Professional Documents

Culture Documents

Control boxes for gas burners up to 120kW

Uploaded by

dcarunchioOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Control boxes for gas burners up to 120kW

Uploaded by

dcarunchioCopyright:

Available Formats

SR3 - VE3 - BV3 - GV2 CONTROL BOXES

CONTROL BOXES FOR FORCED DRAUGHT GAS BURNERS, WITH POWER UP TO 120KW.

DESCRIPTION The SR3 - VE3 - BV3 - GV2 safety devices are suitable to control forced draught gas burners for civil and industrial applications. The BV3 control is used for fast boilers in which hot water (or steam) taking has to occur within short times, which cannot be granted by using the SR3 and VE3 devices. The GV2 control box is used for small boilers in which a longer safety time is generally allowed. According to TV Bayern, Monaco, the SR3 control is in compliance with the German regulation DIN 4788, part 3, for power up to 120KW. It also obtained the DIN-DVGW 89.11fBN approval, now expired and not renewable. The Laboratorio di Macchine e Termotecnica del Centro Studi ed Esperienze in Rome, Capannelle, tested the SR3 control for power up to 93KW, which obtained the certification no. 3704/81/77/3A and the approval of the Ministry of the Interior for fire prevention (circulars no. 68 and no. 42). TECHNICAL DATA: Supply voltage:

on request: Operating temperature range: Protection degree: Starting power consumption: Operating power consumption: Max. current rating - burner motor: - EV valve: - ignition transformer: - alarm: Regulators (T, PA, PG): Times: - prepurge time (TV): SR3 - VE3: BV3 - GV2: - safety time (TS): GV2: SR3 - VE3 - BV3: - dropout time on running flame failure: Flame control: - minimum ionization current: - recommended ionization current: - minimum insulation resistance between probe, cable and ground: - voltage on the detection probe: Weight including socket:

220V(-15% +10%) 50Hz ( 5%) 110V -10C +60C IP40 10VA 6,5VA I max. 4A 2A 2A 1A 6A

50 s 20 s 15 s 3s <1 s 0,5 A 7A > 50M 300V 550 g

FLAME CONTROL A transformer having one primary and two secondary windings supplies the electronic flame detection circuit at low voltage, and the detection probe with about 300V. This supply system offers the big advantage of having constant ionization values, even if the network is a live-live installation. To check the efficiency of the flame detection circuit, you have to proceed as follows: connect a low impedance ammeter, as shown in Fig.1; the R1 ... Rn resistors in series must give the total resistance value of 200M (e.g. 20 resistors of 10M 1/4W 5%). If the control box is supplied with 220V, the measured current value is about 0,5+0,6A DC, which causes the flame relay to switch on. Lower current values indicate that the circuit is damaged or only partially efficient.

4009_r00

1/4

Fig.1 CONSTRUCTION The components of the control box are fixed on a pressed frame made of thermohardening material, with high dielectric resistance. The plastic casing protects the device from possible damages resulting from crashes, incautious opening, dust and contact with the external environment. Flexible unipolar conductors of different sizes connect the components of the control, except for the flame detection and prepurge control circuit, which is mounted on a printed circuit. OVERALL DIMENSIONS The overall dimensions of the control box are shown in Fig.2.

(*) The dimensions differ according to the type of socket: 5 with socket A 9 with socket B

Sockets A - B Fig.4

h: Dimensions depending on the type of socket: 95 with socket A 99 with socket B 98.3 with socket N

Fig.2 ACCESSORIES The control is provided with inbuilt reset button and luminous lockout signal. It can be supplied with kanthal flame detection probes in different executions (see, for instance, Fig.3). The casing is arranged for the fitting of core hitches and/or cable holders on its sides; also these accessories can be supplied on request. Socket N Fig.5 Fig.3 CONNECTION As regards the interconnection system of this control, several solutions are possible and different types of connecting sockets can be employed (see Fig.4 and Fig.5). Socket N differs from sockets A and B for its dimensions and the greater number of terminals connecting neutral and ground.

2/4

DIRECTIONS FOR INSTALLATION Control boxes are safety devices and must not be opened; the manufacturers responsibility and guarantee are invalidated if the control is opened. For safety reasons a regulation shutdown must occur every 24 hours. The control can be mounted in any position.

4009_r00

Live and neutral must be connected correctly; a mistake could cause a dangerous situation. The earth terminal of the control, the metal frame of the burner, the earth of the ignition transformer and the earth of the main supply must be well connected. Make sure that the discharge of the ignition transformer does not hit the detection probe. The connecting wire of the detection probe must not be longer than 20 m. Avoid putting the detection cable close to power or ignition cables. Use a heat resistant cable and detection probe, well insulated to the ground and protected from humidity or water in general. Always check the control before the first start and also after any replacement or after a long period of nonoperation of the system. In particular make sure that: The connections are corresponding to the scheme below. The intervention of limiters and safety devices causes a safety shutdown according to the application. The level of the flame signal is high enough. A short circuit between detection probe and burner casing does not cause any flame simulation. In running state, a leakage of the detection probe to the ground causes the interruption of the oil flow and the starting of a new ignition cycle in the case of the BV3 and VE3 controls, while it causes a lockout in the case of the SR3 and GV2 controls.

RESET OF THE CONTROL To reset the control after a lockout, act on the button after waiting for the restoration of the lockout thermal, which usually takes about 20 seconds. ELECTRIC SCHEME SR3

LIVE

FLAME DETECTION CIRCUIT

NEUTRAL

ELECTRIC SCHEME VE3

LIVE

THERMAL TIMERS The safety time is given by a compensated thermal timer. The fixed value of 220 V/20C does not vary of more than 25% with voltage (-15% +10%) and temperature (-10 +60C) variations. The prepurge time is obtained by means of a compensated thermal timer too; in the controls type SR3 and VE3 it is possible to obtain very exact prepurge times even after frequent and repeated starts of the unit, by exploiting the bimetal both in the heating and in the cooling stage. OPERATING CYCLE When thermostats and gas pressure switch are closed, the control box starts up the burner motor. During this period the device carries out a self-check; if the check is positive the cycle continues, and at the end of the prepurge stage the valve and the ignition transformer are simultaneously supplied. During the safety time the flame has to become steady, otherwise the control effects a lockout. Consequently, the valve and the ignition transformer are deenergized, while the lockout signal is supplied. If a limiter or regulator is opened, the oil flow is immediately stopped and the burner is switched off. The enclosed cycle diagrams are useful for a better understanding of the operating cycle of each control box. Abnormal operation: - Air flow failure SR3 - VE3: in case of failure of the air pressure switch the control proceeds to lockout at the end of the prepurge time. BV3: in case of failure of the air pressure switch the control continues the prepurge stage. - Parasitic flame The presence of a parasitic flame signal at start or during the prepurge time causes a lockout immediately or at the end of the prepurge time. Flame failure during operation causes different behaviour, according to the type of control: SR3 - GV2: reignition attempt with transformer supply for a max. period corresponding to the safety time; after this delay, in case no spark restoration occurs, the control performs a lockout. VE3 - BV3: repetition of the whole ignition cycle.

4009_r00

FLAME DETECTION CIRCUIT

NEUTRAL

ELECTRIC SCHEME GV2

LIVE

FLAME DETECTION CIRCUIT

NEUTRAL

ELECTRIC SCHEME SYMBOLS

BF: postpurge and lockout thermal BRM: operation relay ER: detection probe M: burner casing PA: air pressure switch SB: lockout signal TC: boiler thermostat TR: ignition transformer BRF: flame detection relay BRR: repetition cycle relay EV: gas valve MB: burner motor PG: gas pressure switch TA: ambient thermostat TP: thermal programmer 3/4

ELECTRIC SCHEME BV3

LIVE

ELECTRIC SCHEME SYMBOLS BF: postpurge and lockout thermal BRM: operation relay EV: gas valve MB: burner motor PG: gas pressure switch TA: ambient thermostat TP: thermal programmer

BRF: flame detection relay ER: detection probe M: burner casing PA: air pressure switch SB: lockout signal TC: boiler thermostat TR: ignition transformer

FLAME DETECTION CIRCUIT

NEUTRAL

BRAHMA S.p.A. Via del Pontiere, 31 37045 Legnago (VR) Tel. +39 0442 635211 - Telefax +39 0442 25683 http://www.brahma.it E-mail : brahma@brahma.it 4/4

03/03/26 Subject to amendments without notice

4009_r00

You might also like

- Dogs - Pink Floyd chords and tabsDocument2 pagesDogs - Pink Floyd chords and tabsdcarunchioNo ratings yet

- IGBT NoteDocument3 pagesIGBT NoteBheshNo ratings yet

- AHIBA IR Pro Assembly Manual - REV BDocument13 pagesAHIBA IR Pro Assembly Manual - REV BAniceto Fernandez LimachiNo ratings yet

- Liebert Deluxe System 3 - Operation and Maintenance ManualDocument80 pagesLiebert Deluxe System 3 - Operation and Maintenance Manualroblevel3No ratings yet

- XXXXXX: Voltage Drop& Cable Sizing CalculationsDocument5 pagesXXXXXX: Voltage Drop& Cable Sizing CalculationsPradeesh Vijayan (v.prathi)No ratings yet

- Ba BT300 DLT1201 enDocument212 pagesBa BT300 DLT1201 enKan ChoraNo ratings yet

- McQuay Horizontal Water Source Heat Pump - 1/2 To 6 TonDocument74 pagesMcQuay Horizontal Water Source Heat Pump - 1/2 To 6 Tononewheeldoin200100% (1)

- Report 6 (EEE111)Document3 pagesReport 6 (EEE111)Kamal Ahmad75% (8)

- Rm7890a1015 PDFDocument12 pagesRm7890a1015 PDFHéctor VelásquezNo ratings yet

- Manual de Diodos PDFDocument229 pagesManual de Diodos PDFruben riveraNo ratings yet

- Technical Data Sheet For HSV Stud Anchor Technical Information ASSET DOC 2331315Document9 pagesTechnical Data Sheet For HSV Stud Anchor Technical Information ASSET DOC 2331315dcarunchioNo ratings yet

- 7800 Series Burner ControlDocument57 pages7800 Series Burner ControldanterpoNo ratings yet

- 8h APDD 672A, SG Tech - Guide 2011Document90 pages8h APDD 672A, SG Tech - Guide 2011Joao OliveiraNo ratings yet

- 750 193levelmasterDocument50 pages750 193levelmasterJesus CovarrubiasNo ratings yet

- MWCP 2007 PDFDocument72 pagesMWCP 2007 PDFcesar luis gonzalez rodriguezNo ratings yet

- RFC 430Document96 pagesRFC 430birinderNo ratings yet

- Shimaden Digital Controller: Basic FeaturesDocument8 pagesShimaden Digital Controller: Basic FeaturesFranciscoNo ratings yet

- Manual de Control de FlamaDocument42 pagesManual de Control de FlamaJuanJoseBfNo ratings yet

- Used Boiler O&M ManualDocument194 pagesUsed Boiler O&M ManualAlexis CruzNo ratings yet

- EPM 04 04C 04CS EN A4034 Rev9Document4 pagesEPM 04 04C 04CS EN A4034 Rev9khaldoun samiNo ratings yet

- Riello BurnersDocument28 pagesRiello BurnersRomly MechNo ratings yet

- Hyundai Caja Moldeada ResumidoDocument8 pagesHyundai Caja Moldeada Resumidonicor55100% (1)

- Assignments in PLC Module Assignment-1: All Theoretical Notes Should Be Mentioned in Note BookDocument8 pagesAssignments in PLC Module Assignment-1: All Theoretical Notes Should Be Mentioned in Note Bookshubham thakurNo ratings yet

- Datasheet ET1100Document10 pagesDatasheet ET1100Manal FeghaliNo ratings yet

- Sune M: 2V Gel Series Vrla BatteryDocument2 pagesSune M: 2V Gel Series Vrla BatteryAnton KrvavicaNo ratings yet

- Control de Flama Honeywell 215Document12 pagesControl de Flama Honeywell 215Moreno NuevoNo ratings yet

- Manual PFCL - 01i PDFDocument32 pagesManual PFCL - 01i PDFAnonymous uw1GPbmen5100% (1)

- Etekcity ZAP 3L Remote Power OutletDocument28 pagesEtekcity ZAP 3L Remote Power OutletMacraméNo ratings yet

- ABB PID Functional Description PDFDocument33 pagesABB PID Functional Description PDFgicntNo ratings yet

- Manual Smar Tt301Document58 pagesManual Smar Tt301yo_soy_yvette100% (1)

- Dampening Solution Circulator Alpha.d-Line: Technische Daten / Technical DataDocument5 pagesDampening Solution Circulator Alpha.d-Line: Technische Daten / Technical DataGraftec100% (2)

- Manual MT-3000 Modelo 3101 PDFDocument261 pagesManual MT-3000 Modelo 3101 PDFTomás Brown SanabriaNo ratings yet

- Datasheet TachogeneratorDocument4 pagesDatasheet TachogeneratorNurulHidayatNo ratings yet

- High performance audio amplifier notesDocument7 pagesHigh performance audio amplifier notesrory957No ratings yet

- Warning Warning Warning Warning: Operator'S ManualDocument42 pagesWarning Warning Warning Warning: Operator'S ManualLuisNo ratings yet

- Manual MPS3000Document66 pagesManual MPS3000cchung147554No ratings yet

- Boiler Manual Updated 20131Document50 pagesBoiler Manual Updated 20131api-251989125No ratings yet

- Labtechnics LM1 Puck Mill 415V 50Hz PDFDocument21 pagesLabtechnics LM1 Puck Mill 415V 50Hz PDFfullmetalnzsNo ratings yet

- 2500 OR 2503 SERIES CONTROLLER/TRANSMITTER INSTRUCTION MANUALDocument32 pages2500 OR 2503 SERIES CONTROLLER/TRANSMITTER INSTRUCTION MANUALJesus GBNo ratings yet

- C7015 Infrarroja PDFDocument16 pagesC7015 Infrarroja PDFAlfredo Mitzi HernandezNo ratings yet

- ERC 102 Refrigeration Controller: Reference ManualDocument60 pagesERC 102 Refrigeration Controller: Reference ManualAnalista ValidacionesNo ratings yet

- B 103 06Document12 pagesB 103 06Jesus Melchor Melchor100% (1)

- Flygt MAS 711 pump monitoring systemDocument8 pagesFlygt MAS 711 pump monitoring systemrianandiyahooNo ratings yet

- 2.0 VISION 2020i: 2.1 PrecautionsDocument3 pages2.0 VISION 2020i: 2.1 PrecautionsTran Van TienNo ratings yet

- Catalogo Durma PDFDocument17 pagesCatalogo Durma PDFAlfredo Orellana100% (1)

- 160-1.48-RP3 11-97 Micro Computer Control CenterDocument8 pages160-1.48-RP3 11-97 Micro Computer Control Centerbr11uno100% (1)

- User Manual: Screw Air Compressor Controller MAM-KY02SVF B - VF - Monitor-200Document23 pagesUser Manual: Screw Air Compressor Controller MAM-KY02SVF B - VF - Monitor-200Biplob MiaNo ratings yet

- Manual Grimm enDocument95 pagesManual Grimm enJonatan Enriquez50% (2)

- 040 - EL-6 Programing Manual-Maxiwash SP PDFDocument36 pages040 - EL-6 Programing Manual-Maxiwash SP PDFLinh TranNo ratings yet

- Technical Instruction F-50SH Compressor Unit - IM - CD33ZZ-080 - A 3 2Document65 pagesTechnical Instruction F-50SH Compressor Unit - IM - CD33ZZ-080 - A 3 2Ruturaj UmaranikarNo ratings yet

- Eco 80 Wind Turbine PlatformDocument2 pagesEco 80 Wind Turbine PlatformKarthick Velayutham0% (2)

- Catalogue Brushless DC Drives GB 02 2007Document56 pagesCatalogue Brushless DC Drives GB 02 2007Bianca CerveiraNo ratings yet

- Quincy 106 y 108Document45 pagesQuincy 106 y 108nelsonp12No ratings yet

- MAN-2004-0001-C - User Guide - Pcorr and Permalog Using WebCorr App PDFDocument56 pagesMAN-2004-0001-C - User Guide - Pcorr and Permalog Using WebCorr App PDFGabiBaciuNo ratings yet

- Catalogo He 2004Document85 pagesCatalogo He 2004ferenscribd0% (1)

- Calefaccion Solar SolvisDocument44 pagesCalefaccion Solar SolvisjomarmaeNo ratings yet

- TV Analyzer R&S Fsh3-Tv: Operating ManualDocument445 pagesTV Analyzer R&S Fsh3-Tv: Operating ManualqiqeonNo ratings yet

- Sensor de Llama Honeywell C7012 Purple PeeperDocument20 pagesSensor de Llama Honeywell C7012 Purple PeeperCarlos Tomey0% (1)

- Joslyn Hi-Voltage Overhead Reclosers PDFDocument46 pagesJoslyn Hi-Voltage Overhead Reclosers PDFmohamed0% (1)

- Santerno SINUS M User ManualDocument219 pagesSanterno SINUS M User ManualnelsonNo ratings yet

- MF2 control box for forced draught burnersDocument4 pagesMF2 control box for forced draught burnersamicarelliNo ratings yet

- EUROGAS SERIES AUTOMATIC CONTROL SYSTEMS FOR GASEOUS FUELSDocument4 pagesEUROGAS SERIES AUTOMATIC CONTROL SYSTEMS FOR GASEOUS FUELSRonan CristhiamNo ratings yet

- Detector FogoDocument4 pagesDetector FogoMarcos AugustoNo ratings yet

- BrahmaDocument4 pagesBrahmamegaciclonNo ratings yet

- Gas Separator Top ViewDocument1 pageGas Separator Top ViewdcarunchioNo ratings yet

- Gas Separator General ViewDocument1 pageGas Separator General ViewdcarunchioNo ratings yet

- Gas Separator View 1Document1 pageGas Separator View 1dcarunchioNo ratings yet

- Gas Separator Iso ViewDocument1 pageGas Separator Iso ViewdcarunchioNo ratings yet

- Pipe LineDocument1 pagePipe LinedcarunchioNo ratings yet

- Asme TK MODELDocument1 pageAsme TK MODELdcarunchioNo ratings yet

- Crude Oil Piping Isometric ViewDocument1 pageCrude Oil Piping Isometric ViewdcarunchioNo ratings yet

- DrainDocument1 pageDraindcarunchioNo ratings yet

- Crude Oil PipingDocument1 pageCrude Oil PipingdcarunchioNo ratings yet

- BujiasDocument1 pageBujiasdcarunchioNo ratings yet

- Asme TK Plant SectionDocument1 pageAsme TK Plant SectiondcarunchioNo ratings yet

- Asme TK Lateral SectionDocument1 pageAsme TK Lateral SectiondcarunchioNo ratings yet

- Awwa SpoolDocument1 pageAwwa SpooldcarunchioNo ratings yet

- Recipient EDocument1 pageRecipient EdcarunchioNo ratings yet

- Piping SolidworksDocument1 pagePiping SolidworksdcarunchioNo ratings yet

- Maxon 5500 InstructionsDocument8 pagesMaxon 5500 InstructionsdcarunchioNo ratings yet

- ManifoldDocument1 pageManifolddcarunchioNo ratings yet

- Display Honeywell s7999 Controlinks DisplayDocument12 pagesDisplay Honeywell s7999 Controlinks DisplaydcarunchioNo ratings yet

- Aisi 347 CaracteristicasDocument2 pagesAisi 347 CaracteristicasdcarunchioNo ratings yet

- Performance LogDocument1 pagePerformance LogdcarunchioNo ratings yet

- Maxon 5550 BulletinDocument4 pagesMaxon 5550 BulletindcarunchioNo ratings yet

- Mediciones CEMS - ZZ-025-0802EDocument4 pagesMediciones CEMS - ZZ-025-0802EdcarunchioNo ratings yet

- PipeDocument8 pagesPipedcarunchioNo ratings yet

- 7800 - Relay Cleaver BroksDocument20 pages7800 - Relay Cleaver Broksrubl770622No ratings yet

- Maxon 5500 InstructionsDocument8 pagesMaxon 5500 InstructionsdcarunchioNo ratings yet

- BELIMO LM24 ActuadorDocument2 pagesBELIMO LM24 ActuadordcarunchioNo ratings yet

- Bomba Dosificadora Flyer DMH 2.2 - 3000 LTS-HDocument2 pagesBomba Dosificadora Flyer DMH 2.2 - 3000 LTS-HdcarunchioNo ratings yet

- Actuador Honeywell ML 7999 B - Ds - 65-0264Document12 pagesActuador Honeywell ML 7999 B - Ds - 65-0264dcarunchioNo ratings yet

- Electronic Components and DevicesDocument6 pagesElectronic Components and DevicesSelvam MNo ratings yet

- LT Panel MCC Revalidation Report - (Ril J3 Project) : S.No Check Points Observation RemarksDocument48 pagesLT Panel MCC Revalidation Report - (Ril J3 Project) : S.No Check Points Observation RemarksSanjay Kumar KanaujiaNo ratings yet

- Program Controller For RCA2/RCA: List of ModelsDocument10 pagesProgram Controller For RCA2/RCA: List of ModelsElectromateNo ratings yet

- BQ 24721 CDocument60 pagesBQ 24721 CdanielarteagaNo ratings yet

- MT121050 (12V105Ah) : Cyclic Charging Voltage (25°C)Document1 pageMT121050 (12V105Ah) : Cyclic Charging Voltage (25°C)Anderson Ferney Rodriguez JimenezNo ratings yet

- Vocational Training in Electrical SystemsDocument27 pagesVocational Training in Electrical SystemsMadhav KumarNo ratings yet

- Liebert Npower Guide SpecificationsDocument16 pagesLiebert Npower Guide SpecificationsJOSE MIGUEL AYALA DURANNo ratings yet

- Dibl Extraction: Ssuprem 4/S-PiscesDocument1 pageDibl Extraction: Ssuprem 4/S-PiscesBhaskar KNo ratings yet

- Synchronous MotorDocument21 pagesSynchronous MotorCristele Mae GarciaNo ratings yet

- M o D U L e 0 4 - 0 1 - 0 1 A Electronic Fundamentals: DiodesDocument33 pagesM o D U L e 0 4 - 0 1 - 0 1 A Electronic Fundamentals: DiodesИлларион ПанасенкоNo ratings yet

- Installation Instructions 7639039 7639040 Mixer ExtensionDocument32 pagesInstallation Instructions 7639039 7639040 Mixer ExtensionB0gdanNo ratings yet

- Cathode Ray OscilloscopeDocument24 pagesCathode Ray OscilloscopeAntonovNo ratings yet

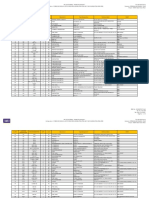

- BILL OF MATERIAL - PVS980-58-5000kVA-L Configuration: PVS980-58-5000kVA-L+K475+F296+F263+30H382+F320+F300+G417+G415+G398+R708+P902+P928Document3 pagesBILL OF MATERIAL - PVS980-58-5000kVA-L Configuration: PVS980-58-5000kVA-L+K475+F296+F263+30H382+F320+F300+G417+G415+G398+R708+P902+P928Francisco Aguirre VarasNo ratings yet

- Tesla Guardian Installation ManualDocument3 pagesTesla Guardian Installation ManualNelson Tawanda MagombedzeNo ratings yet

- Thyristor As A SwitchDocument4 pagesThyristor As A Switchuqink100% (2)

- Schmitt TriggerDocument4 pagesSchmitt TriggerHassan M KhanNo ratings yet

- STW21NM50N MosfetDocument16 pagesSTW21NM50N MosfetrigowNo ratings yet

- Devicenet: Leoni Special Cables GMBHDocument2 pagesDevicenet: Leoni Special Cables GMBHLeodoletaNo ratings yet

- HTP-538 Service Manual Speaker PackageDocument18 pagesHTP-538 Service Manual Speaker PackagerigaboNo ratings yet

- Prescolite Architectural Lighting Catalog G-17 1969Document104 pagesPrescolite Architectural Lighting Catalog G-17 1969Alan MastersNo ratings yet

- Electrical Safety and Meter FundamentalsDocument151 pagesElectrical Safety and Meter FundamentalsRav Pedimonte MontalesNo ratings yet

- MS2244Document9 pagesMS2244Vukica IvicNo ratings yet

- Hybrid Solar Wind Trainer Generates Renewable EnergyDocument3 pagesHybrid Solar Wind Trainer Generates Renewable EnergySasa VrtunicNo ratings yet

- Pioneer DEH546Document77 pagesPioneer DEH546Alessandro SilvaNo ratings yet

- "KEI" Three Core Aluminium & Copper Conductor, XLPE Insulated, Armoured Cable Conforming To IS 7098 Part-2/1985Document7 pages"KEI" Three Core Aluminium & Copper Conductor, XLPE Insulated, Armoured Cable Conforming To IS 7098 Part-2/1985rakeshamechNo ratings yet

- K46CM Repair Guide: Jul/23/2012 John - Jin Csc-GrmaDocument5 pagesK46CM Repair Guide: Jul/23/2012 John - Jin Csc-Grmaanas symbianNo ratings yet

- PAM410 DS en V02Document2 pagesPAM410 DS en V02Irfan AshrafNo ratings yet