Professional Documents

Culture Documents

Ball valve HKSF-W100 technical details

Uploaded by

ccdumitraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ball valve HKSF-W100 technical details

Uploaded by

ccdumitraCopyright:

Available Formats

Ball valve HKSF-W100

Ball valve HKSF-W100

RMA Kehl GmbH & Co. KG Oststrasse 17 D-77694 Kehl / Germany info@rma-kehl.de www.rma-armaturen.de

Ball valve HKSF-W100

Design Features: RMA-ball valves type HKSF-W are fully welded and completely maintenance-free designed. The primary metal and secondary soft sealing method with the proven RMA-sealing system offers the following advantages: Each of the seating rings on both the inlet as well as the outlet side are composed of two sealing planes. With this primary metal, sealing is ensured on both sides. The conception of the primary metal and secondary soft sealing system is based on the precision machining of metal sealing ball valves (e.g. common lapping of ball and seating rings). The flexible soft sealing in the seating rings is first effective at low pressure ranges. The seating rings are pressed onto the ball by means of pressure springs. Additionally, the seating rings are designed in such a way that a piston effect increases the contact force proportionally to the pressure. In this way, a pure metal sealing is formed. Even at high operating pressures, the flexible soft sealing ring suffers no damage. Guard rings are used to prevent ejection or forcing out of the soft sealing ring at all pressure stages and in all switch positions. On request, a third emergency sealing system (sealing compound system) can be added to both seating rings as well as to the spindle sleeve. For this reason a special chambering groove is incorporated in the seating rings to enable a pre-defined emergency sealing. Double Block and Bleed: Proof of sealing is provided in both end positions, even under maximum operating pressure of the ball valve, using a special, self-protected bleed nipple or, if required, using drain and vent pipes with an additional ball valve. Sealing Types Single Piston and Double Piston: RMA-ball valves are available in two sealing types: single piston and double piston seating ring systems. In the single piston-system the sealing ring on the outlet side raises when a pre-defined overpressure is present inside the valve body thus allowing this excess pressure to escape to the outlet side. The lack of pressure within the body provides proof of sealing. We recommend the single piston-system for all liquid media. This system prevents damage to the body caused by excessive overpressure through thermal expansion. In this way, additional external pressurerelieve is not necessary. In the double piston-system the seals and seating rings on the inlet and outlet side provide total sealing of the body inner chamber in both end positions of the ball valve. The ball valve provides sealing on the inlet and outlet sides. In this way, it is also possible to provide proof of sealing by pressurisation from outside the body. We recommend the double piston-system for all gaseous media. This system offers protection in two respects to the user.

Ball valve HKSF-W100

Ball Bearing: RMA-ball valves are trunnion mounted with maintenance-free bearings in all sizes (DN 50 and greater) and all pressure ratings. The precision machining and special low friction bearings ensure minimum wear. This is particularly advantageous for the resistance and smooth operating of ball valves. These low torque levels are also an advantage when dimensioning gears, electrical, pneumatic or hydraulic actuators.

Electrostatic Charge: An electric conductive connection between ball and body provides reliable prevention of electrostatic build-up.

Spindle/Sealing: The anti-blow-out-design prevents the spindle from being blown out by the medium transported or pulled out by the user himself. The special double-screw design enables, on the one hand, correct squeezing or adjustment of the steel, PTFE and graphite sealing system manufactured by RMA and, on the other hand, rapid replacement of sealing rings under full operating pressure.

Connection: Inline connection on site can be ensured either with flange ends, in accordance with standard requirements, or with welding ends gauged to suit the pipes to be connected. Specific customer requirements may be taken into consideration.

Fire Protection: RMA-ball valves offer the high fire protection level rquired in oil, gas and supply pipelines (e.g. ISO 10497, API 6FA, BS 6755 Part 2).

Materials: For the standard model of the type HKSF-W, materials in accordance with DIN, ASME and NACE MR 01 75 are used.

Ball valve HKSF-W100

Vent and Drain: In accordance with the known relevant group standards, RMA-ball valves are equipped with vent and drain pipes with additional RMA-ball valves with pressure resistant cap and/or with RMA-rotary gate valves on request or due to technical necessity.

Scope of Application: Surface or underground mounted, for use in transport lines, compressor stations, measuring and regulating stations, emergency shut-down units (ESD), drain or vent pipes on pig traps or other installations. RMA-ball valves are suitable for use within a wide range of media e.g. gas, oil, etc. Technically adapted versions for other purposes, e.g. for use in district heating transmission lines, are also possible.

Design: The body is extremely rigid thanks to its fully-welded ball design form. The largely dimensioned ball diameter ensures a high level of overlapping of the sealing surface in the fullyclosed position with a consequently high level of sealing security. In addition, the design form prevents turbulence in the medium transported which also helps limit premature wear. The low weight and minimum number of weld seams required are further advantages of this design.

Operation: RMA-ball valves are available with hand, geared, electrical, electro-hydraulic, hydro-pneumatic or any other operating mechanism. Diverse accessories such as position indicators, remote control options, etc. can be added.

Temperature Range: The temperature range for RMA-ball valves type HKSF-W extends as standard from -29 C to +80 C. Designs for higher or lower temperatures for corresponding operating conditions are in our programme as well.

Ball valve HKSF-W100

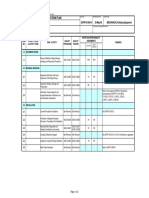

Dimensions & Weights

Size DN [mm] 25 50 80 100 150 200 250 300 350 400 450 500 550 600 700 800 900 1000 1100 1200 1400 [inch] 1" 2" 3" 4" 6" 8" 10" 12" 14" 16" 18" 20" 22" 24" 28" 32" 36" 40" 44" 48" 56" Diameter D1 mm 25 51 76 102 152 203 254 305 337 387 438 489 540 591 686 781 876 978 1.067 1.168 1.384 H1 mm 70 95 110 130 150 190 235 270 300 335 372 410 450 505 580 655 730 790 870 950 1.135 Height H2 mm 155 185 240 290 395 525 630 720 770 880 950 1.060 1.110 1.200 1.280 1.440 1.590 1.765 1.925 2.105 2.455 Length L AE = L FL mm 216 292 356 432 559 660 787 838 889 991 1.092 1.194 1.295 1.397 1.549 1.778 2.083 2.159 2.311 2.489 2.921 G AE kg

9 14 27 35 115 240 351 513 752 920 1.362 1.675 2.244 2.600 3.770 5.500 7.800 10.500 12.200 19.900 31.000

Weights G ANSI FL kg

13 19 37 69 175 323 539 705 995 1.190 1.675 2.000 2.809 3.350 5.000 7.200 9.500 12.500 14.800 22.500 36.000

H2

D1

H1

D1

Remarks:

L AE

L FL

Lengths according to API 6D; as far as defined. Ball valves with other lenghts on request Lengths of flange design with ANSI-flanges with flat sealing plane type "RF". When ordering flange ball valves, please specify whether ANSI-flanges type "RF", type "RTJ" or DIN-flanges are required. Ball valves with reduced bore on request. WE = with welding ends FL = with flange ends

H1

H2

Ball valve HKSF-W100

Ball-sealing system

The primary metal and secondary soft sealing system comprises: 2 metal sealing planes (chrome steel) (4) and 1 flexible soft sealing ring (PTFE/carbon) (1) The soft sealing (1) is positioned in such a way that it is first effective at low operating pressures. As the operating pressure increases, the application force of the seating ring (6) on the ball (7) increases accordingly (piston effect). The permanent spring force therefore receives additional support. In this case, the soft sealing ring (1) is pushed back so far that sealing is achieved entirely with the metal sealing planes (4). In case of damage to the metal sealing planes (4), the soft sealing ring (1) enters into effect. This is achieved by increasing the pressure on the reverse side of the soft sealing ring (1). The later is pressed onto the ball (7). For this activation it is irrelevant whether the leakage is due to the metal sealing plane (4) on the body side or on the medium side. Slipping, extraction, breaking off or other damage to the soft sealing ring (1) is virtually not possible.

Sealing ring O-ring with back-up rings Seating ring Spring

Holder

Ball

O-ring Emergency sealing

Metal sealing

Ball valve HKSF-W100

Operating spindle-sealing system

1 2

1. Threaded pin 2. Cylinder screw 3. Spacer ring (13% chrome steel) 4. Graphite ring 5. Tension ring (13% chrome steel) 6. Lip sealing ring (PTFE) 7. Groove tension ring (13% chrome steel) 8. Fastening ring 9. O-ring (NBR or Viton) 10. O-ring (NBR or Viton) 11. Clamping ring (13% chrome steel) 12. Stopping disk 13. Operating spindle up to DN 400 (13% chrome steel) over DN 400 (chrome steel or nickel-plated steel) 14. Emergency sealing 15. Second possibility to re-tight Other materials due to technical

3 4 5 6 7 14 8 9 10 11 15 12 13

The sealing system is composed of three seals:

graphite ring lip sealing ring O-ring

(4) (6) (9 + 10)

Radial re-tensioning of the lip sealing ring (6) is easily achieved by tightening the threaded pins (1). The graphite ring (4) can also be re-tensioned by tightening the cylinder screw (2) (remove the threaded pins). The O-ring (10) and the lip sealing ring (6) can be recharged by injecting a sealing compound (14). Should it still prove necessary to replace the set of sealing rings, then this task can be carried out with the valve under pressure. unscrew the gear plate replace the set of sealing rings (4/5/6) Under no circumstances may the fastening ring (8) be removed as this is used to ensure axial clamping of the operating spindle (13). It is recommended that the O-rings (9 + 10) be refilled with a sealing compound before replacing the sealing rings (15).

Ball valve HKSF-W100

Some examples for variations in equipment, manufactured according to customers needs.

for above ground installation see picture 1.1 and 1.2 with welding ends incl. gearbox and hand wheel incl. emergency sealing at a) ball / seating ring b) operating spindle with ball valve for drain and vent with support

picture 1.1

picture 1.2

see picture 2.1 and 2.2 with welding ends incl. gearbox, motor and additional emergency hand wheel for manual operation on site incl. emergency sealing at a) ball / seating ring b) operation spindle with ball valve for drain and vent with support

picture 2.1

picture 2.2

Ball valve HKSF-W100

Some examples for variations in equipment, manufactured according to customers needs.

for underground installation

see picture 3.1 and 3.2 with welding ends with stem extension up to operating height incl. gearbox above ground and hand wheel incl. emergency sealing at a) ball / seating ring (accessible above ground) b) operating spindle with possibility of drain and vent above ground through vertically guided pipes with one ball valve above ground and one ball valve underground with support buried parts are coated with PUR parts above ground are coated with primer and painted on request

picture 3.1

picture 3.2

see picture 4.1 and 4.2 with welding ends incl. gearbox below ground with stem extension and actuating square shaft in road cap (a position indicator is recommended) incl. emergency sealing at a) ball / seating ring b) operating spindle with possibility of drain and vent through vertically guided pipes and one ball valve in road cap with support buried parts are coated with PUR

picture 4.1 picture 4.2

You might also like

- Rubber Design Vibration and Noise ControlDocument14 pagesRubber Design Vibration and Noise Controlcvishwas1159No ratings yet

- List of Components of Oil Drilling Rigs PDFDocument7 pagesList of Components of Oil Drilling Rigs PDFAdelina96No ratings yet

- Shaffer ShpericalDocument11 pagesShaffer Shpericaljeinerdt100% (1)

- BP - Tb0002inspection of Small-Bore Fittings and PipeworkDocument4 pagesBP - Tb0002inspection of Small-Bore Fittings and PipeworkMohd Khairul100% (1)

- MS 1228 1991 Sewer DesignDocument82 pagesMS 1228 1991 Sewer Designaubar100% (5)

- Frequently Asked Questions: Geberit SupertubeDocument9 pagesFrequently Asked Questions: Geberit Supertubemohaideen kasimNo ratings yet

- FlowTek Ball Valve DesignDocument0 pagesFlowTek Ball Valve DesignGohilakrishnan ThiagarajanNo ratings yet

- Ball Valve Catalogue-2Document12 pagesBall Valve Catalogue-2tndeshmukhNo ratings yet

- Branch Reinforcement Pad Requirement CalculationDocument1 pageBranch Reinforcement Pad Requirement Calculations.mladinNo ratings yet

- AUMATIC AC 01.1 - ACExC 01.1, Parallel, Operation and SettingDocument92 pagesAUMATIC AC 01.1 - ACExC 01.1, Parallel, Operation and SettingccdumitraNo ratings yet

- Piping QC Guide (For Saudi Aramco Project)Document11 pagesPiping QC Guide (For Saudi Aramco Project)HengNo ratings yet

- Rotary Drilling Rig ComponentsDocument130 pagesRotary Drilling Rig Componentsgarry_dirak100% (21)

- CENTERLINE Butterfly Valves GuideDocument29 pagesCENTERLINE Butterfly Valves GuideNNNo ratings yet

- SAE J20 Dated 6-2006 Coolant HoseDocument18 pagesSAE J20 Dated 6-2006 Coolant Hoseanon_94010986No ratings yet

- Piping Design GuideDocument245 pagesPiping Design GuideclintlakeyNo ratings yet

- SAUDI ARAMCO CENTRIFUGAL PUMP INSPECTION PLANDocument3 pagesSAUDI ARAMCO CENTRIFUGAL PUMP INSPECTION PLANJithuJohn100% (1)

- Crane - Series.rs Center LineDocument23 pagesCrane - Series.rs Center LinenedwestNo ratings yet

- WKM Pow R Seal Gate Valves BrochureDocument28 pagesWKM Pow R Seal Gate Valves BrochureKhai Huynh100% (1)

- Perar Trunnion Ball ValvesDocument54 pagesPerar Trunnion Ball ValvesUday GokhaleNo ratings yet

- Optimizing Pressure Relief SystemsDocument6 pagesOptimizing Pressure Relief SystemssgrsthNo ratings yet

- LT Pipeline Ball ValvesDocument19 pagesLT Pipeline Ball ValvessiswoutNo ratings yet

- Pipeline 2008 PDFDocument200 pagesPipeline 2008 PDFsarahbstNo ratings yet

- L&T Ball ValveDocument12 pagesL&T Ball ValvecdsenthilNo ratings yet

- Corner Bracing Connection Capacity Based On AISC 360-10/16 Design CriteriaDocument10 pagesCorner Bracing Connection Capacity Based On AISC 360-10/16 Design CriteriaMahesh MNo ratings yet

- M32-W o IncineratorDocument137 pagesM32-W o IncineratorAlex100% (1)

- BV : 1 : 1 : 13 - Concise for Ball Valve DocumentDocument16 pagesBV : 1 : 1 : 13 - Concise for Ball Valve DocumentRamaswamy Neelakantan NNo ratings yet

- SDV PPTDocument58 pagesSDV PPTSai Kamala100% (2)

- Grove G9 Wafer Gate ValveDocument9 pagesGrove G9 Wafer Gate Valvetxlucky80No ratings yet

- These Are Two Different Types of Ball ValvesDocument18 pagesThese Are Two Different Types of Ball Valvesgabi_nanaNo ratings yet

- TRIPLE OFFSET BUTTERFLY VALVE TX Literature PDFDocument8 pagesTRIPLE OFFSET BUTTERFLY VALVE TX Literature PDFjdietz4No ratings yet

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Pipeline Equipment - Ball Valves EtcDocument43 pagesPipeline Equipment - Ball Valves Etckrish69No ratings yet

- Technical Bulletin: Valtek Mark One Control ValvesDocument20 pagesTechnical Bulletin: Valtek Mark One Control ValvesOscar CruzNo ratings yet

- Trunnion Eng Final MensiDocument28 pagesTrunnion Eng Final MensiPedro DutraNo ratings yet

- D 500203 X 012Document20 pagesD 500203 X 012Aarthi PadmanabhanNo ratings yet

- Broen Butterfly Valves v9Document13 pagesBroen Butterfly Valves v9bojanmileticNo ratings yet

- Valve0114 PDFDocument14 pagesValve0114 PDFbinhjukiNo ratings yet

- Product Specifications for FOXTOP Control Valve System PSS 4-24A1 FDocument0 pagesProduct Specifications for FOXTOP Control Valve System PSS 4-24A1 Fcico_ctNo ratings yet

- IOM Ball Valve Top EntryDocument8 pagesIOM Ball Valve Top Entrytoader56No ratings yet

- 2011 07 Mar00080 en Katalog Typs WebDocument28 pages2011 07 Mar00080 en Katalog Typs WebzayerirezaNo ratings yet

- SWI Products MetalDocument21 pagesSWI Products MetalPrasanth PrasadNo ratings yet

- Fisherr 8510 and 8510B Eccentric Disc Control Valves (EMA) : FeaturesDocument20 pagesFisherr 8510 and 8510B Eccentric Disc Control Valves (EMA) : FeaturesFabián HerreraNo ratings yet

- Válvulas Bola SegmentadaDocument12 pagesVálvulas Bola SegmentadarehynaldoNo ratings yet

- WKM Pow R Seal Gate Valve IomDocument20 pagesWKM Pow R Seal Gate Valve IomKhai Huynh100% (1)

- Catalog de ValvulasDocument4 pagesCatalog de ValvulasPepe PintoNo ratings yet

- BS 5351 Ball Valves CatalogDocument10 pagesBS 5351 Ball Valves CatalogcatalineulaNo ratings yet

- Fissher VeeBallDocument24 pagesFissher VeeBallJim KovalskyNo ratings yet

- Pfeiffer Br26d EngDocument4 pagesPfeiffer Br26d EngAleksandr KrigerNo ratings yet

- Rising DiscDocument8 pagesRising DiscwenigmaNo ratings yet

- Flowserve Vlatb001Document20 pagesFlowserve Vlatb001Selva KumarNo ratings yet

- Ad00912v Wkmsaf T SealDocument36 pagesAd00912v Wkmsaf T SealJulia WadeNo ratings yet

- Sapag JHP Valves Jun04 enDocument18 pagesSapag JHP Valves Jun04 enanwar01No ratings yet

- Rotary Unions Swivel Joints: Manufactured in The UK With Over 70 Years ExperienceDocument36 pagesRotary Unions Swivel Joints: Manufactured in The UK With Over 70 Years ExperienceSaurav DasNo ratings yet

- RVC 05 NPT Product SpecsDocument6 pagesRVC 05 NPT Product SpecsAnonymous WVJNMWNo ratings yet

- KN Ife Ga Te & Bu Tte Rfly Va Lve S E: Valves & EquipmentDocument14 pagesKN Ife Ga Te & Bu Tte Rfly Va Lve S E: Valves & EquipmentravishankarNo ratings yet

- KLINGER Ballostar KHA 3 Pieces Ball Valve DN 10 - 150: Edition 2011Document36 pagesKLINGER Ballostar KHA 3 Pieces Ball Valve DN 10 - 150: Edition 2011Andy LuthorNo ratings yet

- 12-8 FBU-S Parker Straight Compression FittingDocument16 pages12-8 FBU-S Parker Straight Compression FittingMROstop.comNo ratings yet

- FisherDocument20 pagesFishermanmohansingh1999No ratings yet

- Rod Lock CylindersDocument7 pagesRod Lock CylindersmaciasrobNo ratings yet

- VJ Flexlock BroDocument9 pagesVJ Flexlock BroAhmad ShakeelNo ratings yet

- Valvulas de Bola - JAMESBURYDocument4 pagesValvulas de Bola - JAMESBURYcasv9No ratings yet

- Double Eccentric Butterfly Valves R1Document20 pagesDouble Eccentric Butterfly Valves R1Sandi AslanNo ratings yet

- Ball Valve Flange TypeDocument7 pagesBall Valve Flange TypeperoooNo ratings yet

- WKM HP Butterfly BrochureDocument28 pagesWKM HP Butterfly BrochureAarthi PadmanabhanNo ratings yet

- Cokebuster: A Proven SolutionDocument11 pagesCokebuster: A Proven Solutionengg_mech77No ratings yet

- Clarkson KGFDocument8 pagesClarkson KGFJorge Castro CucurellaNo ratings yet

- OZKAN Butterfly ValvesDocument11 pagesOZKAN Butterfly ValvesAhmed AbdelwaneesNo ratings yet

- Sure Seal LBF Series Lined Butterfly Valves for Demanding ApplicationsDocument8 pagesSure Seal LBF Series Lined Butterfly Valves for Demanding ApplicationsbbmokshNo ratings yet

- Series 3TF y 3TSDocument17 pagesSeries 3TF y 3TSAlfredo Van HousteNo ratings yet

- Veljan Hydraulic CatlogueDocument20 pagesVeljan Hydraulic CatlogueRaji SuriNo ratings yet

- Process Piping Systems: Scrubber Design and Installation RequirementsDocument6 pagesProcess Piping Systems: Scrubber Design and Installation RequirementsCamilo Andres Cardozo FajardoNo ratings yet

- TI FLOWSIC600 en 8010125Document228 pagesTI FLOWSIC600 en 8010125ccdumitraNo ratings yet

- Catalog Combined PDF Rev1 Total PDFDocument251 pagesCatalog Combined PDF Rev1 Total PDFccdumitraNo ratings yet

- Michell HCDPMeas enDocument61 pagesMichell HCDPMeas enccdumitraNo ratings yet

- Traductor Presiune Rtx1000 DruckDocument8 pagesTraductor Presiune Rtx1000 DruckccdumitraNo ratings yet

- Catalog Combined PDF Rev1 Total PDFDocument251 pagesCatalog Combined PDF Rev1 Total PDFccdumitraNo ratings yet

- BrochureDocument6 pagesBrochureccdumitraNo ratings yet

- Air Compressor SF8Document70 pagesAir Compressor SF8ccdumitraNo ratings yet

- p2 - Niwatec Unit ContolDocument1 pagep2 - Niwatec Unit ContolccdumitraNo ratings yet

- HB Ac2 Parallel enDocument116 pagesHB Ac2 Parallel enccdumitraNo ratings yet

- 03 Dew Point Measurements Andy Benton Michell EngezerDocument64 pages03 Dew Point Measurements Andy Benton Michell EngezerccdumitraNo ratings yet

- 20709120Document102 pages20709120ccdumitraNo ratings yet

- 03 Dew Point Measurements Andy Benton Michell EngezerDocument64 pages03 Dew Point Measurements Andy Benton Michell EngezerccdumitraNo ratings yet

- Modbus AumaDocument112 pagesModbus AumaccdumitraNo ratings yet

- Ba Sar1!07!16 Ac1 Nonin Modbus enDocument80 pagesBa Sar1!07!16 Ac1 Nonin Modbus enccdumitraNo ratings yet

- Manual Gasmonitor EnglezaDocument143 pagesManual Gasmonitor EnglezaccdumitraNo ratings yet

- Manual OpDocument6 pagesManual OpccdumitraNo ratings yet

- Pressure Vessel Fabrication & Inspection: Poyyara ConsultantsDocument82 pagesPressure Vessel Fabrication & Inspection: Poyyara ConsultantsRajeeb MohammedNo ratings yet

- O-Cell Specs PDFDocument10 pagesO-Cell Specs PDFMohamed MamdohNo ratings yet

- Model 7601 Transducer Data Sheet-FlowmeterDocument2 pagesModel 7601 Transducer Data Sheet-FlowmeterJorgeSerracínNo ratings yet

- ERHARD Butterfly Valves enDocument32 pagesERHARD Butterfly Valves enMaryug HrNo ratings yet

- PHE-SPE-ICS-411 - Generation and Distribution of Hydraulic EnergyDocument22 pagesPHE-SPE-ICS-411 - Generation and Distribution of Hydraulic Energyminecrf project and mining chennelNo ratings yet

- En 10305-1Document33 pagesEn 10305-1cataldocataldoNo ratings yet

- Nicotra Axial FAN ADFDocument2 pagesNicotra Axial FAN ADFElsa Novita Mardiana100% (1)

- Transporting of ConcreteDocument5 pagesTransporting of ConcreteSreenath TalankiNo ratings yet

- Installation, Operation, Service & Repair Parts ManualDocument8 pagesInstallation, Operation, Service & Repair Parts Manualibula emmanuelNo ratings yet

- Jointing large concrete pipesDocument6 pagesJointing large concrete pipessosi2020No ratings yet

- Alkali Boil Out Procedure - Rev-1Document10 pagesAlkali Boil Out Procedure - Rev-1vahab shaikNo ratings yet

- Anna University CHENNAI - 600 025: B.Tech. Chemical Engineering (Full Time)Document113 pagesAnna University CHENNAI - 600 025: B.Tech. Chemical Engineering (Full Time)Abner kolinNo ratings yet

- Dom Bobr Wagon PDFDocument42 pagesDom Bobr Wagon PDFShantanu DuttaNo ratings yet

- HH PRINCE MISHAL BIN KHALID F. AL-SAUD RESIDENCE RIYADH CHILLER BUILDING BILLDocument74 pagesHH PRINCE MISHAL BIN KHALID F. AL-SAUD RESIDENCE RIYADH CHILLER BUILDING BILLLevy MalagambaNo ratings yet

- European Union. European Regional Development Fund. Investment in Your FutureDocument56 pagesEuropean Union. European Regional Development Fund. Investment in Your FuturemactersaitNo ratings yet

- BOM RMCC Parking-Shed Rev2Document15 pagesBOM RMCC Parking-Shed Rev2Ephrem Marx AparicioNo ratings yet