Professional Documents

Culture Documents

Som Experiments

Uploaded by

Anudeex ShettyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Som Experiments

Uploaded by

Anudeex ShettyCopyright:

Available Formats

M.E.Ss P.I.I.T.

, NEWPANVEL MECHANICAL &AUTOMOBILE ENGINEERING DEPARTMENTS STRENGTHOF MATERIALS LABORATORY EXPERIMENTS

EXPERIMENT NO. 1

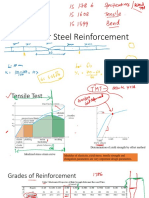

TENSILE TEST ON MILD STEEL BAR

Aim: To conduct tension test on Mild Steel (M.S.) bar so as to achieve the following objectives:

1. To plot stress-strain curve.

2. To observe elastic and plastic zones.

3. To determine the stresses corresponding to Proportional Limit, Elastic Limit, Yield points, Ultimate

Strength and Fracture (Breaking) Strength.

4. To determine Modulus of Elasticity, Poissons Ratio, and measure of Ductility.

5. To determine the Modulus of Resilience and Fracture Toughness.

Apparatus: Universal Testing Machine (UTM), Vernier Callipers, Scale, Mild Steel specimen, marker.

Procedure:

1. Measure the diameter of the specimen (d) using Vernier Callipers, and mark the gauge points on the

specimen so the gauge length between the two points is at least five times the diameter (L/d 5).

2. Fix the bar firmly in the appropriate crossheads of the UTM so that it is subjected to a tensile load.

Use the middle crosshead (operated by lead screws) for adjustment purpose.

3. Select a suitable loading range depending on the diameter and material of the specimen.

4. Note down the initial scale reading (S

0

) required for the measurement of strain.

5. Switch on the machine, close the release valve, and open the control valve so that the load is increased

gradually and at the required rate.

6. Record the load at suitable intervals and the corresponding scale readings.

7. Record the readings till failure (rupture) occurs. Note specially the fluctuation in both directions of the

load pointer while taking the readings. This corresponds to yielding phenomenon. Also observe the

necking phenomenon. This starts at a stage after Ultimate Strength has been reached.

8. After fracture, turn off the loading valve and open the release valve for the oil to return back to its tank.

9. Remove the broken specimen, and put off the machine.

10. Measure the new length of the broken specimen by putting the fractured area in close contact, and also

the new diameter.

11. Observe the cup-and-cone failure zone of the specimen.

12. Get the Stress-Strain values from Load-Deformation values and plot the - curve. The Load-

Deformation curve may also be obtained simultaneously from the Plotter arrangement of UTM.

Results and Conclusions:

1. The following important stress values have been found out:

a. Yield Stress (

y

) = ______ MPa

b. Ultimate Tensile Strength (

u

) =______ MPa

c. Fracture (Breaking) Stress (

f

) = ______ MPa

2. Youngs Modulus of Elasticity (E) =Slope of linear - curve = ______ MPa

3. Poissons Ratio () =______ (till

u

not exceeded).

4. Ductility:

a. % Reduction in c/s area =_______ %

b. % Elongation =_______%

5. Modulus of Resilience (U

R

) =____ J

6. Modulus of Toughness (U

T

) =____ J

7. Ductility measured as % reduction in area, is based on the minimum diameter at fracture and so is a

measure of highest strain along gauge length. But, ductility measured as % elongation at fracture, is an

average over an arbitrary chosen length (gauge length). % reduction in area is not affected by

arbitrariness of L/d ratio, and hence is a more fundamental measure of ductility than is the elongation.

8. Ductile materials are tougher than Brittle materials.

Mild Steel Specimen:

End for gripping d

Gauge length l

M.E.Ss P.I.I.T., NEWPANVEL MECHANICAL &AUTOMOBILE ENGINEERING DEPARTMENTS STRENGTHOF MATERIALS LABORATORY EXPERIMENTS

Experimental Set-up: UNIVERSAL TESTING MACHINE

Observations:

1. Diameter of the bar (d) =_____ mm

Area (A) =______ mm

2

2. Gauge length of the bar (l) =_____ mm.

3. Initial Scale Reading (S

0

) =_____ mm.

4. Reduced diameter of the bar (d) =_____ mm.

Area (A) =_______ mm

2

5. Final Gauge length of the bar (l) =______mm.

6. Diameter of bar (till

u

not exceeded) =d

u

=_______mm.

Observation Table:

Sr. No.

Load

P (kN)

Scale Reading

S

i

(mm)

Elongation

l = S

i

S

0

(mm)

Stress

= P/A (MPa)

Strain

= l / l

Calculations:

1. Poissons Ratio () =Lateral Strain / Linear Strain (till

u

not exceeded) =(d/d)/ (l/l) = ________

2. Ductility:

a. % Reduction in c/s area =[(AA)/A] x 100 = _______ %

b. % Elongation =[(ll)/l] x 100 =_______%

3. Modulus of Resilience (U

R

) =Amount of elastic energy which a material can absorb

=(

E

2

/2E) =____ J

4. Modulus of Toughness (U

T

) =Amount of energy which a material can absorb prior to fracture

(

f

x ) = ____ J

M.E.Ss P.I.I.T., NEWPANVEL MECHANICAL &AUTOMOBILE ENGINEERING DEPARTMENTS STRENGTHOF MATERIALS LABORATORY EXPERIMENTS

EXPERIMENT NO. 2

COMPRESSION TEST ON BRITTLE MATERIAL USING UTM

Aim: a. To conduct compression test on brick and/or concrete materials using Universal Testing Machine.

b. To plot stress-strain curve for compression.

c. To determine the Modulus of Elasticity, Ultimate Strength or Rupture Strength.

d. To observe the failure zone of the brittle materials.

e. To measure ductility in terms of % compression and % increase in cross-sectional area.

Apparatus: Universal Testing Machine, Brick and Concrete specimens, Scale, Vernier Callipers, Marker.

Theory: The specimen for compression test is most commonly a simple cylinder having a ratio of length to

diameter, L/d, in the range 1 to 3. However, values of L/d up to 10 are sometimes used where the primary

objective is to accurately determine the modulus of elasticity in compression. Specimens with square or

rectangular cross sections may also be tested.

Buckling may occur if L/d ratio is relatively large. If this happens, the test result is meaningless as

a measure of the fundamental compressive behavior of the material. Conversely, if L/d is small, the test

result is affected by the details of the conditions at the end. In particular, as the specimen is compressed,

the diameter increases due to the Poisson effect, but friction retards this motion at the ends, resulting in

deformation into a barrel shape. Although this effect can be minimized by proper lubrication of the ends, it

is difficult to avoid entirely. As a result, in materials that are capable of large amounts of deformation in

compression, the choice of too small of an L/d ratio may result in a situation where the behavior of the

specimen is dominated by the end effects. Again the test does not measure the fundamental compressive

behavior of the material. Hence, L/d =3 is taken for ductile materials, and L/d =1.5 or 2 are taken for

brittle materials, where the small amount of deformation that occurs causes less difficulty with end effects.

Procedure:

1. Take the brittle material of suitable dimensions.

2. Place the specimen properly between the middle and lower crossheads of the UTM, and adjust the

positions of the crossheads so that they just touch the specimen without inducing any compressive

load.

3. Note down the initial scale reading.

4. Select suitable loading range of the UTM.

5. Making sure the release valve is closed, open the control valve so that the load is applied slowly and

gradually at a constant rate.

6. Record the loads at suitable intervals and the corresponding scale readings till fracture occurs.

7. Close the control valve and open the release valve to drain out the oil back in the oil tank.

8. Remove the fractured specimen and put off the machine.

9. Note down the dimensions of the fractured specimen.

10. Observe the fractured zone.

Results: The following important stress values have been found out:

1. Ultimate Tensile Strength (

u

) =Fracture (Breaking) Strength (

B

) = ______ MPa

2. Youngs Modulus of Elasticity in compression (E

C

) =Slope of - curve = ______ MPa

3. Poissons Ratio () =______ (till

u

not exceeded).

4. Ductility:

a. % increase in c/s area =_______ %

b. % compression =_______%

5. Modulus of Toughness (U

T

) =____ J

Conclusions: The initial portions of compressive stress-strain curves have the same general nature as those in

tension. Many materials that are brittle in tension have this behavior because they contain cracks or voids

that grow and combine to cause failures along planes of maximum tension, i.e., perpendicular to the

specimen axis. Examples are gray cast iron, concrete etc. Such voids or cracks have much less effect in

compression, so that materials that behave in a brittle manner in tension usually have considerably higher

compressive strengths. Quite ductile behavior can even occur for materials that are brittle in tension, e.g.,

polymers.

M.E.Ss P.I.I.T., NEWPANVEL MECHANICAL &AUTOMOBILE ENGINEERING DEPARTMENTS STRENGTHOF MATERIALS LABORATORY EXPERIMENTS

Where compressive failure does occur, it is generally associated with a shear stress, so that the

fracture is inclined about 45 to the specimen axis. This type of fracture is evident for gray cast iron, an

aluminium alloy and concrete.

The ultimate strength behavior in compression differs in a qualitative way from that in tension.

Note that the decrease in load prior to final fracture in tension is associated with the phenomenon of

necking. This of course does not occur in compression. In fact, an opposite effect occurs, in that the

increasing cross-sectional area causes the stress-strain curve to rise rapidly rather than showing a

maximum.

As a result, there is no load maximum in compression prior to fracture, and the engineering

ultimate strength is same as the engineering fracture (breaking) strength. Brittle and moderately ductile

materials will fracture in compression. But many ductile metals and polymers simply never fracture.

Instead, the specimen deforms into an increasingly larger and thinner pancake shape until the load required

for further deformation becomes so large that the test must be suspended.

Brittle materials are found to be less tough than ductile materials, because even though stress

values are high, but the corresponding strains are very small.

Specimen Dimensions:

Observations:

1. (Width x Thickness x Length) of the specimen (for rectangular c/s): W =_____ mm, T =______ mm,

L =______ mm.

Diameter of the Specimen (for circular c/s) =D =______mm, Length (L) =_______ mm.

2. Initial Scale Reading S

0

=______ mm.

3. Final dimensions of the specimen:

W =_____ mm, T =______ mm, L =______ mm. (rectangular c/s)

D =____ mm, L =_____ mm (circular c/s)

Observation Table:

Sr. No.

Load

P (kN)

Scale Reading

S

i

(mm)

Compression

l = S

i

S

0

(mm)

Stress

= P/A (MPa)

Strain

= l / l

Calculations:

1. Poissons Ratio () =Lateral Strain / Linear Strain = ________

2. Ductility:

c. % increase in c/s area =[(AA)/A] x 100 = _______ %

d. % compression =[(LL)/L] x 100 =_______%

3. Modulus of Toughness (U

T

) =Amount of energy which a material can absorb prior to fracture

(1/2) x ( x ) = ____ J

M.E.Ss P.I.I.T., NEWPANVEL MECHANICAL &AUTOMOBILE ENGINEERING DEPARTMENTS STRENGTHOF MATERIALS LABORATORY EXPERIMENTS

EXPERIMENT NO. 3

ROCKWELL HARDNESS TEST

Aim: a. To understand the principle of the Rockwell Hardness Test.

b. To obtain the Rockwell Hardness Numbers (HRB & HRC) for the given test specimen.

Apparatus: Rockwell Hardness Testing Machine, Standard Cone and Ball type indentors and their attachments,

Test specimens.

Principle of Test: A penetrator of standard type is forced into the surface of the test piece in two stages. A

preliminary initial load of 10 kg

f

is applied and an additional load (140 kg

f

for cone and 90 kg

f

for ball

indentors) is later applied as shown in the figure, for 20 seconds, and removed. The permanent increase in

depth of indentation is a measure, under specific conditions, from which a value is deduced known as

Rockwell Hardness Number (HRB-Hardness Rockwell Ball & HRC-Hardness Rockwell Cone).

Procedure:

1. Select a test piece of which the hardness is to be measured. Ensure that the surface is free from dirt,

oxides, scales or other harmful matter, if any.

2. Select a suitable type of indentor and fix it into the attachment of the machine.

3. Place the selected test (work) piece over the table such that it is properly supported making sure that it

doesnt step when the major (additional) load is applied.

4. Raise the main screw by rotating the hand-wheel so that the indentor just touches the surface of the test

piece at a suitable location.

5. Apply the preliminary load F

0

(10 kg

f

) to establish reference position for depth measurement, thereby

penetrating through any surface scales or foreign particles. This is done by rotating the hand-wheel

further and ensures that proper pressure is applied, making sure the small pointer on the dial gauge

doesnt overstep the red-point mark.

6. Apply additional load F

1

(140 kg

f

for diamond-cone and 90 kg

f

for ball indentors) by operating the

hand lever, and wait for a period of 20 seconds. Thereby, the total load (F =F

0

+F

1

) is obtained and

the movement of the indicator of the dial gauge stops.

7. The lever is operated again in backward direction to remove the additional load. At this stage, the

indicator of the dial gauge moves in the reverse direction and becomes stationary.

8. Read the position of the indicator on the dial gauge, and this will give the Rockwell Hardness Number.

Use B scale for Ball indentor and C scale for Cone indentor.

9. Follow the same procedure for different readings. Omit the first two readings as these tend to give

faulty results. Take the average of the rest of the readings.

Conclusions: The Rockwell Hardness Number of the given test specimen (Carbon Steel) is found to be _____HRB

and _______HRC. These are found to be in good agreement with the established values for the material.

Hence, suitable tests may be further carried out to estimate hardness for different materials, with the use of

corresponding standard indentor types. Also, hardness tests may be carried out for cylindrical work-pieces

(on cylindrical surfaces) by taking suitable correction factors.

Note: Each Rockwell hardness scale has a maximum useful value around 100. An increase of one unit of

regular Rockwell hardness represents a decrease in penetration of 0.002 mm. Hence, the hardness number

is:

002 . 0

h

M HRX

=

where, h =(h

2

h

1

) is in millimeters and M is the upper limit of the scale. For regular Rockwell hardness,

M=100 for scales using the diamond point (C scale), and M=130 for all scales using ball indentors

(B scale). The hardness numbers are designated HRX, where X indicates the scale involved.

In practice, the hardness numbers are read directly from the dial on the hardness tester, rather than

being calculated.

M.E.Ss P.I.I.T., NEWPANVEL MECHANICAL &AUTOMOBILE ENGINEERING DEPARTMENTS STRENGTHOF MATERIALS LABORATORY EXPERIMENTS

Diamond Cone Brale Indentor

Experimental Set-up: ROCKWELL HARDNESS TESTER

Observation Table:

Sr. No. Indentor Type Total Load F (kg

f

)

Rockwell Hardness

Number (HRX)

Average Reading

(HRX)

1

Ball Type Indentor

Diameter of Ball =1.588 mm

100

HRB

HRB 2 HRB

3 HRB

4 Diamond Cone Type Indentor

(Brale Indentor)

Included angle at tip =120

150

HRC

HRC 5 HRC

6 HRC

M.E.Ss P.I.I.T., NEWPANVEL MECHANICAL &AUTOMOBILE ENGINEERING DEPARTMENTS STRENGTHOF MATERIALS LABORATORY EXPERIMENTS

EXPERIMENT NO. 4

BRINELL HARDNESS TEST

Aim: a. To understand the principle of the Brinell Hardness Test.

b. To obtain the Brinell Hardness Number (BHN or HB) for the given test specimen.

Apparatus: Brinell Hardness Testing Machine, Standard Ball type indentor and its attachment, Test specimen,

Hand Microscope and Micrometer Unit for measuring indentation diameter.

Principle of Test: A ball indentor of diameter D is forced by applying a load into the surface of the test piece.

The diameter of indentation d marked on the surface of work-piece is measured, and BHN is calculated

by dividing the test load by the curved surface area of the indentation.

Procedure:

1. Select a test piece of which the hardness is to be measured. Ensure that the surface is free from dirt,

oxides, scales or other harmful matter, if any.

2. Choose a ball indentor of standard diameter D and fix it into the attachment of the machine.

3. Place the test piece over the table such that it must be properly supported making sure it doesnt slip

when the major load is applied.

4. Raise the main screw by turning the hand wheel so that the indentor just touches the surface at a

suitable location.

5. Apply the preliminary load F

0

(10 kg

f

) to establish reference position for depth measurement, thereby

penetrating through any surface scales or foreign particles. This is done by rotating the hand-wheel

further and ensures that proper pressure is applied, making sure the small pointer on the dial gauge

doesnt overstep the red-point mark.

6. Apply additional load F

1

by operating the hand lever, and wait for a period of 20 seconds. Thereby,

the total load (F =F

0

+F

1

=187.5 kg

f

) is obtained and the movement of the indicator of the dial gauge

stops.

7. The lever is operated again in backward direction to remove the additional load. At this stage, the

indicator of the dial gauge moves in the reverse direction and becomes stationary.

8. Remove the test piece and use hand-microscope & micrometer unit to measure the diameter of

indentation d on the test specimen. Use the formula to calculate BHN.

9. Follow the same procedure for different readings. Omit the first two readings as these tend to give

faulty results. Take the average of the rest of the readings.

Results and Conclusions:

1. The Brinell Hardness Number for the given test-specimen (Carbon Steel) = _______HB.

2. As per empirical correlation, Ultimate tensile strength of the material:

u

= ________MPa.

3. These are found to be in good agreement with the established values for the material. Hence, suitable

tests may be further carried out to estimate hardness for different materials, with the use of

corresponding standard indentor types.

M.E.Ss P.I.I.T., NEWPANVEL MECHANICAL &AUTOMOBILE ENGINEERING DEPARTMENTS STRENGTHOF MATERIALS LABORATORY EXPERIMENTS

Observations:

1. Specification of Standard Test Specimen (made of Carbon Steel): RE / 2.5 / 187.5 kg

f

/ 202 HB.

2. Least Count of Microscope Micrometer =0.01 mm.

3. Indentor Diameter D =2.5 mm.

4. Test Load P =187.5 kg

f

.

Observation Table:

Sr. No. Diameter of Indentation d (mm) Average d (mm) BHN (or HB)

Calculations:

Brinell Hardness Number (BHN) =

tation reaOfInden SphericalA

kgf in TestLoad

=

( ) | |

5 . 0

2 2

2

d D D

D

P

|

.

|

\

|

=___________

Ultimate Tensile Strength

u

3.45 BHN = __________ MPa.

M.E.Ss P.I.I.T., NEWPANVEL MECHANICAL &AUTOMOBILE ENGINEERING DEPARTMENTS STRENGTHOF MATERIALS LABORATORY EXPERIMENTS

EXPERIMENT NO. 5

IZOD IMPACT TEST

Aim: a. To observe the behaviour of specimen under Izod Impact Load.

b. To measure the amount of energy absorbed by the specimen using Impact Testing Machine.

Apparatus: Impact Testing Machine (Pendulum type), Specimen of mild steel material.

Theory:

Toughness is a measure of the amount of energy a material can absorb before fracturing. It becomes of

engineering importance when the ability of a material to withstand an impact load without fracturing is considered.

Impact test conditions were chosen to represent those most severe relative to the potential for fracture, viz.,

(1) deformation at a relatively low temperature, (2) a high strain rate (i.e., rate of deformation), and (3) a triaxial

stress state (which may be introduced by the presence of a notch). The impact test is a common method which

measures the impact energy (notch toughness).

A material possessing a large amount of impact resistance is said to be a tough material. Toughness is the

ability of the material to resist both fracture and deformation. Toughness is different from either strength or

ductility. To be tough, a material must be both fairly strong and fairly ductile to resist both cracking and bending

under impact loading.

Impact testing machines usually take the form of a pendulum which is carried to strike a sudden blow

against the test specimen in a certain standard manner. The energy absorbed from the swinging pendulum by the

specimen is taken as the impact energy value of the material used. The load is applied as an impact blow from a

weighted pendulum hammer that is released from a cocked position at a fixed height "h". The specimen is positioned

at the base as shown. Upon release, a knife edge mounted on the pendulum strikes and fractures the specimen at the

notch, which acts as a point of stress concentration for the high velocity impact blow. The pendulum continues its

swing, rising to a maximum height "h", which is lower than "h". Based on the difference between h and h, the

energy absorption of the specimen is computed.

Notches are provided in the impact specimen to increase the stress concentration and the tendency to

fracture.

Procedure:

1. Set the pointer to the maximum energy level on the scale when the pendulum is freely suspended.

2. Raise the pendulum hammer to the required height. Release it allowing a free swing and observe the

initial energy.

3. Raise the pendulum again to the same height as before and clamp it and set the point to the maximum

energy on the scale.

4. Place the specimen as a vertical cantilever beam at the bottom in the anvil so that the notch faces the

hammer and is half inside and half above the top surface of the anvil.

5. Release the hammer by operating the mechanism. The hammer strikes the specimen and breaks or

bends the specimen.

6. Note the final reading on the scale.

7. Calculate the shock absorbing capacity.

Conclusions:

1. The specimen bends and breaks, or partially bends and breaks indicating different degrees of

toughness.

2. Notch is placed facing the hammer resembling a cantilever beam, so that failure occurs in the tensile

zone corresponding to the maximum stress concentration zone.

3. Shock absorbing capacity under impact loading of mild steel material is found to be _________ J.

M.E.Ss P.I.I.T., NEWPANVEL MECHANICAL &AUTOMOBILE ENGINEERING DEPARTMENTS STRENGTHOF MATERIALS LABORATORY EXPERIMENTS

Loading Arrangement Specimen Dimensions

Experimental Set-up: IZOD IMPACT TESTING MACHINE

Observation Table:

Sr. No. Material Initial Energy IE

(J)

Final Energy FE

(J)

Shock Absorbing

Capacity

(Toughness)

FE-IE (J)

M.E.Ss P.I.I.T., NEWPANVEL MECHANICAL &AUTOMOBILE ENGINEERING DEPARTMENTS STRENGTHOF MATERIALS LABORATORY EXPERIMENTS

EXPERIMENT NO. 6

CHARPY IMPACT TEST

Aim: a. To observe the behavior of specimen under Charpy Impact Load.

b. To measure the amount of energy absorbed by the specimen using Charpy Testing Machine.

Apparatus: Impact Testing Machine (Pendulum type), Specimen of mild steel material.

Procedure: The procedure for this test is similar to that of Izod Impact Test. The difference here is that the striking

energy is much more greater, and the specimen is kept as a simply supported beam and placed on the anvil

so that the notch faces opposite direction to the striking edge of the hammer. Here, the same V-notch may

be used for the specimen, or use can be made of a U-notch at half the depth value. Stress concentration is

produced at the notch to a greater extent which induces the failure to take place at that location.

Conclusions:

1. The shock absorbing capacity of mild steel material =_______ J.

2. The specimen bends and breaks, or partially bends and breaks indicating different degrees of

toughness.

Loading Arrangement

Observation Table:

Sr. No. Material Initial Energy IE

(J)

Final Energy FE

(J)

Shock Absorbing

Capacity

(Toughness)

FE-IE (J)

M.E.Ss P.I.I.T., NEWPANVEL MECHANICAL &AUTOMOBILE ENGINEERING DEPARTMENTS STRENGTHOF MATERIALS LABORATORY EXPERIMENTS

EXPERIMENT NO. 7

FLEXURE TEST ON TIMBER BEAM USING UTM

Aim: a. To observe the bending phenomenon of a rectangular timber beam for given loading, till fracture occurs.

b. To compare flexure of timber beams of same cross section, but with different orientations.

c. To determine the bending strength, elastic modulus of the material.

Apparatus: Timber beams, Universal Testing Machine, Supports, Spanner for tightening, Loading tool, Scale.

Theory: Bending (flexure) tests on smooth (unnotched) bars of material are commonly used, as in various

ASTM (American Standard for Testing & Materials) standard test methods for flat metal spring material,

and for concrete, natural building stone, wood, plastics, and glass. Bending tests are especially needed to

evaluate the tension strength of brittle materials; as such materials are difficult to test in simple uniaxial

tension due to cracking in the grips. The specimens usually have rectangular cross sections and may be

loaded in either three-point bending or four-point bending. Here, we use 3-point bending for the

experiment.

In bending, note that the stress varies through the depth of the beam in such a way that yielding

first occurs in a thin surface layer. This results in the load versus deflection curve not being sensitive to the

very beginning of yielding. Also, if the stress-strain curve is not linear, as after yielding, the simple elastic

bending analysis is not valid. Hence, bending tests are most meaningful for brittle materials that have

approximately linear stress-strain behavior up to the point of fracture.

For materials that do have approximately linear behavior, the fracture stress may be estimated

from the failure load in the bending test using simple linear elastic beam analysis.

I

y M.

=

where, M=Bending Moment, y=half depth of beam, I=moment of inertia of c/s area about the neutral axis.

f

() is usually identified as the bend strength or the flexural strength or rupture modulus in bending.

Yield strengths in bending are also sometimes evaluated. Here, load corresponding to fracture is

replaced by load corresponding to a strain offset at the beginning of yielding.

The elastic modulus may also be obtained from a bending test. In a 3-point bending test, using

linear-elastic analysis, the maximum deflection occurs at the mid-span.

EI

PL

48

3

=

The value of E may then be calculated from the slope (dP/dy) of the initial linear portion of the

load versus deflection curve.

|

.

|

\

|

=

d

dP

I

L

E

48

3

Elastic moduli derived from bending are generally reasonably close to those from tension or

compression tests of the same material, but there are possibilities of several discrepancies.

Procedure:

1. Take two timber beams of same length and same size.

2. Support the first beam on simple supports, and place it symmetrically.

3. Fix the loading tool in the jaws of the middle crosshead of UTM.

4. Adjust the load pointer such that it is at zero position when the tool just touches the beam centrally.

5. Note down the initial scale reading.

6. Operate the control valve, and gradually apply the load at a consistent rate.

7. Note down the different loads and the corresponding scale readings till the specimen shows first sign

of crack.

8. Stop the loading, operate the release valve.

9. Repeat the experiment for other beam having same cross section but with different orientation.

10. Compute the results and compare the two orientations.

M.E.Ss P.I.I.T., NEWPANVEL MECHANICAL &AUTOMOBILE ENGINEERING DEPARTMENTS STRENGTHOF MATERIALS LABORATORY EXPERIMENTS

Results and Conclusions:

1. ORIENTATION 1:

1. Elastic Modulus (E) =_______ MPa.

2. Flexural Strength () = ______ MPa.

2. ORIENTATION 2:

1. Elastic Modulus (E) =_______ MPa.

2. Flexural Strength () = ______ MPa.

3. The values of E and for both orientations are found to be more or less same. Hence,

E=_______MPa and =______MPa may be taken as the average values for timber material.

4. Orientation 2 is found to withstand a greater amount of load even though the cross section dimensions

are same, which is due to a greater value of the area moment of inertia, signifying more resistance to

bending. Conversely, for the same amount of load, orientation 2 is found to consist of less amount of

induced bending stress compared to the other orientation. Hence, the orientation 2 is preferred for

safe design.

Loading of specimen: Orientation 1 Orientation 2

Observations:

1. Length of the specimen (L) =_____ mm.

2. Width of the specimen (W) =_____ mm.

3. Thickness of the specimen (T) =_____ mm.

4. Distance of the extreme-most fiber from neutral axis (y

1

) =______ mm, (y

2

) =______mm.

5. Maximum load to fracture (P) =______ kN.

6. Initial Scale Reading (S

0

) =______ mm.

7. Slope of P- curve = ________ N/mm.

Observation Table: (for both orientations, draw separate tables).

Sr. No. Load P (kN) Scale Reading S

i

(mm) Deflection at mid-span

= S

i

S

0

(mm)

Calculations:

1. Maximum Bending Moment (at mid-span) =M =P.L/4 =__________ N-mm. (calculate for both

orientations i.e., M

1

and M

2

).

2. Area Moment of Inertia =I =AB

3

/12 =_________ mm

4

.

(Note: Here, A = Length of parallel edge of c/s, to the Neutral Axis; and B = Length of

perpendicular edge. Calculate I for both the orientations i.e. I

1

and I

2

).

3. Flexure Strength

I

y M.

= =_________ MPa. (calculate for both orientations).

4. Modulus of Elasticity = |

.

|

\

|

=

d

dP

I

L

E

48

3

=________ MPa. (calculate for both orientations).

P

P/2 L P/2

y

1

y

2

M.E.Ss P.I.I.T., NEWPANVEL MECHANICAL &AUTOMOBILE ENGINEERING DEPARTMENTS STRENGTHOF MATERIALS LABORATORY EXPERIMENTS

EXPERIMENT NO. 8

TENSILE TEST ON THIN ALUMINIUM ROD USING TENSILE TESTING MACHINE

Aim: To conduct tensile test on thin aluminium rod using tensile testing machine so as to achieve the following

objectives:

1. To plot stress-strain curve.

2. To observe elastic and plastic zones.

3. To determine the stresses corresponding to Proportional Limit, Elastic Limit, Yield points, Ultimate

Strength and Fracture (Breaking) Strength.

4. To determine Modulus of Elasticity, Poissons Ratio, and measure of Ductility.

5. To determine the Modulus of Resilience and Fracture Toughness.

Apparatus: Tensile Testing Machine, thin aluminium rod, vernier calipers, allen key, scale.

Procedure:

1. Measure the diameter of the aluminium rod.

2. Take a suitable gauge length so that it may be fixed between jaws of the tensile testing machine.

3. Adjust the scale and load setting of the machine.

4. Mark initial scale reading corresponding to zero load.

5. Gradually increase the load by putting the machine on. The movement of bottom jaw of the machine

is electrically operated instead of the hydraulic action as seen in UTM.

6. Note down the intermediate loads and the corresponding scale readings till fracture occurs.

7. Unload the specimen after fracture.

8. Rejoin the pieces, and measure the final length and the diameter of the specimen.

Results and Conclusions:

1. The following important stress values have been found out:

a. Yield Stress (

y

) = ______ MPa

b. Ultimate Tensile Strength (

u

) =______ MPa

c. Fracture (Breaking) Stress (

f

) = ______ MPa

2. Youngs Modulus of Elasticity (E) =Slope of linear - curve = ______ MPa

3. Poissons Ratio () =______ (till

u

not exceeded).

4. Ductility:

a. % Reduction in c/s area =_______ %

b. % Elongation =_______%

5. Modulus of Resilience (U

R

) =____ J

6. Modulus of Toughness (U

T

) =____ J

7. Ductility measured as % reduction in area, is based on the minimum diameter at fracture and so is a

measure of highest strain along gauge length. But, ductility measured as % elongation at fracture, is an

average over an arbitrary chosen length (gauge length). % reduction in area is not affected by

arbitrariness of L/d ratio, and hence is a more fundamental measure of ductility than is the elongation.

8. Ductile materials are tougher than Brittle materials.

Aluminium Rod Specimen:

Length L d

M.E.Ss P.I.I.T., NEWPANVEL MECHANICAL &AUTOMOBILE ENGINEERING DEPARTMENTS STRENGTHOF MATERIALS LABORATORY EXPERIMENTS

Experimental Set-up: TENSILE TESTING MACHINE

Observations:

1. Diameter of the bar (d) =_____ mm

Area (A) =______ mm

2

2. Gauge length of the bar (l) =_____ mm.

3. Initial Scale Reading (S

0

) =_____ mm.

4. Reduced diameter of the bar (d) =_____ mm.

Area (A) =_______ mm

2

5. Final Gauge length of the bar (l) =______mm.

6. Diameter of bar (till

u

not exceeded) =d

u

=_______mm.

Observation Table:

Sr. No.

Load

P (kN)

Scale Reading

S

i

(mm)

Elongation

l = S

i

S

0

(mm)

Stress

= P/A (MPa)

Strain

= l / l

Calculations:

1. Poissons Ratio () =Lateral Strain / Linear Strain (till

u

not exceeded) =(d/d)/ (l/l) = ________

2. Ductility:

a. % Reduction in c/s area =[(AA)/A] x 100 = _______ %

b. % Elongation =[(ll)/l] x 100 =_______%

3. Modulus of Resilience (U

R

) =Amount of elastic energy which a material can absorb

= (

E

2

/2E) =____ J

4. Modulus of Toughness (U

T

) =Amount of energy which a material can absorb prior to fracture

(

f

x ) = ____ J

M.E.Ss P.I.I.T., NEWPANVEL MECHANICAL &AUTOMOBILE ENGINEERING DEPARTMENTS STRENGTHOF MATERIALS LABORATORY EXPERIMENTS

EXPERIMENT NO. 9

TORSION TEST ON DUCTILE MATERIAL USING TORSION TESTING MACHINE

Aim: To conduct torsion test on mild steel shaft using torsion testing machine so as to achieve the following

objectives:

1. To plot torque-angular deflection (T-) curve.

2. To determine the shear modulus (G).

3. To estimate the shear strength () and fracture strength (

max

).

4. To observe the failure zone.

Apparatus: Torsion testing machine, mild steel rod, vernier callipers, scale.

Theory: Tests of round bars loaded in simple torsion are relatively easy to conduct, and unlike tension tests

they are not complicated by the necking phenomenon. The angle of twist , which is proportional to shear

strain, is generally increased at a constant rate. Torque T, which is of course related to shear stress, is

measured as the test proceeds. Within the initial linear-elastic behavior portion of the test, the shear

modulus G is proportional to the slope (dT/d) and so can be evaluated.

Fracture strength values are subject to a similar situation as in bending tests, namely that non-

linear stress-strain behavior may result in stresses calculated based on linear-elastic behavior not being

accurate. This limitation can be overcome by testing thin-walled tubes in torsion, for which the error is

always small. However, even for solid bars in torsion, the test results may be useful for comparing the

strength and ductility of various materials.

Procedure:

1. Measure the diameter d and length l of the specimen.

2. Fix the specimen between the two jaws of the machine tightly, and adjust the pointer to zero of the

twisting moment scale, and to zero of the angle-of-twist disc.

3. Apply the torque and record the torques and the corresponding angle of twists.

4. Record the twisting moment at fracture, and observe the failure zone of the specimen.

Results and Conclusions:

1. Shear modulus (Modulus of Rigidity, G) =_________ MPa.

2. Fracture strength (Shear Strength,

max

) =________ MPa.

3. In a torsion test, brittle materials fail on planes of maximum tension, which occur at 45 to both the

specimen axis and the specimen surface. This produces a helical spiral fracture. In contrast, ductile

materials generally fail on planes of maximum shear, that is, on planes transverse and longitudinal to

the specimen axis, as for the mild steel material.

Mild Steel Specimen:

Length L d

M.E.Ss P.I.I.T., NEWPANVEL MECHANICAL &AUTOMOBILE ENGINEERING DEPARTMENTS STRENGTHOF MATERIALS LABORATORY EXPERIMENTS

Experimental Set-up: TORSION TESTING MACHINE

Observations:

1. Diameter of the shaft (d) =_____ mm

2. Gauge length of the bar (l) =_____ mm.

Observation Table:

Sr. No. Torque T

(kg

f

-cm)

Angle of Twist

(degrees)

Torque T

(N-mm)

Angle of Twist

(radians)

Calculations:

1. Polar moment of inertia (J

p

) =(/32) x d

4

=________ MPa.

2. From Torsion formula:

l

G

Jp

T

=

|

|

.

|

\

|

|

.

|

\

|

=

Jp

l

x

T

G

i.e., G =(Slope of T- graph within elastic limit) x (l/J

p

)

3. Shear strength () is found from the relation:

r Jp

Te

= where, T

e

=Torque at elastic limit, r =radius.

4. Fracture strength (

max

) is found from the relation:

r Jp

T max max

= where, T

max

=Torque at fracture.

_____________________________________________________________________________________________

You might also like

- Strength of MaterialDocument18 pagesStrength of MaterialMamta SinghNo ratings yet

- Strength of Materia Lab Manual UET, LahoreDocument14 pagesStrength of Materia Lab Manual UET, LahoreRizwan Khurram100% (3)

- Mos Lab Manual PDFDocument34 pagesMos Lab Manual PDFs.rihanaNo ratings yet

- Strength of Materials Laboratory ExperimentsDocument20 pagesStrength of Materials Laboratory Experimentskenneth iyahenNo ratings yet

- Lab 1 Compresive Test PDFDocument10 pagesLab 1 Compresive Test PDFDhania BaharuddinNo ratings yet

- Experiment 1Document7 pagesExperiment 1waseemjuttNo ratings yet

- Tension TestDocument7 pagesTension TestmanmathkNo ratings yet

- btech3rd-CE SOM LAB MANUALDocument21 pagesbtech3rd-CE SOM LAB MANUALvkmstp2005No ratings yet

- Lab Manual: International Islamic University Malaysia Department of Mechanical EngineeringDocument36 pagesLab Manual: International Islamic University Malaysia Department of Mechanical EngineeringMuhamad HilmiNo ratings yet

- Uniaxial TestDocument6 pagesUniaxial Testanil chejaraNo ratings yet

- Ass 05 Tension in Circular RoodsDocument11 pagesAss 05 Tension in Circular RoodsMia HussainNo ratings yet

- Ansys Full ReportDocument12 pagesAnsys Full ReportikhwanmazliNo ratings yet

- Deney 6Document4 pagesDeney 6haticekus035No ratings yet

- SM Lab (Tension Test)Document15 pagesSM Lab (Tension Test)Sushilkumar MagadeNo ratings yet

- Engineering Council Certificate Level Engineering Materials C102 Tutorial 6 - Materials TestingDocument11 pagesEngineering Council Certificate Level Engineering Materials C102 Tutorial 6 - Materials TestingcataiceNo ratings yet

- Ramkrishna Mahato Government Engineering College: S0Lid Mechanics LaboratoryDocument34 pagesRamkrishna Mahato Government Engineering College: S0Lid Mechanics LaboratoryMaynak DeyNo ratings yet

- Lab Manual 1Document9 pagesLab Manual 1Hallowfied KawsarNo ratings yet

- Strength of Materials LabDocument30 pagesStrength of Materials LabDipesh GugaleNo ratings yet

- SM Lab ManualsDocument27 pagesSM Lab ManualspraveenampilliNo ratings yet

- BME Mannual BT 203-1Document41 pagesBME Mannual BT 203-1shivanshu tiwariNo ratings yet

- CE6411 Strength of MaterialsDocument38 pagesCE6411 Strength of Materialsamns99No ratings yet

- Experiment Name: Tensile Test of Steel: ObjectivesDocument4 pagesExperiment Name: Tensile Test of Steel: ObjectivesKalikiri navyaNo ratings yet

- FM and SM Lab ManualDocument87 pagesFM and SM Lab ManualGeorge OliverNo ratings yet

- Flexural or Bending Test Lab ReportDocument9 pagesFlexural or Bending Test Lab ReportKalKatu MaLam73% (22)

- 3-Exp#03 Tensile TestDocument7 pages3-Exp#03 Tensile TestD7ooM_612No ratings yet

- CVP243 Steel ReinforcementDocument9 pagesCVP243 Steel ReinforcementManikyaMayankNo ratings yet

- Tensn TST On DEF BarDocument2 pagesTensn TST On DEF BarAnonymous mzF3JvyTJsNo ratings yet

- Lab#1 - Tensile Test HandoutDocument7 pagesLab#1 - Tensile Test Handoutgrbxjgsh59No ratings yet

- Unit - IIIDocument215 pagesUnit - IIINishigandha Bansode100% (1)

- Laboratory Manual of Tensile TestDocument11 pagesLaboratory Manual of Tensile TestVIPAN KUMARNo ratings yet

- Mechanics of Solids Laboratory Manual: Tensile TestDocument8 pagesMechanics of Solids Laboratory Manual: Tensile TestVIPAN KUMARNo ratings yet

- Real O.V Tensile TestingDocument14 pagesReal O.V Tensile TestingOshane ThomasNo ratings yet

- Fatigue AnalysisDocument23 pagesFatigue AnalysisarnoldmarshalNo ratings yet

- Material Testing LabDocument79 pagesMaterial Testing LabBrijesh VermaNo ratings yet

- Som Manual-2013 RegDocument26 pagesSom Manual-2013 RegsugunavidiyadarNo ratings yet

- Tensile Test PresentationDocument36 pagesTensile Test PresentationalkharfaneNo ratings yet

- TensileTest SheetDocument7 pagesTensileTest SheetKhubaib MalikNo ratings yet

- Mapua Institute of Technology School of Mechanical and Manufacturing EngineeringDocument20 pagesMapua Institute of Technology School of Mechanical and Manufacturing EngineeringEriane GarciaNo ratings yet

- Tensile Testing Asm StandardDocument13 pagesTensile Testing Asm StandardNinad PawarNo ratings yet

- Tensile Test of Mild SteelDocument6 pagesTensile Test of Mild SteelAnshuman Dash100% (2)

- Construction Materials and Testing, Lab Experiment-No - 9Document10 pagesConstruction Materials and Testing, Lab Experiment-No - 9Lester de GuzmanNo ratings yet

- Tensile Test Lab ReportDocument4 pagesTensile Test Lab ReportElisha NissiNo ratings yet

- Unconsolidated Undrained TriaxialDocument14 pagesUnconsolidated Undrained TriaxialSulaksha WimalasenaNo ratings yet

- LabEx No. 4 Tensile Test of Reinforcing BarDocument4 pagesLabEx No. 4 Tensile Test of Reinforcing BarianzkieeNo ratings yet

- Tension Test On Steel Rod - Procedure and ResultsDocument6 pagesTension Test On Steel Rod - Procedure and ResultsTapabrata RoyNo ratings yet

- ASM Lab Record BookDocument36 pagesASM Lab Record BookNandan HegdeNo ratings yet

- Exp 2 ErianeDocument15 pagesExp 2 ErianeEriane GarciaNo ratings yet

- Theory:: Experiment No. 03 Aim: Shear Test On Mild Steel and Aluminum (Single and Double Shear Tests) Apparatus UsedDocument5 pagesTheory:: Experiment No. 03 Aim: Shear Test On Mild Steel and Aluminum (Single and Double Shear Tests) Apparatus UsedRaj TondayNo ratings yet

- Strength of Materials Lab Manual: 1. Tension Test On MS Bar and HYSD BarsDocument61 pagesStrength of Materials Lab Manual: 1. Tension Test On MS Bar and HYSD Barsswe_maniNo ratings yet

- Compression TestDocument12 pagesCompression TestMoustafa AllamNo ratings yet

- Mos Lab Manul by Abhidhesh YadavDocument45 pagesMos Lab Manul by Abhidhesh YadavabhiNo ratings yet

- Mate 453 Tensile TestDocument23 pagesMate 453 Tensile TestElijah ObengNo ratings yet

- Steel Tensile TestDocument10 pagesSteel Tensile Testafiq2697No ratings yet

- Utm Comp 9Document3 pagesUtm Comp 9Tanu RdNo ratings yet

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryFrom EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryNo ratings yet

- BE IT Syllabus Sem-III (BIT MESRA)Document3 pagesBE IT Syllabus Sem-III (BIT MESRA)Anudeex ShettyNo ratings yet

- Physics DPP 4 (JP & JR) Advanced FCDocument30 pagesPhysics DPP 4 (JP & JR) Advanced FCAnudeex ShettyNo ratings yet

- Curricula and Syllabi: - B.Tech - M.Tech Dual DegreeDocument447 pagesCurricula and Syllabi: - B.Tech - M.Tech Dual DegreeKritika KuraniNo ratings yet

- 1 Gennext G.Ram Books 2 Science Wonders Aman Publications 3 Social Studies Part-Iv Deamwave 4Document2 pages1 Gennext G.Ram Books 2 Science Wonders Aman Publications 3 Social Studies Part-Iv Deamwave 4Anudeex ShettyNo ratings yet

- Maxima and MinimaDocument4 pagesMaxima and MinimaAnudeex ShettyNo ratings yet

- Athletics ProjectDocument45 pagesAthletics ProjectAnudeex Shetty72% (29)

- Roll No Name Unit1 Term 1 Unit2 Term 2 Total 1 Robin 2 Akash 3 Seema 4 Reka 5 Teena 6 RobinDocument1 pageRoll No Name Unit1 Term 1 Unit2 Term 2 Total 1 Robin 2 Akash 3 Seema 4 Reka 5 Teena 6 RobinAnudeex ShettyNo ratings yet

- Athletics ProjectDocument45 pagesAthletics ProjectAnudeex Shetty72% (29)

- Sports Events Are Essentially Social in CharacterDocument3 pagesSports Events Are Essentially Social in CharacterAnudeex ShettyNo ratings yet

- Yeh Zarra Nabi Bana Mohabaat Mein T (C) Eri, R (U) oDocument2 pagesYeh Zarra Nabi Bana Mohabaat Mein T (C) Eri, R (U) oAnudeex ShettyNo ratings yet

- 11 Chemistry Notes Ch07 EquilibriumDocument8 pages11 Chemistry Notes Ch07 EquilibriumShishirRanjanNo ratings yet

- FINAL IE Lab ManualDocument34 pagesFINAL IE Lab ManualAnudeex ShettyNo ratings yet

- Maths Class 11 HOTS Important Question 22Document8 pagesMaths Class 11 HOTS Important Question 22srinidhiNo ratings yet

- Nsep 2012 PaperDocument14 pagesNsep 2012 PaperAnudeex Shetty100% (1)

- 11 Chemistry Notes Ch13 HydrocarbonsDocument23 pages11 Chemistry Notes Ch13 HydrocarbonsSahil ChaudharyNo ratings yet

- VIT Maths SyllabusDocument2 pagesVIT Maths SyllabusAnudeex ShettyNo ratings yet

- Simona PC FR Rail: Flame Retardent Interior Linings For Rail VehiclesDocument2 pagesSimona PC FR Rail: Flame Retardent Interior Linings For Rail VehiclesAbdelmajid HmNo ratings yet

- Kleyn Successful (2012) G1 MaterialDocument9 pagesKleyn Successful (2012) G1 MaterialcarlmarxNo ratings yet

- Strain Life ApproachDocument65 pagesStrain Life Approachsjdjd ddjdjfNo ratings yet

- Methods of ReliabilityDocument26 pagesMethods of ReliabilityNISHANT ROYNo ratings yet

- Sag Angle and Purlin Connection DesignDocument2 pagesSag Angle and Purlin Connection DesignsabdarNo ratings yet

- Postbuckling Behavior of Steel-Plate Shear Walls Under Cyclic LoadsDocument18 pagesPostbuckling Behavior of Steel-Plate Shear Walls Under Cyclic LoadsAravind BhashyamNo ratings yet

- Strength of Mat'l Part 1Document82 pagesStrength of Mat'l Part 1Nick Decillo94% (189)

- Die Cast Aluminum - General Purpose WSS-M2A171-A1 Die Cast Aluminum - Medium Duty Applications WSS-M2A171-A2 1. ScopeDocument5 pagesDie Cast Aluminum - General Purpose WSS-M2A171-A1 Die Cast Aluminum - Medium Duty Applications WSS-M2A171-A2 1. ScopeGreg RaleighNo ratings yet

- ASM Thermal Spray Society (TSS) Accepted Practices Committee On Metallography Accepted Practice To Test Bond Strength of Thermal Spray CoatingsDocument5 pagesASM Thermal Spray Society (TSS) Accepted Practices Committee On Metallography Accepted Practice To Test Bond Strength of Thermal Spray CoatingsKhin Aung ShweNo ratings yet

- Asce - Sei 41-17 RC Column PDFDocument12 pagesAsce - Sei 41-17 RC Column PDFRafael Emilio Machaca MamaniNo ratings yet

- All Units - 1456964101350 - 1457010306455 PDFDocument554 pagesAll Units - 1456964101350 - 1457010306455 PDFDixit ShubhamNo ratings yet

- Astm D2850 15Document3 pagesAstm D2850 15rsoasadigmoniem2023No ratings yet

- Endurance Limit - Approximate EstimationDocument37 pagesEndurance Limit - Approximate EstimationDrSatnam SinghNo ratings yet

- Astm B 101Document5 pagesAstm B 101naina ka madhavNo ratings yet

- L&T TechnicalDocument5 pagesL&T TechnicalvigneshwarimahamuniNo ratings yet

- Hybrid Composite Materials: November 2010Document6 pagesHybrid Composite Materials: November 2010berhaneNo ratings yet

- Crouch 2015Document42 pagesCrouch 2015Gülden ÇİMENNo ratings yet

- Uniz Resin Spec PDFDocument11 pagesUniz Resin Spec PDFYerayNo ratings yet

- p608 PDFDocument8 pagesp608 PDFMohamed TabetNo ratings yet

- Composite MaterialDocument24 pagesComposite MaterialShakir Al MohiminNo ratings yet

- B 632 - B 632m - 01 - Qjyzmi9cnjmyts1sruqDocument8 pagesB 632 - B 632m - 01 - Qjyzmi9cnjmyts1sruqmalika_00No ratings yet

- Thermo-Mechanical Fatigue Behaviour and Life Prediction of C-1023 Nickel Based SuperalloyDocument14 pagesThermo-Mechanical Fatigue Behaviour and Life Prediction of C-1023 Nickel Based SuperalloyAchmad Arifudin HidayatullohNo ratings yet

- EnercalcDocument11 pagesEnercalcALEJANDRO PEREZ LUQUENo ratings yet

- Bertero Bozorgnia, Paper Damage Spectrum.Document8 pagesBertero Bozorgnia, Paper Damage Spectrum.mariocp310No ratings yet

- Principles of Reinforced Concrete - Module 4Document12 pagesPrinciples of Reinforced Concrete - Module 4Moshe MallariNo ratings yet

- Deform Pset AnswersDocument11 pagesDeform Pset AnswersUragon's gamingNo ratings yet

- Design of An INTZE TankDocument78 pagesDesign of An INTZE TankSTAR PRINTING100% (1)

- 14 Chapter 5Document73 pages14 Chapter 5DNo ratings yet

- LCs With FDs As A Technique For Seismic Retrofit of Steel MRFs - Draft - For - RG PDFDocument8 pagesLCs With FDs As A Technique For Seismic Retrofit of Steel MRFs - Draft - For - RG PDFborisbelevNo ratings yet

- Strength of MaterialsDocument57 pagesStrength of MaterialsFrancis Dwight Maglinte100% (2)