1 pageScribd 12ilyaskureshiNo ratings yet

- ThreadsDocument21 pagesThreadsNguyễn Duy BiênNo ratings yet

- Comparison of Proposed Six Stroke Internal Combustion Engine With Four Stroke Engine Using Ideal CycleDocument5 pagesComparison of Proposed Six Stroke Internal Combustion Engine With Four Stroke Engine Using Ideal CycleilyaskureshiNo ratings yet

- Test of basicDocument1 pageTest of basicilyaskureshiNo ratings yet

- Guide to Short Nonsense TextDocument1 pageGuide to Short Nonsense TextilyaskureshiNo ratings yet

- Arrangement of Six Stroke EngineDocument6 pagesArrangement of Six Stroke Engineilyaskureshi100% (1)

- The Centre For Entrepreneurship Development: Applica T Ion For The P o ST of Project LeaderDocument3 pagesThe Centre For Entrepreneurship Development: Applica T Ion For The P o ST of Project LeaderilyaskureshiNo ratings yet

- The Centre For Entrepreneurship Development: Applica T Ion For The P o ST of Project LeaderDocument3 pagesThe Centre For Entrepreneurship Development: Applica T Ion For The P o ST of Project LeaderilyaskureshiNo ratings yet

- MS Exel MS Excel Tutorials in HindiDocument42 pagesMS Exel MS Excel Tutorials in HindiNeeraj DeodeNo ratings yet

- Jee Main 2014 Analysis by Resonance Revised 2Document7 pagesJee Main 2014 Analysis by Resonance Revised 2ilyaskureshiNo ratings yet

- Matlab For Optimization PDFDocument49 pagesMatlab For Optimization PDFBerhanu ZelalemNo ratings yet

- Cor-Ten Weathering Steel: Metaltech-UsaDocument1 pageCor-Ten Weathering Steel: Metaltech-UsailyaskureshiNo ratings yet

- Boiler Selection PDFDocument25 pagesBoiler Selection PDFShafqat AfridiNo ratings yet

- Adult HIV Confidential Case Report FormDocument4 pagesAdult HIV Confidential Case Report FormilyaskureshiNo ratings yet

- Fee Regulatory Committee: (Technical) (Technical) (Technical) (Technical)Document1 pageFee Regulatory Committee: (Technical) (Technical) (Technical) (Technical)ilyaskureshiNo ratings yet

- Pressure Vessel Design in ANSYSDocument5 pagesPressure Vessel Design in ANSYSRohan KarandeNo ratings yet

- Tax Deduction at Source on SalariesDocument112 pagesTax Deduction at Source on SalariesArnav MendirattaNo ratings yet

- Coa Zebra AstralDocument1 pageCoa Zebra AstralilyaskureshiNo ratings yet

- AMETank PDFDocument6 pagesAMETank PDFMadan Yadav50% (2)

- Bell&Gossett Circuit SettersDocument2 pagesBell&Gossett Circuit SettersilyaskureshiNo ratings yet

- Camworks InstallgdeDocument142 pagesCamworks InstallgdeilyaskureshiNo ratings yet

- Computational Analysis of Combustion of Separated Coal-Gas in O /CODocument9 pagesComputational Analysis of Combustion of Separated Coal-Gas in O /COilyaskureshiNo ratings yet

- Schoeller-Bleckmann Nitec GMBH: High-Pressure Equipment and Vessel Fabrication For The Fertilizer IndustryDocument3 pagesSchoeller-Bleckmann Nitec GMBH: High-Pressure Equipment and Vessel Fabrication For The Fertilizer IndustryilyaskureshiNo ratings yet

- EPF SchemeDocument93 pagesEPF SchemeShirshak GhimireNo ratings yet

- Design of Pressure Vessel Using Asme Code, Section Viii, Division 1Document7 pagesDesign of Pressure Vessel Using Asme Code, Section Viii, Division 1bbmoksh100% (2)

- Form 10 DDocument6 pagesForm 10 DilyaskureshiNo ratings yet

- Electrical Layout Design and Load Calculation GuideDocument75 pagesElectrical Layout Design and Load Calculation Guide2GI20AT021 Devki HanamshetNo ratings yet

- Tata Steel - AR400 & 450Document2 pagesTata Steel - AR400 & 450Gabriel CamargoNo ratings yet

- Mems Lecture PlanDocument2 pagesMems Lecture PlanMahesh Kumar K BNo ratings yet

- Wall Mounted PDFDocument5 pagesWall Mounted PDFAhmed AzadNo ratings yet

- User ManualDocument3 pagesUser ManualrafeeqcscsNo ratings yet

- Thornel T300 052112 PDFDocument2 pagesThornel T300 052112 PDFDavid CoutinhoNo ratings yet

- Doha Clinic-Revised (7 Months)Document4 pagesDoha Clinic-Revised (7 Months)DU A NENo ratings yet

- RCC54 Circular Column ChartingDocument13 pagesRCC54 Circular Column Chartingbunheng lonNo ratings yet

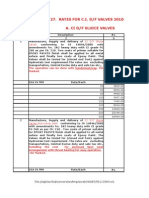

- Valve RatesDocument34 pagesValve RatesDeepthy VasavanNo ratings yet

- Internal PHE BOQ - R1Document7 pagesInternal PHE BOQ - R1SajeshKumarNo ratings yet

- Design and Analysis of Reinforced Concrete Multistory Commercial Building Using Aci-318 Metric Manually and Extensive Design by Robot AnalysisDocument178 pagesDesign and Analysis of Reinforced Concrete Multistory Commercial Building Using Aci-318 Metric Manually and Extensive Design by Robot AnalysisAbdul Azeem Baig100% (2)

- Tensile Membrane Structures: Name of Project Page - of - July 9, 2013Document18 pagesTensile Membrane Structures: Name of Project Page - of - July 9, 2013jackNo ratings yet

- OECSwceDocument12 pagesOECSwceChristopher WeeksNo ratings yet

- FormingPotential EN PDFDocument28 pagesFormingPotential EN PDFNhan LeNo ratings yet

- Precast Concrete Structures: A Concise GuideDocument267 pagesPrecast Concrete Structures: A Concise GuidepelinNo ratings yet

- FALLSEM2021-22 MEE3001 TH VL2021220103058 Reference Material I 23-Aug-2021 Module 2 Design Against Fluctuating LoadDocument78 pagesFALLSEM2021-22 MEE3001 TH VL2021220103058 Reference Material I 23-Aug-2021 Module 2 Design Against Fluctuating LoadJude JohnNo ratings yet

- Sylvania PDFDocument4 pagesSylvania PDFRob N HoodNo ratings yet

- Role of Shear To High Rise BuildingsDocument18 pagesRole of Shear To High Rise BuildingsAxmed ShirwacNo ratings yet

- Building Works Index and Cost AnalysisDocument128 pagesBuilding Works Index and Cost AnalysisPja ShanthaNo ratings yet

- ASTM E 139-06 Standard Test Methods For Conducting Creep, Creep-Rupture, and Stress-Rupture Tests of Metallic Materials1Document14 pagesASTM E 139-06 Standard Test Methods For Conducting Creep, Creep-Rupture, and Stress-Rupture Tests of Metallic Materials1Angel RamirezNo ratings yet

- AWS D1.5/D1.5M Bridge Welding Code ChangesDocument36 pagesAWS D1.5/D1.5M Bridge Welding Code ChangesedwinNo ratings yet

- Concrete Quantity CalculationDocument3 pagesConcrete Quantity Calculationtruth finderNo ratings yet

- The Role of Tribology in Engineering Materials: Friction, Lubrication and WearDocument40 pagesThe Role of Tribology in Engineering Materials: Friction, Lubrication and Wearemad sabri100% (1)

- Spur Gears Component GeneratorDocument4 pagesSpur Gears Component GeneratorRodrigo NavarreteNo ratings yet

- Materials Challenges in Nuclear EnergyDocument24 pagesMaterials Challenges in Nuclear EnergyW.t. HanNo ratings yet

- Boiler IntroductionDocument17 pagesBoiler IntroductionDavid SilalahiNo ratings yet

- Busbar Sizing Us StandardsDocument16 pagesBusbar Sizing Us StandardsZaferullah KhanNo ratings yet