Professional Documents

Culture Documents

7201

Uploaded by

hidalguenxeOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7201

Uploaded by

hidalguenxeCopyright:

Available Formats

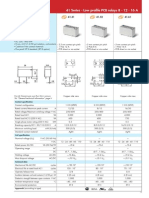

72 Series - Monitoring relays 16 A Features

Level control relays for conductive liquids 72.01 - Adjustable sensitivity 72.11 - Fixed sensitivity Emptying or filling functions LED indicator Reinforced insulation (6 kV - 1.2/50 s) between: - supply and contacts - electrodes and supply - contacts and electrodes 35 mm rail (EN 50022) mount Control about a single level or between Min./Max. limits 72.01 available also for supply 400 V

72.01

72.11

Sensitivity range (5...150) k adjustable Delay time (0.5s or 7s) switch selectable Emptying or filling functions switch selectable

Sensitivity fixed 150 k Delay time fixed: 1s Emptying or filling functions link selectable

L/+ N/54.6 35 42.3

U = 24 V DC 24 V AC 50/60 Hz (110...125)V AC 50/60 Hz (230...240)V AC 50/60 Hz FL EL

L/+ N/-

U = 24 V DC 24 V AC 50/60 Hz (110...125)V AC 50/60 Hz (230...240)V AC 50/60 Hz

FS FS ES

A1 A2 12 11 14 A1 A2 12 11 14 Z1 Z2

F = Filling

44.8

84

LEVEL

B1 B2 B3

LEVEL

Z1 Z2 B1 B2 B3 Z1 Z2

E = Emptying

T=1s R = 150 k

R = (5150)k

58

FOR UL HORSEPOWER AND PILOT DUTY RATINGS SEE General technical information page V

Contact specification Contact configuration Rated current/Maximum peak current Rated load AC1 Rated load AC15 (230 V AC) Single phase motor rating (230 V AC) Breaking capacity DC1: 30/110/220 V Minimum switching load Standard contact material Supply specification Nominal voltage (UN) Rated power AC/DC Operating range Technical data Electrical life at rated load AC1 Electrode voltage Electrode current Run-on time Max sensitivity range Ambient temperature Protection category Approvals (according to type) cycles V AC mA s k C V AC V DC VA (50 Hz)/W AC DC A VA VA kW A Rated voltage/Maximum switching voltage V AC

FL = Filing 7s delay FS = Filling 0.5s delay ES = Emptying 0.5s delay EL = Emptying 7s delay

1 CO (SPDT) 16/30 250/400 4,000 750 0.55 16/0.3/0.12 500 (10/5) AgCdO 24 - 110...125 230...240 24 2.5/1.5 (0.8...1.1)UN (0.8...1.1)UN 100 103 4 0.2 0.5 - 7 (selectable) 5150 (adjustable) 6 20+60 IP20 400 2.5/1.5 (0.9...1.15)UN

1 CO (SPDT) 16/30 250/400 4,000 750 0.55 16/0.3/0.12 500 (10/5) AgCdO 24 - 110...125 230...240 24 2.5/1.5 (0.8...1.1)UN (0.8...1.1)UN 100 103 4 0.2 1 150 (fixed) 6 20+60 IP20

mW (V/mA)

Insulation between supply/contacts/electrode (1.2/50 s) kV

72 Series - Monitoring relays 6 A Features

3 Phase - Rotation and phase loss monitoring relay Universal voltage monitoring (UN from 208 V to 480 V, 50/60 Hz) Phase loss monitoring, under phase regeneration Positive safety logic - make contact opens if the relay detects an error Small size (17.5 mm wide) 35 mm rail (EN 50022) mount European patent pending for the fully innovative principle at the root of the 3 phase monitoring and error survey system

72.31

Phase rotation monitoring Phase loss monitoring

56.5 43.5 26.5 17.5

L1 L2 L3

A2

UN= (208...480) V AC 3~ (50/60 Hz)

A1 A3

A1

A2

A3

45

84

3~U

11

14

14

12

11

12

Contact specification Contact configuration Rated current/Maximum peak current Rated load AC1 Rated load AC15 (230 V AC) Single phase motor rating (230 V AC) Breaking capacity DC1: 30/110/220 V Minimum switching load Standard contact material Supply specification Nominal system voltage (UN) Frequency Rated power Operating range Technical data Electrical life at rated load AC1 Switch-off/reaction time Ambient temperature Protection category Approvals (according to type)

2

1 CO (SPDT) A VA VA kW A 6/15 250/400 1,500 250 0.185 3/0.35/0.2 500 (10/5) AgCdO V AC 3 ~ Hz VA 50 Hz/ W V AC 3 ~ cycles s C 208...480 50/60 8/1 170...500 100 103 <0.5/<0.5 20+50 IP20

Rated voltage/Maximum switching voltage V AC

mW(V/mA)

72 Series - Monitoring relays 6 -16 A

Ordering information

Level control relays Example: 72 series level control relay, adjustable sensitivity range, (230240)V AC supply voltage.

7 2 . 0

Series Type 0 = Sensitivity range adjustable (5...150)k 35 mm rail (EN 50022) mount 1 = Sensitivity fixed 150 k 35 mm rail (EN 50022) mount No. of poles 1 = 1 CO (SPDT)

1 . 8 . 2 4 0 . 0

Supply voltage 024 = 24 V 125 = (110125)V AC 240 = (230240)V AC 400 = 400 V AC (72.01 only) Supply version 8 = AC (50/60 Hz) 9 = DC

Monitoring relays Example : 3 phase line monitoring relay, phase rotation and loss monitoring, supply voltage (208480)V AC 3~.

7 2 . 3

Series Type 3 = 3 phase AC line monitoring No. of poles 1 = 1 CO

1 . 8 . 4 0 0 . 0

Supply voltage 400 = (208...480)V AC 3~ Supply version 8 = AC (50/60 Hz)

72 Series - Monitoring relays 6 - 16 A

Technical data for 72.01 and 72.11

Insulation Insulation between supply and contacts between electrodes, Z1-Z2 and supply* between contacts and electrodes between open contacts EMC specifications Type of test Electrostatic discharge contact discharge air discharge Radio-frequency electromagnetic field (80 1000 MHz) Fast transients (burst) (5-50 ns, 5 kHz) on Supply terminals Surges (1.2/50 s) on Supply terminals Radio-frequency common mode (0.15 80 MHz) on Supply terminals Radiated and conducted emission Other data Current absorption on Z1 and Z2 Power lost to the environment Screw torque Max. wire size mm Max cable length between electrode and relay

2

Dielectric strength 4,000 V AC 4,000 V AC 4,000 V AC 1,000 V AC Reference standard EN 61000-4-2 EN 61000-4-2 EN 61000-4-3 EN 61000-4-4 EN 61000-4-5 EN 61000-4-6 EN 55022 mA W W Nm <1 1.5 3.2 0.8 solid cable 1x6 / 2x4 1x10 / 2x12 AWG m

Impulse (1.2/50 s) 6 kV 6 kV 6 kV 1.5 kV

4 kV 8 kV 10 V/m 4 kV 4 kV 10 V class B

without contact current with rated current

stranded cable 1x4 / 2x2.5 1x12 / 2x14

200 (max. capacitance of 100 nF/km)

* There is no electrical isolation between electrodes and supply voltage for the 24 V DC types (72.x1.9.024.0000). Therefore, for SELV applications it would be necessary to use a SELV (non-grounded) power supply. In the case of a PELV (grounded) power supply take care to protect the level control relay against harmful circulating currents by ensuring that no electrodes are grounded. However, there is no such problem for the 24 V AC types (72.x1.8.024.0000) which, by virtue of an internal isolating transformer, assure reinforced isolation between electrodes and supply.

Technical data for 72.31

Insulation Insulation between supply and contacts between open contacts EMC specifications Type of test Electrostatic discharge contact discharge air discharge Fast transients (burst) (5-50ns, 5kHz) on A1, A2, A3 Surge (1.2/50 s) Other data Start up time (NO contact closure after energising) Regeneration level (Maximum) Power lost to the environment Screw torque Max. wire size mm

2

Dielectric strength 3,000 V 1,000 V Reference standard EN 61000-4-2 EN 61000-4-2 EN 61000-4-4 EN 61000-4-5 s W W Nm <2

Impulse (1.2/50 s) 5 kV 1.5 kV

4 kV 8 kV 2 kV 4 kV

differential mode

80% of average of other 2 phase without contact current with rated current 1 1.4 0.8 solid cable 1x6 / 2x4 1x10 / 2x12 AWG stranded cable 1x4 / 2x2.5 1x12 / 2x14

72 Series - Monitoring relays 16 A

Functions for 72.01 and 72.11

U B1 B2 B3 = Supply voltage = Max level electrode = Min level electrode = Common = Contact 11-14 Z1-Z2 = Link to select emptying (Type 72.11) LED Supply voltage OFF ON ON ON NO output contact Open Open Open (Timing in Progress) Closed Contacts Open 11 - 14 11 - 14 11 - 14 11 - 12 Closed 11 - 12 11 - 12 11 - 12 11 - 14

Function and Run-on time Type 72.01 FL = Level control by Filling, Long (7sec) run-on delay. FS = Level control by Filling, Short (0.5sec) run-on delay. ES = Level control by Emptying, Short (0.5sec) run-on delay. EL = Level control by Emptying, Long (7sec) run-on delay. Type 72.11 F = Level control by Filling, Z1Z2 open. Run-on time fixed at 1sec. E = Level control by Emptying, Z1Z2 linked. Run-on time fixed at 1sec.

Filling functions

Wiring diagram

Type 72.01

L/+ N/-

Examples with 3 electrodes

U = 24 V DC 24 V AC 50/60 Hz (110...125)V AC 50/60 Hz (230...240)V AC 50/60 Hz

A1 A2 12 11 14

U Level B1 B2 B3

FS

FL FS ES EL

LEVEL

B1 B2 B3

Filling Control between Min. and Max. levels. Under normal operation the liquid level can be expected to cycle between the Minimum and the Maximum electrodes, B2 and B1 (plus a degree of over and under-shoot). Switch On: On power-up, if the liquid is below B1 the output relay will operate after time T has expired. On the liquid level falling below B2, the output relay will operate after time T has expired.

T T T T T

R = (5150)k

Type 72.11

L/+ N/-

A1

A2

12

11 14 Z1 Z2

F = Filling

LEVEL

B1 B2 B3 Z1 Z2

T=1s R = 150 k

Switch Off: On the liquid level reaching electrode B1, the output relay will de-energise after time T has expired. On power-off, the output relay will immediately de-energise.

Wiring diagram

Type 72.01

L/+ N/-

Examples with 2 electrodes

U = 24 V DC 24 V AC 50/60 Hz (110...125)V AC 50/60 Hz (230...240)V AC 50/60 Hz

A1 A2 12 11 14

U Level B1 B2 B3

FS FS ES EL

FL

Filling Control about a single level, B1. Under normal operation the liquid evel can be expected to cycle about the level set by electrode B1 with a degree of over and under-shoot. Switch On: On power-up, if the liquid is below B1 the output relay will operate after time T has expired. On the liquid level falling below B1, the output relay will operate after time T has expired. Switch Off: On the liquid level reaching electrode B1, the output relay will de-energise after time T has expired. On power-off, the output relay will immediately de-energise.

LEVEL

B1 B2 B3

R = (5150)k

Type 72.11

L/+ N/-

A1 A2 12 11 14 Z1 Z2

F = Filling

T T

LEVEL

B1 B2 B3 Z1 Z2

T=1s R = 150 k

72 Series - Monitoring relays 16 A

Emptying functions

Wiring diagram

Type 72.01

L/+ N/-

Examples with 3 electrodes

U = 24 V DC 24 V AC 50/60 Hz (110...125)V AC 50/60 Hz (230...240)V AC 50/60 Hz

A1 A2 12 11 14

U Level B1 B2 B3

EL FS ES

EL

FL

LEVEL

B1 B2 B3

Emptying Control between Max. and Min. levels. Under normal operation the liquid level can be expected to cycle between the Maximum and the Minimum electrodes, B1 and B2 (plus a degree of over and under-shoot). Switch On: On power-up, if the liquid level is above B2 the output relay will operate after time T has expired. On the liquid level rising to B1, the output relay will operate after time T has expired. Switch Off: On the liquid level falling below electrode B2, the output relay will de-energise after time T has expired. On power-off, the output relay will immediately de-energise.

R = (5150)k

Type 72.11

L/+ N/-

A1

A2

12

11 14

E = Emptying

Z1 Z2

LEVEL

B1 B2 B3 Z1 Z2

T T

T=1s R = 150 k

Wiring diagram

Type 72.01

L/+ N/-

Examples with 2 electrodes

U = 24 V DC 24 V AC 50/60 Hz (110...125)V AC 50/60 Hz (230...240)V AC 50/60 Hz

A1 A2 12 11 14

EL FS ES

EL

FL

Level

Emptying Control about a single level, B1. Under normal operation the liquid level can be expected to cycle about the level set by electrode B1 with a degree of over and under-shoot. Switch On: On power-up, if the liquid is above B1 the output relay will operate after time T has expired. On the liquid level rising to B1, the output relay will operate after time T has expired. Switch Off: On the liquid level falling below electrode B1, the output relay will de-energise after time T has expired. On power-off, the output relay will immediately de-energ

LEVEL

B1 B2 B3

R = (5150)k

Type 72.11

L/+ N/-

A1 A2 12 11 14

Z1 Z2

E = Emptying

LEVEL

B1 B2 B3 Z1 Z2

T=1s R = 150 k

Applications for 72.01 and 72.11

FILLING function: Examples with 3 electrodes and with a contactor connected to the contact.

L1 L2 L3 N S

EMPTYING function: Examples with 3 electrodes and with a motor pump connected directly to the contact.

L1 L2 L3 N S

The 72 series level control relays work by measuring the resistance through the liquid, between the common (B3) electrode and Min. and Max. electrodes (B2 and B1). If the tank is metalic, then this can be substituted as the B3 electrode. Take care to ensure that the liquid has a suitable resistivity see below: SUITABLE LIQUIDS - City water - Well water - Rainwater - Sea water - Liquids with low-percentage alcohol - Wine - Milk, Beer, Coffee - Sewage - Liquids fertilizer UN-SUITABLE LIQUIDS - Demineralised water - Fuels - Oil - Liquids with high-percentage alcohol - Liquid gas - Paraffins - Ethylene glycol - Paint

A1 A2

12

11 14

A1 A2

12 11 14

B1 B2 B3

B1 B2 B3

Max Min Com

Max Min Com

72 Series - Monitoring relays 6 A

Functions for 72.31

L1, L2, L3 = Supply voltage = Contact 11- 14 LED status Supply voltage OFF - Incorrect phase rotation - Phase loss Normal operation Supply voltage OFF Open ON ON Closed 11 - 12 11 - 14 11 - 14 11 - 12 NO output contact Contacts Closed Open

L1 L2 L3

UN= (208...480) V AC 3~ (50/60 Hz)

UN

L1

0.8 UN (*)

Switch off - Incorrect phase rotation - Phase loss Output contact (11 - 14) - Closed, if monitored system healthy (*) Phase loss monitoring possible under regeneration up to 80% of the average of the other 2 phases

A1

A2

A3

L2

3~U

L3

14 11 12

11 - 14

72 Series - Monitoring relays

Accessories for 72.01 and 72.11

Suspended electrode for conductive liquids, complete with cable. Suitable for level monitoring in wells and reservoirs not under pressure. All materials used are compatible with food processing applications (according to European Directive 2002/72 and cod. FDA title 21 part 177). Order appropriate number of electrodes - additional to the relay. 072.01.06 Cable length: 6 m (1.5 mm2) Cable length: 15 m (1.5 mm2) Technical data Max. liquid temperature

6m/15m

072.01.06 072.01.15 C +100

23

Electrode holder with two pole connector, one connected directly to the electrode and the second connected to the grounded installation thread. Suitable for metal tank with G3/8 linkage. Electrode not incuded. Order appropriate number of electrodes holders - additional to the relay. Technical data

072.51

58

072.51 C bar mm + 100 12 6

Max liquid temperature Max tank pressure Cable grip

1 2

ch 22 11

G 3/8 M4 10 9

M4 6 14

Electrode holder with three poles. Electrode not incuded. Order appropriate number of electrodes holders - additional to the relay. Technical data Max liquid temperature

072.53

23

072.53 C + 130

66

5

10 83 80

12

18

20

91 25 2 GAS M4

72 Series - Monitoring relays

Accessories for 72.01 and 72.11

Electrode and electrode connector, multiple electrodes may be interconneced to provide required length Technical data Electrode - 500 mm long, M4 thread, stainless steel Inter-electrode connector - M4 thread, stainless steel 072.500

Illustration of interconnection of electrodes.

072.500 072.501

072.501

72 Series - Monitoring relays

Application notes for 72.01 and 72.11

Applications The main application for these relays is for the sensing and control of the level of conductive liquids. Selectable options allow for this control to be achieved either through a filling operation or through an emptying operation, and in either case positive logic is used. Level control can be achieved around a single level using 2 electrodes, or between Minimum and Maximum levels using 3 electrodes. Additionally, the 72.01, with its adjustable sensitivity setting, can be ideal for monitoring the conductivity of liquids. Positive safety logic These relays work according to the principle that it is the closure of a normally open output contact that will be used to control the pump, both in filling and emptying applications. Consequently, in the event of a failure of the supply local to the relay, the filling or emptying will cease. This is generally considered to be the safest option. Overrunning of tank on filling Care must be exercised to ensure that the tank cannot overrun. Factors that have to be considered are the pump performance, the rate of discharge from the tank, the position of the single level electrode (or maximum electrode), and the run-on time delay. Keeping the time delay to a minimum will minimise the possibility of tank overrun, but will increase the installed switching rate. Prevent dry running of pump on emptying Care must be exercised to ensure that the pump cannot run dry. Similar considerations must be given as outlined above. In particular, keeping the run-on time delay to a minimum will minimise the risk, but again, it will increase the installed switching rate. Run-on time In commercial and light industrial applications the use of a short Run-on time delay is more appropriate, due to the relatively small size of tanks and the consequential need to react quickly to the change in level. Larger scale industrial applications involving larger tanks and powerful pumps must avoid a frequent switching cycle, and the use of the 72.01 set for the longer Run-on time of 7 seconds is suggested. Note that the short run-on time will always achieve closer control to the desired level(s), but at the cost of more frequent switching. Electrical life of the output contact The electrical life of the output contact will be enhanced where a larger distance between the Max. and Min. electrodes (3-electrode control) can be realised. A smaller distance, or level control to a single level (2-electrode control), will result in more frequent switching and therefore a shorter electrical life for the contacts. Similarly, the long run-on time will enhance, and the short time will reduce, electrical life. Pump control Small single-phase pumps within the kW (0.55 kW - 230 V AC) rating stated may be driven directly by the level relay output contact. However, where very frequent switching is envisaged, it is better to slave a higher power relay or contactor to drive the pump motor. Large pumps (singlephase and three-phase) will of course require an interposing contactor. Electrodes and cable lengths Normally 2 electrodes or 3 electrodes will be required for control about a single level, or control between Min. and Max. levels, respectively. However, if the tank is made of conductive material it is possible to use this as the common electrode, B3, if electrical connection can be made to it. The maximum permitted length of cable between the electrode and the relays is 200m, for a cable not exceeding 100nF/km. A maximum of 2 relays and associated electrodes can be employed in the same tank if two different levels need monitoring. Note: It is permitted to make direct electrical connection between terminals B1-B3, and B2-B3, (without using electrodes/liquid), but in this case it is not possible to set up the sensitivity. Electrode choice The choice of electrodes may depend on the liquid being monitored. Standard electrodes 072.01.06 and 072.51 are suitable for many applications but some liquids may be corrosive for example, and may therefore require custom made electrodes - but these can usually be used with the 72.01 and 72.11 relays. On site commissioning To confirm the suitability of the relay sensitivity to the resistance between electrodes it is suggested that the following checks are made. For convenience it is suggested that the fill function and the shortest run-on time are selected. Commissioning Follow these setting-up instructions to achieve correct operation: 72.01 Select the function FS (Filling and Short delay of 0.5 s), and set the sensitivity control to 5 k. Ensure that all electrodes are immersed in the liquid - expect the output relay to be ON. Then, slowly rotate the sensitivity control in the 150 k direction until the level relay switches OFF (internal output relay will switch OFF and red LED will switch slowly flash). (If the level relay does not switch OFF then, either the electrodes are not immersed, or the liquid has too high impedance or the distance between electrodes is too long). Finally, select the filling or emptying function as required, run in real time and confirm that the level relay works as required. 72.11 Select the Filling function F, (Z1 Z2 open). Ensure that all electrodes are immersed in the liquid, but leave electrode B3 disconnected output relay should be ON. Connect electrode B3, and the level relay should switch OFF (internal output relay will switch OFF and red LED will switch slowly flash). (If the level relay does not switch OFF then, either the electrodes are not immersed, or the liquid has too high impedance or the distance between electrodes is too long.) Finally, select the filling or emptying function as required, run in real time and confirm that the level relay works as required.

10

You might also like

- Finder Relays Series 60Document6 pagesFinder Relays Series 60javedafridiNo ratings yet

- General purpose relay guide with AgCdO contactsDocument15 pagesGeneral purpose relay guide with AgCdO contactstwinvbooksNo ratings yet

- Abb Af16 22 00Document8 pagesAbb Af16 22 00LarreinetaNo ratings yet

- Re7rm11bu PDFDocument7 pagesRe7rm11bu PDFToth VasileNo ratings yet

- Notice Technique SV110230 en PDFDocument2 pagesNotice Technique SV110230 en PDFe-genieclimatique.comNo ratings yet

- LTC1073fa DatasheetDocument16 pagesLTC1073fa DatasheetKushal KshirsagarNo ratings yet

- Telemecanique ContactorDocument26 pagesTelemecanique ContactorgeoghoNo ratings yet

- 50N06 Mosfet Datasheet PDFDocument8 pages50N06 Mosfet Datasheet PDFjoshomecNo ratings yet

- LT1073 Usos y Aplicaciones 1.5V To 12VDocument16 pagesLT1073 Usos y Aplicaciones 1.5V To 12VJose Alberto Zamacona VargasNo ratings yet

- Data Sheet: Current Relays, RMC-111D, RMC-122D, RMC-132D ANSI Codes 50/51Document8 pagesData Sheet: Current Relays, RMC-111D, RMC-122D, RMC-132D ANSI Codes 50/51LUATNo ratings yet

- Eaton 031885 ETR4 51 W en - GBDocument4 pagesEaton 031885 ETR4 51 W en - GBblade_king_3No ratings yet

- Carlo Gavazzi Level RelayDocument5 pagesCarlo Gavazzi Level RelayPeter CalvoNo ratings yet

- Relais Temporise Mur3 CrouzetDocument5 pagesRelais Temporise Mur3 CrouzetAidolan UlrichNo ratings yet

- Finder Relays Series 60 PDFDocument6 pagesFinder Relays Series 60 PDFzrcjsyllNo ratings yet

- Zelio Control RM35LM33MWDocument6 pagesZelio Control RM35LM33MWZainul FananiNo ratings yet

- Finder Serie 55Document14 pagesFinder Serie 55youri59490No ratings yet

- DatasheetDocument13 pagesDatasheetebertecnicoNo ratings yet

- RMC-131D Differential Current Relay Data SheetDocument8 pagesRMC-131D Differential Current Relay Data Sheetdavid loughlinNo ratings yet

- Product data sheet for RE7ML11BU time delay relayDocument9 pagesProduct data sheet for RE7ML11BU time delay relaydefmerol01No ratings yet

- Data Sheet: Issued November 2009 12491Document45 pagesData Sheet: Issued November 2009 12491leonan barcellosNo ratings yet

- Tda 7250Document12 pagesTda 7250killer_jj100% (1)

- Finder 16A 12V DC Relay Datasheet.Document10 pagesFinder 16A 12V DC Relay Datasheet.velizarkoNo ratings yet

- ABB Substation Automation Trip Circuit Supervision Relay RXTCS Technical Data SheetDocument6 pagesABB Substation Automation Trip Circuit Supervision Relay RXTCS Technical Data SheetEr Anoop GuptaNo ratings yet

- 700 td557 - TIMERDocument8 pages700 td557 - TIMER_golob_No ratings yet

- RMC 131d Data Sheet 4921240104 UkDocument8 pagesRMC 131d Data Sheet 4921240104 UkAilton NevesNo ratings yet

- Toshiba Field Effect Transistor SpecificationDocument6 pagesToshiba Field Effect Transistor Specificationvanderlei_pinheiroNo ratings yet

- CMS 156 Technical Data ENUDocument1 pageCMS 156 Technical Data ENUKhairun Nizam SarminNo ratings yet

- f6150sv Ts Us LRDocument4 pagesf6150sv Ts Us LREngr Irfan AkhtarNo ratings yet

- SFA350 :: ROAL Living EnergyDocument6 pagesSFA350 :: ROAL Living EnergyroalscribdNo ratings yet

- MFA350 :: ROAL Living EnergyDocument6 pagesMFA350 :: ROAL Living EnergyroalscribdNo ratings yet

- ENP Liebert NX UPS SpecificationDocument5 pagesENP Liebert NX UPS SpecificationChathura DharmasenaNo ratings yet

- 30V P-Channel MOSFET Technical DocumentDocument5 pages30V P-Channel MOSFET Technical DocumentYonatan RivadeneyraNo ratings yet

- ATV212HD45N4: Product Data SheetDocument11 pagesATV212HD45N4: Product Data SheetArren KhanNo ratings yet

- Earth Leakage Relays Elrm44v-1-ADocument1 pageEarth Leakage Relays Elrm44v-1-Aapi-230026640No ratings yet

- Toshiba Field Effect Transistor Silicon N Channel MOS Type Spec SheetDocument6 pagesToshiba Field Effect Transistor Silicon N Channel MOS Type Spec SheetJoão Paulo GiacomelloNo ratings yet

- Ap5002 - PWM Control 2a Step-Down ConverterDocument10 pagesAp5002 - PWM Control 2a Step-Down ConverterAmador Garcia IIINo ratings yet

- Switching Regulator Applications: Absolute Maximum RatingsDocument6 pagesSwitching Regulator Applications: Absolute Maximum RatingsincarnatedbuddhaNo ratings yet

- RA 5-1 Interface Relays: ApplicationDocument3 pagesRA 5-1 Interface Relays: Applicationpata nahi hai mujeNo ratings yet

- Ordering Information: PCB Power Relay - G5NB-EDocument4 pagesOrdering Information: PCB Power Relay - G5NB-ELean Choon SweeNo ratings yet

- DS90LV018A 3V LVDS Single CMOS Differential Line Receiver: General Description FeaturesDocument9 pagesDS90LV018A 3V LVDS Single CMOS Differential Line Receiver: General Description FeaturesIan McNairNo ratings yet

- A314JDocument16 pagesA314JHeriberto FloresNo ratings yet

- LTC 1625Document24 pagesLTC 1625Sakura KunNo ratings yet

- DatasheetDocument10 pagesDatasheetCristina Nae0% (1)

- Safety XCS CatDocument16 pagesSafety XCS CatCicero MelloNo ratings yet

- G 2 RDocument19 pagesG 2 RRaul Ernesto Ventura HernandezNo ratings yet

- Isolated voltage transducer for electric measurements up to 1500VDocument8 pagesIsolated voltage transducer for electric measurements up to 1500VNaga SahityaNo ratings yet

- P605Document7 pagesP605Octavio RamirezNo ratings yet

- Safety-Related, For Circuits Up To SIL 2 According To IEC 61508Document4 pagesSafety-Related, For Circuits Up To SIL 2 According To IEC 61508kingkong1129No ratings yet

- 2 SK 3568Document6 pages2 SK 3568Angel De Dios RosoNo ratings yet

- Tda 7250Document11 pagesTda 7250Mazariegôs JJNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)