Professional Documents

Culture Documents

Mines and Its Techology

Uploaded by

vjykumar27Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mines and Its Techology

Uploaded by

vjykumar27Copyright:

Available Formats

*FAQS*

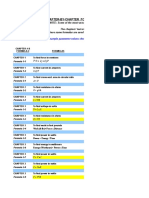

1) What is VSI & what are the applications / uses of VSI? Ans.: VSI is Vertical Shaft Impactor. Applications of VSI Crusher: a) VSI Crusher is used to shape the material (For Ex. Stone); It converts flaky to cubical material. b) It is used as a crusher to crush the product of maximum 40 mm to fines below 4.75 mm. Uses of VSI Crusher: Generally VSI Crushers are used in construction industries for manufacturing cubical aggregates & crushed sand. Following Chart shows uses of VSI Crusher.

VSI CRUSHER

Construction Industries

Sand (Below 4.75 mm) Aggregates

Minerals Processing

Quartz Iron Ore Phosphate Garnet Granite Quartzite Aluminum Oxide Dolomite etc.

Cement Industries

Cement Clinkers Lime Stone etc.

Refractory Industries

Refractory Bricks Concrete Waste Ceramic Waste Glass Waste etc.

2) How VSI Crusher Works? (Working Principle) Ans.: VSI Crusher works on Cleavage Crushing Principle (Considering Stone to be crushed). The material to be crushed is feed in the center of the rotor which is rotating at high velocity & imparts material from rotor. The ejected material collides on a rock shell where the kinetic energy inside that material blasts it into the fine particles. Velocity is the most important factor in VSI Crusher. For shaping the material VSI is run at low / less velocity. For crushing purpose VSI should run at high velocity. When material imparts on the crushing chamber, a hard layer of crush material is formed inside the crushing chamber. 3) What is the raw material required for manufacturing Artificial sand? What is the feed size? Ans.: Raw material required for manufacturing Artificial Sand: a) The stone which is durable & used for aggregate manufacturing like 20 mm, 12 mm, 6 mm available in the local area. b) This raw material is available from local jaw crushing companies. Feed size required for manufacturing Artificial Sand:

a) To manufacture artificial sand the recommended feed size is below 16 mm. (Smaller the size, more is the production) b) To manufacture artificial sand as well as cubical aggregates the recommended feed size is below 40 mm. 4) What is the cost of sand making machine? Ans.: Sand making machines are available in different models depending up on capacity & the feed size. Rate varies as per model selected. Following is the model list:

5) What is Throughput Capacity & Output Capacity? Ans.: Throughput capacity is nothing but the total material which is feed inside the VSI Crusher. Output capacity is nothing but the finished product after screening. 6) What are the A series & B series models? Ans.: A series models are used to produce only sand (below 4.75 mm), where the feed size is 0 to 16 mm. B series models are used to produce cubical aggregates (i.e. 20 mm & 12 mm) as well as sand (below 4.75 mm), where the feed size is 0 to 40 mm. 7) How to select model? Ans.: Study the market demand along with the awareness & which product you want. 8) How much area is required for set up the plant & how to select it? Ans.: Area required for set up: Minimum 10,000 sq. feet area is required for setting up the plant. How to select area: a) Area should be in crushing zone, away from residential & agricultural area. b) Raw material should be available with minimum transportation. 9) How much Manpower required for the set up? Ans.: One (1) skilled operator cum supervisor & three (3) helpers for carrying any maintenance work. 10) What are the licenses required? Ans.: Licenses required are: a) Land should be non-agricultural. b) Permit of local government. c) NOC from pollution control board. d) SSI registration e) License from mining department.

11) What is the Profitability Report? Whether this project is profitable? Ans.: Profitability of sand making machine (Considering 30 Tons / Hrs. Capacity): NOTE: This is a guideline how to make profitability report. Rates may vary according to location hence, visitor should workout profitability report according to local rates. Calculation you can do by filling the below table online on the same page. Sr. No. 01 Particulars *Figures only for Guidelines As per customer local supply / Availability

LAND & BUILDING : Land required is minimum 30,000 sq. ft on rent per month 5,000.00

02

PLANT & MACHINES : a) Sand making machine & Electrical b) Excise Duty on above c) Installation & Electric fittings etc. d) Transportation & other misc. e) M.S.E.B. Deposits TOTAL 40,00,000.00 4,94,400.00 1,20,000.00 10,000.00 2,00,000.00 48,24,400.00

03

RAW MATERIAL : 0 to 16 mm material required per month (30 Tons x 8 hrs x 25 days) = 6000 Tons @ Rs. 125.00 7,50,000.00

04

SALARIES & WAGES : a) Operator b) Helpers One @ 7,000/- per month One @ 4,000/- per month TOTAL 7,000.00 4,000.00 11,000.00

05

POWER & WATER : a) Power charges per month b) Misc. maintenance wear & tear per month TOTAL 1,00,000.00 25,000.00 1,25,000.00

06

WORKING CAPITAL REQUIRED : a) Rent for 2 months (1 x 2) b) Raw material for 2 months (Sr. no. 3 x 2) c) Labor charges & salaries for 2 months (Sr. no. 4 x 2) 10,000.00 15,00,000.00 22,000.00

d) Power, wear & tear for 2 months (Sr. no. 5 x 2) TOTAL 07 08 MONTHLY EXPENCES : a) Rent per month (From Sr. no. 1) b) Raw material per month (From Sr. no. 3) c) Salaries & wages per month (From Sr. no. 4) d) Power & water charges (From Sr. no. 5) Interest on Total Capital per month (Sr. no. 7 x 13% / 12) Depreciation (Sr. no. 2 x 15% / 12) TOTAL 09 SALES PROCEED : Selling manufactured sand 30 Tons x 8 hrs x 25 days = 6,000 Tons @ Rs. 380.00 10 GROSS PROFIT PER MONTH (Sr. n. 09 Sr. no. 08) TOTAL (Sr. no. 2 + Sr. no. 6)

2,50,000.00 17,82,000.00 66,06,000.00

5,000.00 7,50,000.00 11,000.00 1,25,000.00 71,569.00 59,275.00 10,21,844.00

22,80,000.00

12,58,156.00

PROFIT TO CAPITAL RATIO COMES TO 81 % FEASIBILITY OF THE PROJECT: Feasibility of the project to manufactured Artificial Sand / Crushed Sand depends up on following points:1) Rates & availability of natural sand is a basic criteria for feasibility. 2) Cost of river sand is calculated on distance of transportation from riverbed to destination along with royalty (Govt. Fees). If cost of river sand is equal to cost of manufactured sand following points have to be considered:a) 25% bulk age is to be considered for wet sand. Sieving. Wastage of 25% is to be considered for oversize material. b) If organic impurities are more than 6%, sand should be washed. Washing cost is not less than Rs. 300.00 for 100 cft. c) Sand from riverbed i.e. natural source doesnt confirm to IS 383 Grade, as natural manufacturing of sand is stopped because of Dam constructed on every riverbed.

SAND MAKING MACHINE IS AVAILABLE IN VARIOUS MODELS AS BELOW:

12) What is material flow diagram for A series machine & B series Machine? What is power requirement for various models along with the list of accessories? How crushed sand is manufactured & what are the equipments required? Ans.:

BC-3 FEEDING HOPPER 0 TO 16 MM MATERIAL

'A' SERIES

+ 16MM BC-3 VIBRO SCREENER CUM FEEDER BC-1 - 16 MM BAG FILTER DUST ARRESTER

OUTLET

VSI CRUSHER

SCREW CONVEYOR

BC-2

FINES (-150 MICRONS) VIBRATORY SCREEN (2 DECK)

BC-4

LIST OF ACCESSORIES

1) FEEDING HOPPER 2) VIBRO SCREENER CUM FEEDER 3) BELT CONVEYORS(BC1 to BC4) 4) VSI CRUSHER / SAND MAKING M/C 5) DUST ARRESTER 6) BAG FILTER 7) VIBRATORY SCREEN 8) FINES STOCKING HOPPER

SAND (BELOW 4.75 MM)

IN AKASHGANGA'S SCOPE OF SUPPLY

OPTIONAL FOR REMOVING FINES (BELOW 0.15 MM)

NOT IN AKASHGANGA'S SCOPE OF SUPPLY

Tentative Power Consumption for Sand making Plant

Throughput (Crushing) Capacity (TPH) 35 to 40 TPH 55 to 60 TPH Production of ZONE I Sand (TPH) 15 to 20 TPH 25 to 30 TPH VSI crusher Model MD 1550 A MD 1550 A Feed Size (mm) 0 to 16 mm 0 to 16 mm Tentative Power consumption (HP) 100 to 135 HP 165 to 180 HP

DISCH

95 to 100 TPH 130 to 140 TPH 195 to 200 TPH

45 to 50 TPH 65 to 70 TPH 95 to 100 TPH

MD 1800 A MD 2000 A MD 2200 A

0 to 16 mm 0 to 16 mm 0 to 16 mm

280 to 310 HP 340 to 370 HP 400 to 450 HP

BC-3 FEEDING HOPPER FEED MATERIAL 0 TO 40 MM

'B' SERIES

+ 40 MM BC-3 VIBRO SCREENER CUM FEEDER BC-1 - 40 MM DUST ARRESTER

OUTLET

BAG FILTER

VSI CRUSHER

SCREW CONVEYOR

BC-2

FINES (- 150 MICRONS) VIBRATORY SCREEN (3 DECK)

BC-4

BC-5

LIST OF ACCESSORIES

1) 2) 3) 4) 5) 6) 7) 8) FEEDING HOPPER VIBRO SCREENER CUM FEEDER BELT CONVEYORS(BC1 to BC5) VSI CRUSHER / SAND MAKING M/C DUST ARRESTER BAG FILTER VIBRATORY SCREEN FINES STOCKING HOPPER

SAND (BELOW 4.75 MM)

20 MM CUBICAL AGGREGATES

IN AKASHGANGA'S SCOPE OF SUPPLY

OPTIONAL FOR REMOVING FINES (BELOW 0.15 MM)

NOT IN AKASHGANGA'S SCOPE OF SUPPLY

Tentative Power Consumption for VSI Crusher Plant

Throughput (Crushing) Capacity (TPH) 35 to 40 TPH 55 to 60 TPH 95 to 100 TPH 95 to 100 TPH 140 to 150 TPH 195 to 200 TPH VSI crusher Model MD 1550 B MD 1550 B MD 1800 B MD 2000 B MD 2200 B MD 2200 B Feed Size (mm) 0 to 30 mm 0 to 30 mm 0 to 30 mm 0 to 40 mm 0 to 40 mm 0 to 40 mm Tentative Power consumption(HP) 100 to 135 HP 165 to 180 HP 280 to 310 HP 280 to 310 HP 340 to 370 HP 430 to 480 HP

DISCH

245 to 250 TPH 295 to 300 TPH 345 to 350 TPH 395 to 400 TPH

MD 2200 B MD 2400 B MD 2400 B MD 2400 B

0 to 40 mm 0 to 40 mm 0 to 40 mm 0 to 40 mm

580 to 620 HP 690 to 730 HP 890 to 940 HP 1080 to 1130 HP

13) What is VSI with D.F.P. (Dust Free Production) Technology? Ans.: D.F.P. (Dust Free Production) Technology is a unique attachment which can be fitted only with Akashgangas VSI Crushers. This attachment is designed for keeping the quality seeking customers in mind. D.F.P. Technology separates maximum fines below 150 microns from crushed product. These particles are settled & collected in a specially designed Dust arrester & a Bag filter. Separation of fines below 150 microns from crushed product helps in reducing the air pollution & increasing the quality of the final product. 14) Do Akashganga helps in promotion of products of its customer in local area? Ans.: Akashganga helps to promote customers by giving technical knowhow marketing skills, tips for marketing etc. 15) After Sales Service Ans.: Akashganga has training facilities for operators of sand making machines & also gives online based services with all technologies. About Artificial Sand / Manufactured Sand / Crushed Sand: 16) What is Sand? Ans.: The technical name of sand is Fine aggregate. Sand means the material below 4.75 mm up to 150 microns with proper gradation of particles as per IS 383 Standard which was published in 1970. Gradation Chart is mentioned below:IS Sieve Designations 10 mm 4.75 mm 2.36 mm 1.18 mm 600 Microns 300 Microns 150 Microns Grading ZONE I 100 90 - 100 60 - 95 30 - 70 15 - 34 5 - 20 0 - 10 Percentage Passing For Grading ZONE II 100 90 - 100 75 - 100 55 - 90 35 - 59 8 - 30 0 - 10 Grading ZONE III 100 90 - 100 85 - 100 75 - 100 60 - 79 12 - 40 0 - 10 Grading ZONE IV 100 90 - 100 95 - 100 90 - 100 80 100 15 50 0 - 10

Because of this gradation voids in the sand is minimized & the sand cant be rejected for any type of project work. 17) What is the role of Sand in Concrete? Ans.: Fine aggregates (Sand) designed by the Indian standard IS 383 is used in cement concrete to achieve good quality concrete for buildings & dam constructions. It is used as filler material to fill the void in aggregates. Sand should be in proper gradation, these gradations mentioned in the IS 383. Till today river sand was used as a fine aggregates which was very economical earlier but, now a days it becoming difficult to gate good quality sand from short distance. Artificial sand is the perfect substitute for River sand which can be used in concrete mix.

18) What are the benefits of Artificial Sand over Natural Sand? Ans.: Artificial Sand / Manufactured Sand / Crushed Sand have following advantages over Natural Sand:Sr. No. 01 Artificial Sand / Manufactured Sand / Crushed Sand Artificial Sand doesnt contain impurities like silt & silica etc. This sand doesnt contain any organic matter so; strength of the structure remains same. Artificial Sand is made from only one type of stone so; the binding strength between the particles is good. Artificial Sand has proper gradation of coarse & fine aggregates so; voids are filled completely. This reduces cement consumption. Artificial Sand better compressive strength as compared to river sand. As the voids are filled properly, strength of the concrete is achieved. Artificial Sand has constant fineness modules of aggregate so; no necessity of the change in concrete mix design. Artificial Sand can be produced in ample quantity so; it is cheaper as compare to Natural Sand. Artificial Sand is manufactured from the Wastage product (i.e. 6 mm / 12 mm material) of Crushers so; it is not much harmful to the nature. Artificial Sand is best as per Vastushastra, as it doesnt contains any pieces of Bones, Woods etc. Natural (River) Sand This sand contains impurities like silt, silica etc. It also contains organic impurities like pieces of wood, leaves, bones etc. which after some time duration gets decayed & weakens strength of structure. Natural Sand is made from different type of stones so; binding strength varies. Natural Sand which is available today, dont have fines below 600 microns in proper gradation. So, voids in the concrete are not filled properly & also increases cement consumption. Natural Sand gives low compressive strength as compare to Artificial Sand. As the voids are not filled properly, strength of the concrete is not achieved. As every truck of Natural Sand has different fineness modules, every time concrete mix design have to be changed. Natural Sand is available in less quantity so; it is costlier. Because of sand dragging, riverbeds had become deep. It is harmful to the nature. Natural Sand contains pieces of bones, woods etc. so; it is not suitable as per Vastushastra.

02

03

04 05 06

07 08

09

19) Does Artificial Sand need to be washed? Ans.: Sand is washed for removing the unwanted impurities below 150 microns like silt, silica etc. As the artificial sand is made from the stone, it doesnt contain impurities like silt, silica & mica. In IS 383, 20% fines below 150 microns are allowed in Crushed stone Sand. If customer requires minimizing the quantity of fines below 150 Microns, then it is necessary to wash the sand.

Akashgangas VSI crusher facilitates an unique attachment of D.F.P. (Dust Free Production) Technology. This helps in removing the fines below 150 microns by using air suction. This is a 100% Dry Process no water is required. So if VSI crusher is installed with D.F.P. Technology, there is no need to wash the sand.

20) How much is the wastage? Ans.: Fines which are blown away in the air at the time of crushing can be considered as wastage. All other material can be converted into Sand. If customer removes the fines below 150 microns then these fines can be supplied to paint manufacturing industries, Multicolor paving block making units, gray putty can be manufactured. 21) What is difference Between Akashgangas Crushed Sand & Other manufacturers Crushed Sand? Whether this sand replaces river sand? Whether we are getting the same strength, what we are getting with River Sand.? Can we use 100% crushed sand? Ans.: 1st you should know what is sand and what is role of the sand in the concrete? The technical name of sand is Fine Aggregates. Government authorities had provided IS code for gradation of sand, i.e. IS 383, published in 1970. In this, sand is divided into 4 different zones as, Zone I, Zone II, Zone III & Zone IV. Sieve analysis for these Zones is attached for your reference. So in short sand is nothing but gradation of particles below 4.75 mm upto 150 Microns. Percentage of above gradations differs for different Zones. Only Akashgangas Sand making machine can give sand as per these gradations. that to stone available in your area.

22) What are Jamuna Sand, Nirman Sand, Crystal Sand, M Sand, and Robo Sand? Ans.: These are names of the sand. The company, who manufactures the sand, sells it with their Brand name. All above are Brand names. The product what they are selling is the same what Akashgangas machine manufacture.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- MEK32Document2 pagesMEK32vjykumar27No ratings yet

- CS80Document4 pagesCS80vjykumar27No ratings yet

- Biodegradable Plastics: "Let Us Give Back To Nature Asmuchaswetake-Immediately"Document10 pagesBiodegradable Plastics: "Let Us Give Back To Nature Asmuchaswetake-Immediately"vjykumar27No ratings yet

- Customer Feedback FormDocument3 pagesCustomer Feedback FormKanagaraj GanesanNo ratings yet

- Cloud ComputingDocument40 pagesCloud ComputingDogan Tuncer89% (9)

- 2307c 1 2328ADocument1 page2307c 1 2328Avjykumar27No ratings yet

- Mines and Its TechologyDocument11 pagesMines and Its Techologyvjykumar27No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Oracle SCM TrainingDocument9 pagesOracle SCM TrainingVishnu SajaiNo ratings yet

- Dont CryDocument8 pagesDont CryIolanda Dolcet Ibars100% (1)

- Tutorial Ip 2 Win EnglishDocument25 pagesTutorial Ip 2 Win EnglishGarry Zein0% (1)

- POSSIBILITIES OF LOW VOLTAGE DC SYSTEMSDocument10 pagesPOSSIBILITIES OF LOW VOLTAGE DC SYSTEMSTTaanNo ratings yet

- Smart Payment MeterDocument2 pagesSmart Payment MeterJesus Castro OrozcoNo ratings yet

- F1FR80 Series Quick-Response SprinklersDocument6 pagesF1FR80 Series Quick-Response SprinklersAtila AmayaNo ratings yet

- Safety Training Evaluation Form: Instructor RatingDocument1 pageSafety Training Evaluation Form: Instructor RatingNate JamesNo ratings yet

- PMO ProceduresDocument21 pagesPMO ProceduresTariq JamalNo ratings yet

- Geometric Design of Highways for EngineersDocument39 pagesGeometric Design of Highways for EngineersZeleke TaimuNo ratings yet

- Pagination script tutorial for PHP MySQL programmersDocument4 pagesPagination script tutorial for PHP MySQL programmersThomas ChinyamaNo ratings yet

- Social Engineering: An Attack Vector Most Intricate To Handle!Document20 pagesSocial Engineering: An Attack Vector Most Intricate To Handle!ishak8No ratings yet

- Sample Lab ReportDocument4 pagesSample Lab ReportHolley WrightNo ratings yet

- Audio (Amplifier) - Electrical DiagnosticsDocument195 pagesAudio (Amplifier) - Electrical DiagnosticsRafael CherechesNo ratings yet

- OkDocument29 pagesOkgouthamlabsNo ratings yet

- Current Developments in Lens DesignDocument12 pagesCurrent Developments in Lens DesignMahabub HossainNo ratings yet

- Electronic Ticket Receipt, November 03 For MR ARAYA GEBRESLASSIE BERHEDocument2 pagesElectronic Ticket Receipt, November 03 For MR ARAYA GEBRESLASSIE BERHEMengstu Gebreslassie50% (2)

- Item No. Specification Requested Offered Specifications 1.1. 1.1 Law and CertificatesDocument23 pagesItem No. Specification Requested Offered Specifications 1.1. 1.1 Law and CertificatesSaša StankovićNo ratings yet

- Schedule of Rates 2011 Rev1Document144 pagesSchedule of Rates 2011 Rev1Screen BiruNo ratings yet

- 7.qad-Dpr-11 ImteDocument4 pages7.qad-Dpr-11 ImteDhinakaranNo ratings yet

- حل جميع المعادلات الكهربائيةDocument60 pagesحل جميع المعادلات الكهربائيةGandhi HammoudNo ratings yet

- Teaching Methodology (Handout)Document1 pageTeaching Methodology (Handout)Sharjeel Ahmed KhanNo ratings yet

- 3P61 Service Manual PDFDocument17 pages3P61 Service Manual PDFgulaab786No ratings yet

- RefrigerationDocument11 pagesRefrigerationBroAmirNo ratings yet

- BSC Prospectus 2019-20Document37 pagesBSC Prospectus 2019-20Gaurav VamjaNo ratings yet

- PJ1117CM-2 5VDocument6 pagesPJ1117CM-2 5VАлексей ГомоновNo ratings yet

- Basic Computer ConceptsDocument77 pagesBasic Computer ConceptsJerry Mugambi100% (1)

- India's Growing Social Media Landscape and Future TrendsDocument5 pagesIndia's Growing Social Media Landscape and Future Trendspriyaa2688No ratings yet

- Gsxp07er Opera1tion Manual PDFDocument94 pagesGsxp07er Opera1tion Manual PDFMohamed SaadAllahNo ratings yet

- bbk-lt2614-lt3214 Service Manual PDFDocument42 pagesbbk-lt2614-lt3214 Service Manual PDFrj arcinasNo ratings yet

- Inspection and Maintenance of Drillpipe Ebook PDFDocument39 pagesInspection and Maintenance of Drillpipe Ebook PDFAntónio OliveiraNo ratings yet